Automatic docking control system for carrier rocket and drain connector

An automatic docking and control system technology, which is applied in transportation and packaging, space navigation equipment, space navigation ground equipment, etc., and can solve the problems of manual docking and other connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

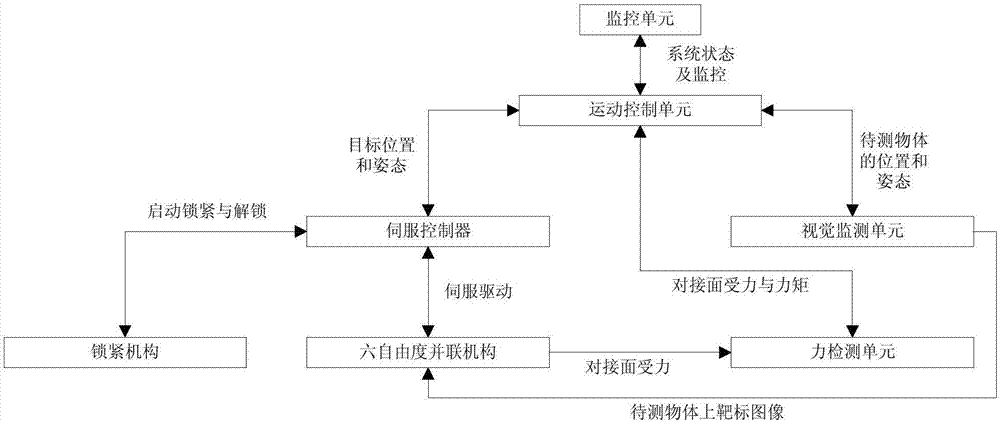

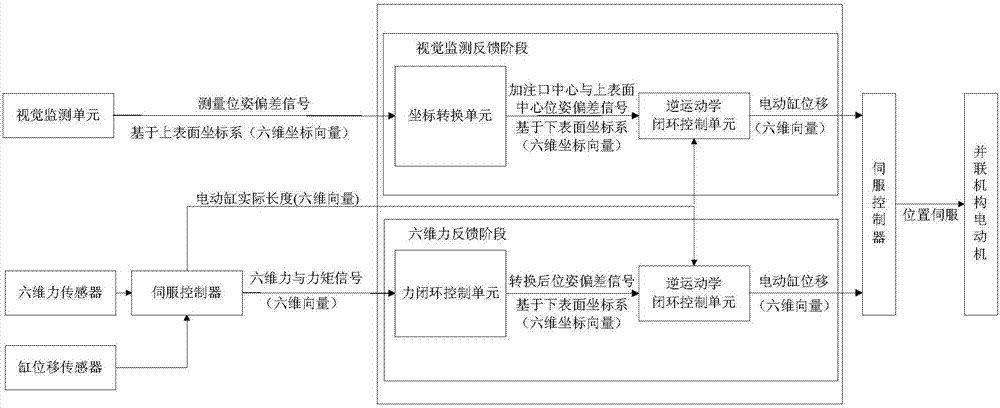

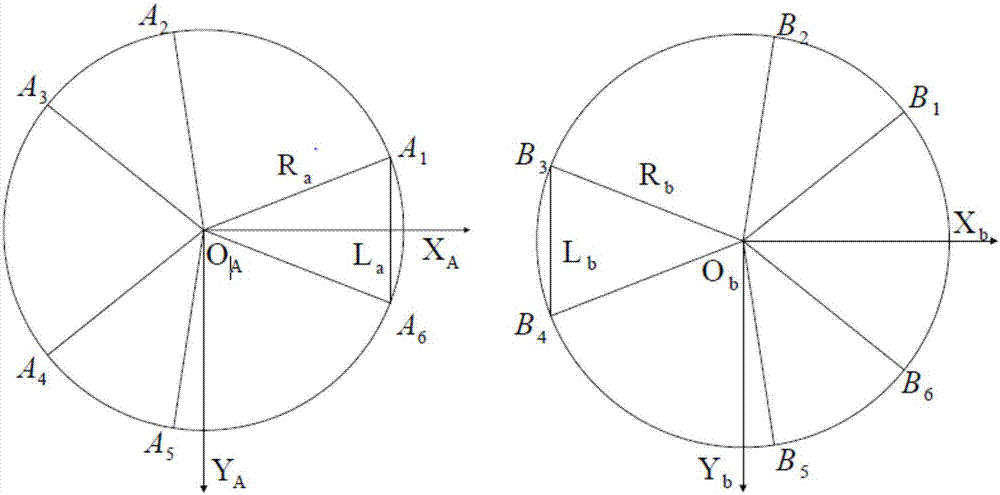

[0077] The basic concept of the present invention is: an automatic docking control system for a launch vehicle loading and unloading connector, including: a monitoring unit, a motion control unit, a servo controller, a force detection unit, a locking mechanism, a six-degree-of-freedom parallel mechanism, and a visual monitoring unit; The visual monitoring unit uses the camera to detect the position and attitude of the interface on the launch vehicle arrow; the force monitoring unit uses the force and torque sensor to detect the force and torque generated after docking; the locking mechanism completes the locking of the filling and releasing connector and the interface on the arrow ; The motion control unit uses the visual monitoring unit and the force detection unit to control the movement of the six-free parallel mechanism; the servo driver completes the driving of the motor. The invention realizes the automatic docking and locking of the filling and releasing connector and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com