Pump water-cooled motor

A technology for water-cooled motors and pumps, applied to pumps, pump devices, pump components, etc., can solve the problems of accelerated bearing wear, small cooling water volume, and poor cooling effect, so as to improve bearing wear, improve overload capacity, and solve damage high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

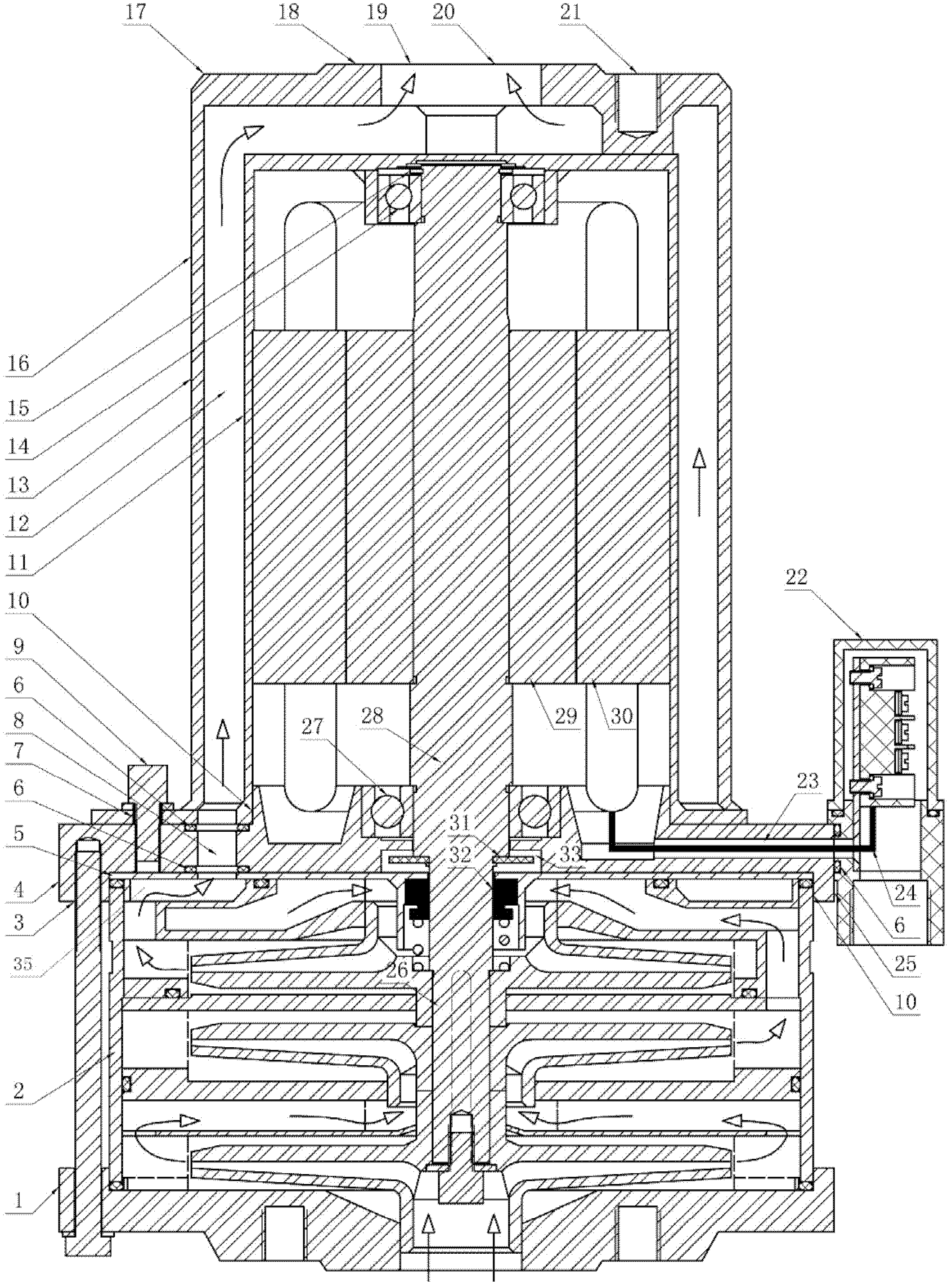

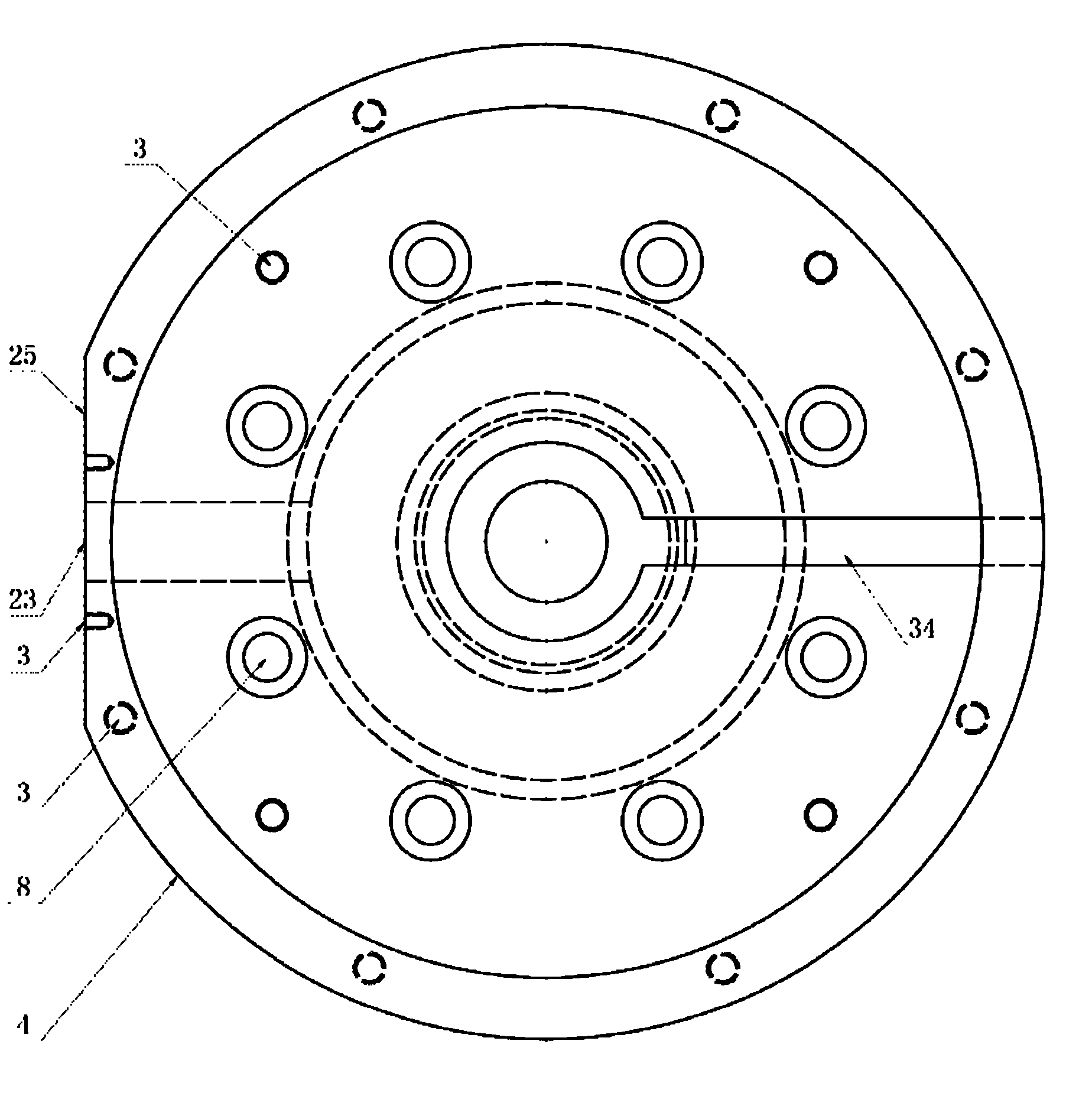

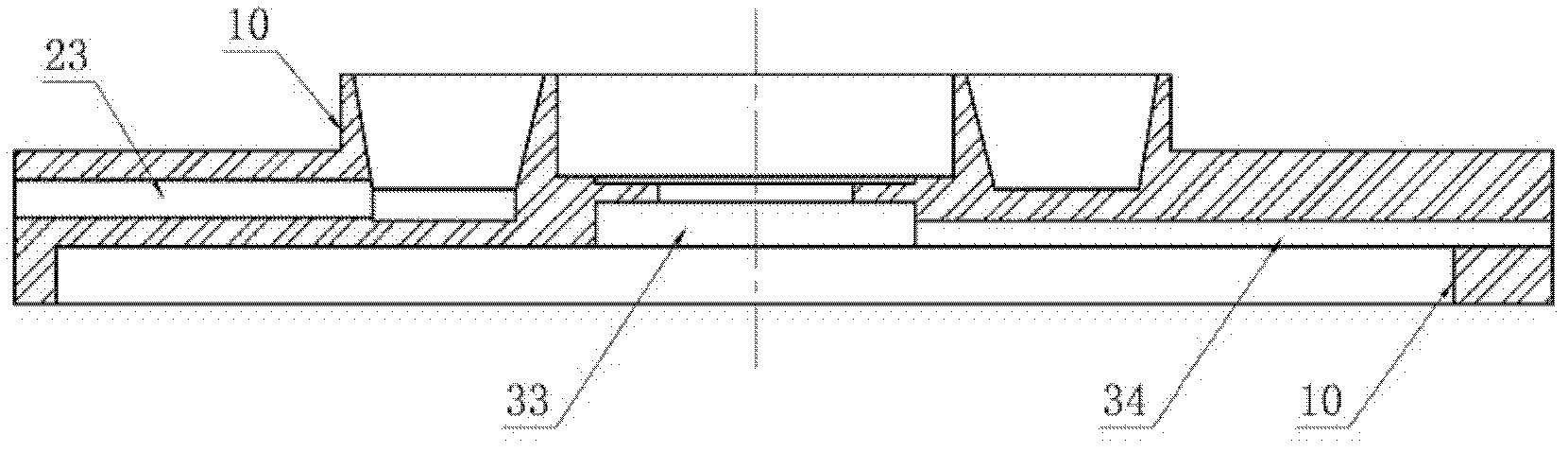

[0019] see figure 1 As shown, a pump water-cooled motor includes a motor 17, a water pump 1, and a motor housing 16. The motor housing 16 forms an integral (also split) outer shell 13 and an inner shell 11, and stainless steel tubes, stainless steel tubes, and inner shells can be used. Plate or steel pipe, steel plate, welded, processed, can also adopt the production process of casting, welding, processing, the pump end of the motor 17 is conductively connected with the water pump 1 through the motor end cover 4, and the pump end bearing is installed in the middle of the motor end cover 4 27; A cooling interlayer 12 is formed between the outer shell 13 and the inner shell 11, the top of the outer shell 13 is provided with a water outlet 20 communicating with the cooling interlayer 12, the flange sealing surface 18 protrudes from the outside, and a threaded flange connection bolt hole 21 is arranged in the center of the ring , the end bearing 14 is installed inside the end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com