Optical fiber core butt joint device

An optical fiber core and equipment technology, applied in the field of optical fiber core docking equipment, can solve the problems of huge workload, time-consuming, and tedious manual switching operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

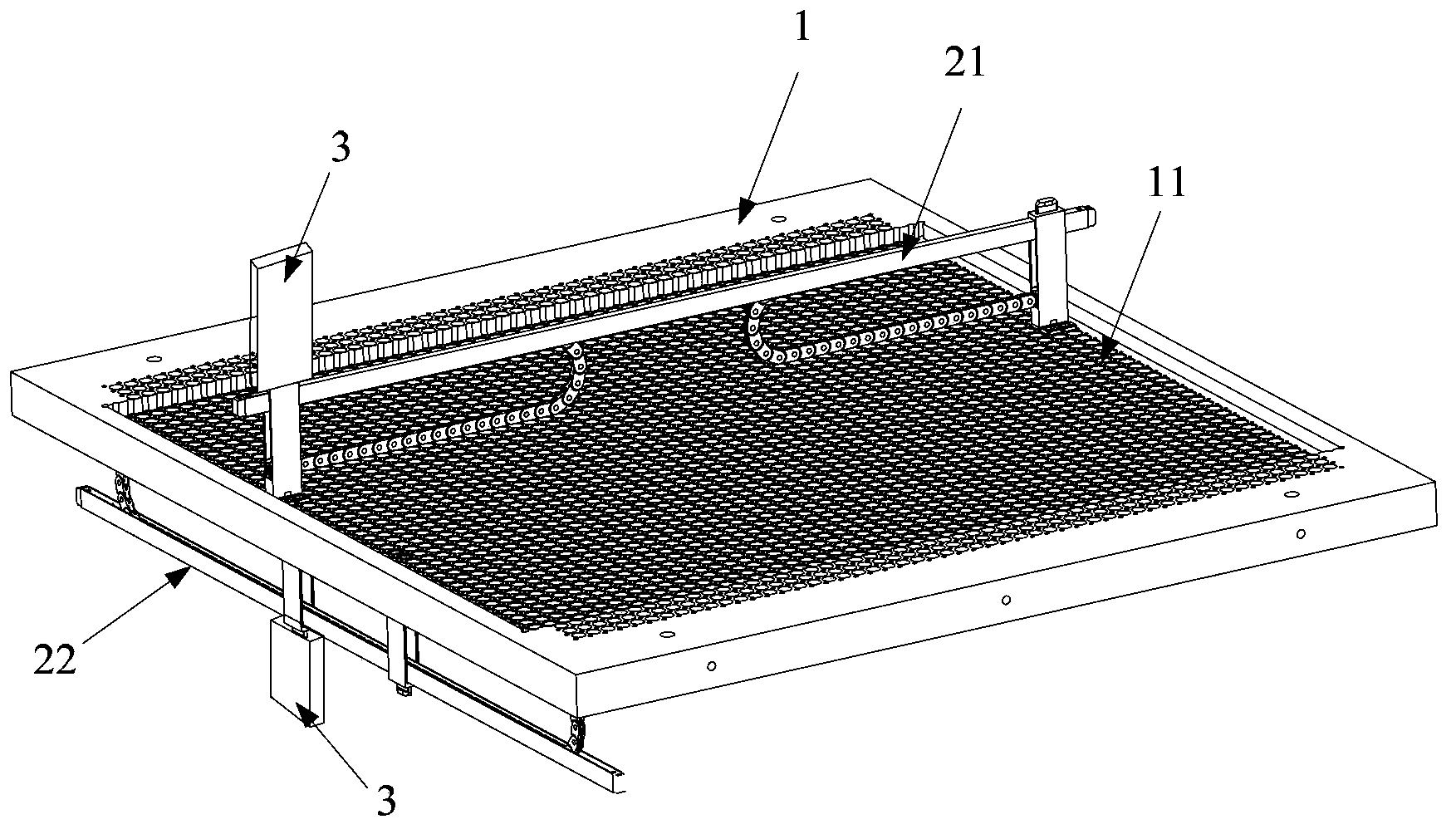

[0049] Such as figure 1 As shown, the embodiment of the present invention provides an optical fiber core butt joint device, including

[0050] A docking plate 1 having a plurality of docking devices, wherein the docking devices include a docking hole 11 at the center thereof;

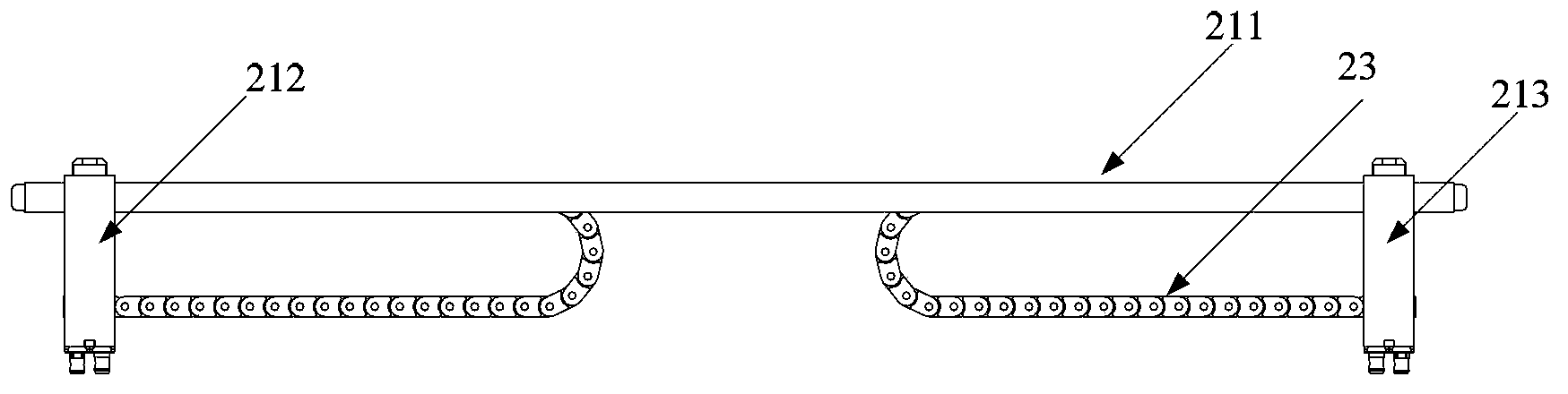

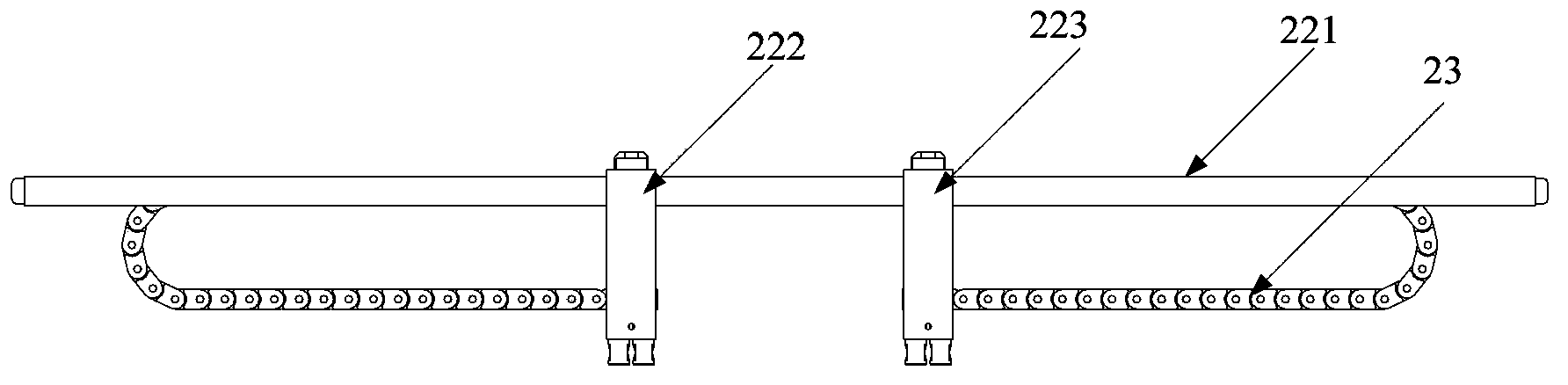

[0051]The fiber core butt connector 2 fixed on the butt plate 1, the fiber core butt connector includes: several parallel line connectors 21 and several parallel rope connectors 22, wherein, as figure 2 As shown, the line connector 21 includes: a first sliding bar 211, a first line fiber core connector 212 and a second line fiber core connector 213 that can slide along the first sliding bar 211, and the first line fiber core connector 213 can slide The input end and the output end of a line fiber core connector 212 are connected by connecting optical fibers, and the input ends and output ends of the second line fiber core connector 213 are connected by connecting optical fibers; image 3 As shown, th...

Embodiment 2

[0068] The basic structure of the optical fiber core butt connector provided by the embodiment of the present invention is basically similar to the structure in the first embodiment, the difference is that, as Figure 8 As shown, the docking device also includes: a plurality of arc-shaped holes 12 distributed along the circumferential direction of the docking hole 11, and the two ends of the arc-shaped holes 12 are away from the docking hole 11 along the arc-shaped hole 12. and a plurality of protrusions 13 located on the inner wall of the docking hole 11 and arranged opposite to the arc-shaped hole 11 along the radial direction of the arc-shaped hole 12, the protrusions 13 and the The arc holes 12 correspond one to one.

[0069] Preferably, the arc-shaped holes 12 are evenly distributed in the circumferential direction of the butt holes 11 . More preferably, the number of the arc-shaped holes 12 is four, but this is not limited in the present invention.

[0070] Since the s...

Embodiment 3

[0073] The basic structure of the optical fiber core butt joint equipment provided by the embodiment of the present invention is basically similar to the structure in the first embodiment, the difference is that, as Figure 9 As shown, the fiber core connector includes: a connecting part 91; a fixing part 92, the fixing part 92 is provided with a cavity 921 passing through its left and right sides, and the bottom of the cavity 921 is provided with two through Hole 922, the through hole 922 penetrates through the fiber core connector; two fiber core link flanges 93, one end of the fiber core link flange 93 is fixed in the through hole 922, and the other One end is provided with a second cylindrical portion 933 for fixing the external access fiber core, and at least one fiber core connection flange 93 is provided with a transparent stepped hole 931 inside. Specifically, the fiber core connecting flange 93 is composed of a concentric first cylindrical portion 932 and a second cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com