Claw pole permanent magnet and electromagnetic hybrid excitation generator rotor production method

A technology of generator rotor and permanent magnet rotor, which is used in motors, manufacturing stator/rotor bodies, electric vehicles, etc., can solve the problems of low residual magnetic induction intensity, unstable output voltage, unadjustable magnetic field, etc., to ensure safety and reliability. Reliable use, stable output voltage, and high magnetic field utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

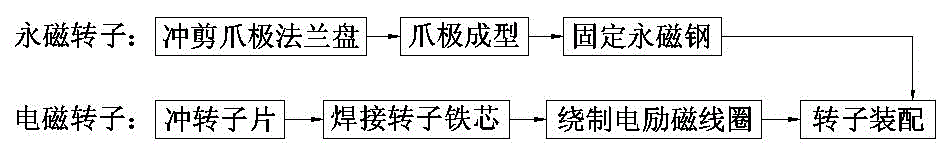

[0011] A method for producing a claw pole permanent magnet and electromagnetic hybrid excitation generator rotor, including permanent magnet rotor production, electric excitation rotor production, and rotor assembly, characterized in that:

[0012] The first step is the production of the permanent magnet rotor: the steel plate is punched and cut into claw-pole flanges, and then the claw-pole flanges are bent into claw poles, and the magnetic isolation bushing with positioning grooves is pressed on the On the shaft, the front claw poles are set on the magnetic isolation bushing with positioning grooves, the claws of the front claw poles face upward, and the axially magnetized circular permanent magnet steel is set on the magnetic isolation bushing, and then the rear The claw poles are set on the magnetic isolation bushing with positioning slots, the claws of the rear claw po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com