Optical fiber core butting connector

A butt joint connector and optical fiber core technology, which is applied in the field of optical fiber communication, can solve the problems of large consumption of fiber optic cables and high cost, and achieve the effect of reducing usage and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

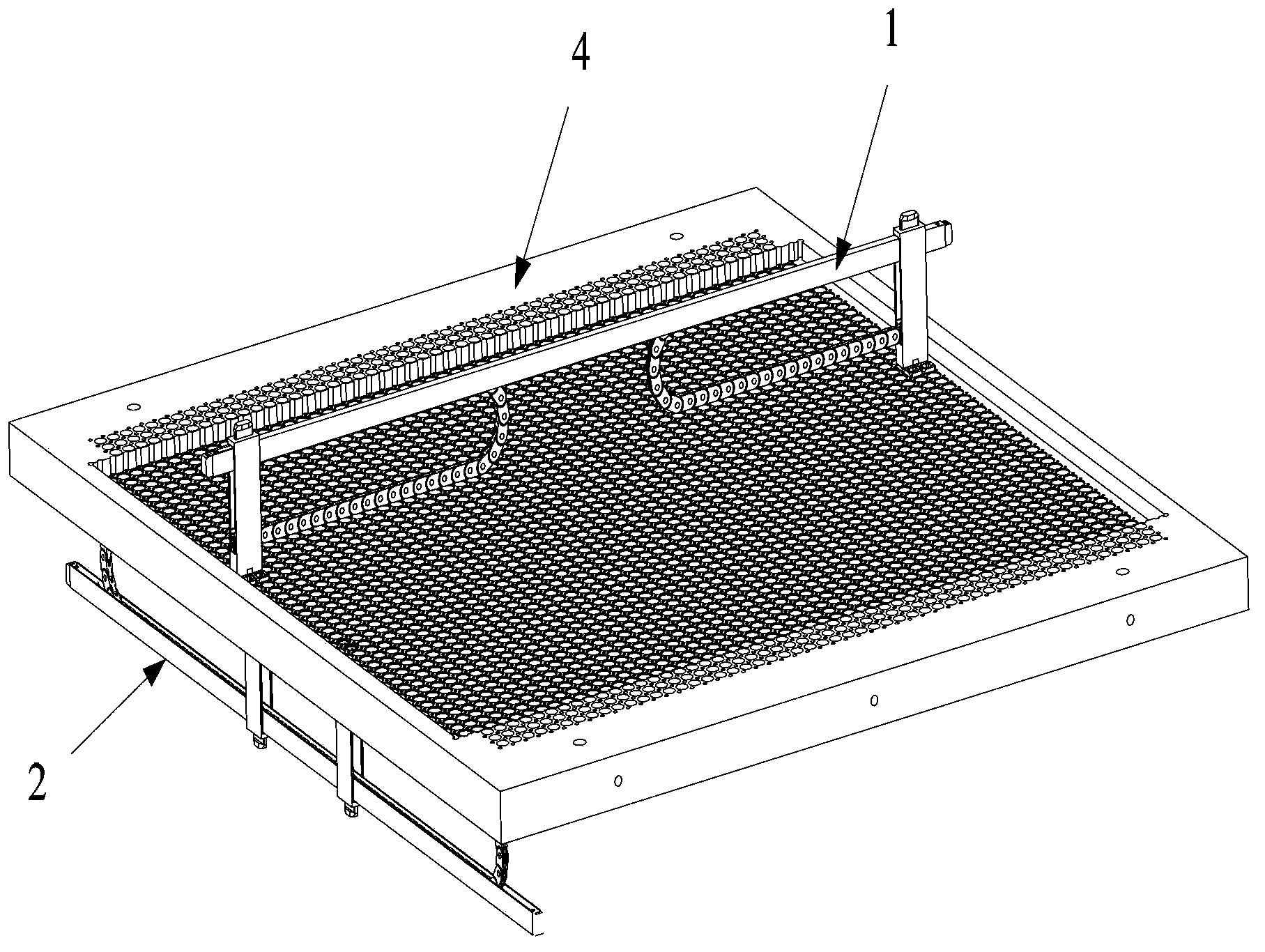

[0033] The optical fiber core butt connector provided by the embodiment of the present invention includes:

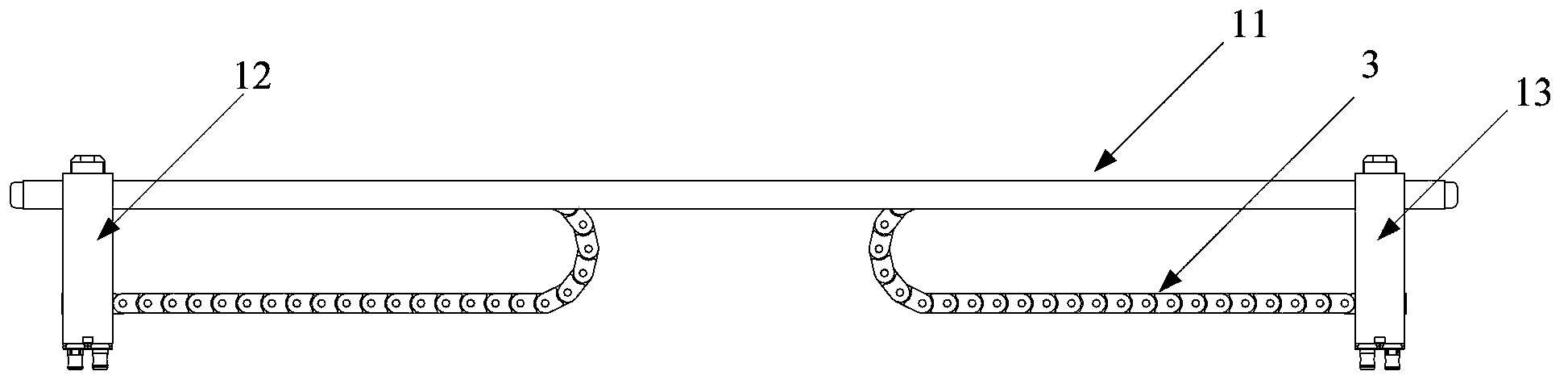

[0034] A number of line connectors 1 parallel to each other, such as figure 1 As shown, the line connector 1 includes: a first sliding rod 11, a first line fiber core connector 12 and a second line fiber core connector 13 that can slide along the first sliding rod 11, wherein the The input end and the output end of the first line fiber core connector 12 are connected by connecting optical fibers, and the input ends and output ends of the second line fiber core connector 13 are connected by connecting optical fibers;

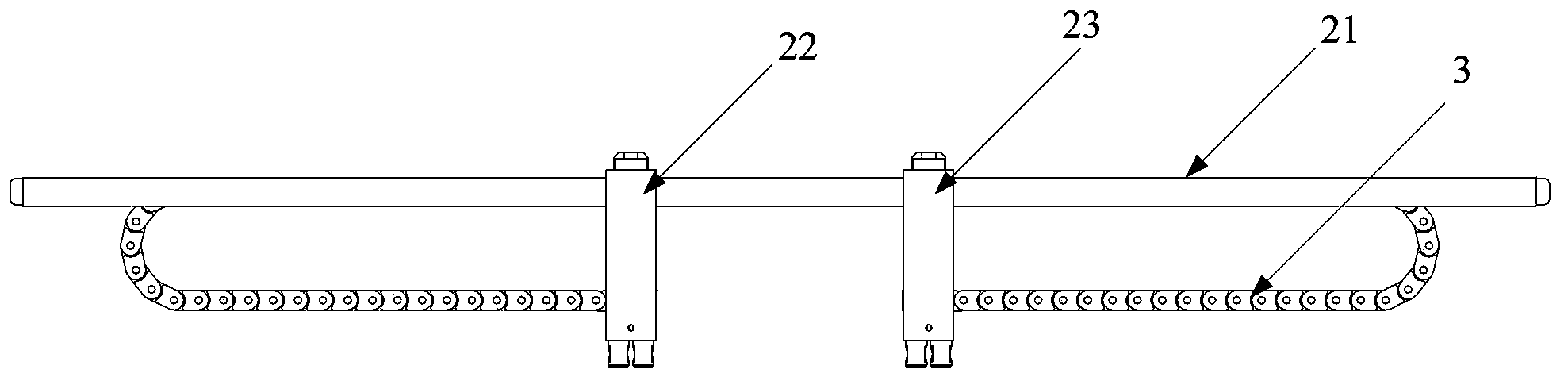

[0035] A number of wire connectors 2 parallel to each other, such as figure 2 As shown, the rope connector 2 includes: a second sliding rod 21, a first rope fiber core connector 22 and a second rope fiber core connector 23 that can slide along the second sliding rod 21, wherein , the first rope fiber core connector 22 is connected to the second rope fib...

Embodiment 2

[0049] The basic structure of the optical fiber core butt connector provided by the embodiment of the present invention is basically similar to the structure in the first embodiment, the difference is that, as Figure 8As shown, the fiber core connector includes: a connecting portion 81; a fixing portion 82, the fixing portion 82 is provided with a cavity 821 through which the left and right sides pass through, and the bottom of the cavity 821 is provided with two through holes side by side 822, the through hole 822 penetrates through the fiber core connector; two optical fiber core link flanges 83, one end of the optical fiber core link flange 83 is fixed in the through hole 822, and the other end There is a second cylindrical portion 833 for fixing the external access fiber core, and at least one fiber core connection flange 83 is provided with a transparent stepped hole 831 inside. Specifically, the fiber core connecting flange 83 is composed of a concentric first cylindric...

Embodiment 3

[0053] On the basis of the second embodiment, in order to facilitate the external device to better clamp the connecting part 81 of the fiber core connector, and drive the fiber core connector to move through the connecting part 81, the embodiment of the present invention core connectors provided, such as Figure 9 As shown, the connecting part 81 is composed of upper and lower parts, wherein, in the direction perpendicular to the direction through which the cavity 821 penetrates, the cross-sectional area of the upper part of the connecting part 81 is larger than that of the lower part of the connecting part 81. Cross-sectional area, so that the upper part of the connecting part 81, the lower part of the connecting part 81 and the fixing part 82 form a groove shape, so that external devices can be easily formed by using the lower part of the connecting part 81 The groove clamps the fiber core connector to move up and down.

[0054] To sum up, the optical fiber core butt conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com