Selection actuator for knitting member

A technology of woven parts and actuators, which is applied in weft knitting, knitting, textiles and papermaking, etc., which can solve the problems such as difficult to reliably select woven parts, and achieve the effects of small changes in magnetic impedance and uniform magnetization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

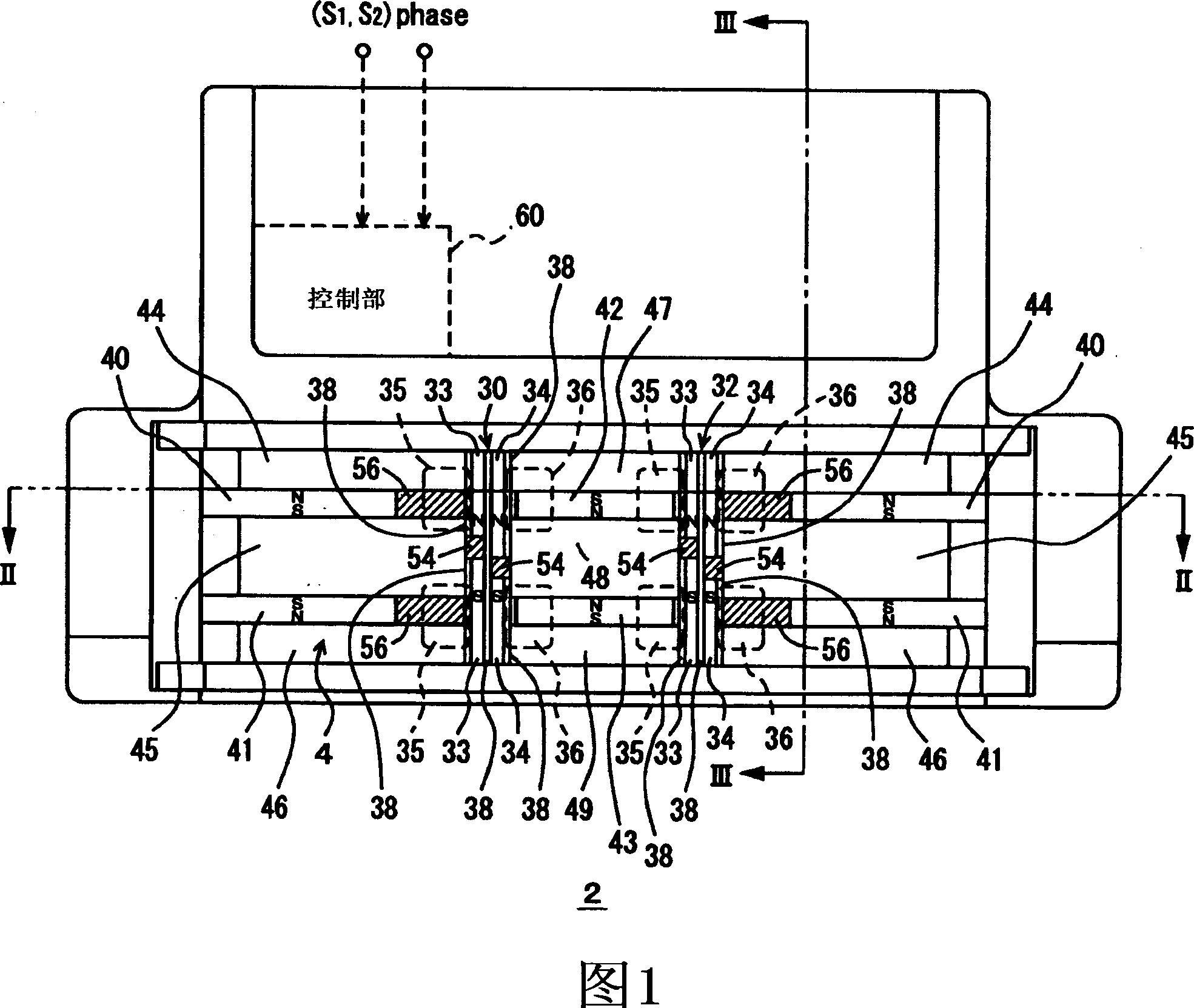

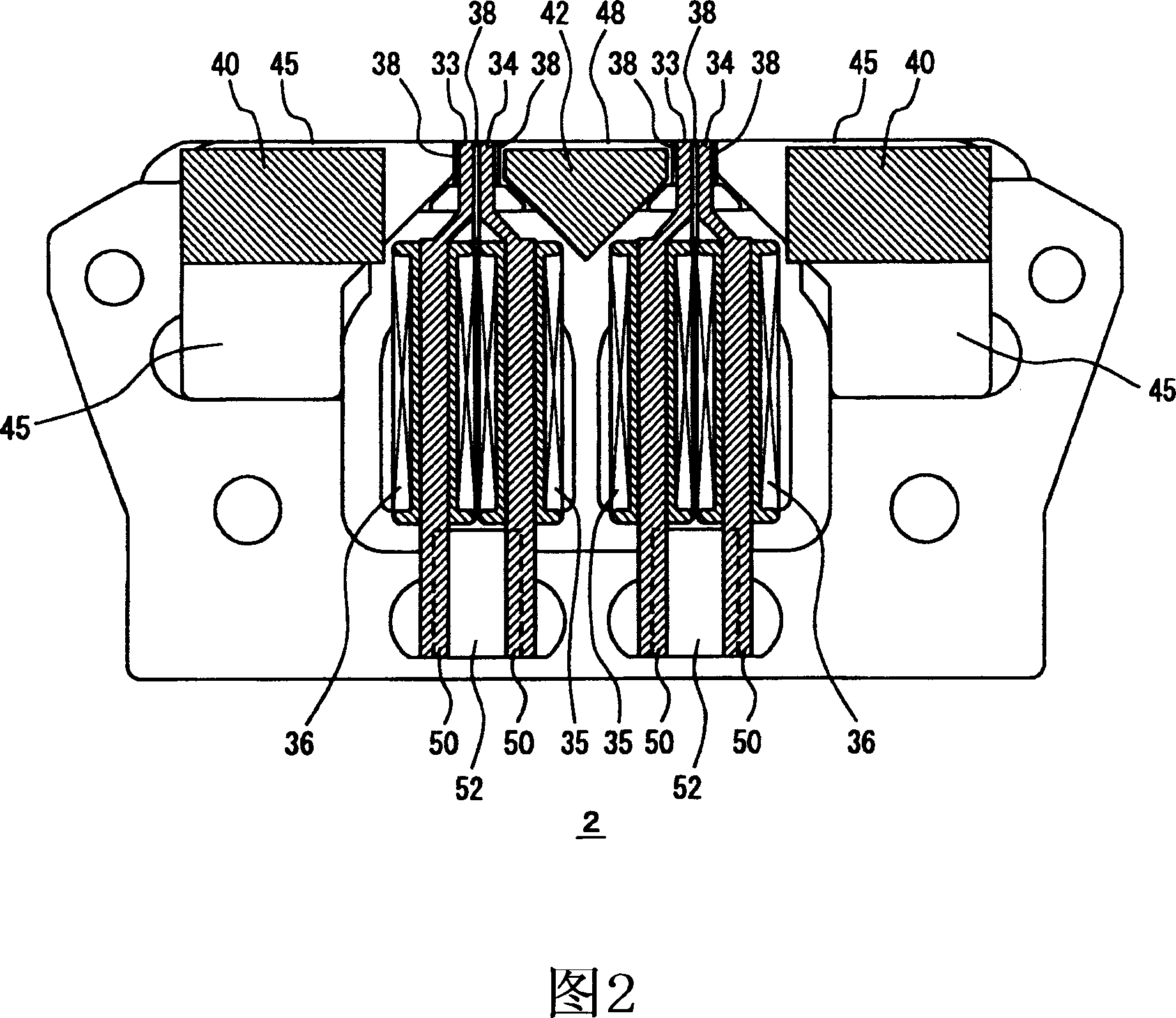

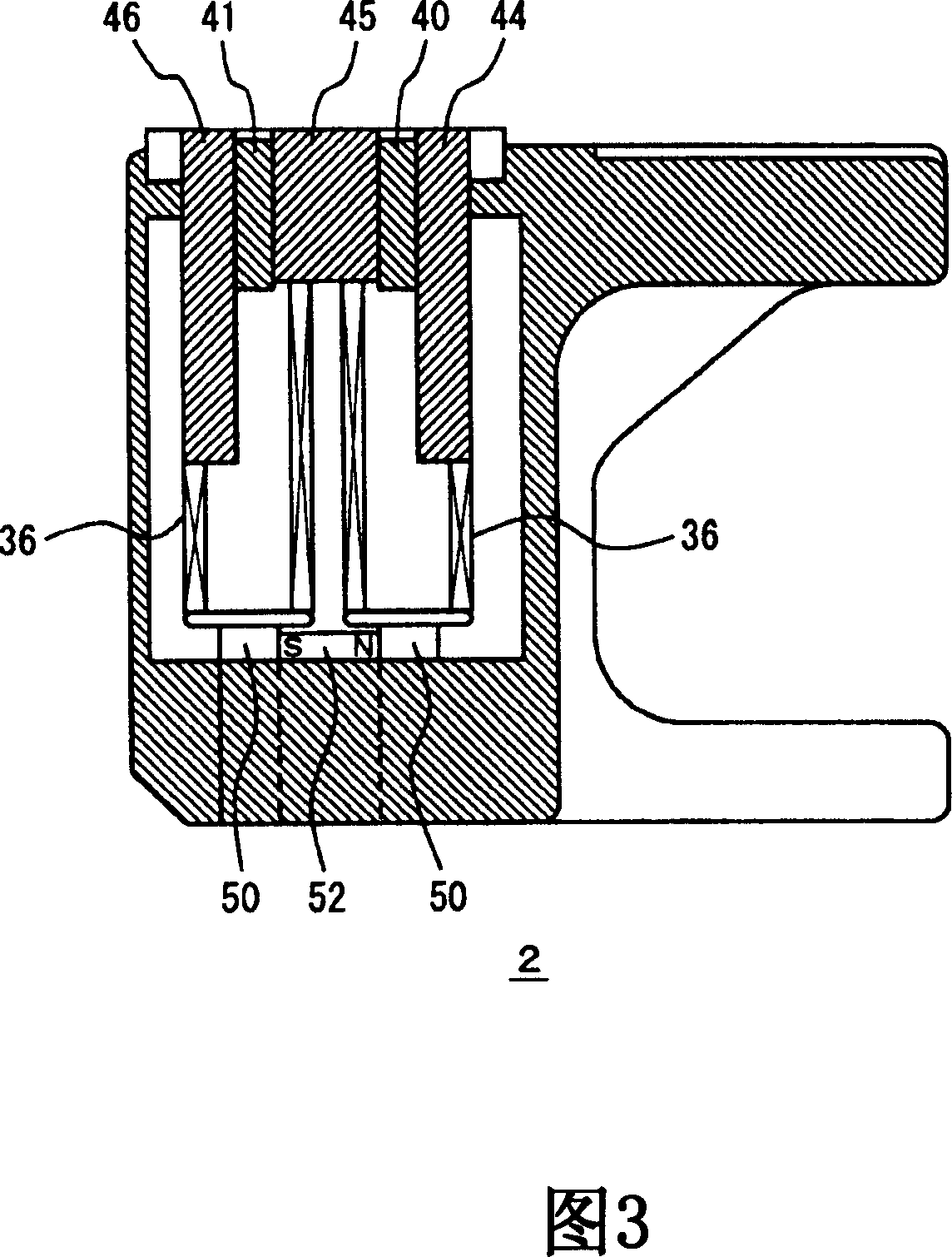

[0077] 1 to 11 show the selective actuator 2 of the embodiment and its modification. The selection actuator 2 has an acting part 4 on the upper surface, and selects the selector jack of the knitting needle of the flat knitting machine, and selects the knitting needle to which the cam of the carriage carriage acts and the knitting needle that is not to act. The relationship between the knitting needle 6 and the selection actuator 2 is shown in FIG. 8. 7 is the foot piece, 8 is the needle selection foot piece, 10 is the needle selection piece, they are part of the knitting needle 6. 12 is a butt provided on the selector jack 10. The selector jack 10 is forced upward in FIG. 8 by the elastic foot 14, and the armature 16 of the selector jack 10 is selected by the selection actuator 2. The knitting needles 6 are housed in the needle bed 18, the carriage 20 moves relative to the needle bed 18, and the selection actuator 2 is installed on the carriage 20. 21 and 22 are metal belts set on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com