Method for quickly freezing cooked crayfish meat at low temperature

A technology for lobster kernels and lobsters, which is applied in the field of food processing, can solve the problems of easily destroying the overall structure and beauty of the shrimp kernels, excessively large volume of quick-frozen crayfish, and product spoilage, etc., and achieves strong promotion and application value, and is not easy to spoilage. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the invention.

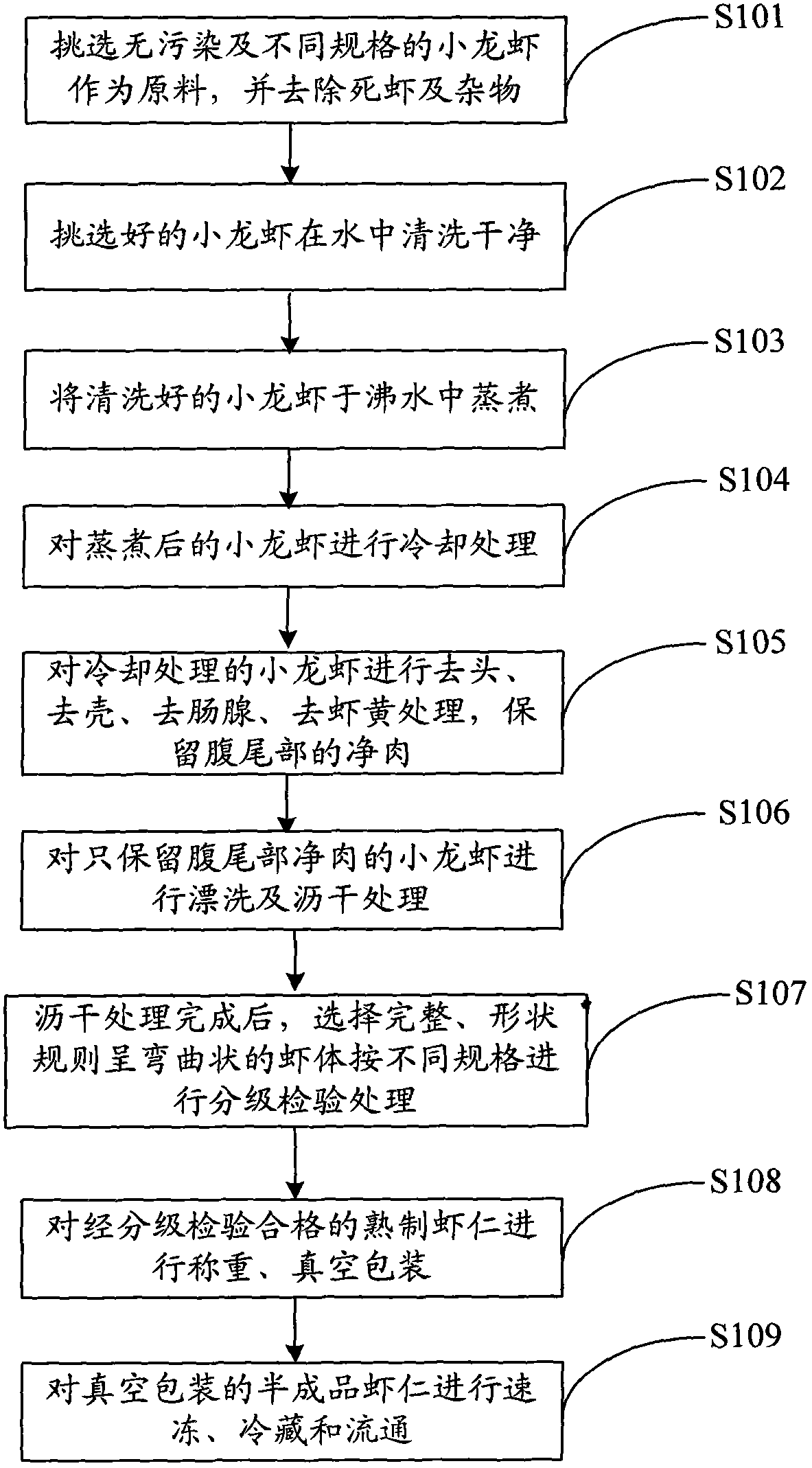

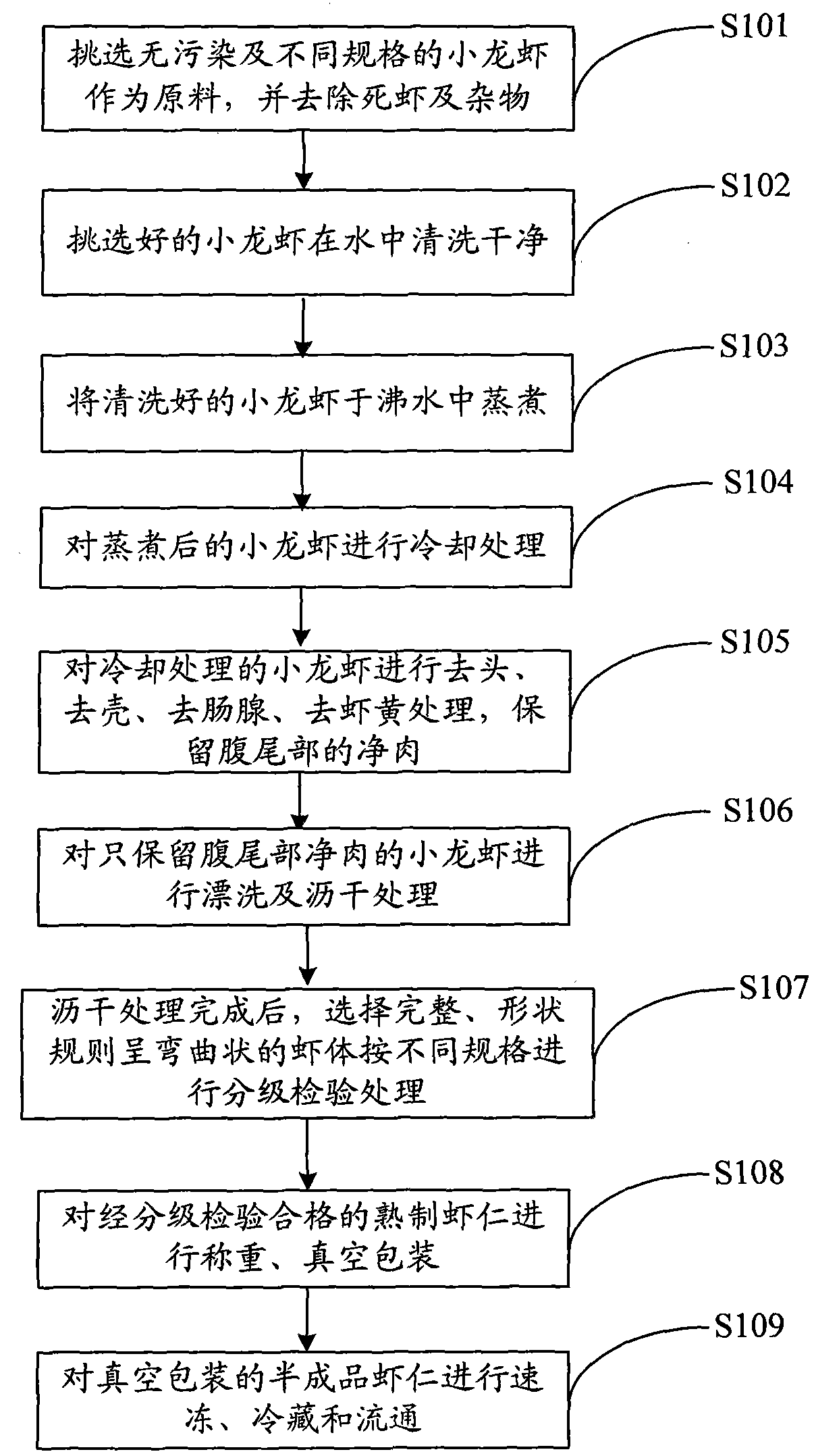

[0025] figure 1 It shows the implementation flow of the method for low-temperature quick-freezing of cooked crayfish meat provided by the embodiment of the present invention.

[0026] The method includes the following steps:

[0027] In step S101, select non-polluted crayfish with different specifications as raw materials, and remove dead shrimp and sundries;

[0028] In step S102, the selected crayfish are cleaned in water;

[0029] In step S103, steam the cleaned crayfish in boiling water;

[0030] In step S104, cooling the cooked crayfish;

[0031] In step S105, the cooled crayfish is subjected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com