Processing device and processing technology for protective films with pull tapes

A processing device and protective film technology, applied in the direction of metal processing, etc., can solve the problem that the bonding area of the easy-to-tear sticker and the protective film cannot be well overlapped, the easy-to-tear sticker cannot bear the force well, and the appearance of the protective film is not beautiful enough, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

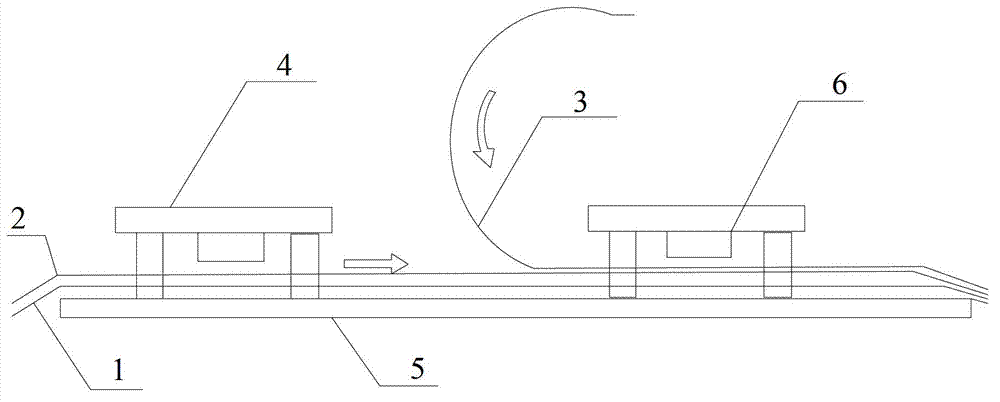

[0036] A kind of processing technology that is easy to tear and paste protective film, adopts the processing device of preferred embodiment 1 of the present invention, comprises following processing steps:

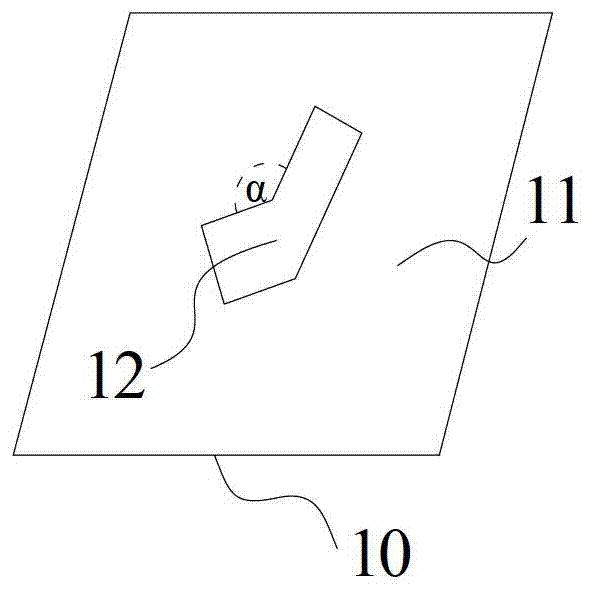

[0037] 1) Die cuts on the protective film: place the protective film material with the protective layer 2 and the release film 1 on the die-cutting machine, place the protective layer with the adhesive side up, and then follow the direction of the protective film raw material conveying Place the first mold base 4 and the second mold base 6 in turn on the die-cutting machine, then place the protective film mold on the first mold base, and punch out the shape consistent with the product to be laminated by the punching knife set of the protective film mold Protective film products, and die-cut the first incision in the shape of "one" on the protective layer of the protective film;

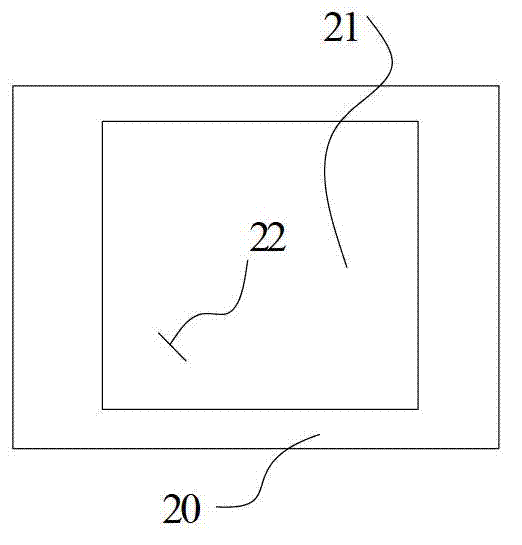

[0038]2) Die-cut easy-to-tear paste: place the easy-to-tear paste mold on the second mold base...

Embodiment 4

[0040] A kind of processing technology that is easy to tear and paste protective film, adopts the processing device of preferred embodiment 1 of the present invention, comprises following processing steps:

[0041] 1) Die cut on the protective film: place the protective film material with the protective layer and the release film on the die-cutting machine, place the protective layer with the adhesive side up, and then place it on the die along the direction of the protective film raw material delivery. Place the first mold base and the second mold base in turn on the cutting machine, then place the protective film mold on the first mold base, and punch out the protective film product with the same shape as the product to be pasted through the punching knife set of the protective film mold. And on the protective layer of the protective film, punch out a square traction block with three sides separated from the protective film;

[0042] 2) Die-cut easy-to-tear paste: place the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com