Motor and motor manufacturing method

A manufacturing method and permanent magnet technology, applied in the manufacture of motor generators, stator/rotor bodies, electromechanical devices, etc., can solve problems such as unbalanced magnetization of permanent magnets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Reference will now be made in detail to the preferred embodiments of the present invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

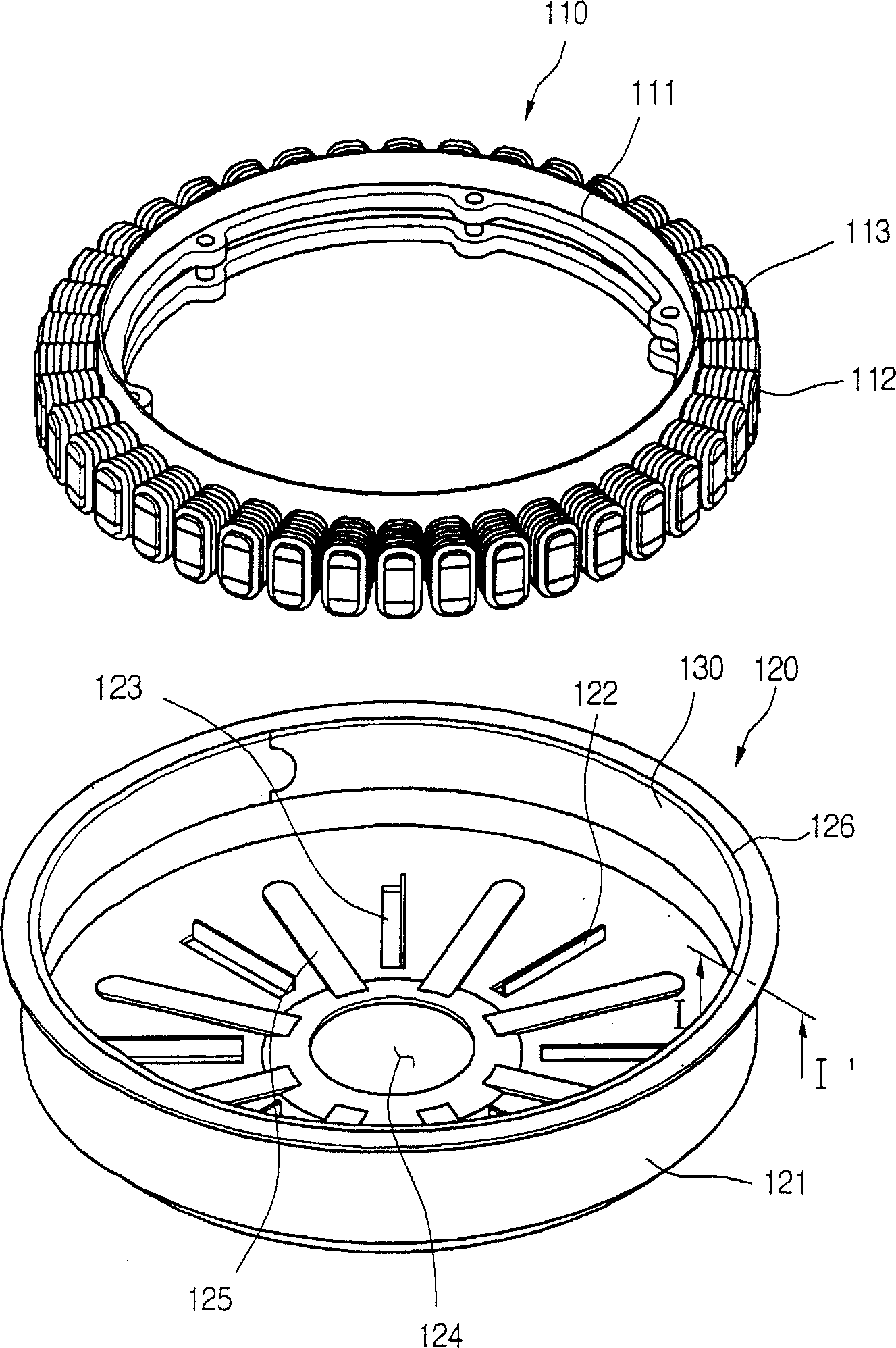

[0033] figure 1 is a perspective view of a disassembled motor according to the present invention.

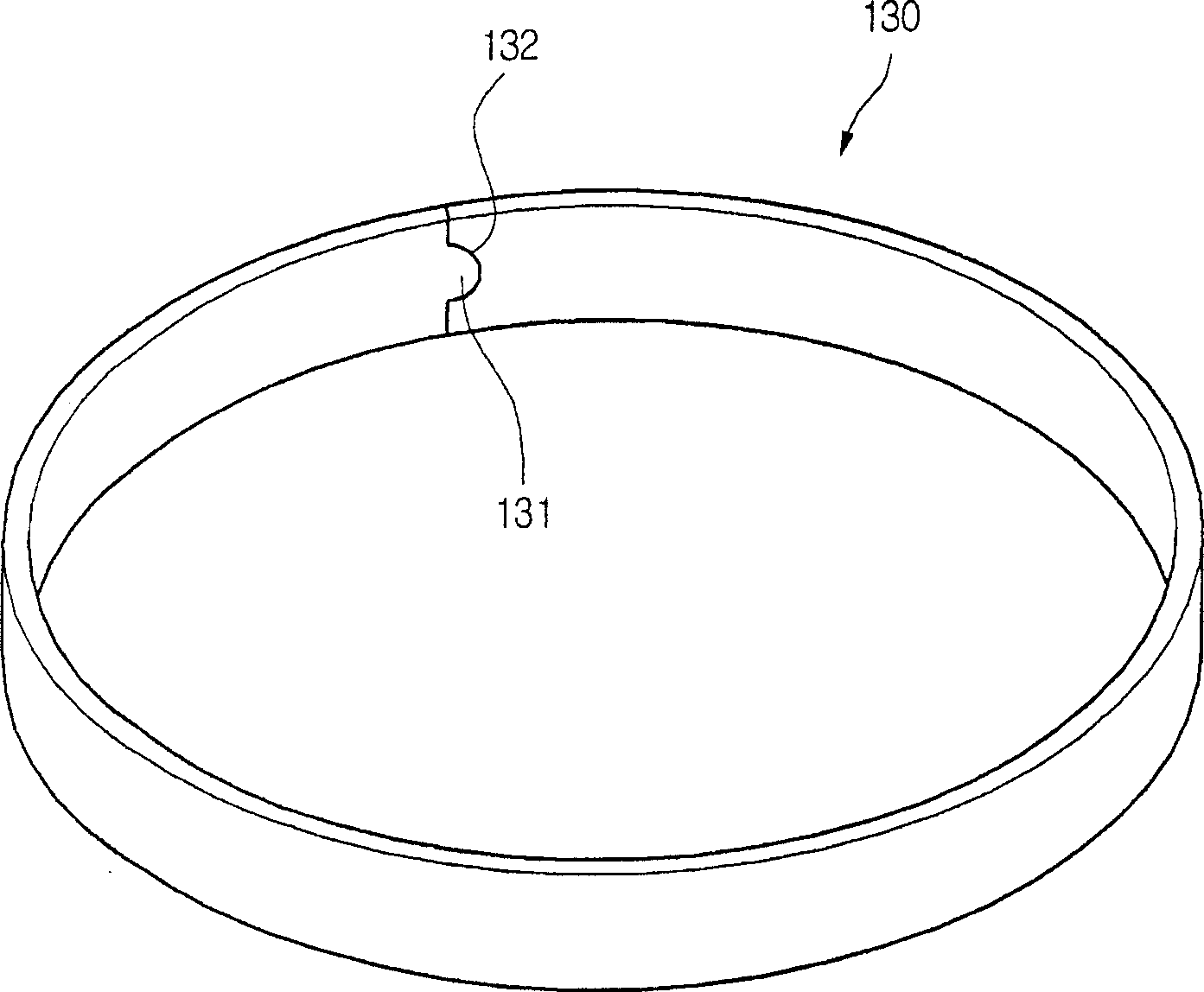

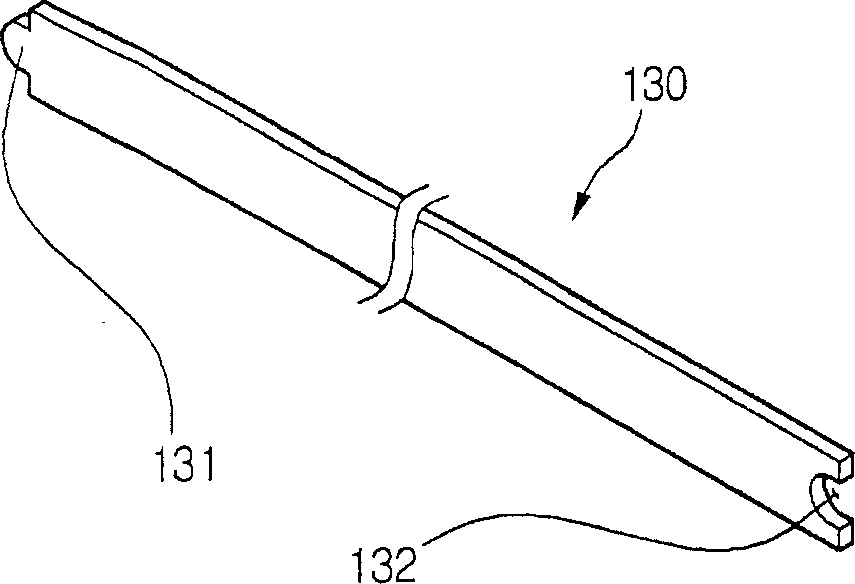

[0034] refer to figure 1 , The motor 100 according to the present invention includes: a stator 110 ; a rotor 120 rotating relative to the stator; and a permanent magnet 130 mounted to the rotor 120 .

[0035] In detail, the stator 110 is in a laminated form using magnets of approximately less than 1 mm. At this time, the number of laminations of magnets may be determined by the desired output of the motor 100 . The stator 110 includes a cylindrical yoke 111 and a plurality of winding portions 112 protruding from the yoke 111 .

[0036] More specifically, the winding portion 112 protrudes a prede...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com