Double slider coupling for drive test of automobile rear axle or final drive assembly

A main reducer and cross slide technology, applied in the direction of couplings, elastic couplings, mechanical equipment, etc., can solve the problems of manual disassembly, the coupling cannot be automatically docked, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

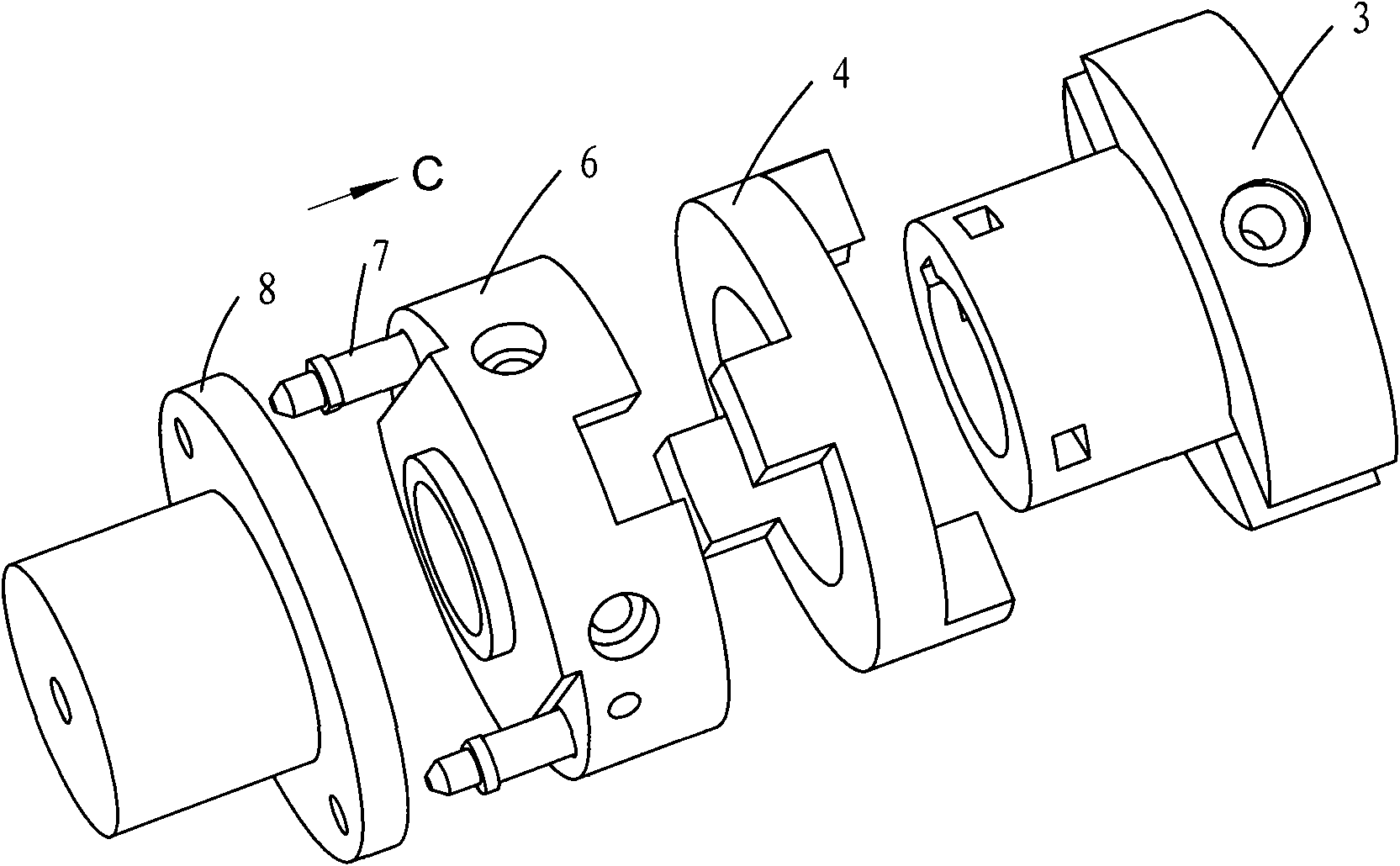

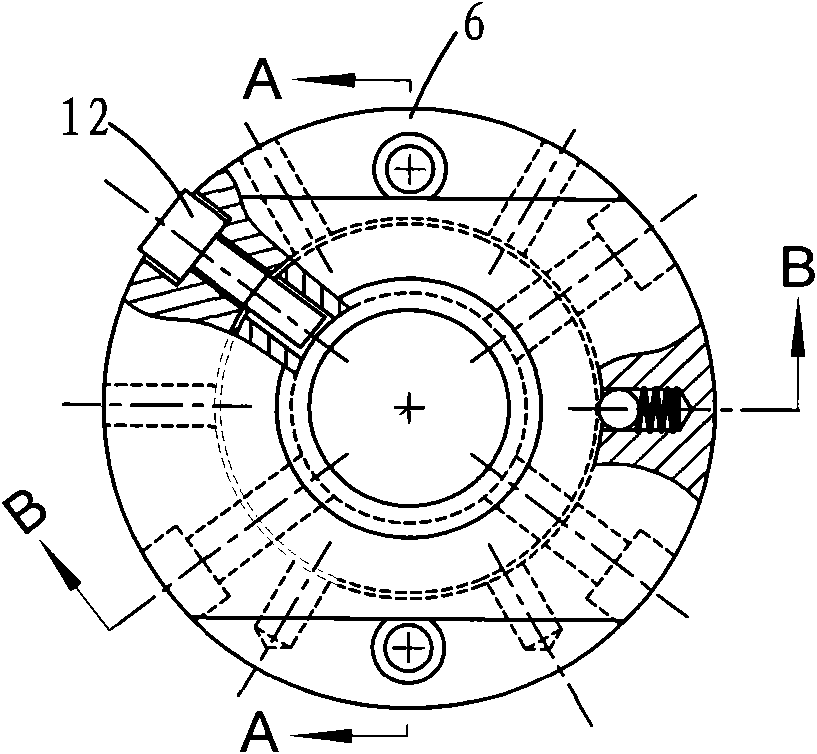

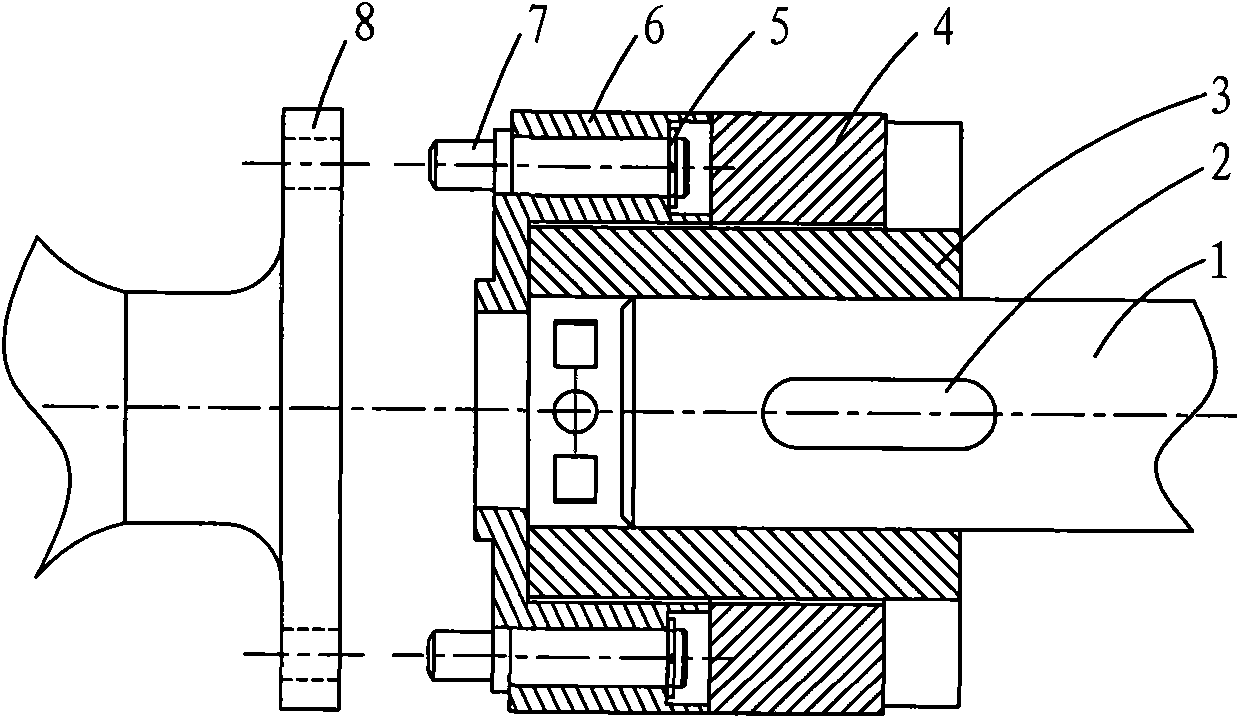

[0028] like figure 1 , figure 2 until Figure 18 As shown, the Oldham coupling used for driving test of automobile rear axle or final drive assembly, including the first half coupling 3, the second half coupling 6 and the middle Oldham between them 4. The first half-coupling 3 , the middle Oldham 4 and the second half-coupling 6 all have central holes, and the central holes on the first half-coupling 3 are used for plug-in connection driving The drive shaft 1 of the device, the first half-coupling 3 is inserted into the center hole of the second half-coupling 6 after passing through the center hole of the middle Oldham slider 4, and the center hole of the second half-coupling 6 The inner diameter is larger than the outer diameter of one end of the first half coupling 3 inserted therein for compensating the coaxiality error between the drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com