Method for widening SCR denitration low-load operation potential based on ammonium bisulfate poisoning recovery characteristics of catalyst

A catalyst sulfuric acid, low-load technology, applied in the direction of chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as equipment failure, unit shutdown, large investment, etc., to reduce investment in transformation, reduce risks, and avoid power generation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A 300MW coal-fired unit: SO in flue gas at the inlet of SCR denitrification system 3 Concentration 10.0μL / L, H 2 O content 9.0%, NOx concentration 500mg / m 3 (dry basis, standard state, 6.0%O 2 ), the NOx emission concentration at the outlet of the denitrification system is 50mg / m 3 (dry basis, standard state, 6.0%O 2 ).

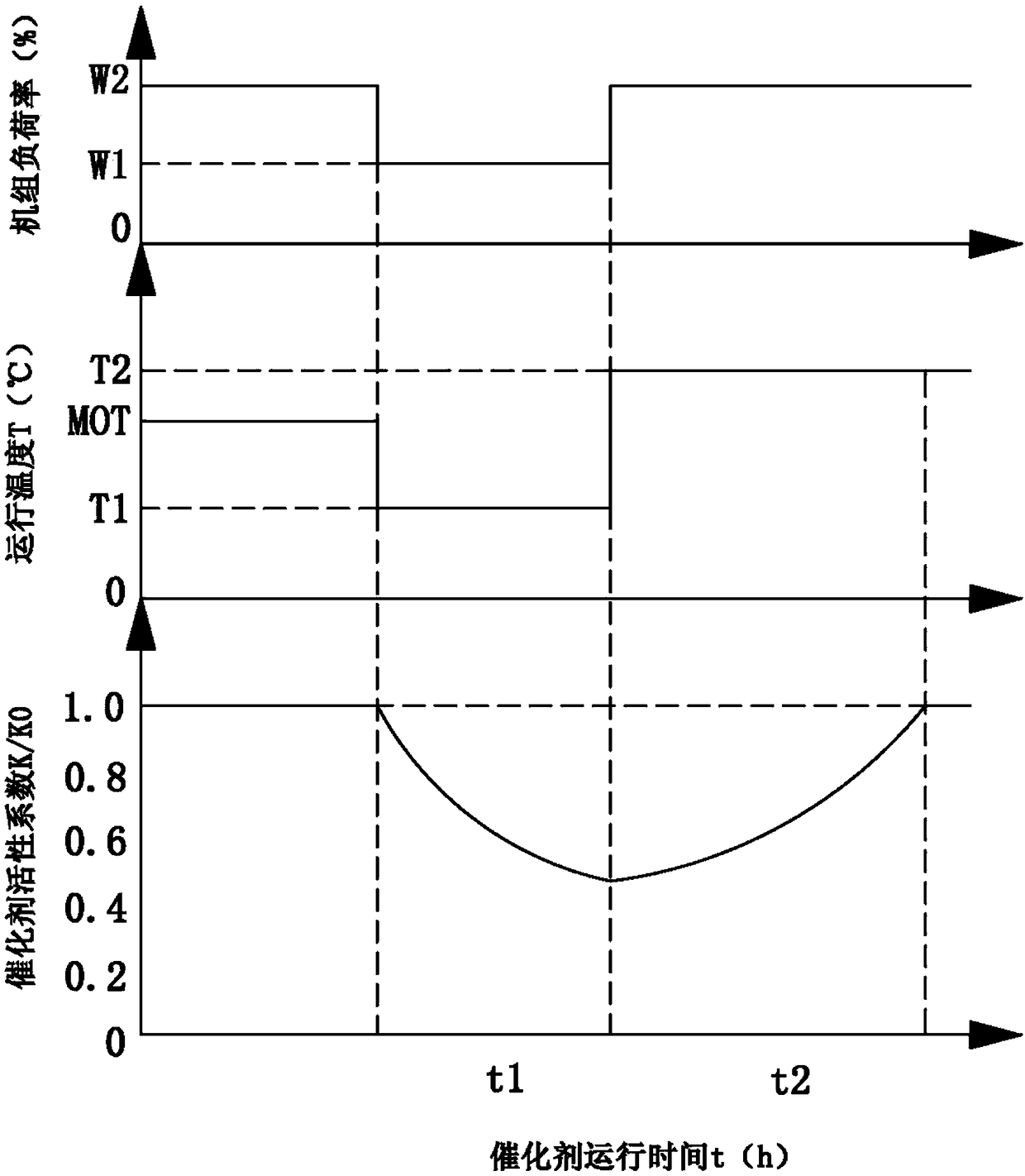

[0027] Based on the recovery characteristics of catalyst ammonium bisulfate poisoning, the method of expanding the potential of SCR denitrification under low load operation includes:

[0028] (1) Determine the minimum continuous ammonia injection temperature (MOT) of the catalyst to be 308°C,

[0029] (2) Make the catalyst operate continuously at a temperature T1 of 283°C, that is, T1 is lower than the minimum continuous ammonia injection temperature (MOT) of 25°C, and the continuous operation time t1 is 5 hours, so that the unit load W1 corresponding to T1 is 38%,

[0030] (3) After the catalyst has been continuously operated at 283°C for more t...

Embodiment 2

[0033] A 600MW coal-fired unit: SO in flue gas at the inlet of SCR denitrification system 3 Concentration 7.0μL / L, H 2 O content 8.5%, NOx concentration 300mg / m 3 (dry basis, standard state, 6.0%O 2 ), the NOx emission concentration at the outlet of the denitrification system is 50mg / m3 (dry basis, standard state, 6.0%O 2 ).

[0034] Based on the recovery characteristics of catalyst ammonium bisulfate poisoning, the method of expanding the potential of SCR denitrification under low load operation includes:

[0035] (1) Determine the minimum continuous ammonia injection temperature (MOT) of the catalyst to be 305°C,

[0036] (2) Make the catalyst operate continuously at a temperature T1 of 280°C, that is, T1 is lower than the minimum continuous ammonia injection temperature (MOT) of 25°C, and the continuous operation time t1 is 6 hours, so that the unit load W1 corresponding to T1 is 40%,

[0037] (3) After the catalyst has been continuously operated at 280°C for more than...

Embodiment 3

[0040] A 1000MW coal-fired unit: SO in flue gas at the inlet of SCR denitrification system 3 Concentration 5.0μL / L, H 2 O content 8.0%, NOx concentration 200mg / m 3 (dry basis, standard state, 6.0%O 2 ), the NOx emission concentration at the outlet of the denitrification system is 50mg / m 3 (dry basis, standard state, 6.0%O 2 ).

[0041] Based on the recovery characteristics of catalyst ammonium bisulfate poisoning, the method of expanding the potential of SCR denitrification under low load operation includes:

[0042] (1) Determine the minimum continuous ammonia injection temperature (MOT) of the catalyst to be 298°C,

[0043] (2) Make the catalyst operate continuously at a temperature T1 of 275°C, that is, T1 is lower than the minimum continuous ammonia injection temperature (MOT) of 23°C, and the continuous operation time t1 is 8 hours, so that the unit load W1 corresponding to T1 is 0%,

[0044] (3) After the catalyst has been continuously operated at 275°C for more th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com