Welding device

A welding device and connecting shaft technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of shortened service life, time-consuming and laborious, damaged power supply parts, etc., so as to improve the safety of plugging and reduce the manufacturing cost. , The effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

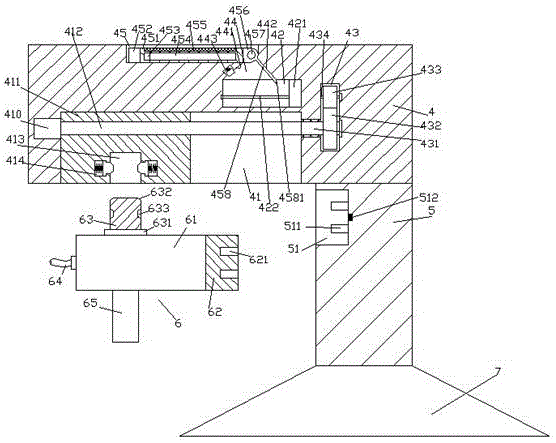

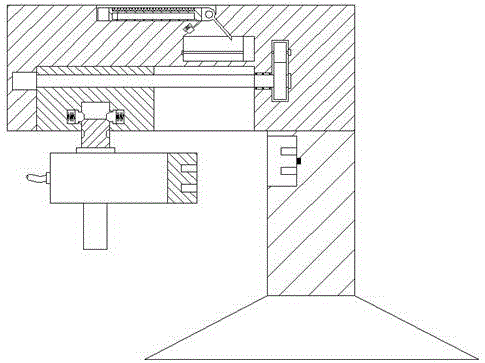

[0026] Such as Figure 1-Figure 6 As shown, a welding device of the present invention includes a base 7, a column 5 fixedly arranged above the base 7, a pushing part 4 fixedly connected to the top of the column 5 and extended to the left, and a plug part 6. An insertion slot 51 is provided in the left end surface of the column body 5, and an insert spring 511 arranged up and down symmetrically is arranged on the right inner wall of the insert slot 51, and the insert spring 511 between two sets of insert springs 511 Insert the sensor 512 on the inner wall on the right side of the groove 51, the top end surface of the pushing part 4 is provided with an installation groove 45, and the bottom end surface on the left side of the pushing part 4 is provided with a sliding groove 41, and the right side of the sliding groove 41 A sliding chamber 42 is provided in the pushing part 4 above, and a force transmission chamber 43 is provided in the pushing part 4 on the right side of the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com