Patents

Literature

269results about How to "Realize automatic docking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Loosening-prevention and high-safety power supply device

ActiveCN106877072ARealize moving up and downRealize automatic dockingCoupling device detailsElectrical connectionEngineering

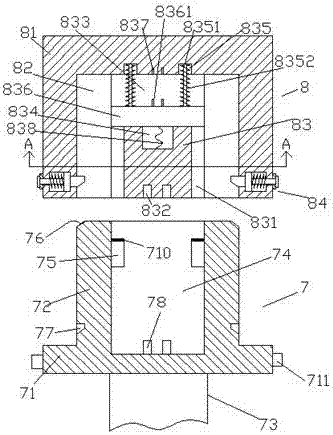

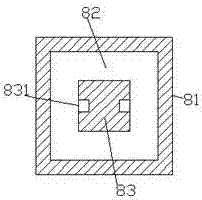

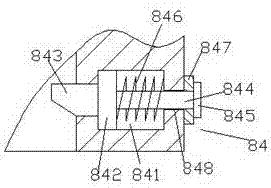

The invention discloses a loosening-prevention and high-safety power supply device. The loosening-prevention and high-safety power supply device comprises a socket part and a plug part, wherein the plug part is connected with the socket part in a matching way, the socket comprises a shell sleeve, an accommodating cavity and a guide block, the guide block is arranged in the accommodating cavity, the top of the guide block is fixedly connected with the center of a top wall in the accommodating cavity, a first sliding groove is formed in the top of the guide block, second sliding grooves are formed in two sides of the guide block and extend along a longitudinal direction of the guide block, a first counter hole is formed in the guide block at the bottom of the first sliding groove, an electrical connection hole is formed in the shell sleeve at the top of the first sliding groove, second counter holes are correspondingly arranged in the shell sleeves at the two sides of the electrical connection hole, guide sliding rods are arranged in the second counter holes and extend downwards, downward extension segments of the guide sliding rods extend into the first sliding groove and are fixedly connected with a bottom wall in the first sliding groove, sliding blocks are connected onto the guide sliding rods in a sliding way, two sides of the sliding blocks extend into the second sliding grooves and are connected with the second sliding grooves in a sliding way, first press springs are wound around the guide sliding rods at upper parts of the sliding blocks, and locking devices are correspondingly arranged in the shell sleeve at a left side and a right side of the bottom of the accommodating cavity.

Owner:JIANGSU XIYI HIGH NEW DISTRICT TECH DEV CO LTD

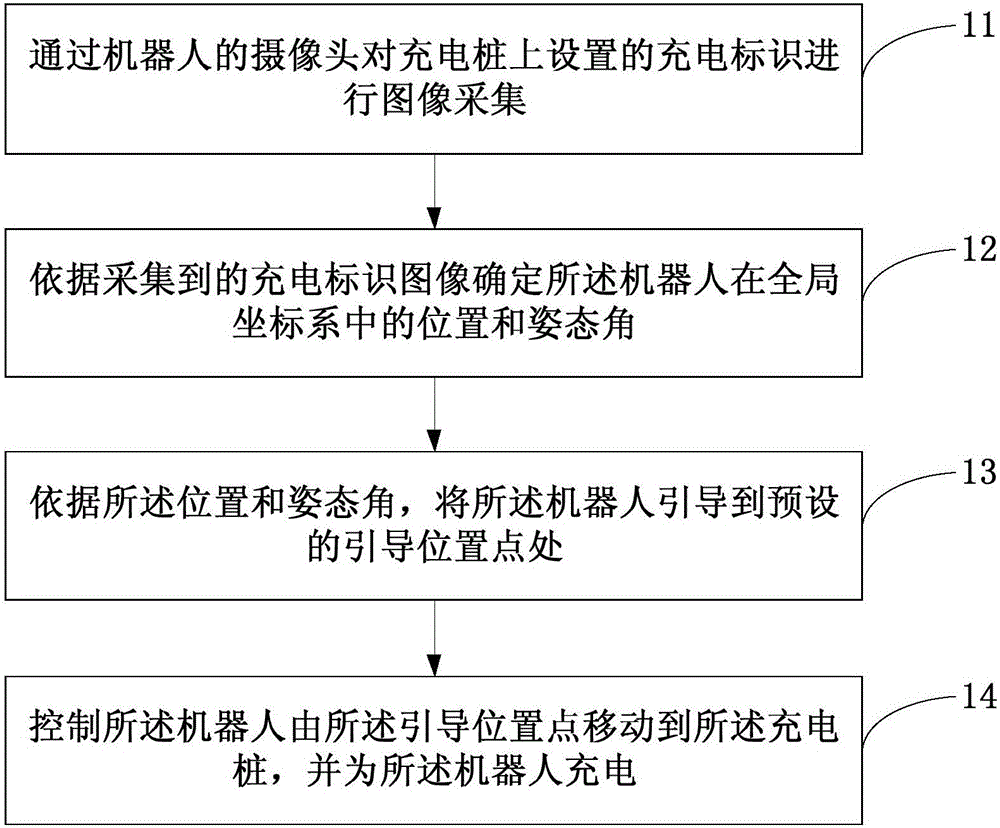

Robot charging method and device

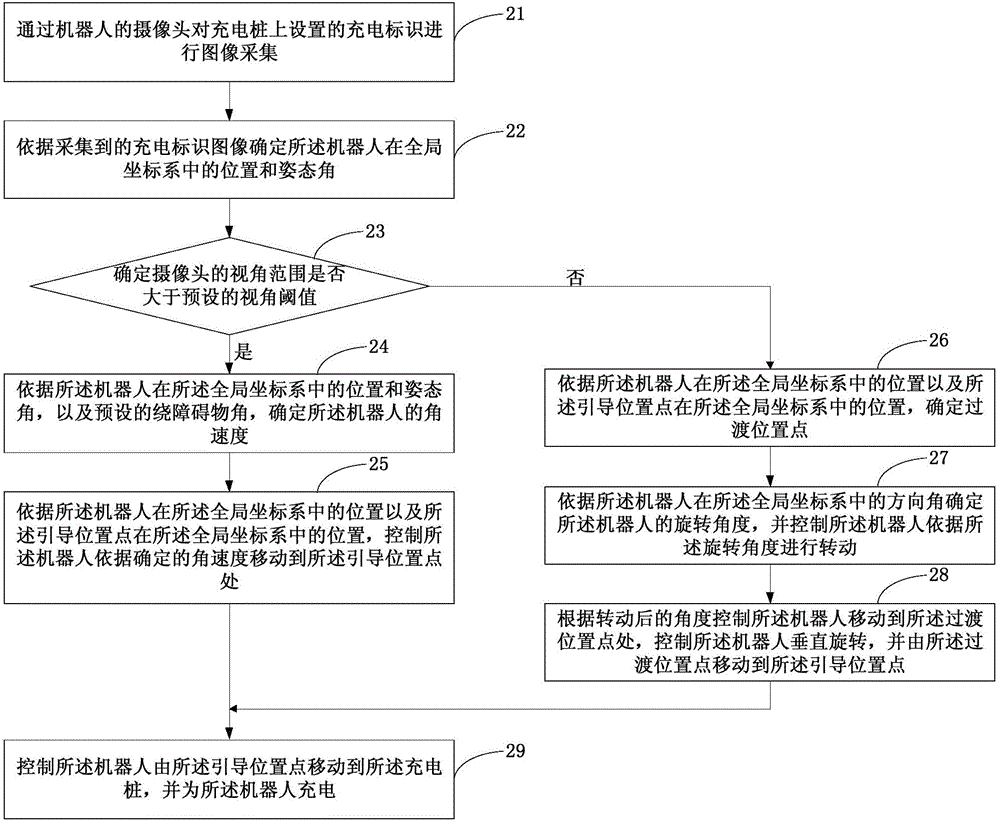

ActiveCN106647747AImprove efficiencyImprove charging efficiencyPosition/course control in two dimensionsVehiclesPerformed ImagingSimulation

The invention discloses a robot charging method and device. The method includes performing image collection on a charge mark arranged on a charge pile through a camera of a robot; determining the position and attitude angle of the robot in an overall coordinate system according to the collected charge mark image; leading the robot to a preset guide position according to the position and attitude angle; controlling the robot to move from the guide position to the charge pile and charging the robot. The technical scheme provided by the invention improves robot charging efficiency.

Owner:北京如布科技有限公司

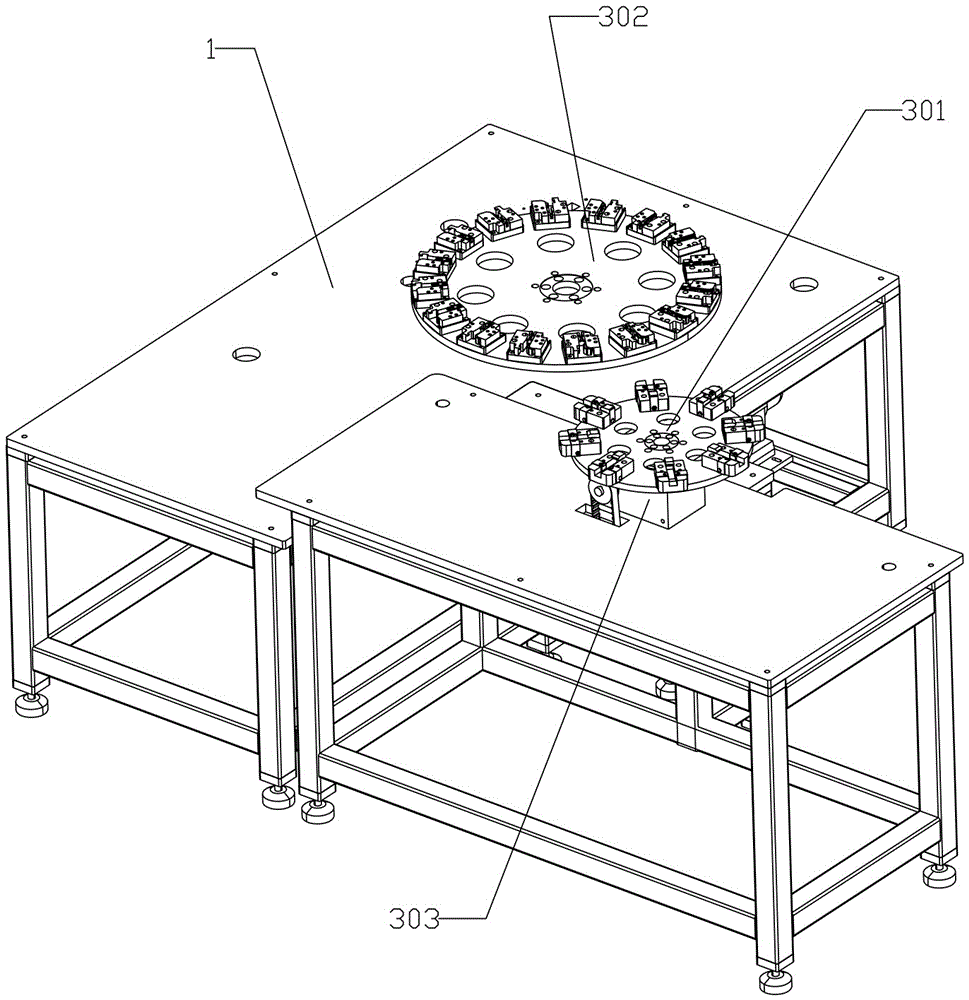

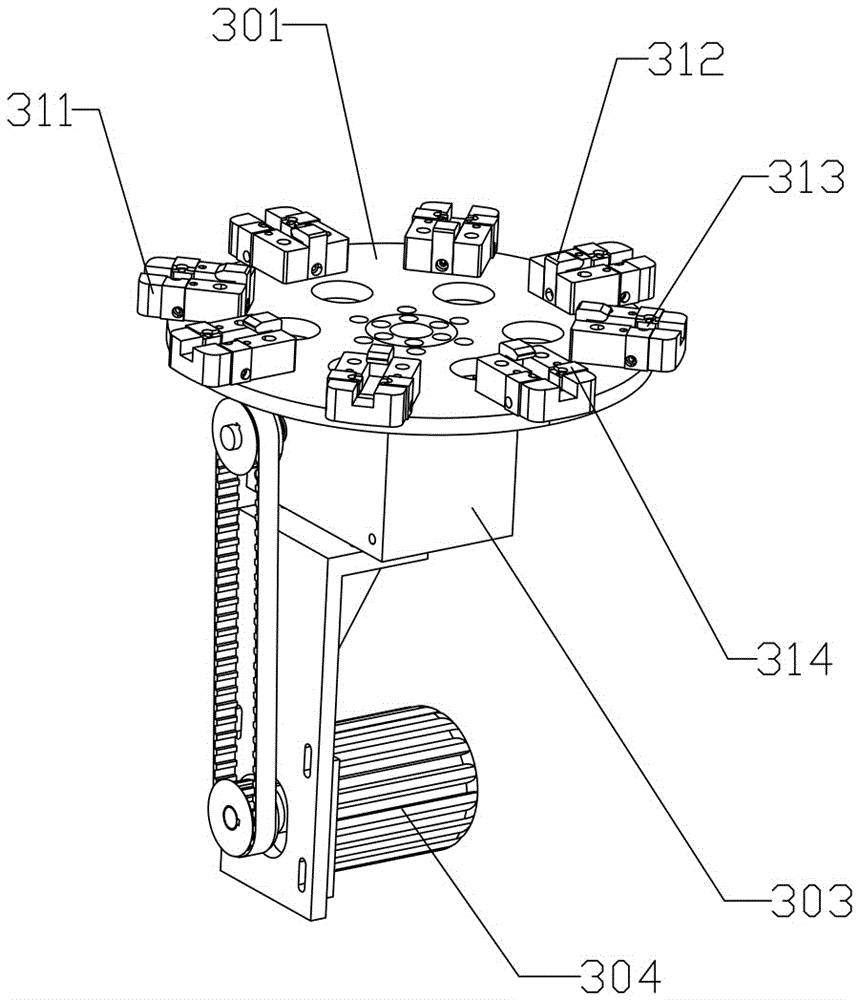

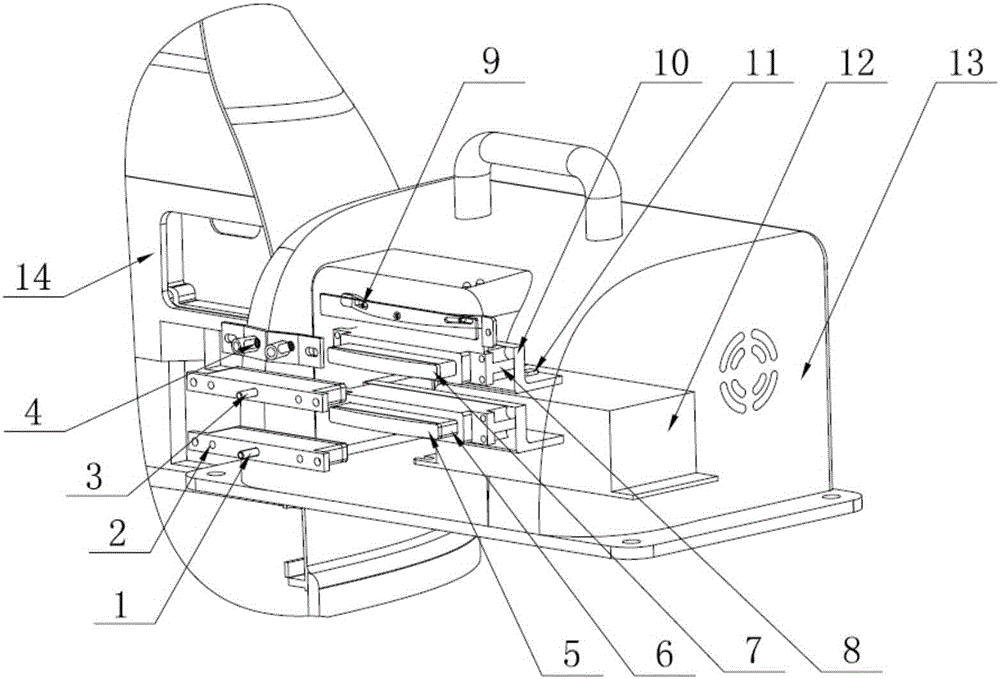

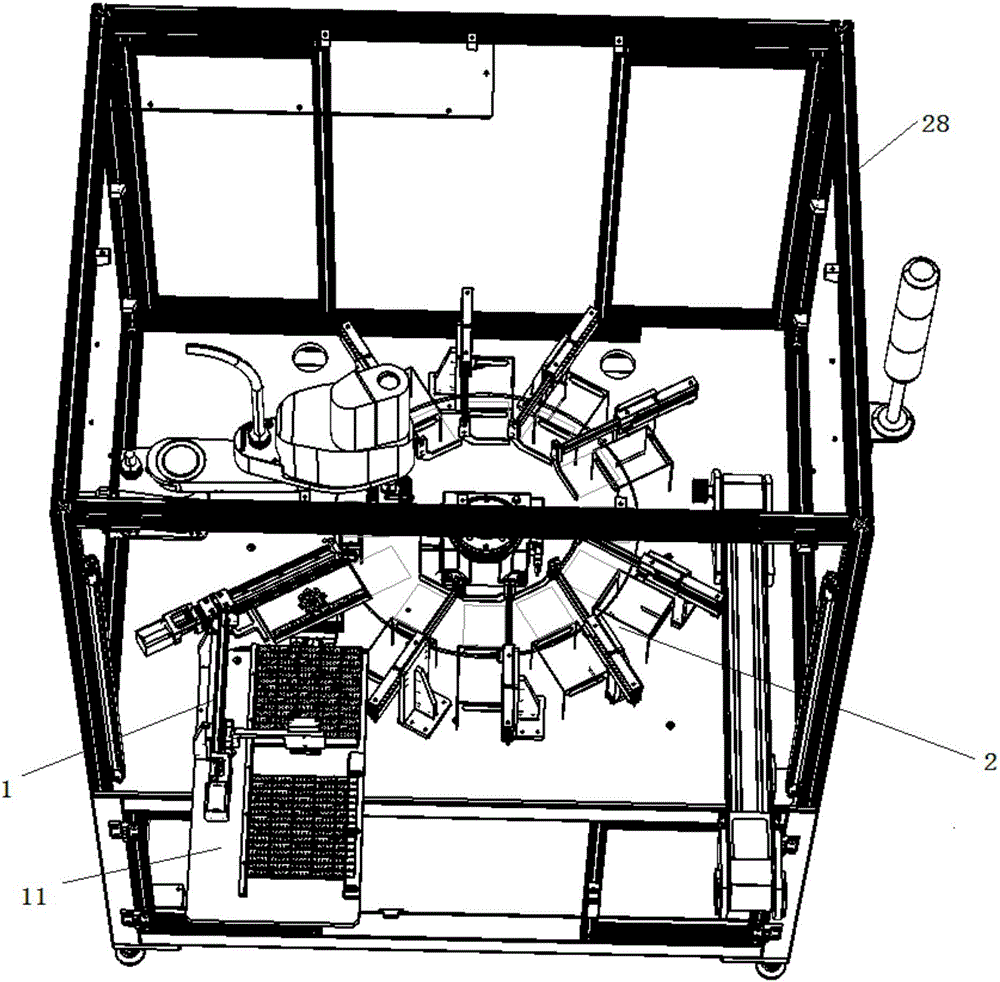

Automatic hinge assembly equipment

InactiveCN105522381AHigh degree of automationImprove stabilityPrecision positioning equipmentAssembly machinesTorsion springAutomation

The invention discloses automatic hinge assembly equipment. The automatic hinge assembly equipment comprises a frame, and is characterized in that the frame is provided with a rotating transmission mechanism with an assembly station, and a screw screwing mechanism, an adjusting block assembly mechanism, a torsion spring rocking rod assembly mechanism, a crank assembly mechanism and a hinge cup assembly mechanism arranged around the rotating transmission mechanism in sequence. The automatic hinge assembly equipment is high in stability and automation degree.

Owner:QINGYUAN SACA PRECISION MFG CO LTD

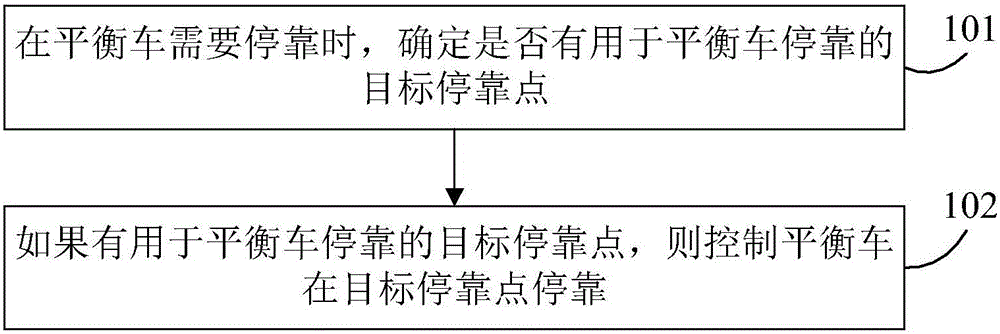

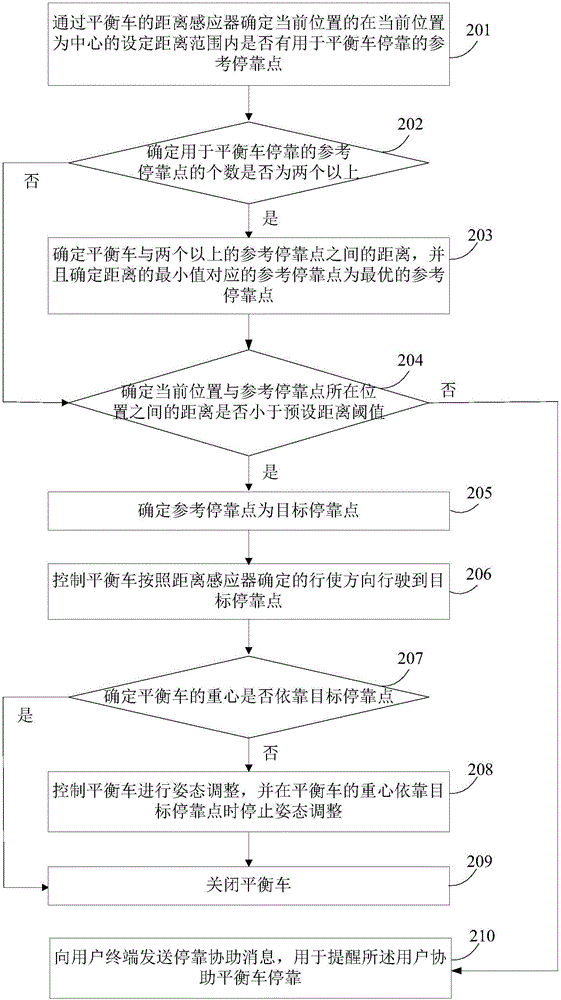

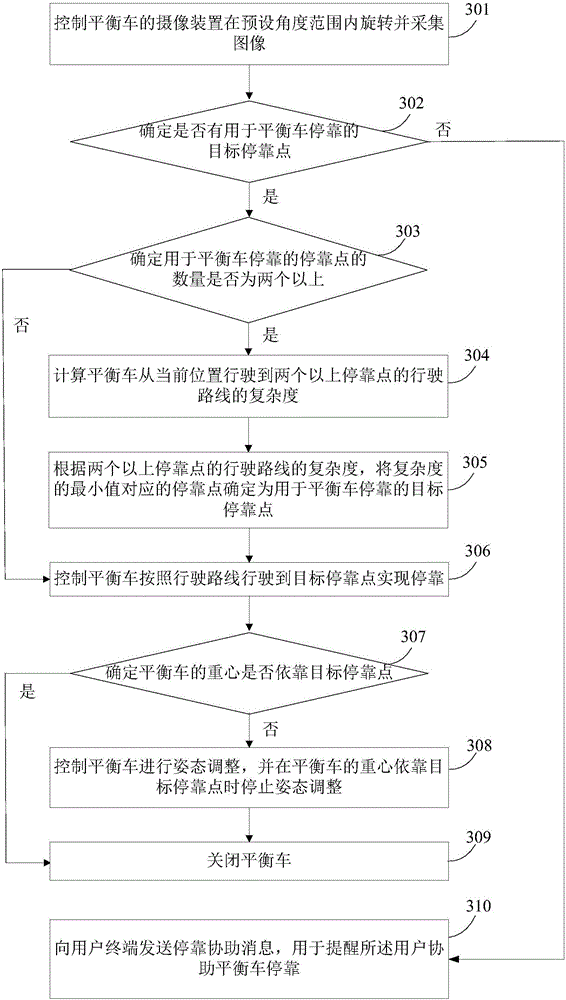

Method and device for stopping balance car

ActiveCN105810007ASolve the problem of participating in docking the balance carImprove experienceInstruments for road network navigationIndication of parksing free spacesAutomotive engineering

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

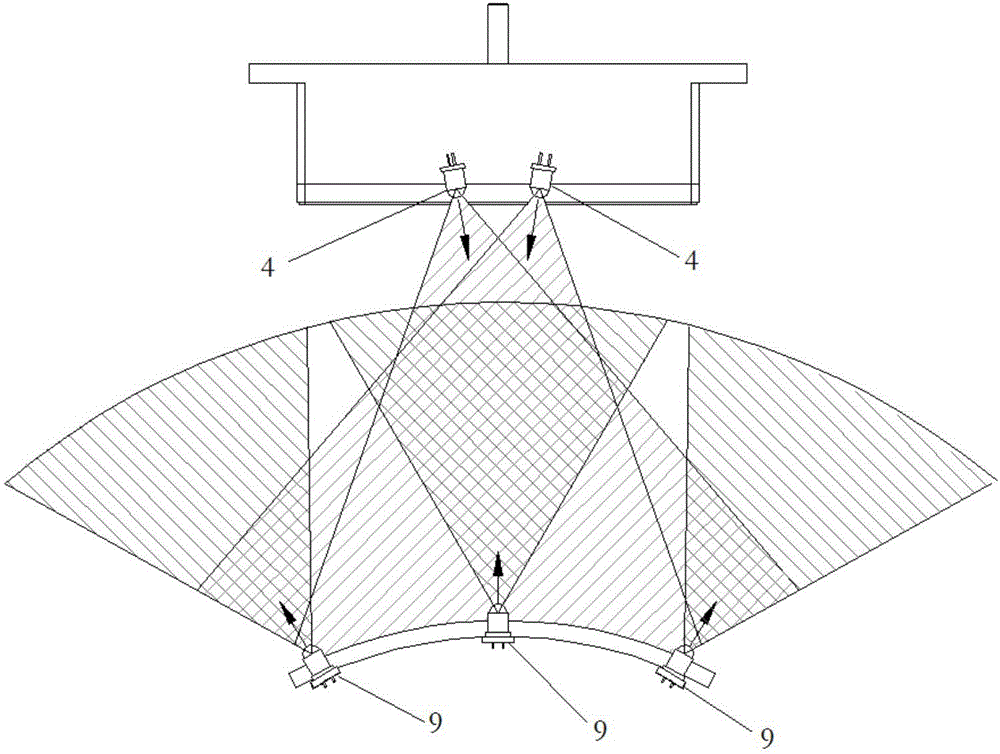

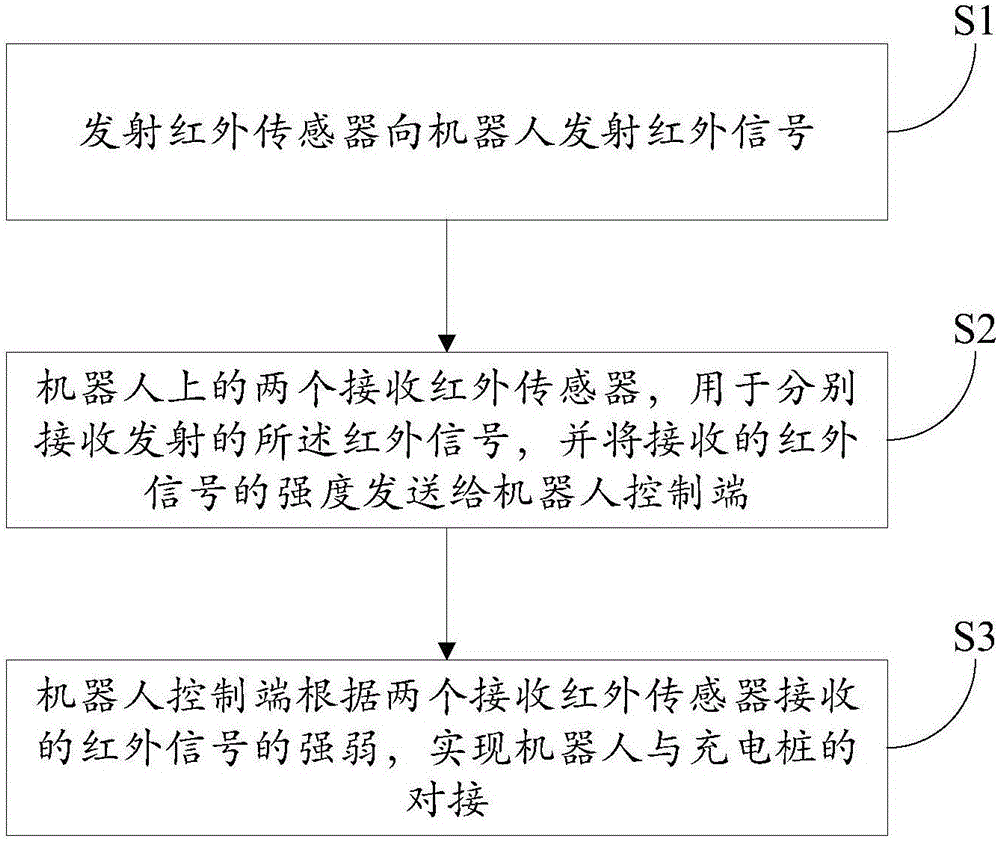

Automatic butt joint charging system and automatic butt joint charging method for robot

ActiveCN106130136ARealize automatic chargingRealize automatic dockingCoupling device engaging/disengagingElectric powerEngineeringElectrode Contact

The invention discloses an automatic butt joint charging system and an automatic butt joint charging method for a robot. The automatic butt joint charging system for the robot comprises a robot and a charging pile, wherein the robot comprises a robot shell, a robot positive electrode contact copper plate, an insulated sleeve, a robot negative electrode contact copper plate, two receiving infrared sensors and a robot control end; the charging pile comprises a charging pile shell, a charging pile positive electrode contact copper plate, a charging insulated sleeve, a charging pile negative electrode contact copper plate, a guide sleeve, (2n+1) transmitting infrared sensors, a baffle, a limiting switch, a charging adapter and a charging pile control terminal. Through detesting the strength of infrared signals received by the receiving infrared sensors at different positions on the robot, automatic butt joint between the robot and the charging pile is realized, and compared with the existing mode in which the charging pile adopts a manual aerial plug for charging, manual operation is reduced, and automatic charging on the robot by the charging pile is realized.

Owner:BEIJING C&W ELECTRONICS GRP

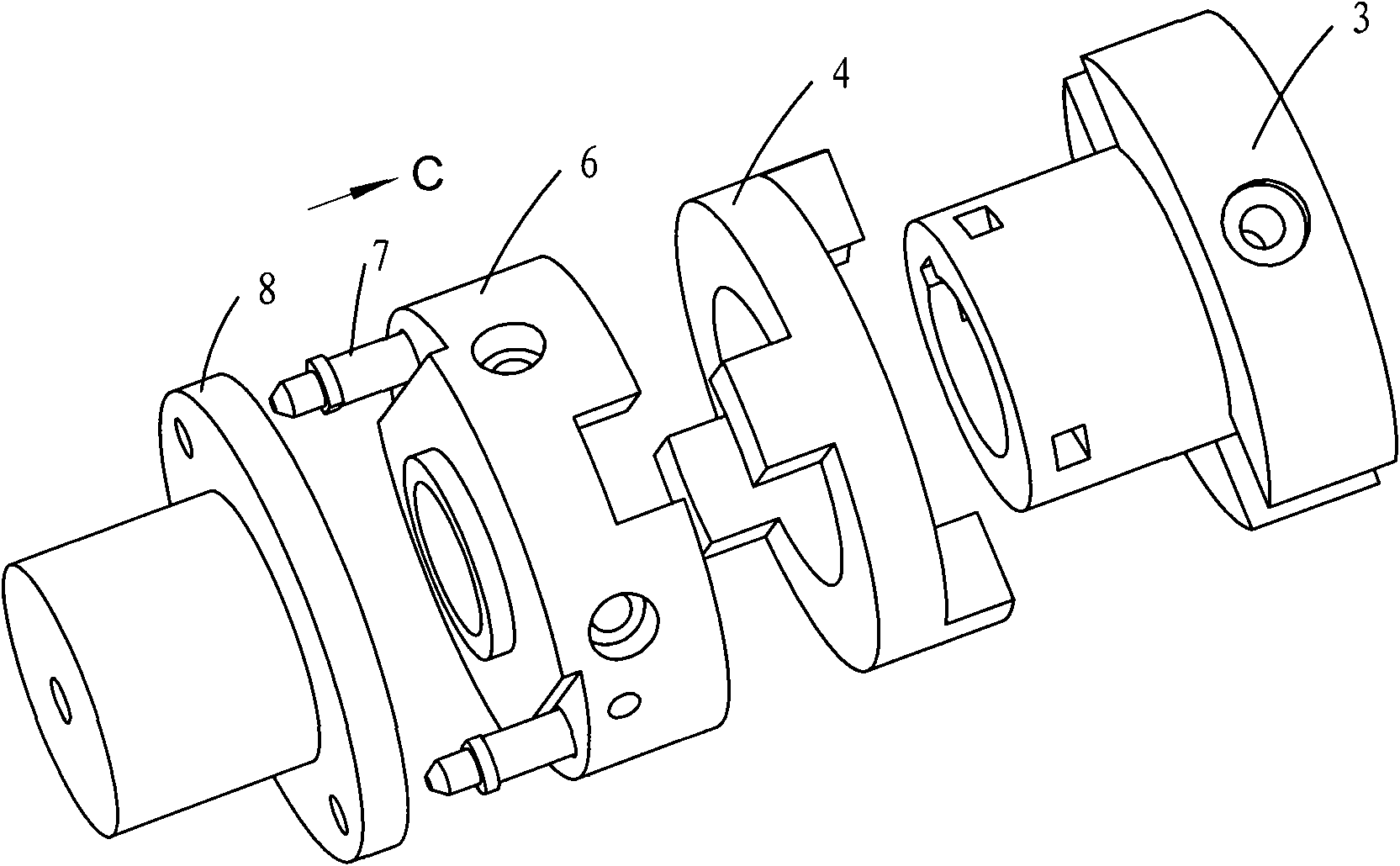

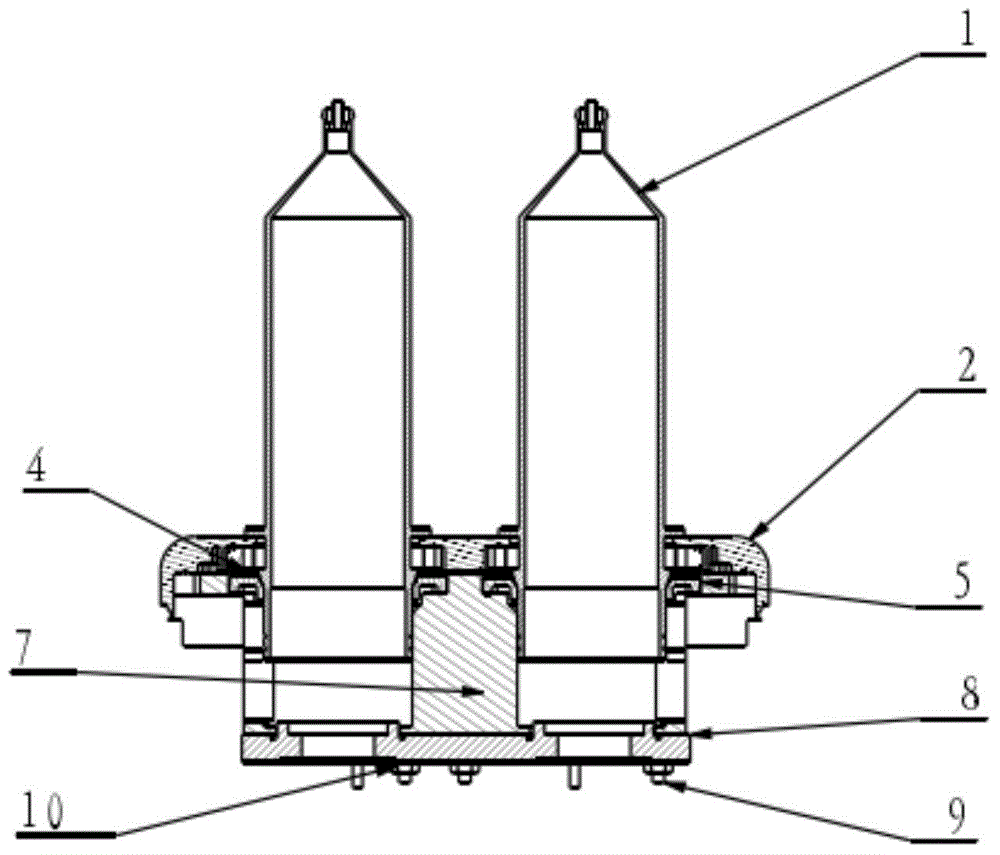

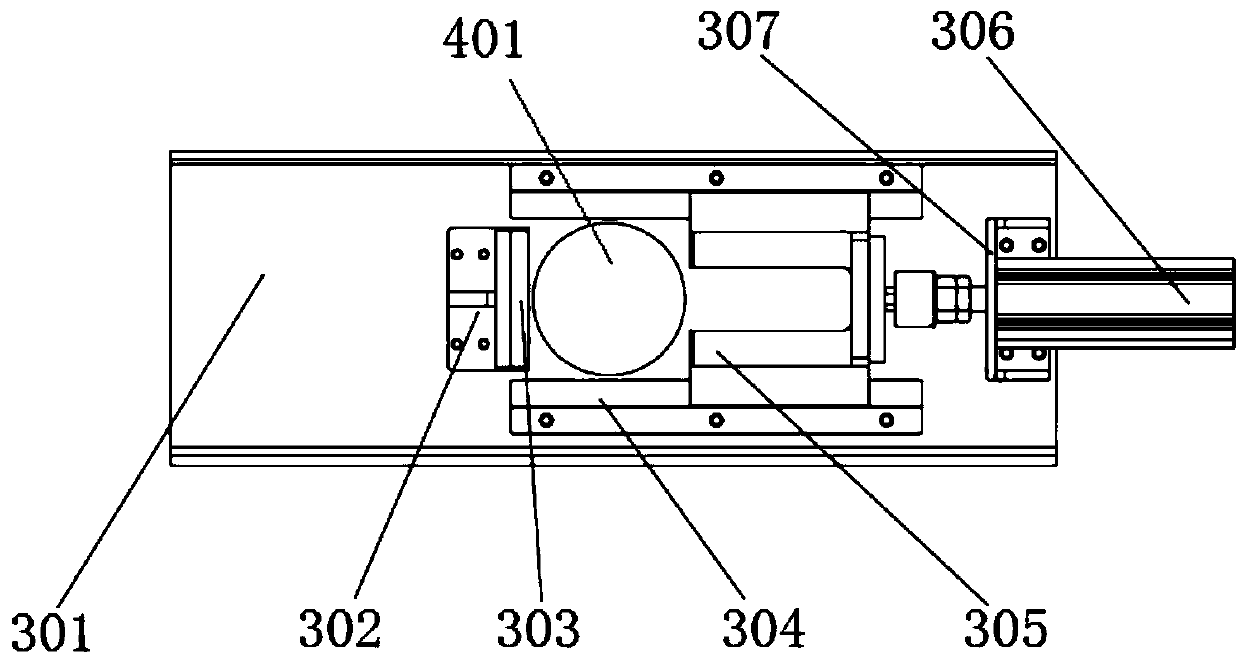

Double slider coupling for drive test of automobile rear axle or final drive assembly

InactiveCN101943222ARealize automatic resetRealize automatic dockingYielding couplingButt jointReduction drive

The invention relates to a double slider coupling for drive test of an automobile rear axle or final drive assembly. The double slider coupling comprises a first half coupling, a second half coupling and a middle double slider between the first half coupling and the second half coupling; the first half coupling, the middle double slider and the second half coupling are all provided with a centre hole; a drive shaft connected with a drive device is inserted into the centre hole of the first half coupling; the first half coupling passes through the centre hole of the middle double slider and then is inserted into the centre hole of the second half coupling; and the inner diameter of the centre hole of the second half coupling is greater than the outer diameter of the end of the first half coupling inserted into the centre hole of the second half coupling so as to compensate for the coaxiality error between the drive shaft and the final drive flange. The double slider coupling has the advantages that: as the double slider coupling can be connected to the drive shaft in a single-shaft supporting way, automatic butt joint between the drive shaft and the flange can be realized; and the working efficiency is improved considerably.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Optical fiber core butt joint device

ActiveCN103439768AReduce participationRealize automatic dockingMultiplex system selection arrangementsCoupling light guidesFiberButt joint

An embodiment of the invention discloses an optical fiber core butt joint device. The optical fiber core butt joint device comprises a butt joint board, an optical fiber core butt joint connector and a mechanical arm, wherein the optical fiber core butt joint connector comprises a plurality of line connectors parallel to one another and a plurality of rope connectors parallel to one another, each line connector comprises a first sliding rod, a first line fiber core connector and a second line fiber core connector, the input end and the output end of each first line fiber core connector are connected with each other through a connection optical fiber, and the input end and the output end of each second line fiber core connector are connected with each other through a connection optical fiber; each rope connector comprises a second sliding rod, a first rope fiber core connector and a second rope fiber core connector, wherein each first rope fiber core connector is connected with each second rope fiber core connector through a connection optical fiber. By means of the optical fiber core butt joint device, automatic butt joint of different line optical fibers in an optical fiber network can be achieved, operation is simple, a great amount of manpower and material resources are saved, and work efficiency is improved.

Owner:STATE GRID CORP OF CHINA +1

Self-adaptive butt-joint automatic charger

ActiveCN103236730ARealize automatic dockingSimple structureBatteries circuit arrangementsCoupling device detailsButt jointCharged body

The invention relates to a charger, in particular to a self-adaptive butt-joint automatic charger. The purpose is to solve the problems that a conventional movable robot cannot be automatically charged, the manufacturing cost of a conventional automatic movable robot charger is high, and control is inaccurate. Two stop dogs are respectively arranged on two sides of the top surface of a charge base of the self-adaptive butt-joint automatic charger, a central rotating mechanism is mounted on the top surface of the charge base, a horizontal moving mechanism is mounted on the top surface of the central rotating mechanism, a charge contact platform is mounted on the horizontal moving mechanism, a positioning guide is mounted at the middle of the mounting surface of the charge contact platform, two charge contact points are respectively mounted on two sides of the positioning guide, the middle of the power-receiving surface of a power-receiving base is provided with a power-receiving positioning socket, two power-receiving contact points are respectively mounted by two sides of the power-receiving positioning socket, a sensor is mounted in the power-receiving positioning socket, and the positioning guide on the charge body can be plugged into the power-receiving positioning socket on the power-receiving base. The self-adaptive butt-joint automatic charger is used for charging movable robots.

Owner:HARBIN INST OF TECH

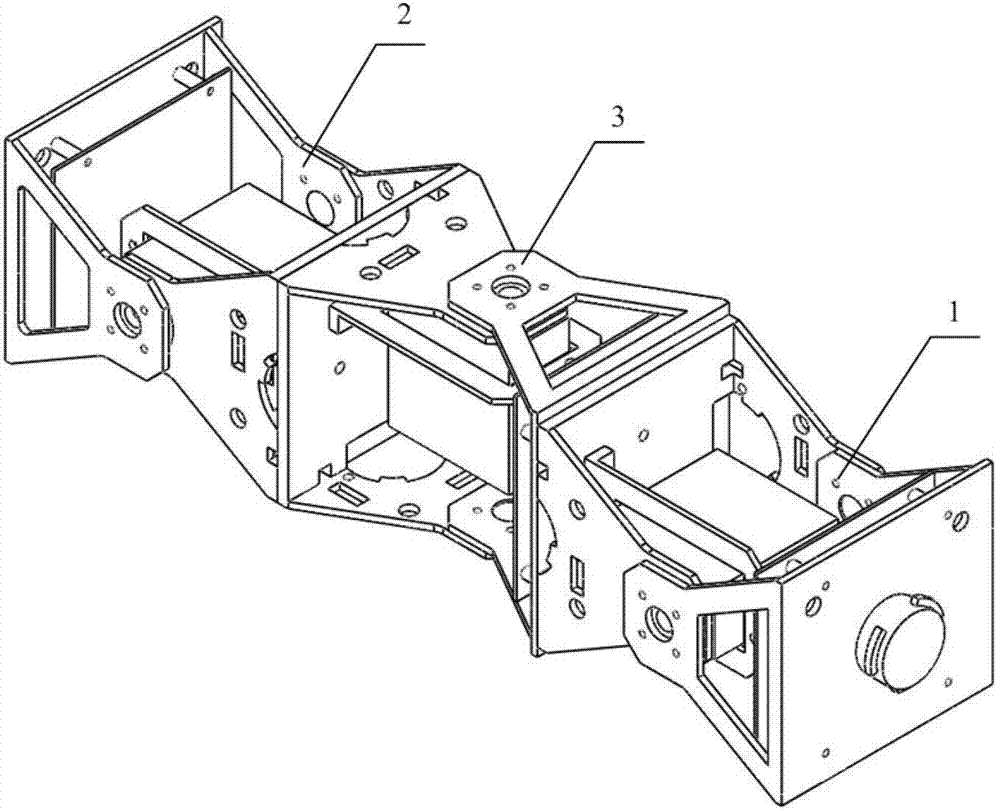

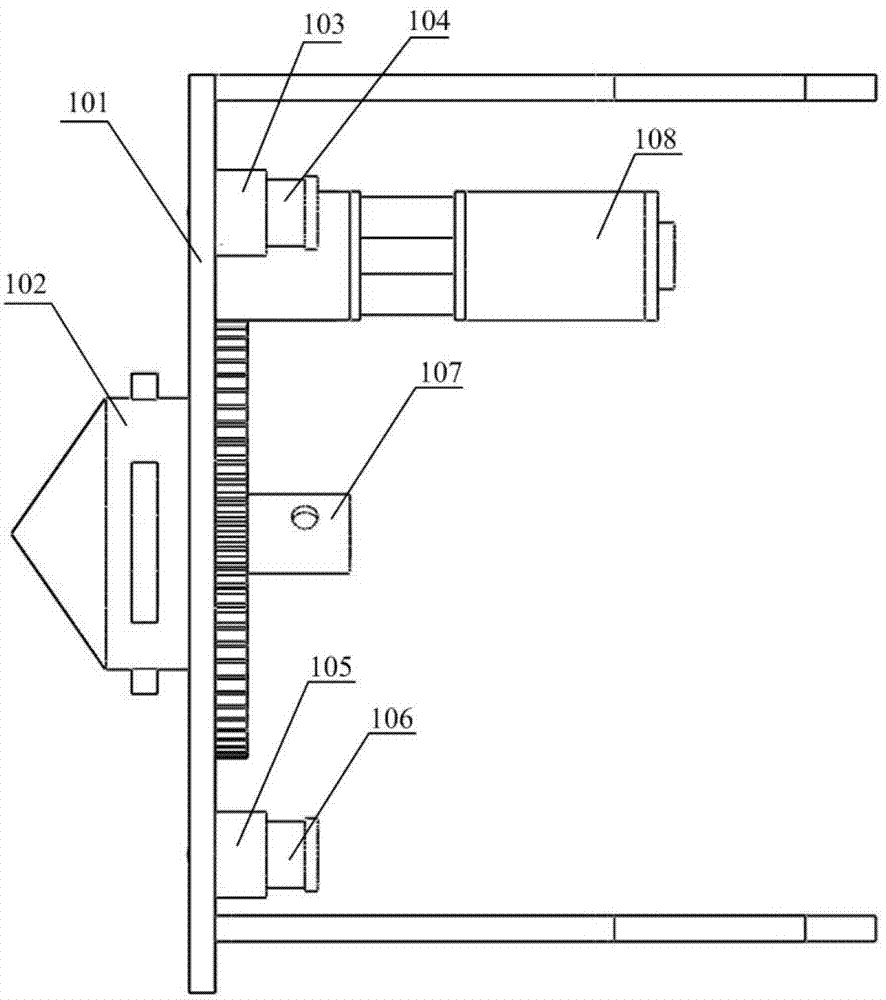

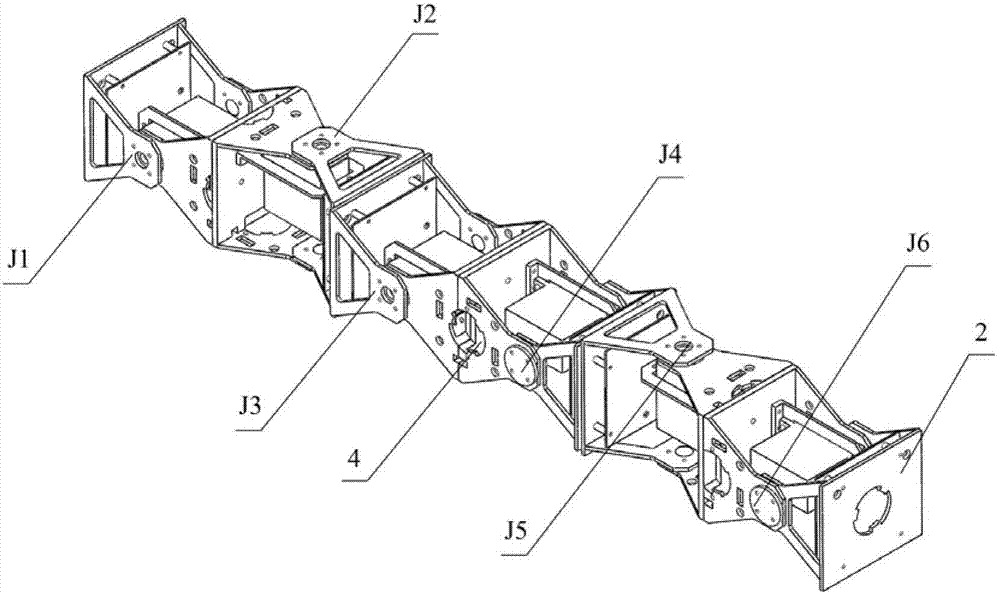

Modular self-reconfigurable robot and method for controlling deformation thereof

ActiveCN102765087ARealize dockingAchieve separationProgramme-controlled manipulatorRelative displacementModularity

The invention relates to a modular self-reconfigurable robot and a method for controlling the deformation of the modular self-reconfigurable robot. The modular self-reconfigurable robot is formed by connecting monomers and can be in a ''-'' configuration and a ''+'' configuration. The initial configuration of the modular self-reconfigurable robot is the ''-'' configuration and comprises a head module, a middle module and a tail module; when a deformation control command is received, the butting mechanisms of the head module, the tail module and the middle module separate, and the middle module rotates until the middle module is perpendicular to the head module and the tail module. The process for butting automatically comprises the steps of adjusting the initial relative angle, the relative angle deviation and the relative displacement deviation of the butted surfaces and locking the abutting mechanism. Therefore, the head module, the tail module and the middle module are finally abutted, the change of the modular self-reconfigurable robot from the ''-'' configuration to the ''+'' configuration, and the change from the ''+'' configuration to the ''-'' configuration can be realized. The monomers can be separated and butted easily and effectively, and the change of the ''-'' configuration and the ''+'' configuration of the modular self-reconfigurable robot between the can be realized.

Owner:NANJING PANDA ELECTRONICS +1

Efficient insertion pipe joint mounting device

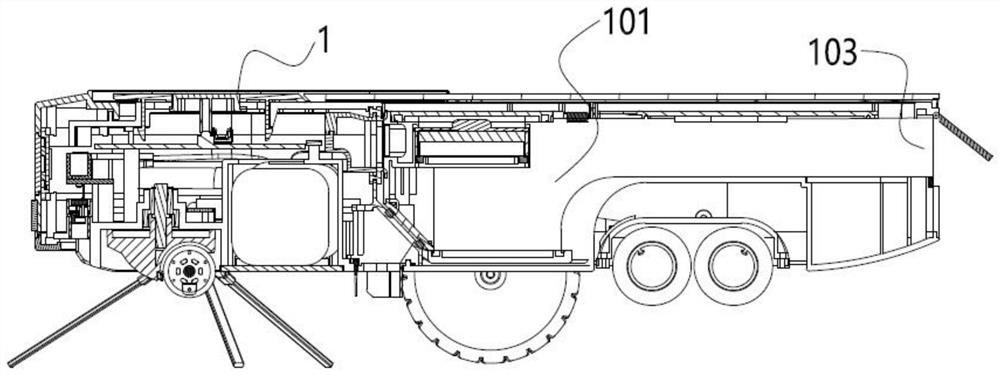

ActiveCN108488484ARealize automatic dockingOvercome time-consuming and labor-intensive shortcomingsPipe laying and repairAutomationPetroleum engineering

The invention discloses an efficient insertion pipe joint mounting device. The efficient insertion pipe joint mounting device comprises a mobile platform, a power device, a traction device, a fixing device and a pipe binding belt; the power device and the traction device are fixedly arranged on the mobile platform; the fixing device is fixedly arranged below the surface of the mobile platform; thefixing device is used for clamping pipe bearing ports; the pipe binding belt is opposite to the fixing device; the two sides of the pipe binding belt are connected with a steel strands; the pipe binding belt is connected with the traction device through the steel strands; the pipe binding belt is used for sleeving pipe insertion ports; the power device is connected with the traction device; the power device drives the steel strands to shrink through the traction device; and the steel strands pull the pipe binding belt to enable the pipe insertion ports to move to the pipe bearing ports. The efficient insertion pipe joint mounting device realizes automatic insertion of the pipe insertion ports and the pipe bearing ports, is high in automation degree, improves the efficiency, shortens the construction period, saves both time and labors, and is low in labor cost.

Owner:中冶南方城市建设工程技术有限公司

Control method of cleaning robot system

PendingCN112545394ARealize automatic cleaningIncrease frictionCarpet cleanersFloor cleanersRobotic systemsProcess engineering

The invention relates to a control method of a cleaning robot system, which comprises a cleaning robot and an integration station, and the integration station is at least used for stopping the cleaning robot. The control method comprises the following steps that the cleaning robot walks from the indoor ground to the integration station to stop; when the cleaning robot stops in place, the dust collecting part on the integration station is in butt joint with the dust discharging part on the cleaning robot, and the cleaning part is located in a cleaning area; a control module controls a first airflow generator to start to work, so that the garbage cavity communicates with a dust collecting box, and garbage in the garbage cavity enters the dust collecting box through the dust discharging partand the dust collecting part; and / or the control module controls the power mechanism to start to work, so that the cleaning area is communicated with the sewage tank, and sewage in the cleaning area enters the sewage tank; according to the scheme, the problems that an existing cleaning robot is poor in mopping effect, garbage in a garbage cavity needs to be manually treated by a user, and mop cloth needs to be manually cleaned are solved, and meanwhile the problems that an existing base station is single in function and cannot meet use requirements are solved.

Owner:杭州匠龙机器人科技有限公司

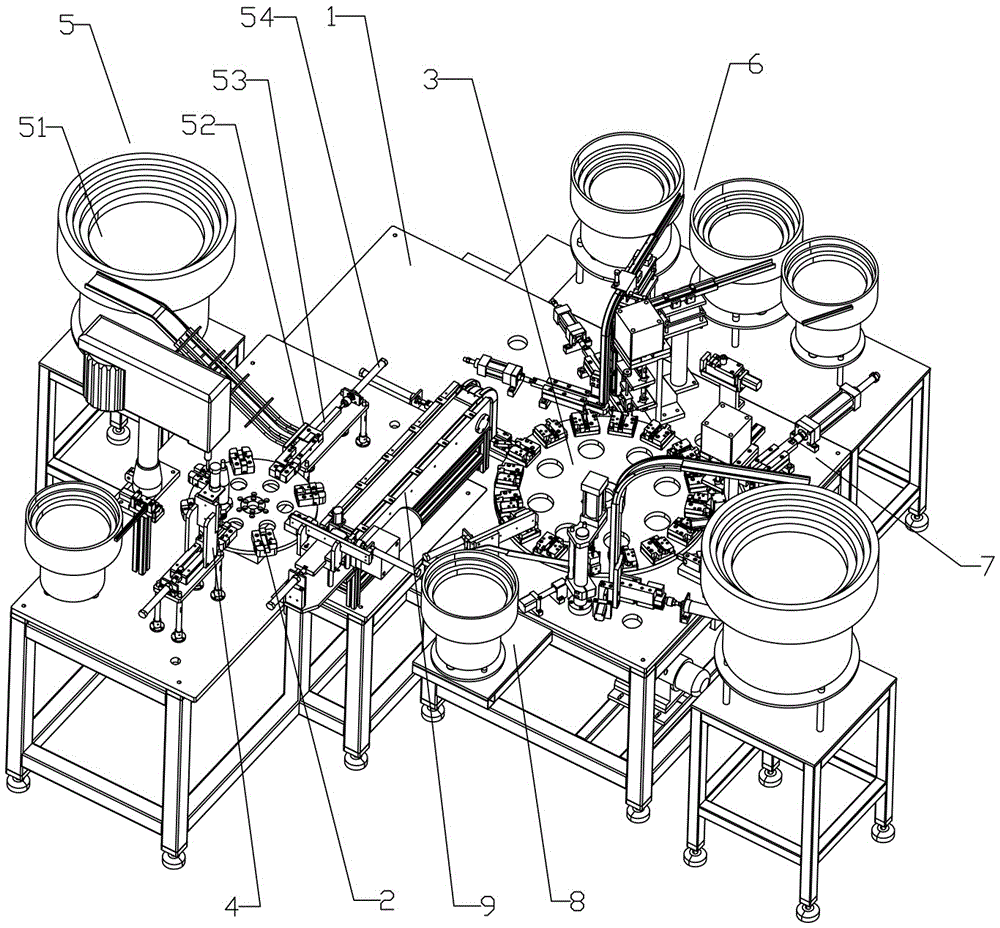

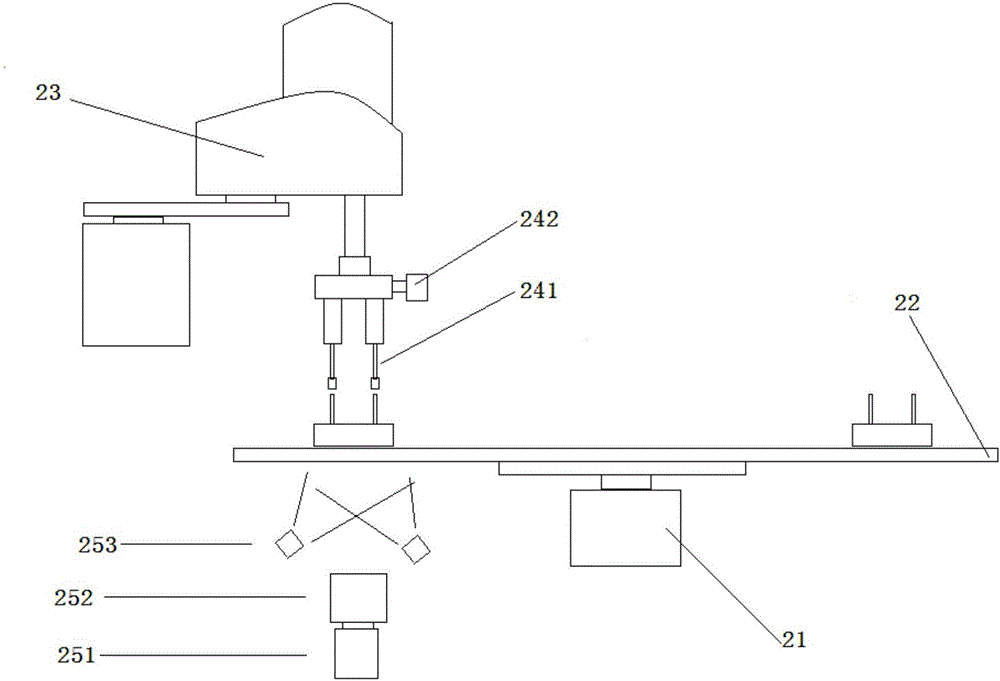

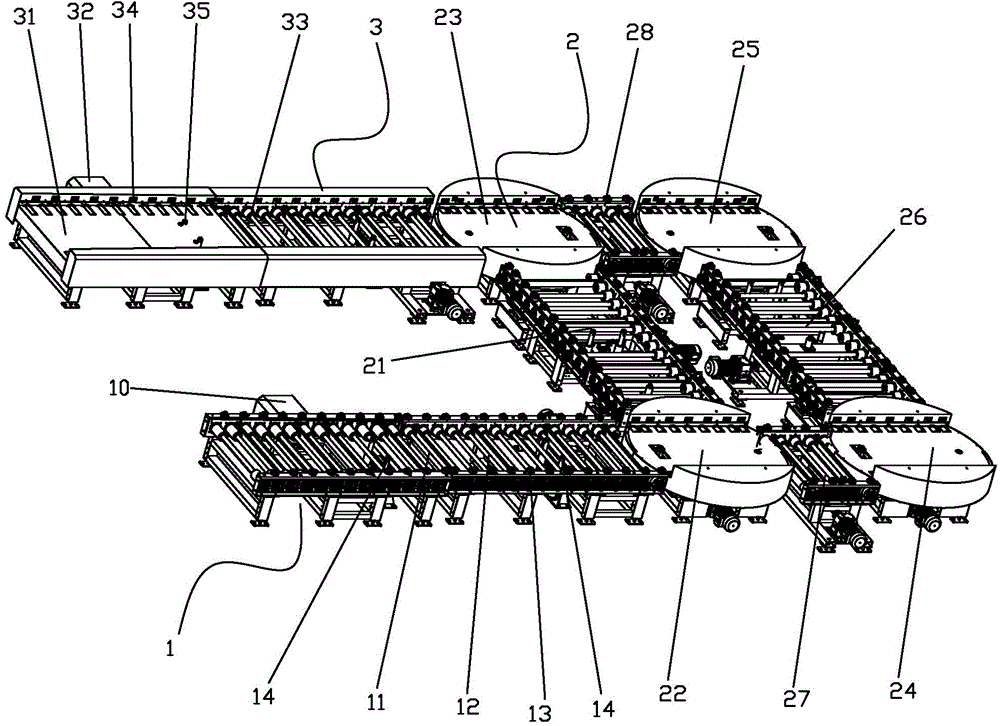

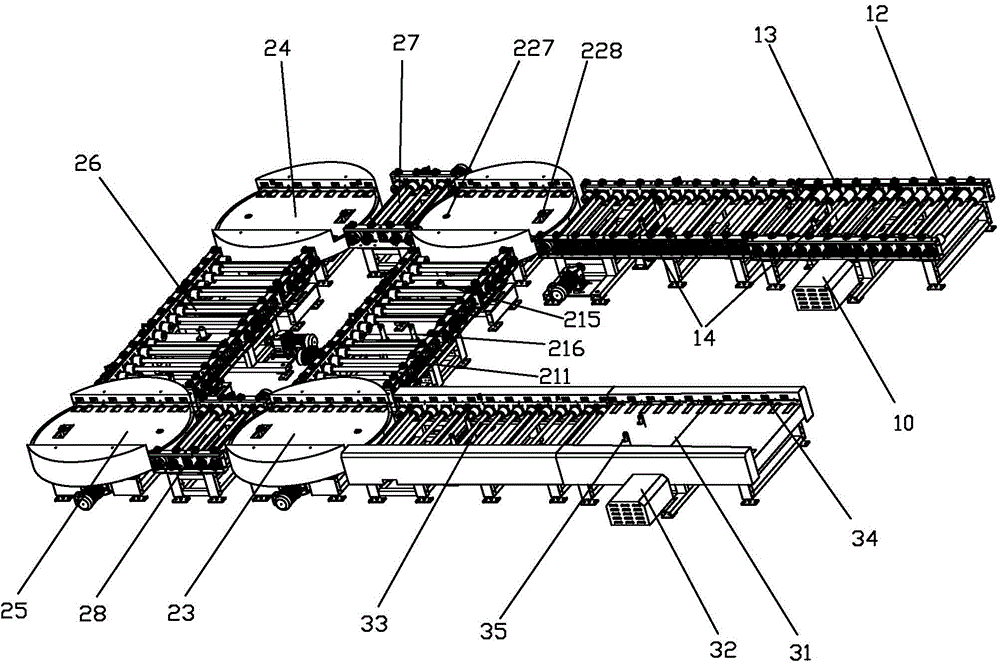

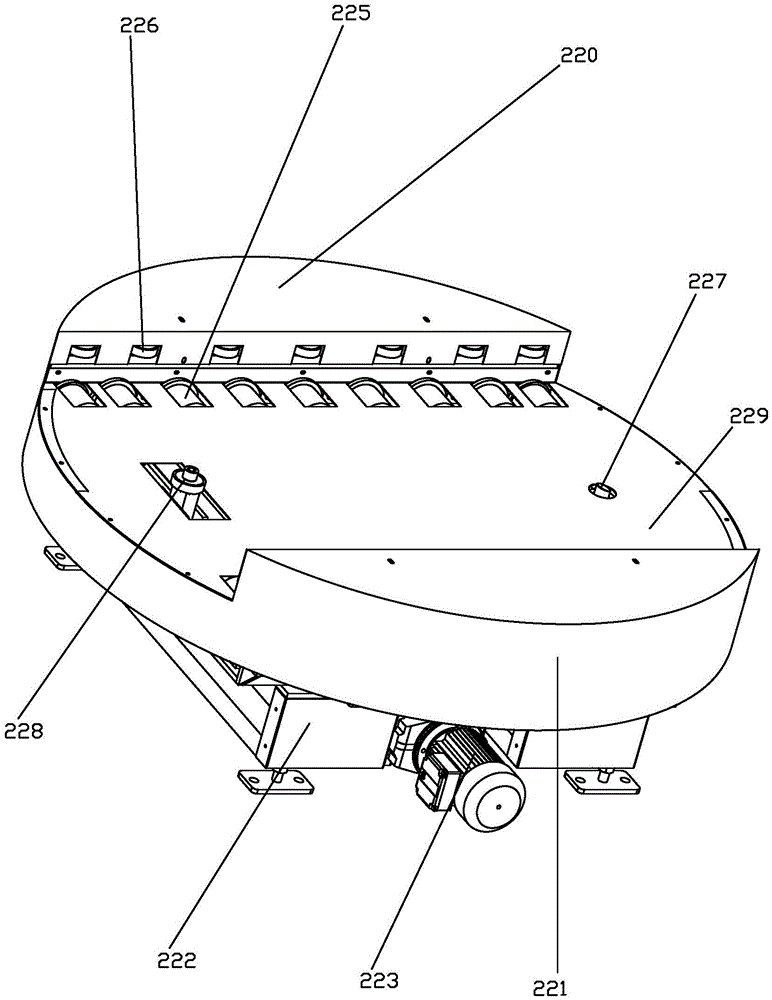

Full-automatic photoelectric detection system for LED nixie tube and method thereof

ActiveCN105548850AAutomatic feedRealize automatic dockingOptically investigating flaws/contaminationTesting optical propertiesComputer hardwareImaging processing

The invention provides a full-automatic photoelectric detection system for an LED nixie tube and a method thereof. The system is composed of an automatic feeding module, an automatic detection module, an automatic blanking module and a main control module. The automatic feeding module connected with the main control module is used for realizing automatic feeding of a measured LED nixie tube; the automatic detection module is used for realizing automatic photoelectric detection of the measured LED nixie tube and consists of a rotating platform, a transparent glass plate, a mechanical arm, a center module, an image acquisition module, an image processing module, an electrical property testing module, and a black box; and the automatic blanking module connected with the main control module is used for carrying out automatic sorting on detected LED nixie tubes. According to the invention, high-efficiency full-automatic testing of LED nixie tubes with different types can be realized; and the photoelectric performance detection of the LED nixie tube is accelerated and the detection accuracy is high.

Owner:WAYRISE INTELLIGENT TECH

Connection structure of water pipes

InactiveCN103807541ARealize automatic dockingGuaranteed concentricityCouplingsHose connectionsJoint componentButt joint

The invention discloses a connection structure of water pipes. The connection structure comprises a movable joint component, a fixed joint component and magnetic pieces, wherein the magnetic pieces are respectively arranged in one end of the movable joint component and one end of the fixed joint component; one ends of the movable joint component and the fixed joint component are magnetically connected by virtue of the magnetic pieces; the magnetic pieces are magnets. By virtue of adopting the technical scheme, the connection structure has the beneficial effects that the structure is simple, automatic water pipe abutting joint is realized, butting joint also can be realized under an eccentric condition, and the concentricity of the abutted water pipes is ensured; friction is prevented from being generated, risks are reduced, requirements on environment are low, and the connection structure is applicable to various structures.

Owner:SUZHOU IND PARK KALERM ELECTRIC APPLIANCES CO LTD

Optical fiber core jointer

The embodiment of the invention discloses an optical fiber core jointer. The optical fiber core jointer comprises a fiber core pulling device, a fiber core fixing device, a fiber core sliding device and an elastic device, wherein grooves matched with raised structures on the side wall of a jointing plate are arranged at the side wall of the fiber core sliding device; the fiber core sliding device is fixed in the horizontal direction to move by the matching between the grooves and the raised structures; the elastic device is only telescopic in the vertical direction; during the specific operation, only external equipment is needed for providing an upwards vertical force for the fiber core pulling device, then the fiber core fixing device is driven to upwards move till the fiber core head of an optical fiber leaves from a jointing surface, then the external equipment is utilized for providing a force in the horizontal direction for the fiber core to drive the fiber core fixing device and the fiber core sliding device to slide to the target jointing position, and finally, the action force of the external equipment is removed, the fiber core pulling device and the fiber core fixing device downwards move under the action of the elastic device, and the automatic jointing of multiple paths of optical fiber cores is realized.

Owner:NINGBO YINGMING ELECTRIC TECH

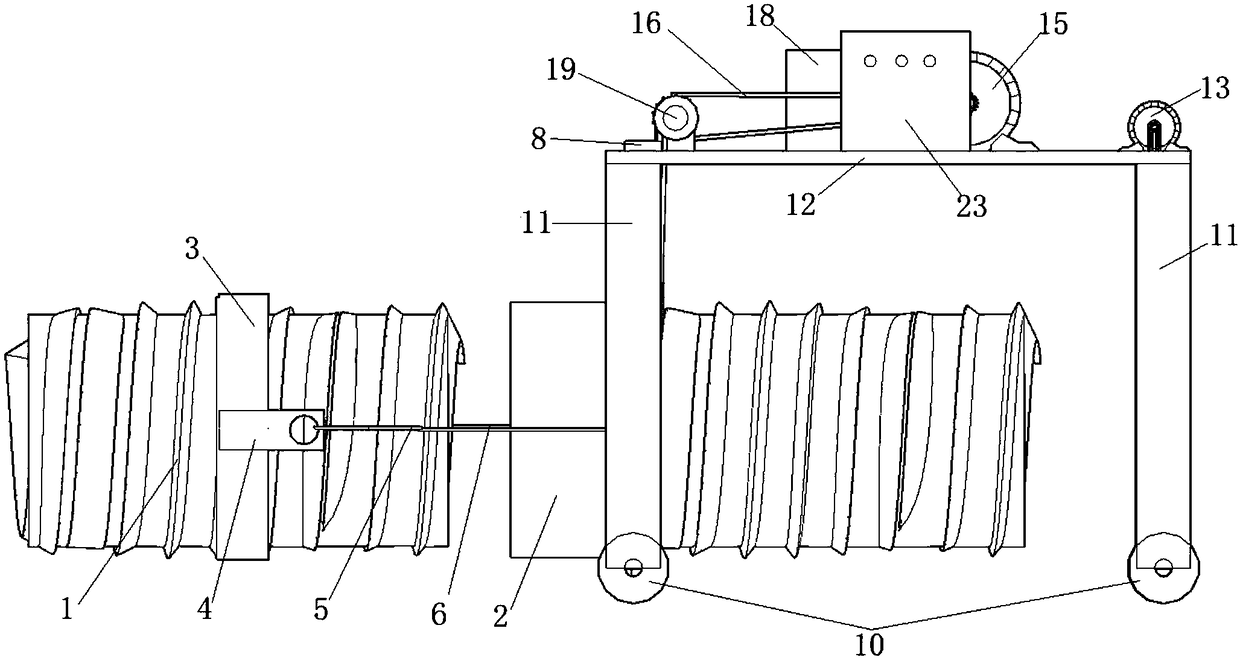

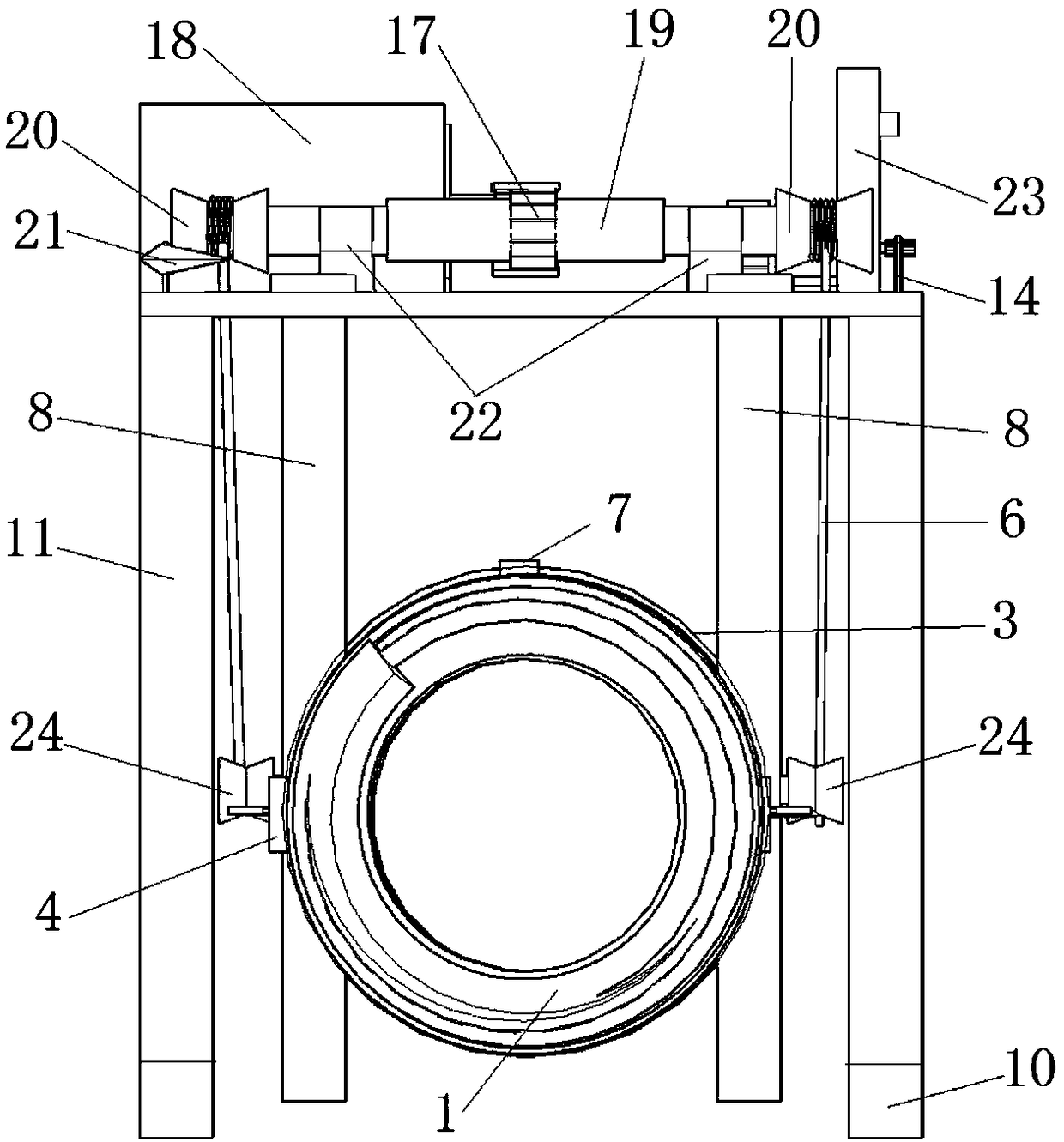

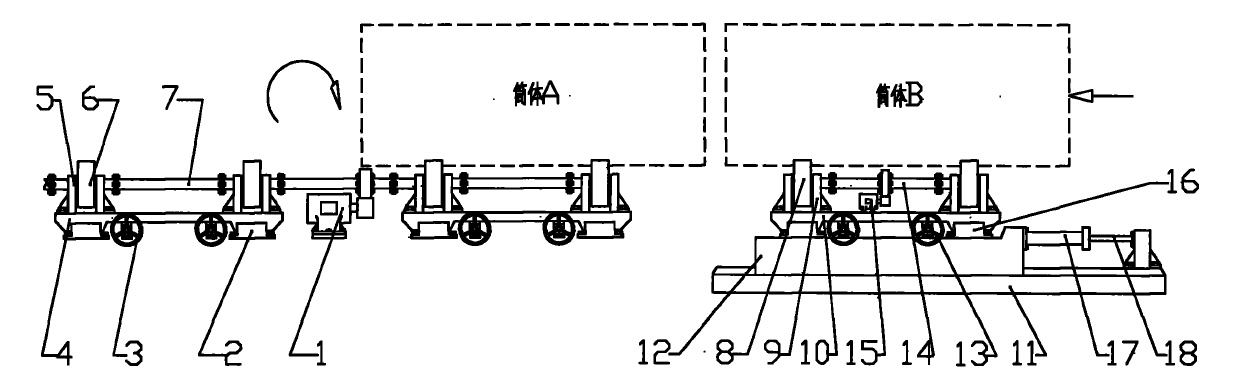

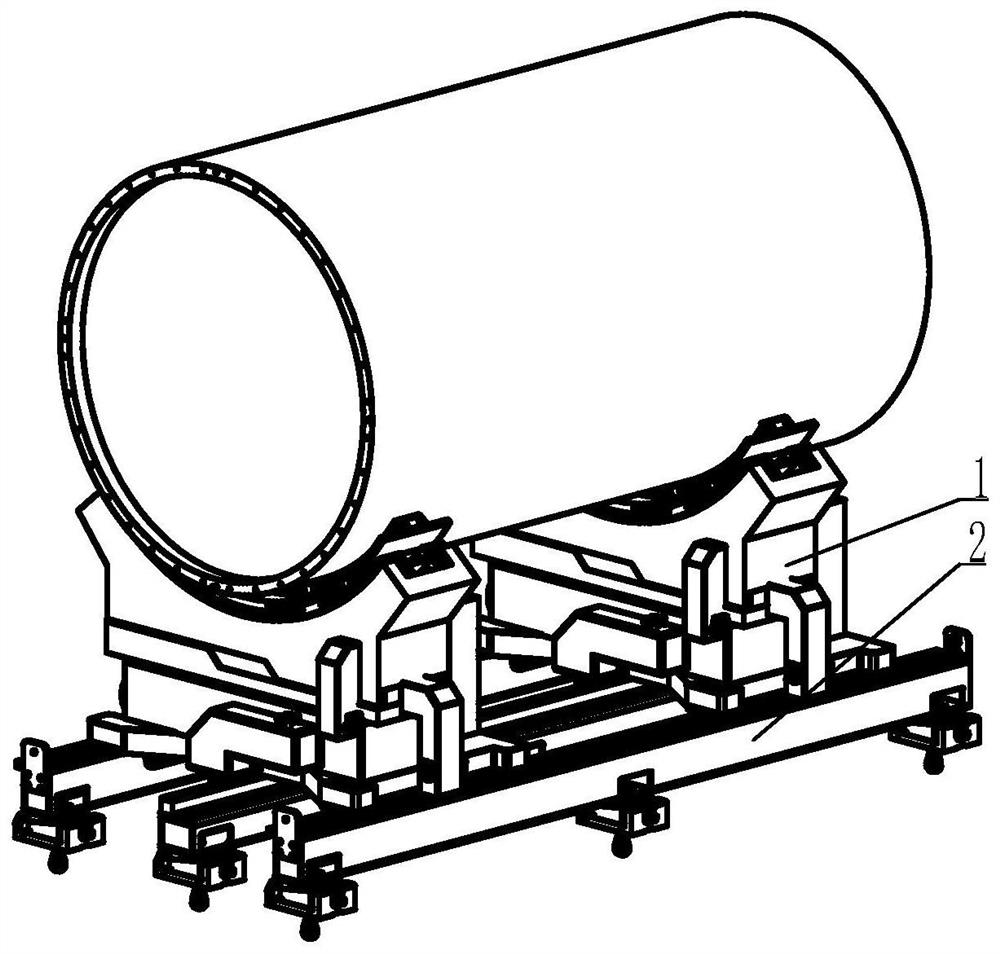

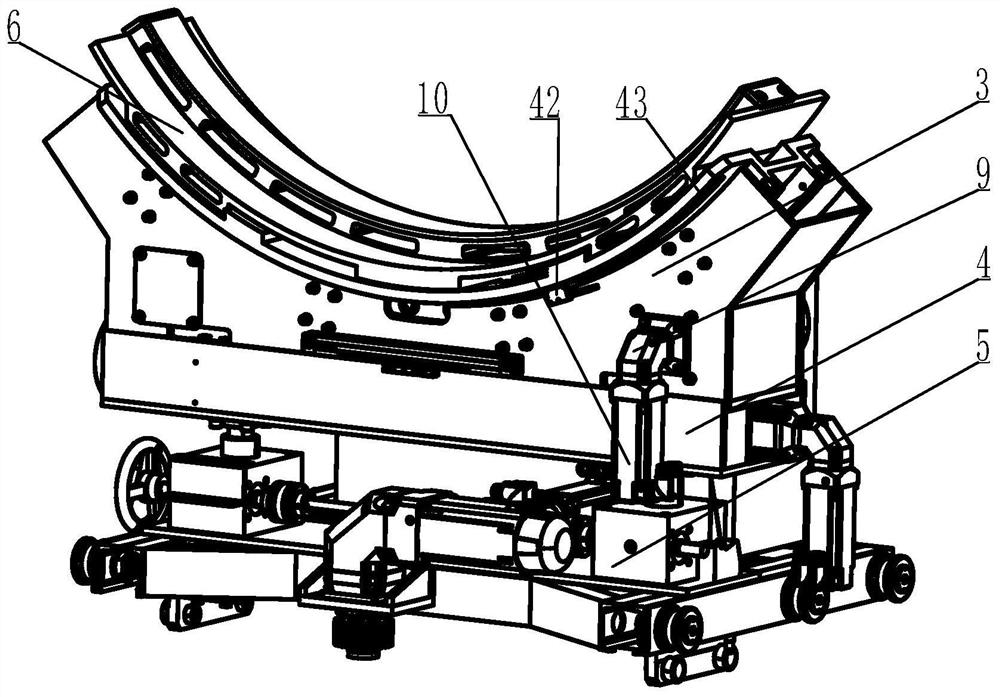

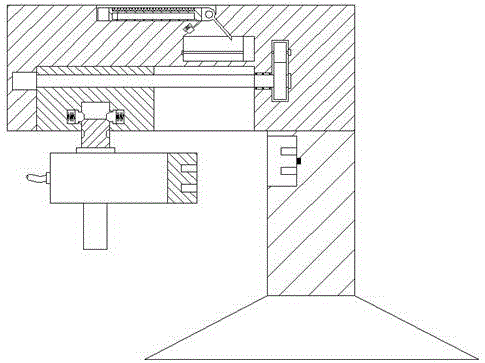

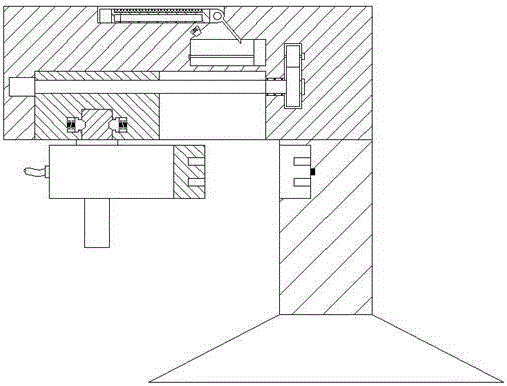

Hydraulic drive automatic gyrorotor butting tooling equipment

InactiveCN101992369AImprove docking accuracyReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesHydraulic cylinderDrive shaft

The invention discloses hydraulic drive automatic gyrorotor butting tooling equipment, which mainly comprises a cylinder rolling rack and a cylinder moving rack. Axes of two rows of transmission shafts on the cylinder rolling rack and axes of two rows of transmission shafts on the cylinder moving rack are positioned on the same plane, and the axes of the transmission shafts on the same side of the two racks are collinear, so that cylinders are butted in the same axis; under the hydraulic driving of the moving rack, the cylinders on the moving rack are displaced linearly, automatically butted,and subjected to circumferential grinding-in, and the butting accuracy of two cylinders is improved; and under the transmission of the hydraulic cylinder of the moving rack, the butted cylinders are driven to displace linearly, circumferentially roll on the rolling rack, and form relative spiral butting-grinding-in motion with the cylinders linearly displacing on the moving rack. The service lifeof the equipment is prolonged, the energy consumption is reduced, and the accuracy is improved; and the equipment has a simple structure, high reliability, high butting accuracy and high speed, is time-saving, labor-saving, safe and high-efficiency, and reduces equipment investment.

Owner:SINOMA TECH (XUZHOU) HEAVY MASCH CO LTD +1

Automatic intelligent filling and conveying device

InactiveCN104944138ARealize automatic dockingReduce walking wasteLiquid bottlingConveyor partsEngineeringMechanical engineering

Owner:GUANGDONG HUACHUANG INTELLIGENT EQUIP CO LTD

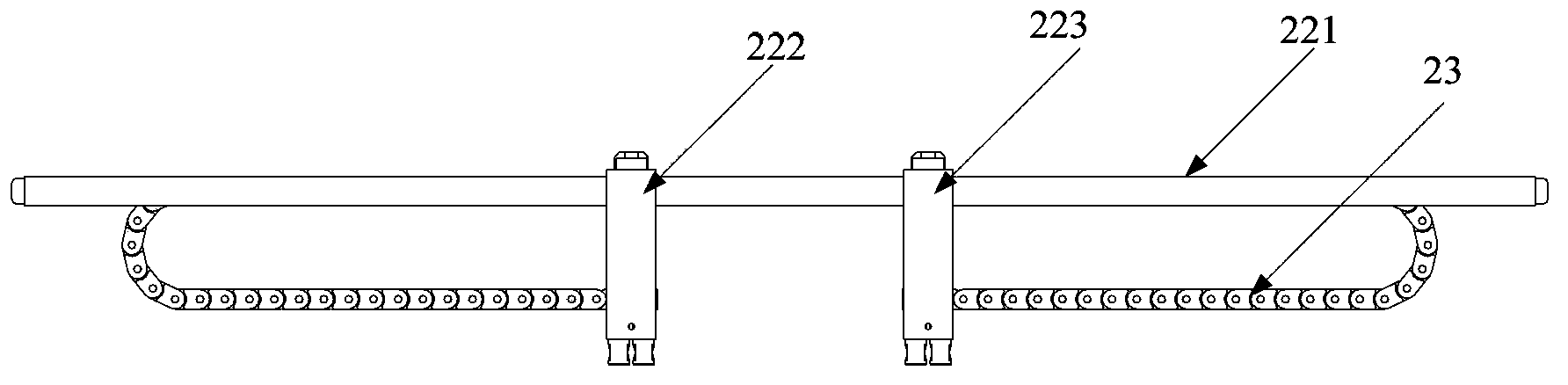

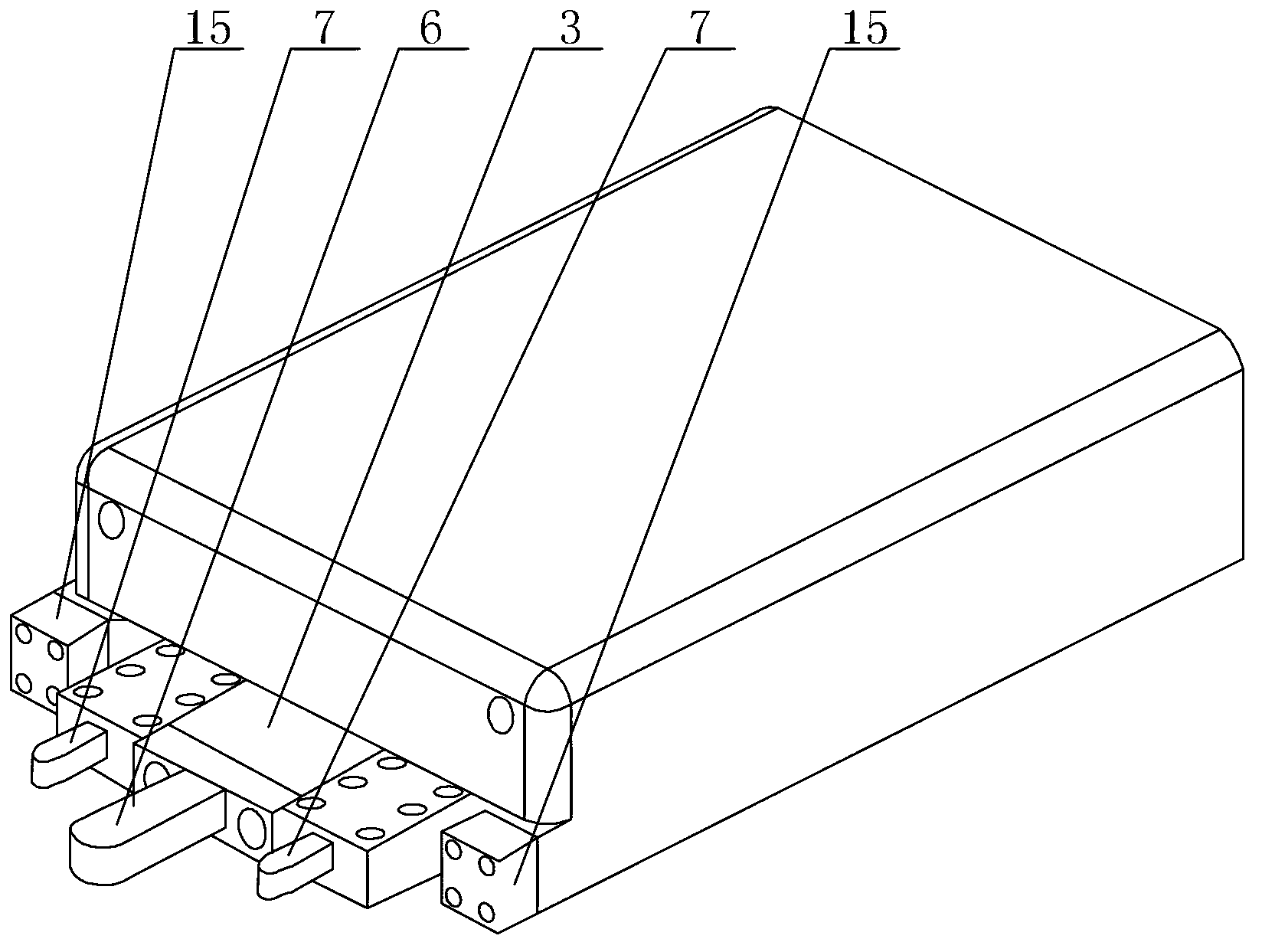

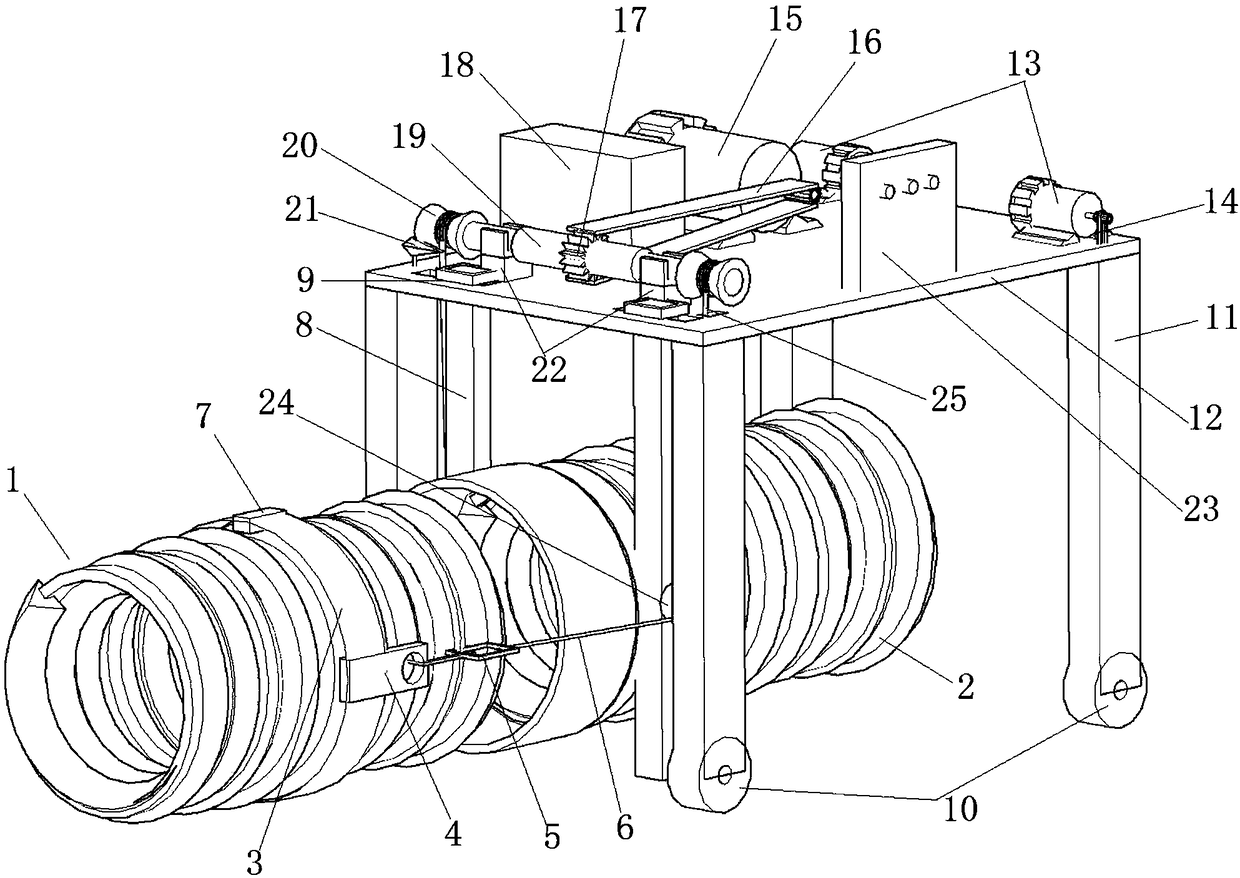

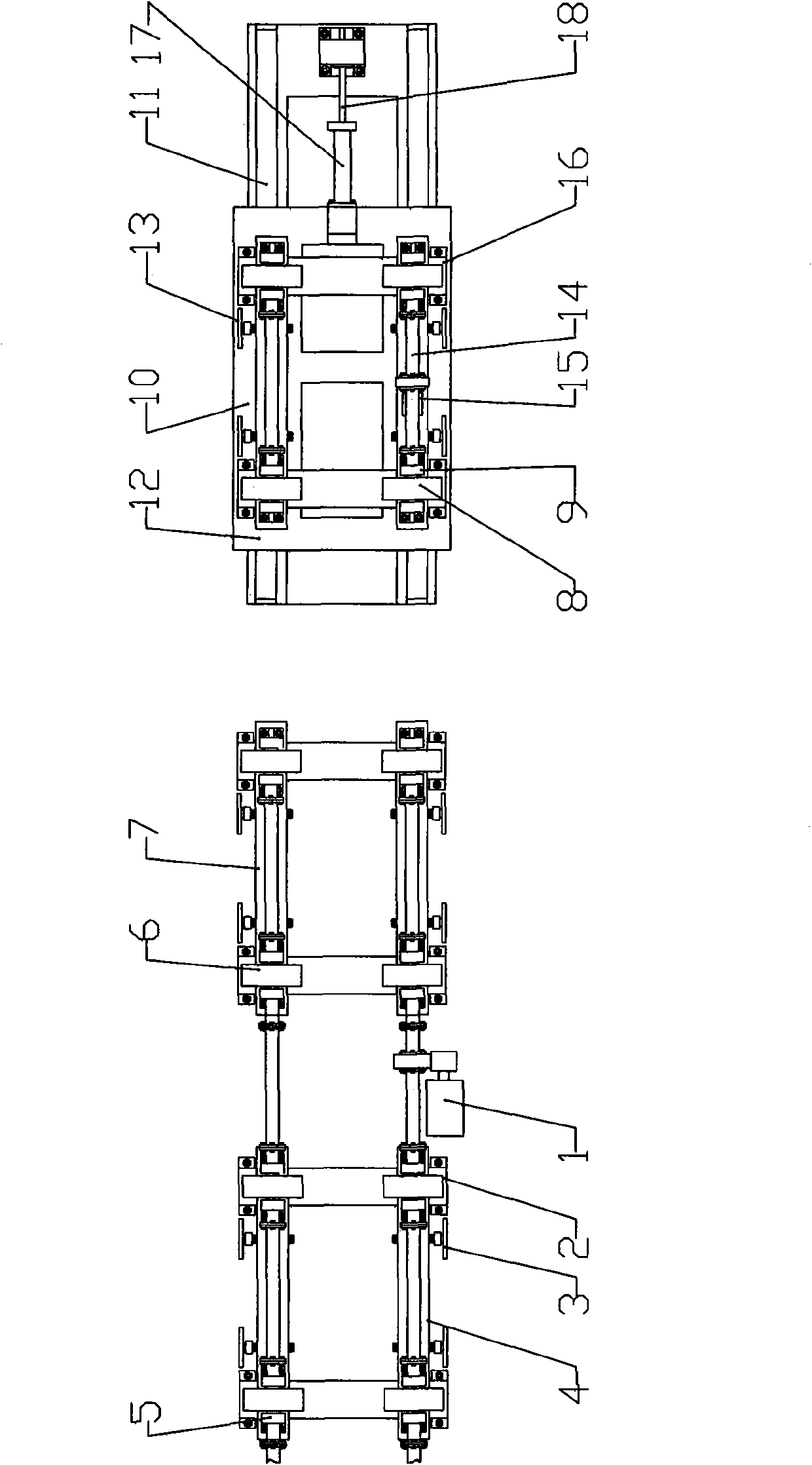

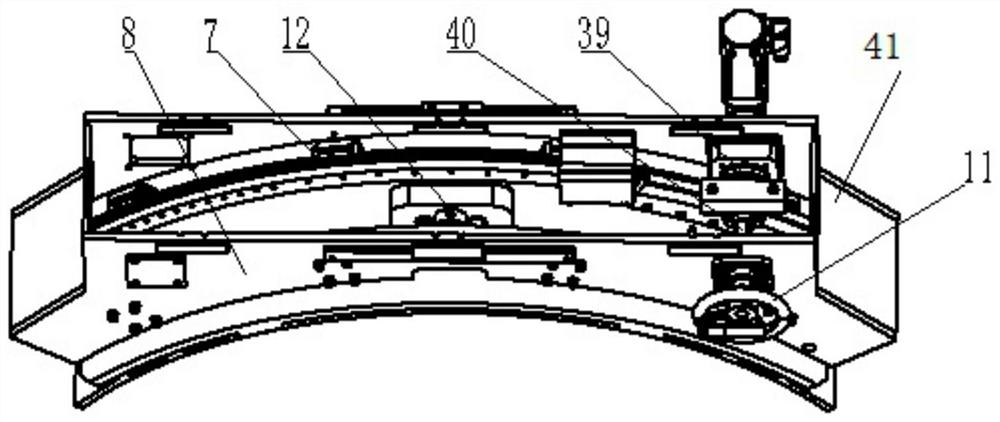

Flexible multi-degree-of-freedom butt joint posture adjusting mechanism

The invention discloses a flexible multi-degree-of-freedom butt joint posture adjusting mechanism which comprises a linear guide mechanism and two posture adjusting mechanisms, and the posture adjusting mechanisms are installed on the linear guide mechanism. Each posture adjusting mechanism comprises a rolling bracket for rolling adjustment, a guide groove for Y-direction translation adjustment and a lifting base for Z-direction lifting adjustment, wherein the rolling bracket is installed in the guide groove, the guide groove is installed in the lifting base, the lifting base is connected with the linear guide mechanism and translates on the linear guide mechanism in the X direction. The flexible multi-degree-of-freedom butt joint posture adjusting mechanism can realize automatic adjustment of postures of cabin section products, has the advantages of high automation degree, high butt joint precision and high assembly efficiency, can reduce the manual operation intensity of butt joint, and reduces manpower resources.

Owner:NANJING CHENGUANG GRP

Recharging seat for automatic dust collector and the joint method between automatic dust collector and recharging seat

The recharging seat includes one charger body and charging seat electrodes on the charger body. The charger body is provided with several bar code shaped installing planes and each of the installing planes has different number of vertical bar codes. According to the bar codes, the automatic dust collector can judge its own position and thus complete the automatic connection to the recharging seat.

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD +1

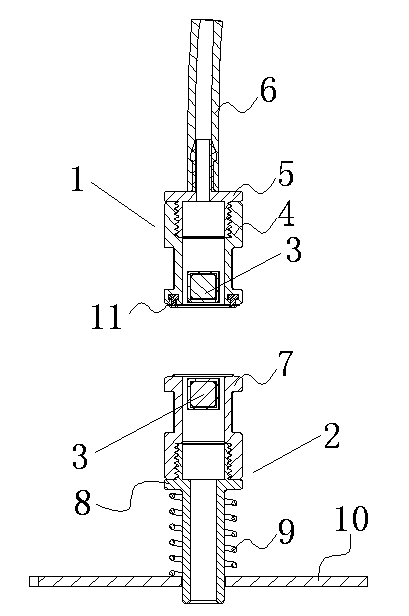

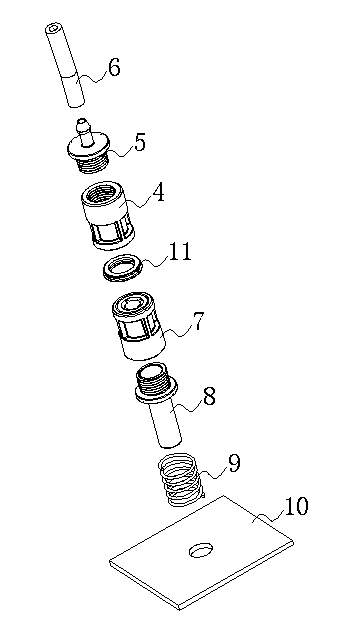

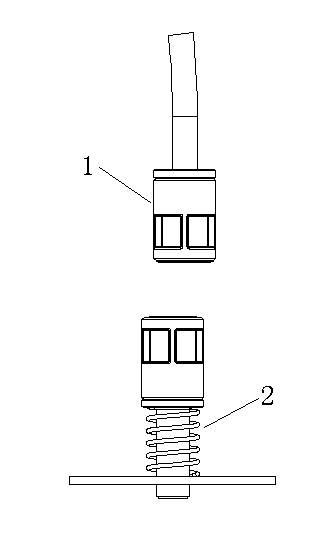

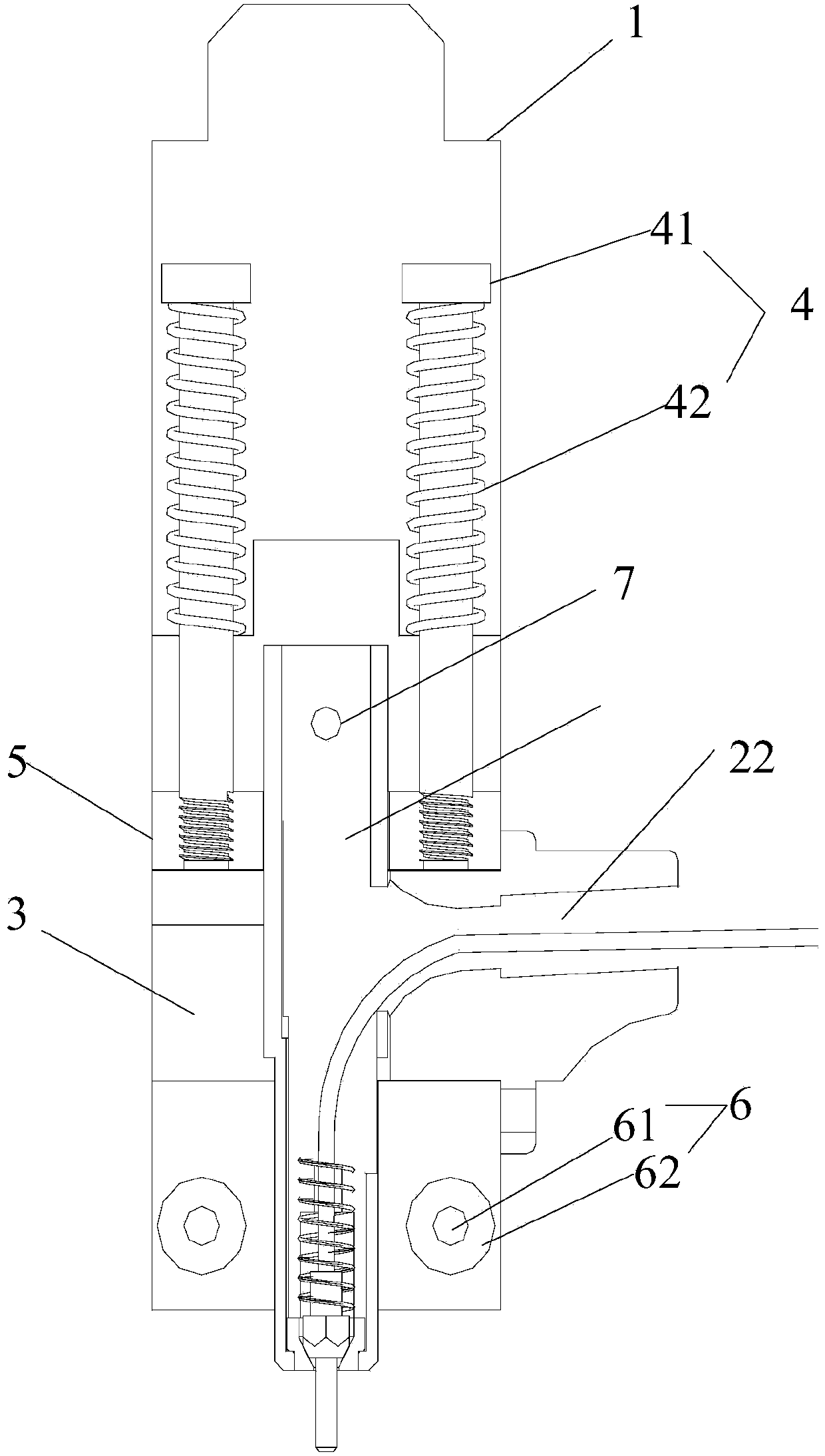

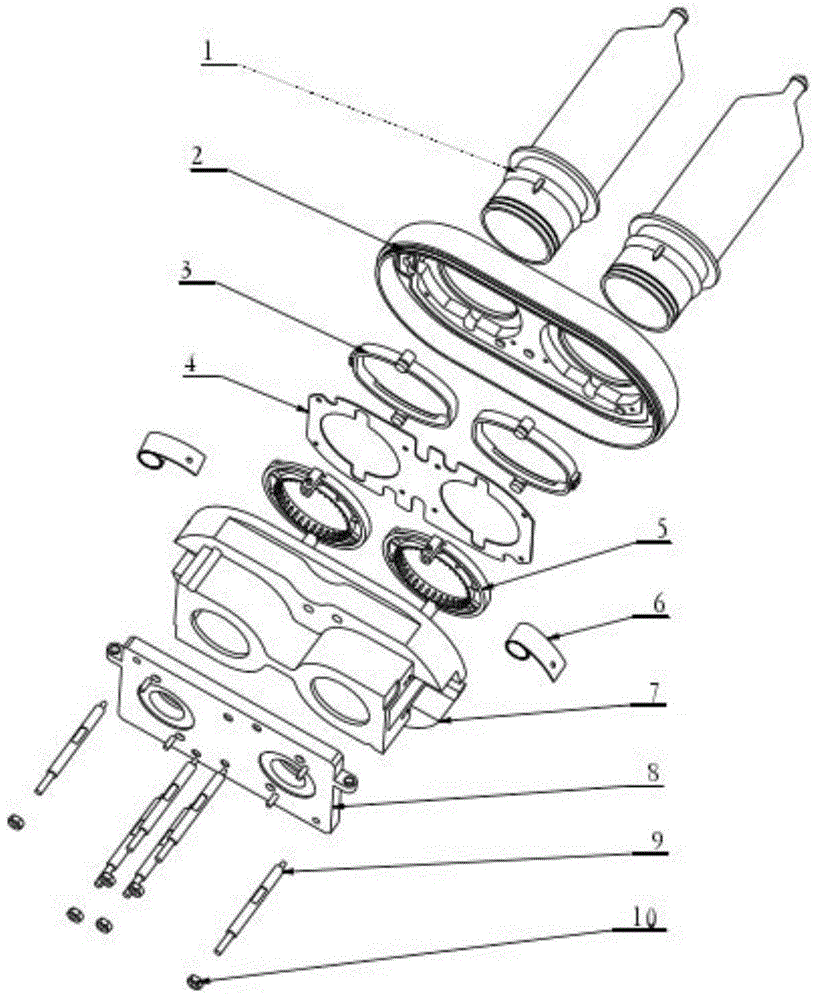

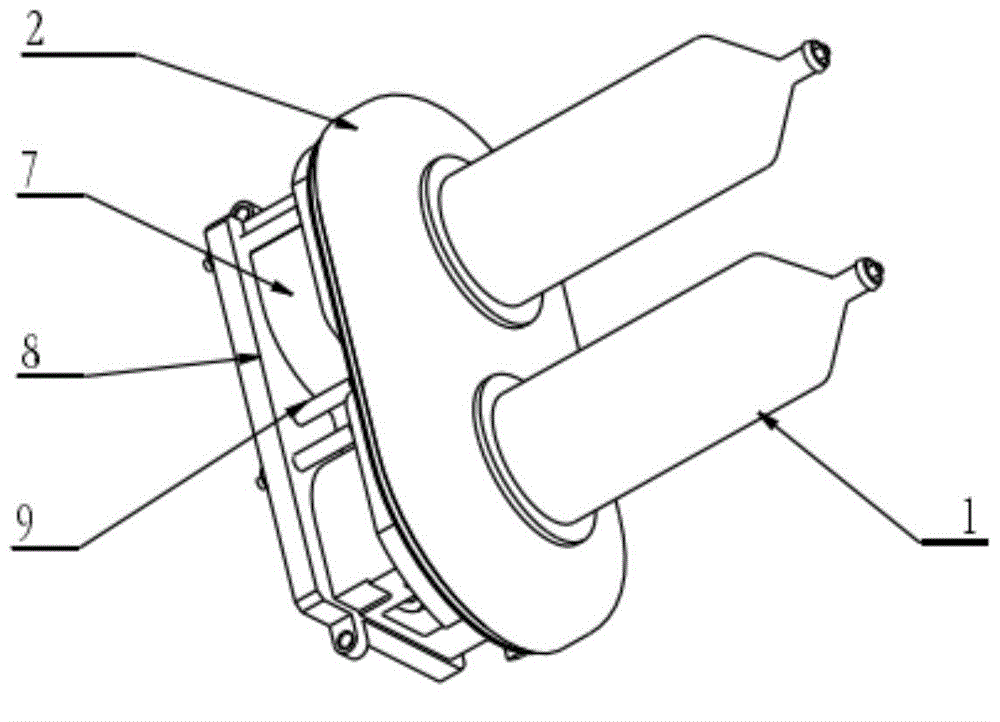

Direct-inserting type high-pressure injector needle cylinder mounting device and method

The invention discloses a direct-inserting type high-pressure injector needle cylinder mounting device and method. The device comprises needle cylinders, a front end cover allowing the needle cylinders to penetrate through, tension sleeves arranged on the needle cylinders in a sleeving mode and fixed by the front end cover, gaskets for fixing the tension sleeves to the front end cover, slot rings arranged on the needle cylinders in a sleeving mode, torsional spring pieces fixed to the slot rings, needle cylinder bases for containing the slot rings and fixing the needle cylinders and a bottom plate matched with the bottoms of the needle cylinder bases. The direct-inserting type high-pressure injector needle cylinder mounting device is simple in structure, convenient to mount, capable of achieving automatic butt joint of the needle cylinders, convenient to operate and meanwhile capable of guaranteeing that a high-pressure injector works reliably.

Owner:NANJING GANKONGTONG CHEM PROD OPERATION PORTION

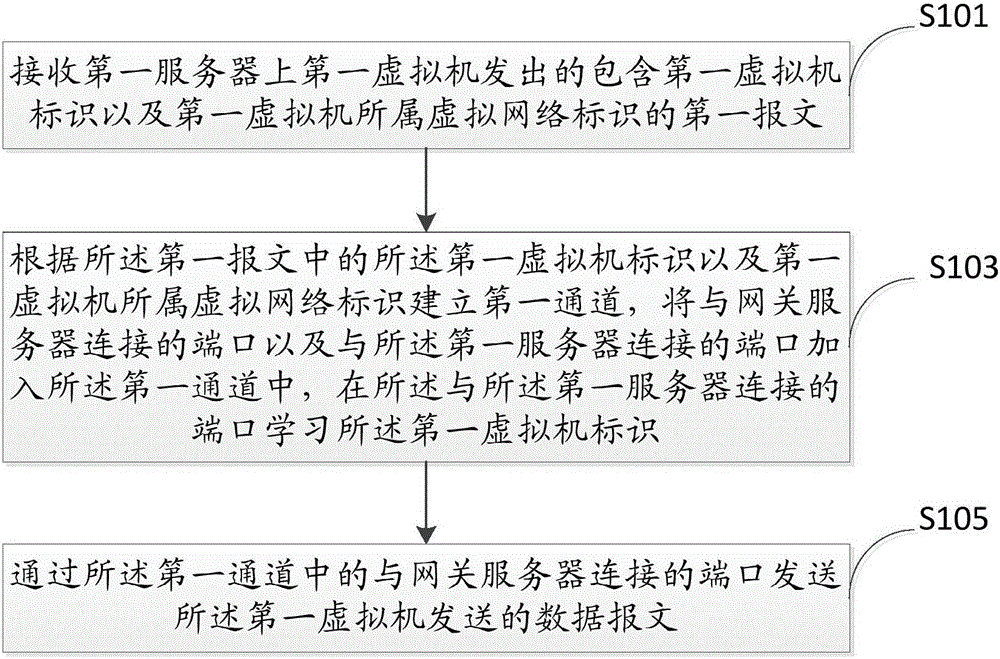

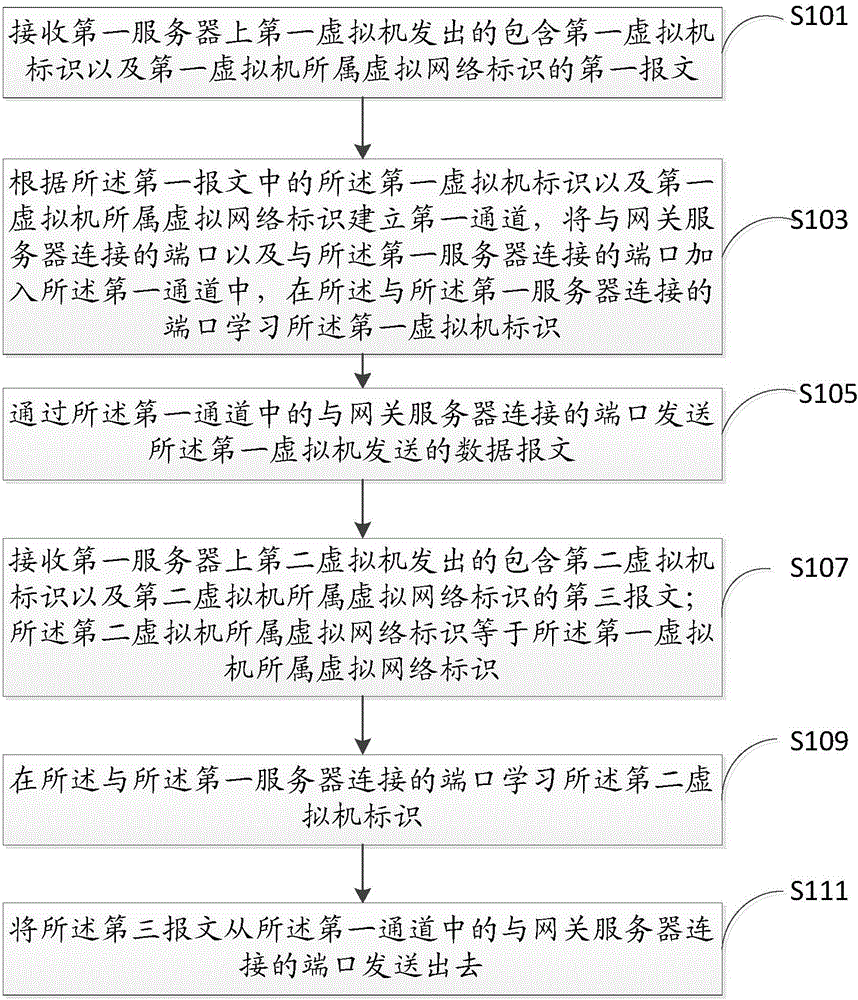

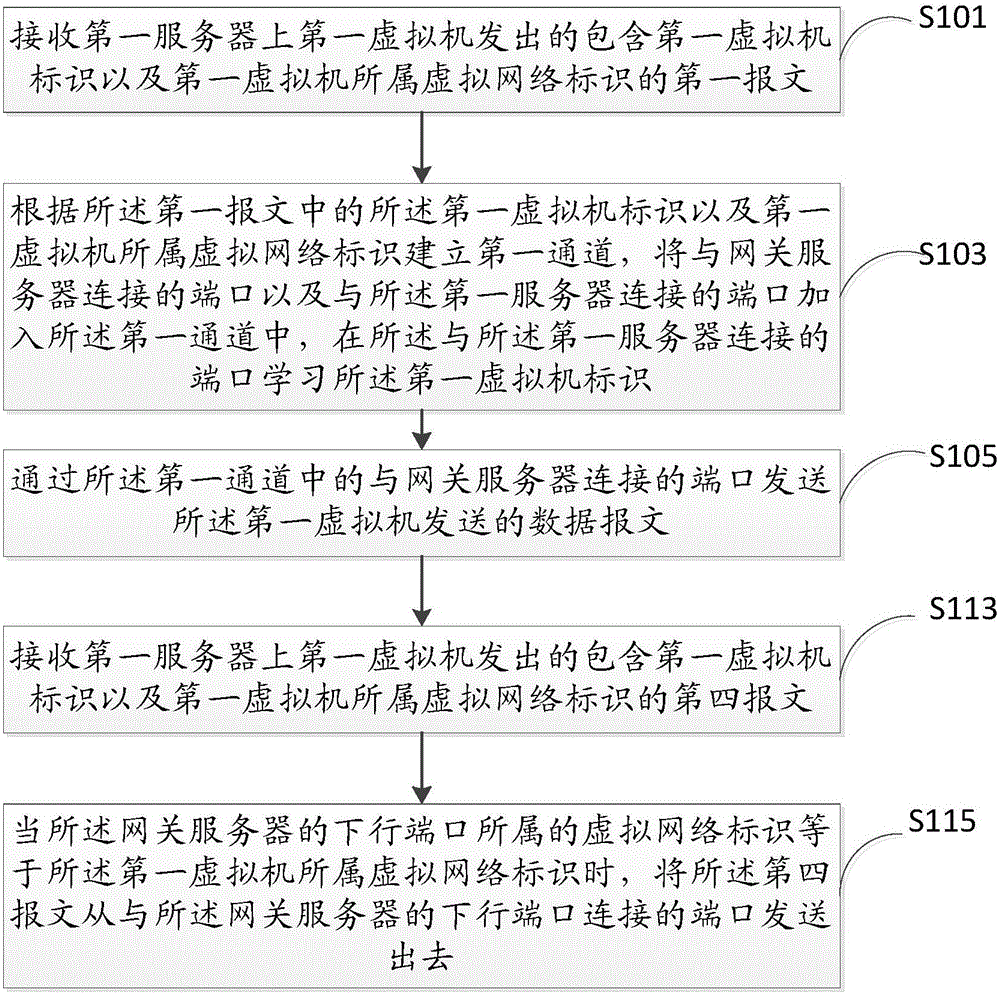

Method and switcher for achieving message forwarding of virtual machine

ActiveCN105978828AReduce complexityIncrease flexibilityNetworks interconnectionData centerPhysical network

The embodiment of the invention provides a method for achieving the message forwarding of a virtual machine, and the method comprises the steps: receiving a first message which is sent by a first virtual machine on a first server and comprises the identification of the first virtual machine and the identification of a virtual network where the first virtual machine belongs; building a first channel according to the identification of the first virtual machine and the identification of the virtual network where the first virtual machine belongs in the first message, enabling a port connected with a gateway sever and a port connected with the first server to be added to the first channel, and learning the identification of the first virtual machine at the port connected with the first server; and transmitting a data message transmitted by the first virtual machine through the port, connected with the gateway server, in the first channel. Meanwhile, the embodiment of the invention also provides a switcher for achieving the message forwarding of the virtual machine. The method and switcher reduce the complexity of operation and maintenance of a data center network, improve the flexibility of the network, and achieve the automatic butt joint of a physical network and a virtual network.

Owner:RUIJIE NETWORKS CO LTD

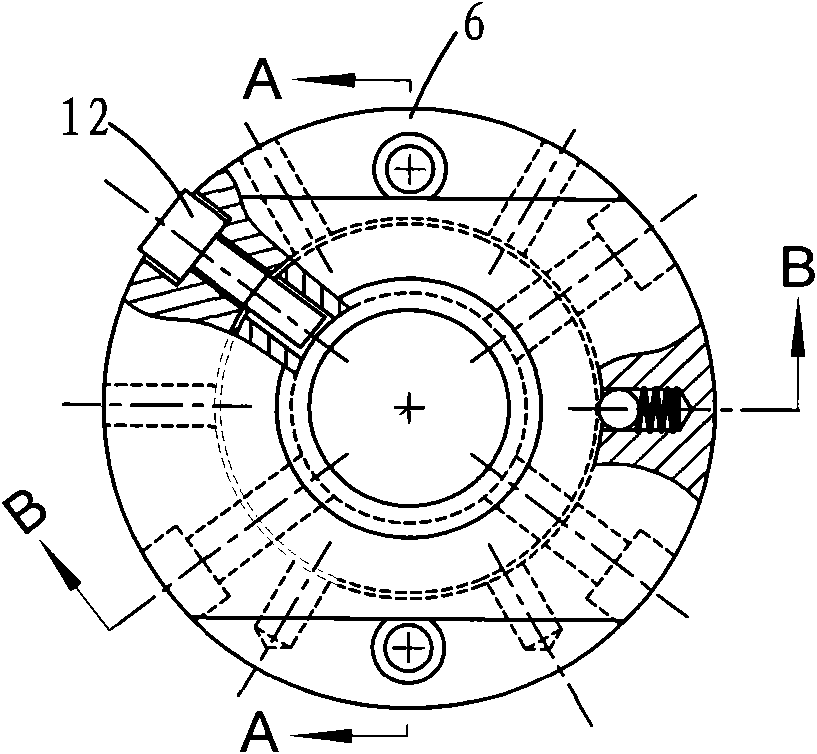

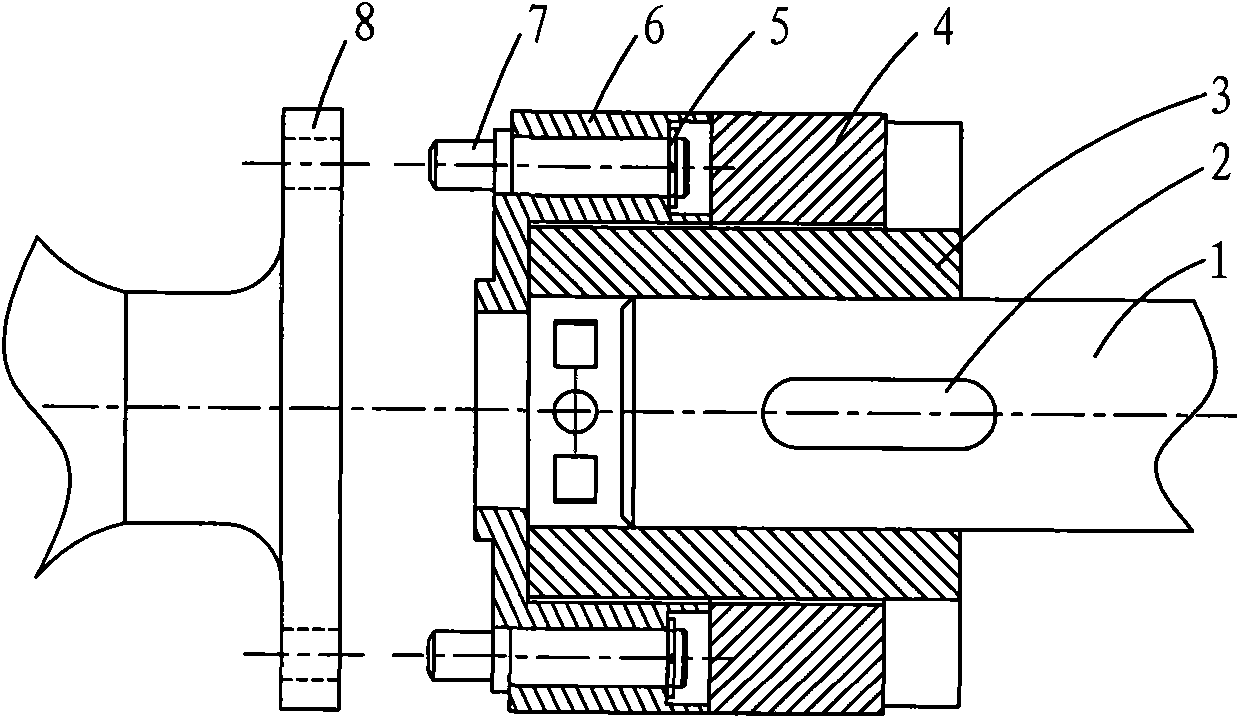

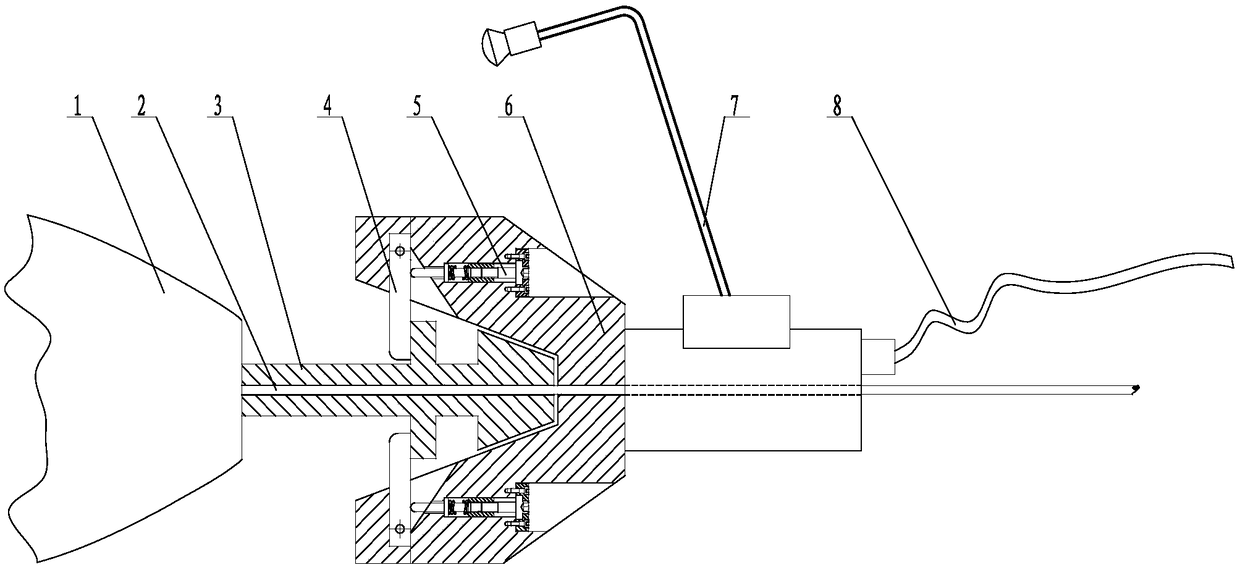

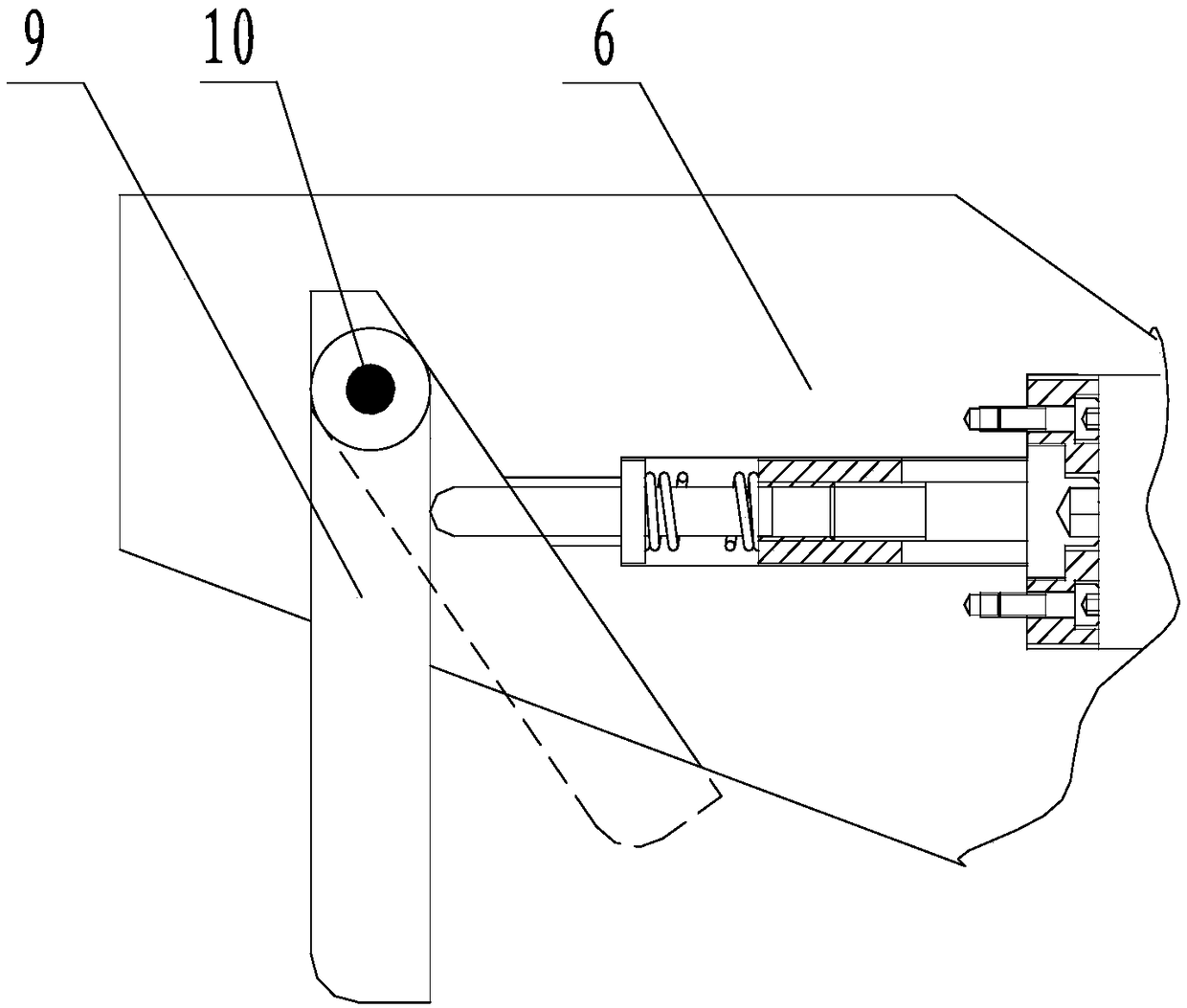

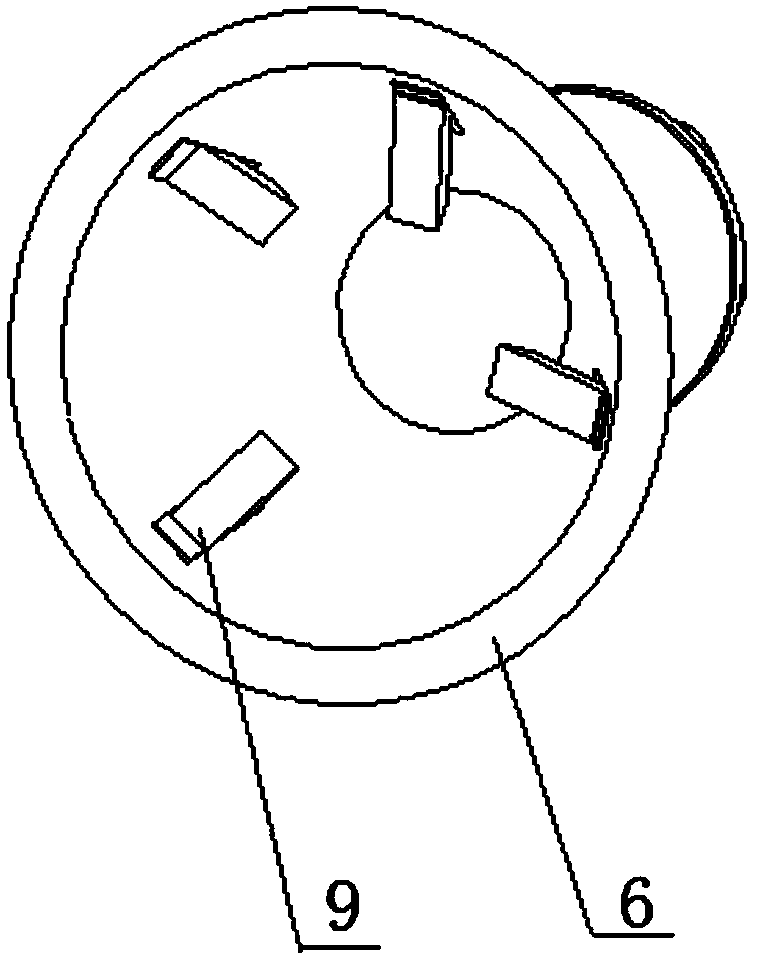

Tapered rod type butt joint traction mechanism for recycling underwater robot

PendingCN109436240ARealize deploymentRealize emergency recoveryVessel salvagingUnderwater equipmentButt jointEngineering

The invention discloses a tapered rod type butt joint traction mechanism for recycling an underwater robot. The traction mechanism comprises a butt joint tapered rod (3), clamping mechanisms (4), resetting mechanisms (5), a hoisting seat (6), an image sonar system (7) and a traction steel wire rope (8), wherein the butt joint tapered rod (3) is rigidly connected with the tail part of the underwater robot (1) through a bolt; four sets of the clamping mechanisms (4), which are fixed through a hinge, are uniformly mounted at the periphery of the hoisting seat (6) and are used for clamping the butt joint tapered rod (3); one resetting mechanism (5) is mounted at the corresponding position of each set of the clamping mechanism (4) to ensure that the butt joint tapered rod (3) is in reliable butt joint with the hoisting seat (6); the other end of the hoisting seat (6) is connected with a water surface mother ship through the traction steel wire rope (8). The tapered rod type butt joint traction mechanism disclosed by the invention has a safe and reliable whole structure; a pure mechanical structure is adopted, so that the reliability and safety of a whole device are greatly improved; automatic butt joint under seaborne complicated sea conditions can be realized.

Owner:750 TEST SITE OF CHINA SHIPBUILDING IND CORP

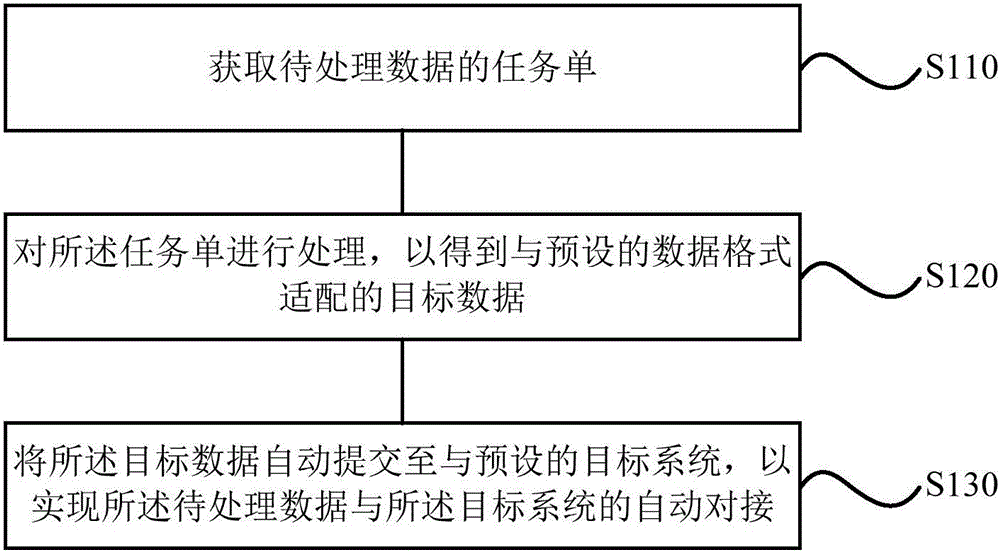

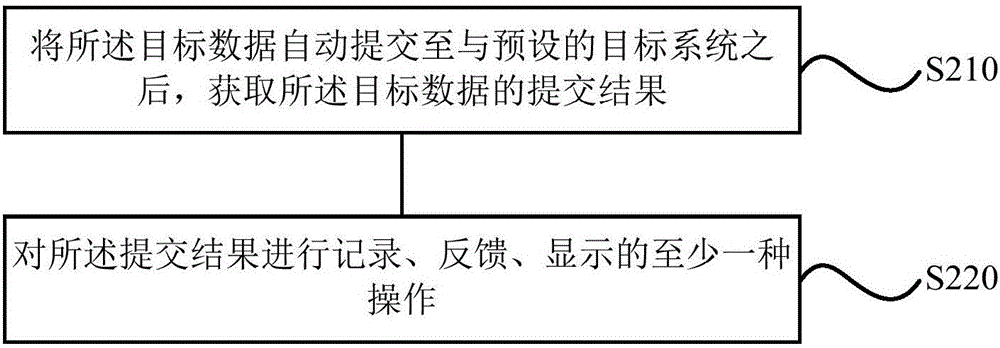

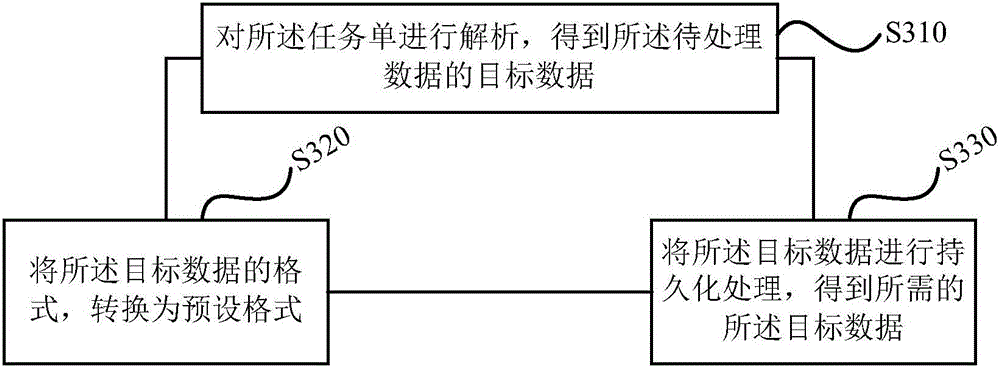

Data processing apparatus and method, and terminal

ActiveCN106528272AImprove work efficiencyImprove reliabilityInterprogram communicationDigital data authenticationGoal systemData processing

The invention discloses a data processing method and apparatus, and a terminal. The method comprises the steps of obtaining a task list of to-be-processed data; processing the task list to obtain target data matched with a preset data format; and automatically submitting the target data to a preset target system, thereby realizing an automatic connection of the to-be-processed data and the target system. According to the scheme, the defects of low working efficiency, high manpower cost, poor reliability and the like in the prior art can be overcome; and the beneficial effects of small repeated work load, high processing efficiency and low manpower cost are achieved.

Owner:北京用友薪福社云科技有限公司

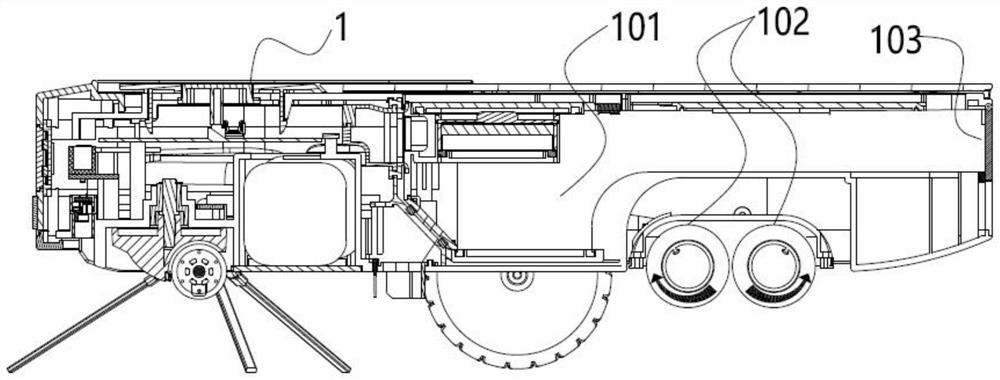

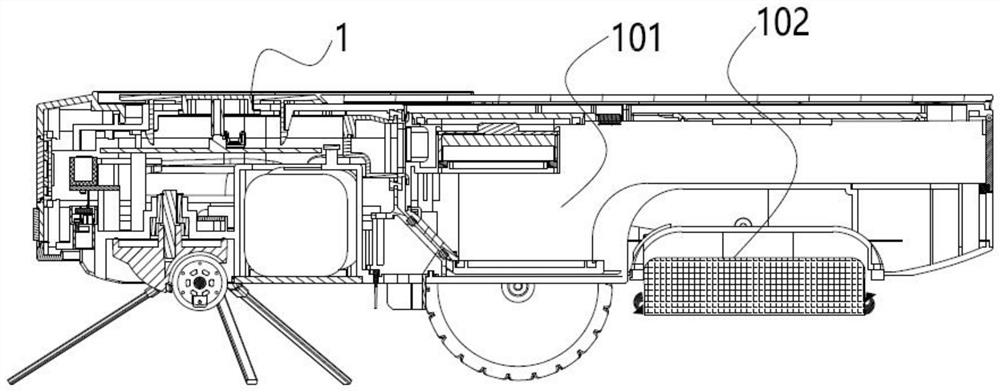

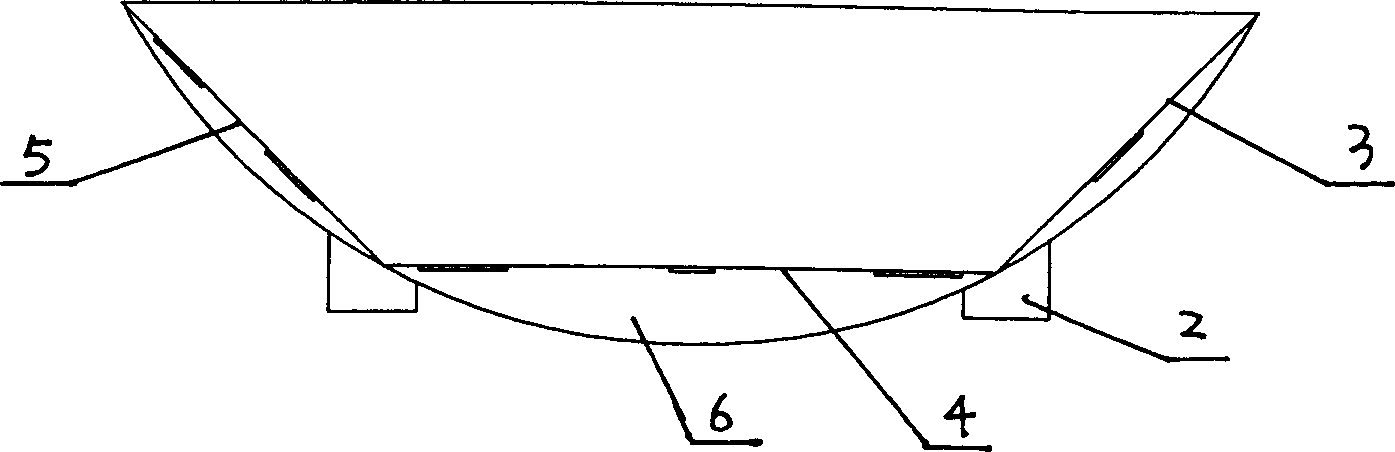

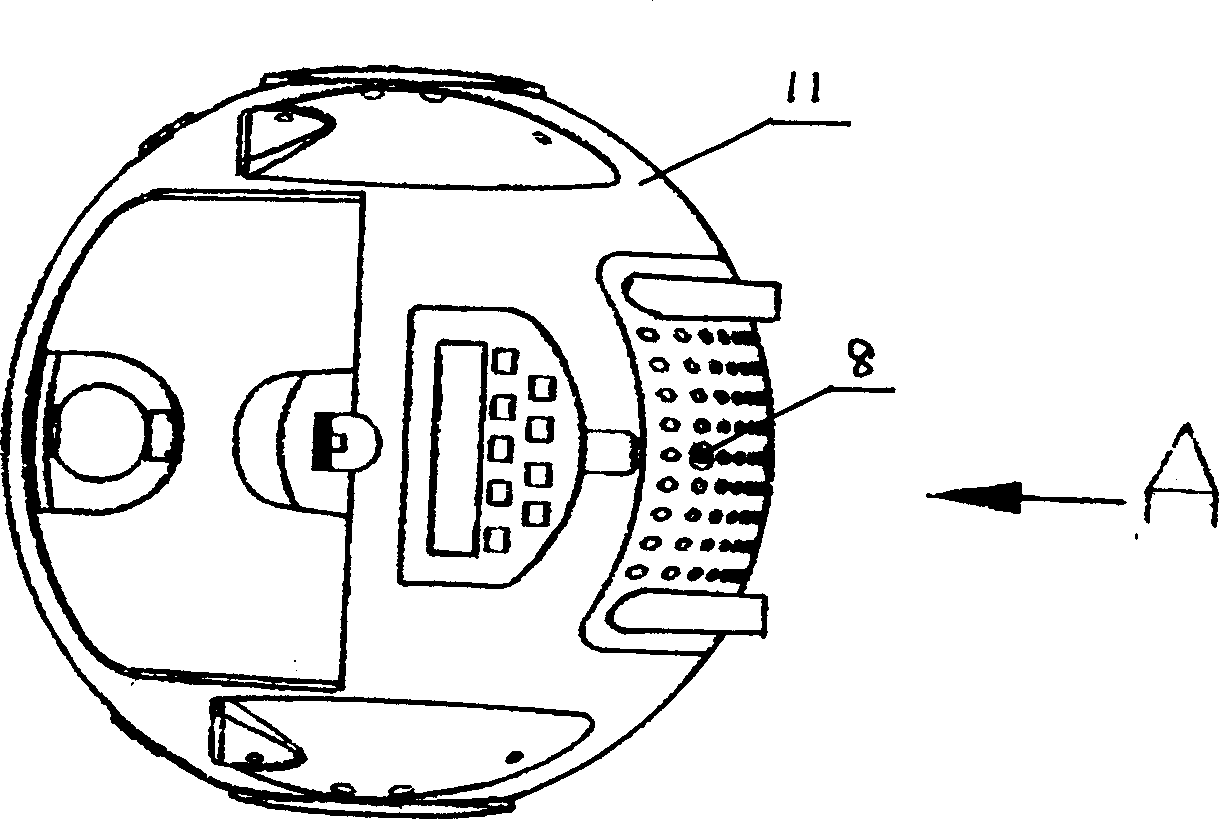

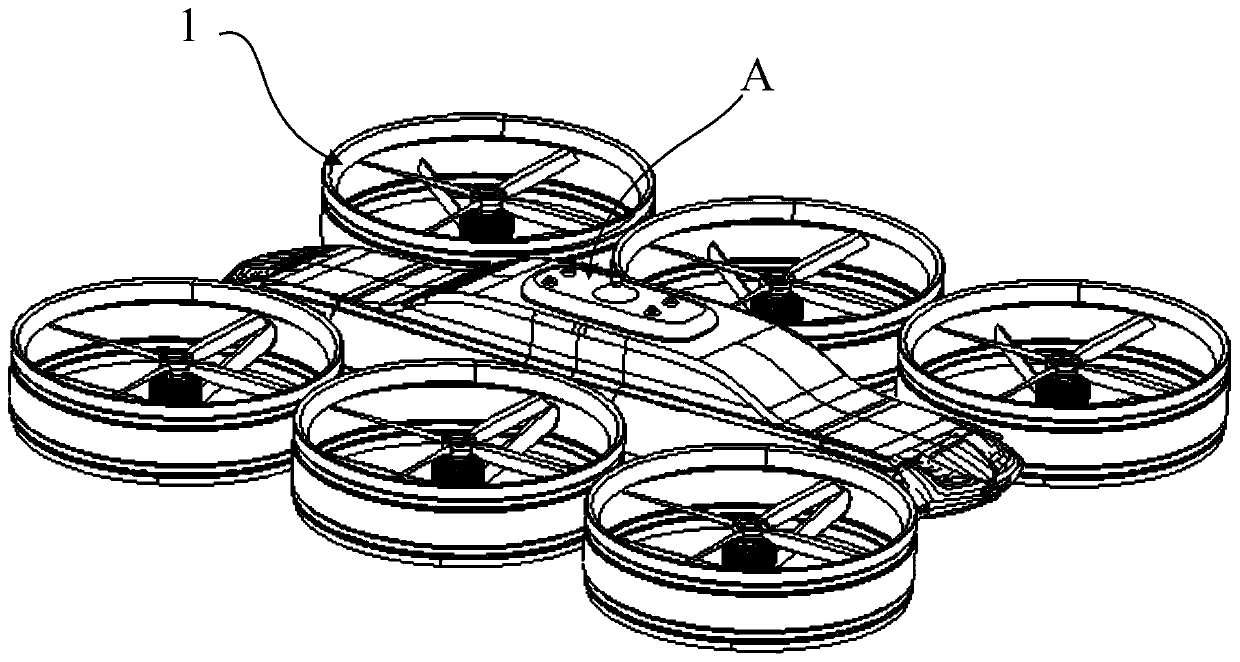

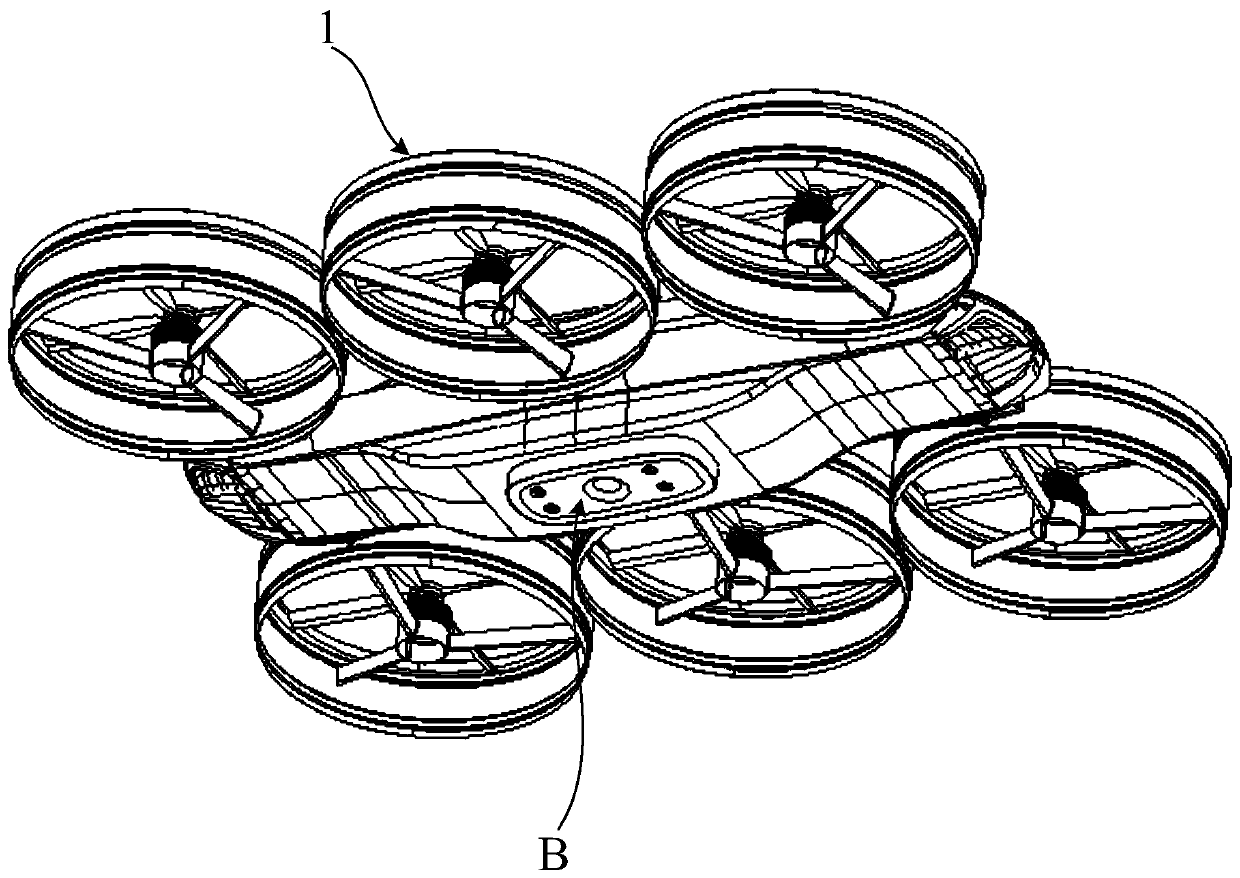

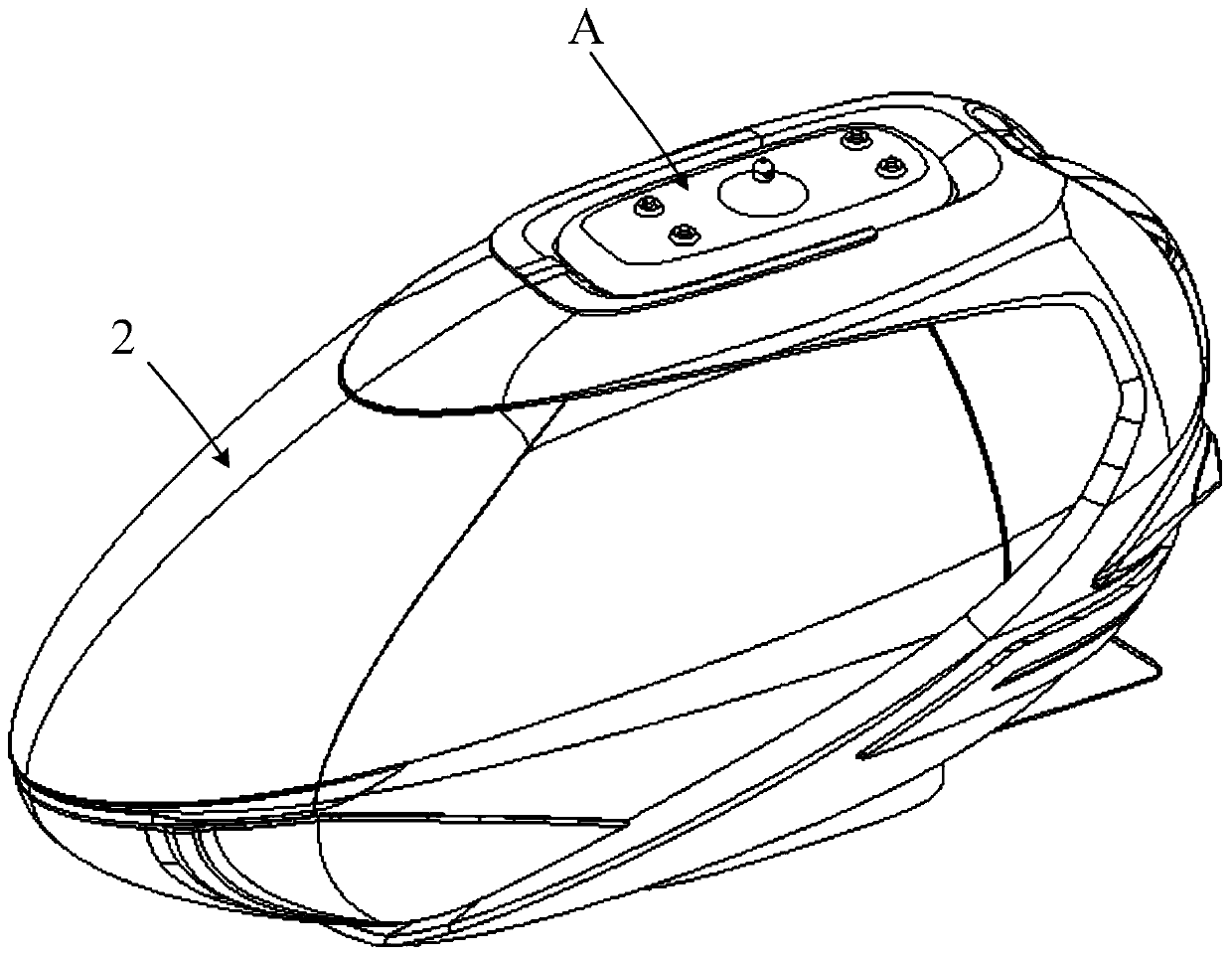

Split type hovercar, consignment method and hovercar dispatching system

PendingCN110877507ARealize automatic dockingIncrease the transportation radiusFreight handlingAircraft convertible vehiclesFlight vehicleButt joint

The invention discloses a split type hovercar which comprises an aircraft and a carrying bin, and at least one first butt joint mechanism and one second butt joint mechanism are arranged on the aircraft. The carrying bin is at least provided with one first butt joint mechanism and one second butt joint mechanism, and the first butt joint mechanism and the second butt joint mechanism can be matchedwith each other to achieve connection and disconnection. According to the split type hovercar, aircraft replacement can be achieved. Goods or personnel are transported in an aircraft replacement mode, the limitation of aircraft energy storage is broken through, the transportation radius of the hovercar is effectively increased on the premise of not depending on construction of a large number of ground stop stations and charging facilities, and the carrying range of the hovercar is greatly expanded. The invention further discloses a consignment method based on the split type hovercar and a hovercar dispatching system.

Owner:COOL HIGH TECH BEIJING CO LTD

Optical fiber core butting connector

The embodiment of the invention discloses an optical fiber core butting connector. The optical fiber core butting connector comprises a plurality of circuit connectors which are mutually parallel and a plurality of cord circuit connectors which are mutually parallel. Each circuit connector comprises a first sliding rod, a first circuit fiber core connector and a second circuit fiber core connector, wherein the first circuit fiber core connector and the second circuit fiber core connector can slide along the first sliding rod, the input end of the first circuit fiber core connector and the output end of the first circuit fiber core connector are connected through a connecting optical fiber, and the input end of the second circuit fiber core connector and the output end of the second circuit fiber core connector are connected through a connecting optical fiber. Each cord circuit connector comprises a second sliding rod, a first cord circuit fiber core connector and a second cord circuit fiber core connector, wherein the first cord circuit fiber core connector and the second cord circuit fiber core connector can slide along the second sliding rod and are connected through a connecting optical fiber. The optical fiber core butting connector has the advantages that automatic joint of a plurality of optical fibers in an optical network can be achieved, switch transmission of data information is achieved, the usage amount of cord circuit optical fibers is reduced, and cost is reduced.

Owner:STATE GRID CORP OF CHINA +1

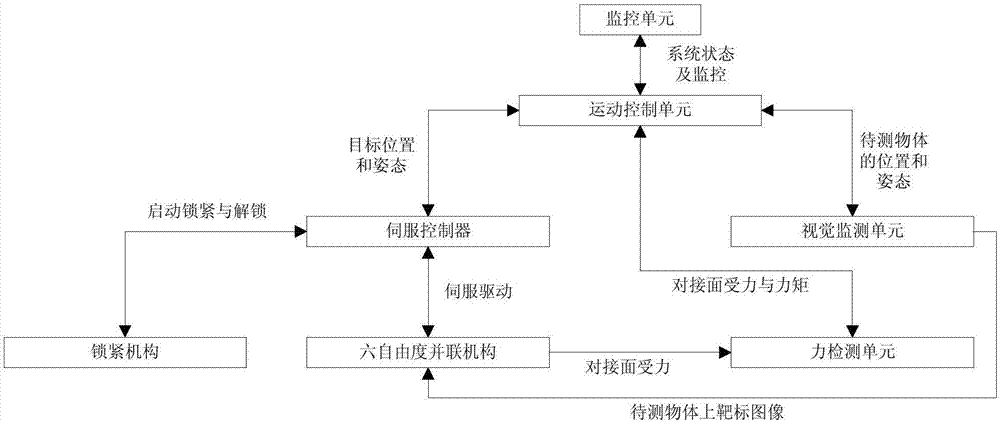

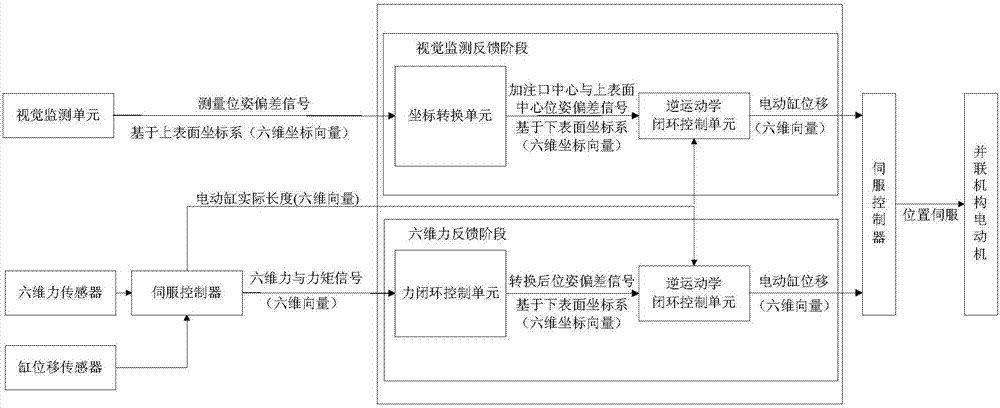

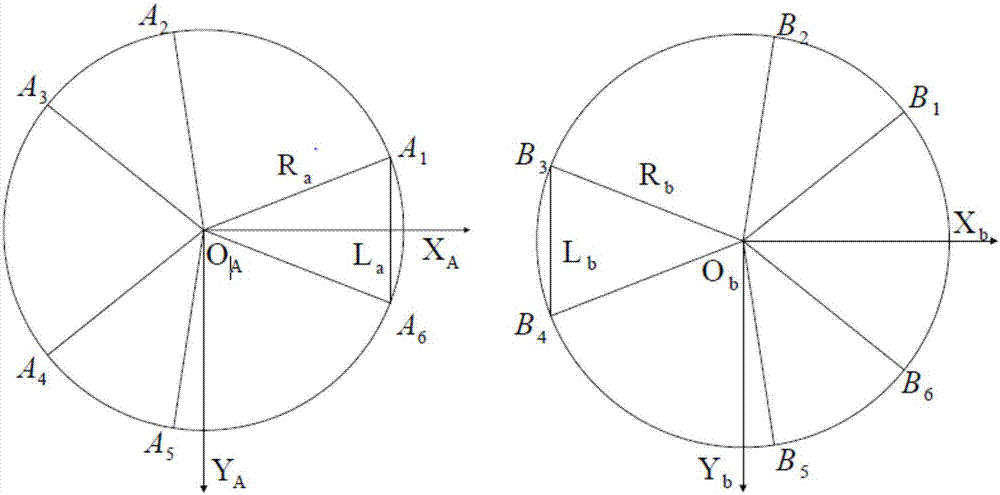

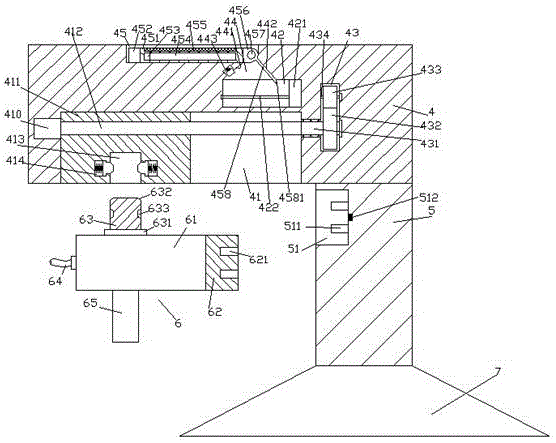

Automatic docking control system for carrier rocket and drain connector

ActiveCN107284699ARealize automatic dockingImprove versatilityCosmonautic ground equipmentsAutomatic controlEngineering

Disclosed is an automatic docking control system for a carrier rocket and a drain connector. The automatic docking control system comprises a monitoring unit, a motion control unit, a servo drive, a force detection unit, a locking mechanism, a six-degree of freedom parallel mechanism and a visual monitoring unit; the visual monitoring unit is used for detecting on-rocket interface position and posture of the carrier rocket by the aid of a camera; the force detection unit is used for detecting force and moment generated from docking of force and a torque sensor; the locking mechanism is used for locking the drain connector and an on-rocket interface; the motion control unit is used for controlling motion of the six-degree of freedom parallel mechanism by the aid of the visual monitoring unit and the force detection unit; the servo drive is used for driving a motor. By the arrangement, the drain connector and the on-rocket interface are automatically docked and locked under the condition of not changing the rocket body, and motion of the on-rocket interface is followed; compared with an existing system with an artificial docking method, the automatic docking control system has the advantages of labor saving, and personnel safety is guaranteed.

Owner:BEIJING INST OF SPACE LAUNCH TECH +1

Welding device

ActiveCN106825866APrevent electric shock accidentsReduce investmentArc welding apparatusMechanical engineeringEngineering

The invention discloses a welding device. The welding device comprises a base, a cylinder, a push portion and a plug head portion, the cylinder is fixedly arranged above the base, the push portion is fixedly connected at the top of the cylinder and extends leftwards, a plugging groove is formed in the left end face of the cylinder, vertically symmetrical plugging springs are arranged on the inner right wall of the plugging groove, a sensor is arranged at the position, between the two plugging springs, of the inner right wall of the plugging groove, a mounting groove is formed in the top end face of the push portion, a sliding groove is formed in the left bottom end face of the push portion, a sliding cavity is formed in the push portion above the right side of the sliding groove, a force transfer cavity is formed in the position, on the right sides of the sliding cavity and the sliding groove, of the push portion, a first toothed wheel is arranged below the inner portion of the force transfer cavity, a second toothed wheel is connected to the top of the first toothed wheel in a mesh manner, a first rotating rod extending leftwards and rightwards is fixedly arranged on the first toothed wheel, and a second rotating rod extending leftwards and rightwards is fixedly arranged on the second toothed wheel. The welding device is simple in structure, convenient to operate, high in safety and capable of achieving plugging automatically and has a prompt function.

Owner:泰安宝巨机械科技有限公司

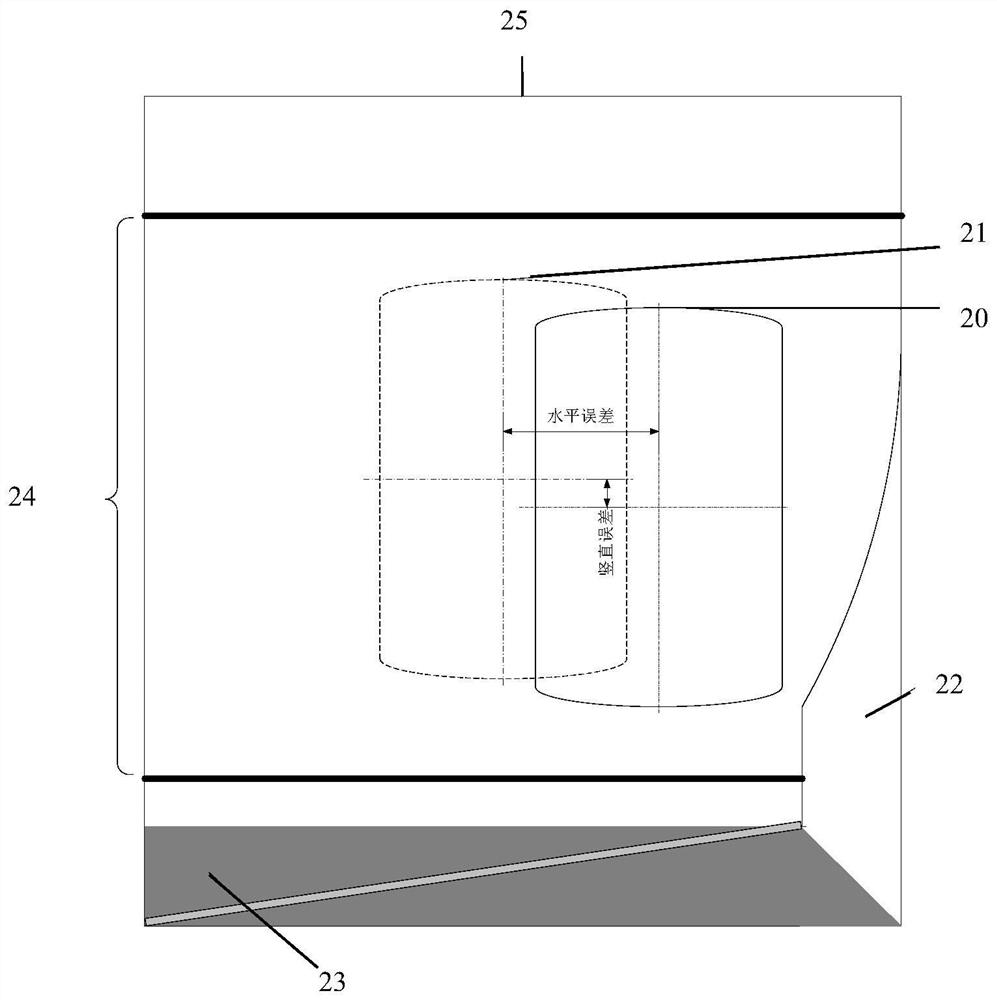

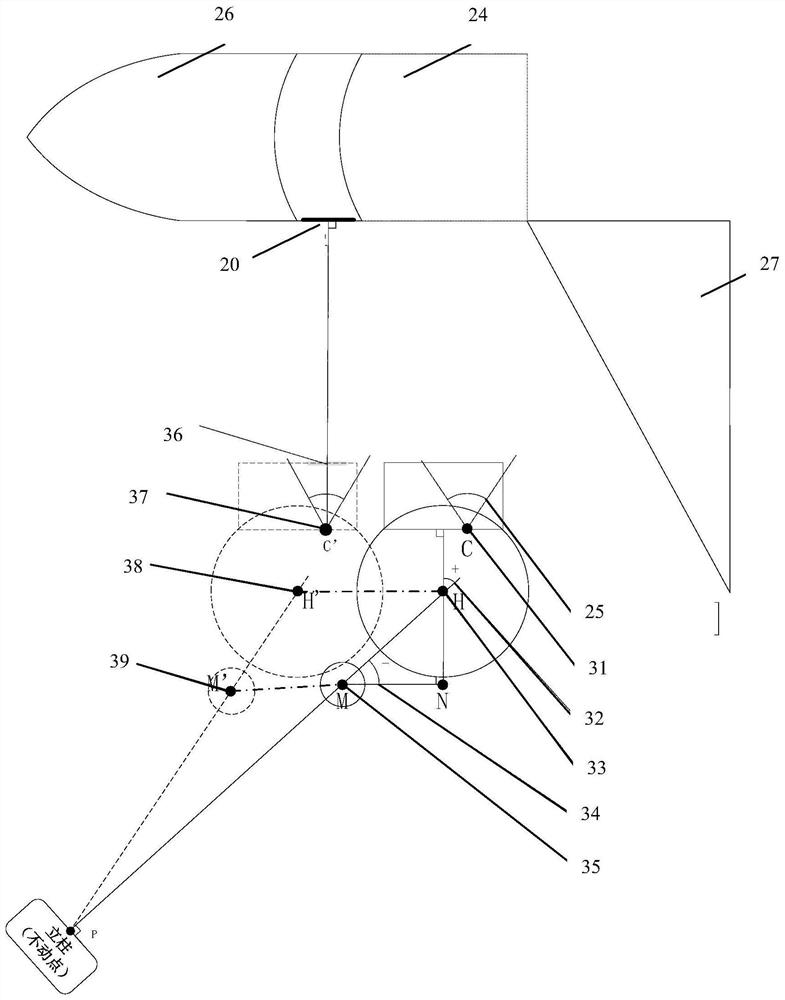

Boarding bridge automatic docking and adjusting system based on image recognition

The invention relates to a boarding bridge automatic docking and adjusting system based on image recognition. The boarding bridge automatic docking and adjusting system based on image recognition comprises a front end camera device, a boarding bridge adjusting device, an image processing module, a cabin door database and a background processing software; a position adjusting device comprises a transverse position monitoring module, a height position monitoring module and a distance monitoring module, wherein the front end camera device collects an airplane cabin door image and is used for recognizing an airplane cabin door and calibrating a position of the airplane cabin door; after the airplane cabin door image is processed by the image processing module, the airplane cabin door image iscompared with an existing airplane cabin door pre-stored in the cabin door database; after a same cabin door is selected, the background processing software forms flight data information of the obtained cabin door into a calibration frame as a calibration image; the calibration image is calibrated and compared with the image collected by the front end camera; and meanwhile, the background processing software has a function of controlling the boarding bridge adjusting device, performs calibration according to data collected by the front end camera device and background data, and automatically controls adjusting of boarding bridge angle and height through the position adjusting device.

Owner:张积洪

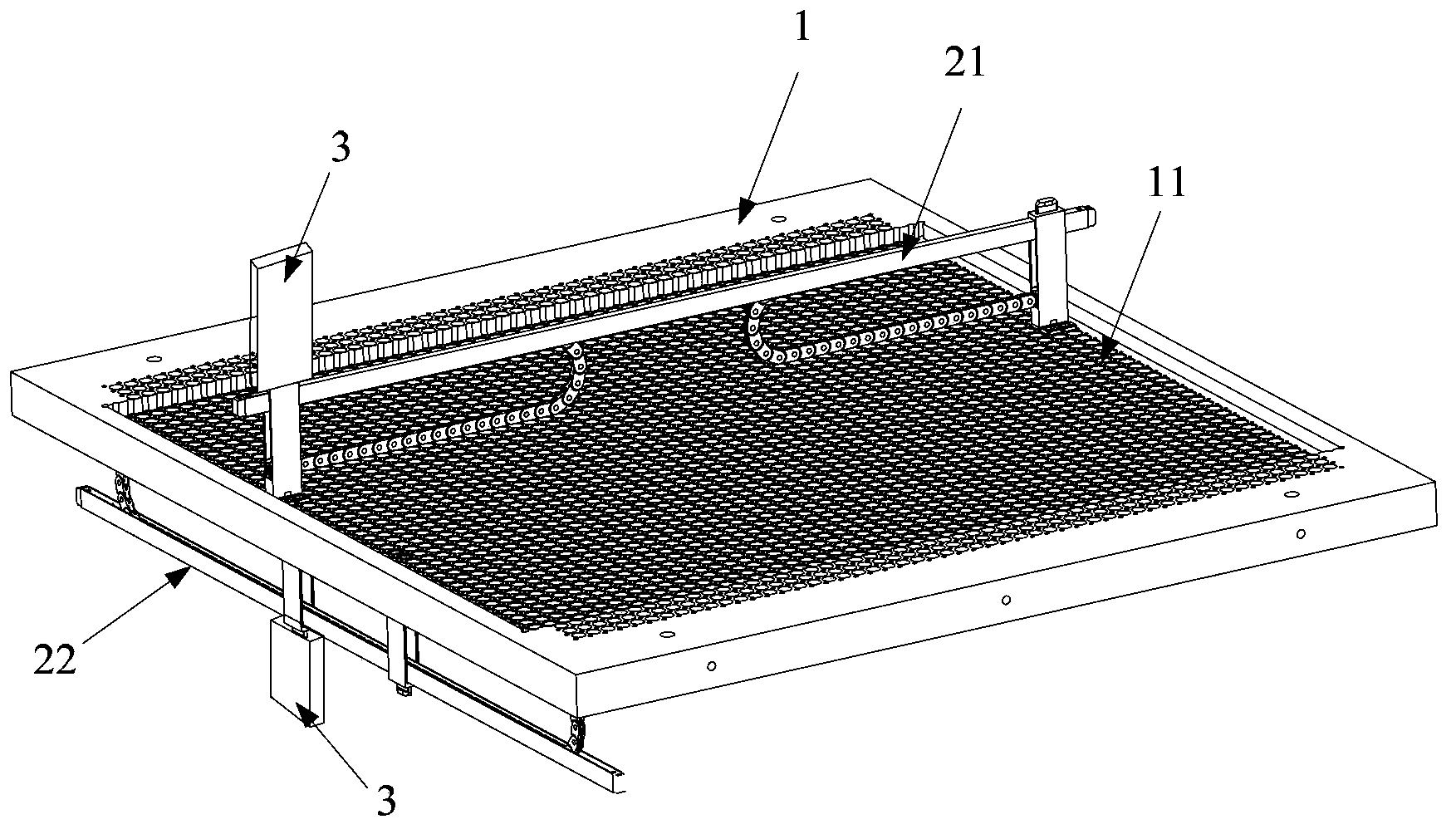

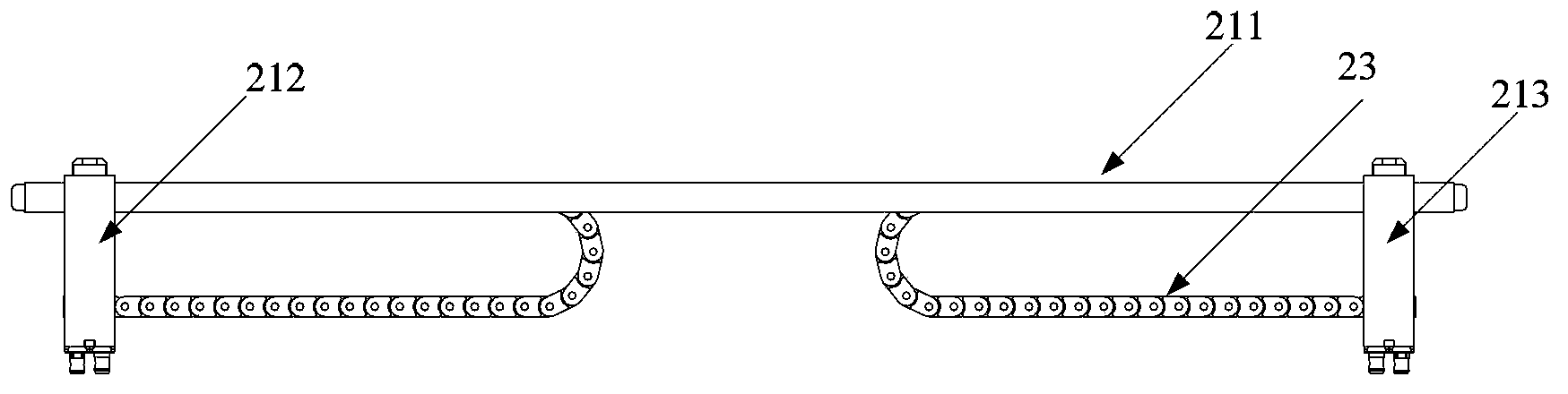

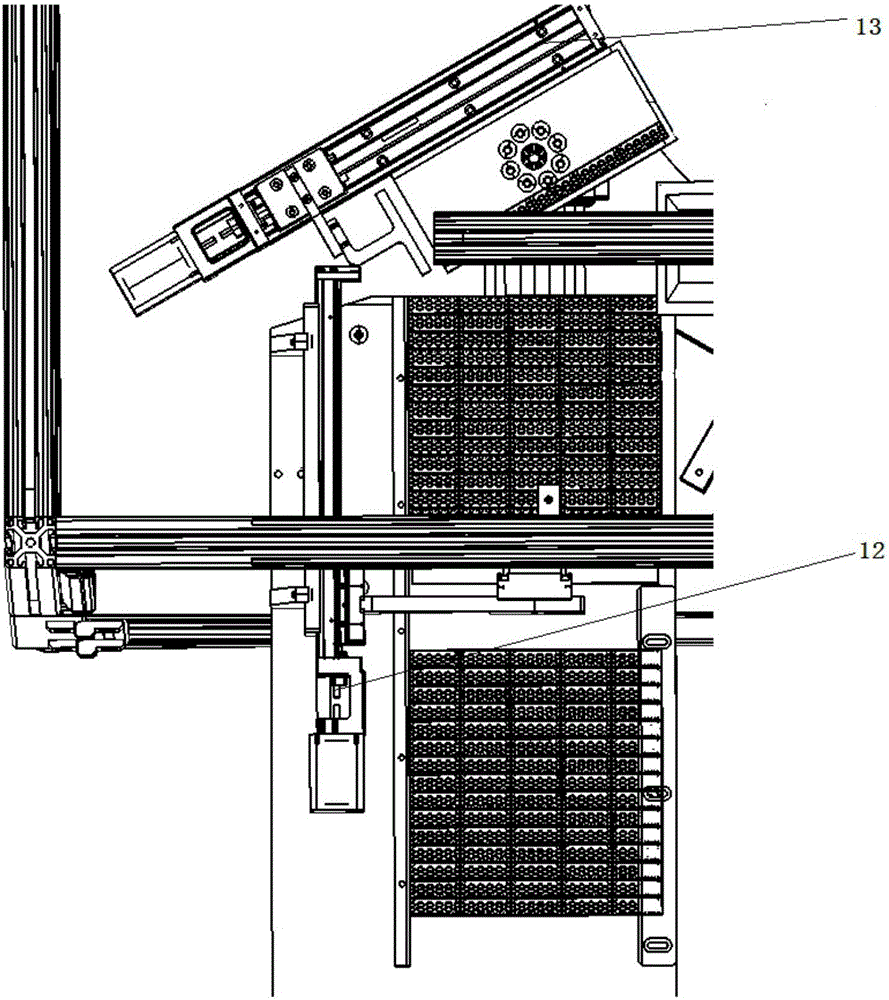

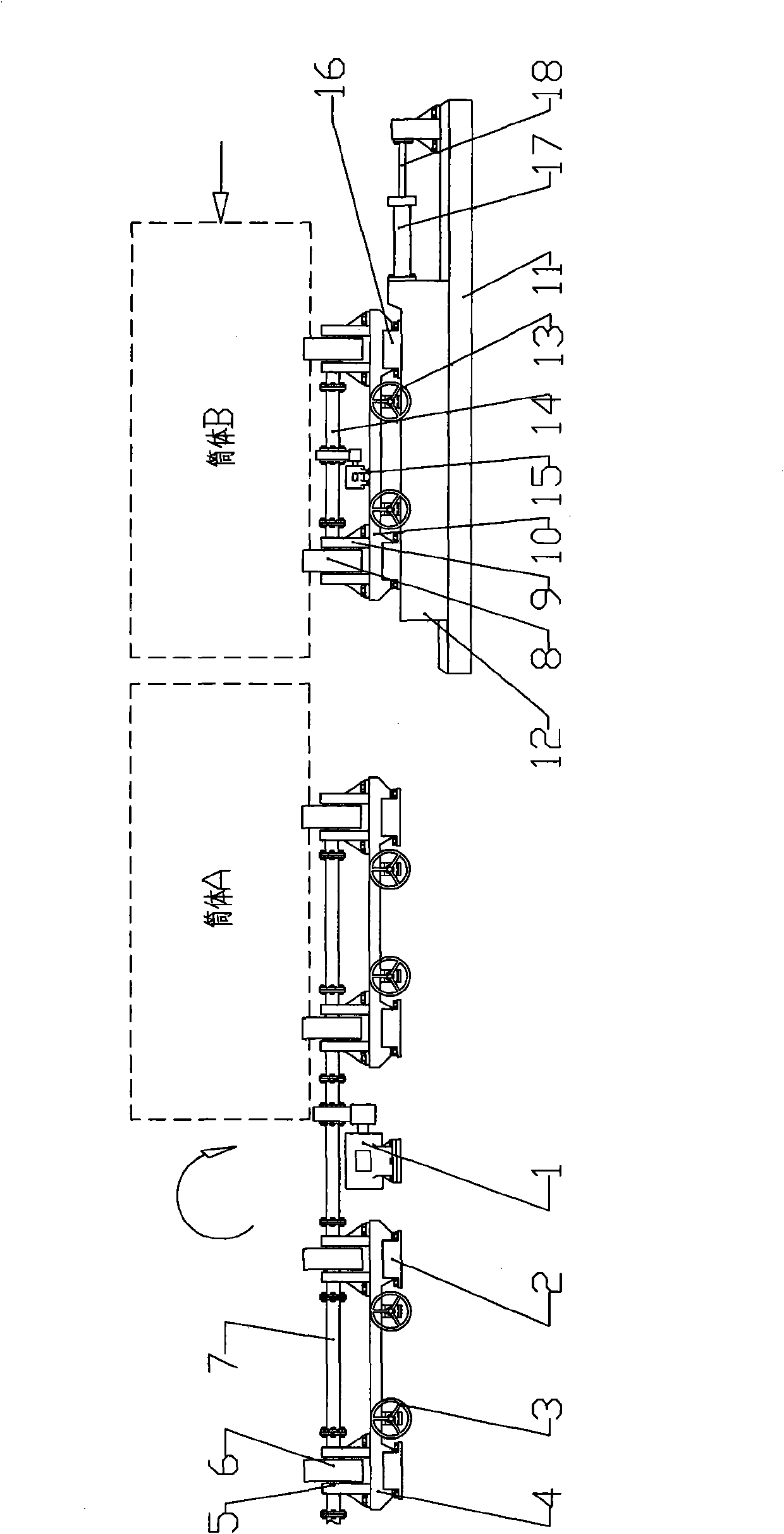

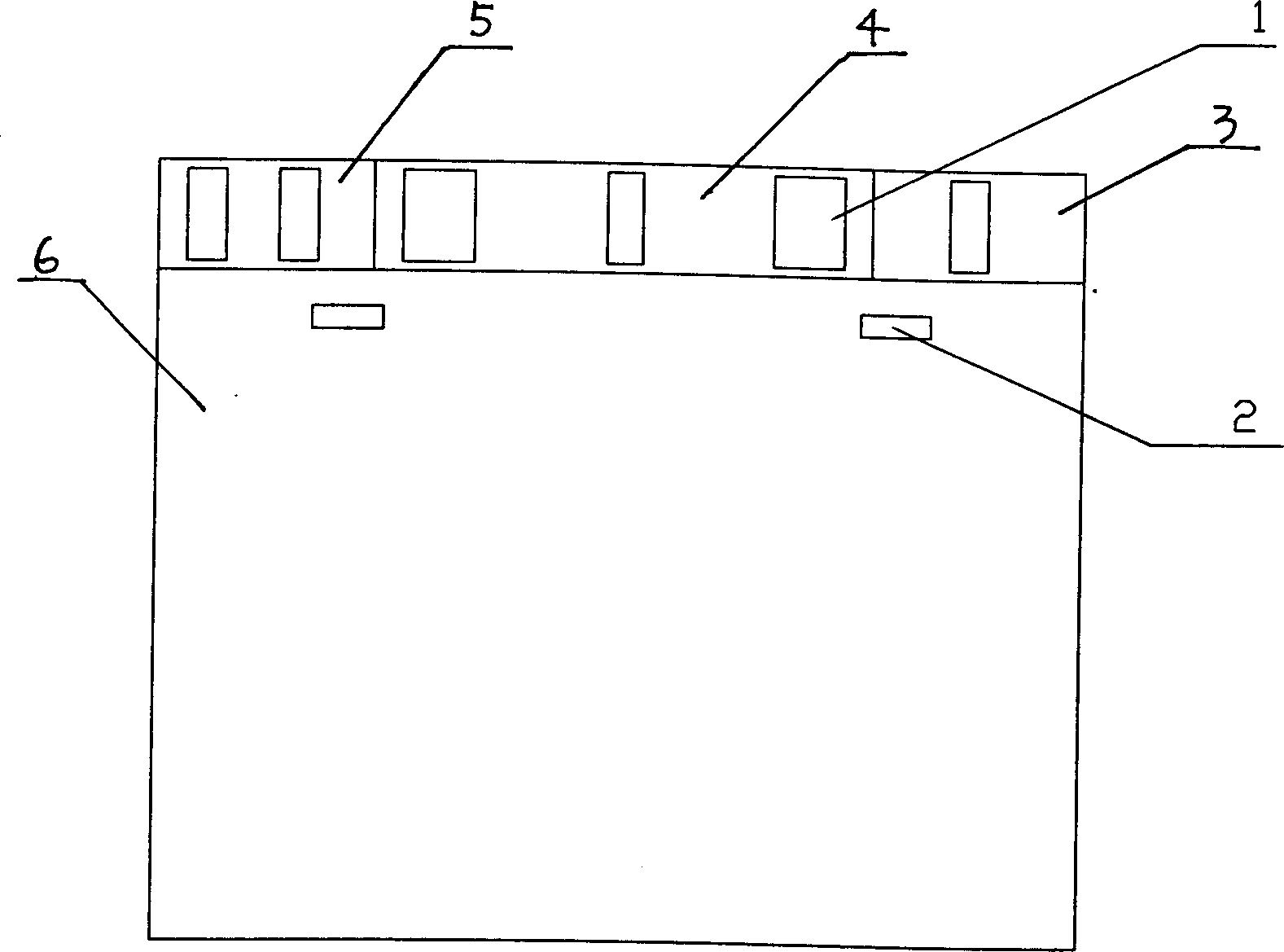

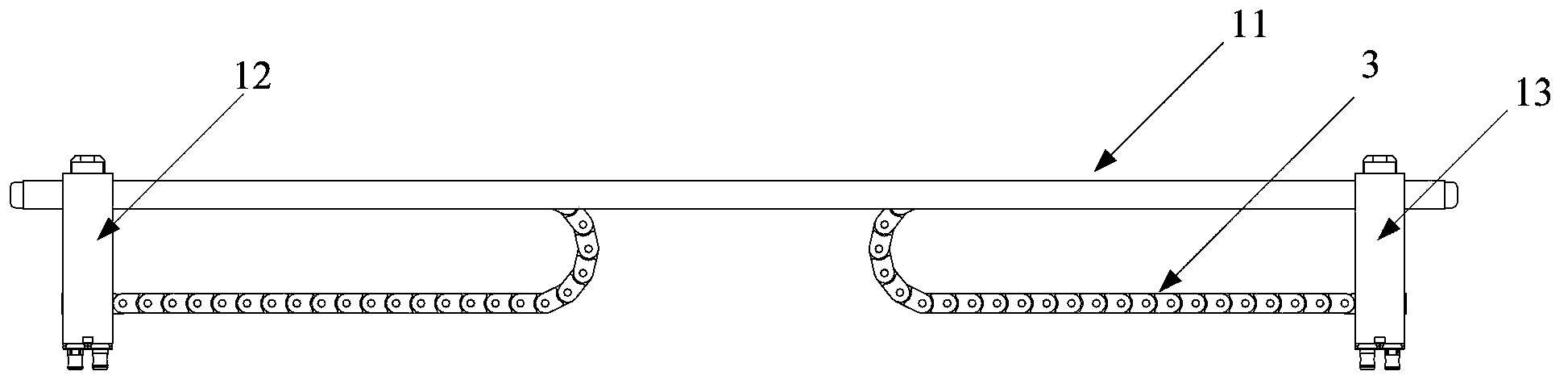

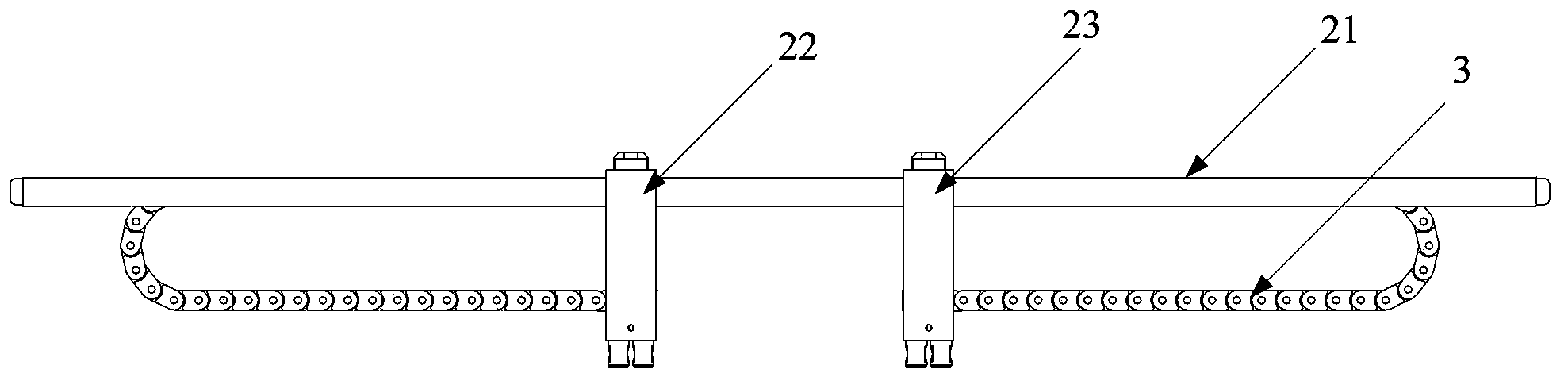

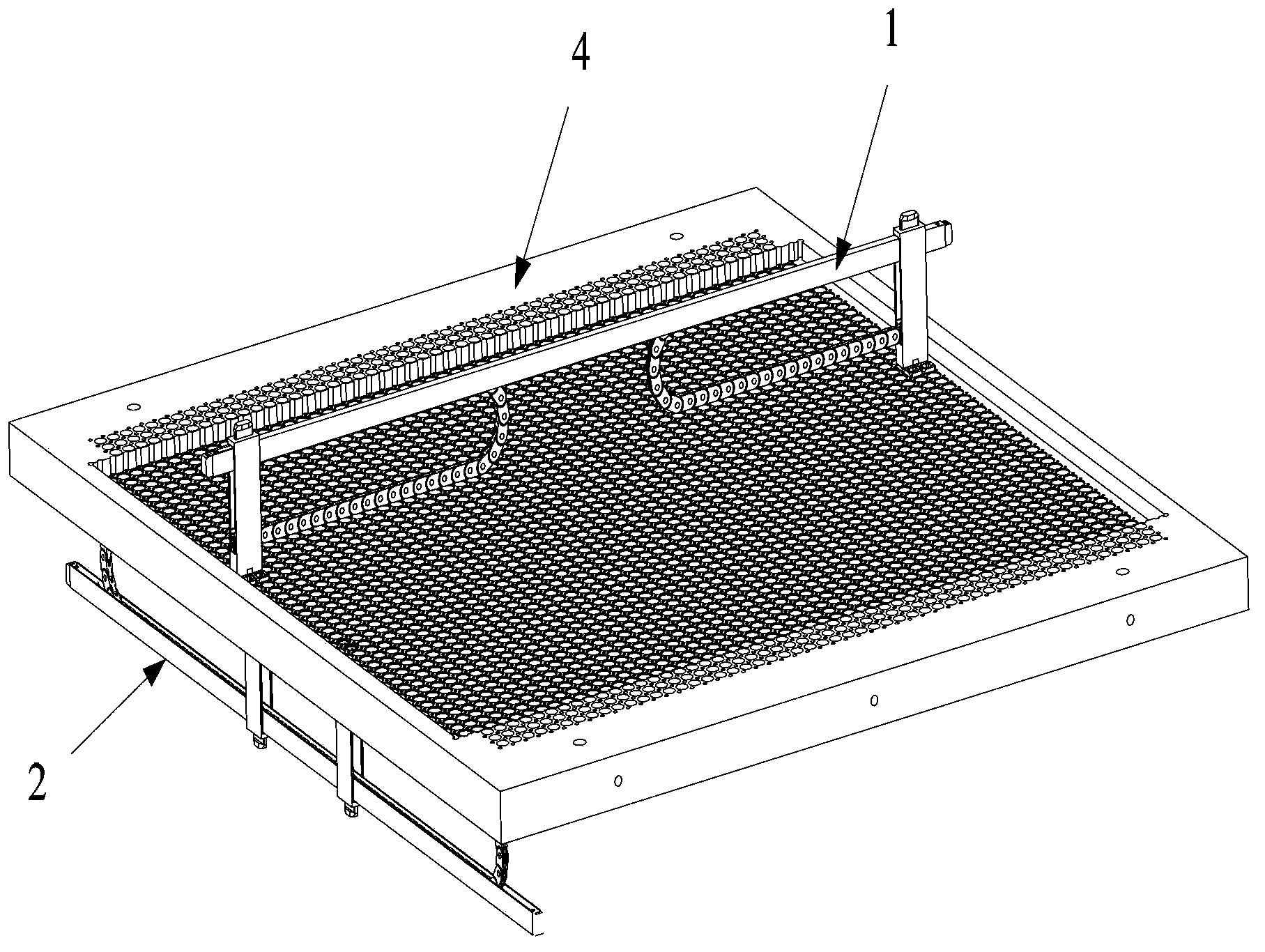

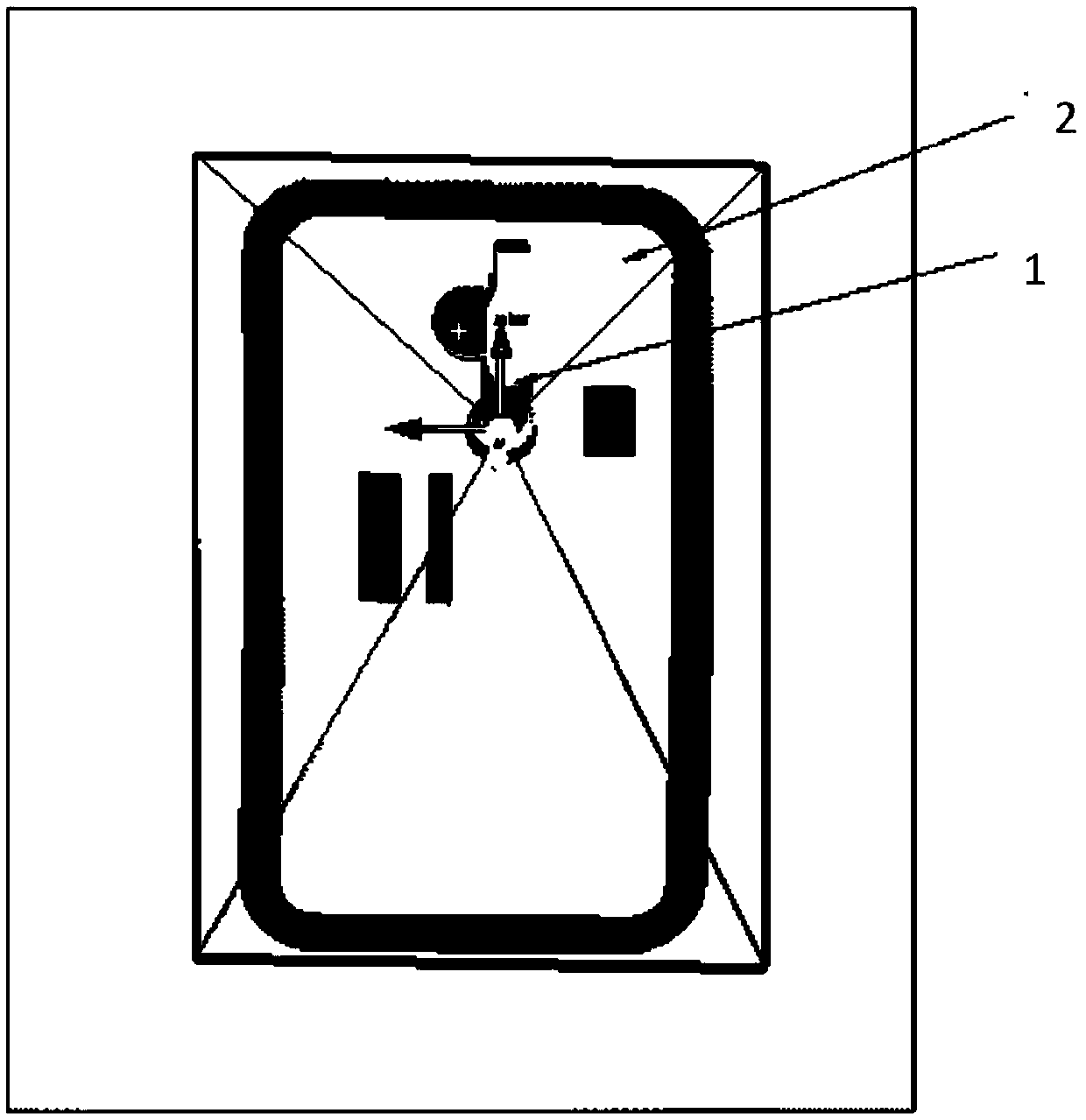

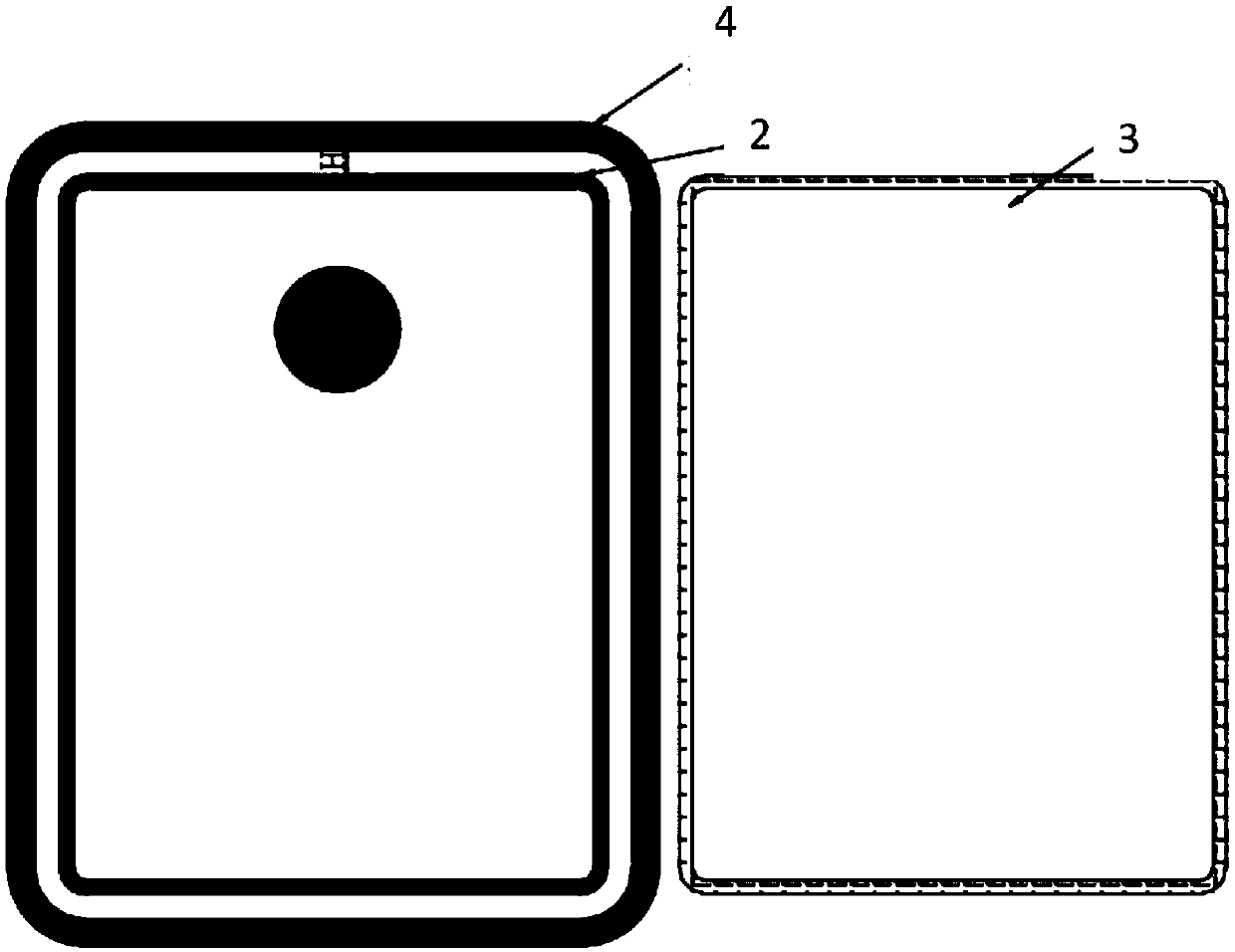

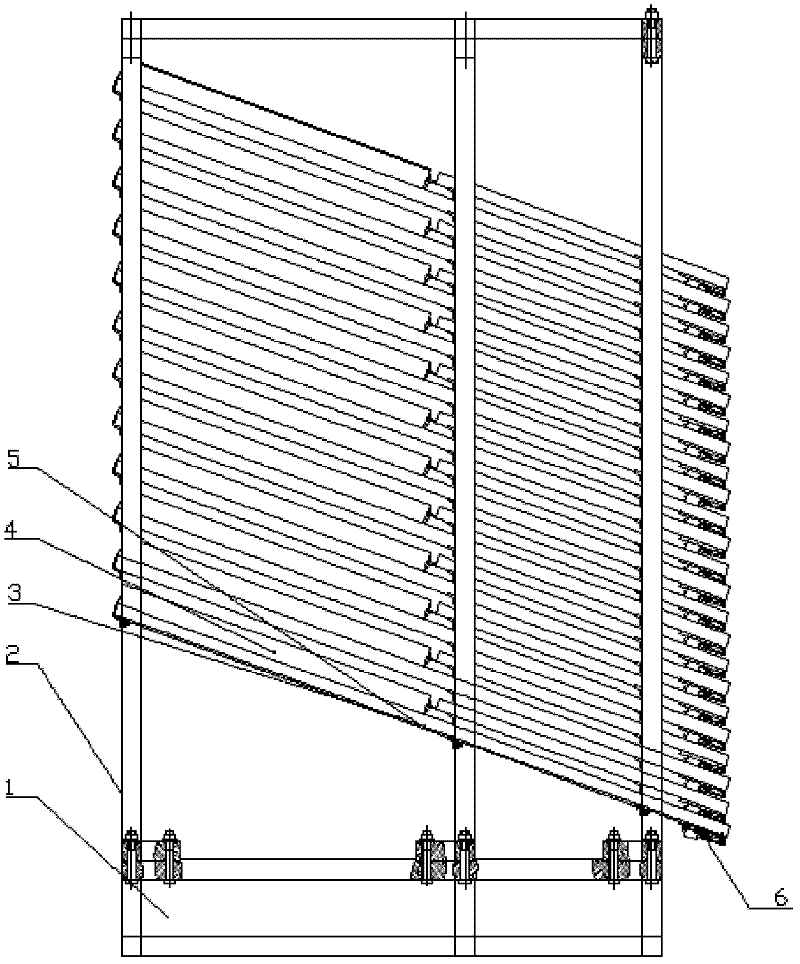

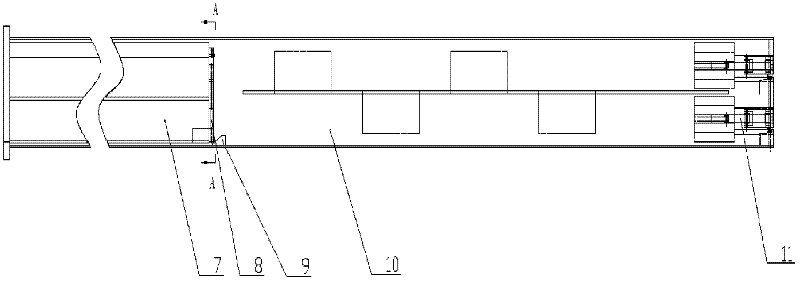

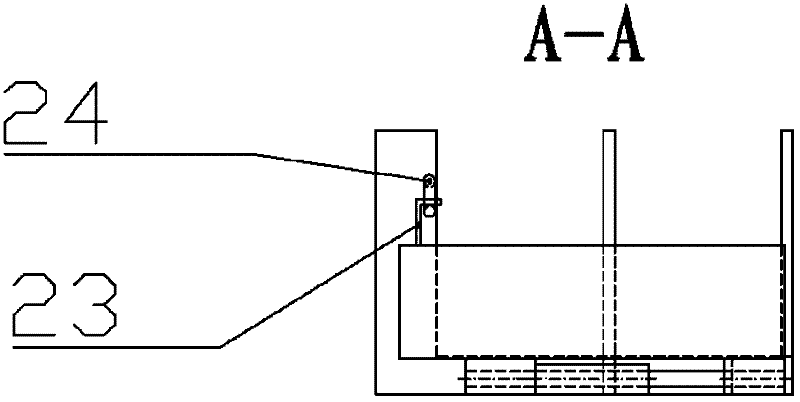

Automatic medicine discharging mechanism of rapid medicine dispensing system using box-type medicine feeding method

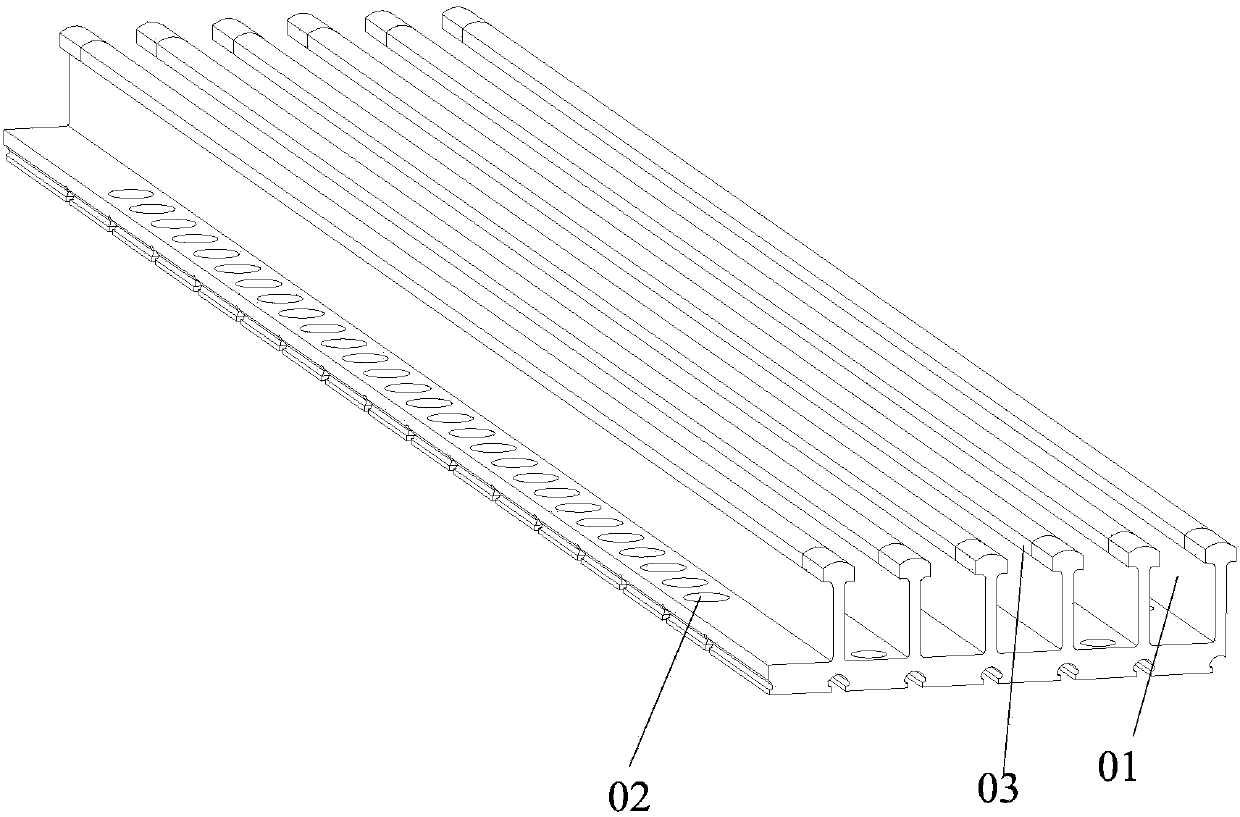

ActiveCN102673929ARealize automatic dockingHigh-speed medicineStorage devicesBiomedical engineeringMedicine cabinet

The invention relates to an automatic medicine discharging mechanism of a rapid medicine dispensing system. According to the specifications and the shape characteristics of medicine boxes, vertical and horizontal medicine tanks and medicine cases are designed and placed in a medicine cabinet shown as an accompanying drawing 1. The medicine tanks and the medicine cases have gradually increasing tank widths according to the thickness of the medicine boxes and are used for storing the medicine boxes with different thicknesses shown in an accompanying drawing 2. The front half parts of the medicine tanks are guide grooves of the medicine boxes and the rear half parts of the medicine tanks are used for bearing the medicine cases. The length of the medicine cases is half of the length of the medicine tanks. When the medicine boxes are at the front half parts of the medicine tanks, a medicine feeding mechanism fills the medicine boxes into the medicine cases and guides the medicine boxes into the medicine tanks, so as to continuously supplement new medicine boxes for the medicine tanks. The automatic medicine discharging mechanism of the rapid medicine dispensing system has the characteristics that since the automatic medicine discharging mechanism is matched with a dual-box-type medicine feeding mechanism, the automatic joint of the medicine cases and the medicine tanks is realized and the effect of synchronization of high-speed medicine discharging and high-speed medicine feeding is realized; since the storage capacity of a main medicine cabinet is great and a synchronous medicine discharging method is adopted, the medicine discharging speed is high; and a sliding block and connecting rod medicine discharging mechanism and a photoelectric detection device at a medicine outlet guarantee the working reliability of the medicine discharging system.

Owner:SHANGHAI VIEW VALLEY TECH +1

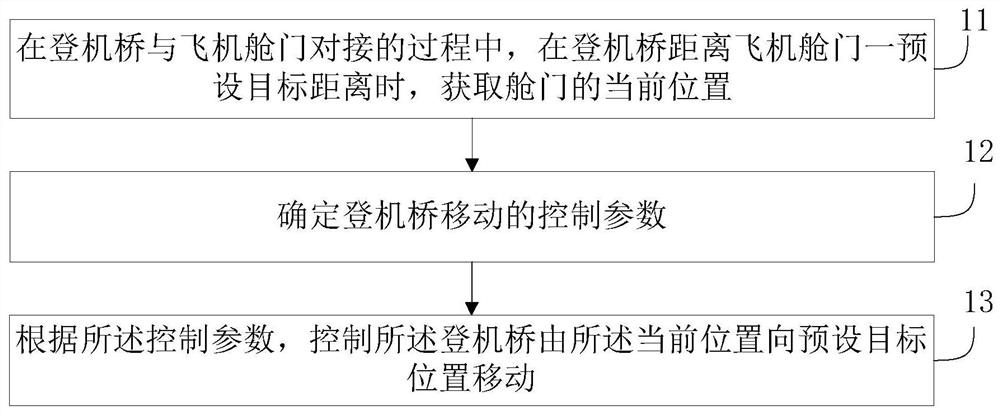

Boarding bridge control method and device

ActiveCN111776243ARealize automatic dockingGround installationsStructural engineeringControl parameters

The embodiment of the invention provides a boarding bridge control method and device. The method comprises the following steps: obtaining the current position of a cabin door in a process that a boarding bridge is in butt joint with the cabin door of an airplane when the boarding bridge is a preset target distance away from the cabin door of the airplane; determining control parameters of movementof the boarding bridge; and controlling the boarding bridge to move from the current position to a preset target position according to the control parameters. According to the scheme, automatic buttjoint of the boarding bridge and the airplane cabin door can be achieved.

Owner:BEIJING BOWEI AIRPORT SUPPORT LTD

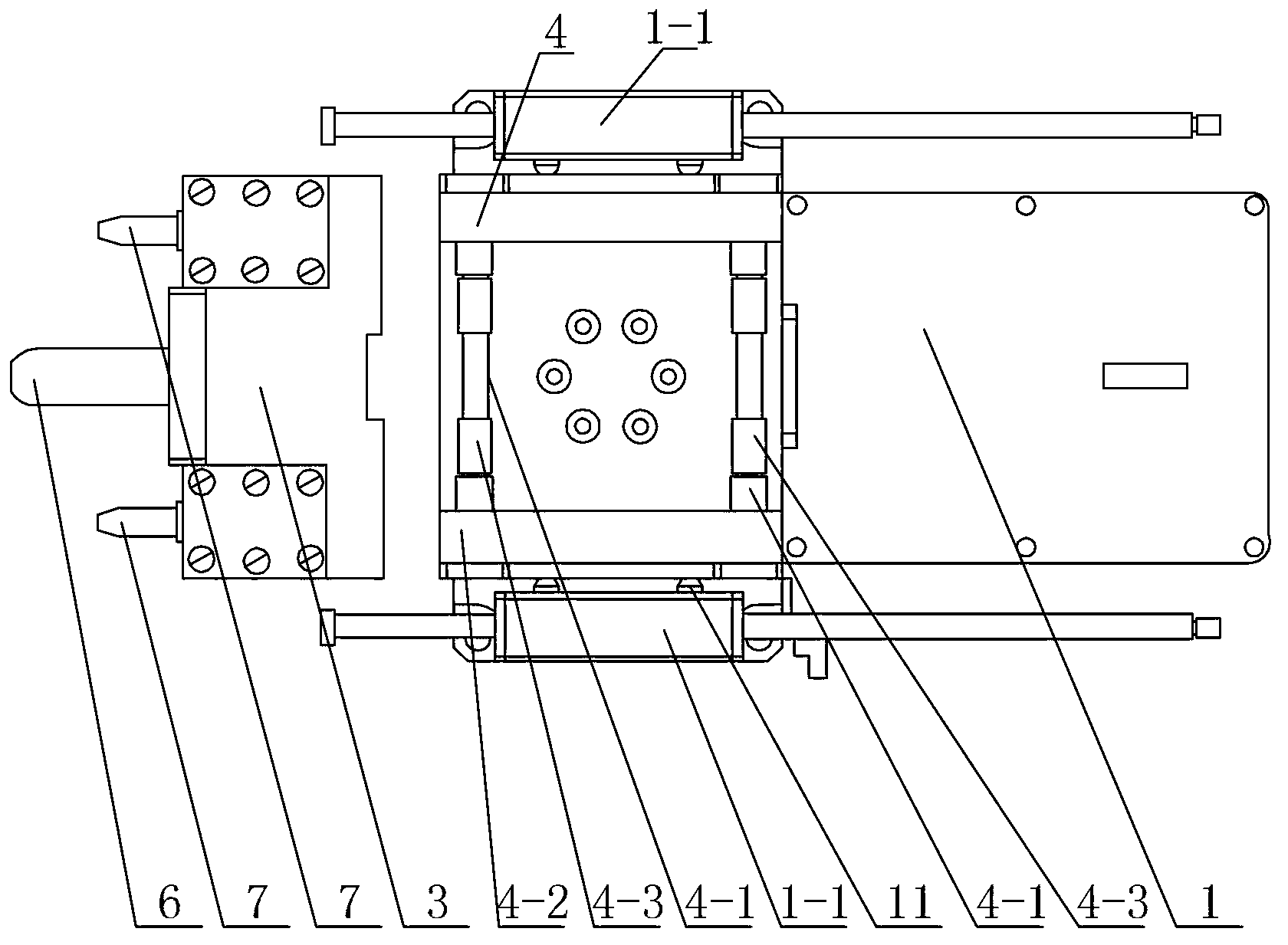

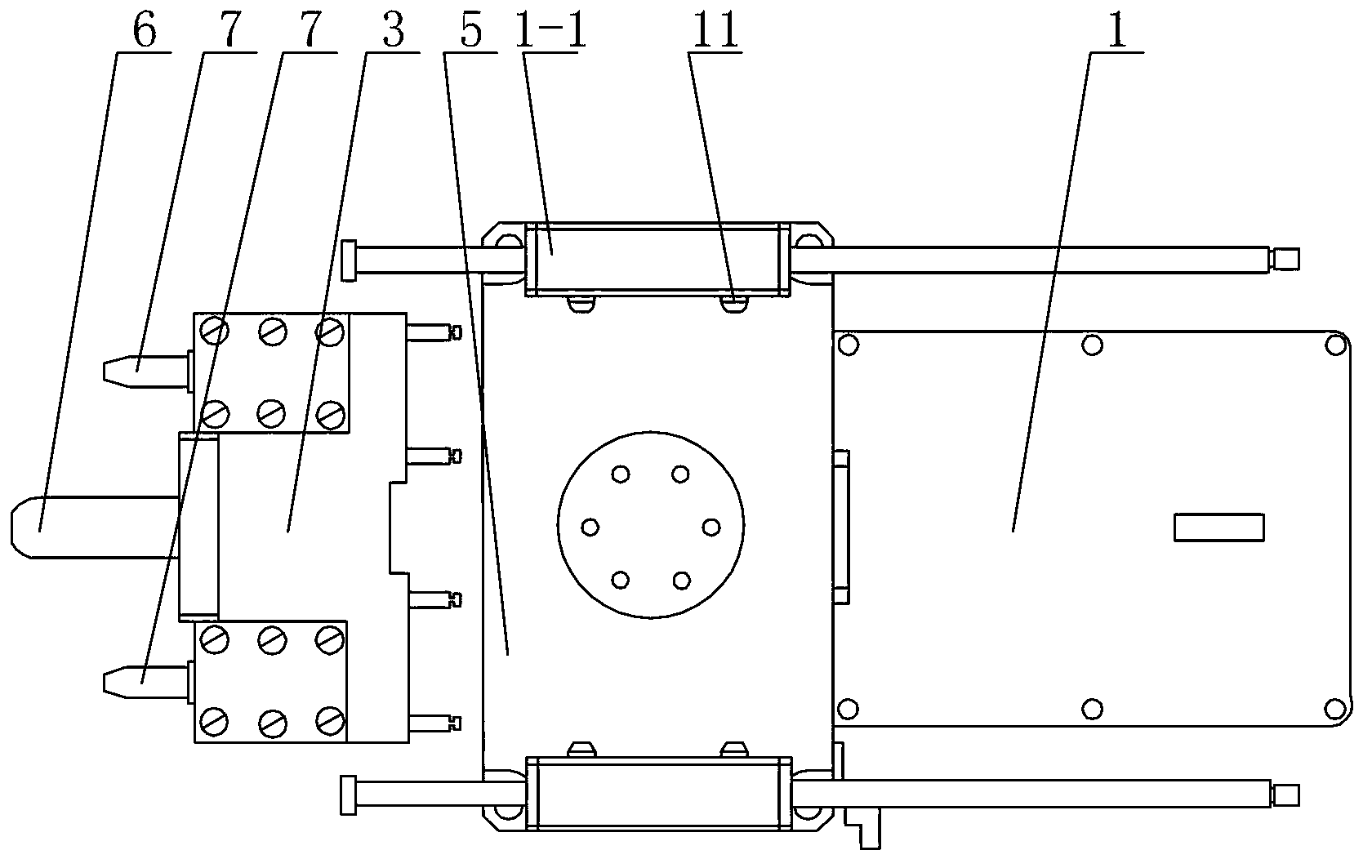

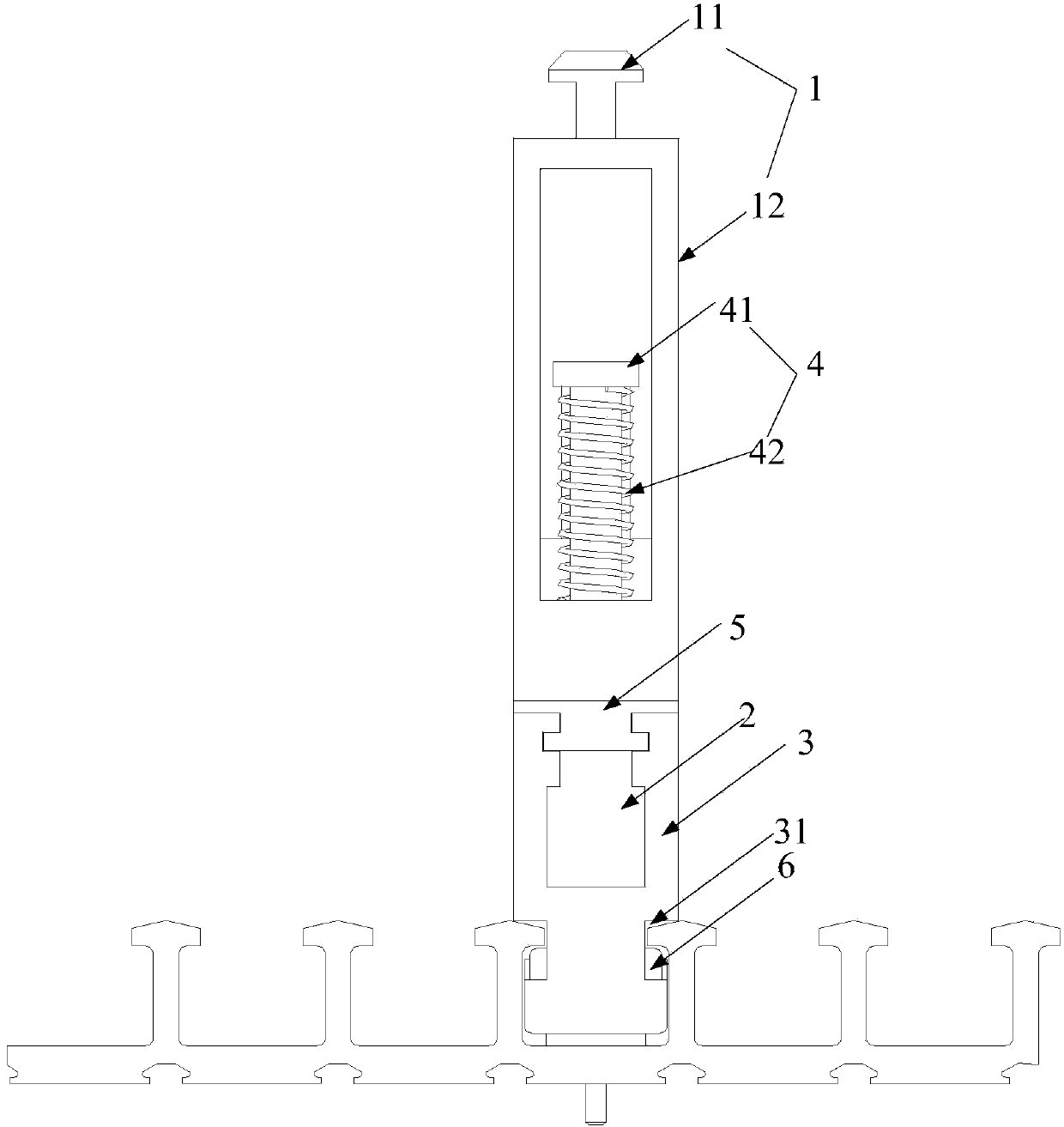

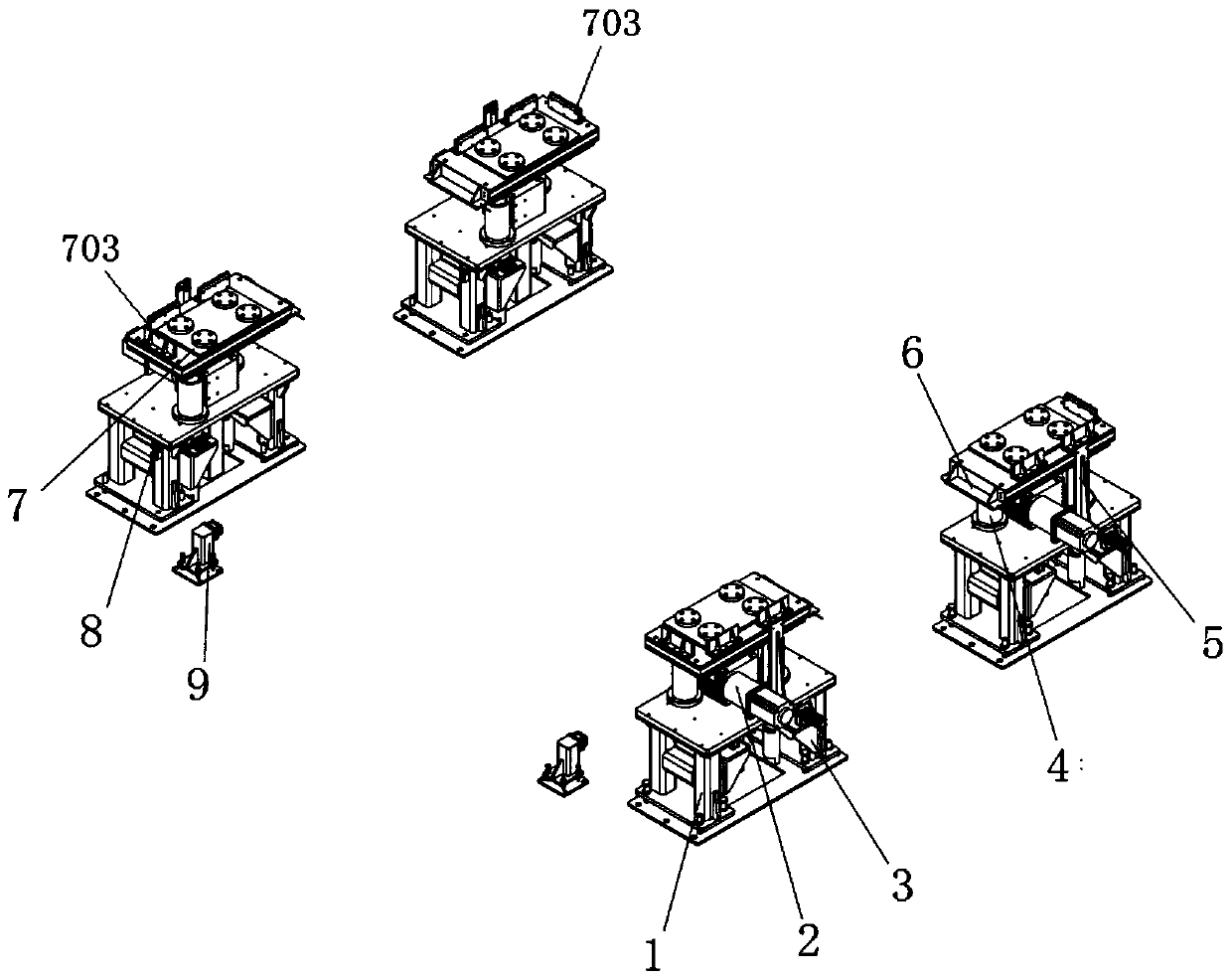

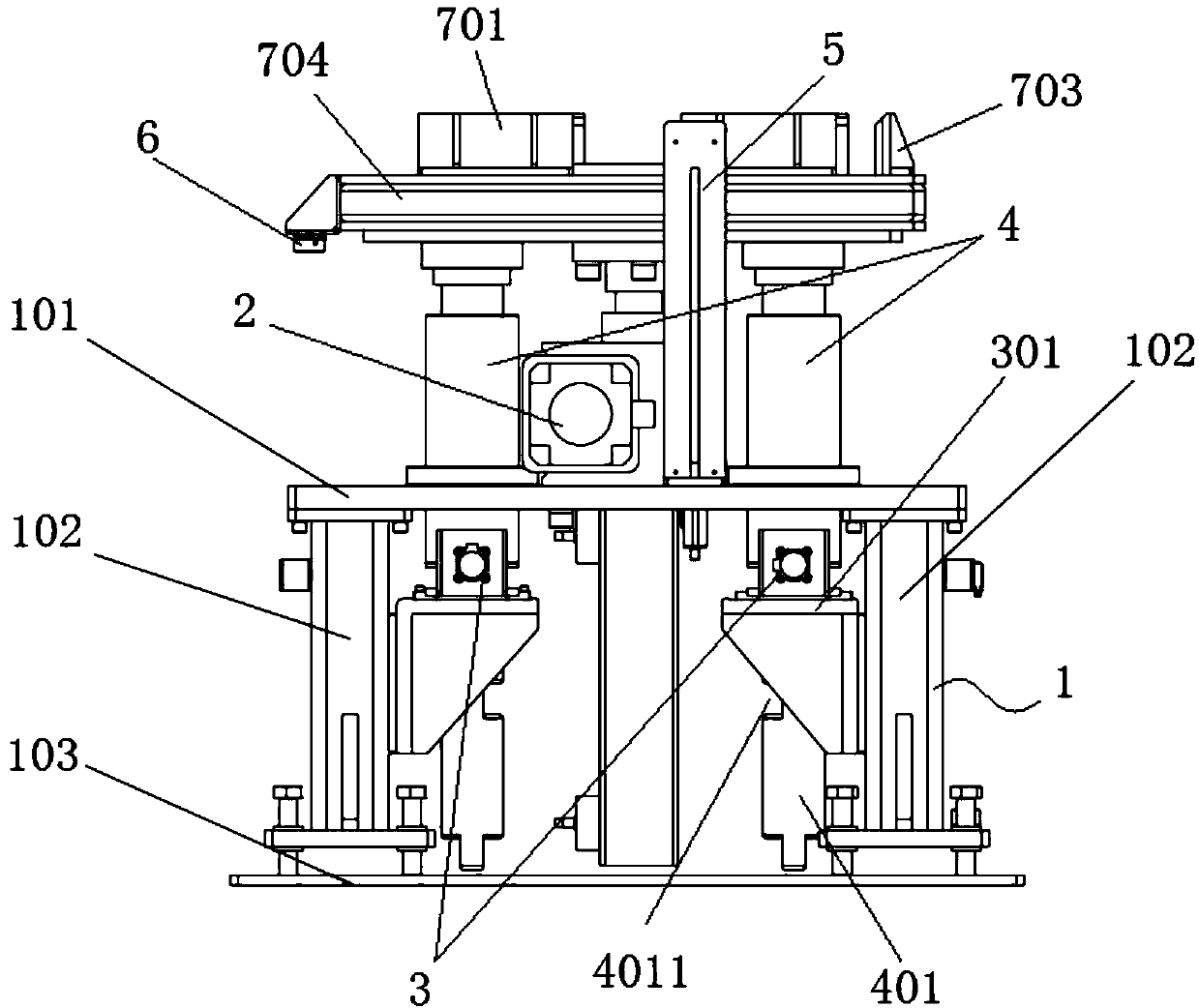

Positioning and lifting system for large structural member

ActiveCN111348577ASmooth liftRealize automatic dockingSafety devices for lifting equipmentsProduction lineClassical mechanics

The invention relates to the technical field of assembly, in particular to a positioning and lifting system for a large structural member. The positioning and lifting system for the large structural member comprises lifting devices and a limiting device, wherein the lifting devices comprise lifting plate assemblies, spiral elevators, guide mechanisms, falling prevention mechanisms and bases, the spiral elevators and the guide mechanisms are both arranged on the bases, the lifting plate assemblies are driven to lift through the spiral elevators, the guide mechanisms are provided with guide columns, the lower sides of the lifting plate assemblies and the upper ends of the guide columns are fixedly connected, the lower ends of the guide columns extend into the bases, the falling prevention mechanisms are arranged in the bases, the falling prevention mechanisms correspond to the guide mechanisms one by one, the falling prevention mechanisms comprise limiting sliding blocks and air cylinders, the lower parts of the guide columns are provided with notches, when the lifting plate assemblies are lifted in place, the limiting sliding blocks are driven by the air cylinders to move and be clamped in the notches on the corresponding guide columns, and lifting detection assemblies are arranged on the base. An in-place detection assembly is provided on either lifting device. The positioningand lifting system for the large structural member ensures the safety and improves the automation level and the working efficiency of a production line.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com