Patents

Literature

59results about How to "Uniform magnetization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

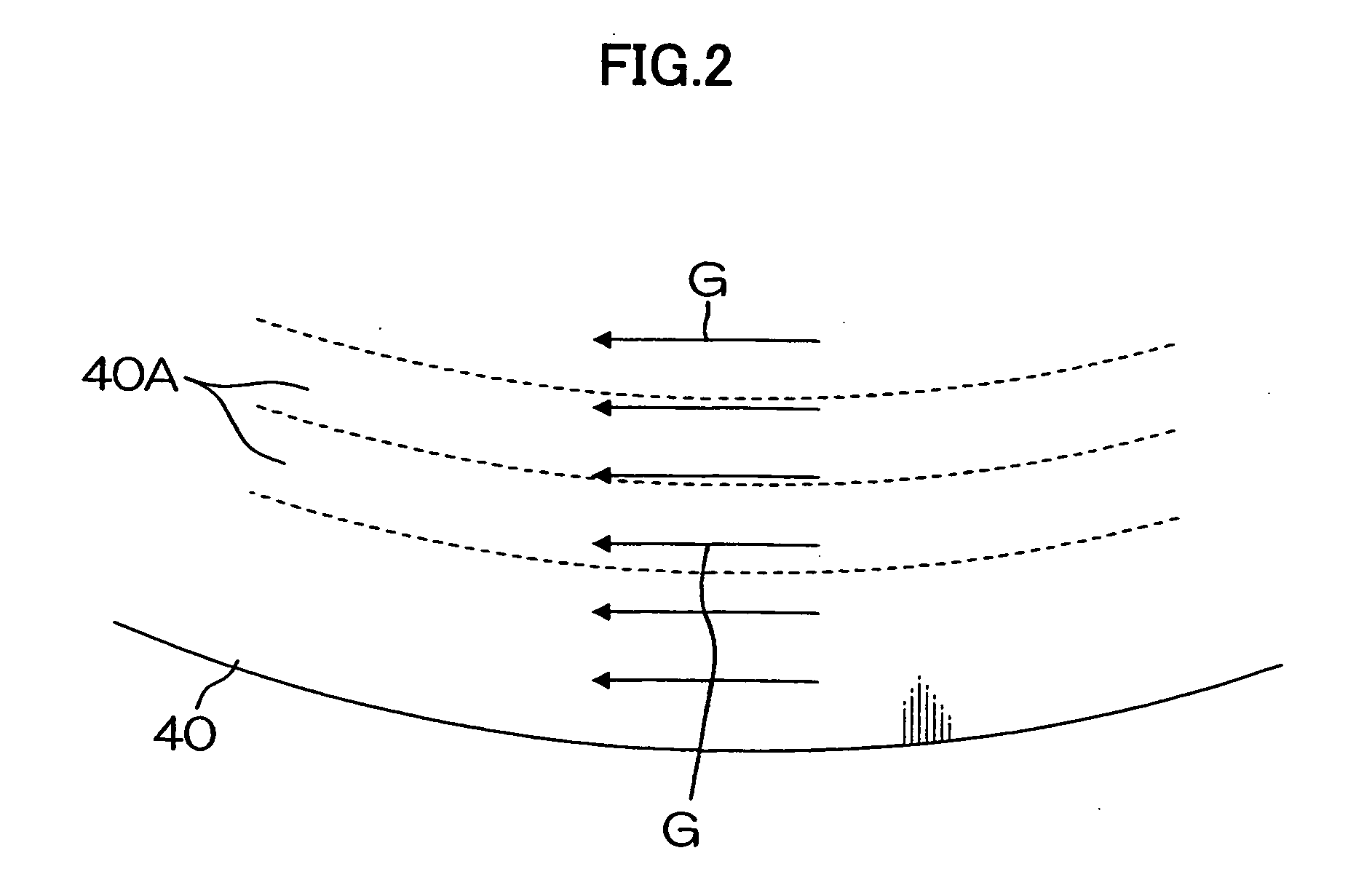

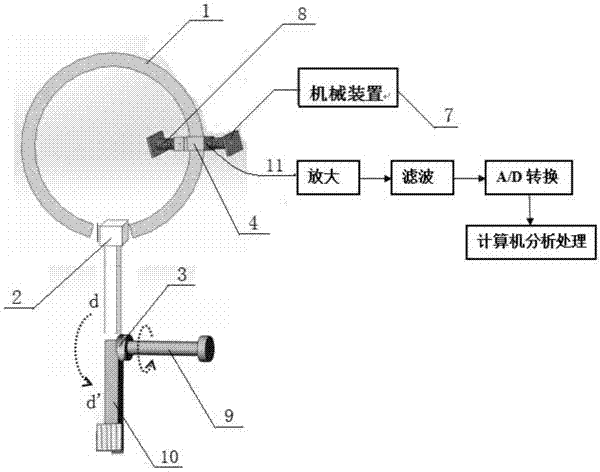

Non-contact pipeline magnetic detection method

ActiveCN103075641AUniform magnetizationEasy to detectPipeline systemsMaterial magnetic variablesPetroleumGeophysics

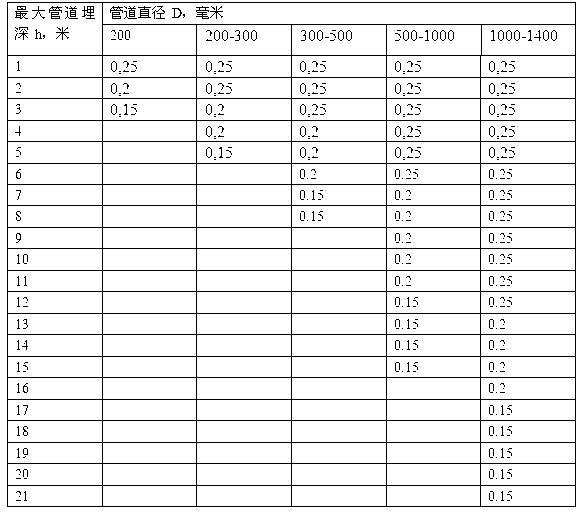

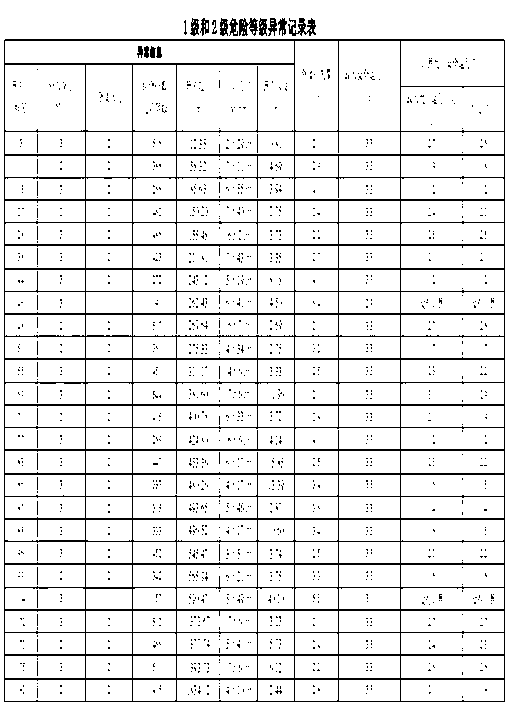

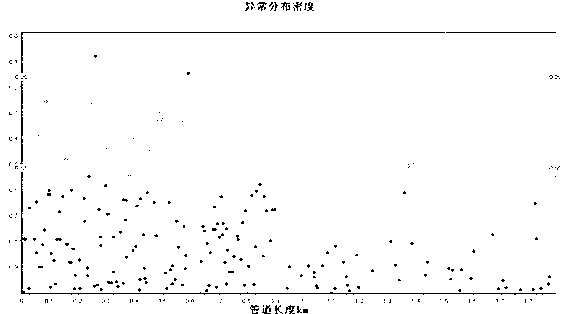

The invention discloses a non-contact pipeline magnetic detection method which relates to a damage detection technology of petroleum and natural gas buried metal pipelines. The non-contact pipeline magnetic detection method comprises the following steps that (1) initial analysis is conducted and the construction period is determined; (2) the ground is cleared and a route is marked; (3) a pipeline is detected; (4) detection data is analyzed and processed; and (5) a data result is processed. According to the non-contact pipeline magnetic detection method, the defects of an existing contact method for detecting the local defects of the pipeline, such as a complicated process in which blind excavation is carried out, the pipeline is cleared and demagnetized, and finally the pipeline is uniformly magnetized, are overcome; and the pipeline is uniformly magnetized by the earth magnetic field, on-line detection can be carried out on the surface of a work piece without clearing the surface of the detected work piece or pre-treating the surface of the detected work piece in other ways, so that the detection process is greatly simplified, the speed is high, the efficiency is high, and the detection depth is greatly increased.

Owner:SICHUAN HUIZHENG PIPELINE TECH

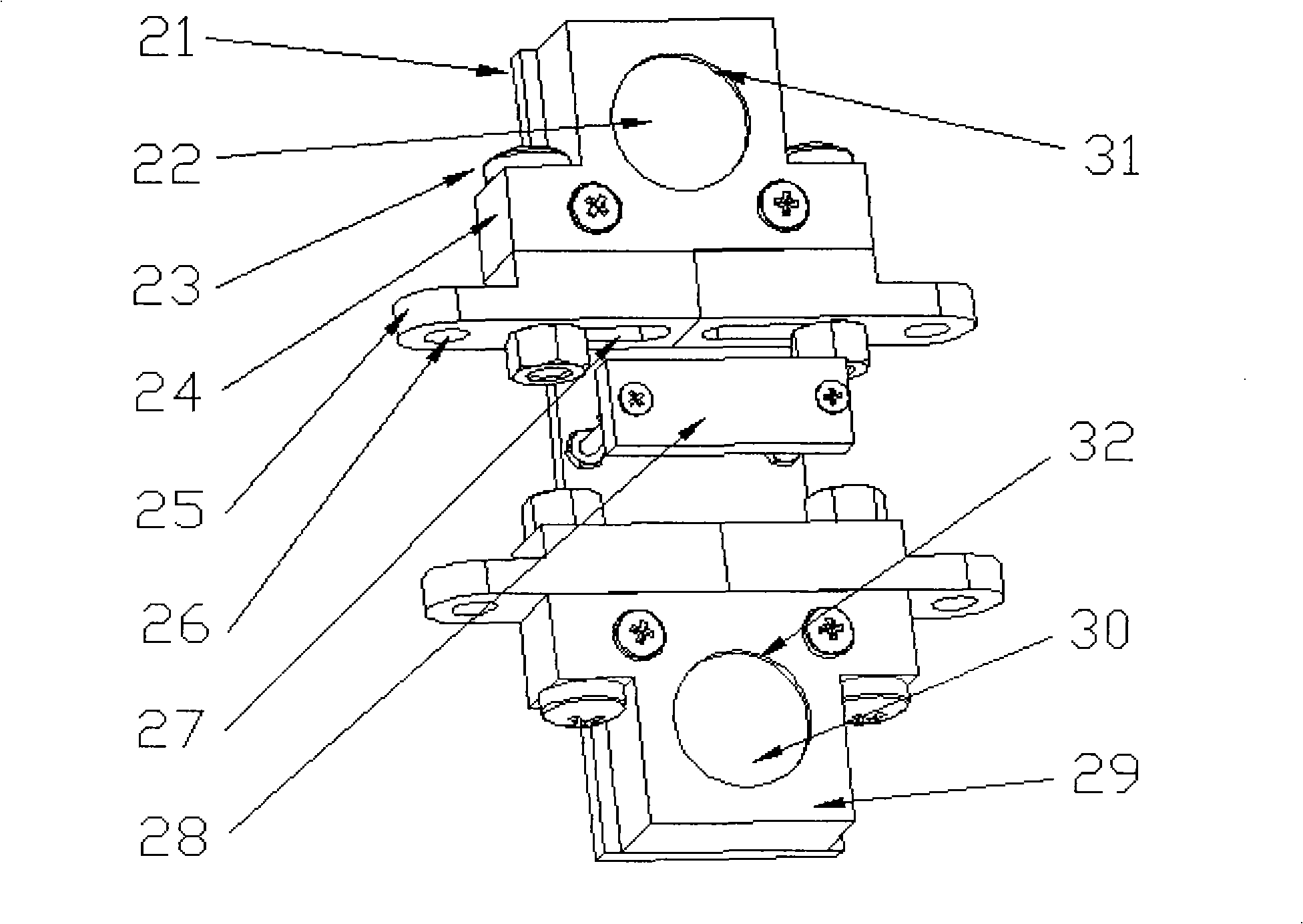

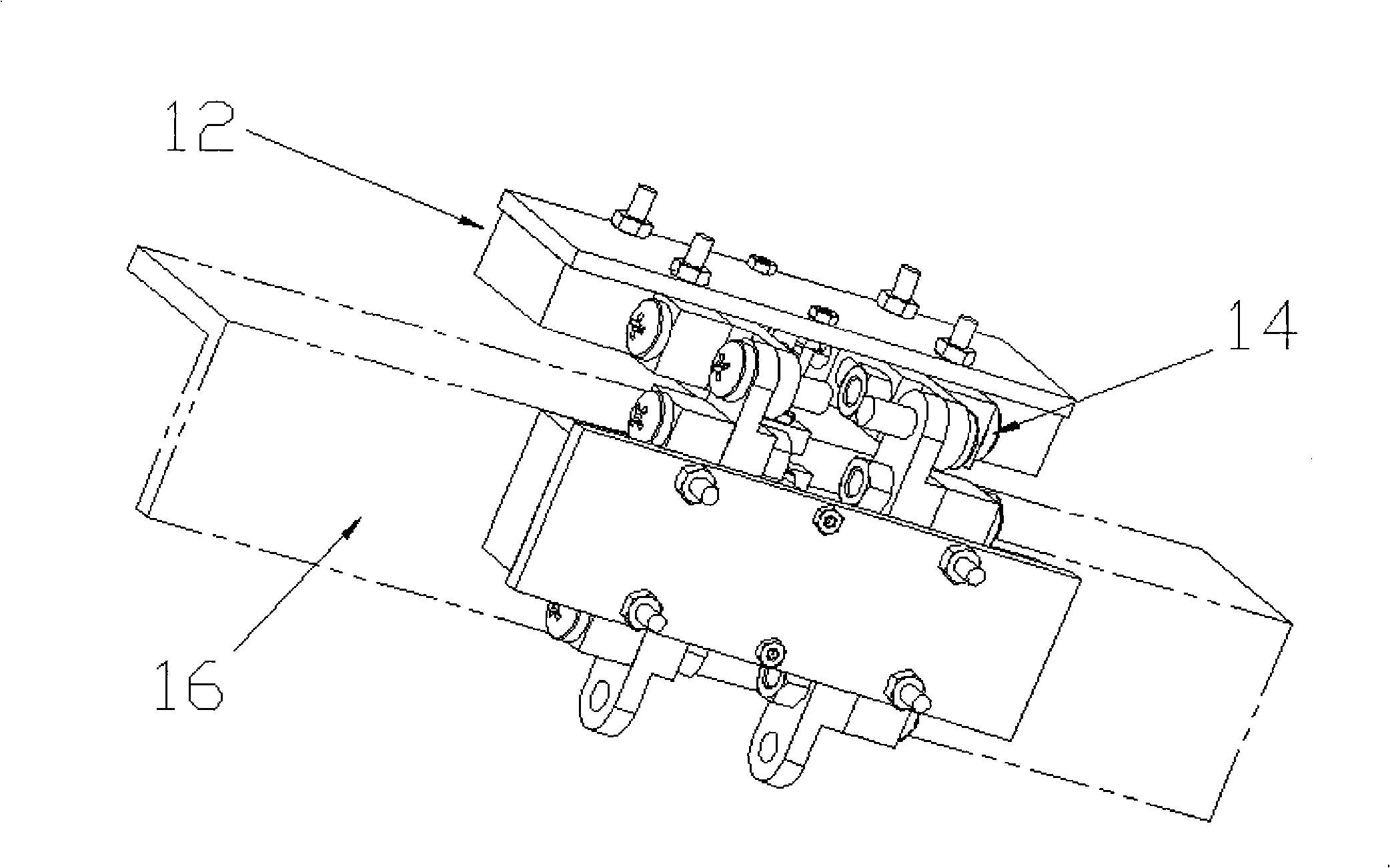

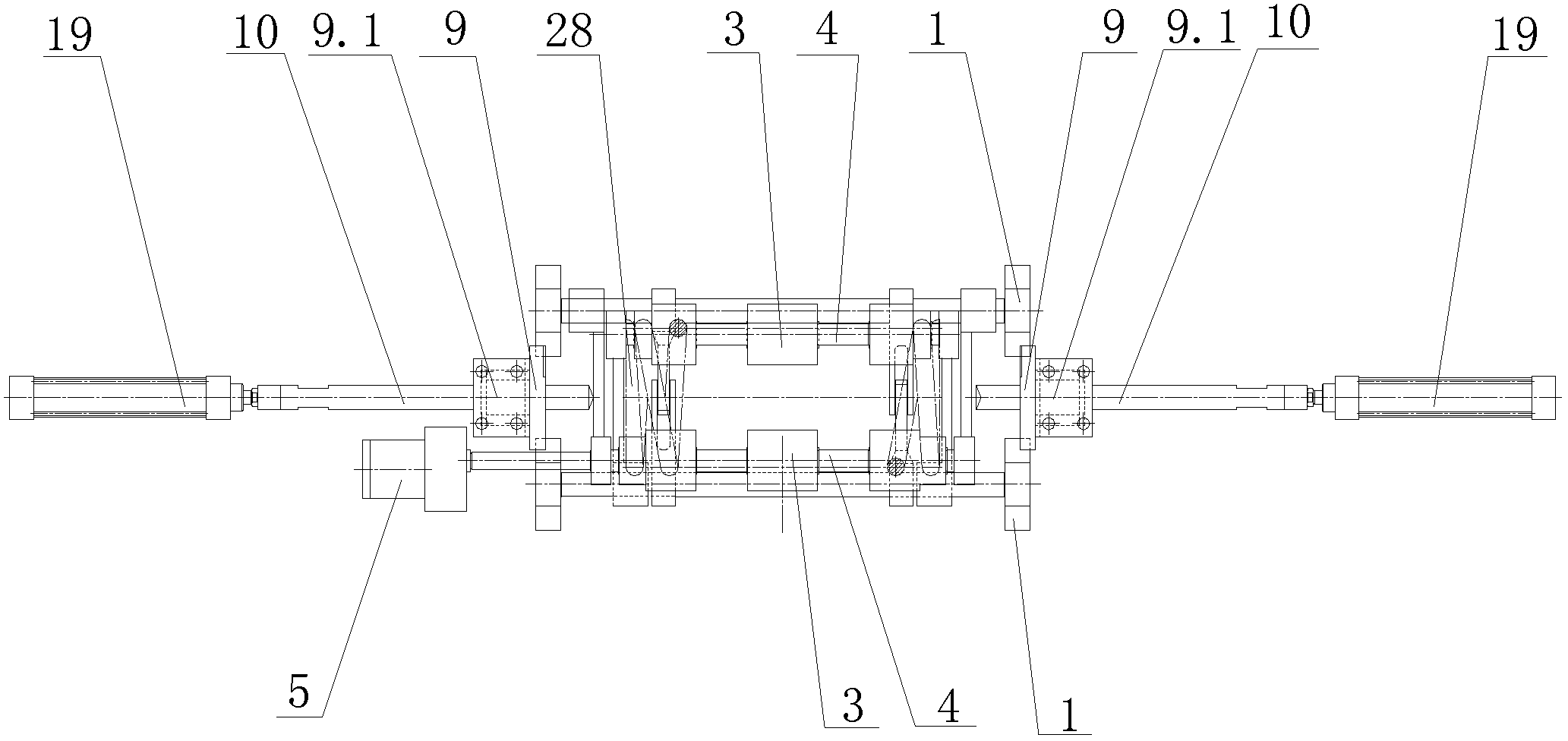

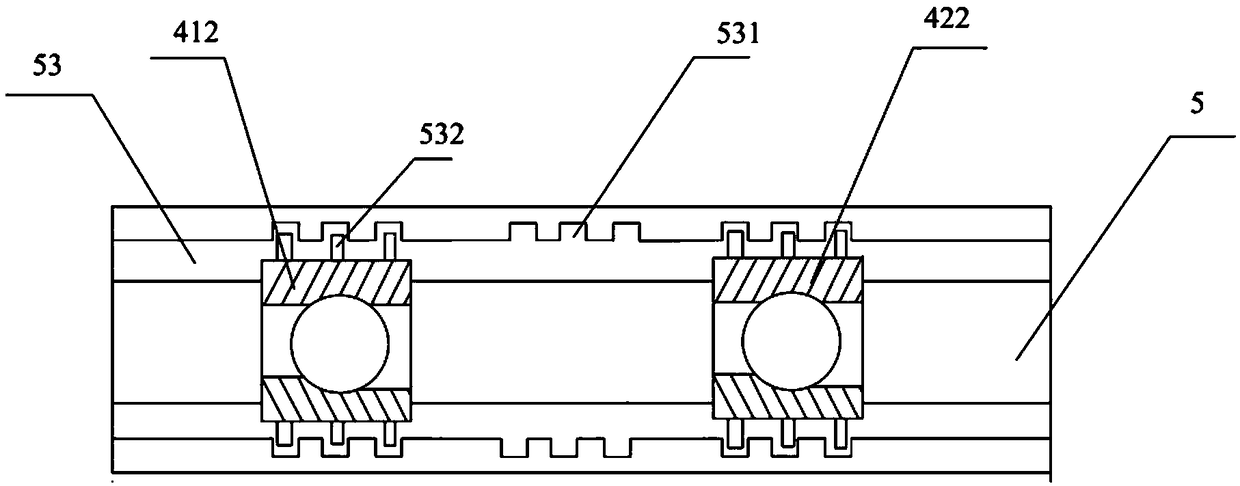

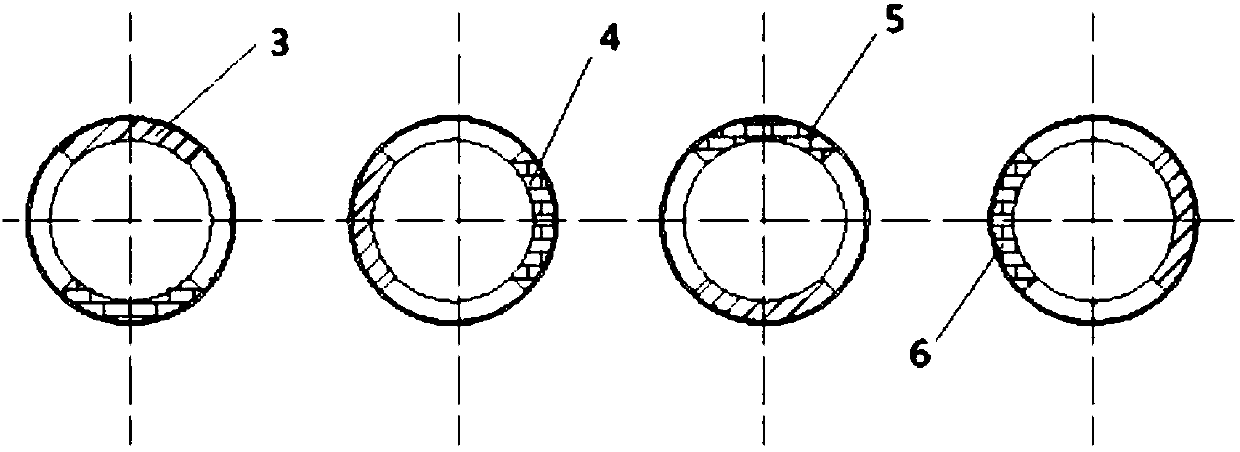

Modularization excitation detection device

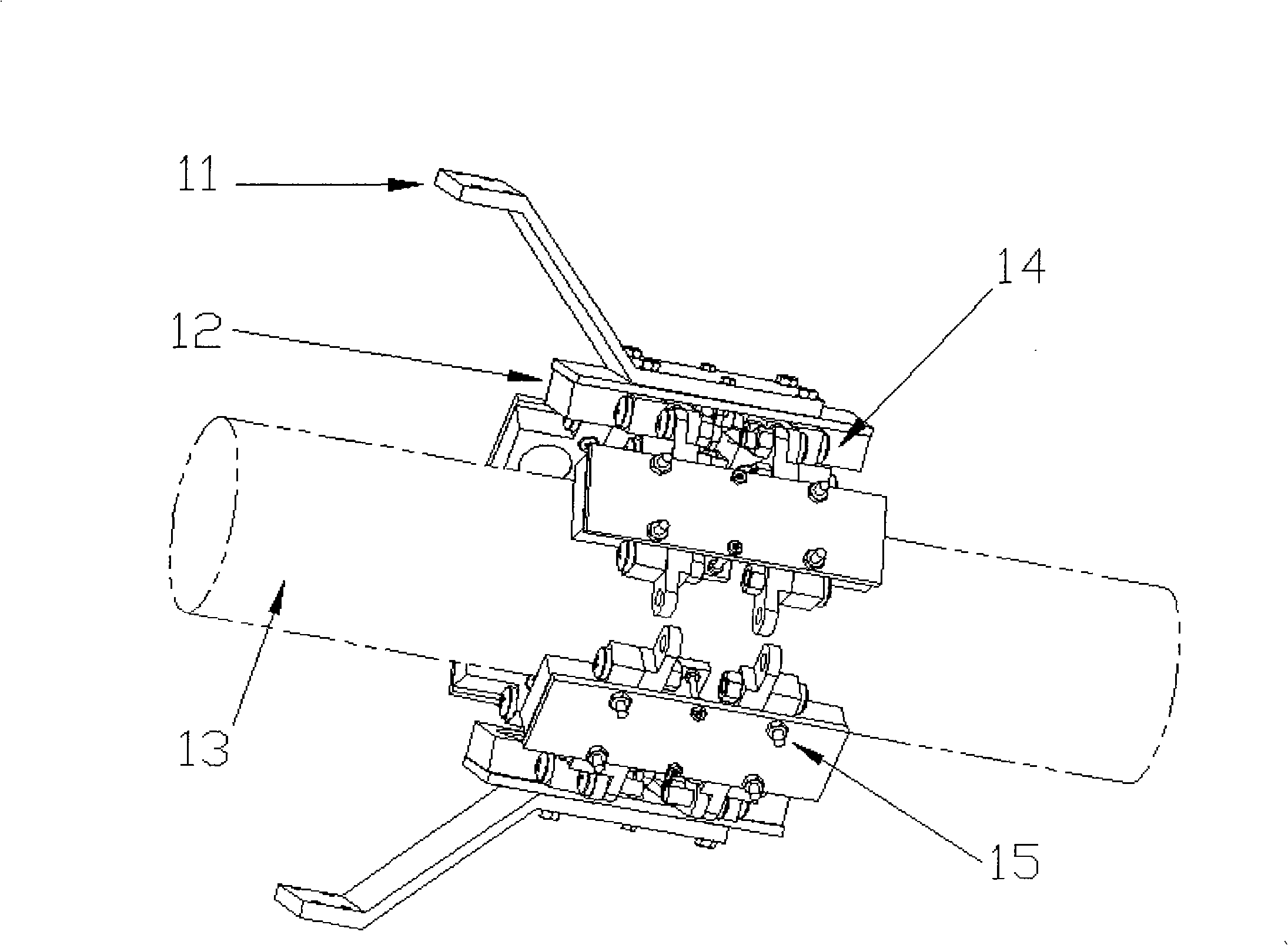

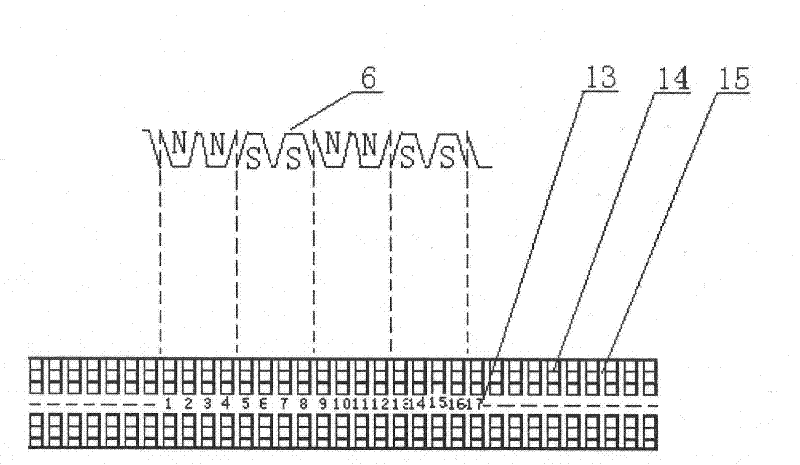

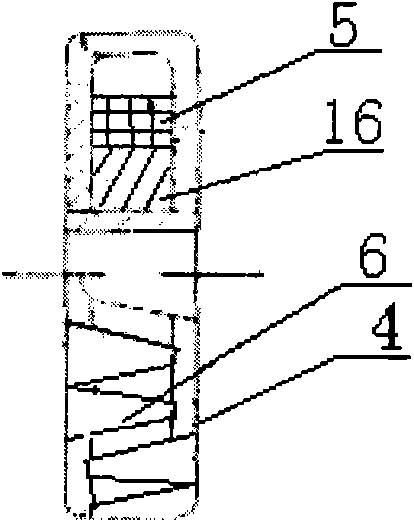

InactiveCN101329304AUniform magnetizationImprove the magnetization effectMaterial magnetic variablesEngineeringSingle section

The invention discloses a modularization excitation detection device, at least comprising two single-section exciters; furthermore, a traction bracket is arranged on at least one single-section exciter; the single-section exciter is provided with a connecting part used for the rotary connection of adjacent single-section exciters. The connecting part is provided with a hole which is internally provided with a connecting bolt; the connecting part is provided with an adjusting trough which is internally provided with an adjusting bolt; furthermore, the connecting part is fixed on a first magnet cover or a second magnet cover by the adjusting bolt. By changing the number of the accessed exciters, the width of each single-section exciter and the angle between the exciters, the cables of different diameters can be magnetized and detected; the smart and changeable modularization exciter can carry out the excitation and detection of other tested parts with complex shapes such as I-steel and angle steel, etc.; the magnetic-leakage signal of the tested part can be conveniently and effectively detected by the methods of permanent magnet excitation and Hall detection.

Owner:SOUTHEAST UNIV

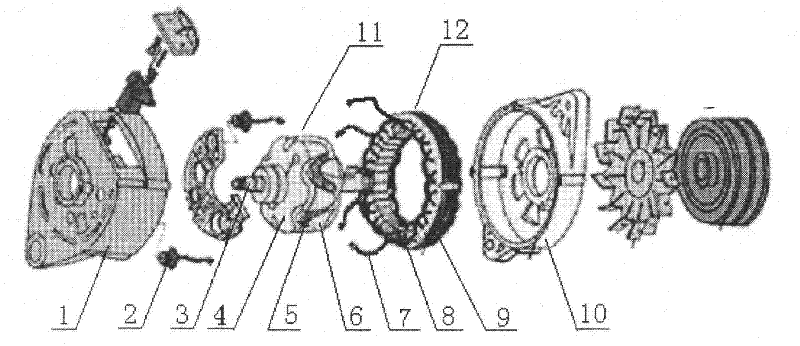

Compound excitation generator for electric automobiles

InactiveCN101667769AStable output voltageCompact structureMagnetic circuit rotating partsElectric machinesPermanent magnet rotorElectronic controller

The invention relates to a compound excitation generator for electric automobiles, which belongs to the technical field of automobile electric motors and appliances and comprises rotors, a stator, a front end cover (15), a back end cover (3) and an electronic controller (2). The compound excitation generator is characterized in that the electric excitation rotor and the permanent-magnet rotor areinstalled on a shaft (1) and separated by a residual shim (10); the electric excitation rotor and the permanent-magnet rotor share an armature winding (11), and the produced magnetic potentials are synthesized by connecting in parallel in a magnetic path; and when in use, the magnitude and the direction of the electrifying current of the electric excitation rotor are regulated, so that the magnetic field superimposed by an electric excitation magnetic field and a permanent-magnet magnetic field can be regulated to ensure that the generator can output direct current with stable voltage within wide rotating speed and load. The generator has the advantages of compact structure, convenient installation, and safe and reliable operation.

Owner:SHANDONG TANGJUN OULING AUTOMOBILE MFG

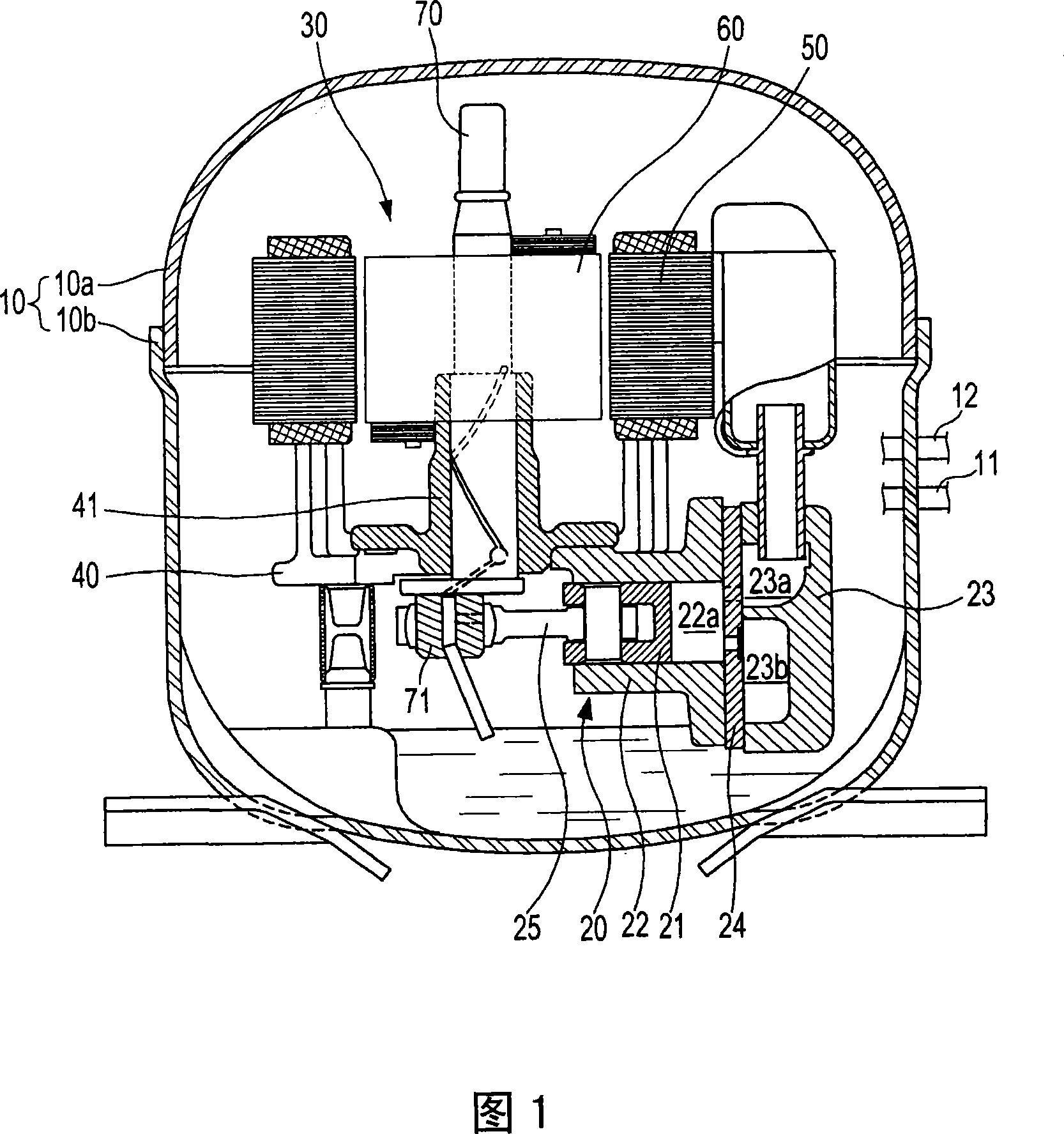

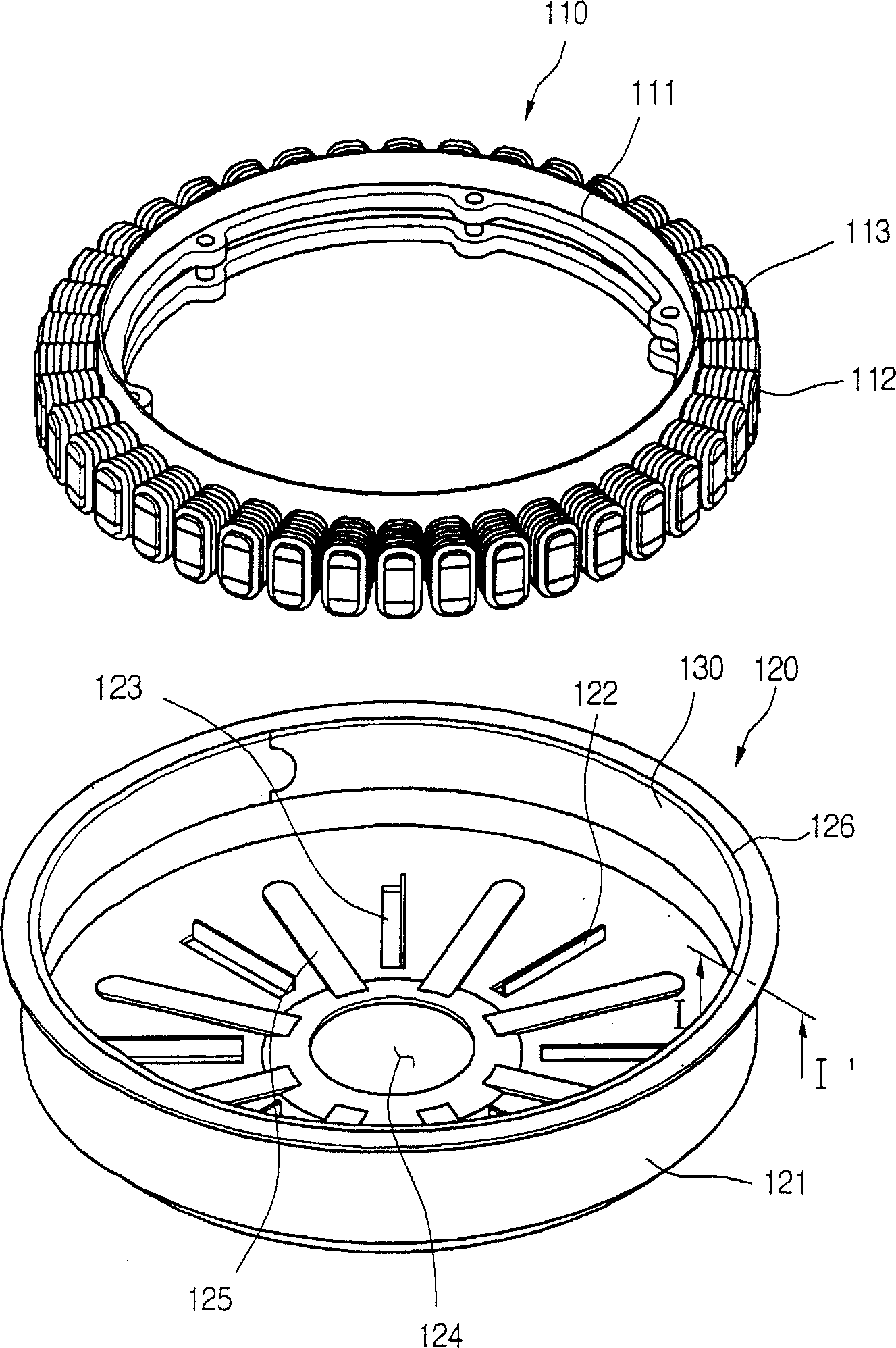

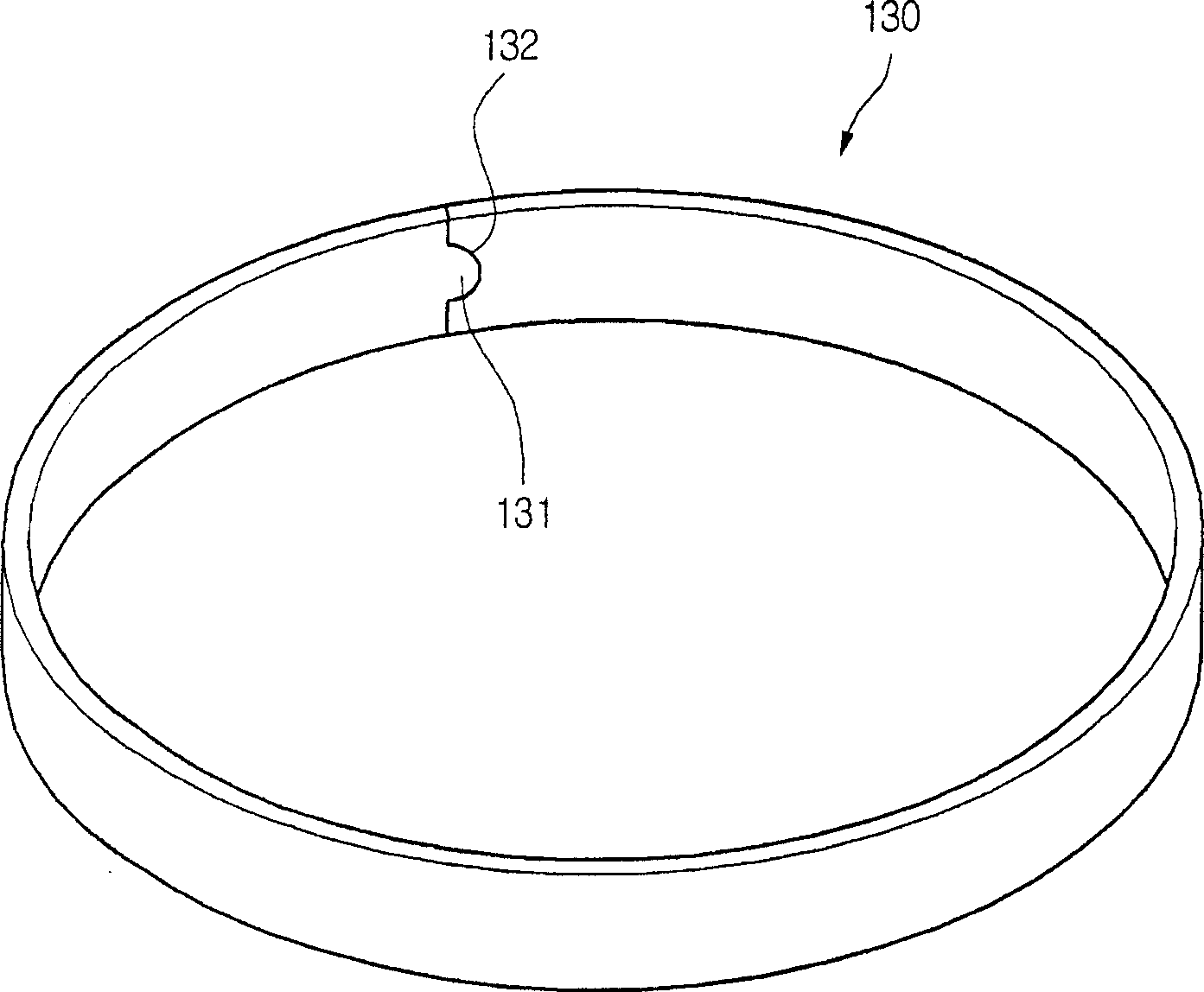

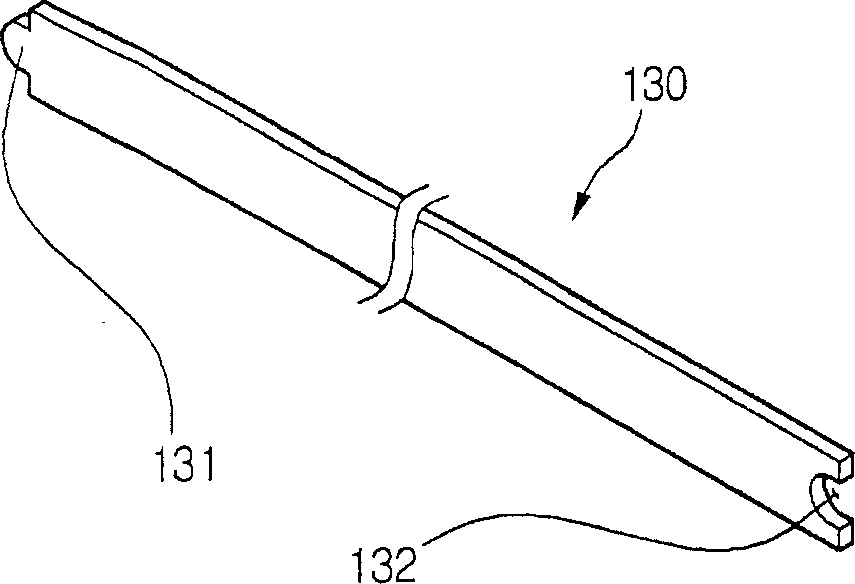

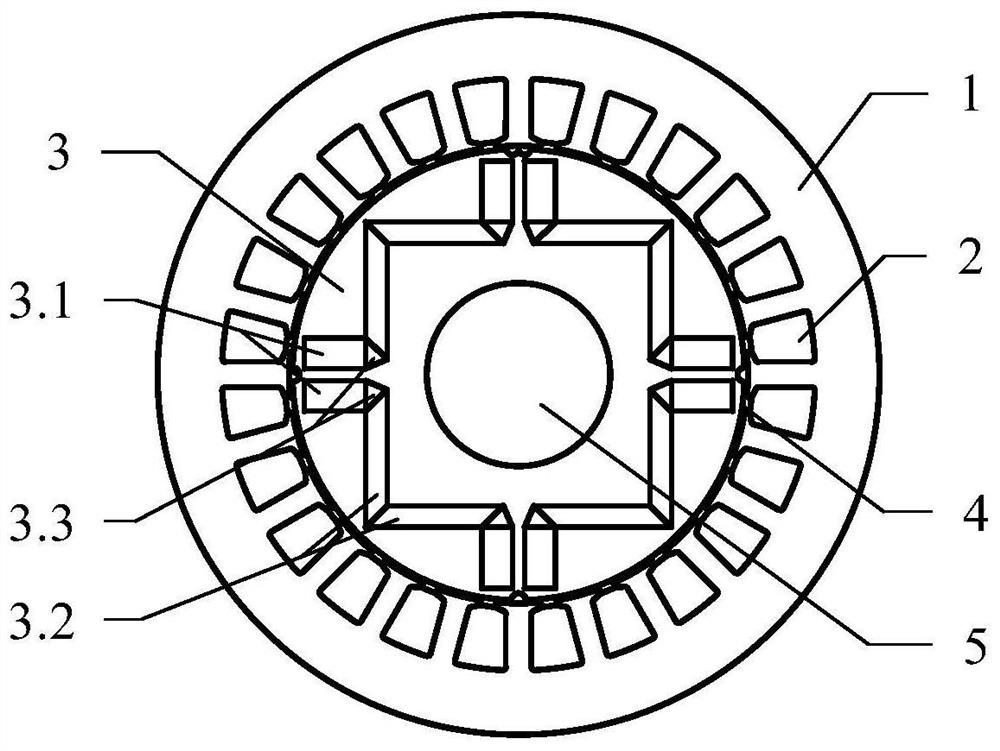

Compressor motor magnet magnetization method

InactiveCN101145716AUniform magnetic alignmentUniform magnetizationMagnetic circuit rotating partsMagnetic bodiesCondensed matter physicsMaterials science

The present invention provides a method that can make the magnetic alignment of the magnets uniform even when the magnets provided on the rotor of the motor arranged in the compressor have been assembled, and can make the magnets uniform over the entire area. Magnet magnetization method for magnetized compressor motors. In the method for magnetizing a magnet of a compressor motor according to the present invention, the compressor motor includes: a stator fixed to a frame and having a coil wound therein; and a rotor rotatably provided inside the stator and having a A plurality of magnets are arranged in alternating polarity, and the above-mentioned magnets are magnetized by applying a magnetizing power supply to the above-mentioned coils in the state where the above-mentioned motor has been assembled. During the process of magnetizing the above-mentioned magnets, the above-mentioned rotor is fixedly supported to prevent It is free to move, and a magnetic member longer than the magnet is inserted between the rotor and the stator.

Owner:SAMSUNG ELECTRONICS CO LTD

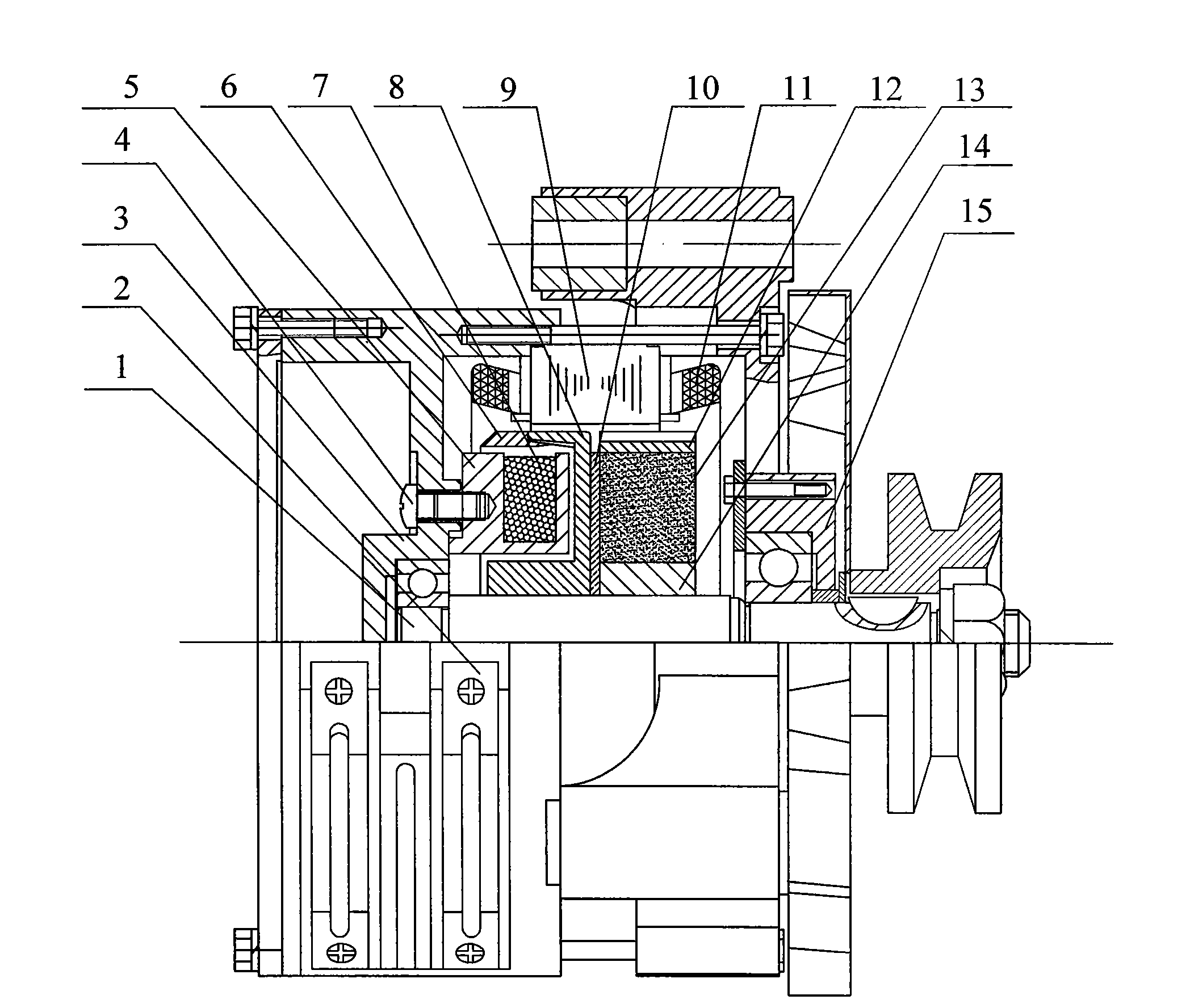

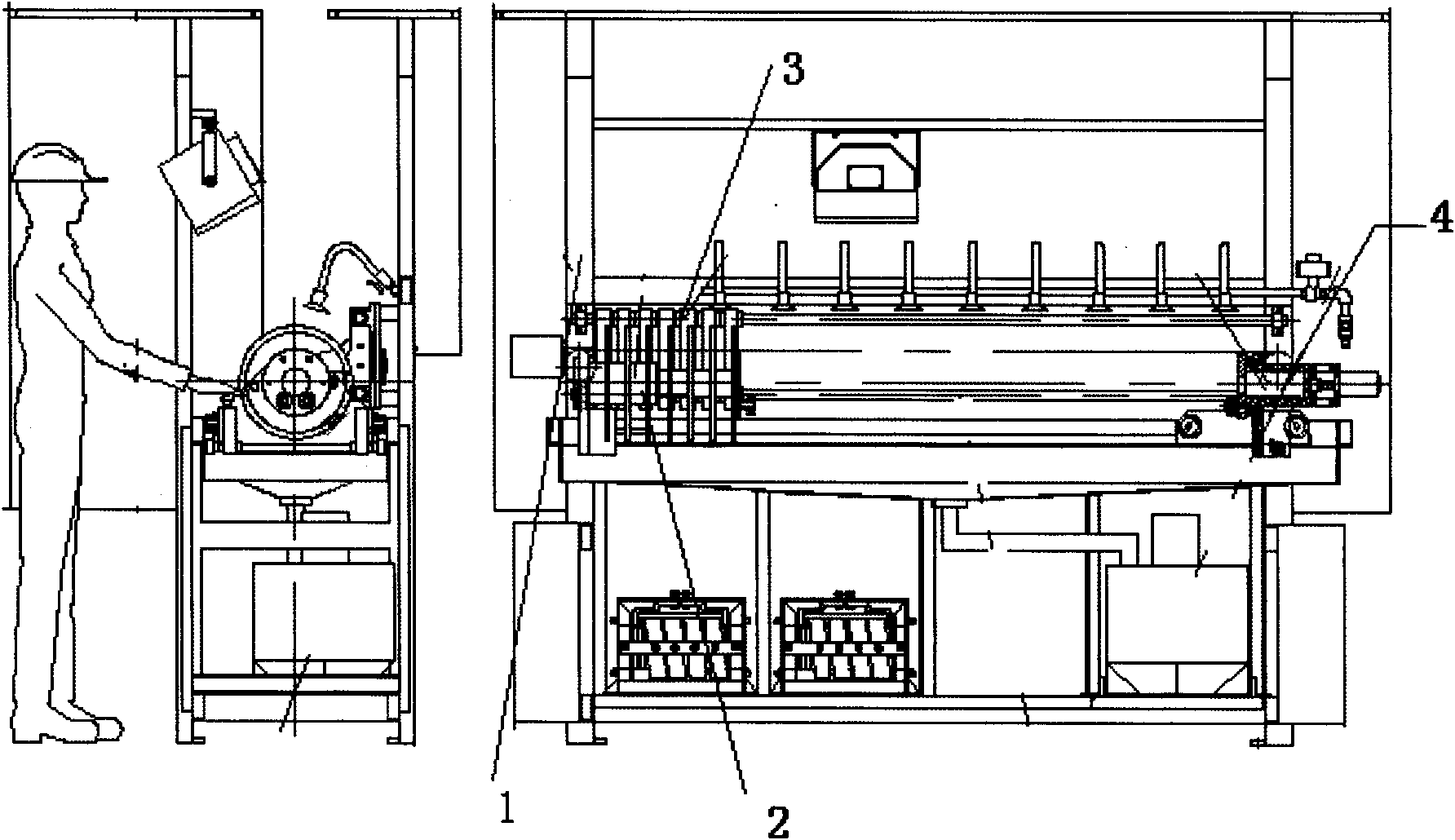

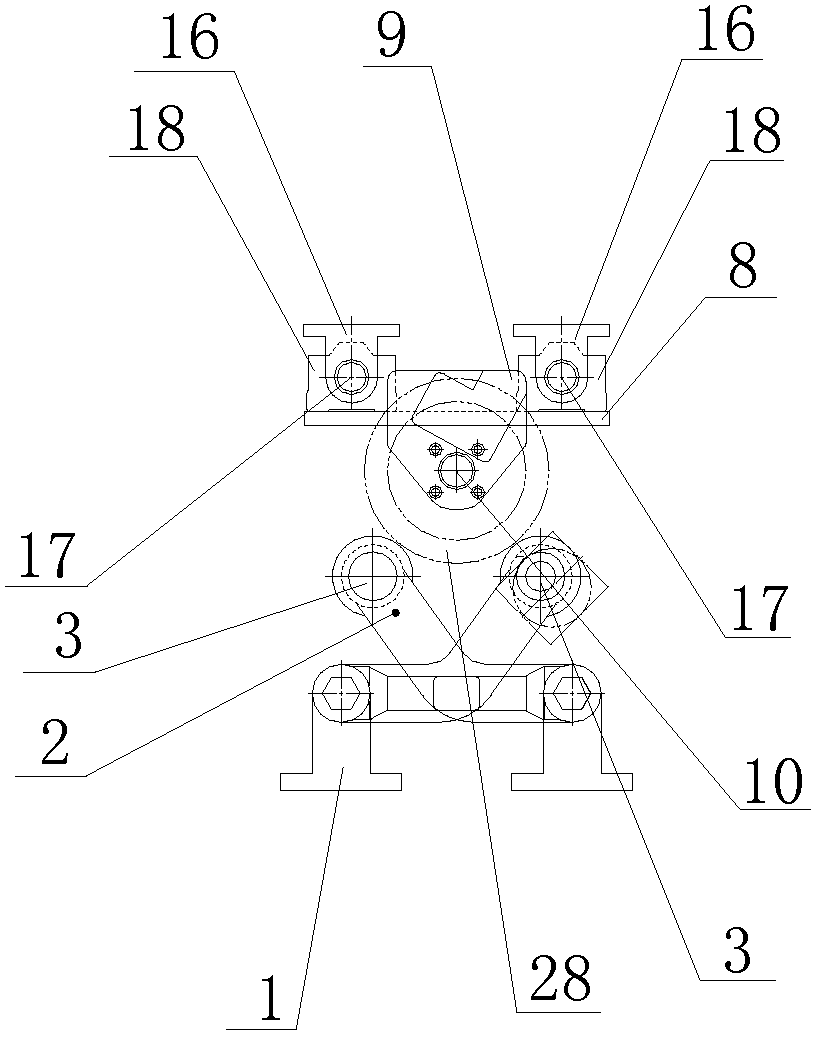

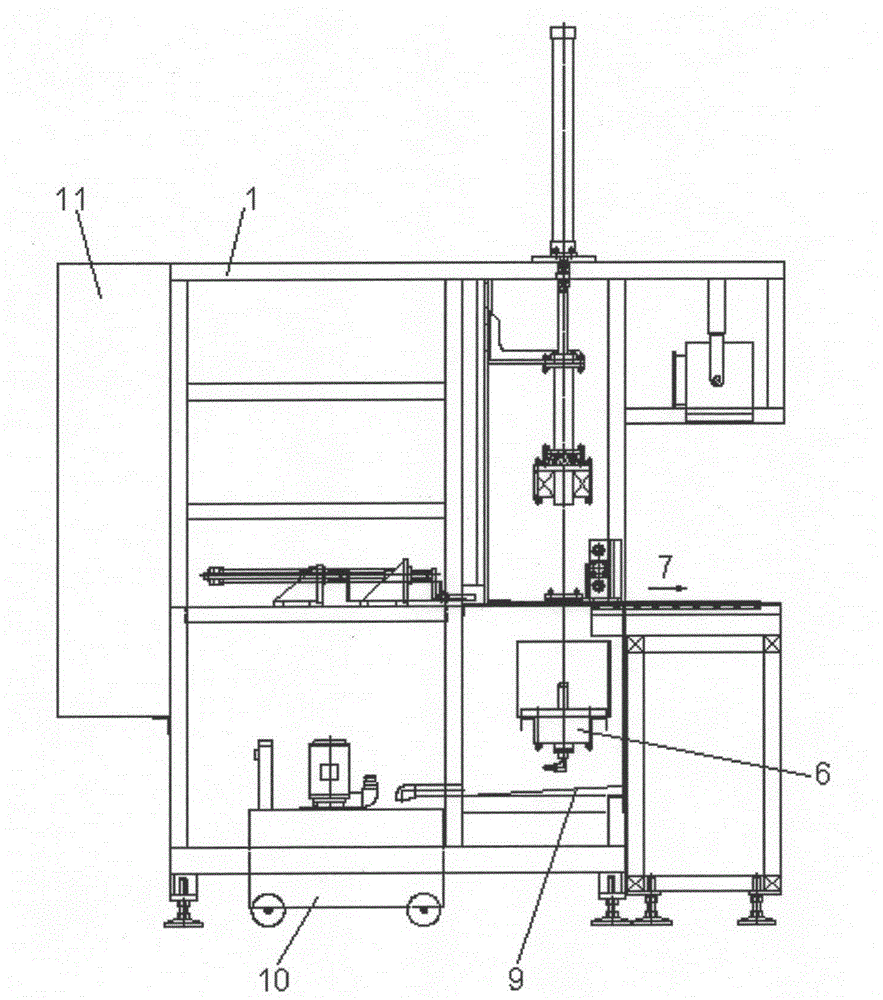

Crankshaft magnetic detector

ActiveCN101915802AUniform magnetic fieldSufficient magnetizationMaterial magnetic variablesFailure rateMagnetization

The invention provides a crankshaft magnetic detector comprising a main body and a control cabinet, wherein a head frame chunk and a tail frame chunk are arranged on a guide rail of a main body frame assembly to clamp an electrified circumferential magnetizing device, a left head-frame chunk base is fixed, the position of a right tail-frame chunk base can be moved and locked according to the length of a crankshaft, an air cylinder which is used for clamping the crankshaft is arranged behind the tail frame chunk, conducting plates which are electrified after clamping the crankshaft are respectively arranged on shafts of the head frame chunk and the tail frame chunk, and the left and right sides of the frame assembly are respectively provided with an electric case and a device pneumatic control case. The crankshaft magnetic detector is characterized in that a multiturn longitudinal magnetizing coil which can longitudinally extend is arranged between the head frame chunk and the tail frame chunk, and a workpiece rotating device is arranged on the chunk conducting plates. The crank magnetic detector can complete longitudinal magnetization or complex magnetization of the whole length of the crankshaft with a length between 800mm and 1500mm once, sufficiently and evenly magnetizes the parts of the crankshaft, is safe and reliable and has low failure rate.

Owner:SHANGHAI CHENGYOU INDAL GROUP +2

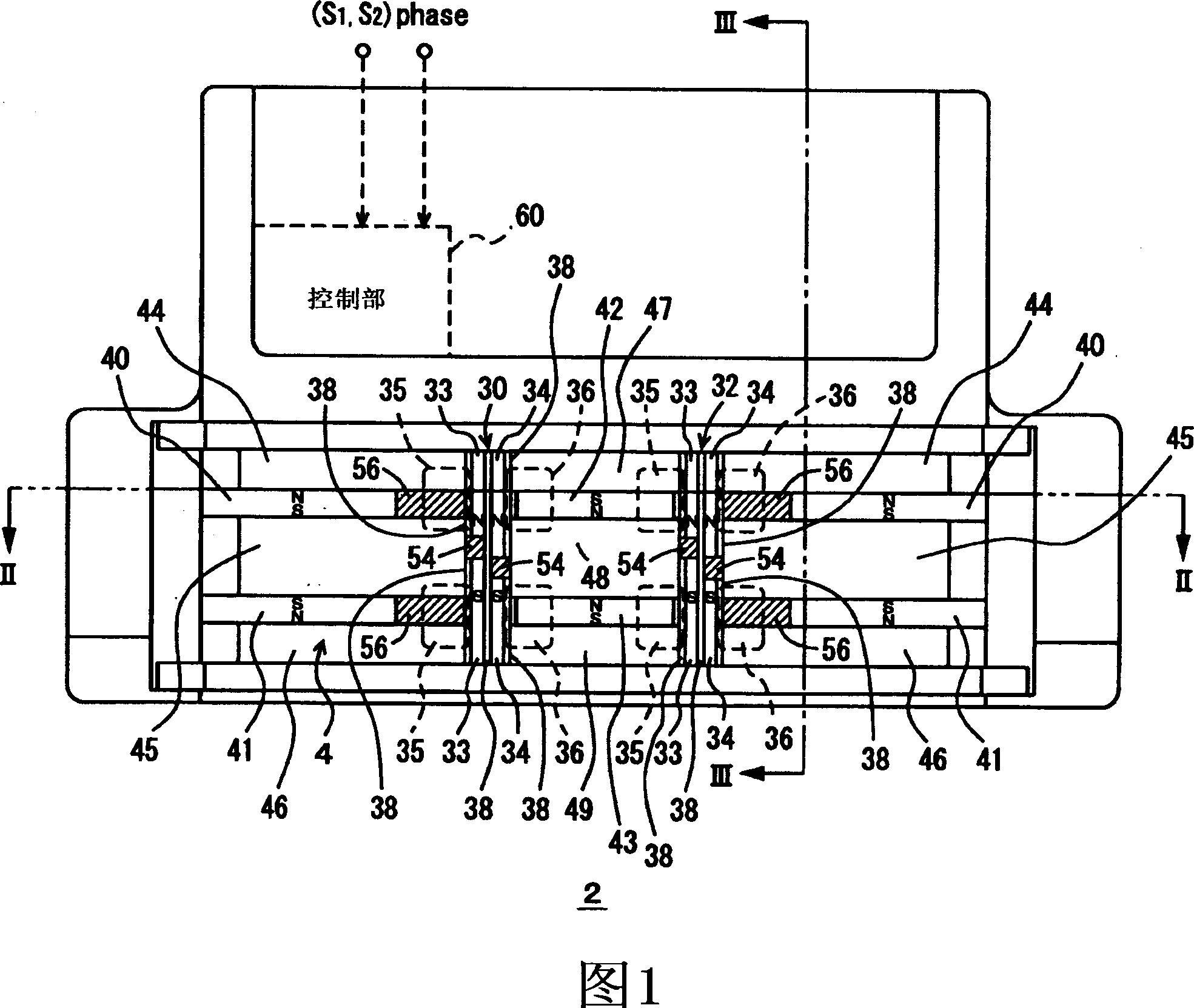

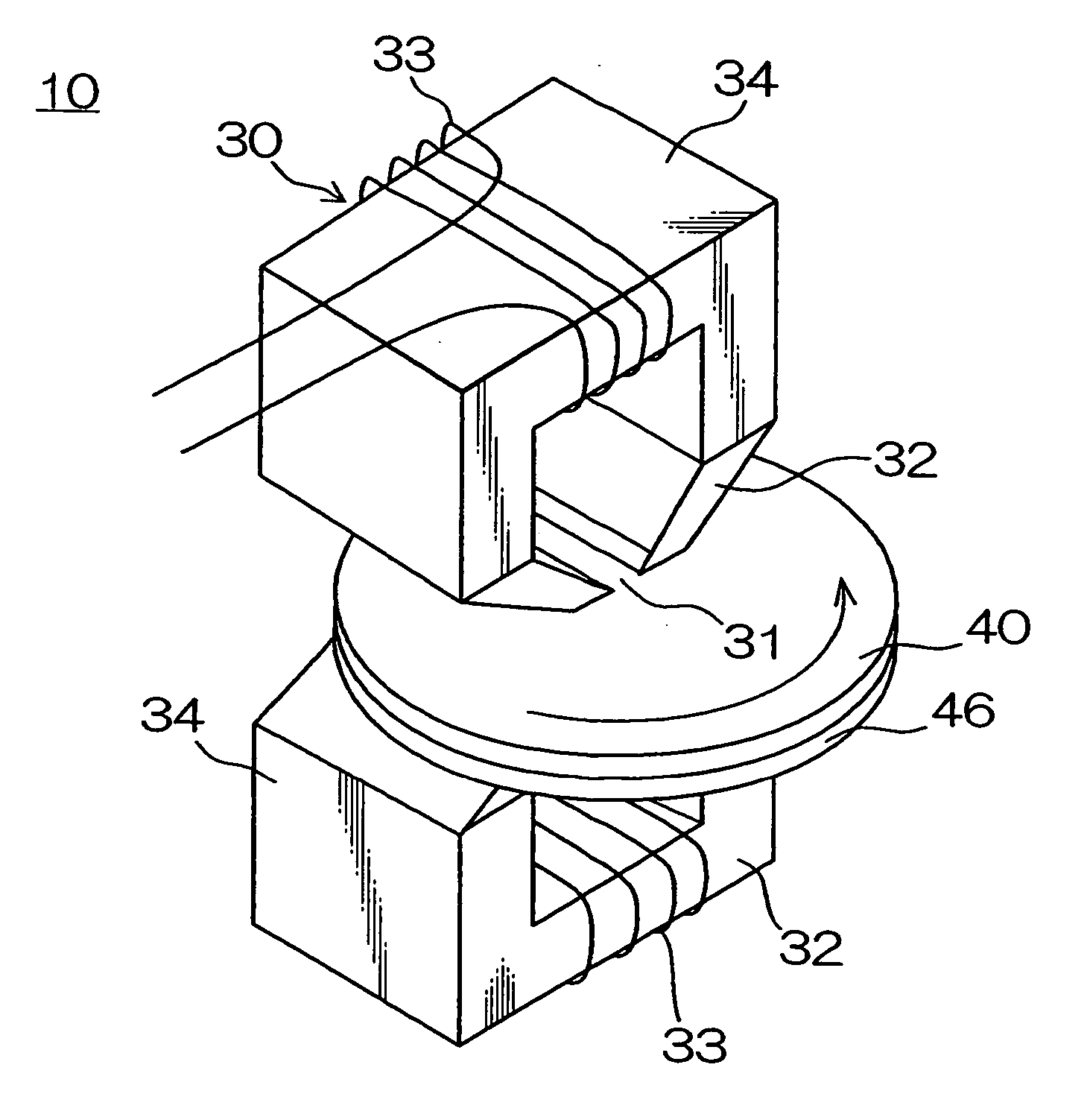

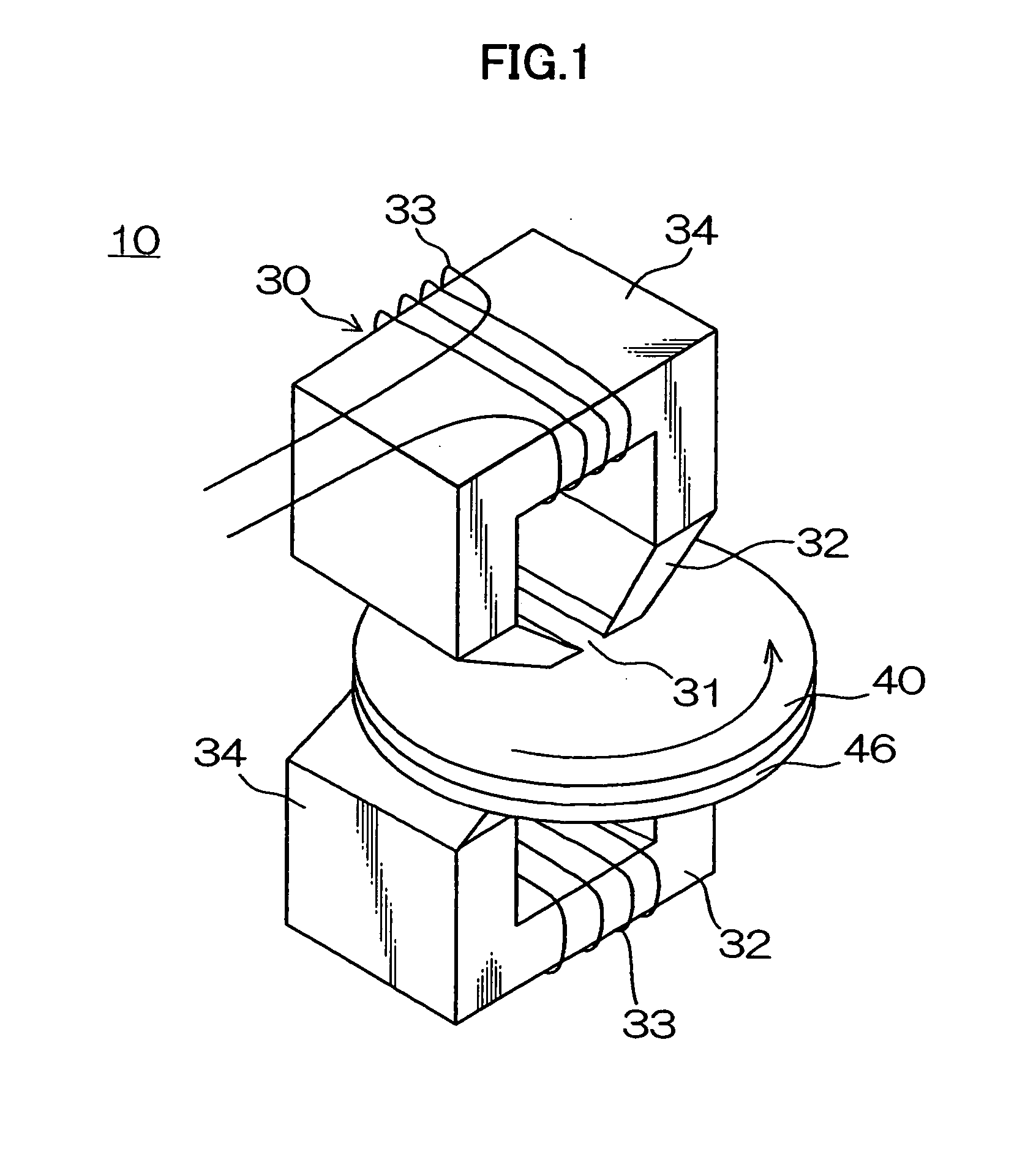

Selection actuator for knitting member

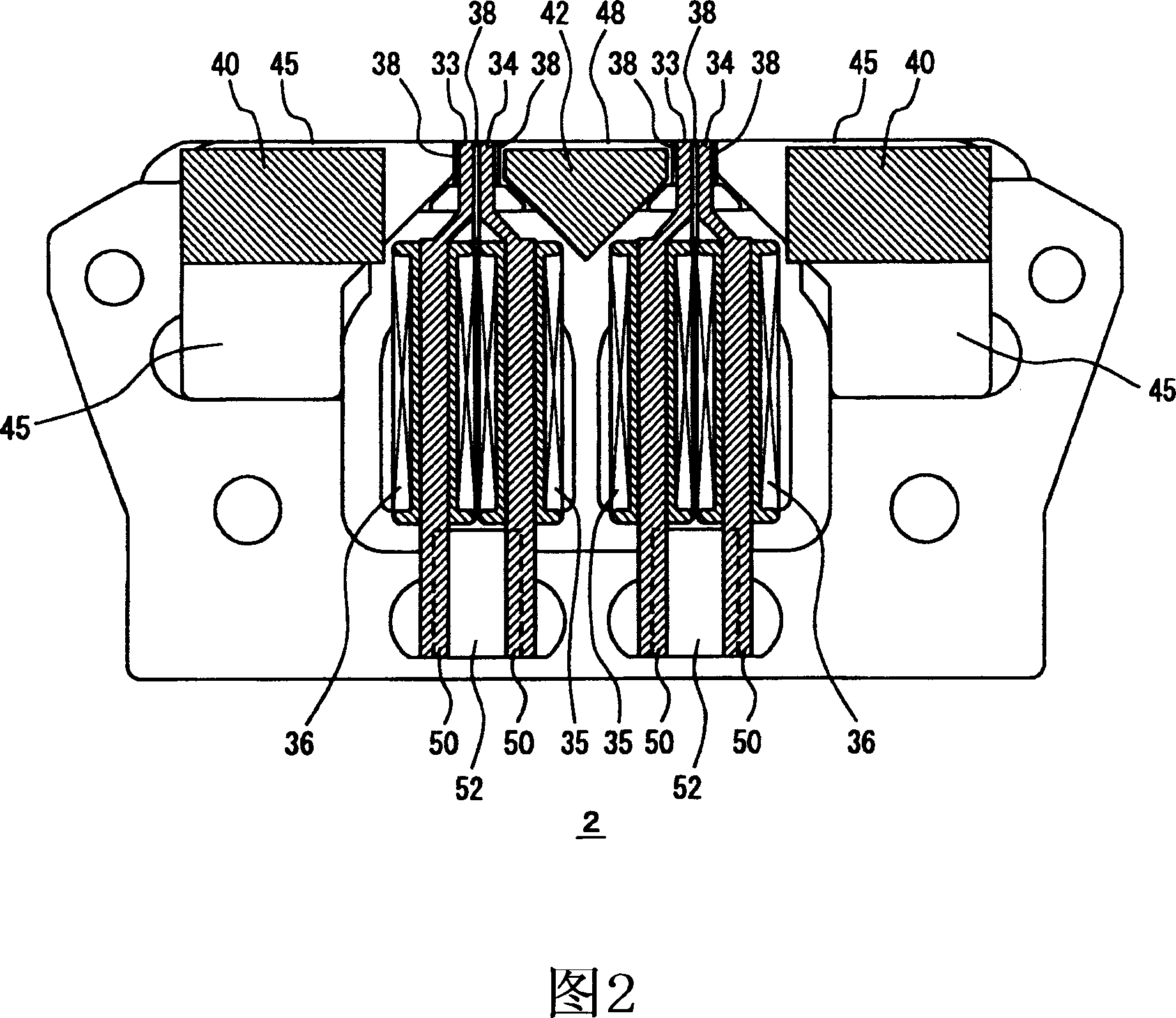

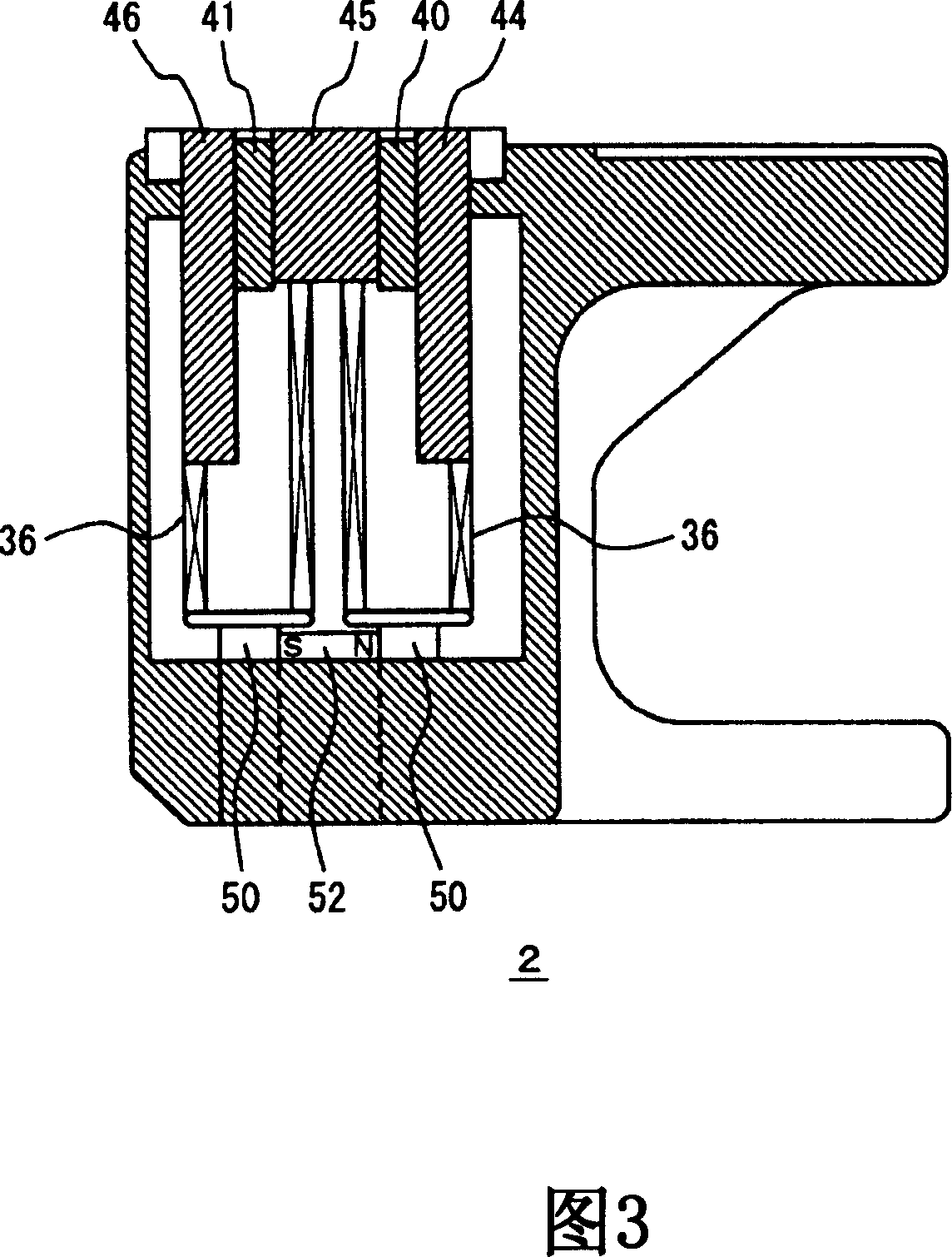

A plurality of control magnetic poles 33n-34n are provided in each selection unit of a selection actuator, and the upstream control magnetic poles 33n, s and downstream control magnetic poles 34n, s are controlled independently based on the relative positions thereof to selectors. The selectors can be selected with a pitch approximately half the pitch at which selection is possible with the conventional selection actuator and the time used for selecting each selector can be extended. Therefore, a knitting member can be reliably selected even in a fine-gauge knitting machine.

Owner:SHIMA SEIKI MFG LTD

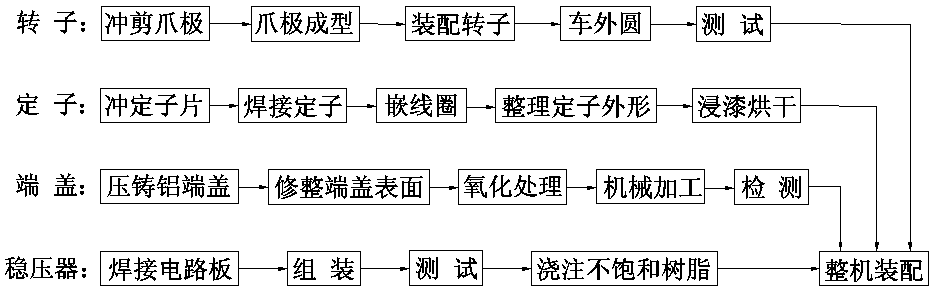

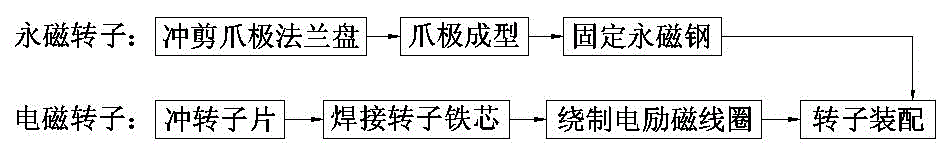

Production method of claw pole type permanent-magnet stable-voltage electric generator

ActiveCN103683696AStable output voltageEnsure safetyManufacturing stator/rotor bodiesElectric machineMagnetization

The invention provides a production method of a claw pole type permanent-magnet stable-voltage electric generator and belongs to the technical field of automotive electrical machines and electric appliances. The production method comprises rotor assembly, stator assembly, end cover machining, voltage stabilizer assembly and complete machine assembly. The claw pole of a rotor converts an axial magnetization type magnetic field into a radial magnetic field, magnetic performance is good, and magnetization is uniform. A stator punched sheet is a round punched sheet formed by three equant sheets, and the utilizing rate of materials is high. A circuit board is encapsulated in a shell body of a voltage stabilizer with 191# unsaturated polyester resin, and then dust resistance, moisture resistance, vibration resistance and shock resistance are achieved. The electric voltage stabilizer enables the output voltage of the permanent-magnet electric generator to be stable under variable-speed and variable-load working conditions, and then the safety and using reliability of the automotive electric appliances are guaranteed.

Owner:张学义

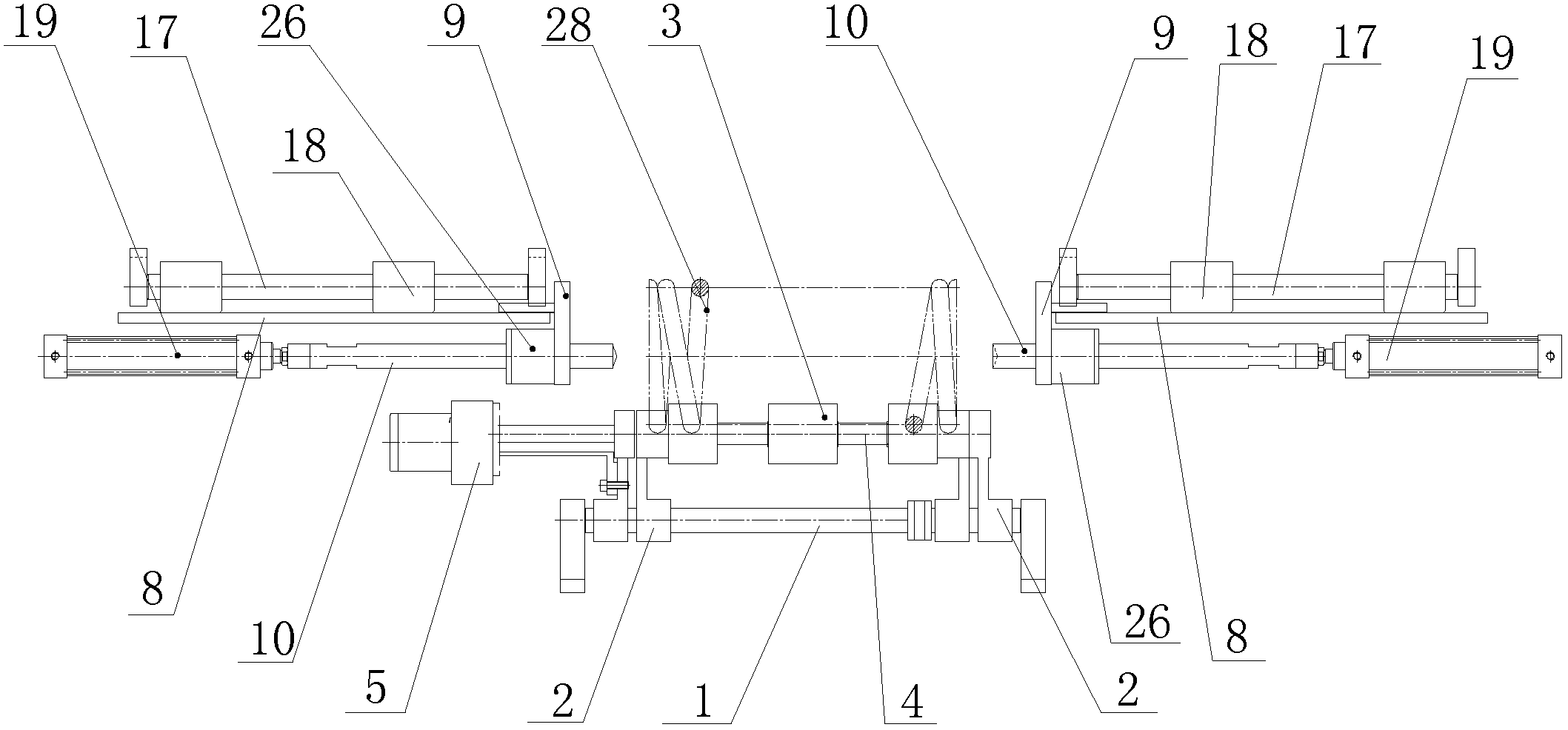

Flaw detection device of buffer spring

ActiveCN103018322AGuaranteed to work properlyFree from outside interferenceMaterial magnetic variablesEngineeringUltimate tensile strength

The invention discloses a flaw detection device of a buffer spring. The flaw detection device of the buffer spring comprises a fixing seat, a rotary support, a roller, a connecting shaft and a rotary motor, wherein support seats are arranged at two ends of the fixing seat; transversely arranged fixing plates are arranged on the support seats; a piston of a first cylinder on each fixing plate is connected with a movable plate; a clamping electrode plate is arranged at one end of the movable plate; circumferential magnetic threading bars inserted into the buffer spring are arranged near the movable plate; the circumferential magnetic threading bars are oppositely arranged and respectively insulated with the movable plate and the clamping electrode plate; the clamping electrode plate and the two circumferential magnetic threading bars are connected with two poles of an external power supply; a convex arc surface is arranged at the end part of one circumferential magnetic threading bar; and a concave arc surface is arranged at the end corresponding to the other circumferential magnetic threading bar, and the convex arc surface is matched with the concave arc surface. By adopting the flaw detection device, the magnetization intensity and the magnetic field distribution of the circumferential magnetic threading bars can be improved; a magnetization effect of the buffer spring for flaw detection is ensured; and interference in a magnetic circuit is avoided, and the flaw detection device can be widely applied to the fields of manufacturing and overhauling of railway vehicles.

Owner:CRRC YANGTZE CO LTD

Heat treatment method and equipment through rotating magnetic field generated from magnetic parts of an apparatus

InactiveCN1760379AImprove magnetization uniformityGood effectMagnetic bodiesEngineeringHeating furnace

A heat treating technology of magnetic device in a rotating magnetic field features that after a maganetic device is fixed to a rotary axle driven by a motor, it is arranged in a heating furnace and a magnetic field for magnetizing it uniformly.

Owner:徐宝田 +1

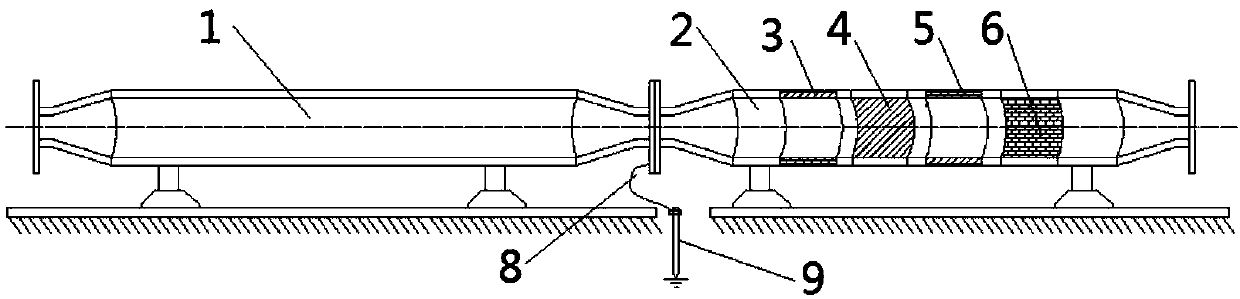

Non-magnetization pipeline-interior detection method

InactiveCN104122323AUniform magnetizationEasy to detectMaterial magnetic variablesMagnetizationPetroleum

The invention discloses a non-magnetization pipeline-interior detection method which relates to a damage detecting technology of buried metal pipelines for petroleum and natural gas. The non-magnetization pipeline-interior detection method comprises the following steps: (1) performing preliminary analysis to determine the construction duration; (2) testing the passing performance of a pipeline; (3) detecting the pipeline; (4) analyzing and processing detection data; and (5) processing data results. The non-magnetization pipeline-interior detection method overcomes various disadvantages, such as the cumbersome process of blind excavation is carried out for clearing and demagnetizing the pipeline and the final uniform magnetization is carried out on the pipeline, in an existing method for detecting local defects inside the pipeline by virtue of magnetization; according to the non-magnetization pipeline-interior detection method, the pipeline is uniformly magnetized by virtue of an earth magnetic field, and the non-magnetization and non-contact detection on the interior of the pipeline can be accomplished just by means of testing the passing performance and simply cleaning the interior of the pipeline by a pipeline cleaner so as to suck metal substances out of the pipeline by a magnet.

Owner:四川昇赛尔科技有限公司

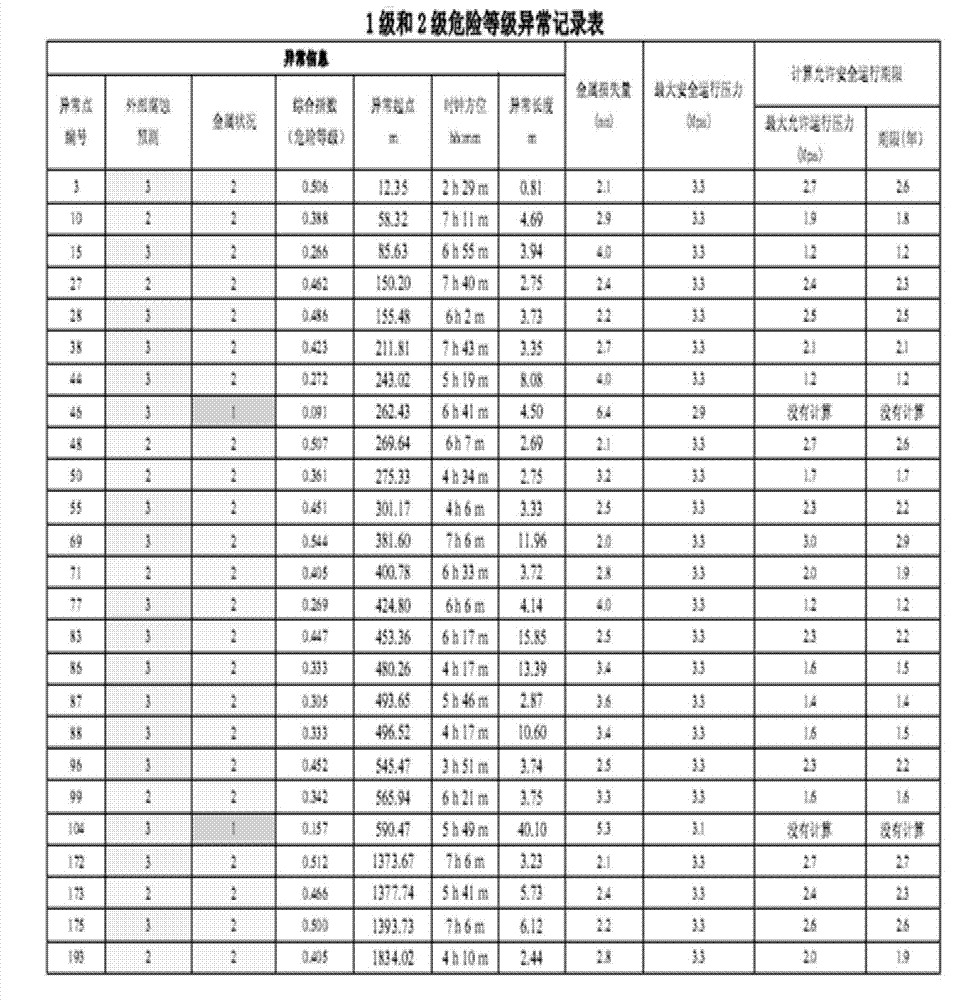

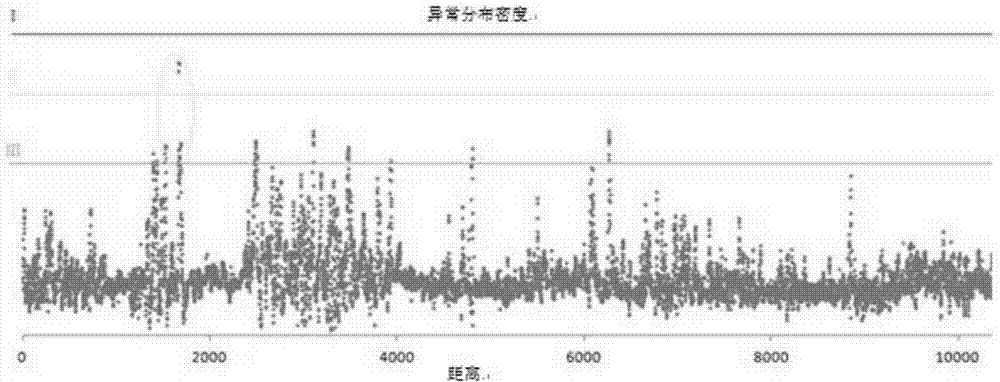

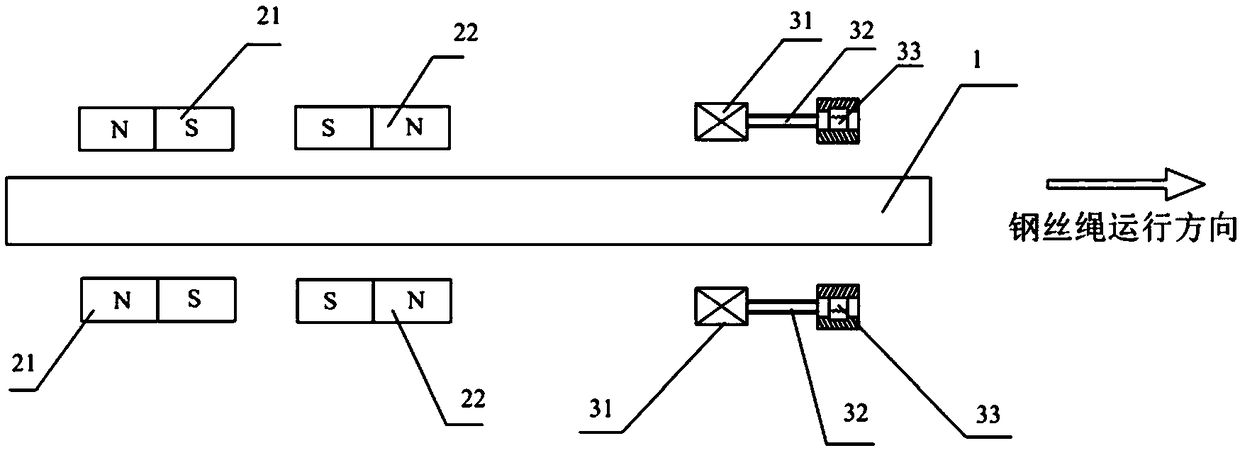

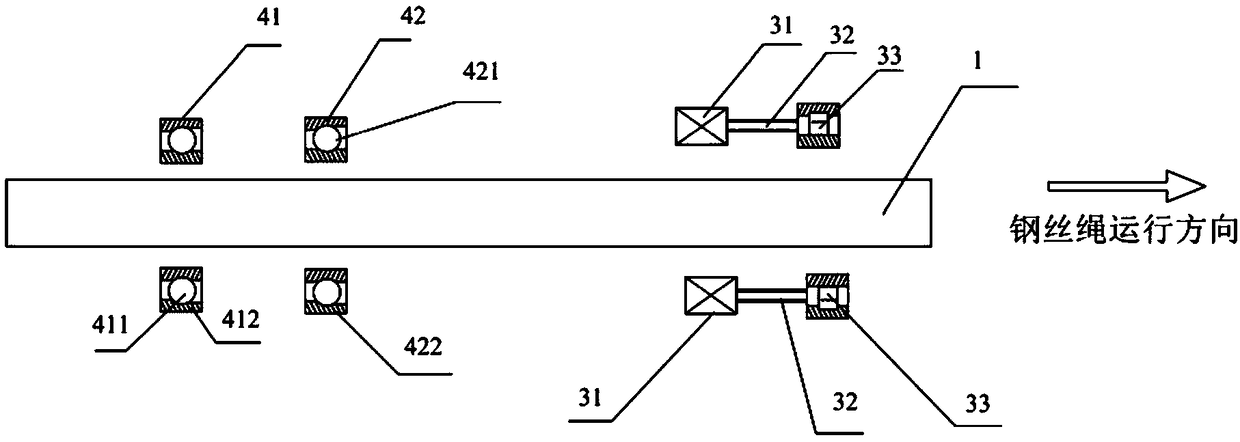

Nondestructive testing device and method for steel wire rope

PendingCN108760874AGood wrappingUniform magnetizationMaterial magnetic variablesNondestructive testingEngineering

The invention discloses a nondestructive testing device and method for a steel wire rope. The device comprises at least one excitation mechanism group, at least one magnetic measurement mechanism anda remote terminal which are arranged sequentially in the running direction of the steel wire rope, wherein the remote terminal is in data connection with the magnetic measurement mechanism; during running of the steel wire rope, at least one round of excitation with completely opposite magnetic field directions is applied to the steel wire rope in the running axial direction of the steel wire rope, and the steel wire rope is subjected to bidirectional saturation magnetization; after saturation magnetization of the steel wire rope, the steel wire rope goes ahead continuously, remanence on the steel wire rope after magnetic fields are removed is called limit remanence, the limit remanence is tested by the magnetic measurement mechanism, processing and judging are performed by a magnetic measurement circuit, fact data is transmitted to the remote terminal, and damage to the steel wire rope is determined accurately. Remanence amount of the steel wire rope can be only related with the damage condition of the steel wire rope but not related with size of an excitation field or an excitation process, so that testing precision of steel wire rope damage condition is improved remarkably.

Owner:曹馨

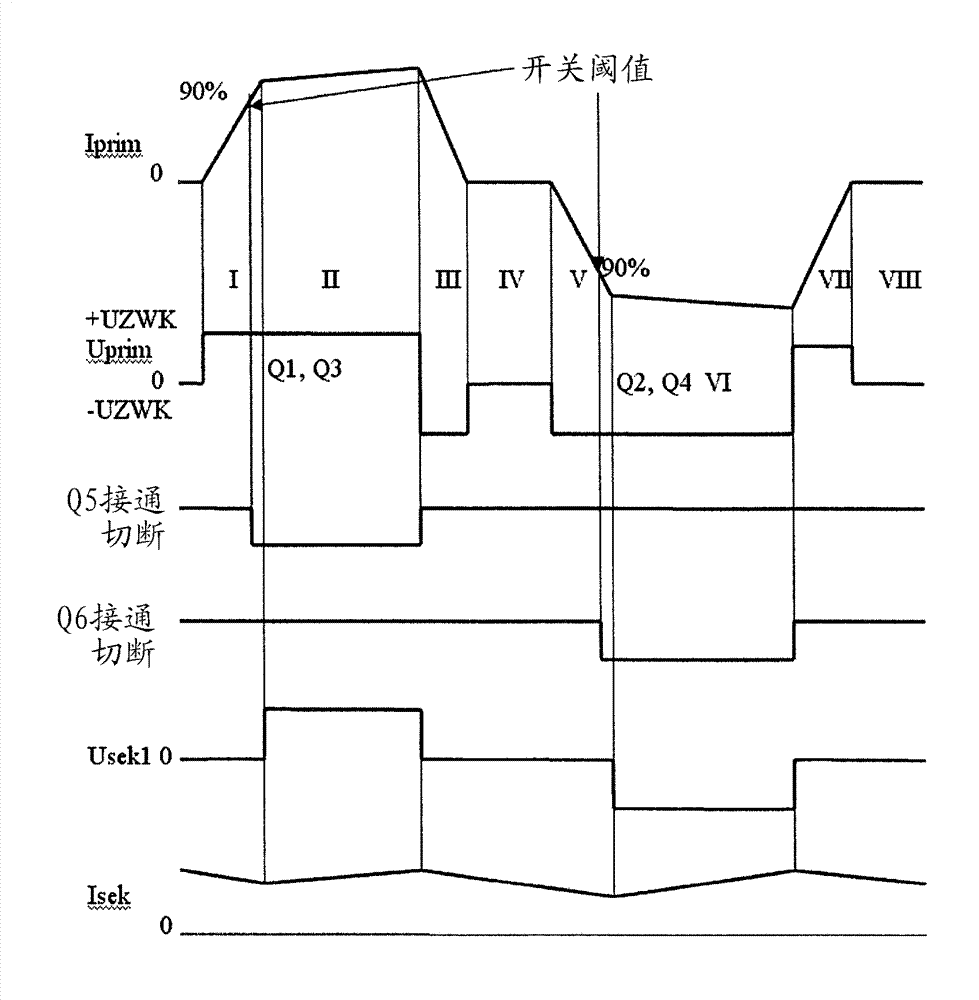

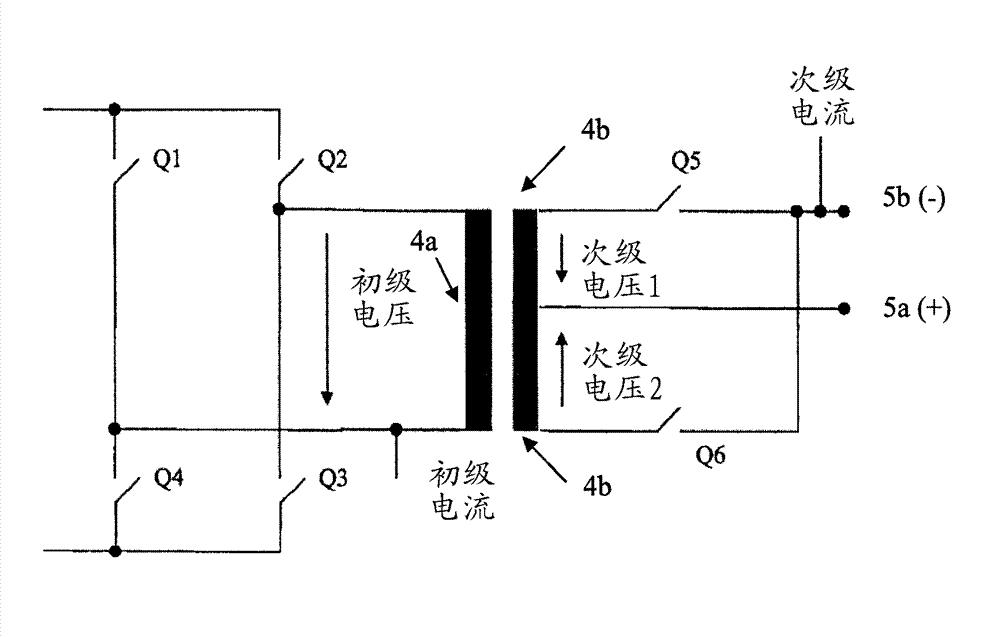

Method for operating resistor welding apparatus

ActiveCN103170719AReduce power lossImprove performanceAc-dc conversion without reversalEfficient power electronics conversionElectrical resistance and conductanceEngineering

The invention relates to a method for operating a resistor welding apparatus. The power transmission manner on the resistor welding apparatus is not the optimum manner. The invention relates to the resistor welding apparatus with a welding transformer, the welding transformer includes first and second secondary windings which are coupled with each other, a primary winding and a synchronous rectifier. The operating resistor welding apparatus runs following a specific method, and power transmission is optimized on the system layer in the method.

Owner:ROBERT BOSCH GMBH

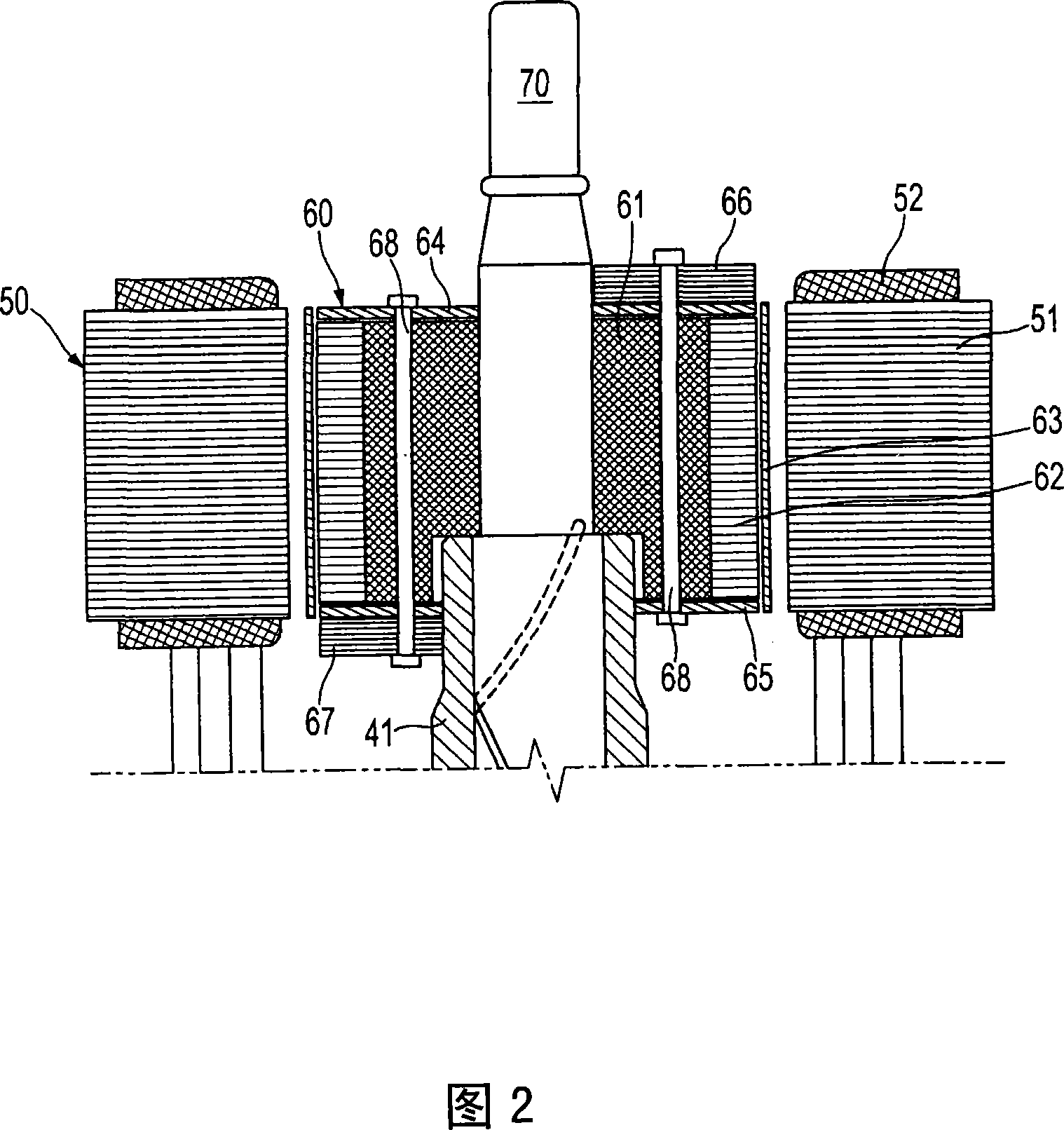

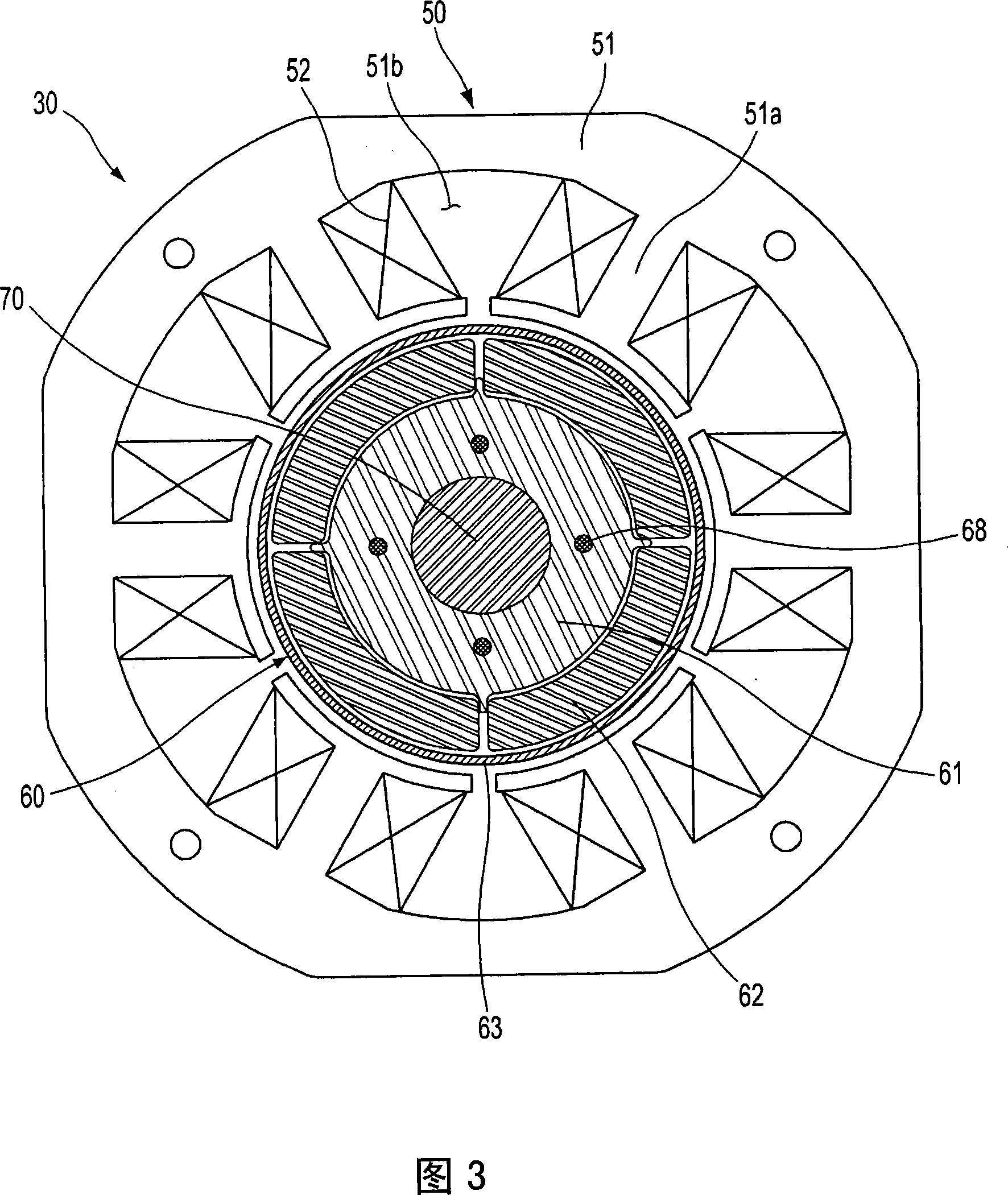

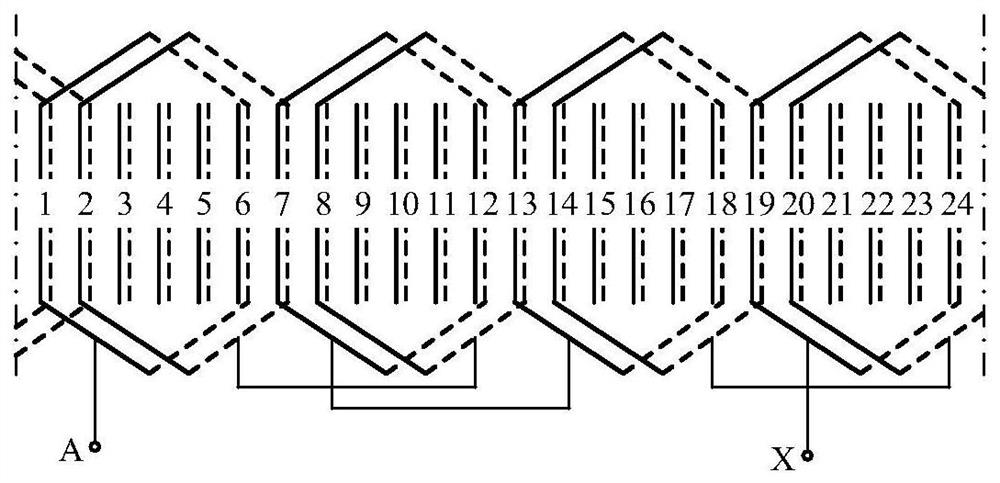

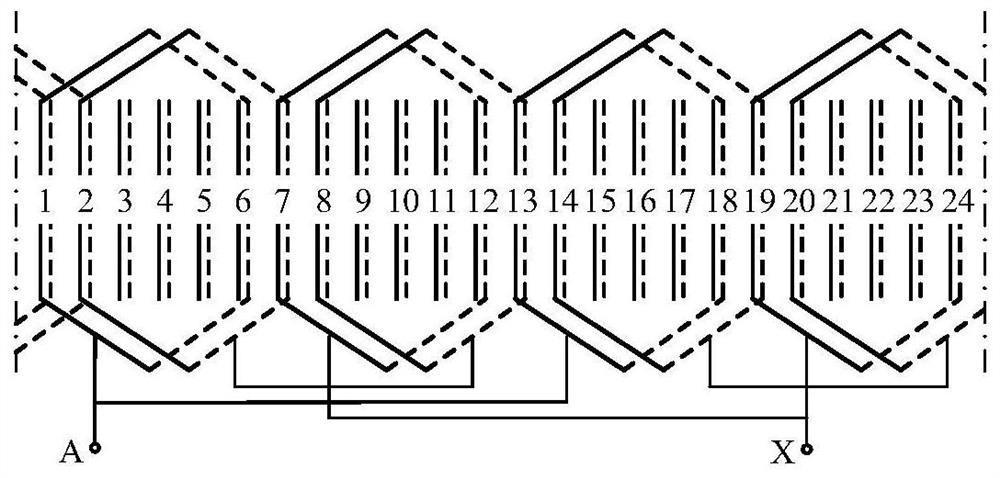

Motor and motor manufacturing method

InactiveCN1909332AUniform magnetizationVibration/Noise ReductionMagnetic circuit rotating partsManufacturing stator/rotor bodiesElectric machineMagnet

Owner:LG ELECTRONICS INC

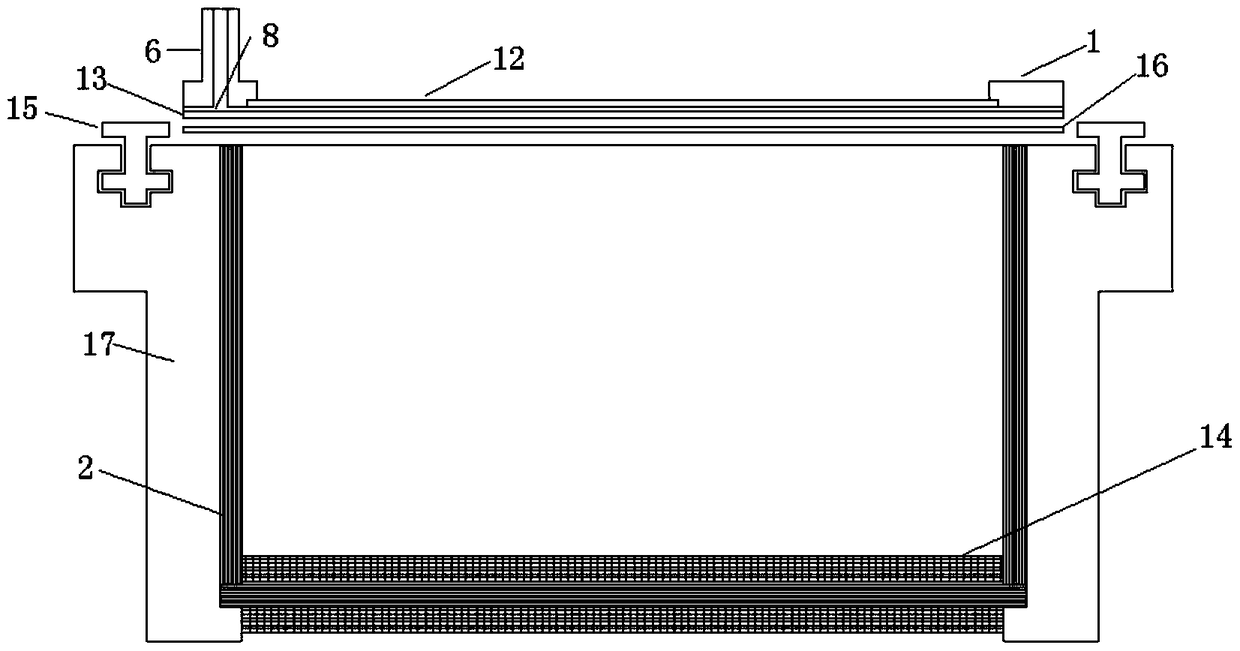

Device for rapidly measuring grain size and magnetic domain wall width of oriented silicon steel sheet

ActiveCN105300859AAccurate measurementAvoid mutual contaminationParticle size analysisIndividual particle analysisInternal pressureFast measurement

The invention discloses a device for rapidly measuring the grain size and magnetic domain wall width of an oriented silicon steel sheet. The device comprises a sample platform and a developing component, wherein the developing component comprises a display window and a contact layer; the display window is a transparent glass plate or a transparent hard plastic plate; a liquid storage cavity used for containing a developing suspension liquid is formed between the display window and the contact layer; the display window is provided with a suspension liquid injection hole used for injecting the developing suspension liquid into the liquid storage cavity and a liquid storage cavity closed hole used for balancing the internal pressure of the liquid storage cavity; the suspension liquid injection hole and the liquid storage cavity closed hole can be opened or closed as needed; a magnet yoke is arranged in the sample platform and is provided with a magnetizing winding; after being electrified, the magnetizing winding is capable of magnetizing the oriented silicon steel sheet put on the sample platform. By virtue of adopting the powder pattern method theory, the device is capable of rapidly measuring the grain size and magnetic domain wall width of the oriented silicon steel sheet.

Owner:武汉钢铁有限公司

DC demagnetization method and apparatus for magnetic recording medium and magnetic transfer method and apparatus

InactiveUS20070002480A1Uniform magnetizationUniform magnetic transferNanoinformaticsPatterned record carriersMagnetizationUltimate tensile strength

According to the present invention, since the applied magnetic field strength is controlled so as to fall between maximum magnetic field strength×0.7 and the maximum magnetic field strength over almost an entire surface of the magnetic recording medium, there is not much variation in the strength of the applied magnetic field relative to media coercivity during DC demagnetization, which makes it possible to obtain uniform magnetization over almost the entire surface.

Owner:FUJIFILM CORP +1

Hybrid permanent magnet memory starter/generator and operation method thereof

InactiveCN113098159AExpand applicationsExpand scopeMagnetic circuit rotating partsStarter detailsPermanent magnet rotorMagnetic barrier

The invention discloses a hybrid permanent magnet memory starter / generator and an operation method thereof, and belongs to the field of permanent magnet synchronous motors. Hybrid permanent magnet memory starter / generator comprises a hybrid permanent magnet rotor, a stator iron core, armature windings, air gaps and a rotating shaft. Two sets of windings are wound on the stator iron core in the same groove and in the same direction to jointly form an armature winding which is also used for adjusting magnetism; the two sets of windings work in a series or parallel state as required; a high-coercivity permanent magnet, a low-coercivity permanent magnet and a triangular magnetic barrier are arranged on the hybrid permanent magnet rotor; two tangentially magnetized low-coercive-force permanent magnets and two radially magnetized high-coercive-force permanent magnets are arranged below each magnetic pole of the hybrid permanent magnet rotor to form a W-shaped structure; and a triangular magnetic barrier is arranged at the junction of each low-coercivity permanent magnet and each high-coercivity permanent magnet. The motor adopts alternating-current pulse magnetic adjustment; when magnetic adjustment is needed, the armature winding is used for applying magnetic adjustment pulses; the permanent magnets are placed on the motor rotor; and the motor is simple in structure, easy and convenient to machine and manufacture, and the technology is mature.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

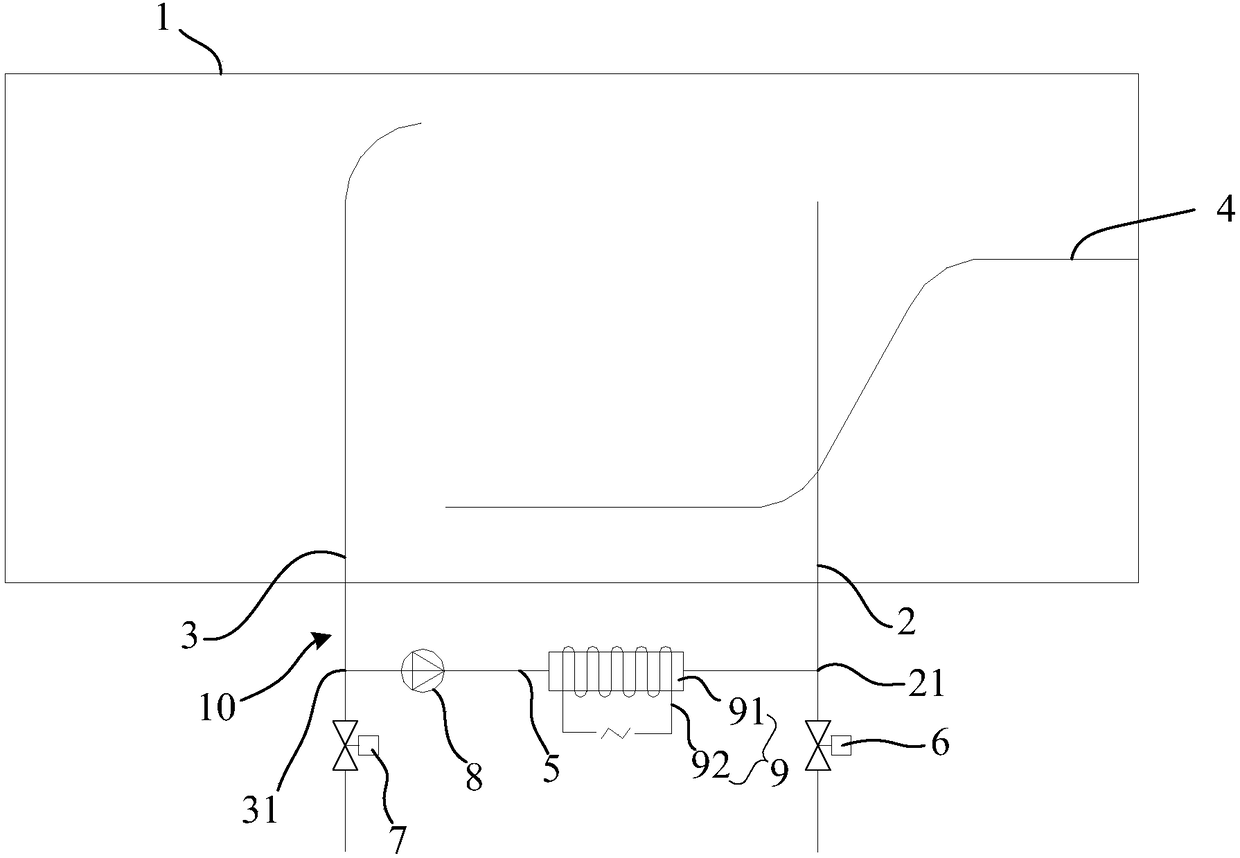

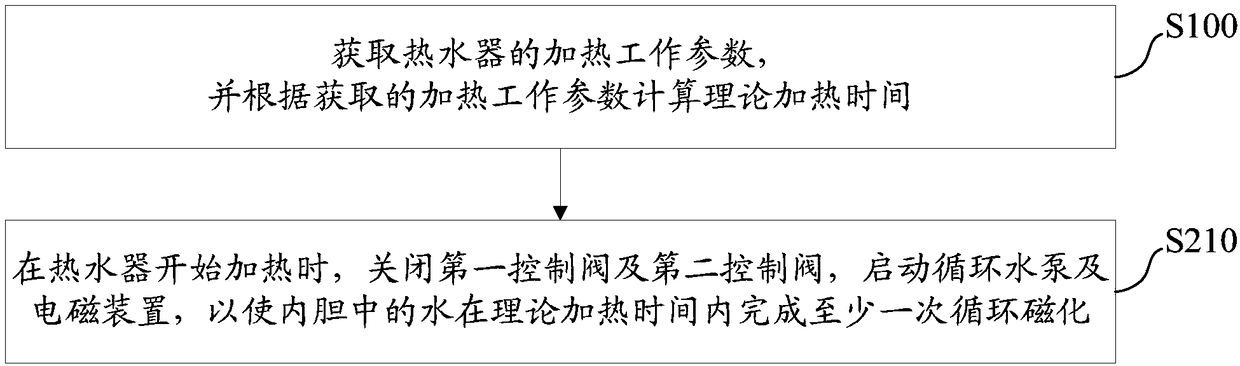

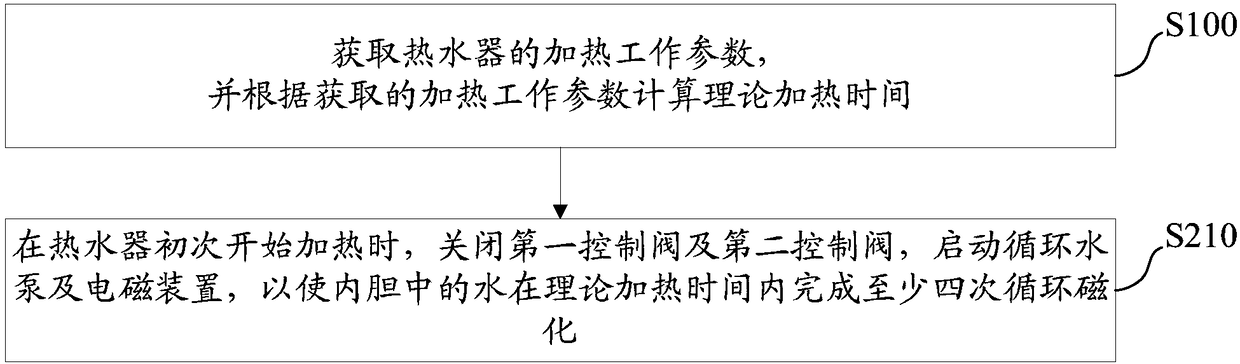

Water heater and control method of water heater

PendingCN108800543AReduced potential for scalingUniform magnetizationWater heatersEngineeringControl valves

The invention discloses a water heater and a control method of the water heater. The water container comprises an inner container, a water inlet tube, a water outlet tube and a heater, and further comprises a circulating branch tube, a first control valve, a second control valve, a circulating water pump and an electromagnetic device, wherein a first interface is arranged on the water inlet tube;a second interface is arranged on the water outlet tube; one end of the circulating branch tube communicates with the first interface, and the other end of the circulating branch tube communicates with the second interface; the first control valve is in series connected between the outer end of the water inlet tube and the first interface; the second control valve is in series connected between the outer end of the water outlet tube and the first interface; the circulating water pump is in series connected on a circulating water path which is defined by the water inlet tube, the water outlet tube and the circulating branch tube; the electromagnetic device is used for magnetizing water which flows through the circulating water path; and the electromagnetic device and the heater are separately arranged. The water heater can guarantee that a water body in the inner container is uniformly magnetized, so that possibility of forming water into scales is reduced.

Owner:WUHU MIDEA KITCHEN & BATH APPLIANCES MFG CO LTD +1

Dual-claw polar multi-phase excitation generator

InactiveCN102185404AIncrease the number ofReduce manufacturing costMechanical energy handlingWindings conductor shape/form/constructionPhase differenceConductor Coil

The utility model provides a dual-claw polar multi-phase excitation generator belonging to the field of automobile electric apparatus. The dual-claw polar multi-phase excitation generator is mainly characterized in that armature windings are n-phase identical armature windings; each phase of the n phases spans n poles on a stator core respectively and is embedded with wires in sequnce; the phase difference of the armature windings is 360 / n degree, wherein n is an integer more than or equal to 4; and every two adjacent claw poles on each flange correspond to every n poles on a stator core. The dual-claw polar multi-phase excitation generator has the advantages that a rectifier has little heating quantity, long service life, simple and reliable voltage stabilizing and low cost, the generator is claw pole shaped, can be machined simply, can be magnetized uniformly, has high utilization degree, low whole-machine cost, and the like.

Owner:邓素华

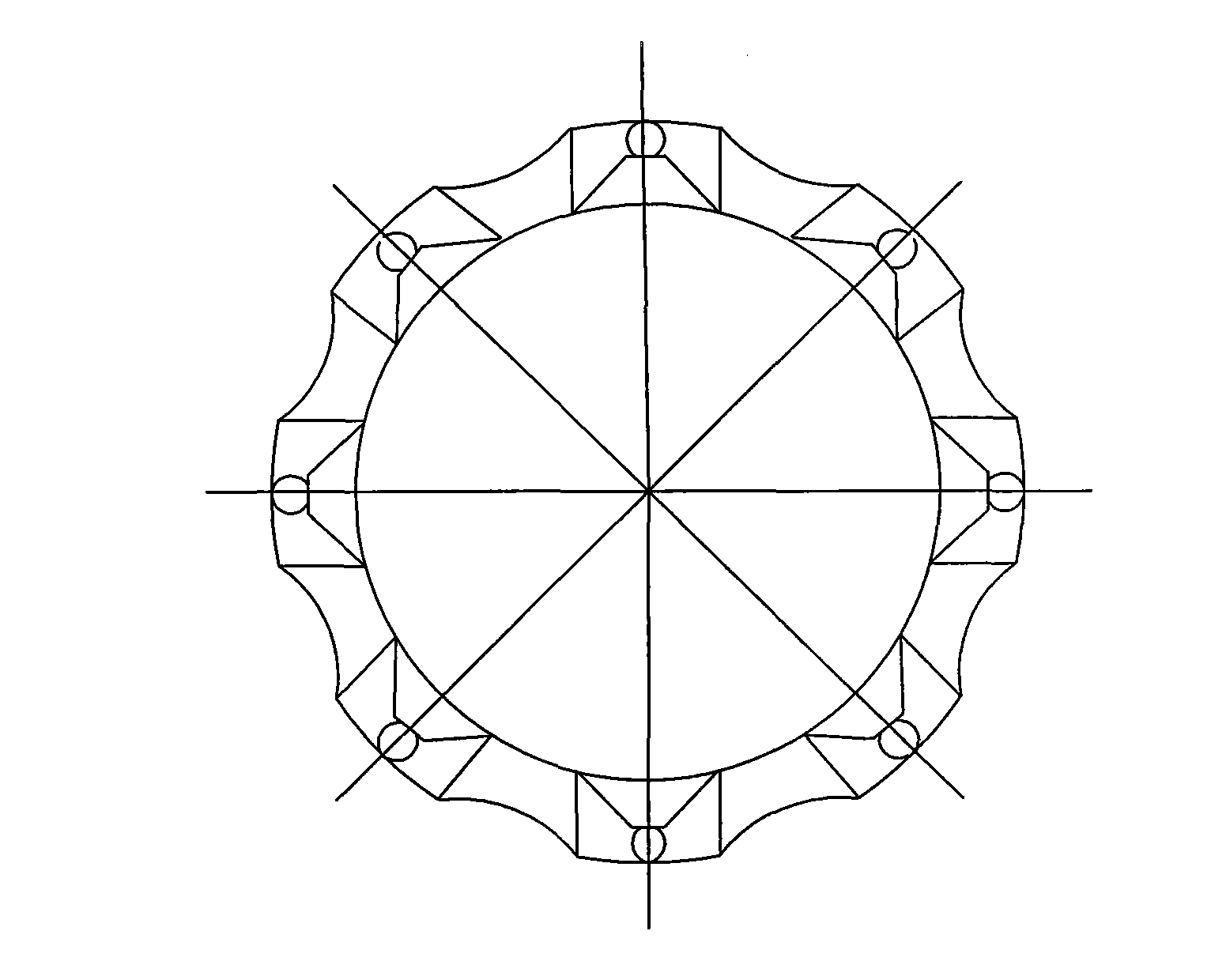

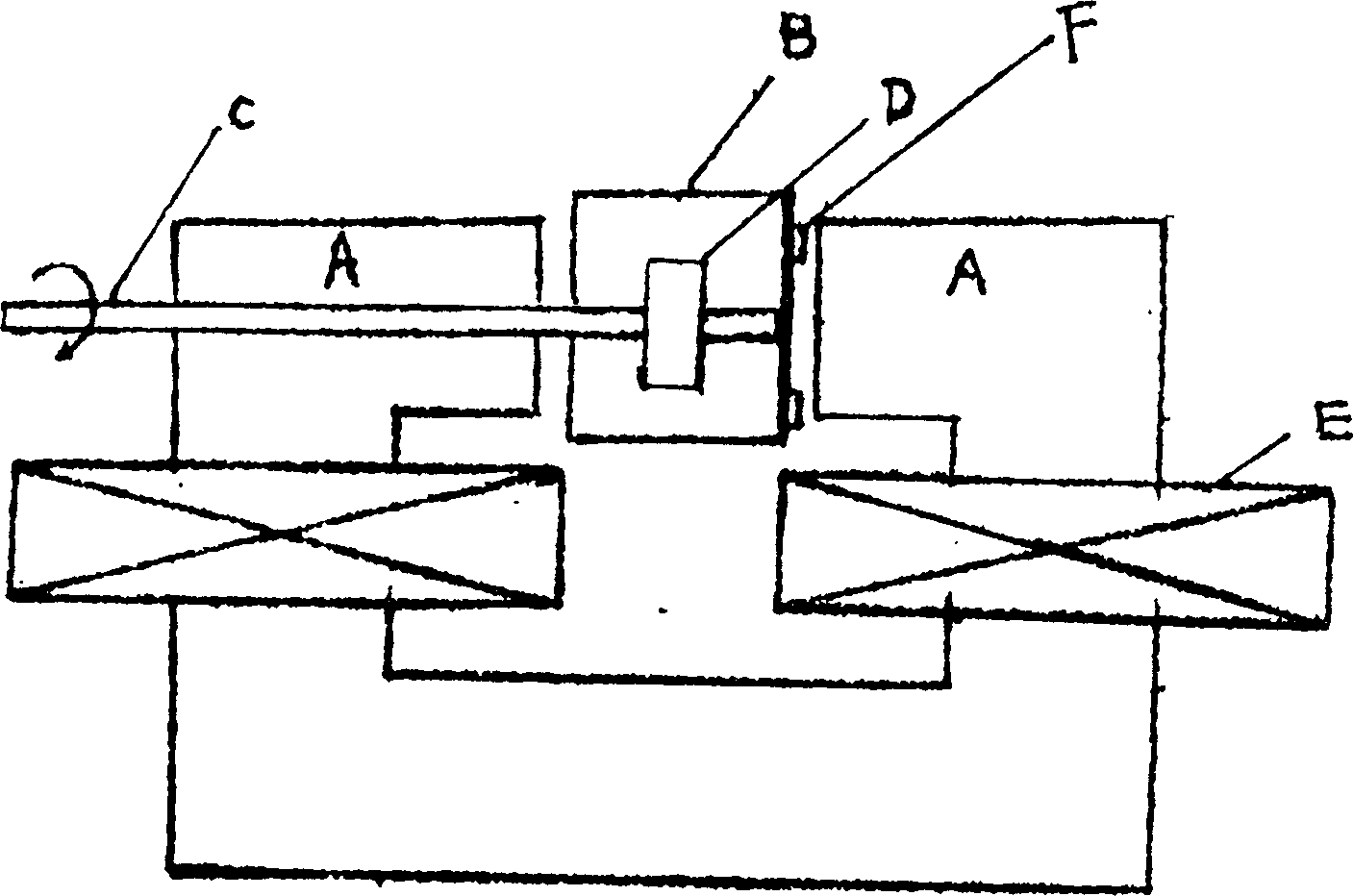

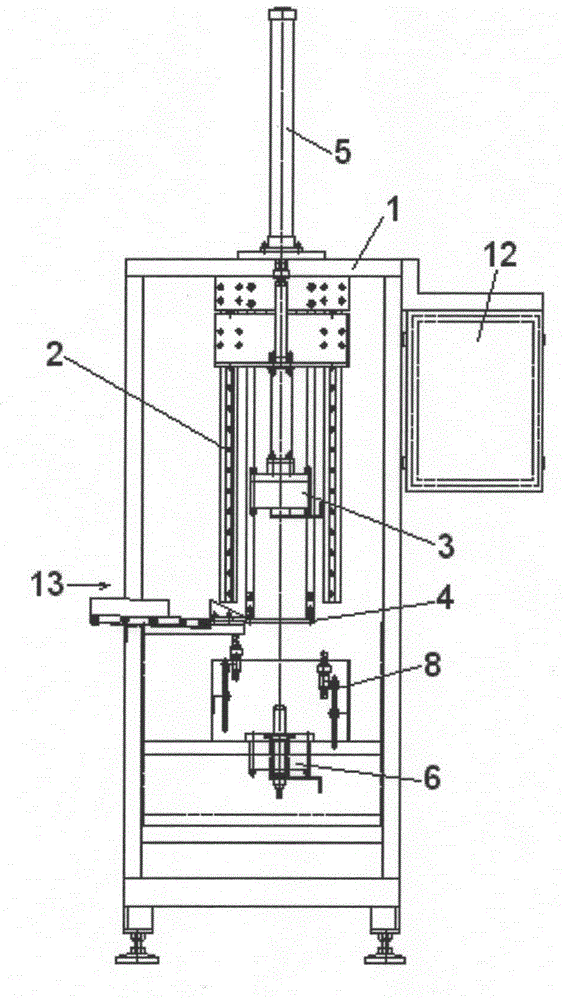

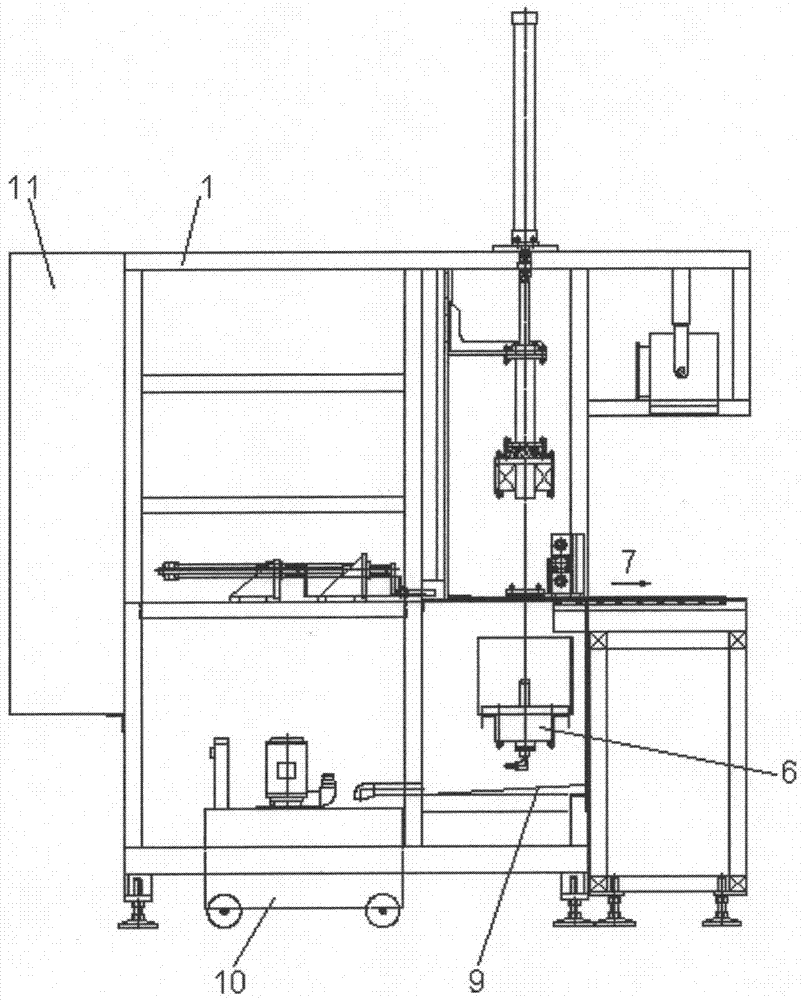

Residual magnetism flaw detection method and device for piston rings based on series-connection closed type magnetization

ActiveCN104764800AImprove magnetization efficiencyAvoid space magnetic field interferenceMaterial magnetic variablesPhysicsMagnetic noise

The invention relates to a residual magnetism flaw detection method and a residual magnetism flaw detection device for piston rings based on series-connection closed type magnetization. The N pole and the S pole of single permanent magnet 2 and a piston ring 1 form an annular magnetic loop, the penetrating-through magnetization in a circumferential direction is realized by the maximum magnetic energy density, a workpiece is scanned by multiple space sensitivity scale magnetic-sensing detection units 4' in a circumferential direction after the magnet is separated, a leakage magnetic field generated by a flaw is picked up and is converted into an electrical signal, and whether a flaw exists in the piston ring or not is judged through signal mutation. According to the residual magnetism flaw detection method, different opening gaps and a trans-scale flaw in irregular cross section of the piston ring 1 can be detected through the array type magnetic-sensing detection units 4' surrounding the piston ring 1, and the flaw detection rate is high; and besides, the problems of magnetic noise and the blind flaw detection end part in magnetic flux leakage detection of the piston ring 1 are solved and the automatic flaw detection of the piston ring 1 can be realized.

Owner:WUHAN HUAYUYIMU TESTING EQUIP CO LTD

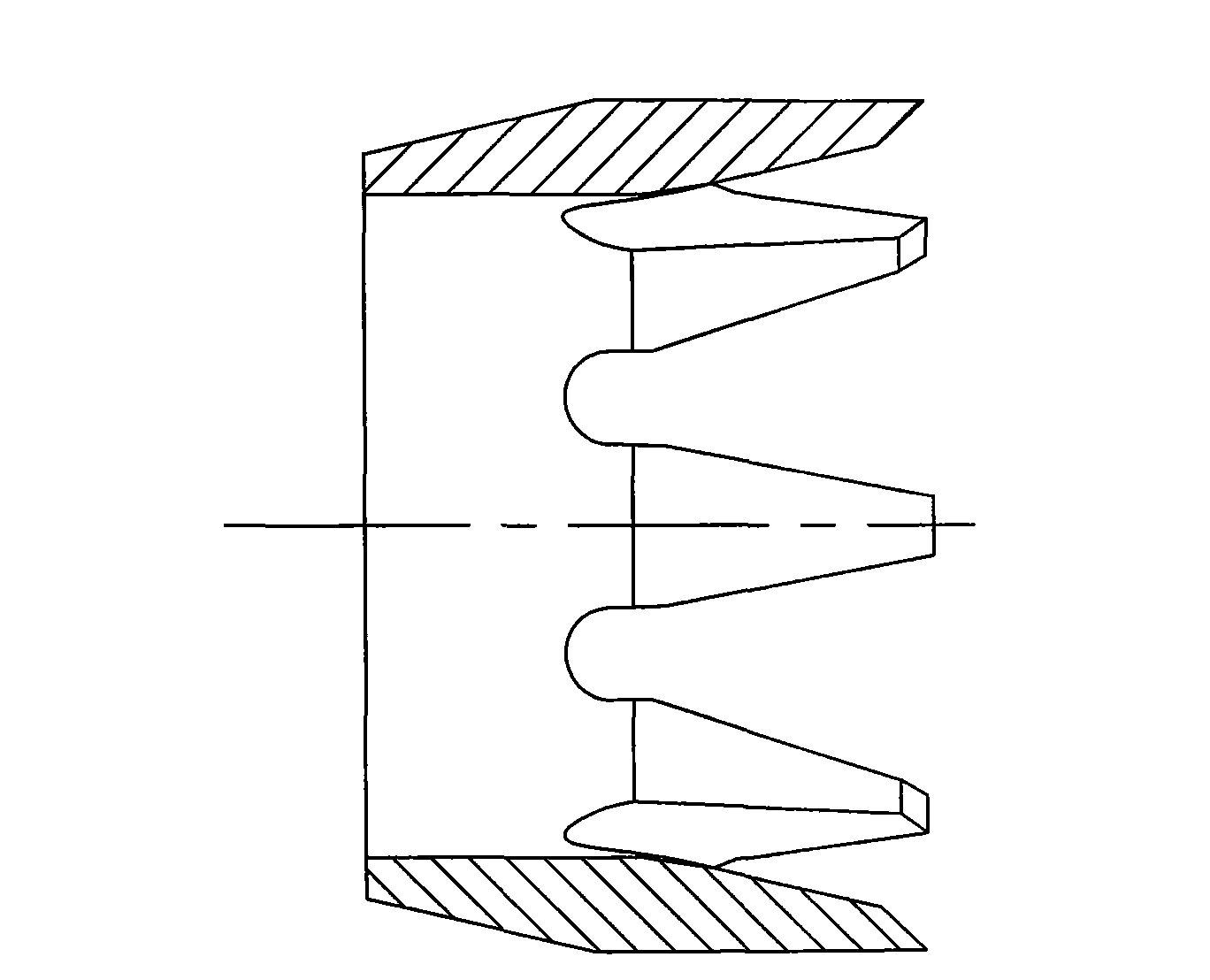

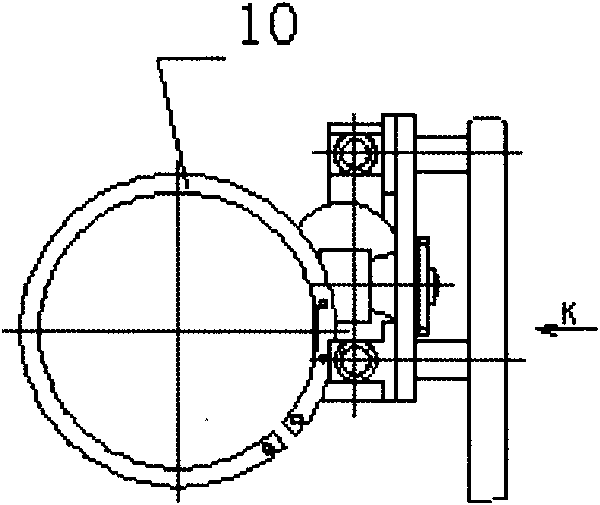

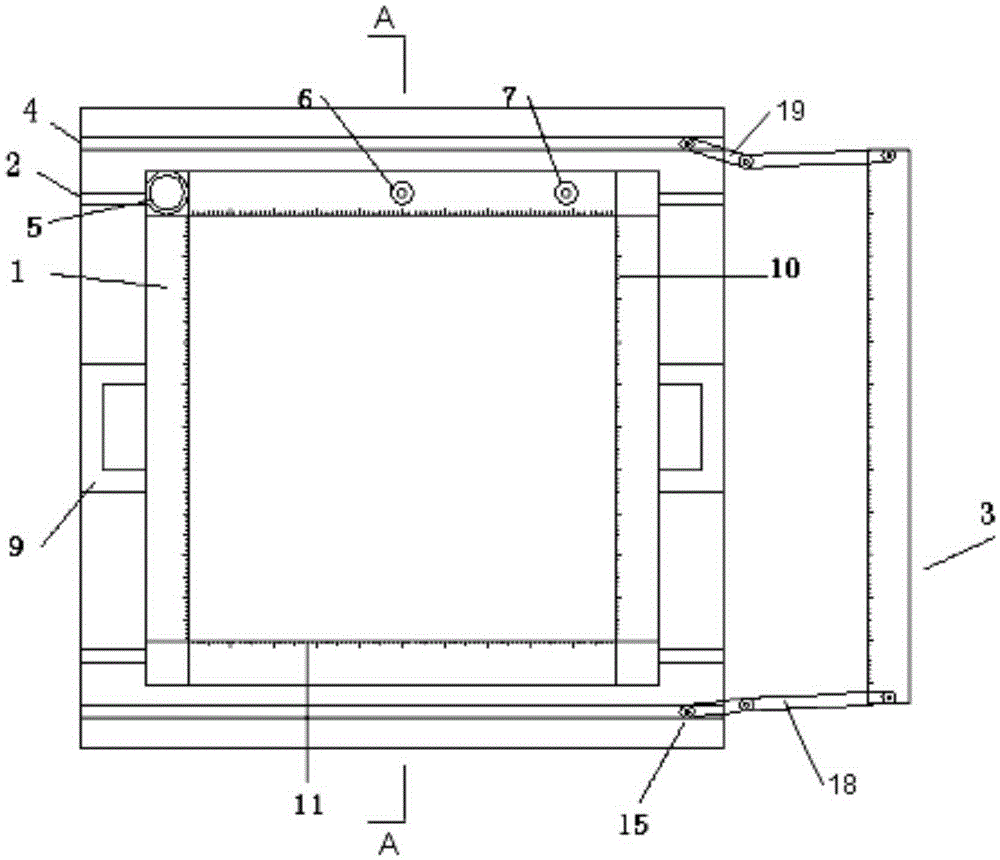

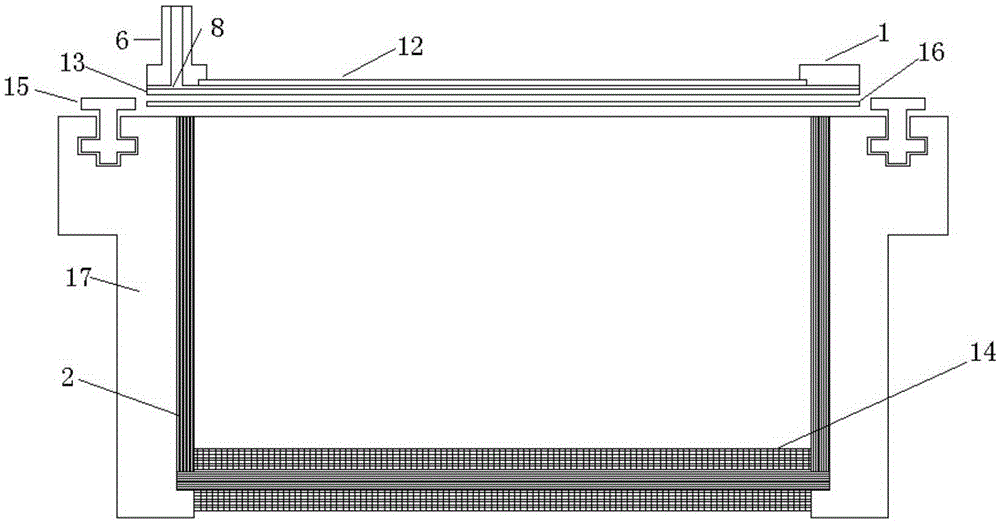

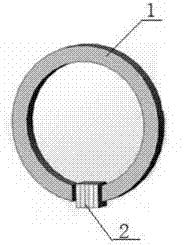

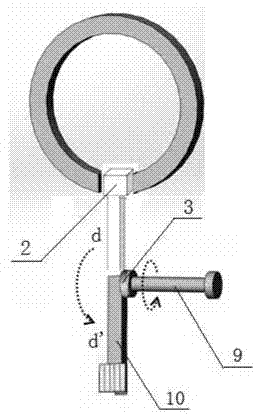

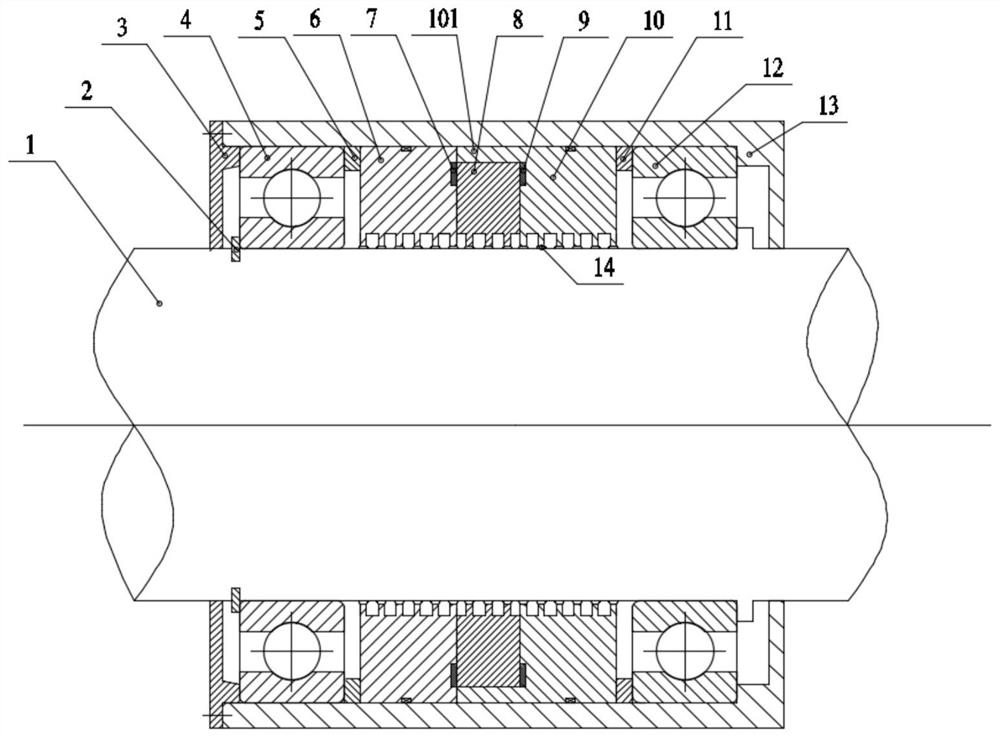

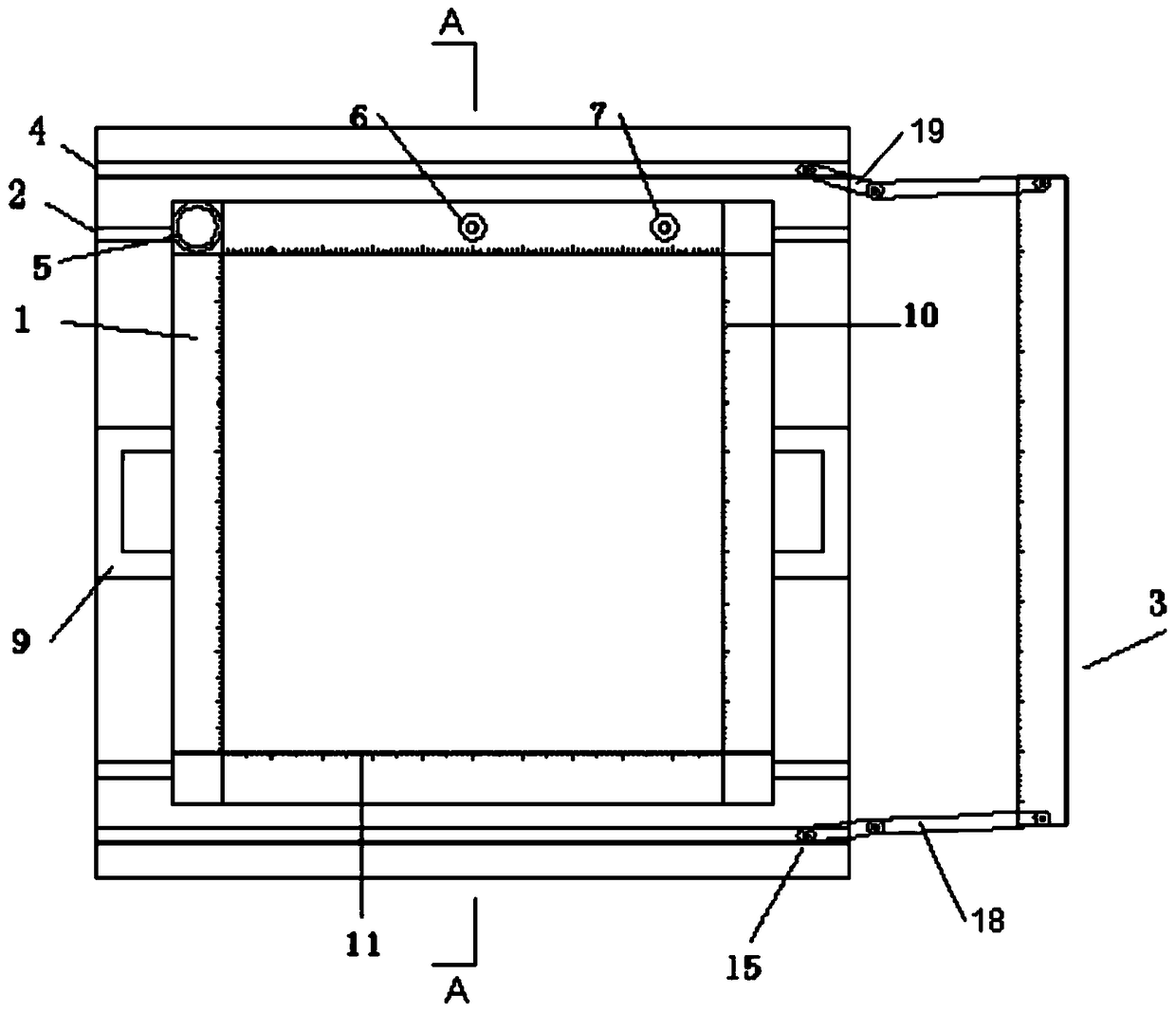

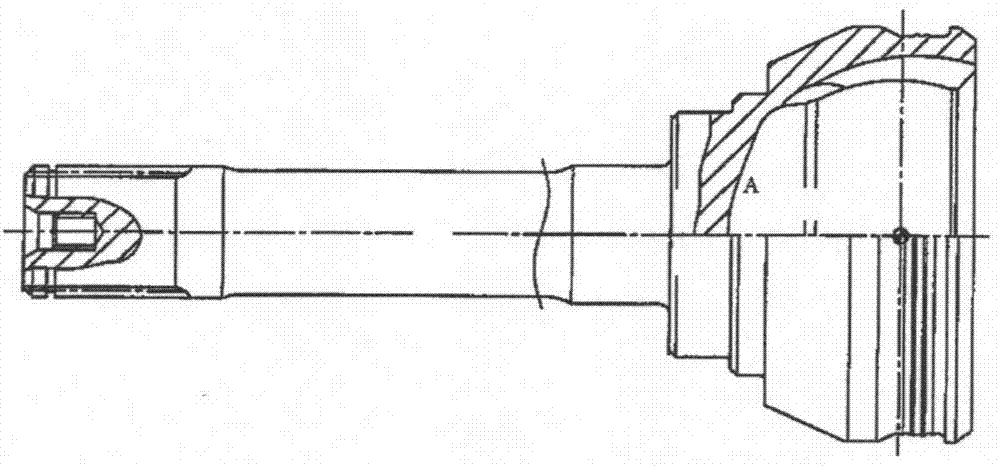

Obliquely magnetized magnetic liquid sealing structure

The invention provides an obliquely magnetized magnetic liquid sealing structure. The structure comprises a shaft (1), a check ring (2), an end cover (3), a first bearing (4), a first magnetic isolation ring (5), a first pole shoe (6), a first magnetic isolation sheet (7), a permanent magnet (8), a second magnetic isolation sheet (9), a second pole shoe (10), an axial bulge (101), a second magnetic isolation ring (11), a second bearing (12), a shaft shell (13) and magnetic liquid (14). The magnetic liquid sealing structure is high in pressure resistance, low in axial size and uniform in magnetic field intensity among all stages of seals, and the defects of a magnetic liquid multi-stage sealing structure are overcome.

Owner:TSINGHUA UNIV

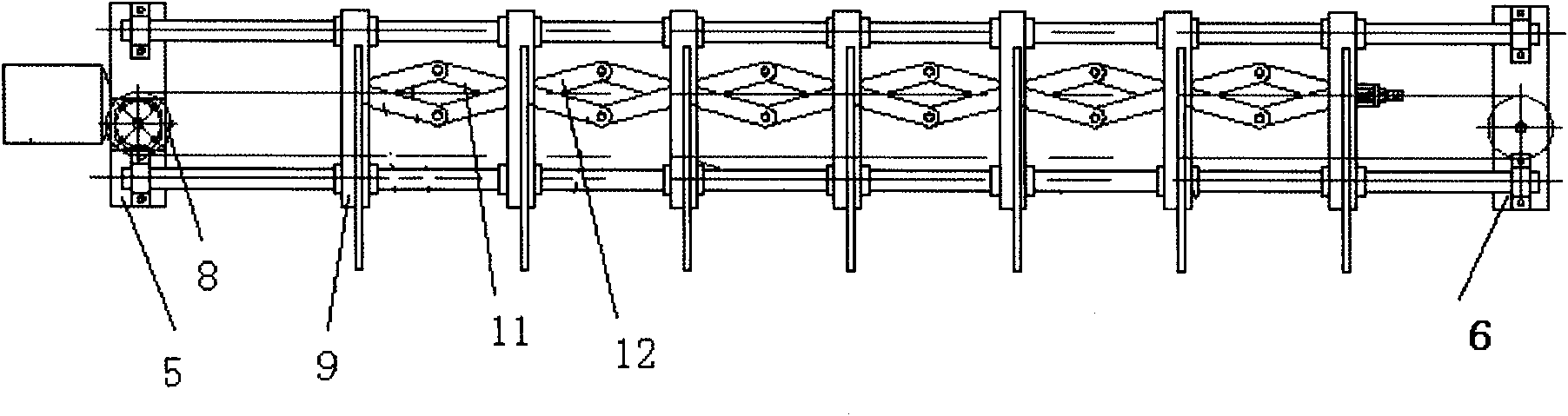

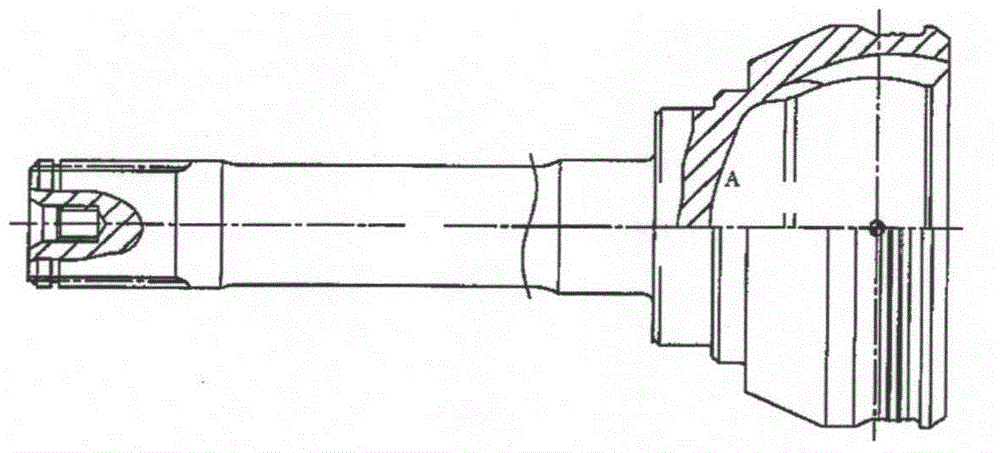

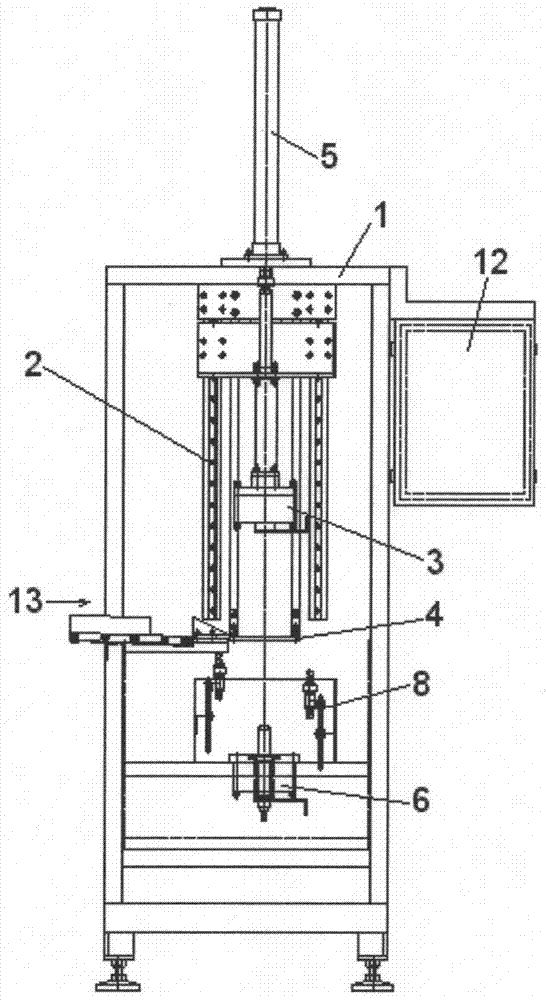

Besides-star wheel magnetic detector

ActiveCN104597119ASufficient magnetizationUniform magnetizationMaterial magnetic variablesFailure rateProduction line

The invention provides a besides-star wheel magnetic detector. The besides-star wheel magnetic detector comprises a main machine body, wherein a linear guideway is arranged on the main machine body, a movable chuck coil device and a besides-star wheel workpiece bearing platform are both arranged on the linear guideway, the movable chuck coil device is arranged above the besides-star wheel workpiece bearing platform, a liquid collecting tank is arranged under the linear guideway, the lower part of a fixed chuck coil device having an inner spraying function is arranged in the liquid collecting tank, the fixed chuck coil device and the movable chuck coil device are coaxially arranged, an outer spraying head is arranged in the liquid collecting tank, the liquid collecting tank is connected with a magnetic suspension liquid tank, and an automatic charging and discharging mechanism is arranged on the side surface of the main machine body. According to the besides-star wheel magnetic detector, the disadvantages of the prior art are overcome, all besides-star wheels with various specifications can be sufficiently and uniformly magnetized under a condition that a tooling is not replaced, a workpiece can be automatically loaded and unloaded conveniently, and the besides-star wheel magnetic detector is safe and reliable, has low failure rate and can be inserted into an automatic production line of a factory.

Owner:SHANGHAI CHENGYOU INDAL GROUP +2

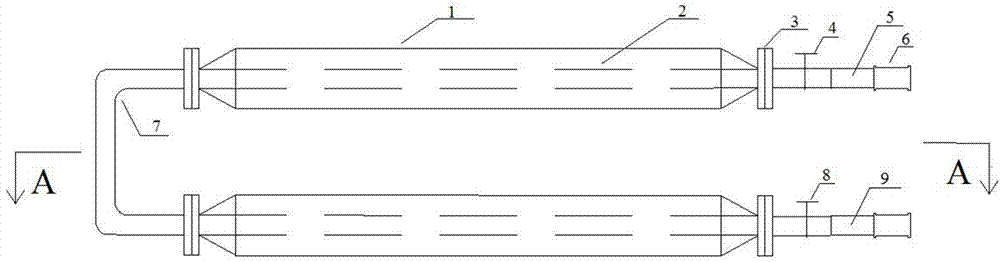

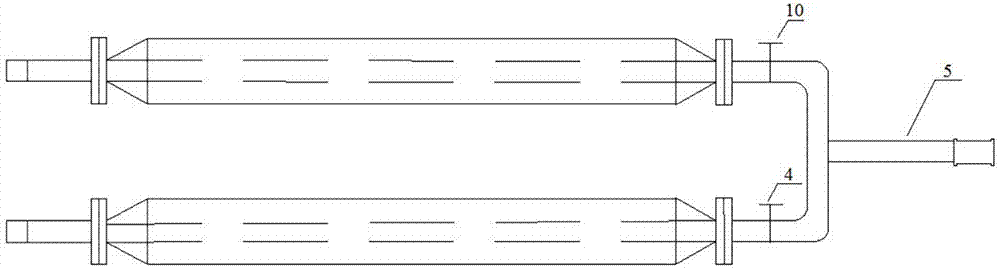

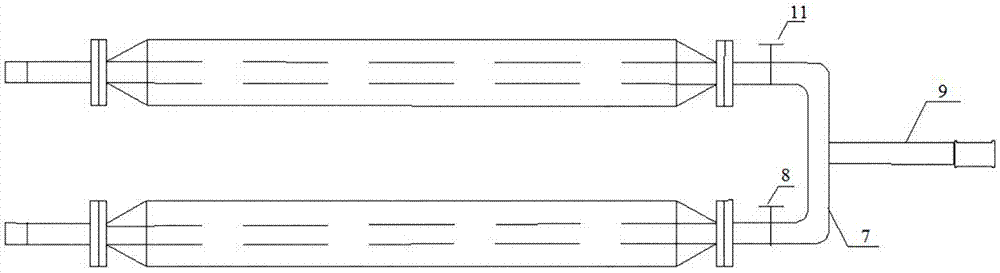

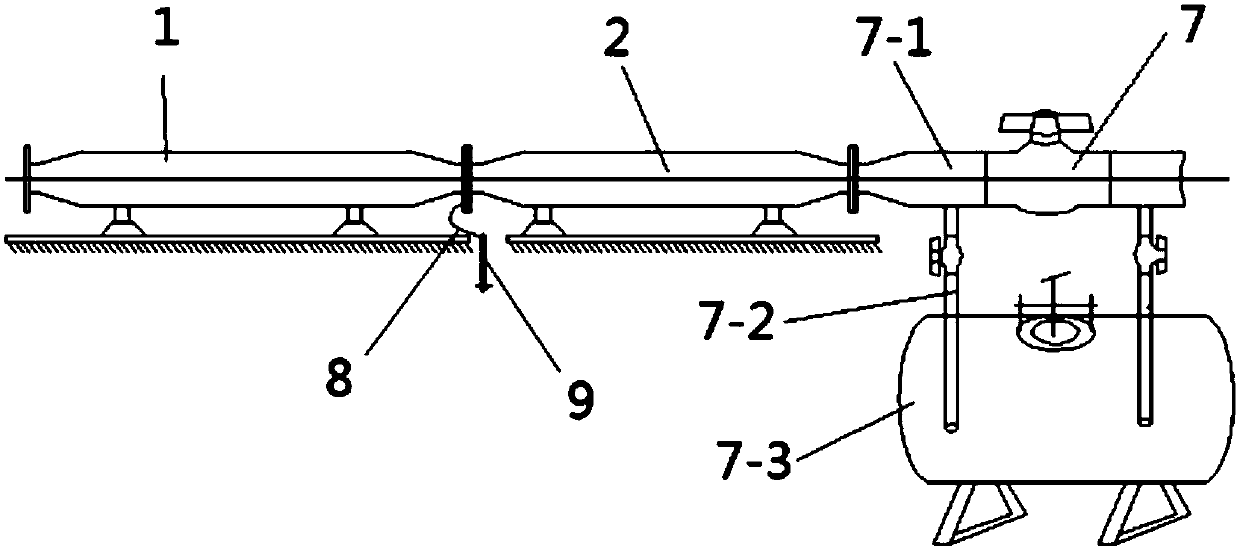

Magnetizing device and method for preparing magnetized water for dust fall of underground coal mine

ActiveCN107032458AImprove the magnetization effectNo external power requiredWaste water treatment from quariesWater/sewage treatment by magnetic/electric fieldsIntrinsic safetySpiral blade

The invention discloses a magnetizing device and method for preparing magnetized water for dust fall of an underground coal mine. The device is formed by collecting a plurality of magnet drums in a U-shaped arrangement mode by using connecting bends in parallel, wherein each of the magnet drums is composed of an external magnet, an internal magnet, a hollow pressure-proof pipe, a spiral blade, a magnetic shield cover, a connecting steel column, a pressure-proof pipe, a closed nut and a flange disc. By arranging the internal and external magnets on a water flow spiral channel formed by the hollow pressure-proof pipe, the spiral blade and the pressure-proof pipe in an alternate arrangement mode, an efficient magnetizing environment of combining pulse cutting magnetizing and spiral turbulence is constructed, so that the water for dust fall flowing through is continuously and efficiently magnetized, the scale of turbulence and magnet pass of a water flow are increased, and the problem that water which is in contact with a magnetic field within a relatively short time is not uniformly magnetized is solved. The device has the characteristics of intrinsic safety, convenience in operation, small size and high magnetizing efficiency. The device is suitable for being placed in every position of the underground coal mine, and can effectively improve the wetting performance of the water for dust fall.

Owner:CHINA UNIV OF MINING & TECH

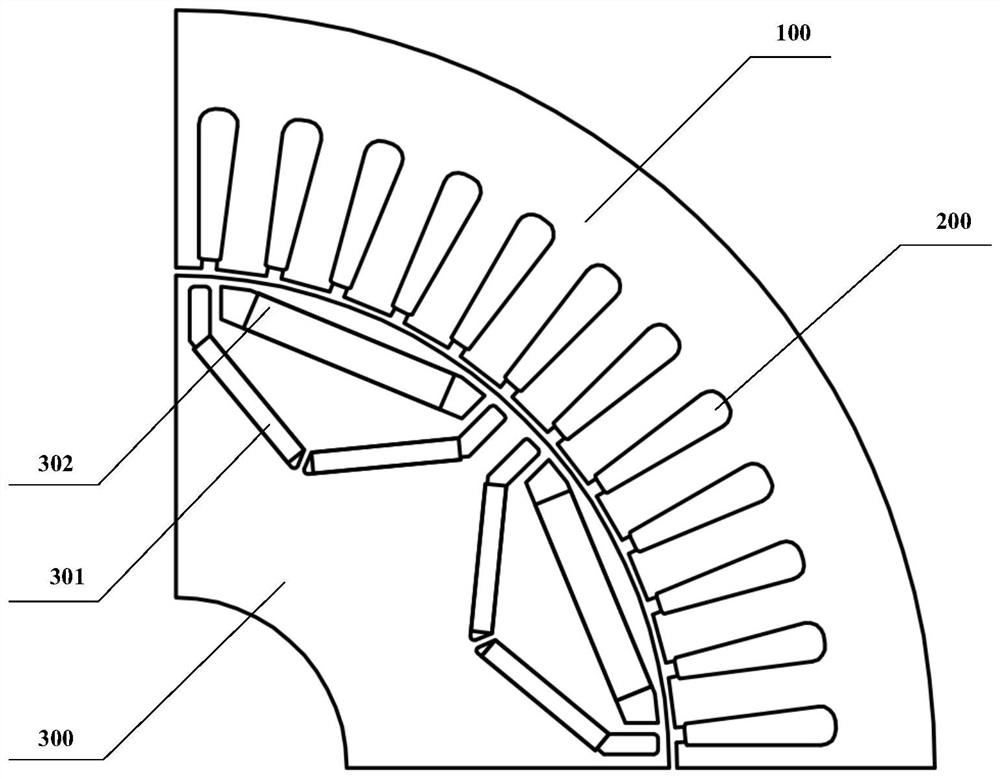

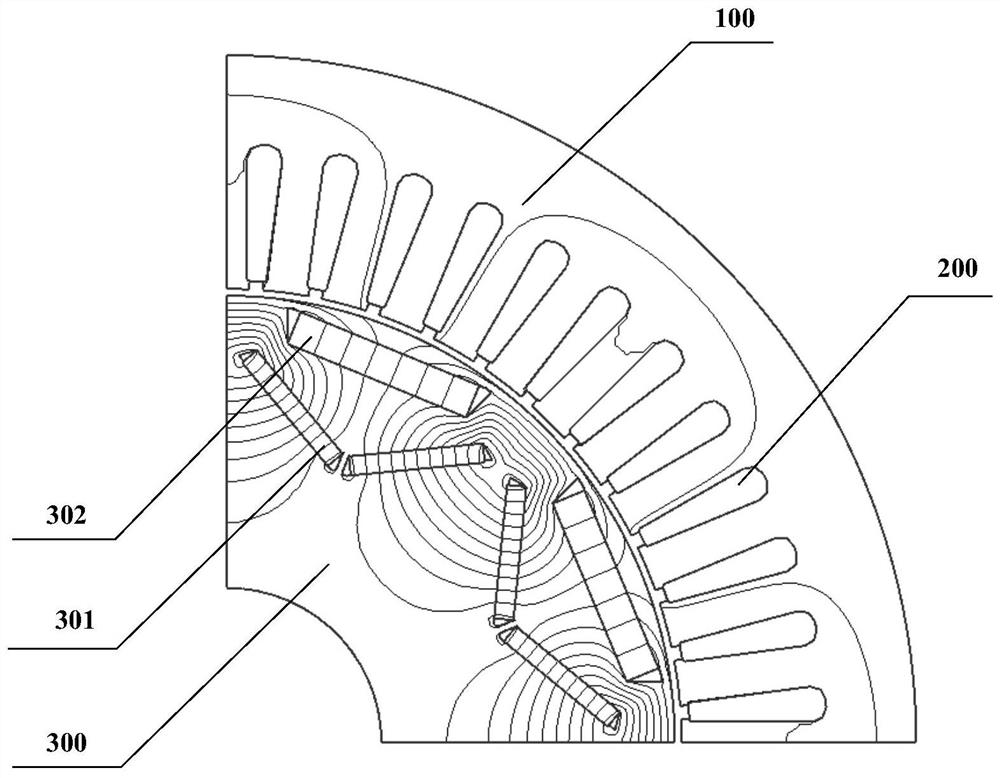

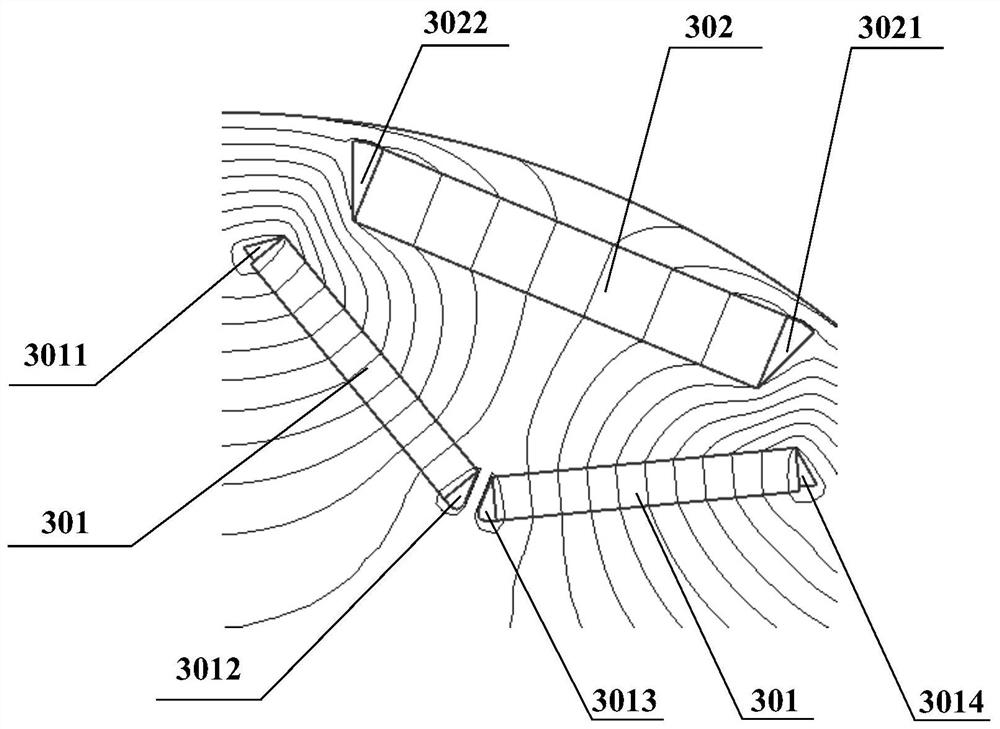

A series hybrid permanent magnet variable flux motor

ActiveCN109660042BReduce the magnetizing currentWork lessMagnetic circuit rotating partsElectric machineCondensed matter physics

The invention discloses a serial hybrid permanent magnet variable flux motor, which comprises a stator (100), an armature winding (200) wound on the stator (100), and a rotor core (300). Each pole of (300) is provided with three permanent magnets that are not in direct contact and placed separately, wherein the second permanent magnet (302) is placed on the outside in a "one" shape, and the two first permanent magnets (301) are in a "V" shape. ” shape is placed on the inner side, the second permanent magnet (302) is a high coercive force permanent magnet or a low coercive force permanent magnet, and the first permanent magnet (301) is a high coercive force permanent magnet or a low coercive force permanent magnet force permanent magnet. In the motor of the present invention, the low coercive force permanent magnet and the high coercive force permanent magnet adopt special placement positions and methods, so that the motor is a magnetic circuit series structure, and the high coercive force permanent magnet acts on the low coercive force permanent magnet. The magnetization effect improves the working point and magnetization degree of the low-coercivity permanent magnet, improves the torque output capability, and reduces the magnetizing current of the motor.

Owner:HUAZHONG UNIV OF SCI & TECH

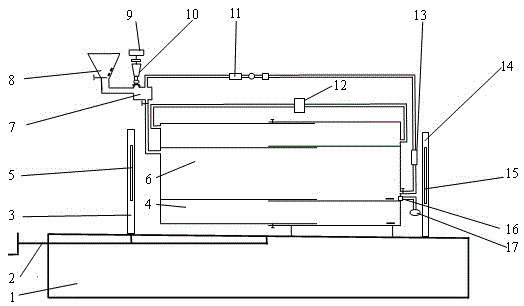

A sludge magnetization dehydration treatment device

ActiveCN103553292BEvenly heatedReasonable heatingSludge treatment by de-watering/drying/thickeningMagnetic tension forceTemperature control

The invention relates to a sludge magnetization dehydration treatment device, which belongs to the technical field of environmental geotechnical engineering. The magnetization dehydration treatment device is composed of a bracket, a magnetic force device, a telescopic heating charging device, a pipeline, a hopper, a chemical sprayer, a sensor, an outer circulation constant temperature water bath, a capillary water absorption time tester, and a sludge collector. The charging device and the variable distance magnetic device can realize the test of sludge dehydration performance with different magnetic field strength gradients; the external circulation constant temperature water bath can ensure that the sludge is heated evenly and the temperature control accuracy is high; the sensor, the chemical sprayer and the control system The connection can monitor data in real time and automatically regulate drug administration, which can improve work efficiency. The invention has reasonable design, simple structure and convenient manufacture, can determine the optimal combination parameters of sludge dehydration under the condition of multi-factor cooperative control, and has no secondary pollution in the sludge dehydration conditioning process, is easy to operate, consumes less energy, and has low cost.

Owner:JIANGSU ZHONGYI ECOLOGICAL SOIL INST

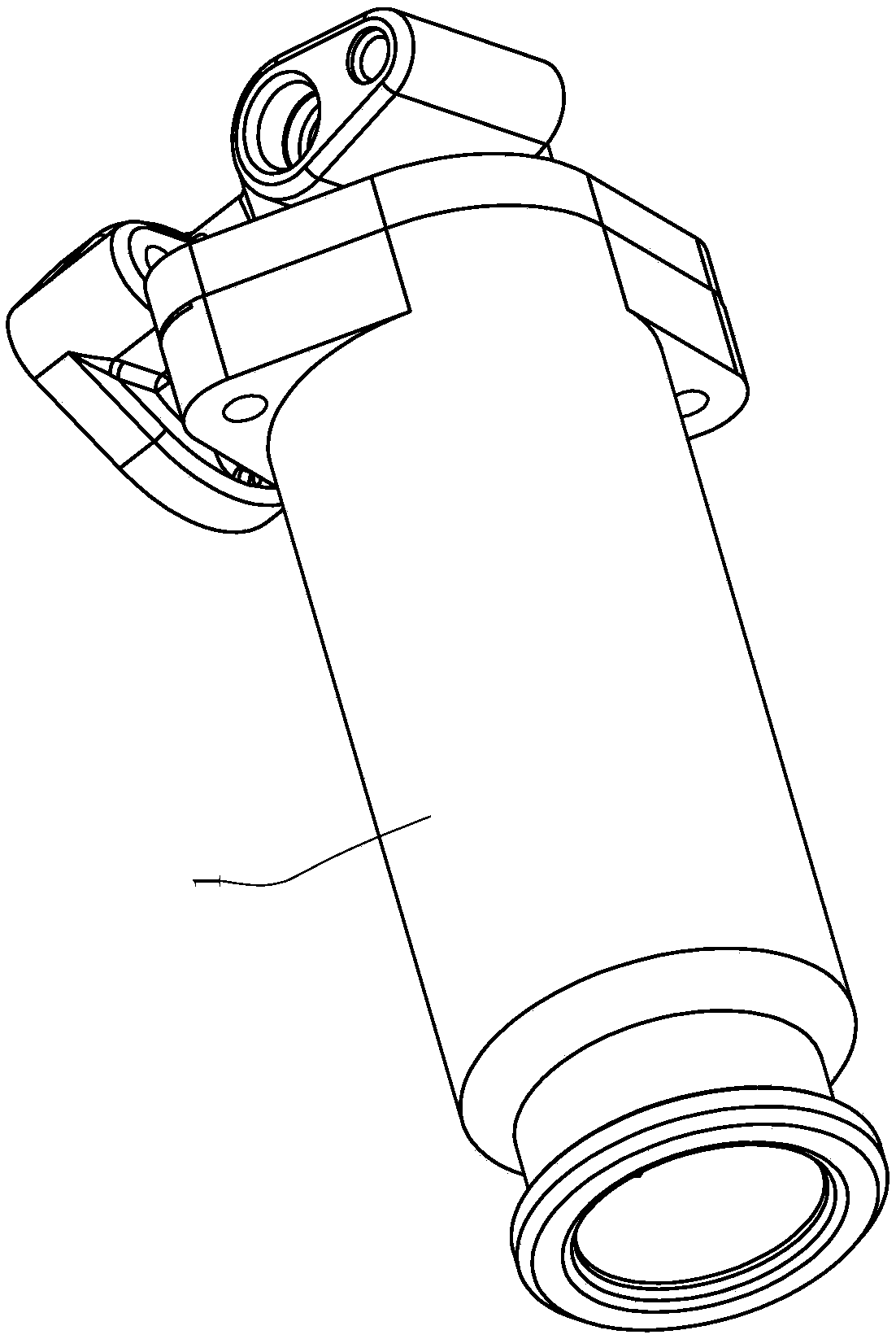

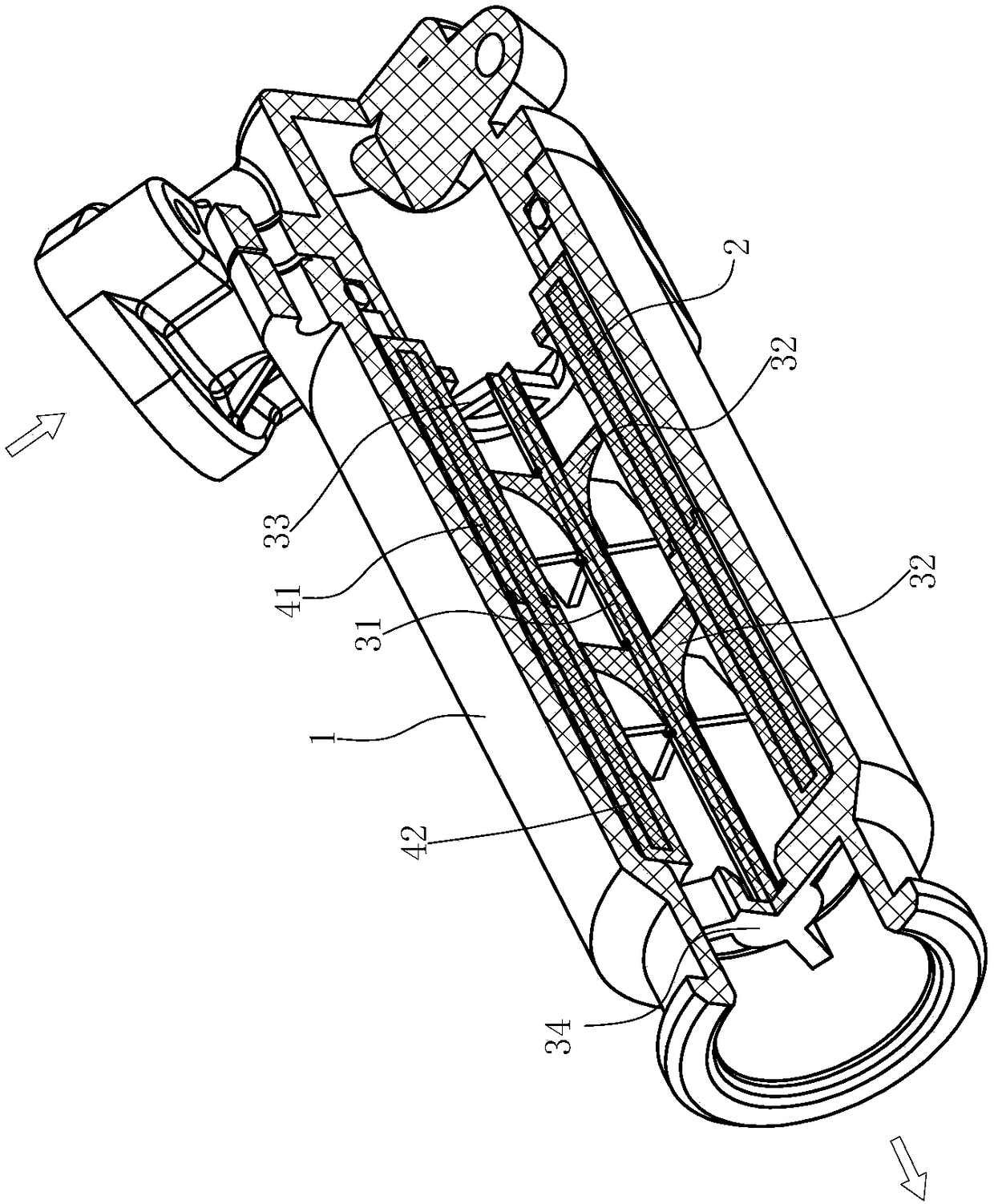

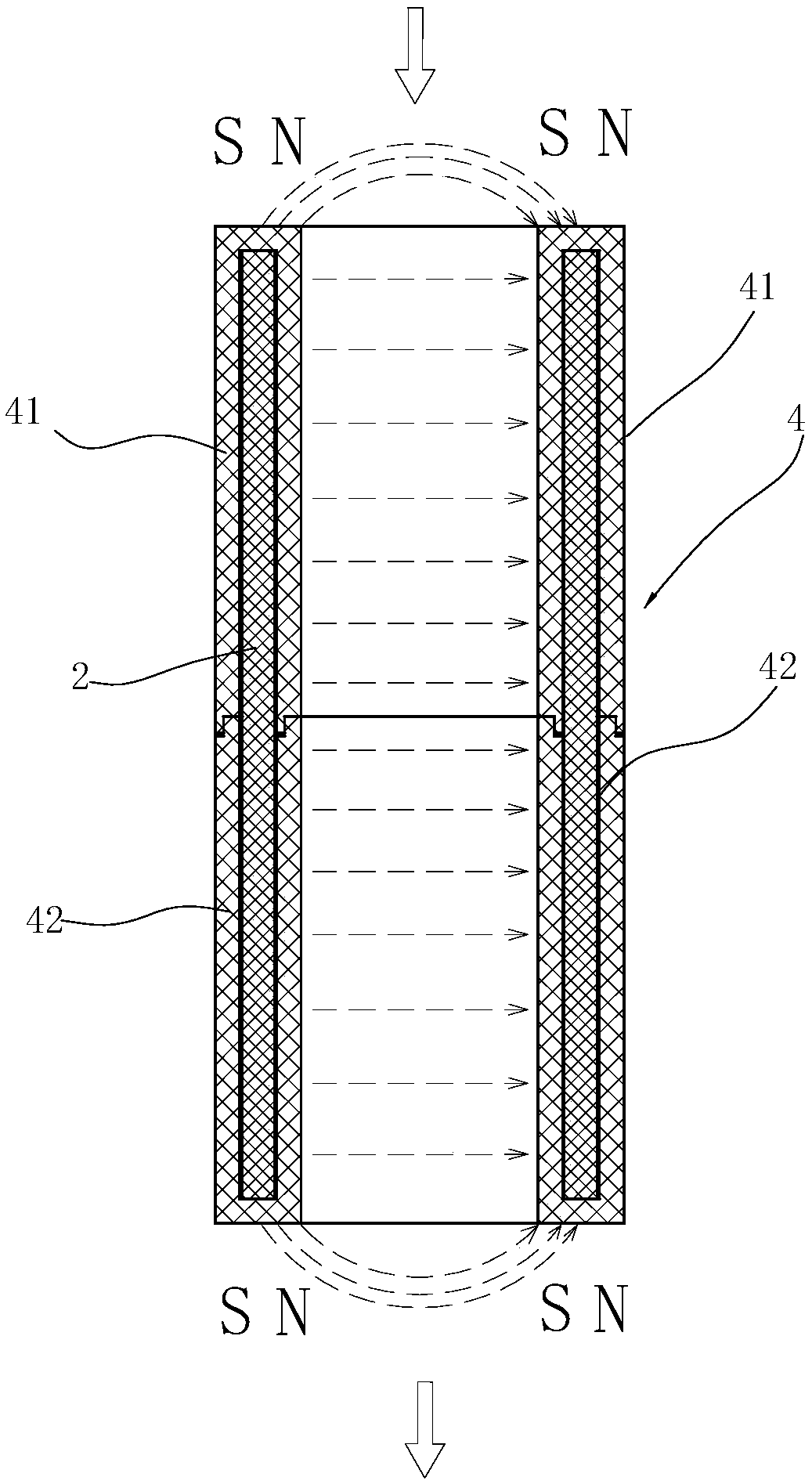

Water magnetization device

PendingCN109502711AAvoid the problem of direct contact with water flow and corrosionSolve the problem of thermal demagnetizationWater/sewage treatment by magnetic/electric fieldsWater/sewage treatment apparatusWater flowMagnetization

The invention relates to a water magnetization device, which comprises a water pipe (1) and magnetic assemblies (2) arranged in the water pipe (1). The water magnetization device is characterized in that at least one group of magnetization assemblies (2) are used, are of tubular structures and are embedded in an annular casing (4); the casing (4) is sleeved by the water pipe (1); turbulent flow assemblies (3) used for separating water flow into at least two flows and enabling the water flow to realize rotational advancing in the length direction of the magnetic assemblies are arranged on the magnetic assemblies (2). Compared with the prior art, the water magnetization device provided by the invention has the advantages that the water flow is divided into a plurality of small flows; rotating eddy current is formed; the contact area of the water flow and the magnetic field is greatly increased; the water flow is subjected to uniform magnetization; the magnetization effect is obviously improved.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

De-electronic magnetization combined activation apparatus for brackish water

ActiveCN108046387AImprove molecular activityImprove physical and chemical propertiesWater/sewage treatment by magnetic/electric fieldsPressurised distribution of liquid fertiliserBrackish waterMagnetization

The invention relates to de-electronic magnetization combined activation apparatus for brackish water. The apparatus comprises a de-electronic activation device arranged on an insulating plate, the de-electronic activation device is made of a metal material, and the de-electronic activation device is of a tubular shape with two ends open; the apparatus also comprises a tubular magnetization activation device with two ends open, one end of the magnetization activation device is in insulated connection with one end of the de-electronic activation device, the magnetization activation device communicates with the de-electronic activation device, and one end, connected with the magnetization activation device, of the de-electronic activation device is provided with a grounding device; and the inner cavity of the magnetization activation device is provided with a first magnet group, a second magnet group, a third magnet group and a fourth magnet group in the axial direction. The activation apparatus for the brackish water provided by the invention can effectively improve the physicochemical properties of the brackish water.

Owner:XIAN UNIV OF TECH

Apparatus for rapid measurement of grain size and magnetic domain wall width of grain-oriented silicon steel sheets

ActiveCN105300859BAccurate measurementAvoid mutual contaminationParticle size analysisIndividual particle analysisContact layerEngineering

The invention discloses a device for rapidly measuring grain size and magnetic domain wall width of oriented silicon steel sheet, which comprises a sample stage and a displaying part; the displaying part includes a display window and a contact layer, and the display window is transparent A glass plate or a transparent hard plastic plate, a liquid storage cavity for filling the visible suspension is formed between the display window and the contact layer; The suspension injection hole, and the closed air hole of the liquid storage chamber used to balance the pressure in the liquid storage chamber, the suspension injection hole and the closed air hole of the liquid storage chamber can be opened or closed as required; the sample table is provided with a magnetic The yoke is provided with a magnetizing winding, and when the magnetizing winding is energized, the oriented silicon steel sample placed on the sample stage can be magnetized. The device adopts the principle of powder grain method, which can quickly and accurately measure the grain size and magnetic domain wall width of grain-oriented silicon steel sheets.

Owner:武汉钢铁有限公司

An alien magnetic detector

ActiveCN104597119BSufficient magnetizationUniform magnetizationMaterial magnetic variablesFailure rateThe Internet

Owner:SHANGHAI CHENGYOU INDAL GROUP +2

Claw pole permanent magnet and electromagnetic hybrid excitation generator rotor production method

ActiveCN103683732BStable output voltageEnsure safetyElectric machinesManufacturing stator/rotor bodiesPermanent magnet rotorElectric machine

Owner:张学义

Non-contact pipeline magnetic detection method

ActiveCN103075641BUniform magnetizationEasy to detectPipeline systemsMaterial magnetic variablesPetroleum oilDegaussing

The invention discloses a non-contact pipeline magnetic detection method and a damage detection technology for buried metal pipelines of petroleum and natural gas. The non-contact pipeline magnetic detection method of the present invention includes the following steps: step 1, preliminary analysis, determining the construction period; step 2, ground cleaning, marking the route; step 3, pipeline detection; step 4, analysis and processing of detection data; step 5 , Processing of data results. The non-contact pipeline magnetic detection method of the present invention overcomes various disadvantages of the existing contact detection method for local defects of pipelines. If blind excavation is required, the pipeline should be cleaned and degaussed, and finally the pipeline should be uniformly magnetized. ;Use the earth's magnetic field to uniformly magnetize the pipeline, without cleaning or other pretreatment on the surface of the workpiece to be inspected, the surface of the workpiece can be detected online, which greatly simplifies the detection process, making the speed, efficiency, and detection The depth is greatly deepened.

Owner:SICHUAN HUIZHENG PIPELINE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com