Optical fiber core jointer

An optical fiber core and butt joint technology is applied in the field of optical fiber communication to achieve the effect of switching and automatic docking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

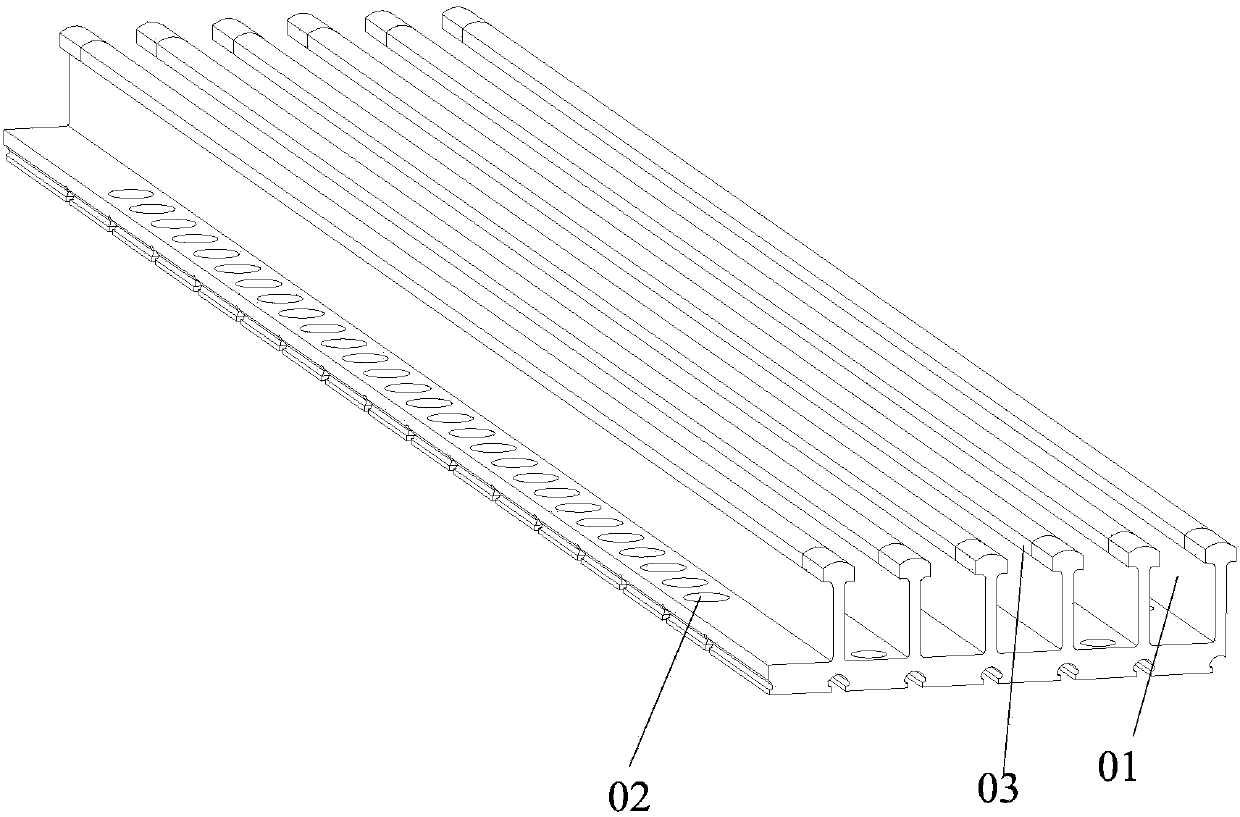

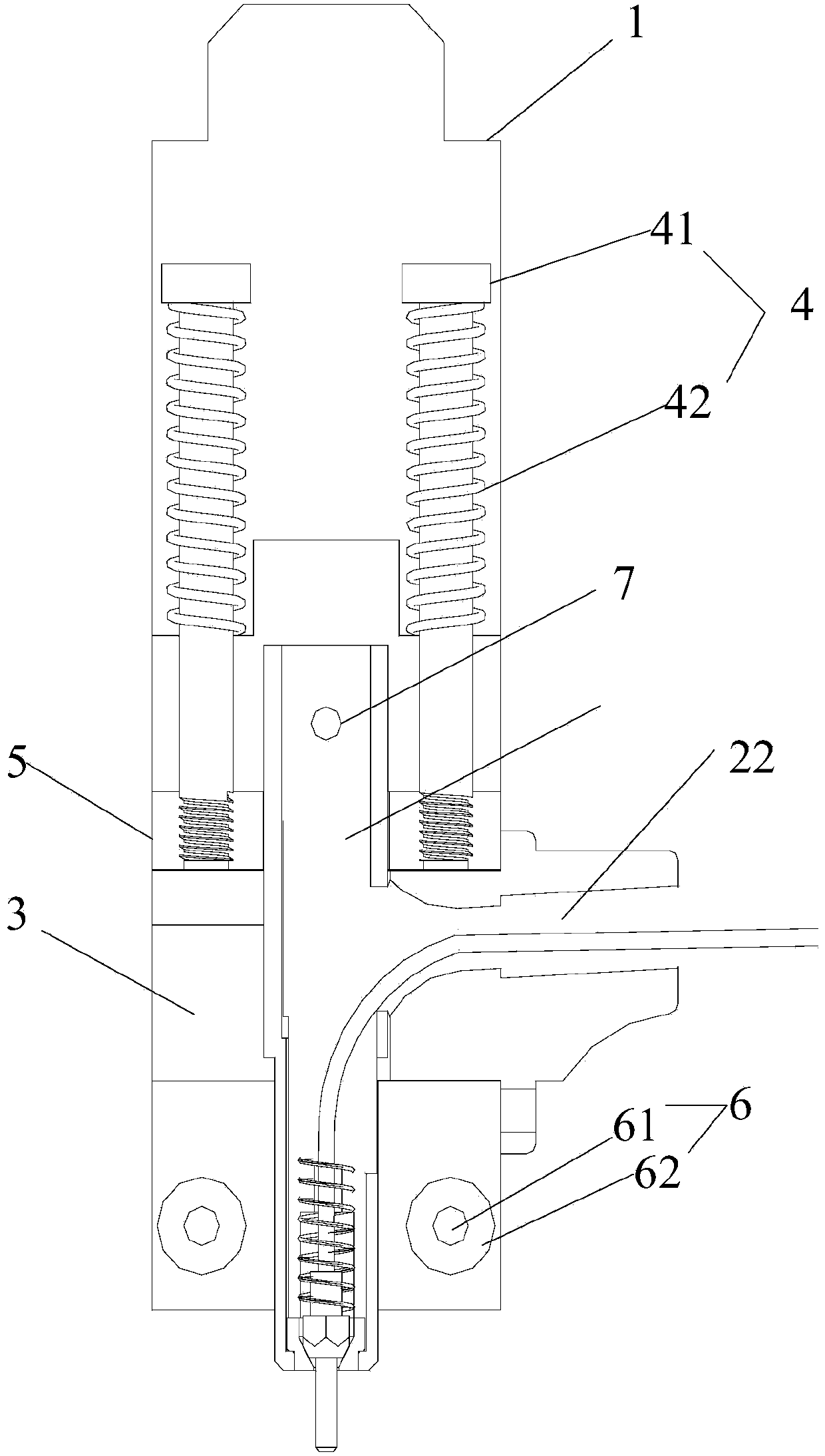

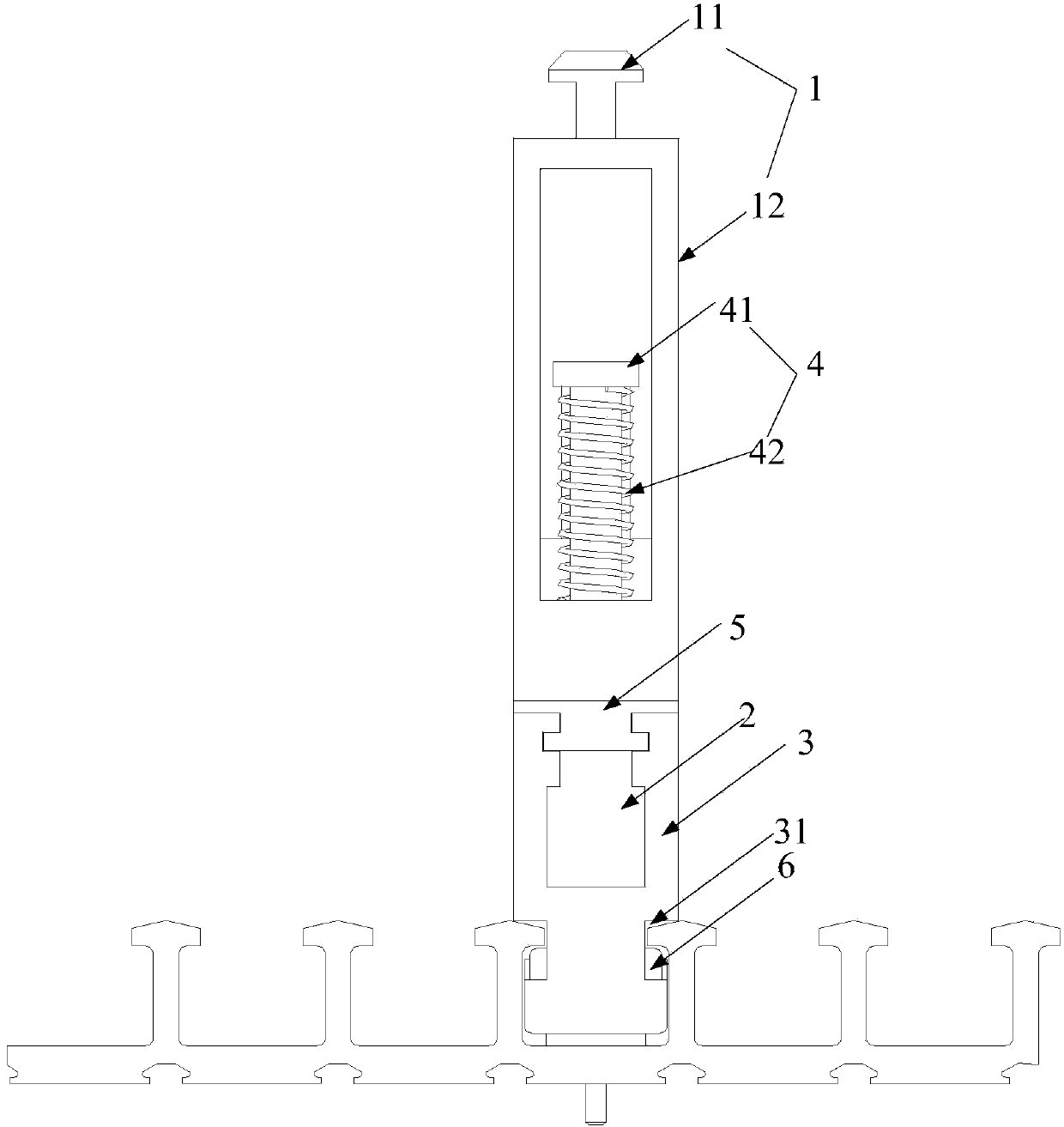

[0031] As mentioned in the background technology section, there is no device that can meet the signing conditions and play the role of fixing and moving the fiber core among the existing optical transmission network devices.

[0032] In view of this, an embodiment of the present invention provides an optical fiber core butt joint, including:

[0033] A fiber core pulling device, the fiber core pulling device includes: a pulling head and a pulling cavity;

[0034] A fiber core fixing device fixedly connected to the pulling cavity, the fiber core fixing device comprising: a first fiber channel located at the center of the fiber core fixing device and a second fiber channel located at the side wall of the fiber core fixing device , wherein the first fiber channel communicates with the second fiber channel, the fiber core passes from the second fiber channel into the fiber core fixing device, and passes through the fiber core from the first fiber channel core fixing device;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com