Method for operating resistor welding apparatus

A technology of resistance welding and triggering device, applied in welding monitoring device, welding power source, welding power source, etc., can solve problems such as high power loss, and achieve the effect of reducing power loss, improving system performance, and uniform magnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

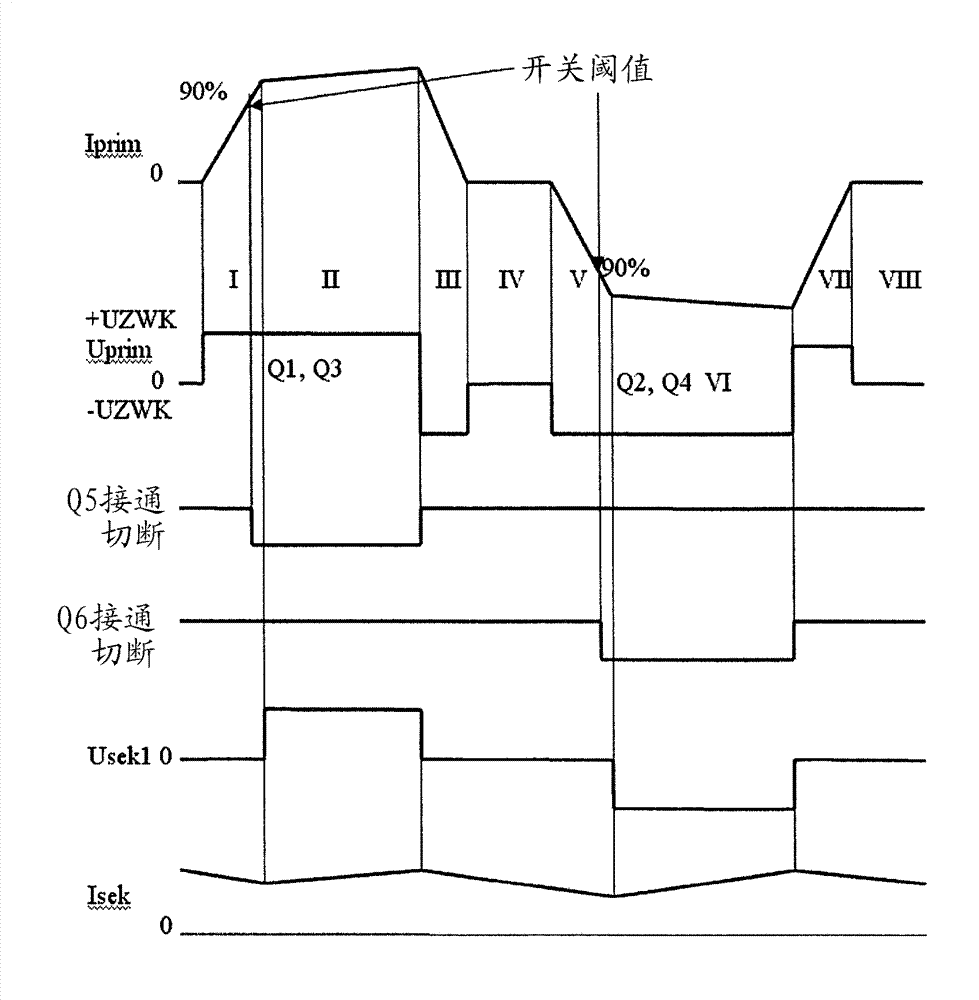

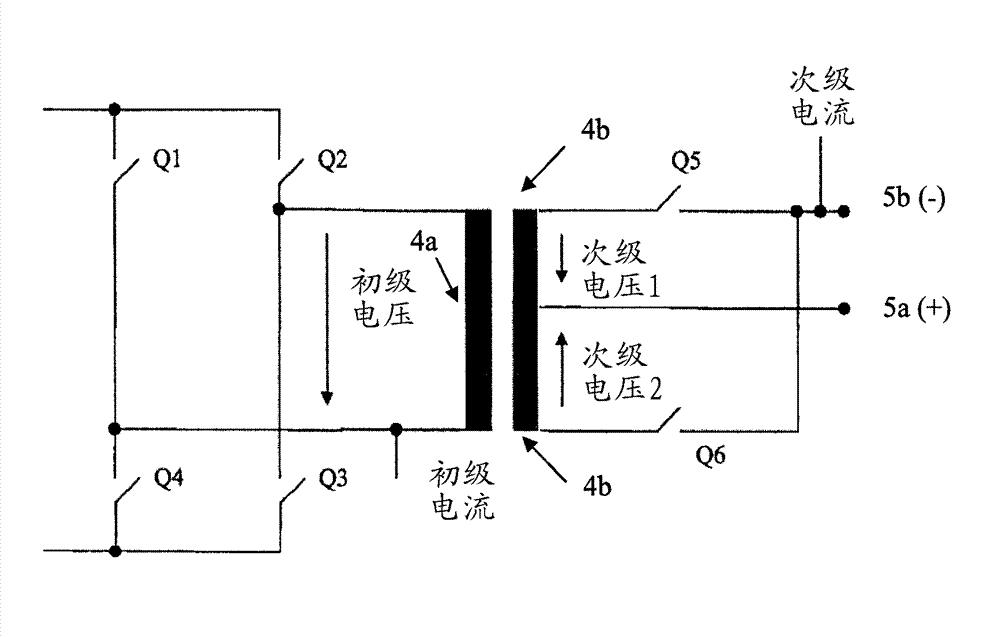

[0029] Figure 1 shows a full bridge together with a synchronous rectifier. Both are installed in resistance welding equipment (not shown).

[0030] The full bridge is shown on the left and comprises two bridge arms. The two bridge arms are at a DC voltage (not shown). Each bridge arm includes two switches Q1 , Q4 and Q2 , Q3 in the form of IGBTs. The IGBTs are triggered by means of pulse trains. In the bridge arm of the device there is the primary winding 4a of the welding transformer. The synchronous rectifier is shown on the right side of FIG. 1 . This synchronous rectifier comprises the two secondary windings 4b and 4c of said welding transformer. The two windings 4b, c are connected in series and have a center tap. In such an embodiment, the corresponding welding electrode 5 a is connected to the center tap, which welding electrode should have a positive potential (+) during the welding process. In this exemplary embodiment (positive potential at the center tap), th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com