Tapered rod type butt joint traction mechanism for recycling underwater robot

An underwater robot and traction mechanism technology, which is applied in the directions of underwater operation equipment, ships, and ship salvage, etc., to achieve the effects of good compatibility, safe and reliable overall structure, and easy installation and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

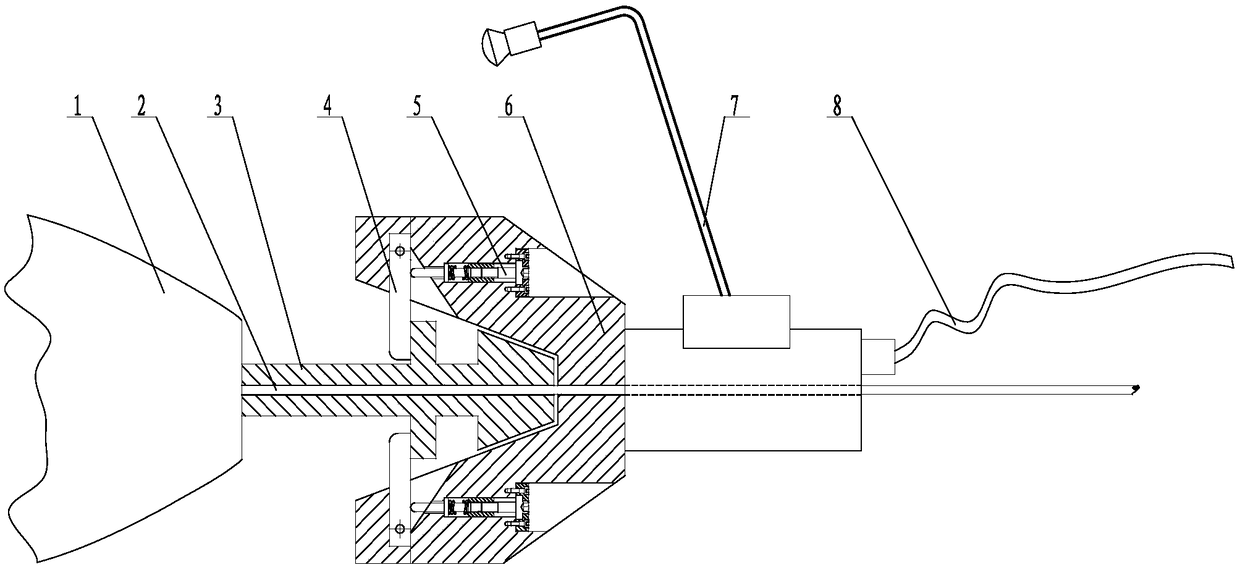

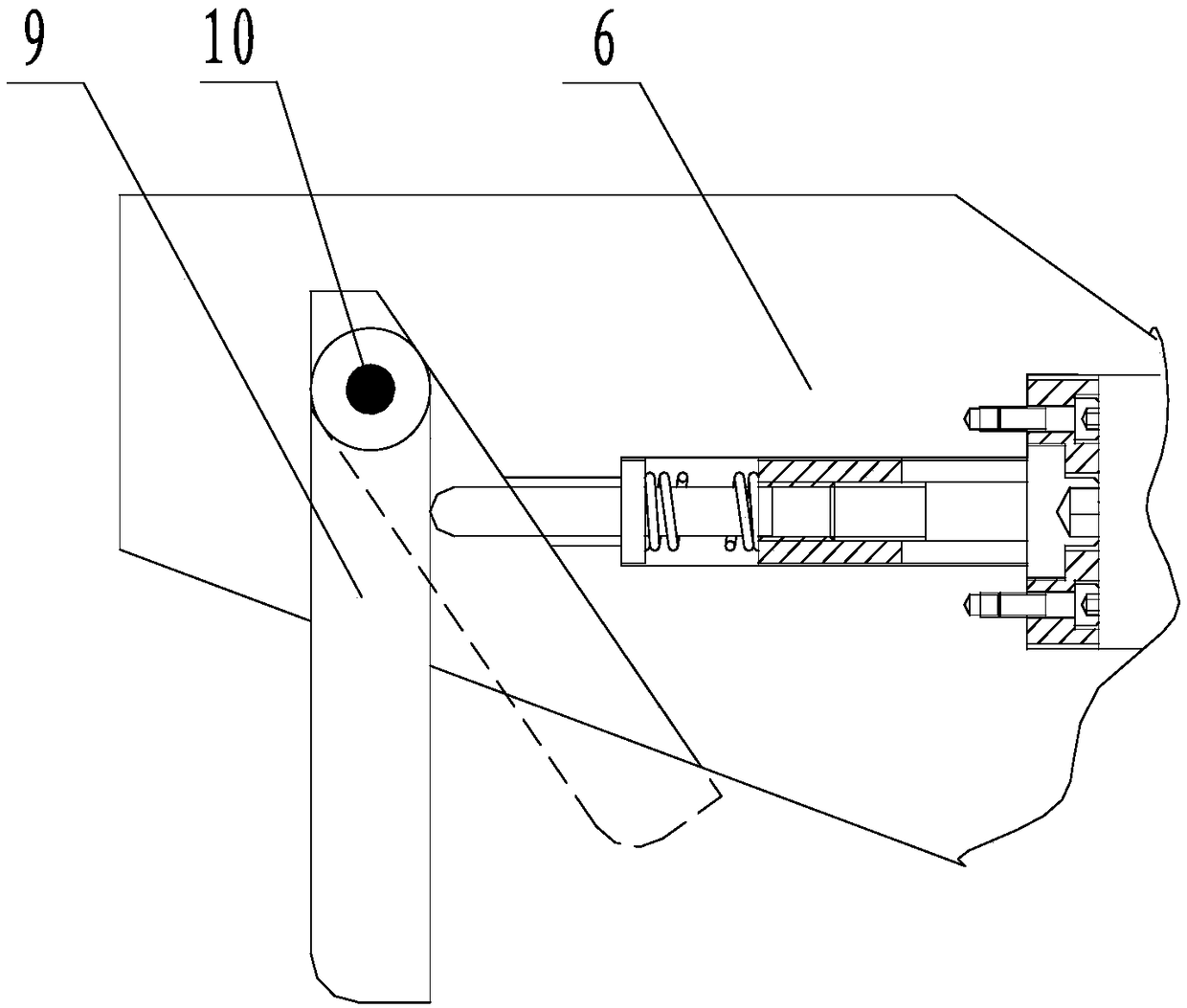

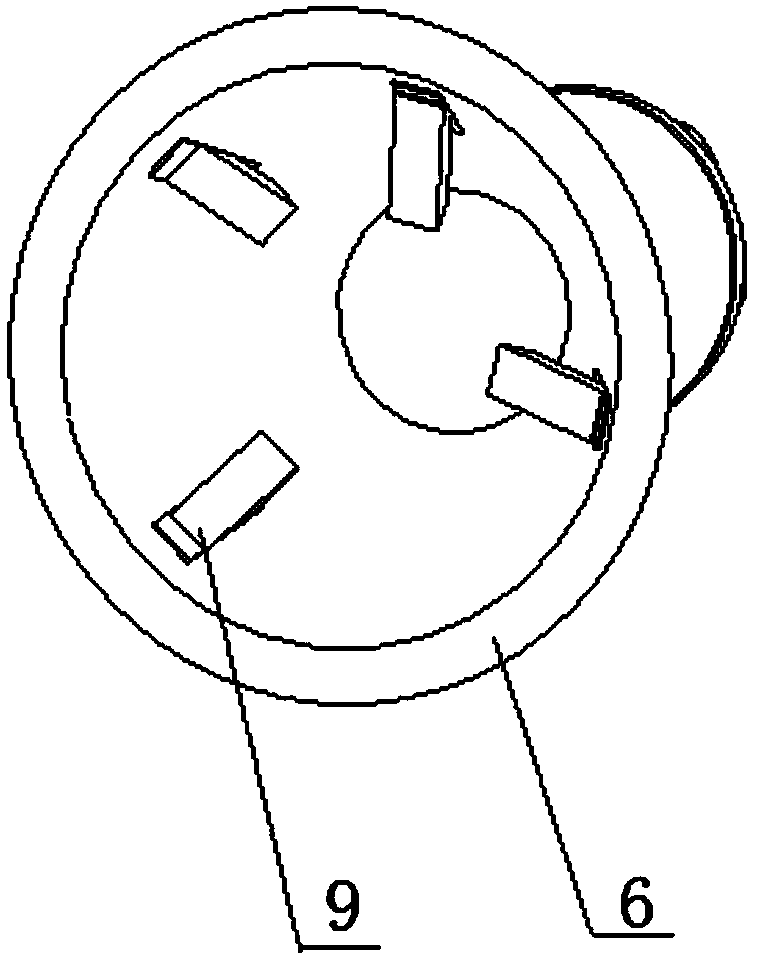

[0024] Such as Figure 1 ~ Figure 3 As shown, the docking structure of this embodiment includes a docking cone rod 3, a clamping mechanism 4, a reset mechanism 5, a lifting seat 6, an image sonar system 7 and a traction wire rope 8, wherein, before the underwater robot is launched, the docking cone rod 3 passes through Bolts are rigidly connected to the tail of the underwater robot 1 and integrated; four sets of hinged clamping mechanisms 4 are installed on the circumference of the lifting seat 6 at 90°, and are used to clamp the ring-shaped groove of the docking cone rod 3. Each set of clamping The reset mechanism 5 is installed at the corresponding position of the mechanism 4. By adjusting the fine-tuning screw 14 in the reset mechanism 5, pushing the moving nut 13 to adjust the tension of the pressure spring 12, and then adjusting the displacement of the ejector rod 11 to ensure the reliability of the docking cone rod 3 and the lifting seat 6 For docking, the other end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com