Patents

Literature

106results about How to "Improve magnetization efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

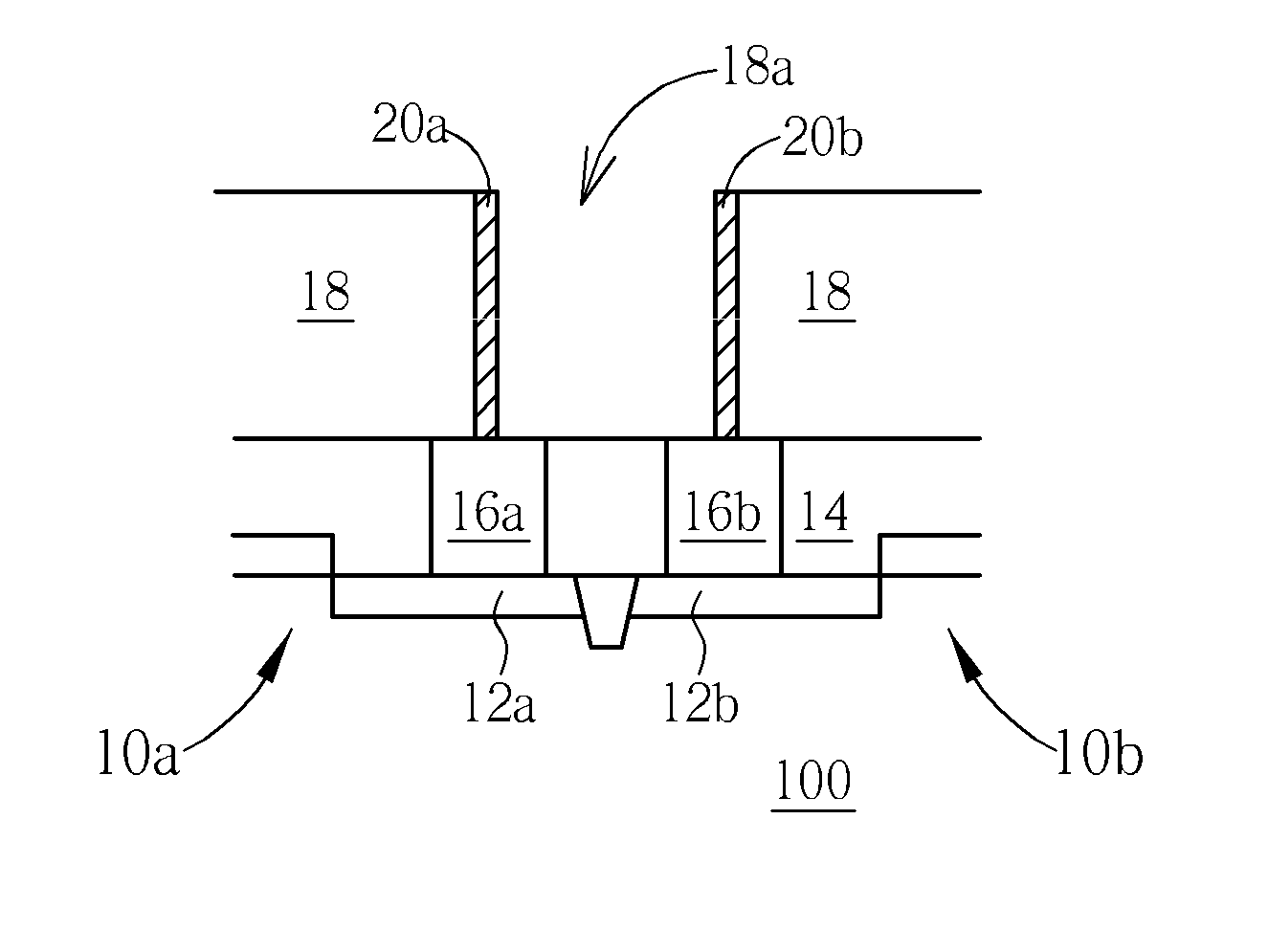

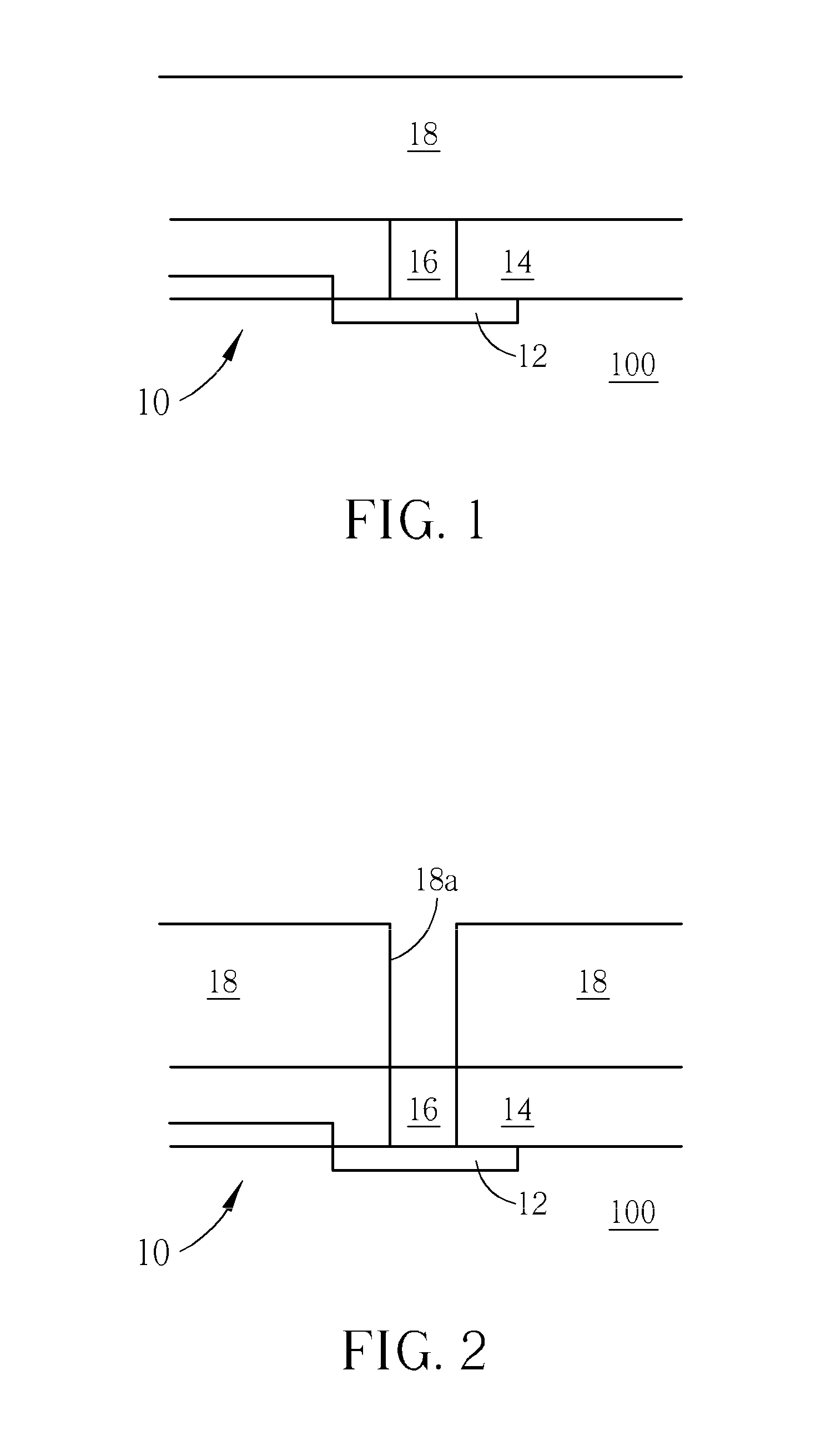

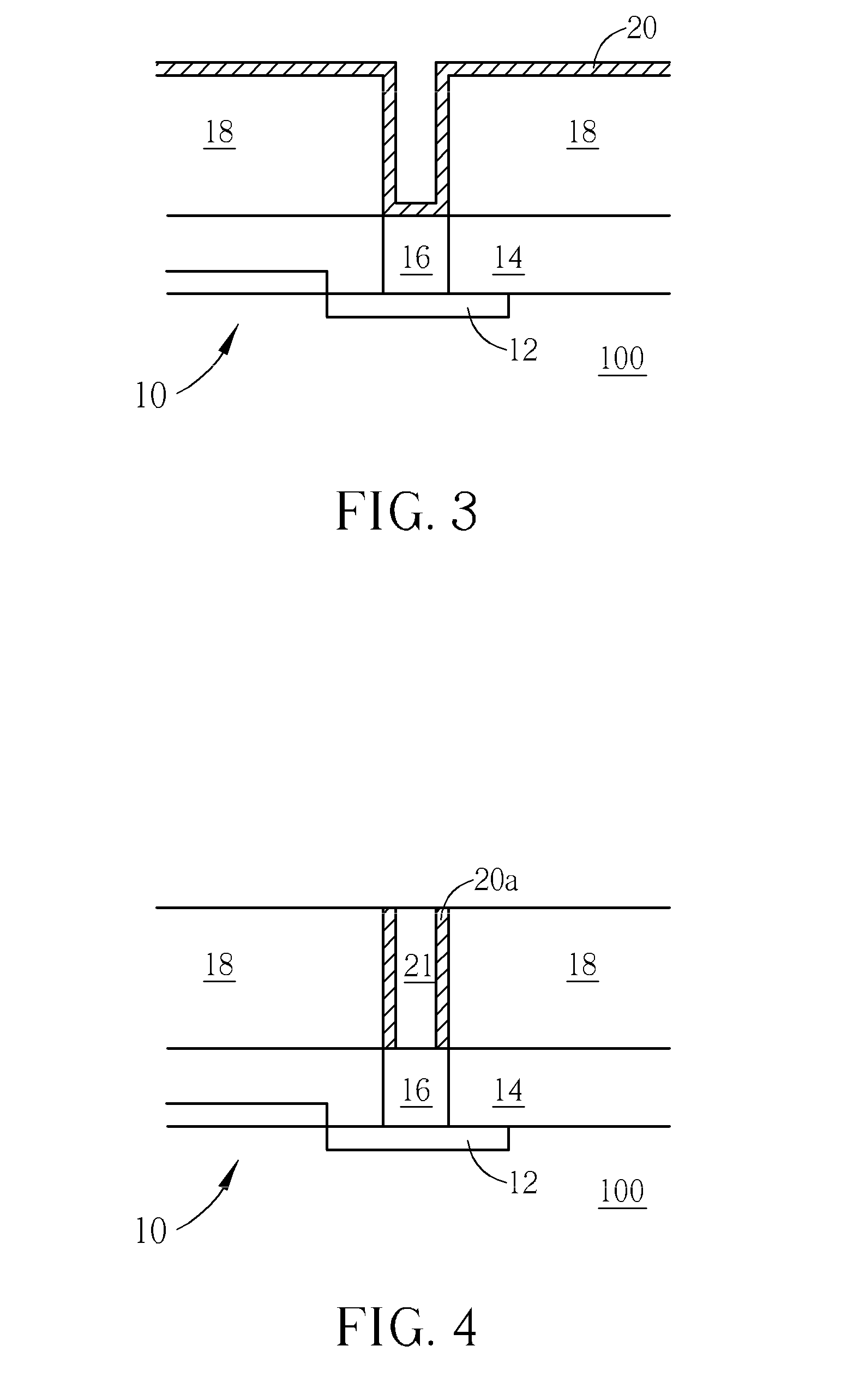

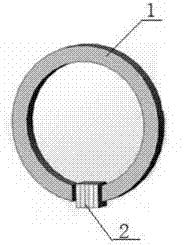

Magnetoresistive random access memory element and fabrication method thereof

ActiveUS20110241138A1Improve magnetization efficiencyNanomagnetismMagnetic-field-controlled resistorsFilling materialsMagnetic reluctance

A magnetoresistive random access memory (MRAM) element includes a bottom electrode embedded in a first insulating layer; an annular reference layer in a first via hole of a second insulating layer on the first insulating layer, the annular reference layer being situated above the bottom electrode; a first gap fill material layer filling the first via hole; a barrier layer covering the annular reference layer, the second insulating layer and the first gap fill material layer; an annular free layer in a second via hole of a third insulating layer on the second insulating layer, the annular free layer being situated above the annular reference layer; and a top electrode stacked on the annular free layer.

Owner:NAN YA TECH

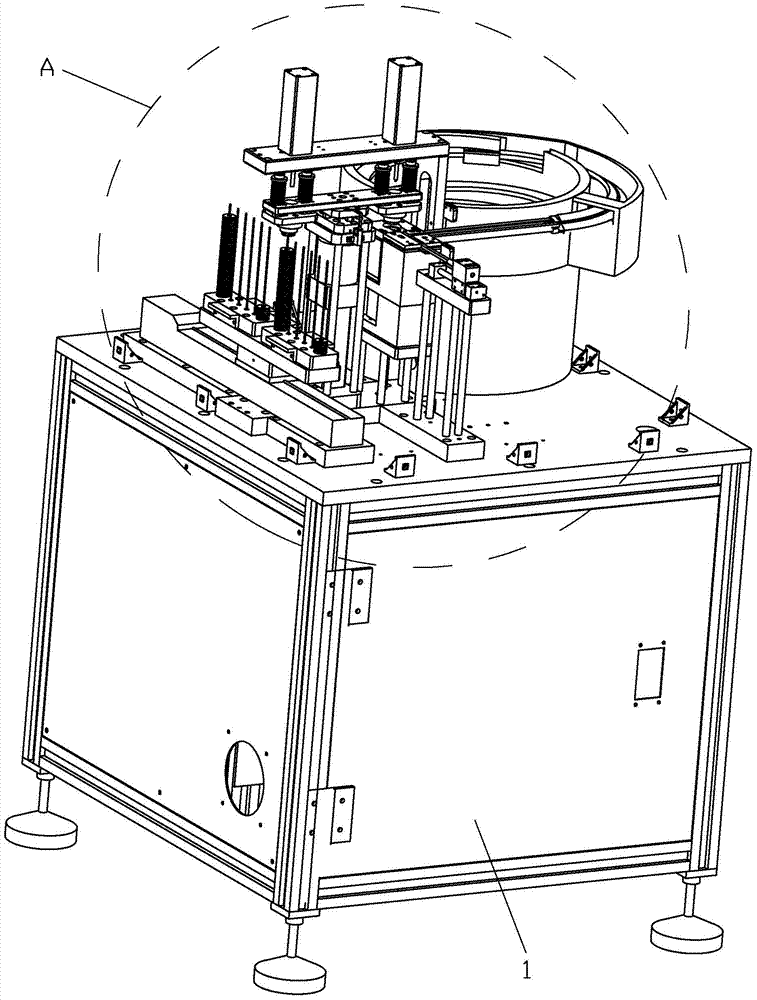

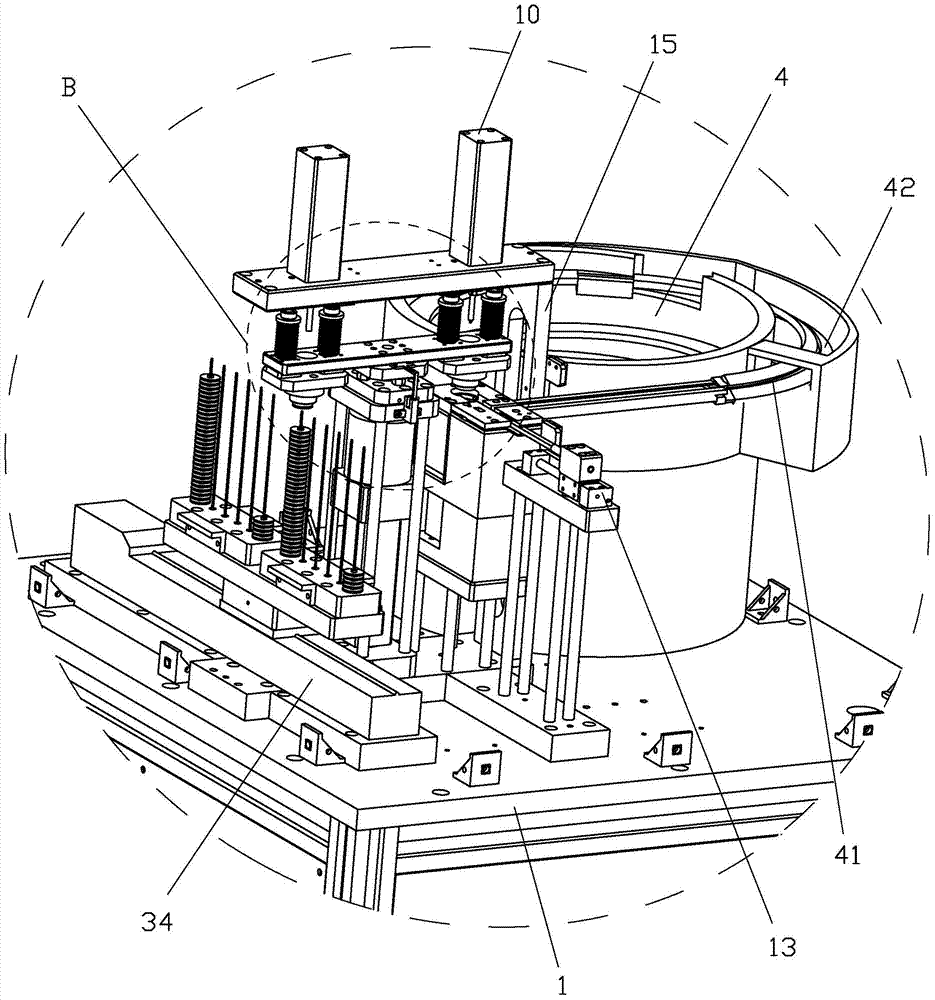

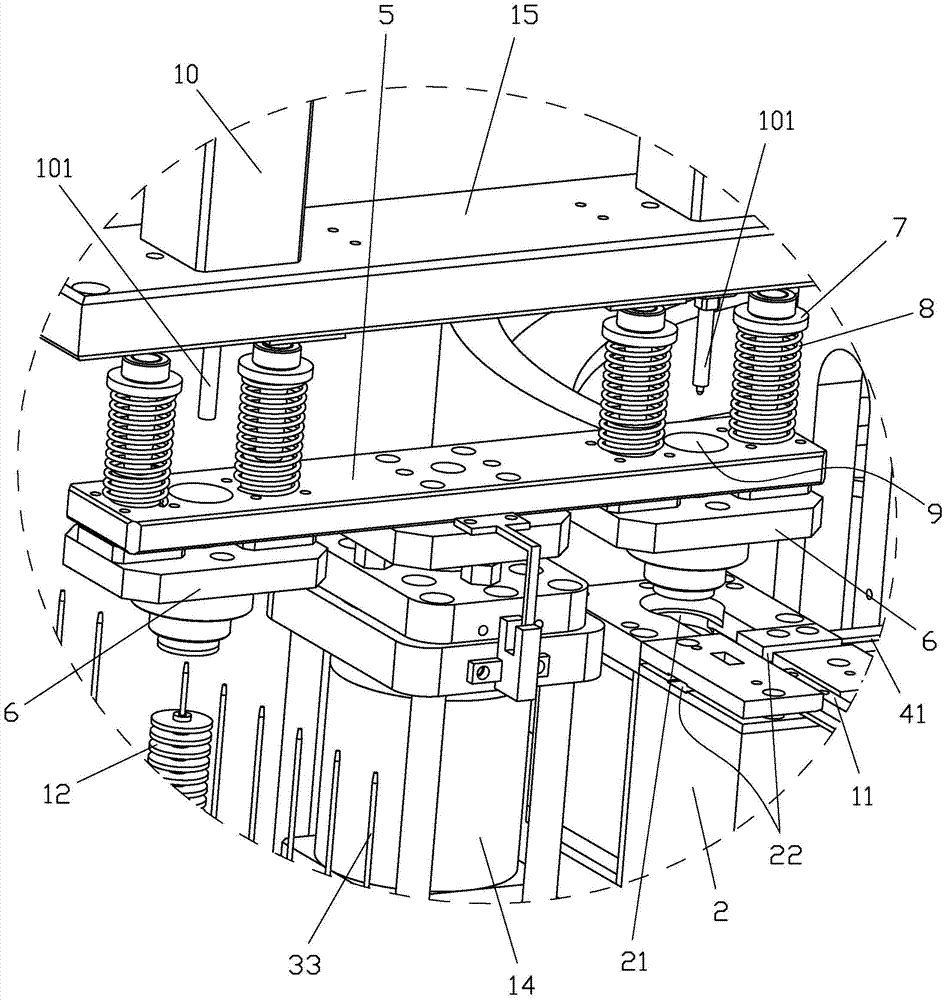

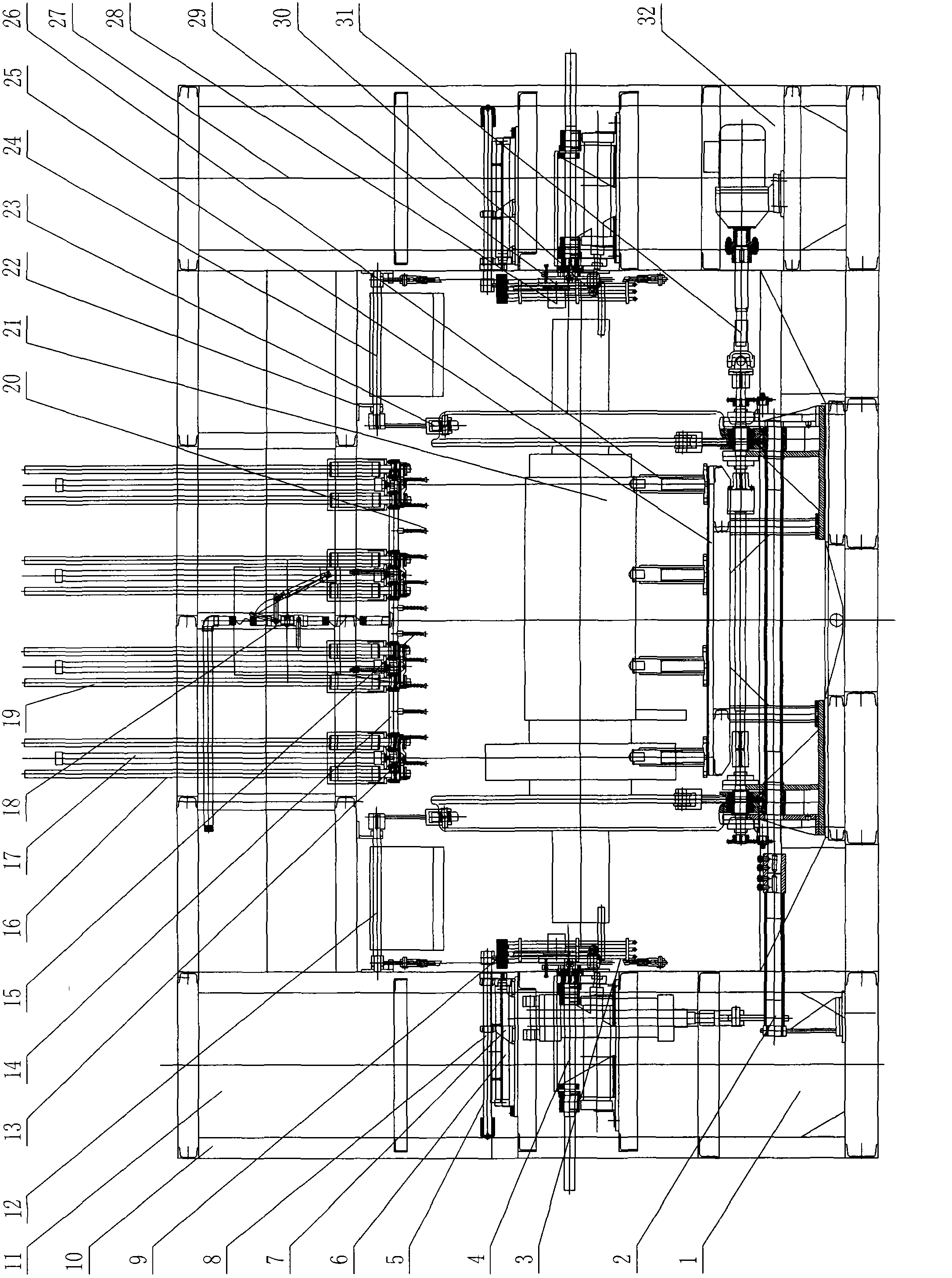

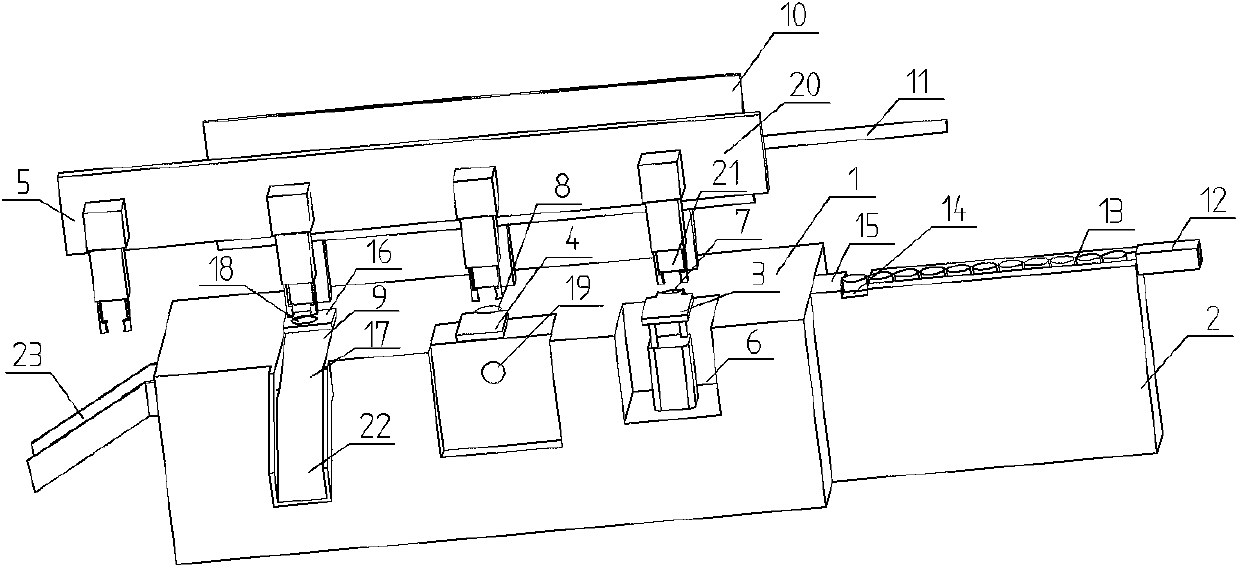

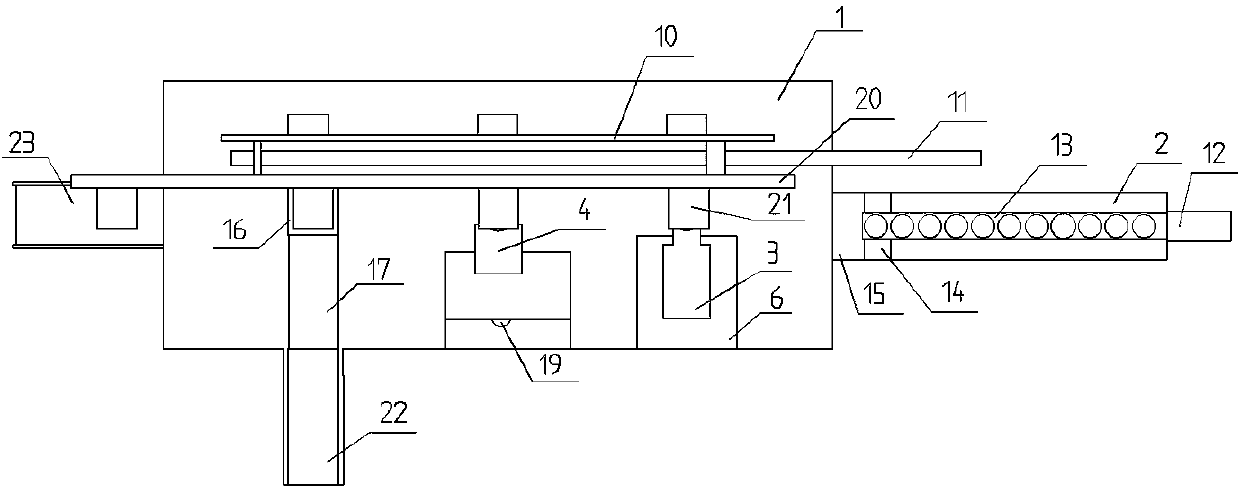

Multi-pole magnetic ring magnetizing equipment with full-automatic feeding, discharging and magnetizing functions

InactiveCN103680810ARealize automatic feedingFully automatedMagnetic bodiesJigging conveyorsEngineeringWork force

The invention discloses a set of multi-pole magnetic ring magnetizing equipment with the full-automatic feeding, discharging and magnetizing functions. A magnetic ring can be automatically fed through a vibrating feeding machine, through the arrangement of a rotating plate and a pushing oil cylinder, when a magnetizing head is made to be located above a magnetizing hole, after a push rod of the pushing oil cylinder acts to penetrate through a through hole in the rotating plate, the magnetizing head is pushed to fall into the magnetizing hole, the magnetic ring in the magnetizing hole can be magnetized automatically, meanwhile, after the push rod of the pushing oil cylinder located above a material collecting table acts to penetrate through the through hole of the rotating plate and a through hole in the magnetizing head, the magnetic ring attracted to the bottom end of the magnetizing head is pushed away from the magnetizing head, and thus automatic discharging is achieved. The manual feeding, magnetizing and discharging method in the traditional technology is abandoned, full-automatic feeding, magnetizing and discharging of the magnetizing equipment are achieved, the magnetizing efficiency is greatly improved, and labor cost is reduced. The multi-pole magnetic ring magnetizing equipment is simple, reasonable and compact in structure, convenient to install and easy to implement and can meet industry development requirements better.

Owner:江门协立磁业高科技有限公司

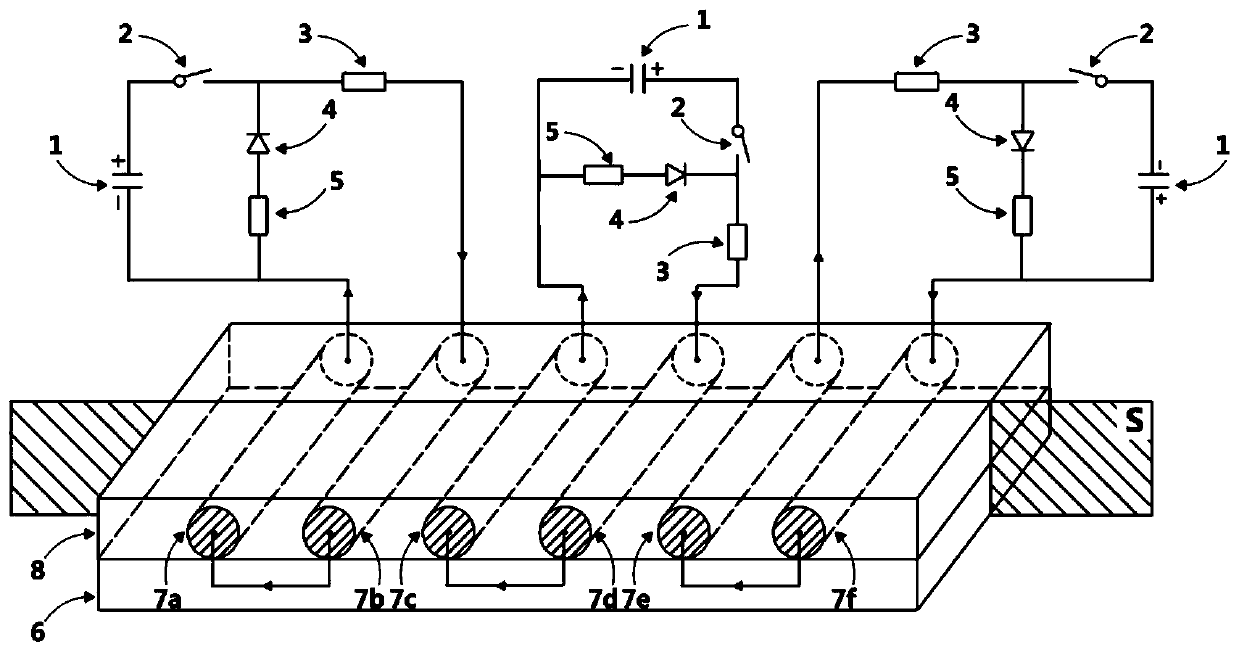

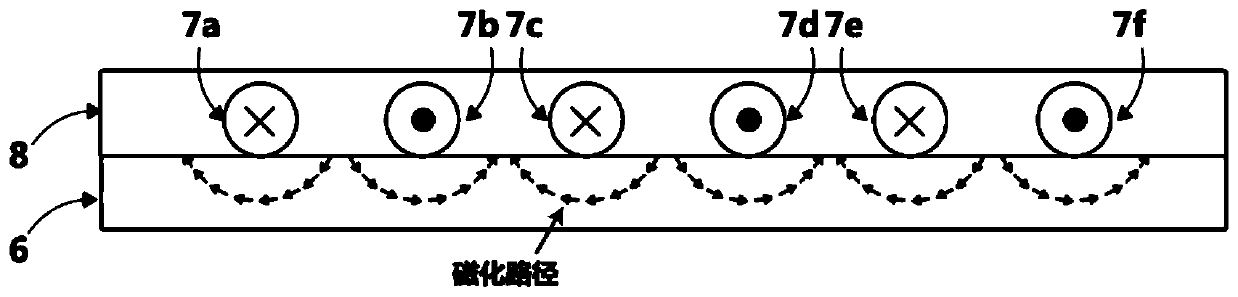

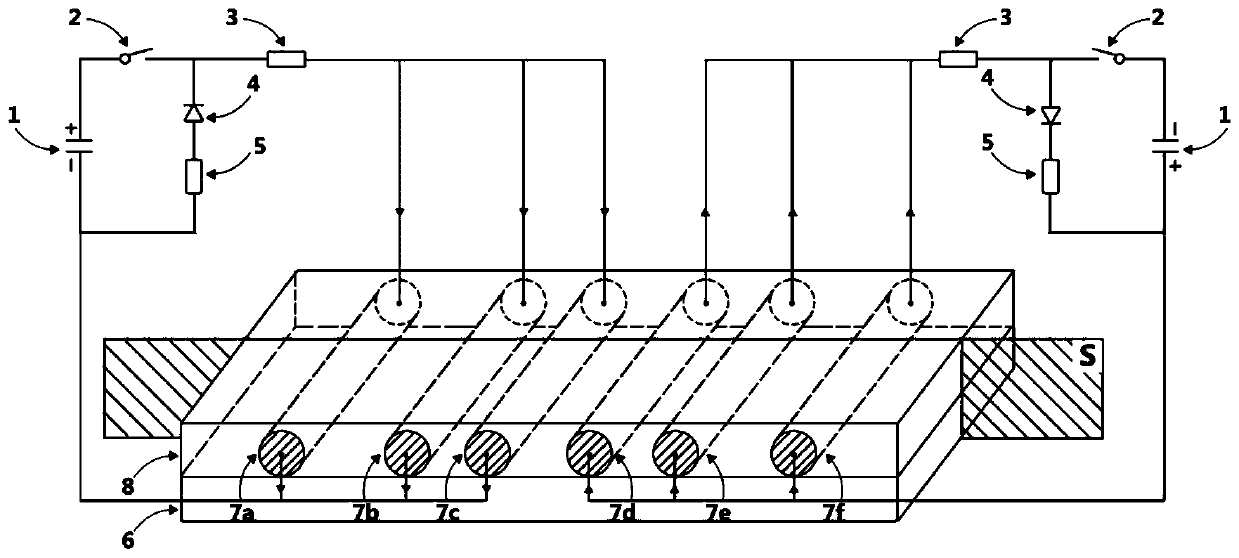

Device and method of regulating and controlling internal magnetization characteristics of magnetic soft robot

The invention discloses a device and a method of regulating and controlling internal magnetization characteristics of a magnetic soft robot. The device comprises a power supply system and an excitation system, wherein the power supply system is used for providing pulse current for the excitation system, and the excitation system controls pulse type magnetization or amplitude reduction oscillationtype demagnetization of the magnetic soft robot through the pulse current. The method comprises the steps: according to a target magnetization path in the magnetic soft robot, the spatial layout of anexcitation unit is determined, a fixing component corresponding to the excitation unit is designed, and the excitation unit is embedded into the fixing component; and under the condition that charging of a discharging capacitor is completed, the discharging switch is triggered to be switched on, a space magnetization magnetic field is generated, and therefore magnetization or demagnetization happens in the magnetic soft robot. According to the device and the method of regulating and controlling internal magnetization characteristics of the magnetic soft robot provided in the invention, distribution of the space magnetization magnetic field is controlled by changing the excitation unit, so that regulation and control of the internal magnetization path of the robot are achieved, and the flexibility of regulation and control of the magnetization path of the magnetic soft robot is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

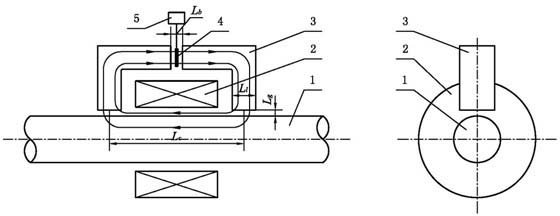

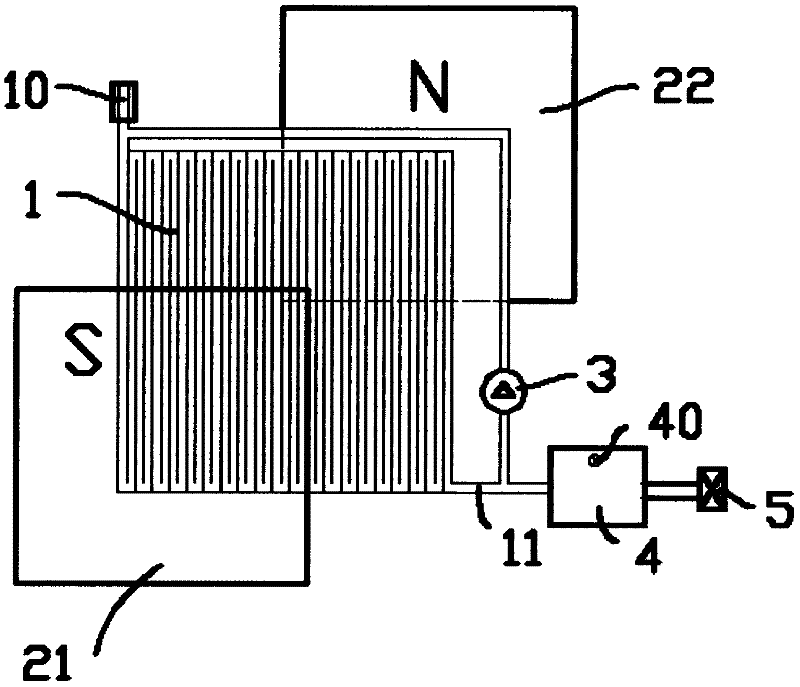

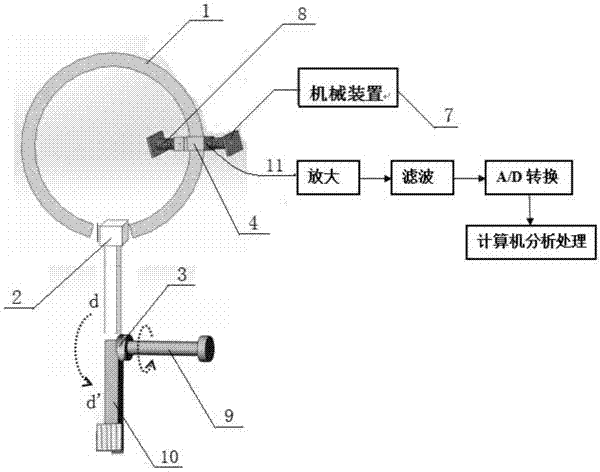

Ferromagnetic cable metal cross-sectional area loss detection method and device

InactiveCN102269734AReduce volumeEasy to adjustMaterial magnetic variablesMagnetic sourceVoltage variation

The invention discloses a method and device for detecting loss of metal cross section area of a ferromagnetic cable rope. The method provided by the invention comprises the following steps of: winding a cable which is connected with a direct-current power supply on a detected cable rope to be used as a direct-current magnetizing coil; distributing an armature group and a magnetism-sensitive element along the circumferential direction of the cable rope; switching on a direct-current power supply and magnetizing the cable rope by a direct-current coil to form a magnetic circuit with the armature group; measuring a magnetic induction intensity value in the circuit by the magnetism-sensitive element which is placed in the magnetic circuit and outputting the value in the form of voltage; obtaining a measuring coefficient through comparing the change of voltages which are output by the magnetism-sensitive element before and after a standard sample is inserted so that the detection of the loss of the metal cross section area of the cable rope is realized. The device provided by the invention comprises the magnetism-sensitive element, the magnetizing coil, a data processor and one or morearmature groups; and each armature group is composed of two symmetrical inverted-L-shaped armatures. By utilizing a way of internally placing a magnetic source, a magnetic field generated by the magnetizing coil is directly acted on the detected cable rope so that a magnetic system needed by the detection method has the advantages of small volume, light weight and convenience for adjusting.

Owner:HUAZHONG UNIV OF SCI & TECH

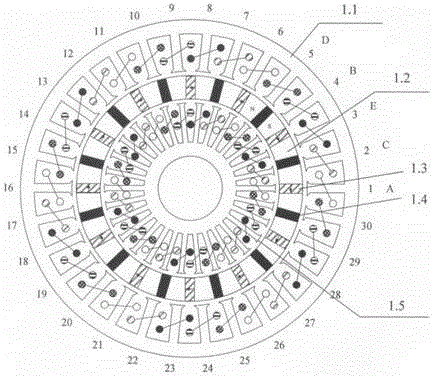

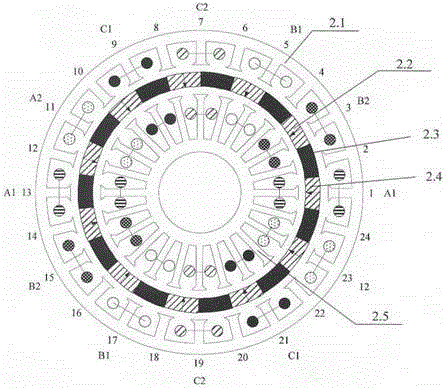

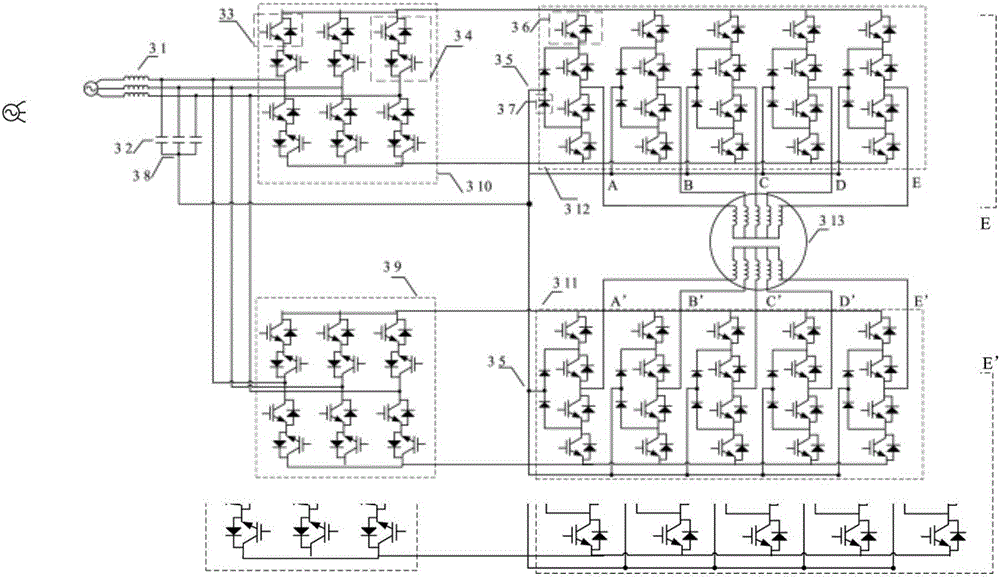

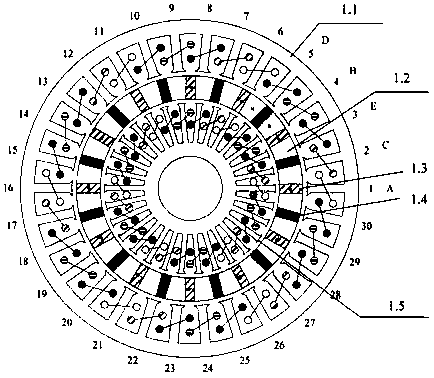

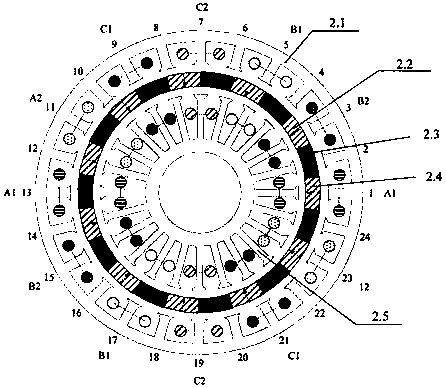

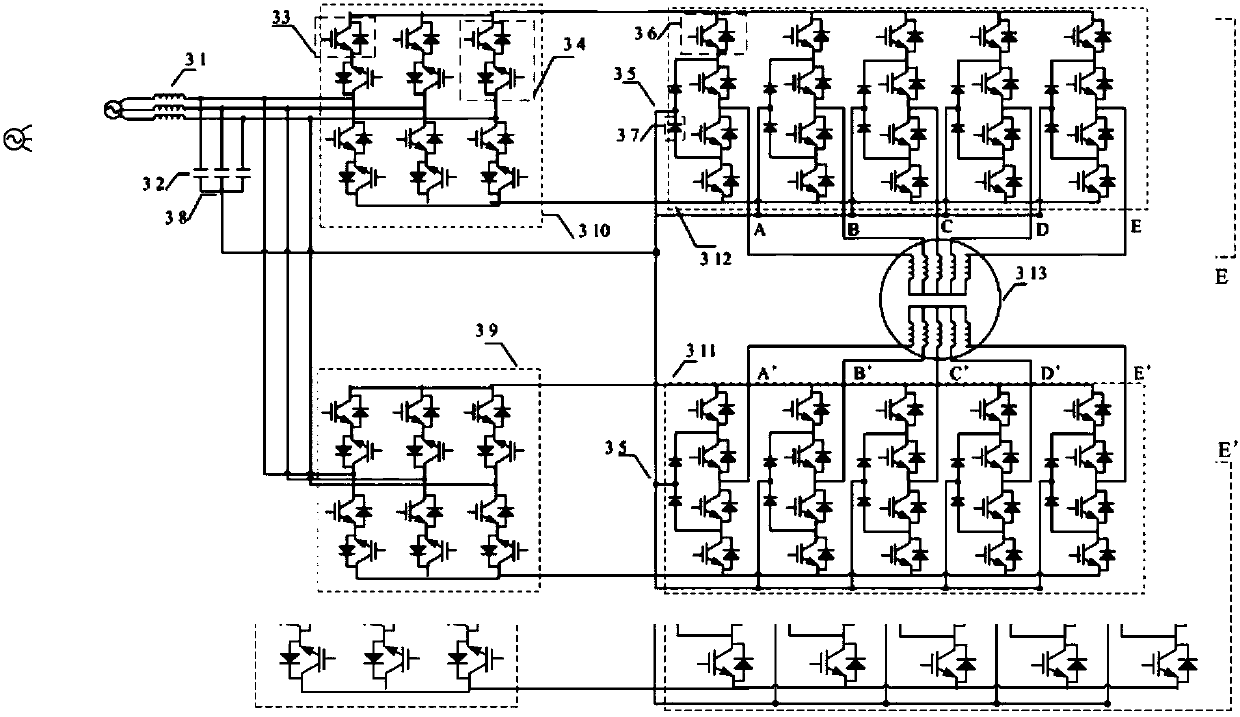

Indirect matrix transformation type multi-phase multi-level permanent magnet motor system and control method thereof

ActiveCN105896856AImprove torque rippleMeet the requirements of compact designElectronic commutation motor controlAC motor controlThree levelPermanent magnet synchronous motor

The invention discloses an indirect matrix transformation type multi-phase multi-level permanent magnet motor system. The indirect matrix transformation type multi-phase multi-level permanent magnet motor system includes a double-stator multi-phase composite permanent magnet synchronous motor, wherein two independent five-phase three-level inverters supplies power for stator winding ports of the motor respectively; an independent controllable rectifier supplies power for each five-phase three-level inverter; the two controllable rectifiers can share one set of LC filter at the power grid side; the LC filter includes a three-phase grid-connected inductor and a three-phase filter capacitor which is connected with the three-phase grid-connected inductor in parallel; and the first five-phase three-level inverter and the second five-phase three-level inverter are respectively connected with the two stator winding ports of the double-stator multi-phase composite permanent magnet synchronous motor. The invention also discloses a control method of the indirect matrix transformation type multi-phase multi-level permanent magnet motor system. The indirect matrix transformation type multi-phase multi-level permanent magnet motor system and the control method thereof can significantly improve reliability, power density, torque smoothness and operation efficiency of the motor driving system, and can lay the foundation of solving the technical difficulty that a high capacity motor traction driving system requires compact designs, reliable operation and energy-efficient aspects.

Owner:SOUTHEAST UNIV

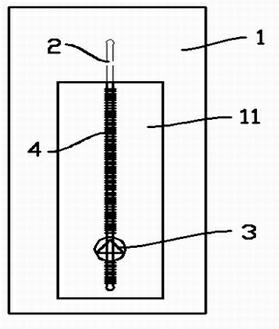

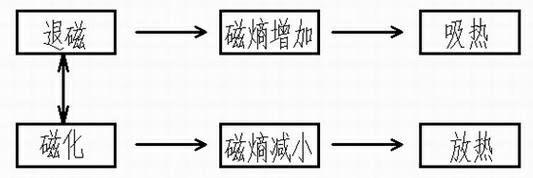

Electromagnetic refrigerating refrigerator

InactiveCN102331132AReduce volumeDemagnetizationLighting and heating apparatusDomestic refrigeratorsEngineeringHome appliance

The invention provides an electromagnetic refrigerating refrigerator, and belongs to household appliances; the refrigerator comprises a shell, a metal circulating pipeline section is arranged on the shell, a part of the circulating pipeline is arranged at the interior of the shell, and the other part of the circulating pipeline is arranged on the exterior of the shell; the external part of the shell is composed of an iron tube, the internal part of the shell is composed of a copper pipe or an aluminum pipe, the circulating pipeline is filled with a magnetic fluid, and the circulating pipeline is connected with a circulating pump in series; the circulating pipeline arranged on the exterior of the shell is wound with a solenoid, and a heat dissipation gap is left among circles of wires in the solenoid; and the refrigerator provided by the invention has the advantages that the refrigerator utilizes a magnetic refrigeration principle to refrigerate, the refrigerator has no refrigeration noise, the stoppage is not easy to occur, the volume is small, and the magnetizing efficient is high.

Owner:SUZHOU JIAYAN ENERGY EQUIP

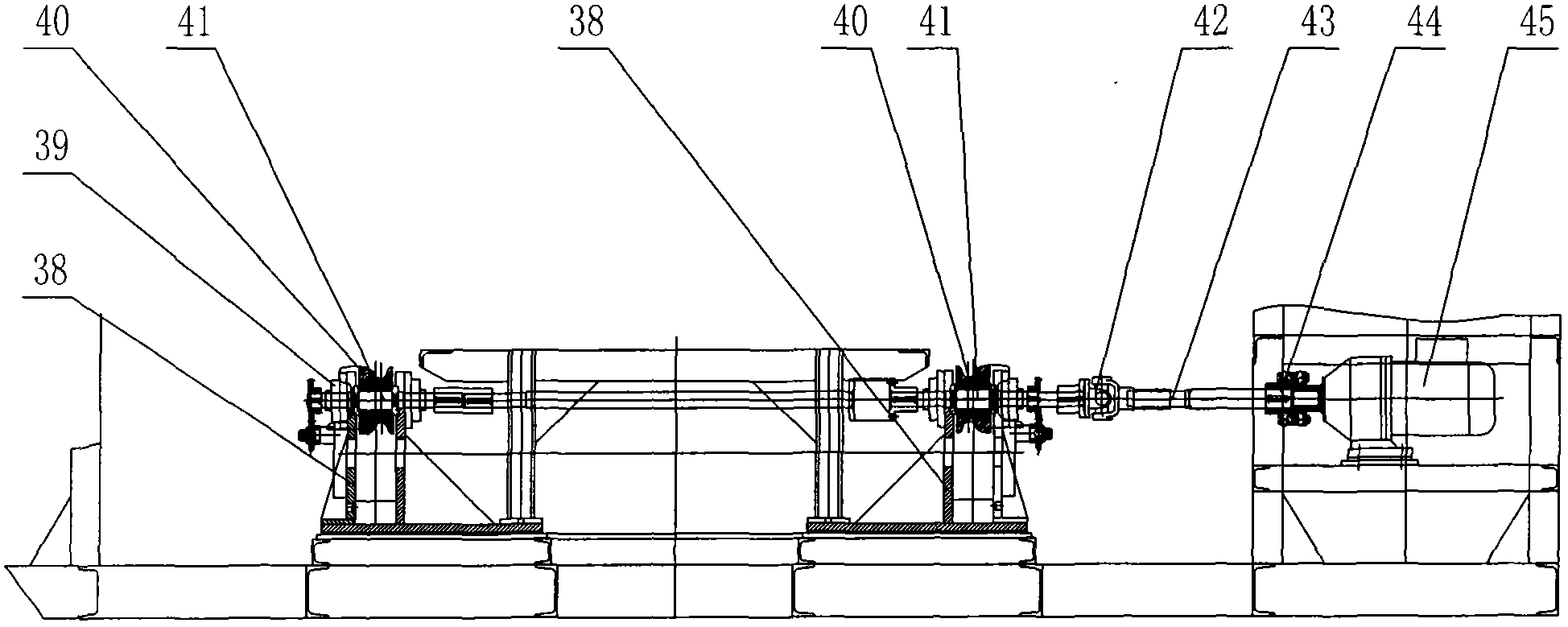

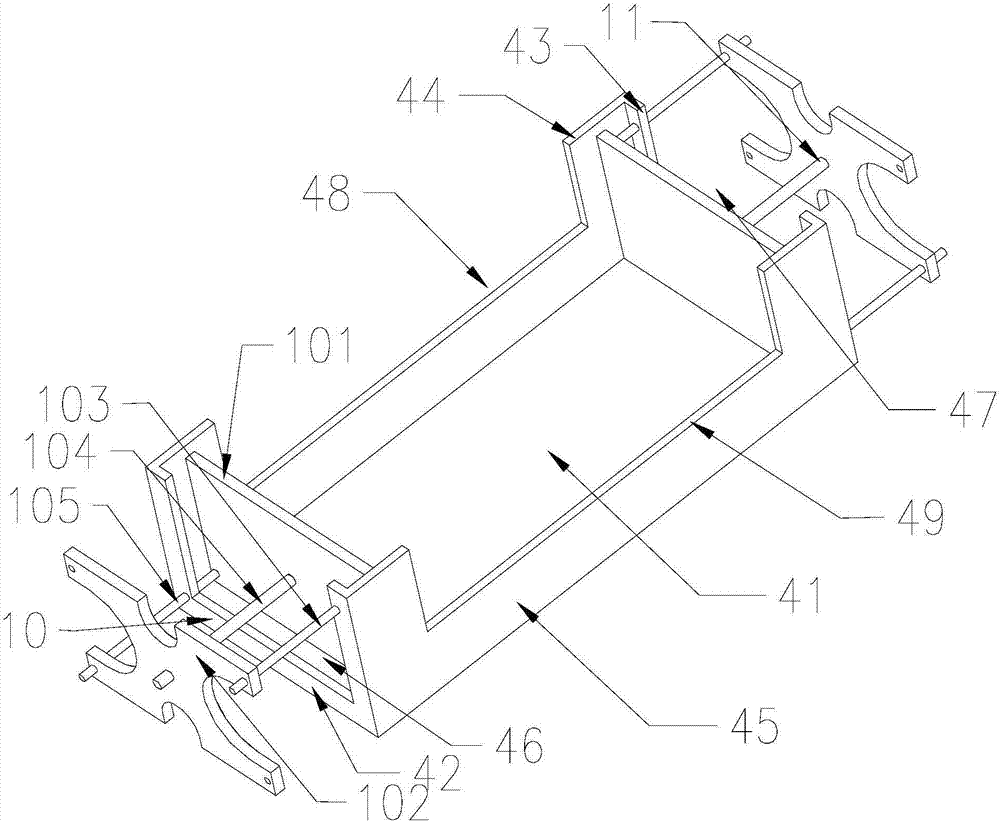

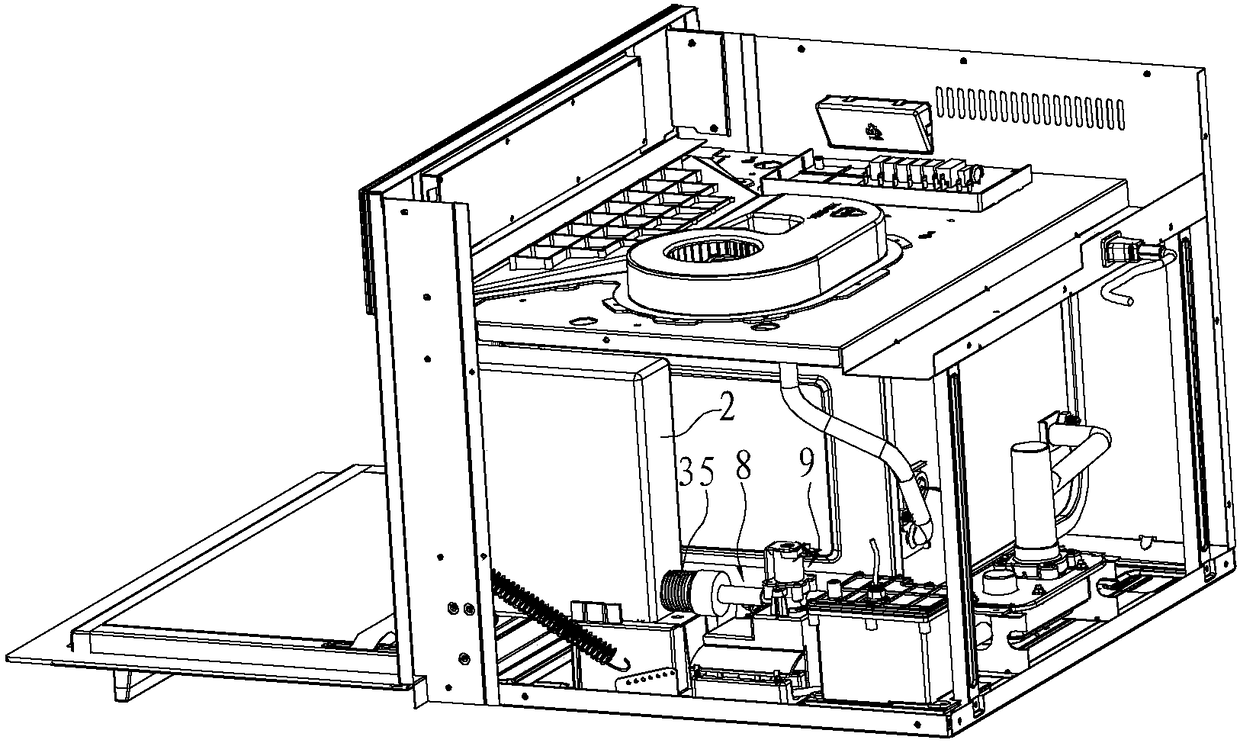

Retractable coil magnetic particle flaw detector with compatible wheel diameter

InactiveCN103675092AAutomatically balance contact pressureAvoid unreliable phenomenaMaterial magnetic variablesNon destructiveMagnetic tension force

The invention discloses a retractable coil magnetic particle flaw detector with a compatible wheel diameter, and belongs to non-destructive magnetic inspection equipment. A programmed control system cabin, a coil movement device, an electrode clamping device, a centering device and a peripheral magnetization current source are sequentially arranged on the left side surface of a frame from top to bottom; an industrial personal computer system cabin, a coil movement device, an electrode clamping device, a centering device and a longitudinal magnetization current source are sequentially arranged on the right side surface from top to bottom; dual rows of retractable coils with compatible wheel diameters are arranged above and below a workpiece; a main spray device is arranged on the side surface of the workpiece; a roller rotation device is arranged below a pair of wheel hubs of the workpiece; a feed and discharge device is arranged on the outer side of the roller rotation device. The retractable coil magnetic particle flaw detector is arranged between two wheel hubs of a wheel shaft; dual rows of retractable coils are adopted, and the compatibility is good. A bridge self-floating device is adopted, the contact pressure between contacts can be automatically balanced, and the phenomenon of unreliable individual contacts is avoided. The magnetic particle flaw detector is good in compatibility, high in magnetization efficiency, high in flaw detection sensitivity, accurate to locate, simple in structure, and low in construction cost.

Owner:射阳县无损检测技术研究所

Magnetostatic field magnetizing device and method at normal temperature

ActiveCN105161251AImprove magnetization efficiencyReduce energy consumptionMagnetic bodiesConveyor partsEngineeringMagnetostatics

Owner:天津博雅全鑫磁电科技有限公司

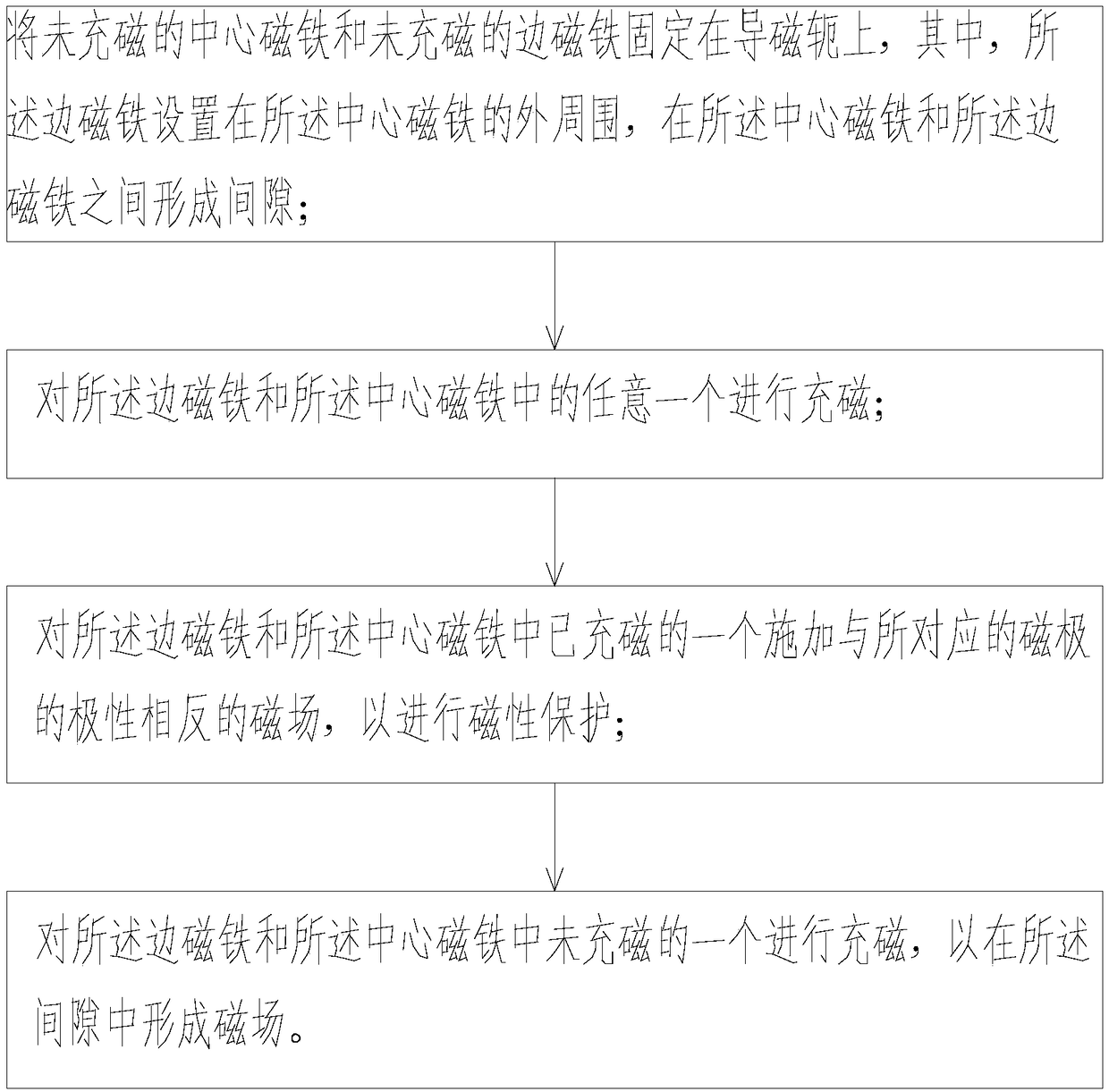

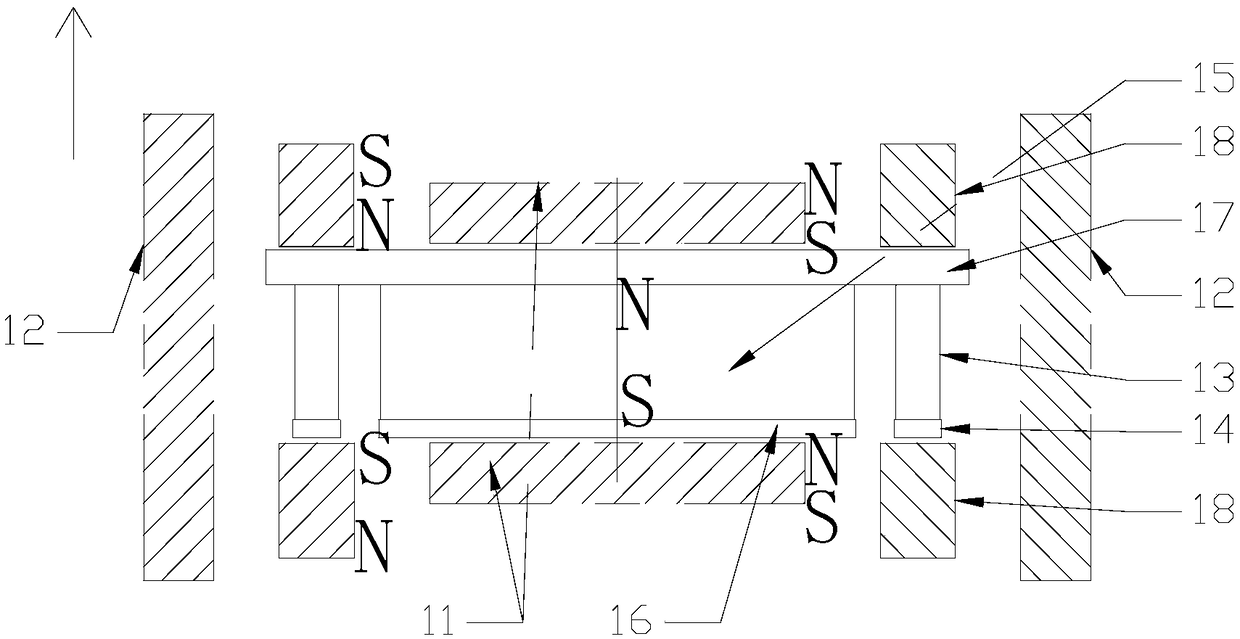

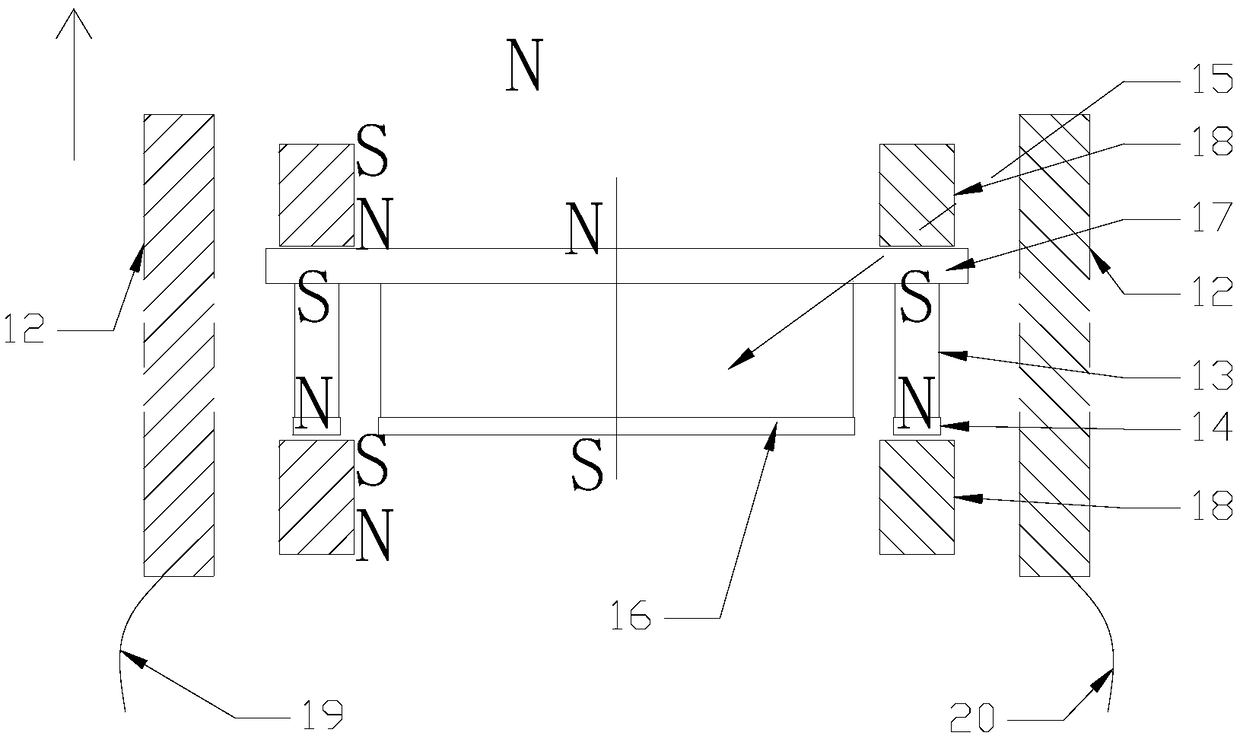

Assembling method of magnetic circuit system and magnetizing system

ActiveCN109195079ARelative position is accurateImprove magnetization efficiencyElectrical transducersEngineeringMagnetism

The present invention discloses an assembling method of a magnetic circuit system and a magnetizing system. The method comprises the steps of: fixing a centring magnet without magnetizing and a side magnet without magnetizing on a magnetic conductive yoke, wherein the side magnet is arranged at the outer periphery of the centring magnet, and a gap between the centring magnet and the side magnet; performing magnetizing for any one of the side magnet and the centring magnet; applying the magnetic field with polarity opposite to a corresponding magnetic pole to the magnetizing one of the side magnet and the centring magnet to perform magnetic protection; and performing magnetizing for the magnetizing one of the side magnet and the centring magnet to form a magnetic field in the gap.

Owner:GOERTEK INC

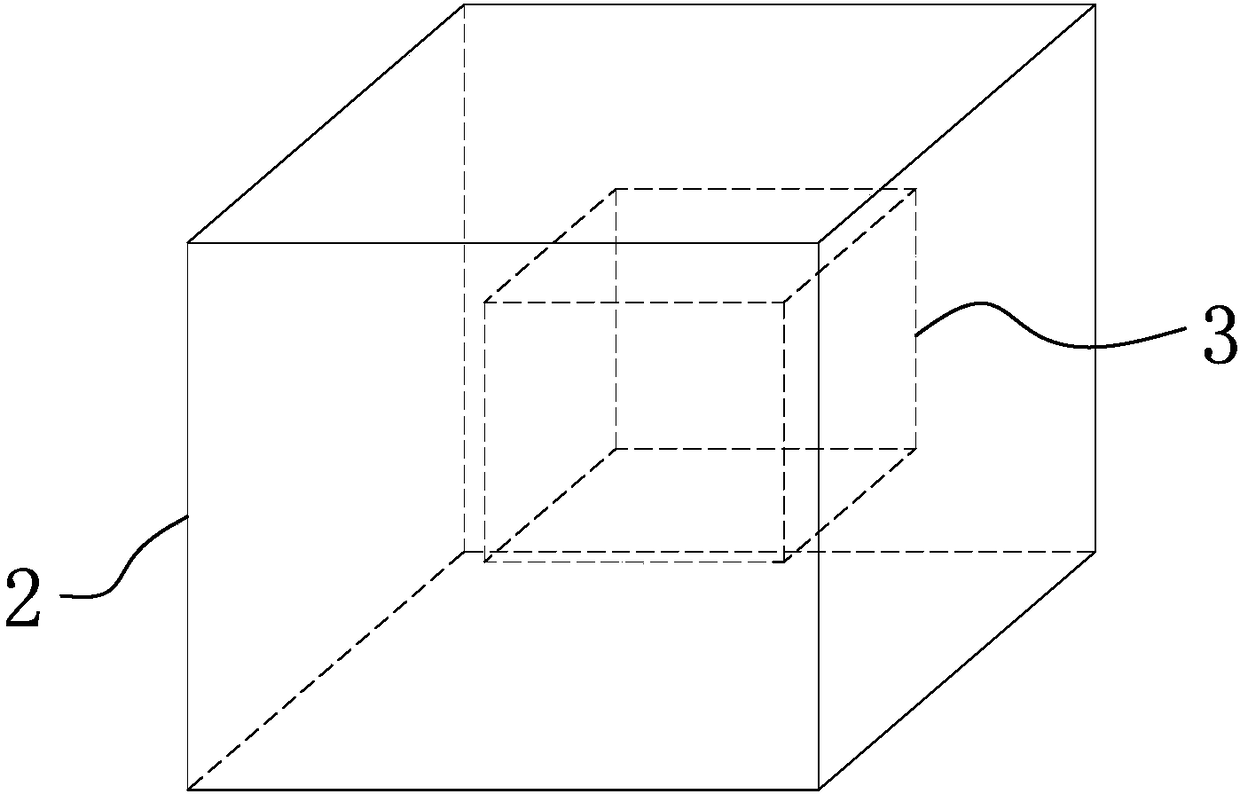

High strength and high efficiency fluid magnetizing tube, magnetizing device and system

InactiveCN1821109AImprove technical indicatorsImprove magnetization efficiencyWater/sewage treatment by magnetic/electric fieldsEnergy based chemical/physical/physico-chemical processesEngineeringHigh intensity

The present invention provides high strength and high efficiency fluid magnetizing tube, magnetizing device and magnetizing system, and belongs to the field of fluid magnetizing technology. The fluid magnetizing tube includes a magnetic tube, a magnetic conducting tube, and a locating and guiding element to form one or several fluid channels and has straight or curved axis. The magnetic tube includes a magnetic ring, an isolating ring of non-ferromagnetic material and a duct; the magnetic conducting tube is high permeability duct or one other magnetic tube; and the end plates possess fluid channel. The magnetizing device includes a casing and several magnetizing tubes connected serially and / or in parallel. The magnetizing system has magnetizing device, conventional pump and power device to perform circular fluid magnetizing. The present invention has high strength axial and radial magnetic field and high fluid magnetizing efficiency.

Owner:朱澄清

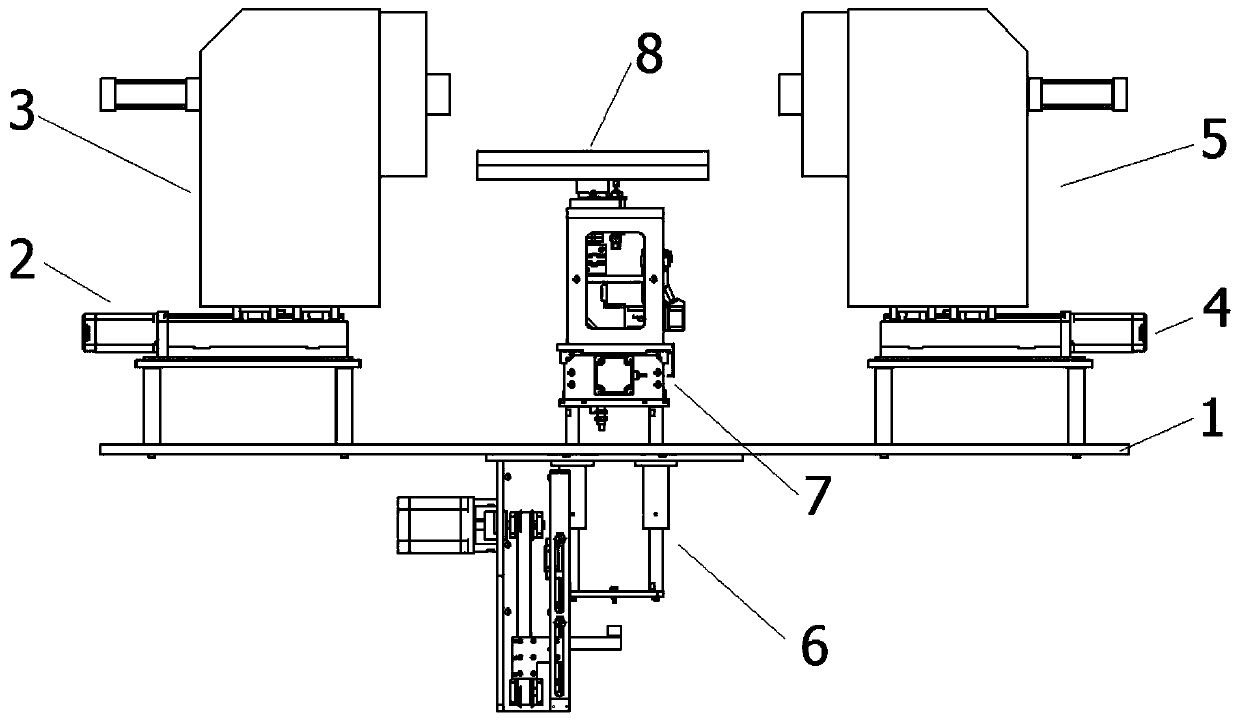

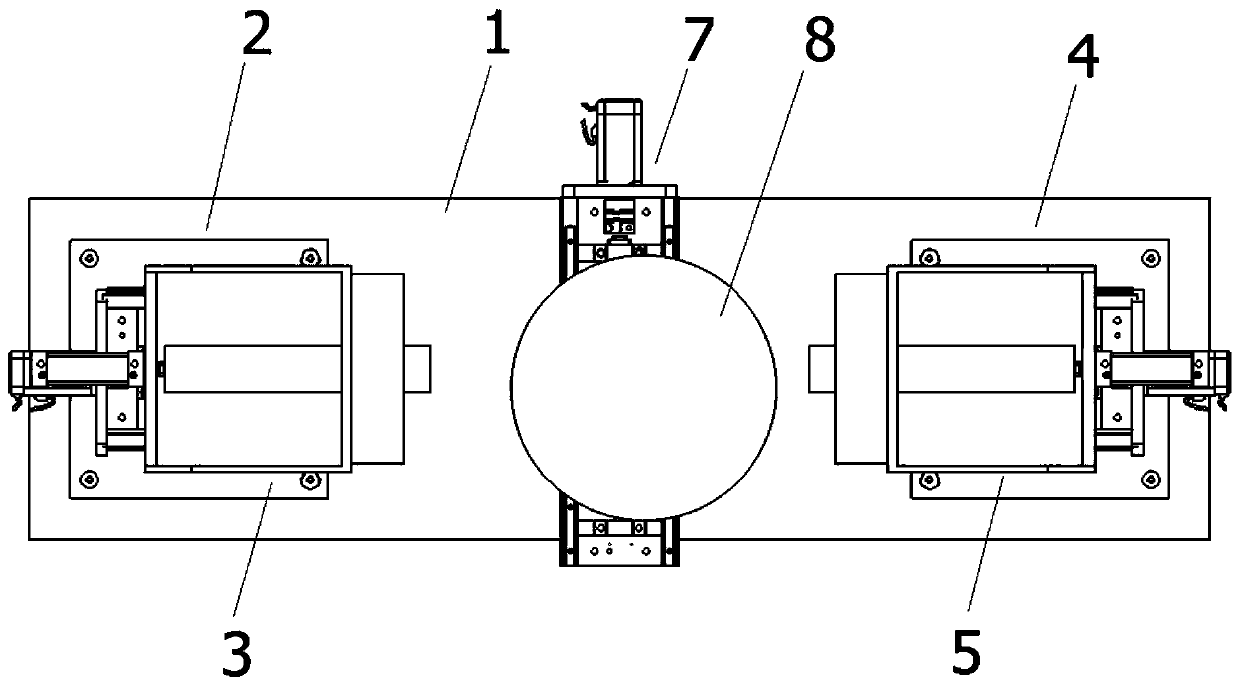

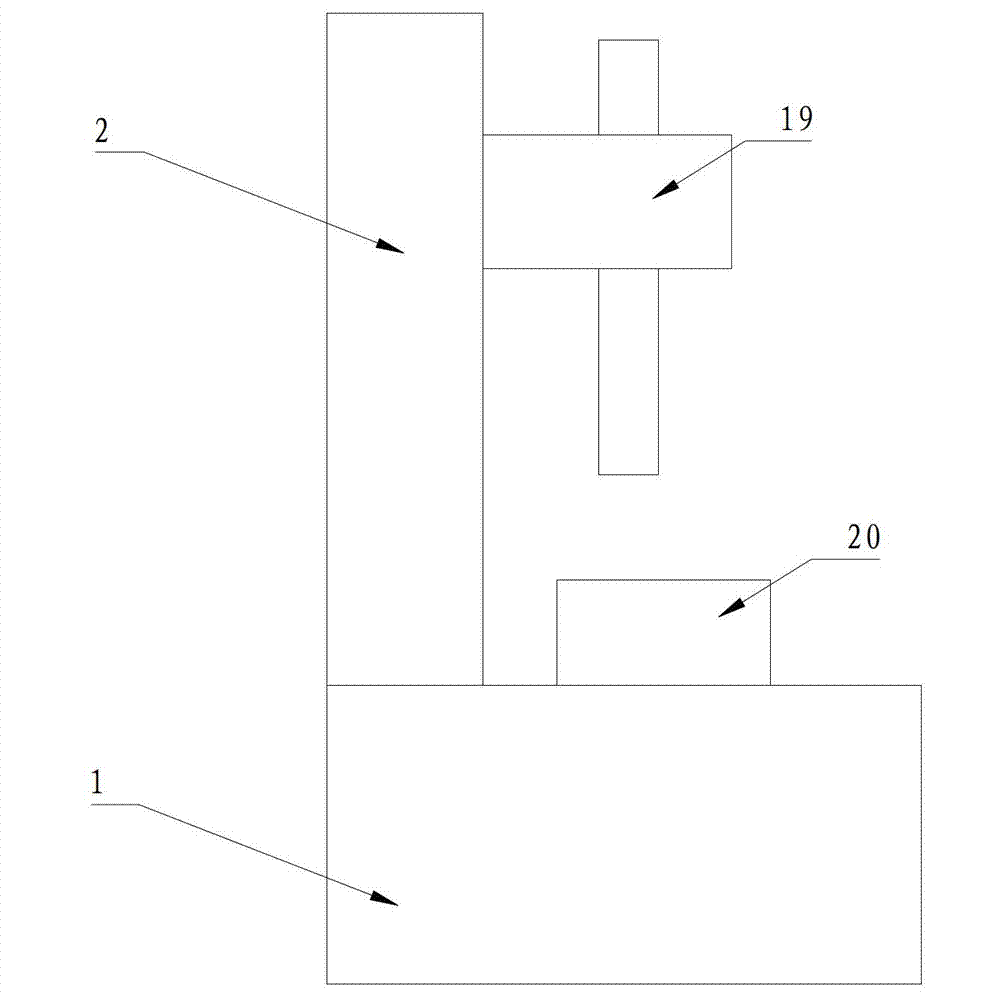

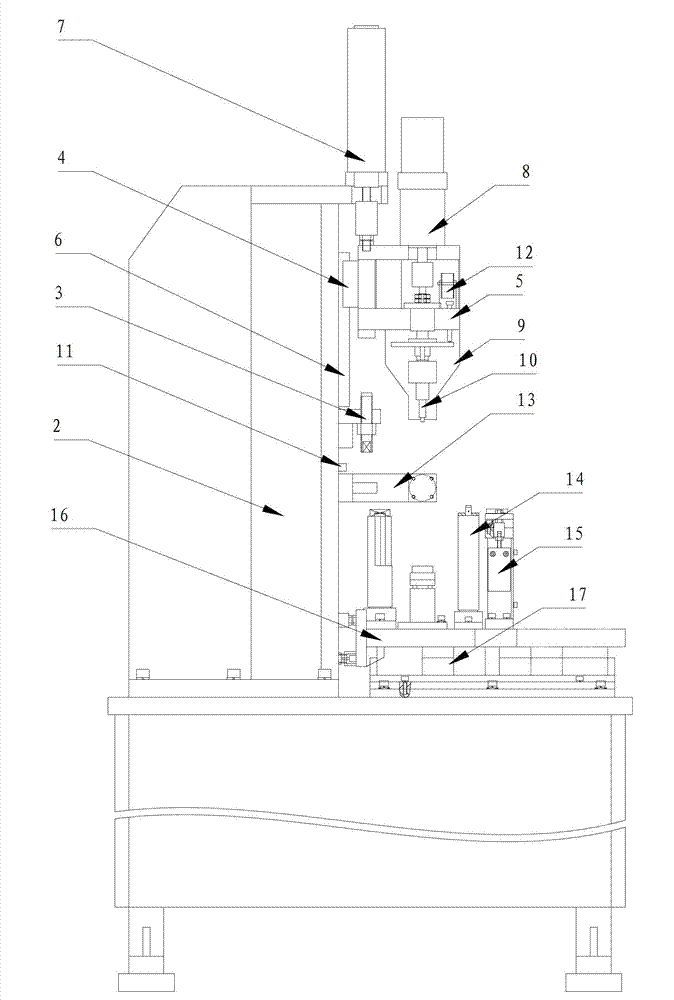

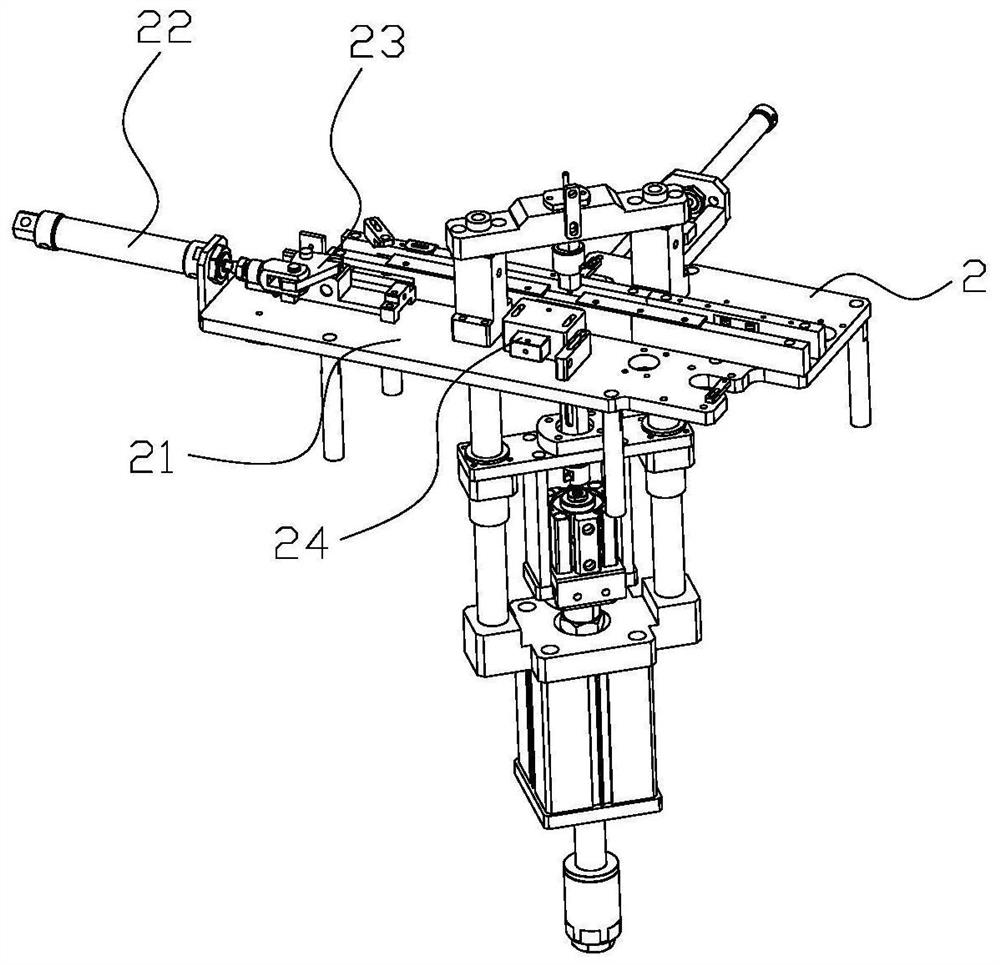

Magnetic powder detection device for omnibearing detection of steel structure

PendingCN111077216AAchieve magnetizationSimple structureMaterial magnetic variablesMechanical engineeringMagnetic powder

The invention discloses a magnetic powder detection device for omnibearing detection of a steel structure. The device comprises a large fixed bottom plate. A left X-axis driving mechanism is fixed tothe left side of the upper end face of the large fixed bottom plate through screws. A left magnetic powder flaw detection mechanism is fixed above the left X-axis driving mechanism through screws. A right X-axis driving mechanism is fixed to the right side of the upper end face of the large fixed bottom plate through screws. A right magnetic powder flaw detection mechanism is fixed above the rightX-axis driving mechanism through screws. A Z-axis driving mechanism is connected to the middle of the lower end face of the large fixed bottom plate through screws. A Y-axis driving mechanism is fixed above the Z-axis driving mechanism through screws. A rotating platform is fixed above the Y-axis driving mechanism through screws. The device is simple in structure and convenient to use, omnibearing magnetization of workpieces of different sizes can be achieved through the left X-axis driving mechanism, the right X-axis driving mechanism, the Y-axis driving mechanism and the rotating platform,omnibearing cracks can be detected at a time, and the practicability is high.

Owner:LIAONING JIDIAN POLYTECHNIC

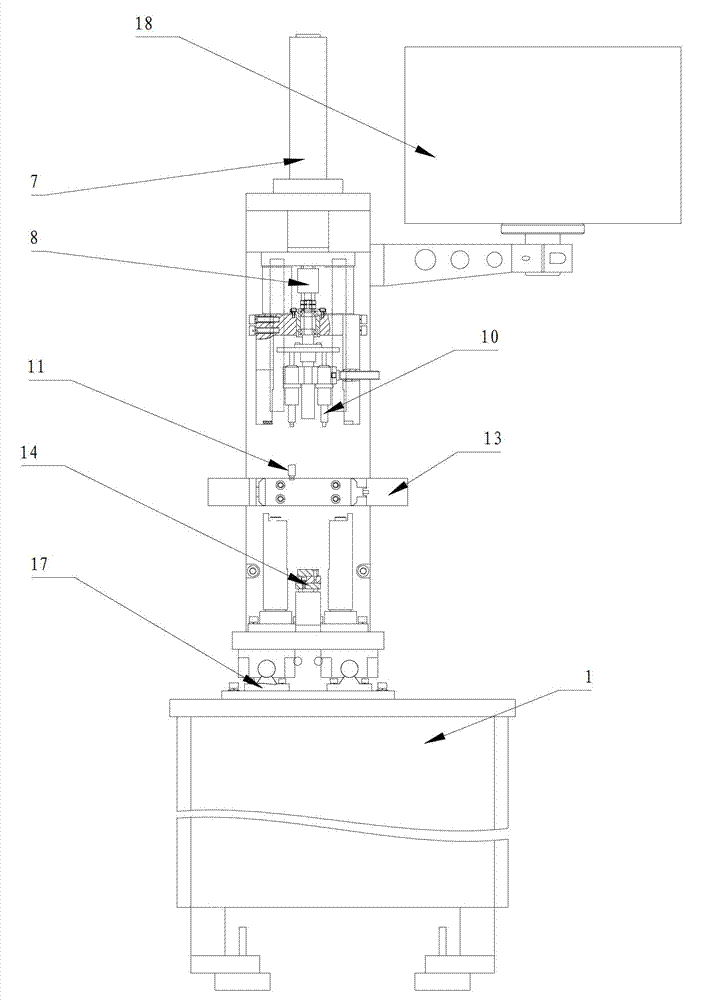

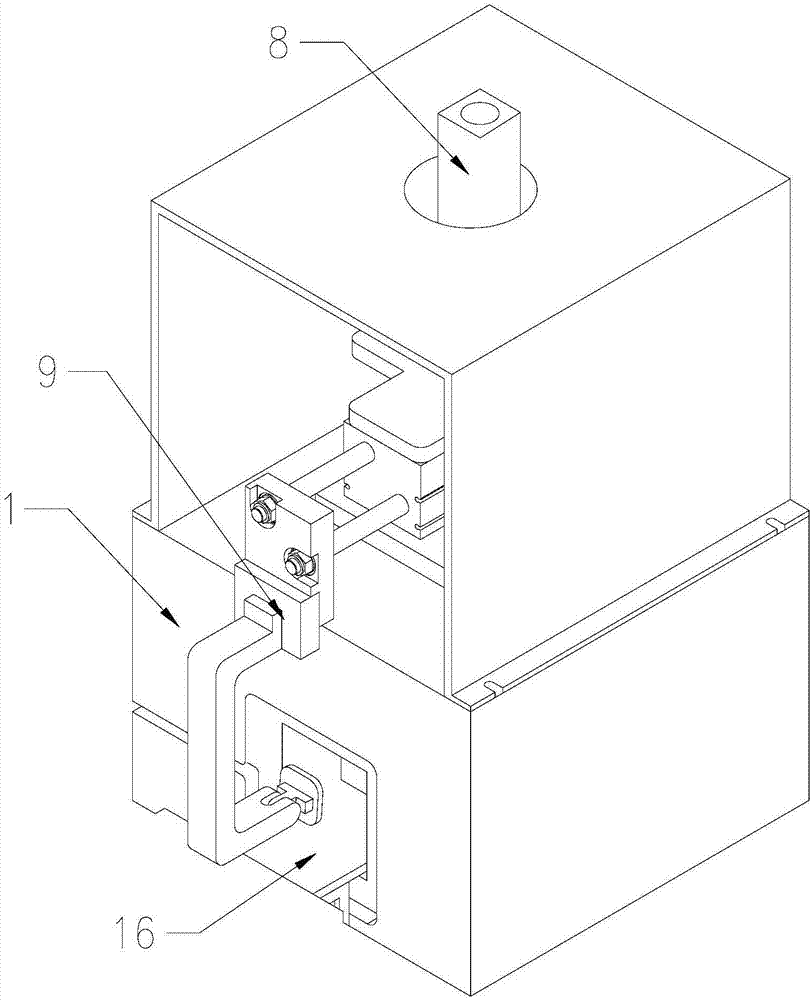

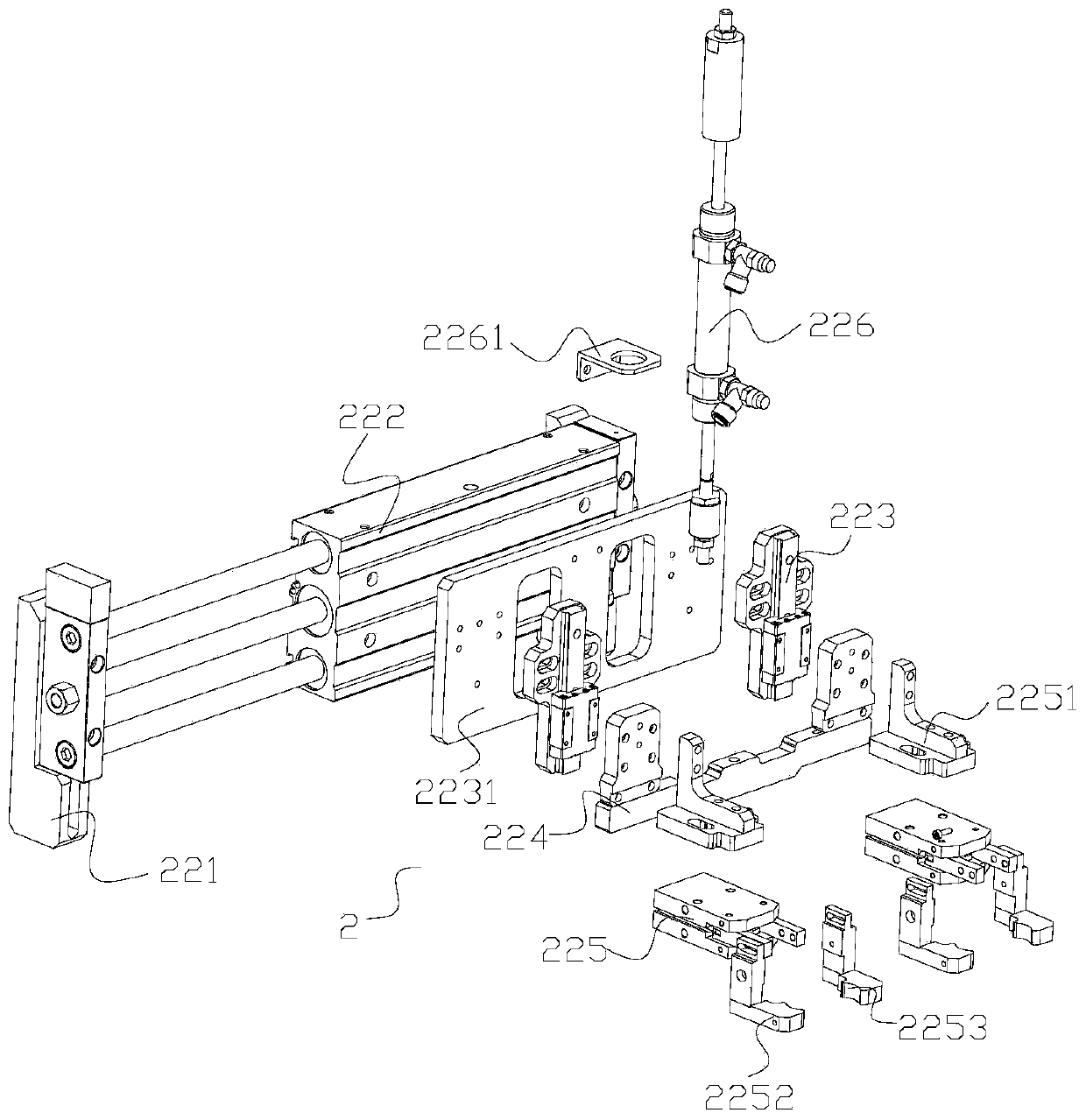

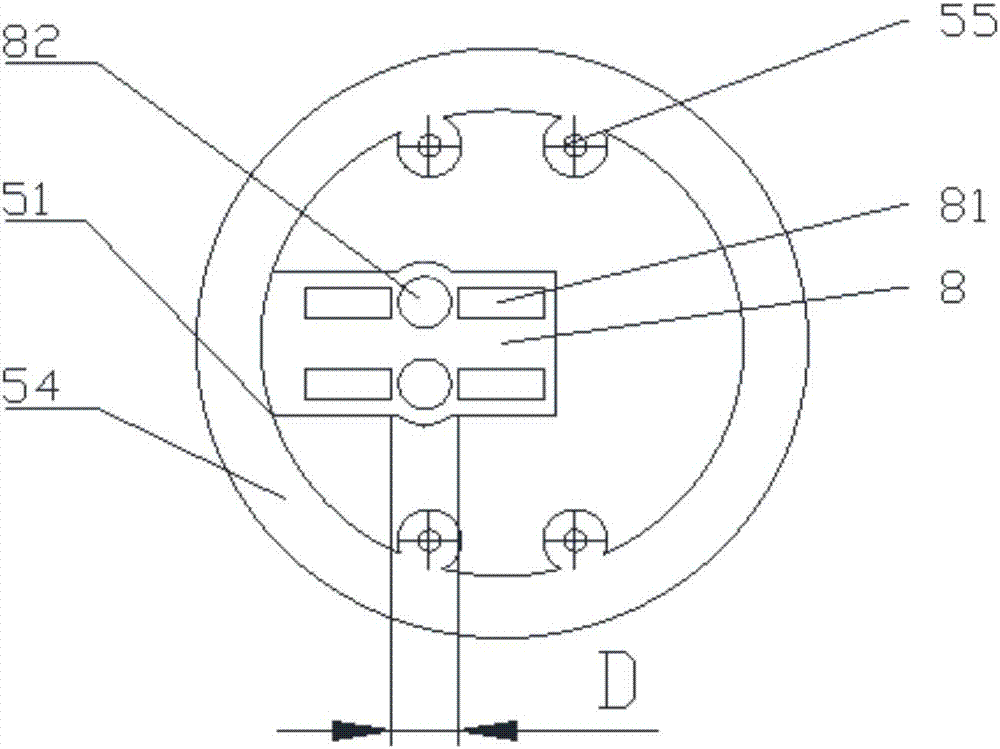

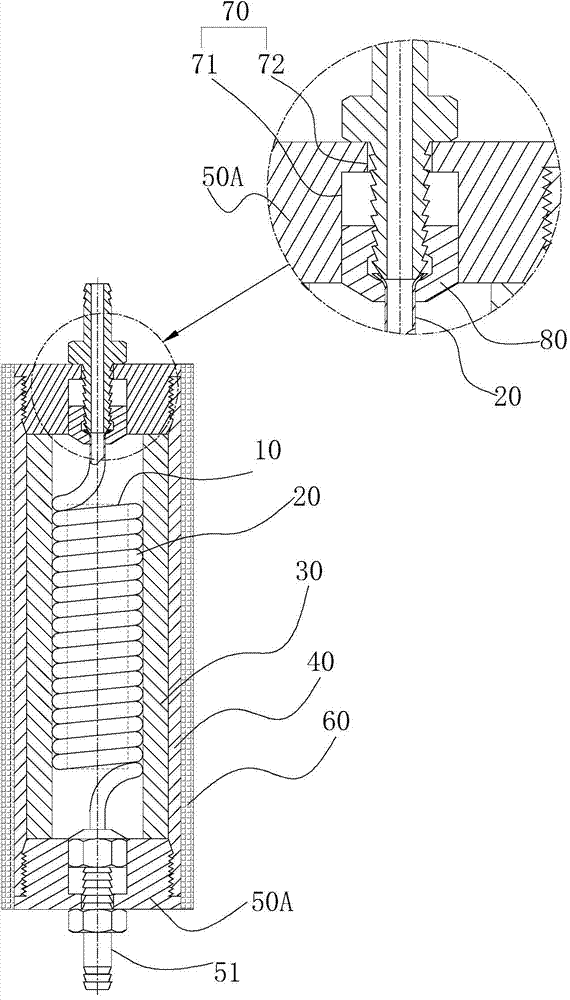

Magnetizing equipment for rotors of compressors

InactiveCN103208346ASimple and fast operationReduce labor costsMagnetic bodiesEngineeringInverter compressor

The invention relates to magnetizing equipment for rotors of compressors. The magnetizing equipment comprises a framework; an upright column is arranged on one side of the framework; a magnetizing mechanism is slidably connected to the upper portion of the upright column by a slide rail column, a rotor positioning device is arranged on the framework and is positioned below the magnetizing mechanism, an intelligent measuring and controlling mechanism is arranged on one side of the upper portion of the upright column, the magnetizing mechanism comprises a positioning mechanism, a lifting cylinder mechanism and a rotor driving mechanism are respectively arranged on the positioning mechanism, and a floating positioning head is arranged at the lower end of the positioning mechanism; and the rotor positioning device comprises a workpiece positioning mechanism and a binding post mechanism. The magnetizing equipment has the advantages that the magnetizing equipment can be operated easily and conveniently, the labor cost is saved, and the magnetizing efficiency and the magnetizing quality are improved; and an operator only needs to place a workpiece (a rotor of an inverter compressor) into a workpiece positioning seat, and the workpiece can be magnetized after a button is started, a charging power supply is automatically shut off after the workpiece is magnetized, the workpiece is automatically turned to a set angle and is automatically locked, and a mechanism returns to an original position.

Owner:BEIJING BRANCH JIKE DEV SCI & TECH

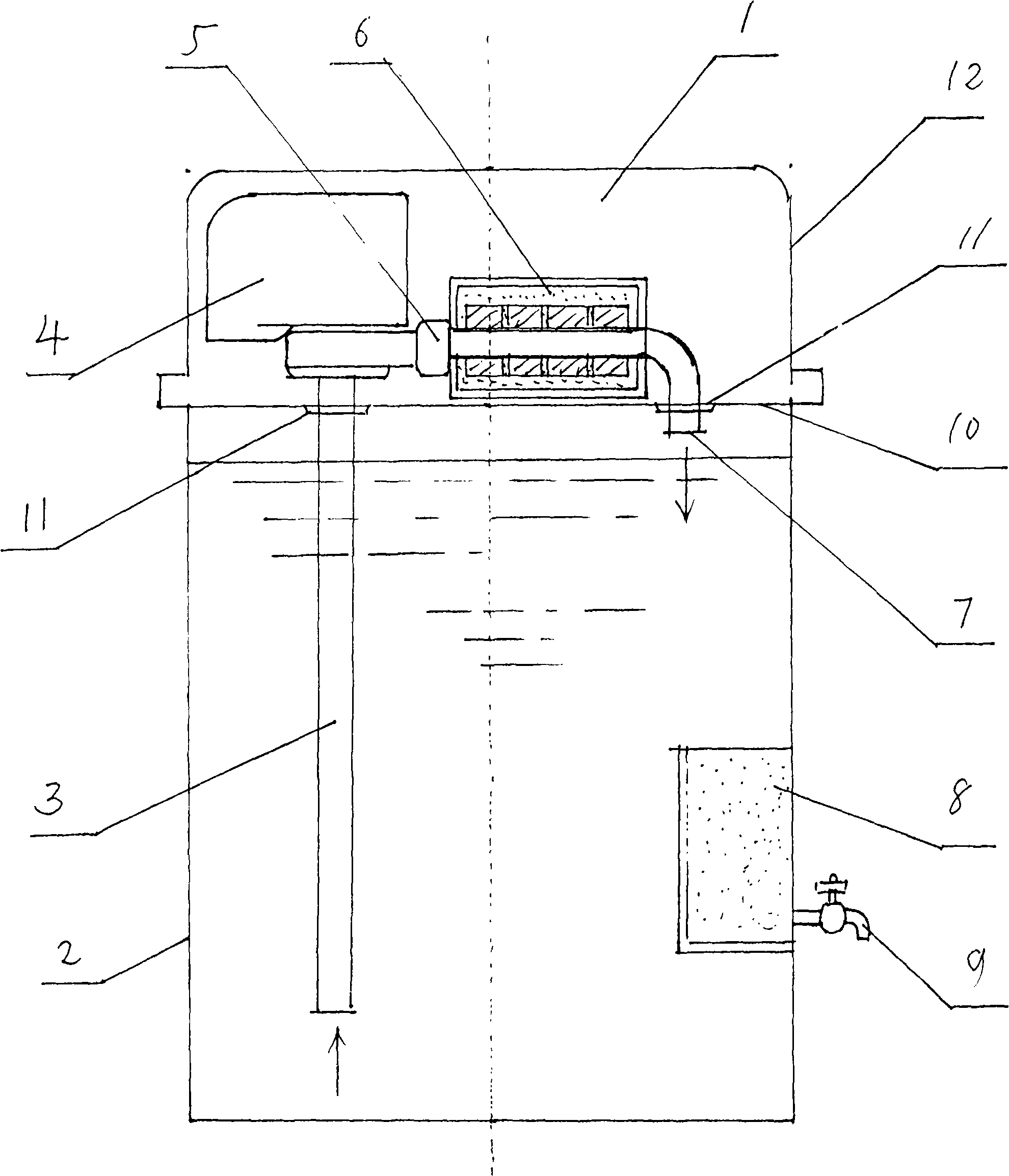

High-efficiency magnetic water processor

InactiveCN101269864ASave electricity costsLow costWater/sewage treatment by magnetic/electric fieldsSocial benefitsAquaculture industry

The invention discloses a high-activity magnetic water processor, which is characterized in that a magnetic water processor and a water storage barrel are included. The magnetic water processor is characterized in that a circulation pump and a magnetic component which are connected in series are included. The water storage barrel is characterized in that the barrel is a circular barrel with a top opening, the lower part at the outer side of the barrel is provided with a magnetic water faucet which is communicated with a filter in the barrel. The high-activity magnetic water processor uses less material and extends the magnetic range through the remagnetization, thereby achieving the purpose of creating higher magnetic efficiency with lower cost. The high-activity magnetic water processor can be widely applied to families and units, and also be applied to drinks, wines, foods, medicines, agriculture, stock raising, and aquiculture industry, etc., and can also obtain better economic and social benefits.

Owner:薛碧 +1

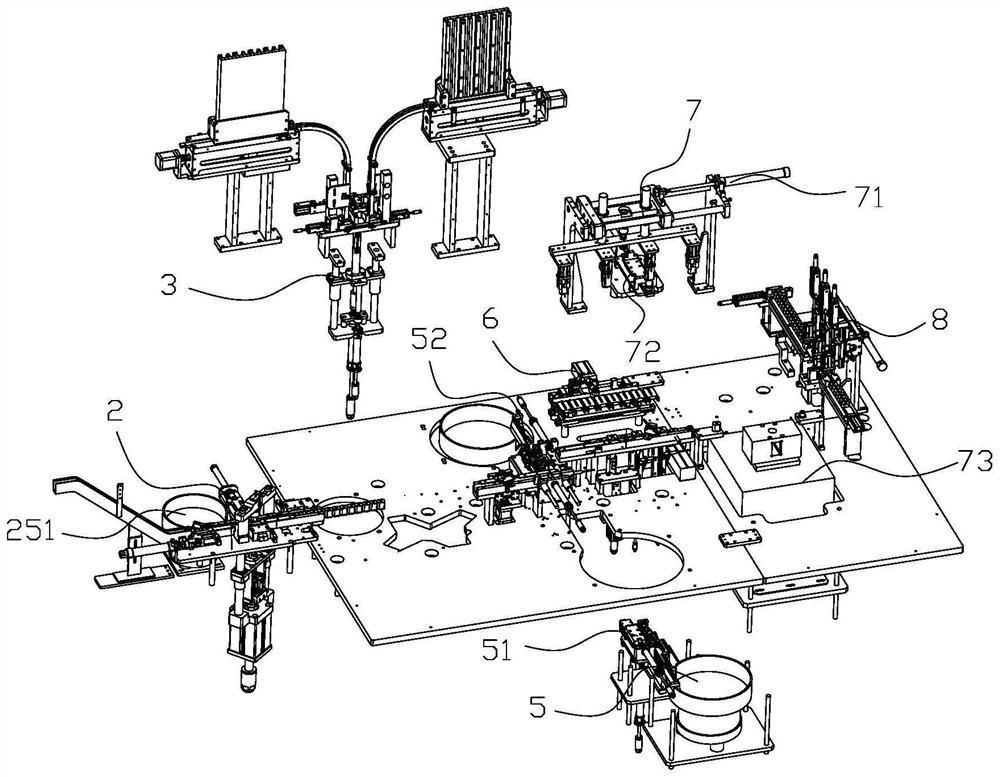

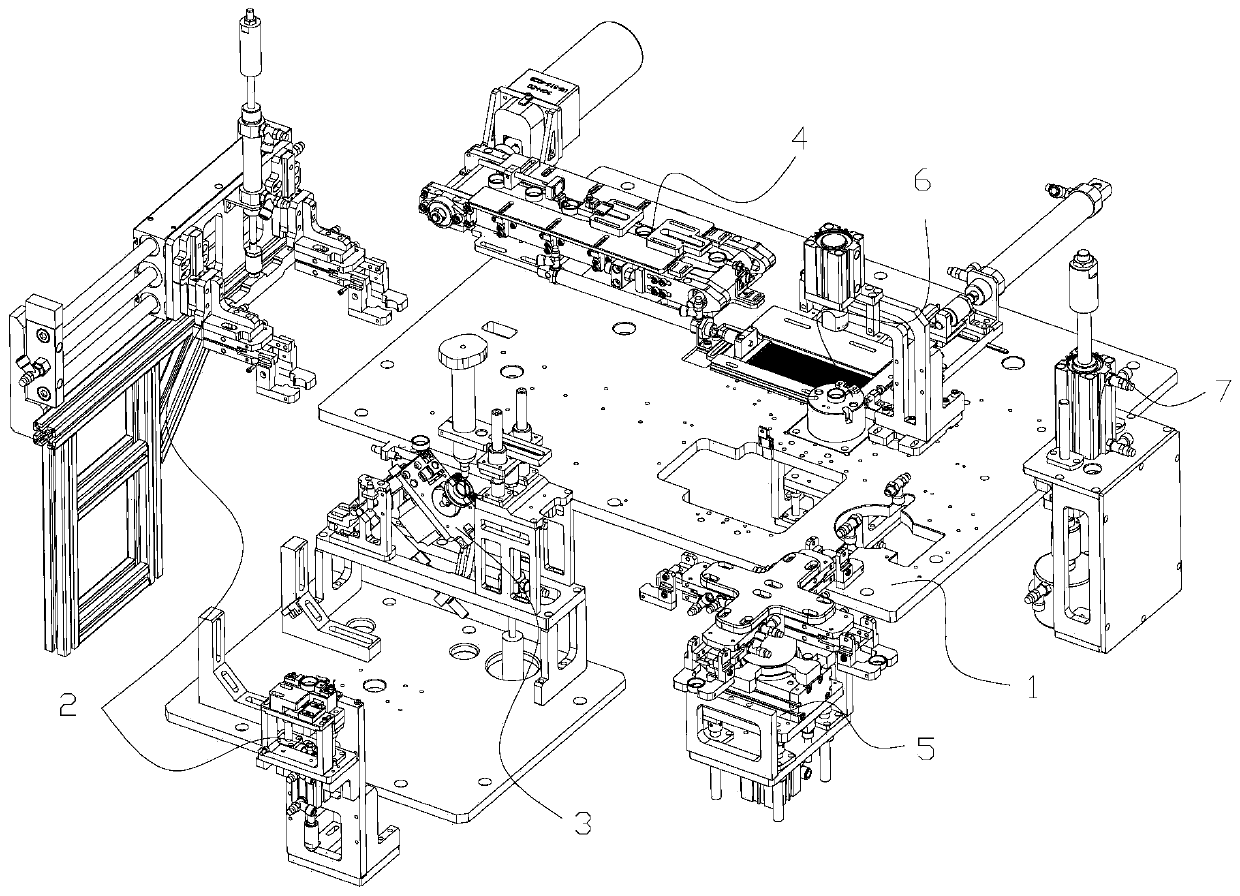

Servo motor and automatic production equipment and method thereof

InactiveCN111618578AAvoid accumulationEasy to assembleAssembly machinesManufacturing dynamo-electric machinesServoElectrical and Electronics engineering

The invention relates to the technical field of servo motors and in particular to automatic production equipment for a servo motor. The automatic production equipment comprises a rack, a shell and bearing feeding and assembling device, a magnetic shoe feeding and assembling device, a slingshot feeding device, a transferring device, a magnetizing device and a discharging and conveying device. The shell and bearing feeding and assembling device, the magnetic shoe feeding and assembling device, the slingshot feeding device, the transferring device, the magnetizing device and the discharging and conveying device are arranged on the rack. The shell and bearing feeding and assembling device is used for feeding a shell and a bearing and installing the bearing on the shell. The magnetic shoe feeding and assembling device is used for feeding two symmetrical magnetic shoes and installing the two magnetic shoes into the shell, and the slingshot feeding device is used for conveying two slingshotsand installing the two slingshots between the two magnetic shoes. The transferring device is used for transferring assembled units to the magnetizing device one by one. The magnetizing device is usedfor magnetizing the assembled units. The automatic production equipment for the servo motor has the advantages that the bearing assembling quality is improved, the matching degree of the magnetic shoes and the slingshots is improved, the magnetic shoe assembling quality and efficiency and the slingshot assembling quality and efficiency are improved, the magnetizing efficiency and quality are improved, and the assembling efficiency of the whole servo motor is improved.

Owner:高鑫斌

Assembly line type magnetic product magnetizing system and magnetizing method thereof

ActiveCN107978417AUniform magnetization saturationImprove securityMagnetic bodiesMagnetizationEngineering

The invention discloses an assembly line type magnetic product magnetizing system, comprising a magnetizer and a solenoid magnetization coil, wherein the magnetizer is connected with the solenoid magnetization coil, and the front end of the solenoid magnetization coil is provided with a front opening that internally communicates with the solenoid magnetization coil; the assembly line type magneticproduct magnetizing system further comprises a worktable, an annular conveyor belt arranged on the worktable, a driver for driving the annular conveyor belt to rotate, six material boxes uniformly distributed on the annular conveyor belt at intervals, an optical fiber sensor, a controller, a feeding control input panel, a discharging control input panel and a clamping mechanism, wherein the controller is respectively connected with the magnetizer, the optical fiber sensor, the feeding control input panel and the discharging control input panel. The scheme of the invention has the advantages of high magnetization efficiency and saturated and uniform magnetization.

Owner:NINGBO YUNSHENG +2

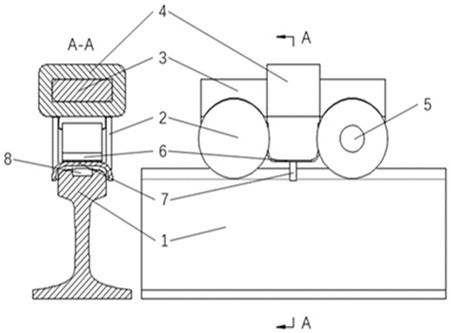

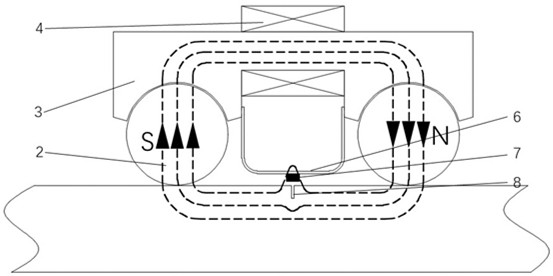

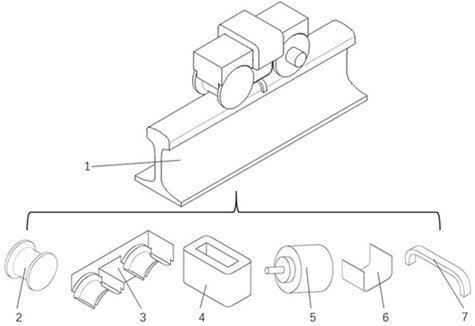

Steel rail magnetic flux leakage detection device based on zero lift-off rolling magnetization

PendingCN111766292AEasy to detectDefect magnetic signal is obviousRailway auxillary equipmentRailway profile gaugesSensor arrayCondensed matter physics

The invention discloses a steel rail magnetic flux leakage detection device based on zero lift-off rolling magnetization. The device comprises a magnetizing coil used for generating an excitation magnetic field, a U-shaped magnet yoke used for forming a magnetizing loop, a profiling rolling magnetizing wheel in direct contact with a steel rail, a magnetic flux leakage detection sensor array used for being installed on a probe mechanism, and a grating encoder used for defect position positioning. The U-shaped magnet yoke, the detected steel rail and the profiling rolling magnetizing wheel forma magnetizing loop. As the profiling rolling magnetization wheel is in direct contact with the steel rail, the magnetic resistance of a magnetization loop can be reduced, the magnetization intensity of the detected steel rail is enhanced and the magnetization depth is increased. Full-coverage magnetization of the upper surface and the side face of the rail head of the steel rail is achieved, magnetic flux leakage detection of the surface and the near surface of the rail head can be finally achieved, and the characteristics of high magnetization capacity and high detection reliability are achieved.

Owner:SICHUAN UNIV

Self-powered intelligent bracelet

InactiveCN108392206AIncrease the strength of the magnetizing fieldImprove magnetization efficiencySensorsMeasuring/recording heart/pulse rateHuman bodyElectrical battery

The invention discloses a self-powered intelligent bracelet which comprises a shell and a circuit unit arranged in the shell. The circuit unit at least comprises a power supply unit, a control module,an acceleration sensor and a biological resistance sensor, and the control module is connected with the acceleration sensor and the biological resistance sensor and used for acquiring sensor information to acquire health state and movement state of a human body. The intelligent bracelet further comprises a self power generation device which is connected with a circuit unit and used for generatingmicro energy in the movement state and storing the same in a rechargeable battery. The biological resistance sensor is arranged to serve as an important parameter for abnormality judging, so that accuracy of human body abnormality detection is improved. In addition, a three-dimensional maglev structure is designed ingeniously to convert human body movement kinetic energy into electric energy to power the intelligent bracelet, so that standby time of the intelligent bracelet is prolonged.

Owner:周小英

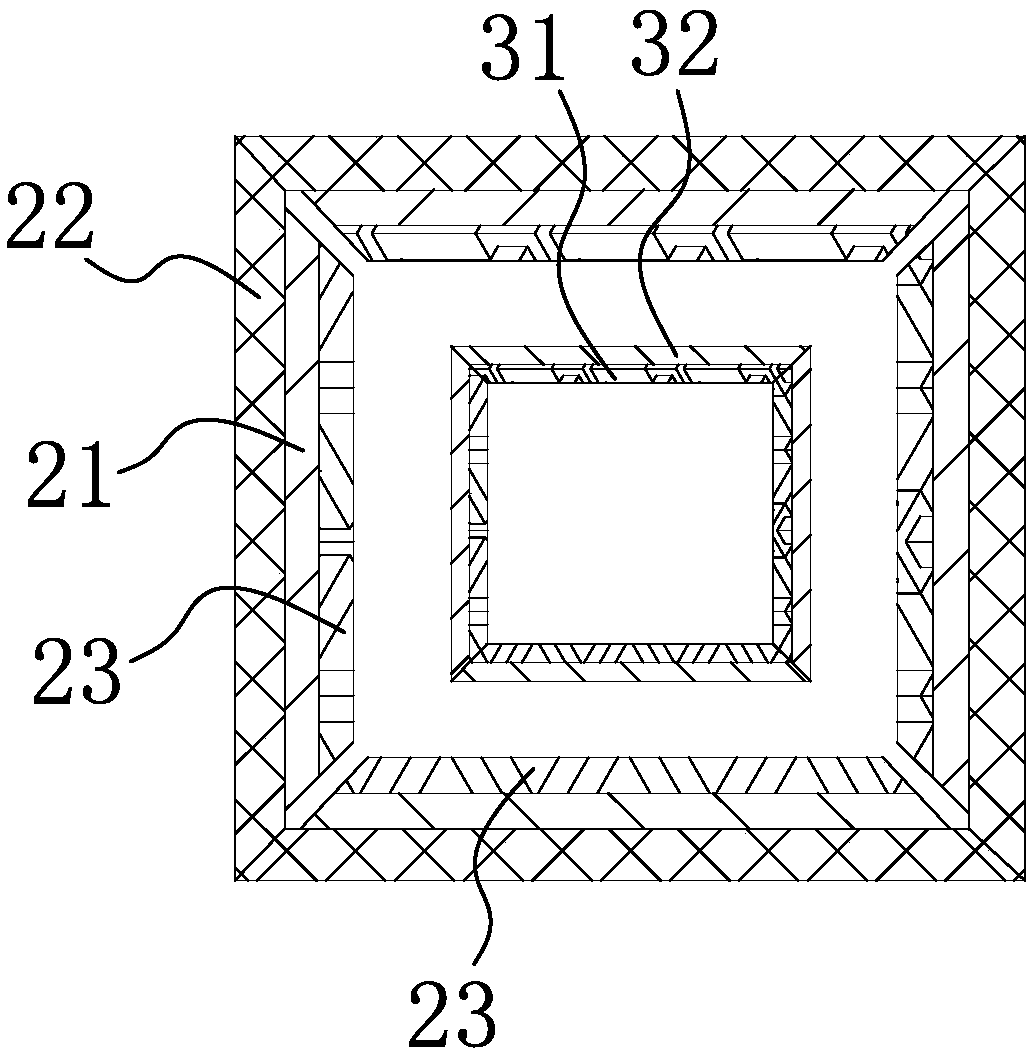

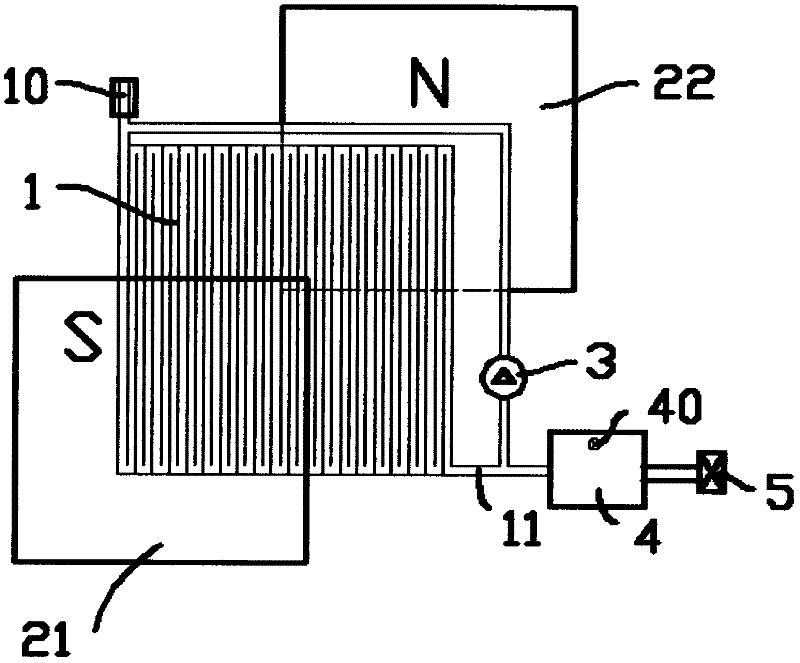

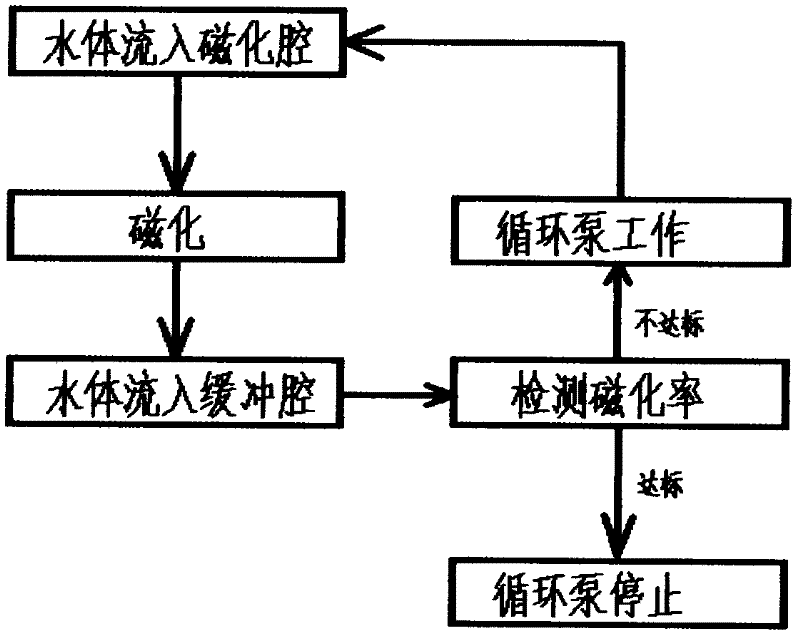

Magnetization water dispenser

InactiveCN102362784AChange cycle timeGood for healthWater/sewage treatment by magnetic/electric fieldsBeverage vesselsMagnetic susceptibilityMagnetization

The invention provides a magnetization water dispenser, which comprises a base case and a water faucet, wherein the base case is provided with a concave cavity for loading a purified water barrel, a hot water cavity and a magnetization cavity are arranged inside the base case, both sides of the magnetization cavity are provided with a magnetic field generating device capable of forming a directional magnetic field in the magnetization cavity, a water delivery fence group consisting of at least one piece of water delivery fence orthometric with the directional magnetic field is also arranged in the magnetization cavity, the water delivery fence is formed by folding one section of a water delivery pipe in a reciprocating way, all water delivery fences are mutually connected in series, a water inlet of the water delivery fence group is connected with a water falling opening of the concave cavity, the water outlet is divided into two paths, one path is connected back to the water inlet through a circulating pump, the other path is connected to a buffer cavity and is then connected to the water faucet through the buffer cavity, a magnetic susceptibility detection meter is arranged in the buffer cavity, and the magnetic susceptibility detection meter is correlative with the circulating pump so that the circulating pump continuously operates when the magnetic susceptibility of the water body does not reach the standard. The purified water can be efficiently magnetized through the magnetization water dispenser, so the magnetized water for promoting the human body health can be provided.

Owner:苏州市伦琴工业设计有限公司

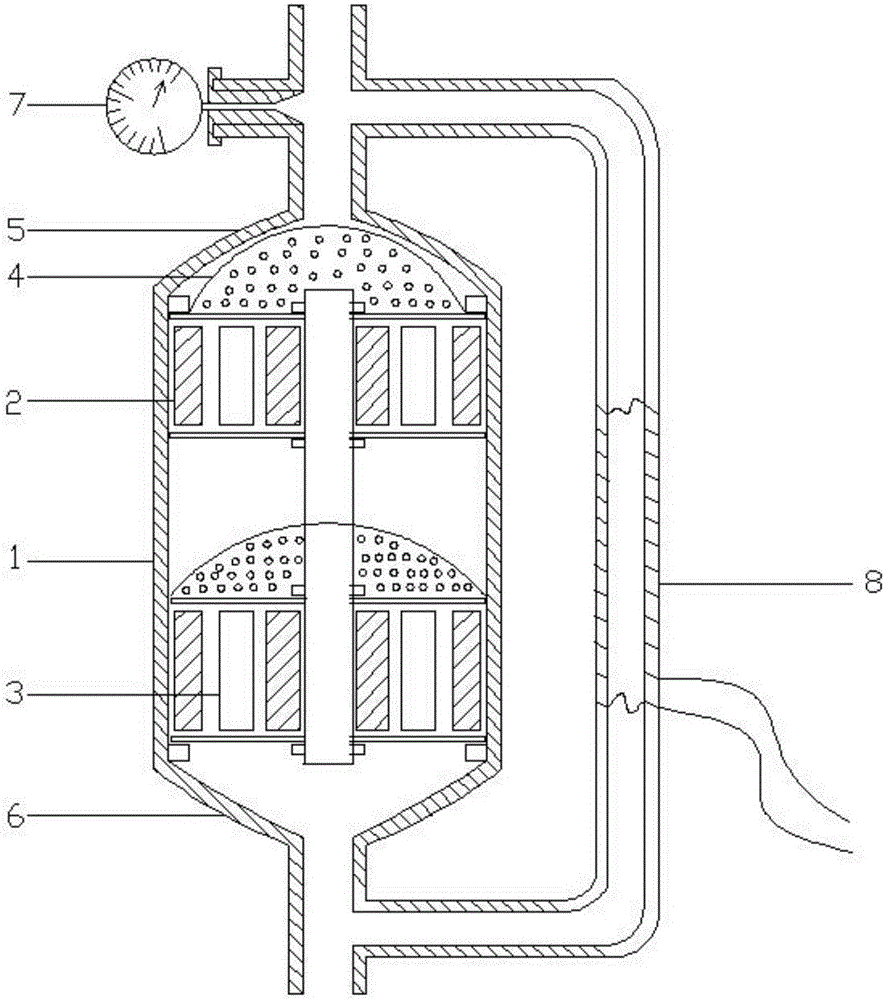

Four-dimensional magnetic suspension auto-modulation recycled oil/gas reformer

InactiveCN105771839AFully magnetizedLow magnetic susceptibilityEnergy based chemical/physical/physico-chemical processesElectrical polarityMagnetization

The invention relates to the field of fuel magnetization energy conservation, in particular to a four-dimensional magnetic suspension auto-modulation recycled oil / gas reformer which comprises a suspension magnetization device main body, permanent magnet porous suspension bodies, plunger type mesoporous suspension auto-modulation magnetic pillars, a plurality of reverse magnetic positioning sealing pads, an upper magnetization cabin sealing cover and a lower magnetization cabin sealing cover, wherein the suspension magnetization device main body is sealed by the upper magnetization cabin sealing cover and the lower magnetization cabin sealing cover; the reverse magnetic positioning sealing pads are arranged inside the sealed suspension magnetization device main body; a four-dimensional magnetic suspension channel is formed between two adjacent reverse magnetic positioning sealing pads; the four-dimensional magnetic suspension channels are formed by the plunger type mesoporous suspension auto-modulation magnetic pillars which are embedded into two permanent magnet porous suspension bodies. The four-dimensional magnetic suspension auto-modulation recycled oil / gas reformer provided by the invention is simple in structure, moreover, the magnetization rate of fuel can be effectively increased, furthermore, the fuel can be more sufficiently combusted, the energy can be relatively well saved, and the environment can be protected.

Owner:YANTAI JIUZHOU FUEL OIL & FUEL GAS ENERGY SAVING TECH

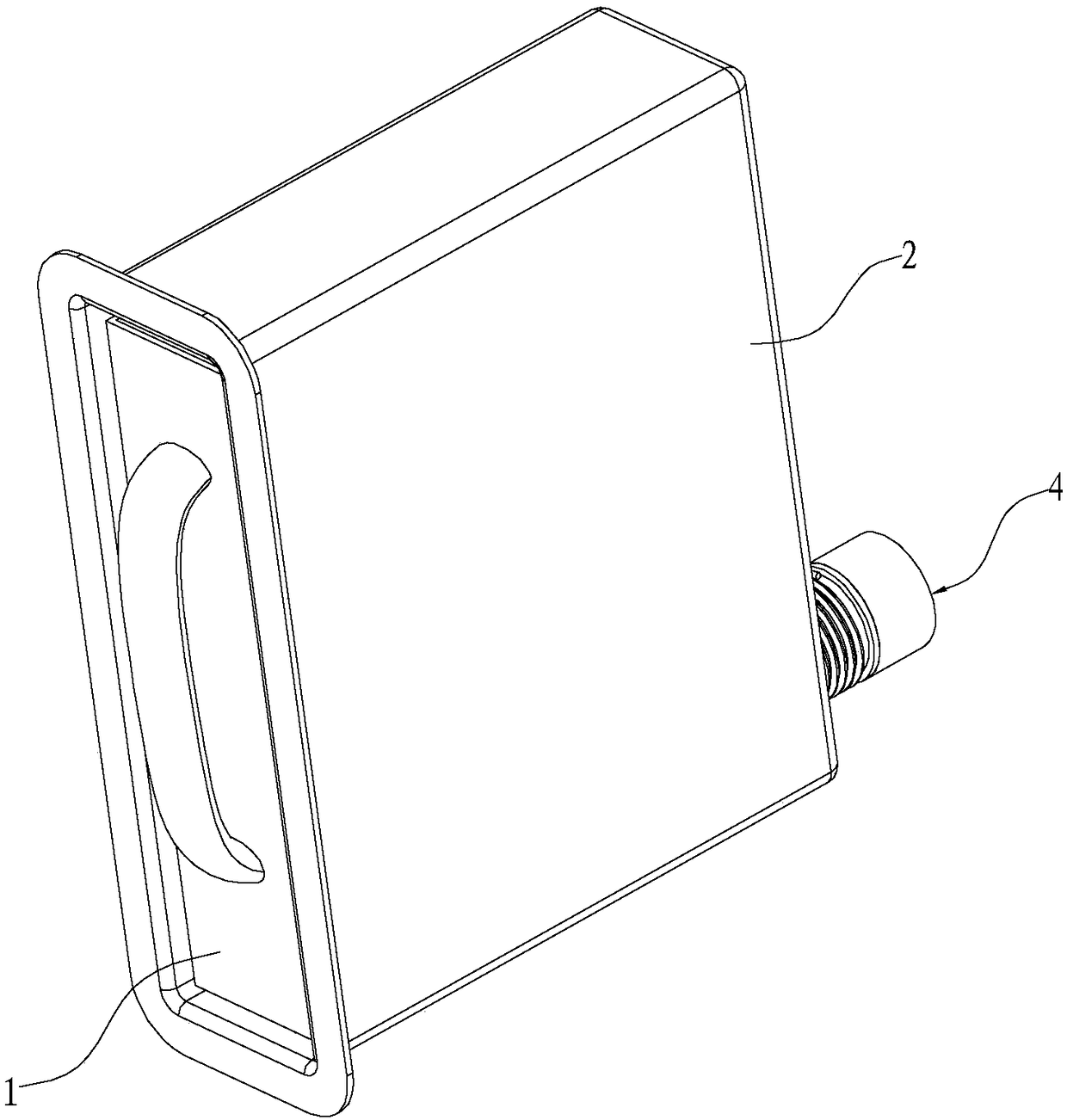

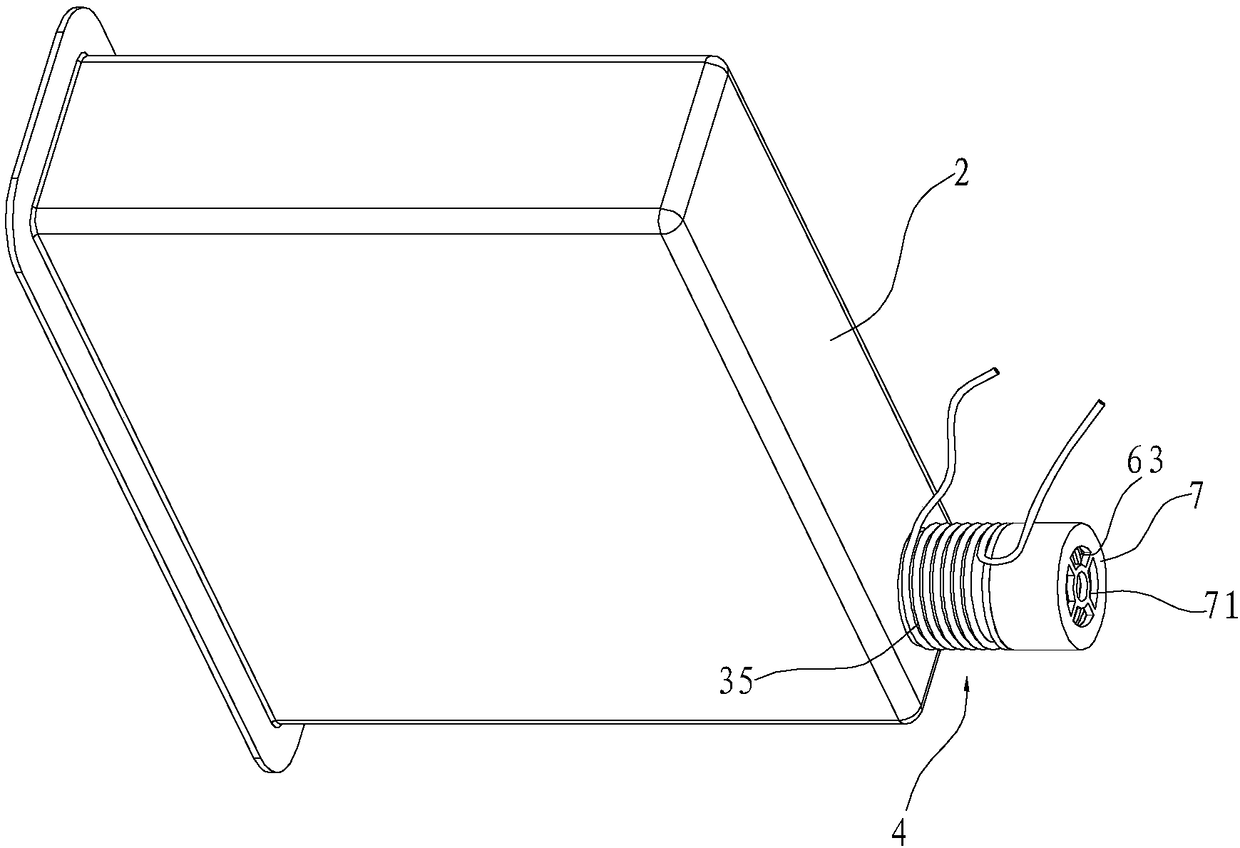

Water tank structure and steaming cooking equipment with same

The invention relates to a water tank structure which comprises a water tank and a water tank base. The water tank base is provided with a water containing opening allowing a water outlet of a water supply box to be inserted, a magnet is installed on the side wall of the water outlet, and an induction coil sleeves the peripheral wall of the portion, at the insertion part of the water outlet, of the water containing opening. The invention further relates to steaming cooking equipment with the water tank structure. Compared with the prior art, whether the water tank is in a pulling state or a take-out state and whether or not pulling / take-out actions are in place are judged according to the change of electromotive force generated by the magnet and the induction coil, not only can operation of a user be facilitated, but also the leakage phenomenon can be further avoided, and meanwhile a magnetic field generated by the induction coil at a water outlet can make water in the water tank generate magnetization; therefore, the solubility of calcium and magnesium in the water is increased, and scale generation is lowered.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

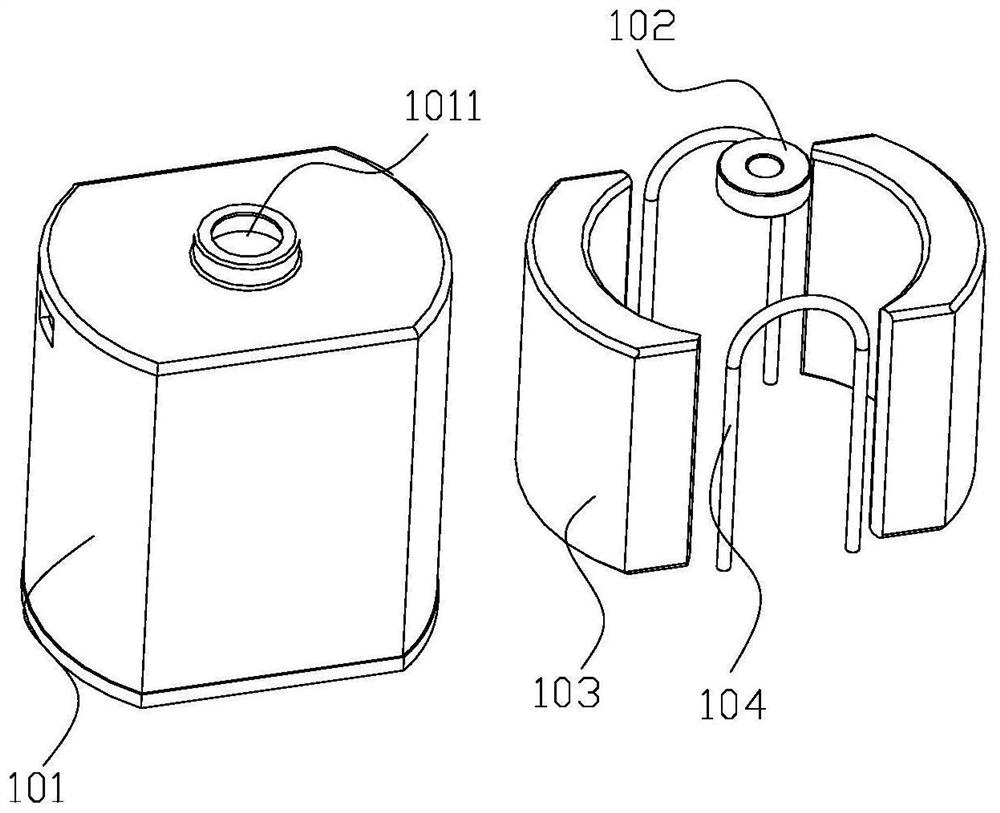

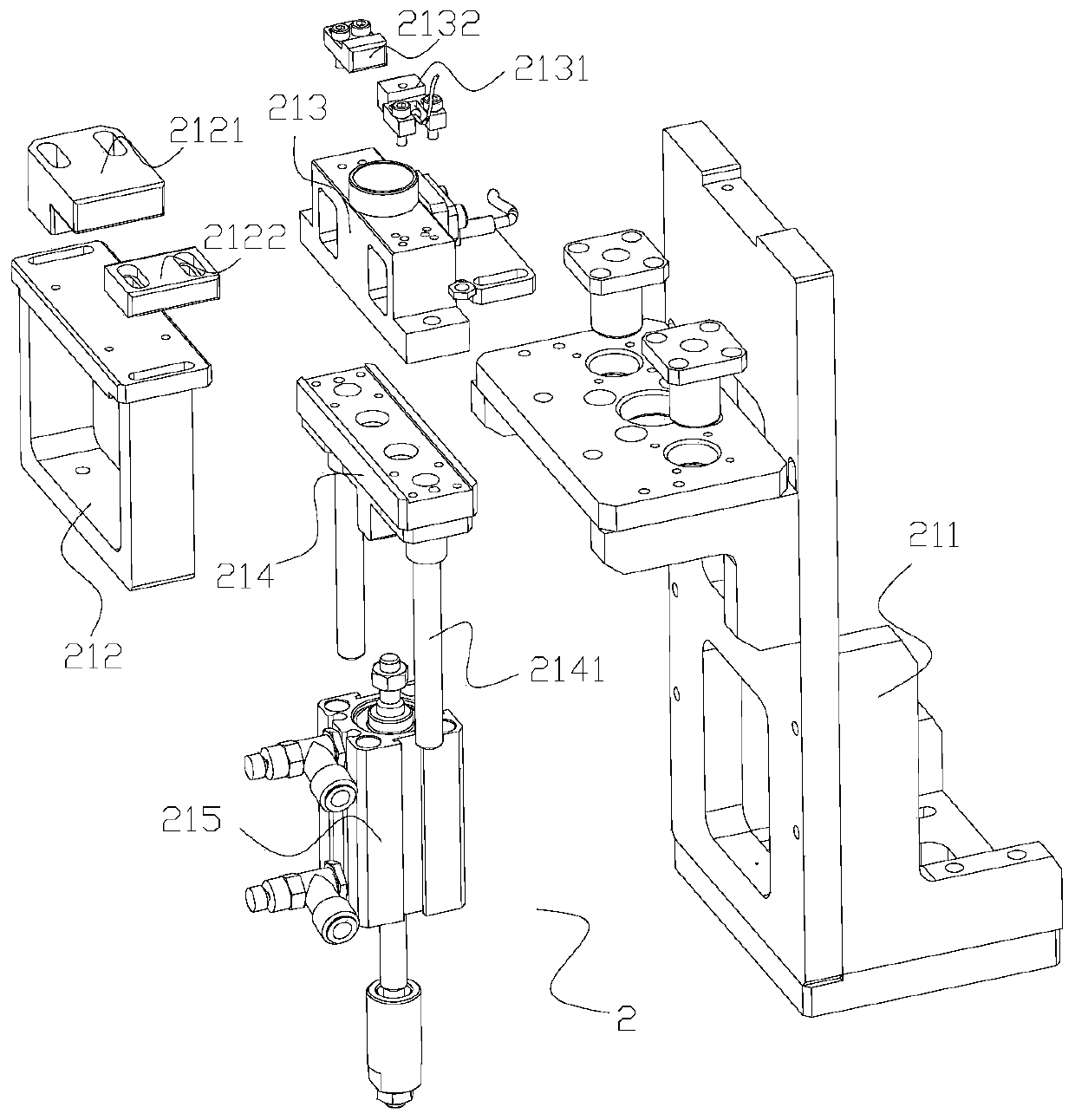

Motor and method and mechanism for magnetizing magnetic frame and magnetic strip of motor

ActiveCN109801768AEfficient assemblyImprove magnetization efficiencyMagnetic bodiesEmbedding prefabricated windingsEngineeringElectrical and Electronics engineering

The invention relates to the field of electromagnetic technology in particular to a method and mechanism for magnetizing the magnetic frame and the magnetic strip of a motor. The method for magnetizing the magnetic frame and the magnetic strip of the motor comprises the following steps: (1) conveying the magnetic frame to a first station on a rotating disk device, conveying the magnetic frame to asecond station by the rotating disk device, and conveying the magnetic strip to a magnetic strip winding assembly device; (2) coiling the magnetic strip by the magnetic strip winding assembly device,and assembling the coiled magnetic strip and the magnetic frame, and conveying the assembled magnetic frame and magnetic strip to a third station by the rotating disk device; (3) magnetizing the assembled magnetic frame and magnetic strip by the magnetizing device; (4) conveying the magnetized and assembled magnetic frame and magnetic strip to a fourth station by the rotating disk device. The mechanism can be lifted and rotated in all directions, automatically coils the magnetic strip, automatically assembles the magnetic strip into the magnetic frame, directly magnetizes a finished product,and improves assembly efficiency and assembly quality.

Owner:嘉兴市中欣自动化设备有限公司

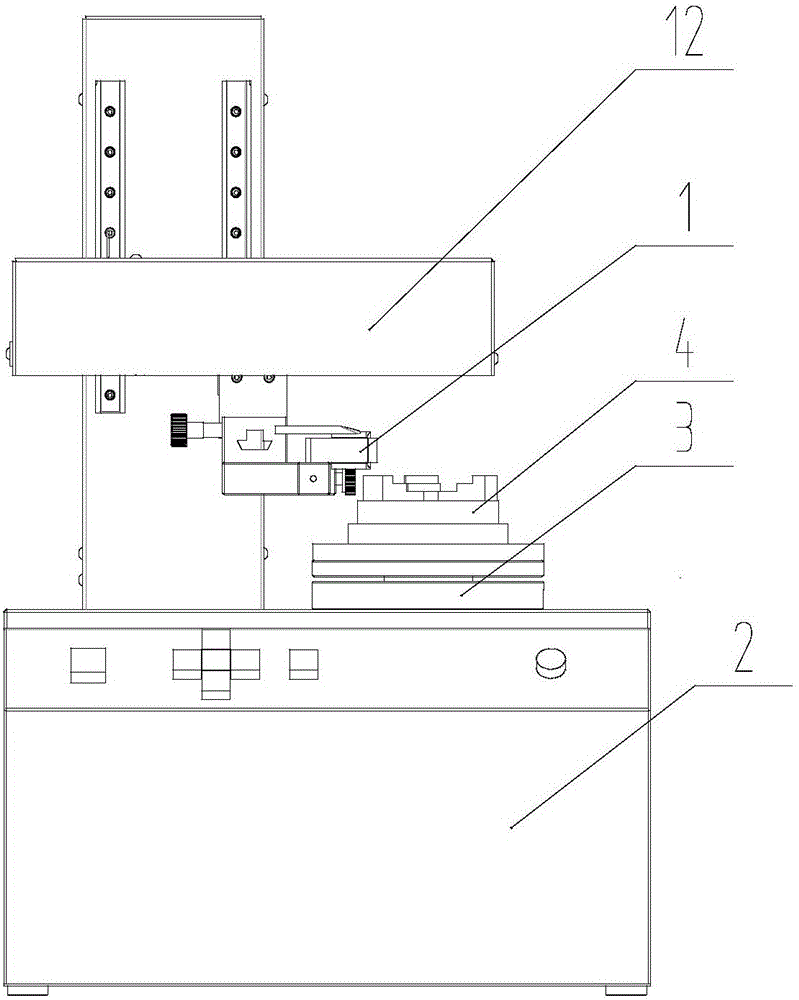

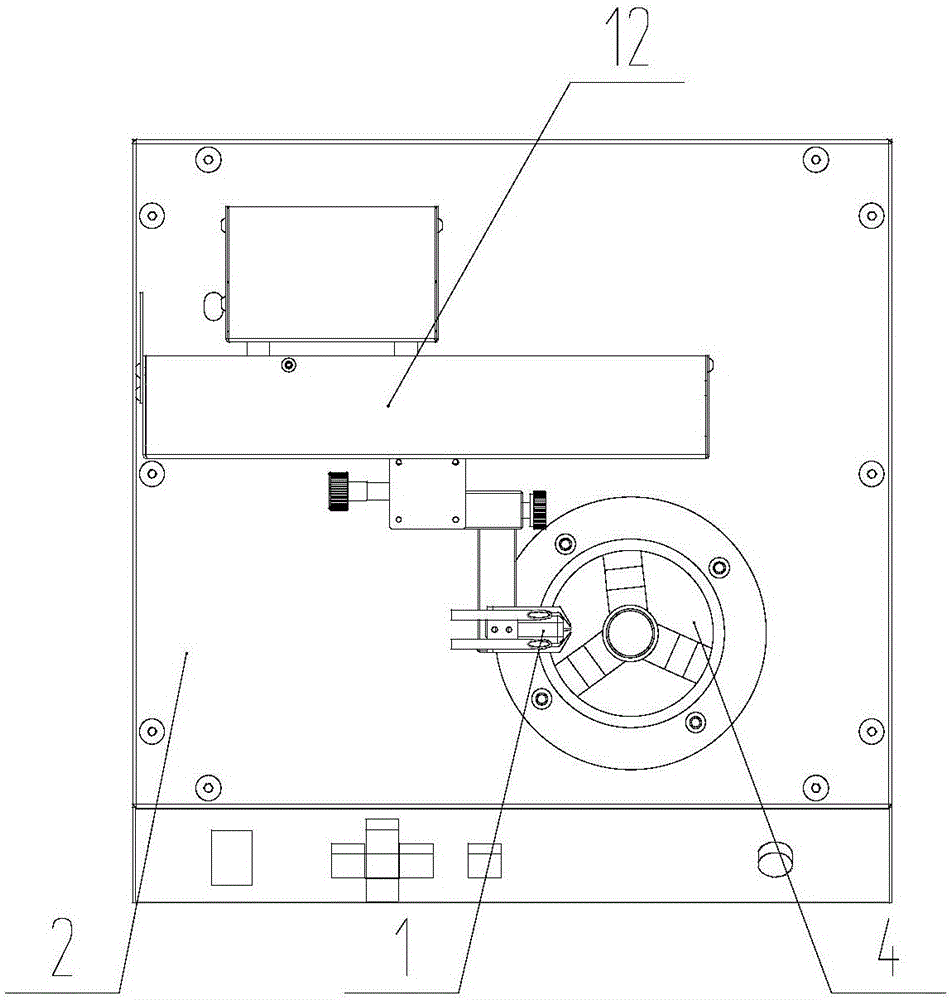

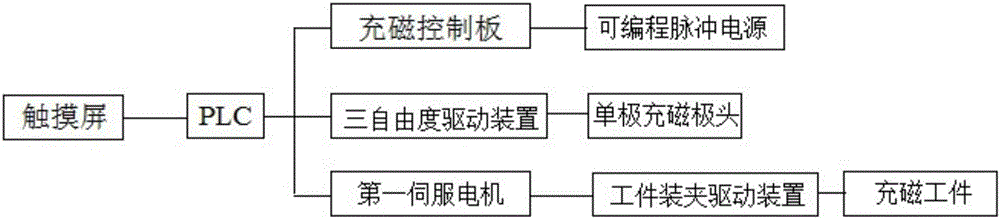

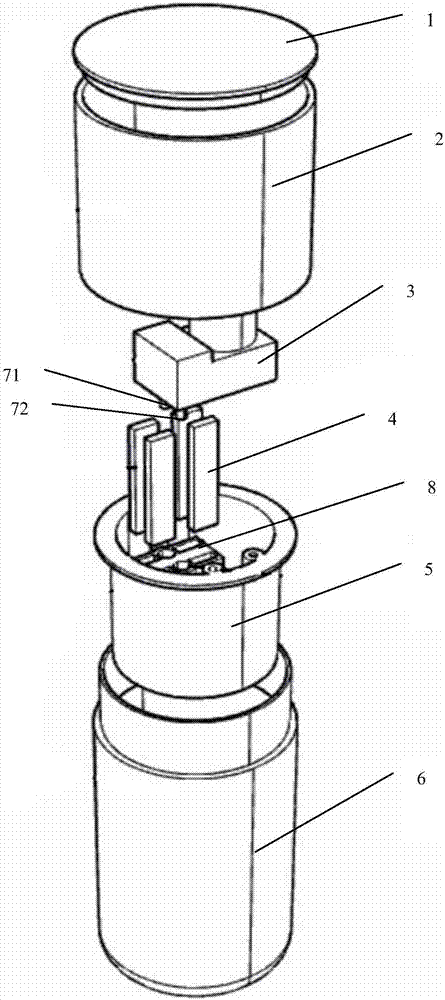

Single pole programmable magnetizing equipment

ActiveCN106601430ACompact structureReduce manufacturing costMagnetic bodiesMagnetizationPulse power supply

The invention discloses single pole programmable magnetizing equipment. A single pole magnetizing head is installed on a three-freedom driving device; a magnetizing work piece is mounted on a work piece assembling driving device; the three-freedom driving device is adjusted, so the single pole magnetizing head can be close to the magnetizing work piece and outputs pulse currents to the single pole magnetizing head; the single pole magnetizing head can magnetize the magnetizing work piece via instant pulse currents provided by a programmable pulse power supply; when one time magnetization is finished, the singe pole magnetizing head drives the magnetizing work piece to move to a next to-be-magnetized position at pulse current interval; and the single magnetizing pole head is reutilized for next time magnetization; the process is continued until the whole magnetizing work piece is magnetized. The single pole magnetizing head is employed for the magnetizing head, so the pole width and size of the single pole magnetizing head are suitable for magnetization of magnetizing products of various sizes and pole numbers; the operation is simple and the whole magnetizing process can be automatically controlled; and high magnetizing efficiency can be improved and high product pass percent can be achieved.

Owner:HANGZHOU MINGZHE MAGNETIC TECH

Magnetic health cup

ActiveCN106859207AImprove the magnetization effectImprove magnetization efficiencyWater/sewage treatment by magnetic/electric fieldsDrinking vesselsEngineeringMechanical engineering

The invention discloses a magnetic health cup, including a body, a central case, a water pump, magnetic steel and an inner seat. The inner seat consists of a cavity of seat formed between side board of the seat and underside of the seat. A fixed block is installed in the cavity of the seat. Four grooves and two flow channels are installed in the fixed block. The flow channels are well versed in the underside of the seat. Each side of the flow channel is installed symmetrically a groove. The magnetic steel is put in the groove. The fixed block is provided with the motor of the water pump. Water inlet and water outlet of the water pump are equipped with a water inlet tube and a water outlet tube respectively. The water inlet tube and the water outlet tube is located in the same flow channel. The central case is a barrel without base and cap. Upper part of the inner seat is suited in the cavity of the central case and is connected with the cavity of the central case. The bottom part of the inner seat is suited in the body and is located in the central case above the body, which is connected separately with the body.

Owner:HANGZHOU HACI IND CO LTD

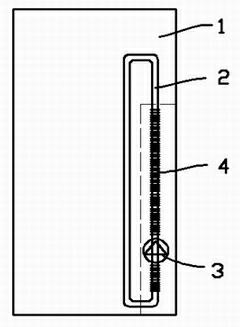

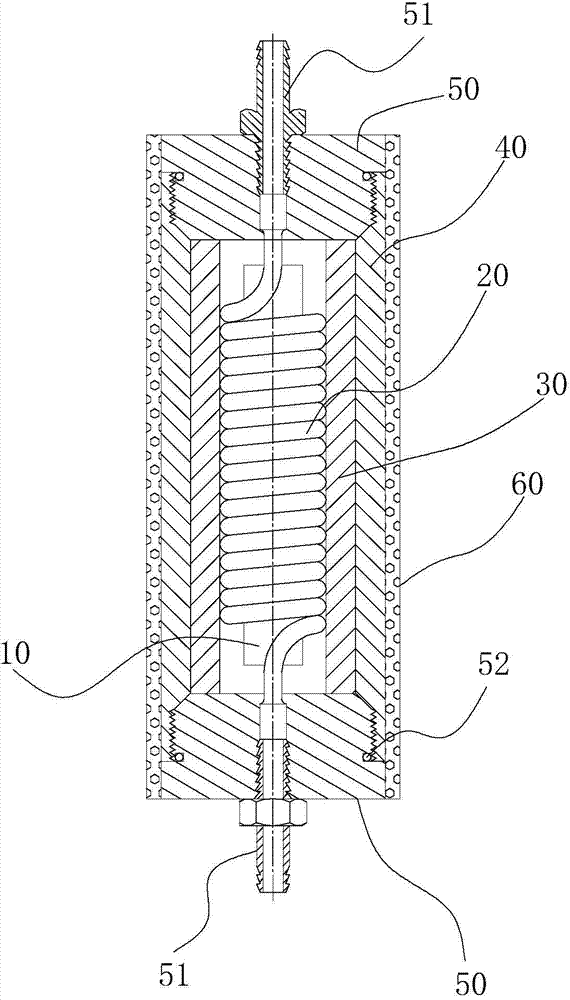

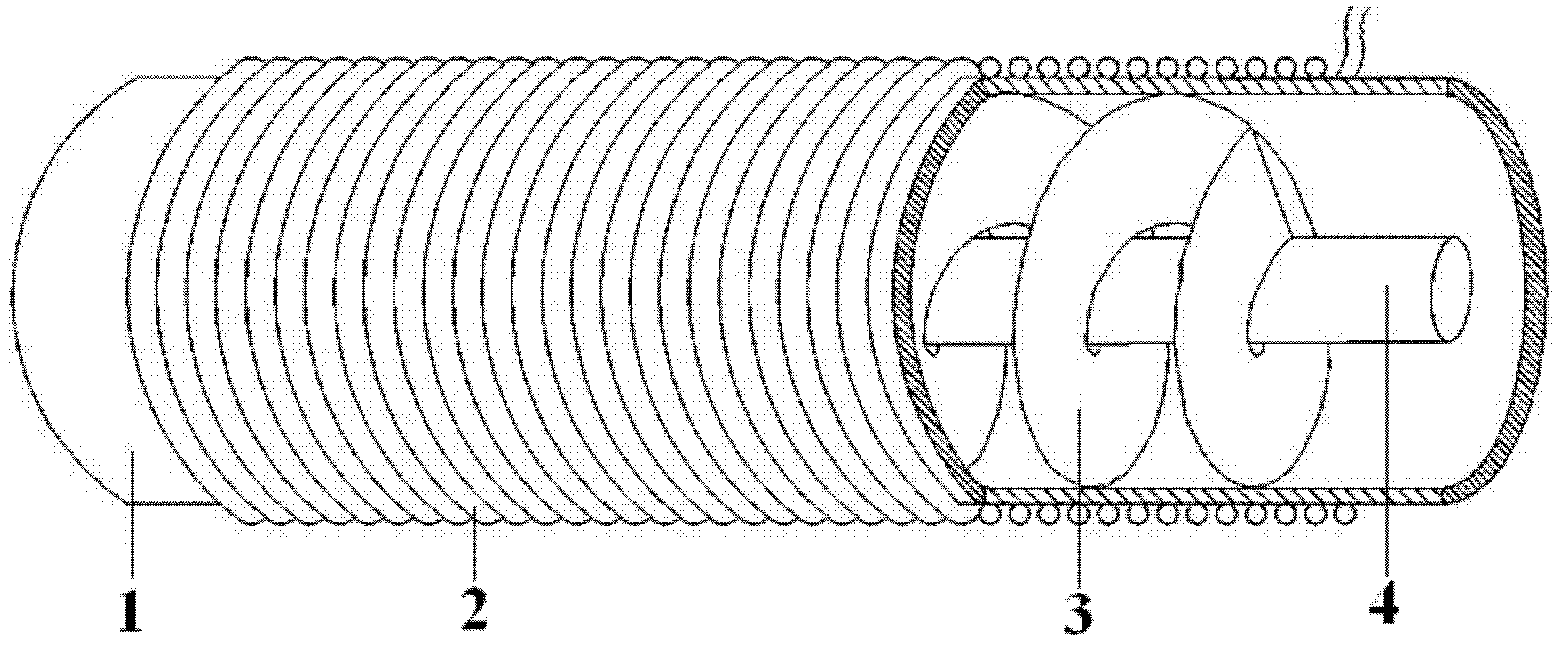

Powerful magnetization device for fluid

ActiveCN103482736AIncrease the magnetic field strengthImprove magnetization efficiencyMagnetic bodiesWater/sewage treatment by magnetic/electric fieldsMagnetic lineMagnetic energy

The invention discloses a powerful magnetization device for a fluid, which comprises a permanent magnet bar and a spiral pipe wound at the periphery of the permanent magnet bar, wherein the periphery of the spiral pipe is further provided with a permanent magnet sleeve pipe; and a fluid to be magnetized flows in the spiral pipe. According to the invention, the fluid to be magnetized flows in the spiral pipe and is magnetized by the permanent magnet bar at the inner side and the permanent magnet sleeve pipe at the outer side, thereby realizing that the magnetic field intensity in the magnet pipe can be up to 20000GS, and ensuring that the fluid maximally cuts magnetic lines in the process of flowing across the magnet pipe. The powerful magnetization device is simple in structure, greatly improves the magnetic field intensity caused by magnetization, solves the defects of the existing magnetization treatment device such as complex structure, multiple parts, large volume, heavy weight and low magnetic energy product utilization ratio, and achieves the advantages of high unit-volume magnetization efficiency, small volume, light weight, simple structure and good manufacturability. Besides, the powerful magnetization device is wide in application range, low in cost and convenient to organize mass production.

Owner:深圳市诺狄环保科技有限公司

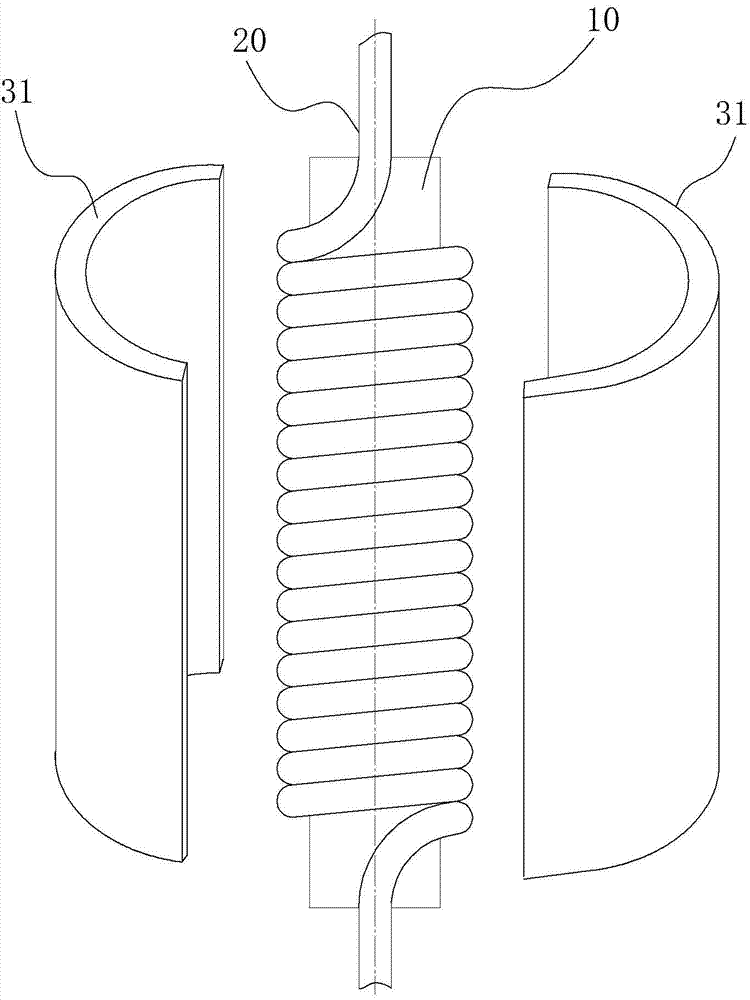

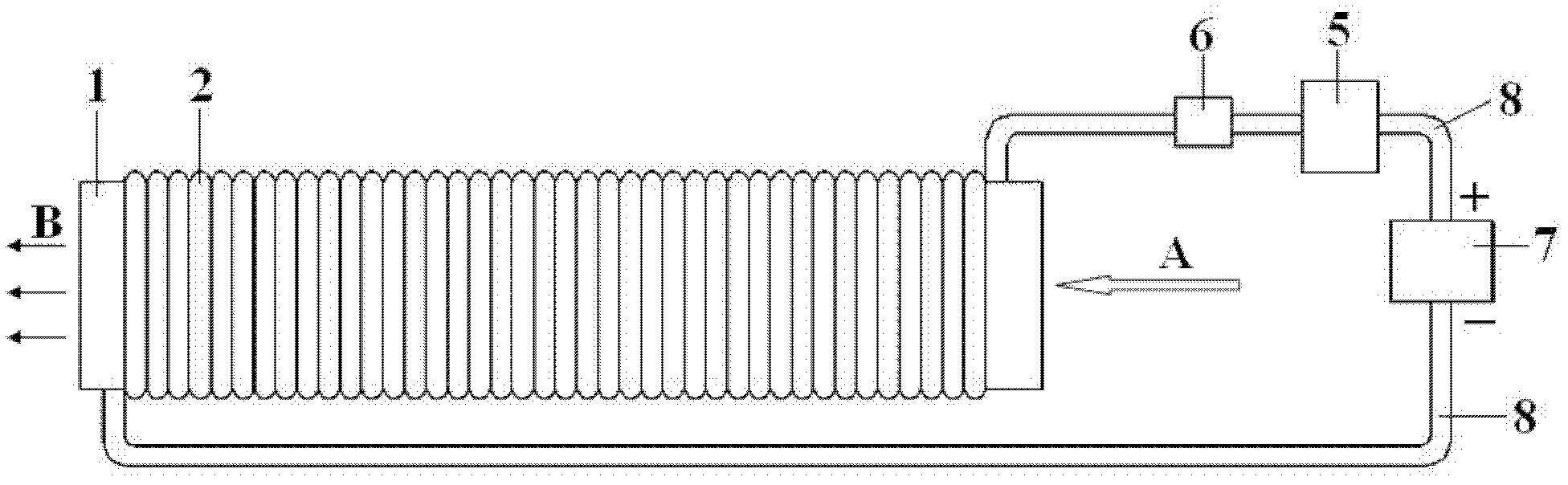

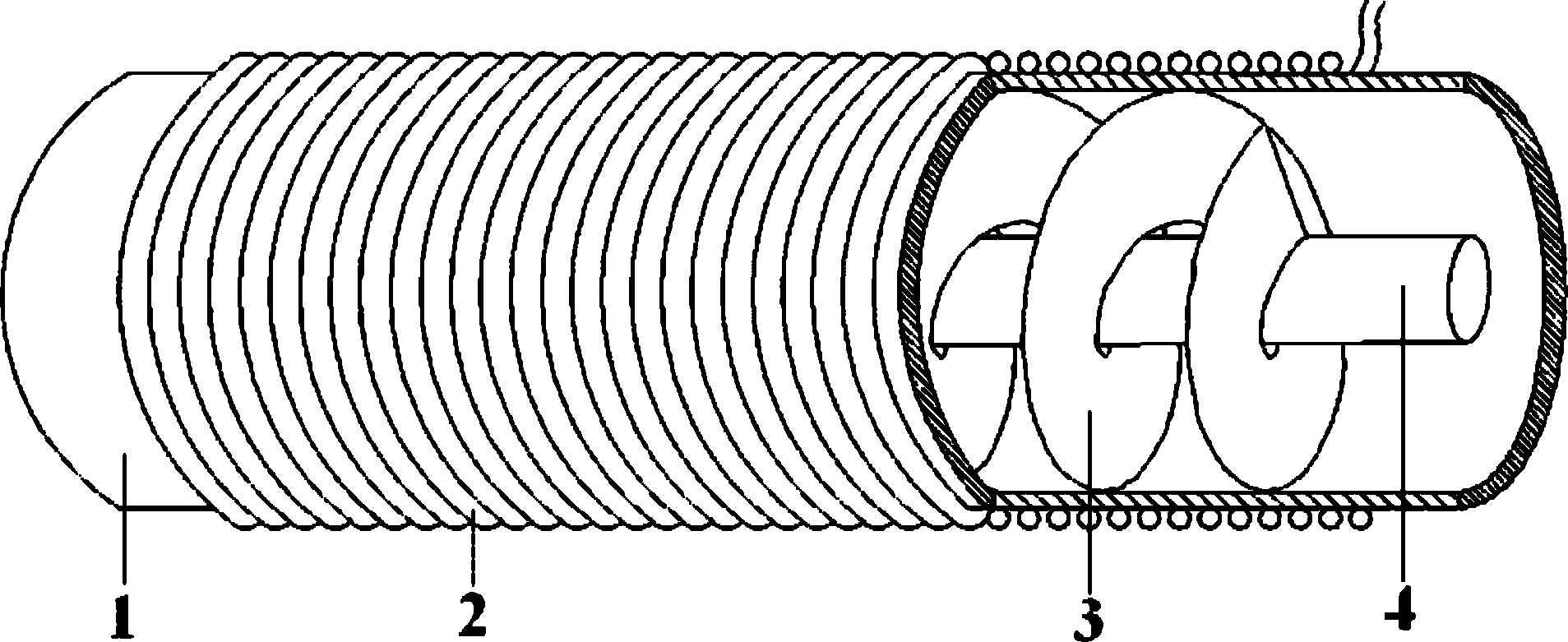

High-efficiency fluid electromagnetic magnetizer

InactiveCN102360716AIncrease distanceImprove magnetization efficiencyMagnetic bodiesWater/sewage treatment by magnetic/electric fieldsTime lagMagnetization

The invention discloses a high-efficiency fluid electromagnetic magnetizer which comprises a tube body, an electromagnetic winding, a guiding spiral sheet and a tube core, wherein electromagnetic wires are wound outside the peripheral surface of the tube body to form the electromagnetic winding, the tube core is arranged in the inner cavity of the tube body, and the guiding spiral sheet is arranged outside the peripheral surface of the tube core. The magnetizer can eliminate fluid turbulence caused by various factors, thereby effectively ensuring the continuity of fluid magnetization, and minimizing the influence of time lag and turbulence on the magnetization effect. Under the condition of ensuring that the fluid motion direction is approximately vertical to the magnetic field direction, the fluid in the tube passes through the magnetizer in a spiral mode at a flow speed as large as possible, thereby ensuring the requirement for vertically cutting magnetic lines in a magnetic field at a high speed, greatly prolonging the effective time of the fluid in the magnetic field, greatly increasing the equivalent space of the effective magnetic field, and greatly improving the magnetization effect. Meanwhile, the volume of equipment can be reduced, and the intensity of the magnetic field generated in the tube body is controlled.

Owner:宜兴市氿润环保研究所有限公司

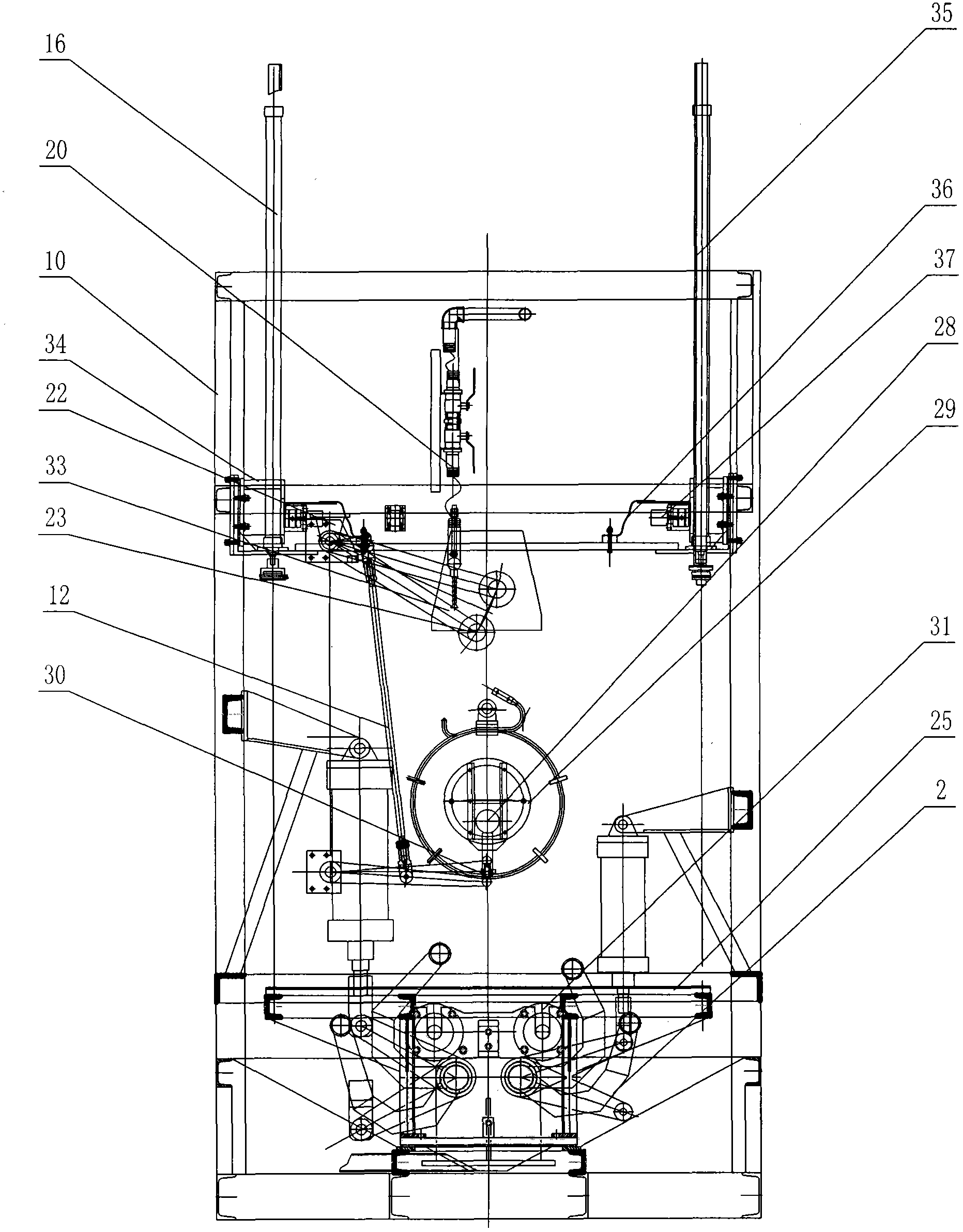

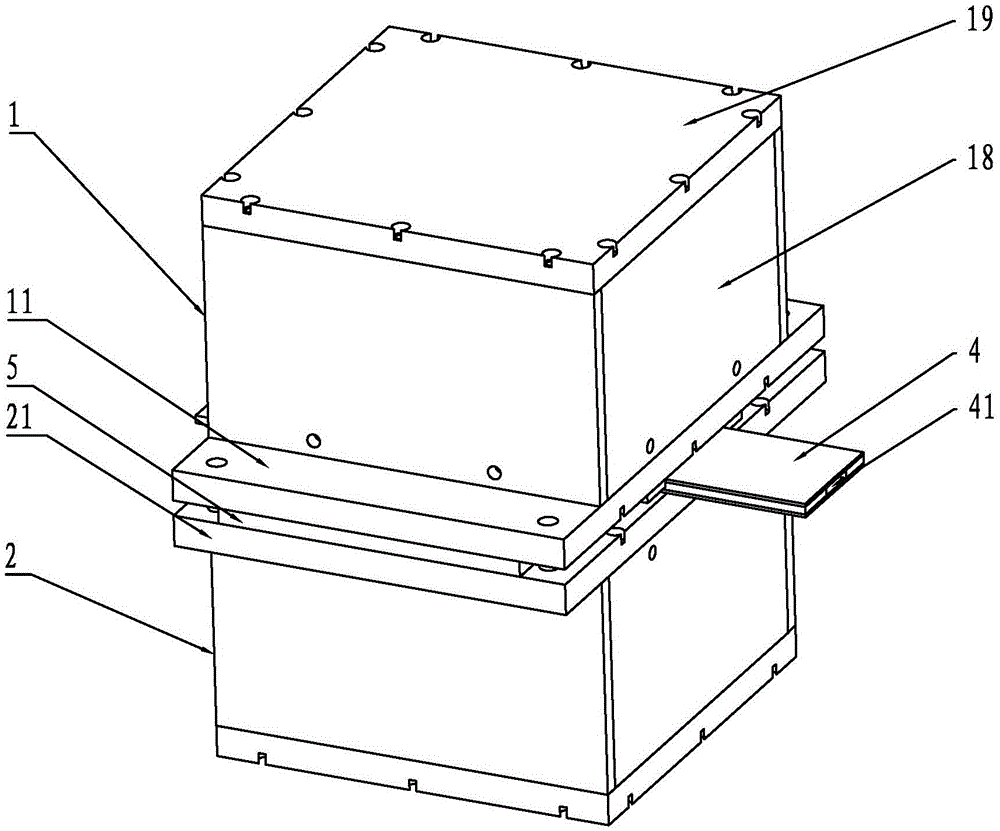

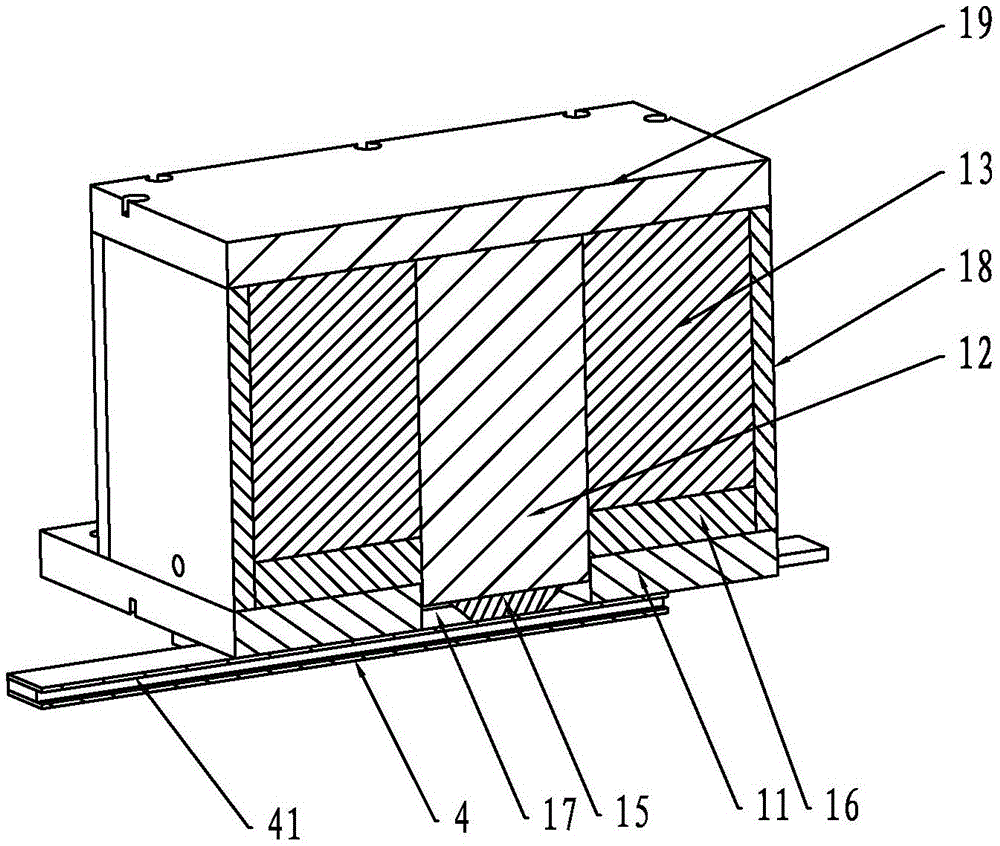

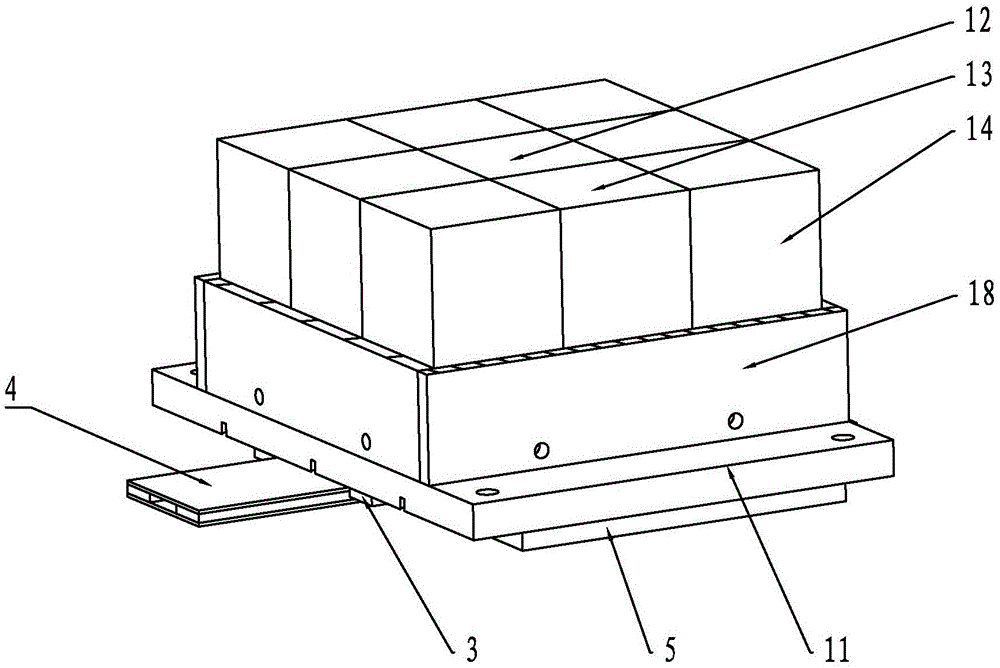

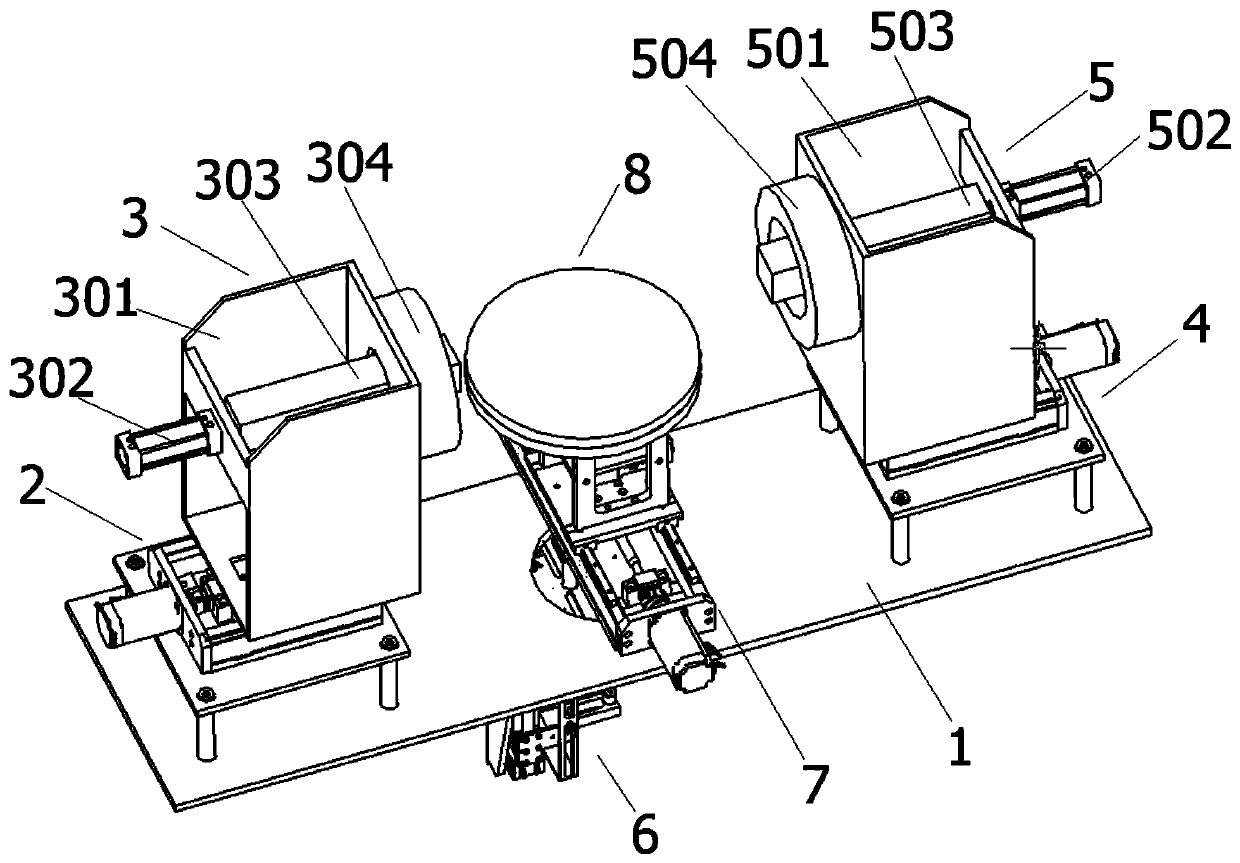

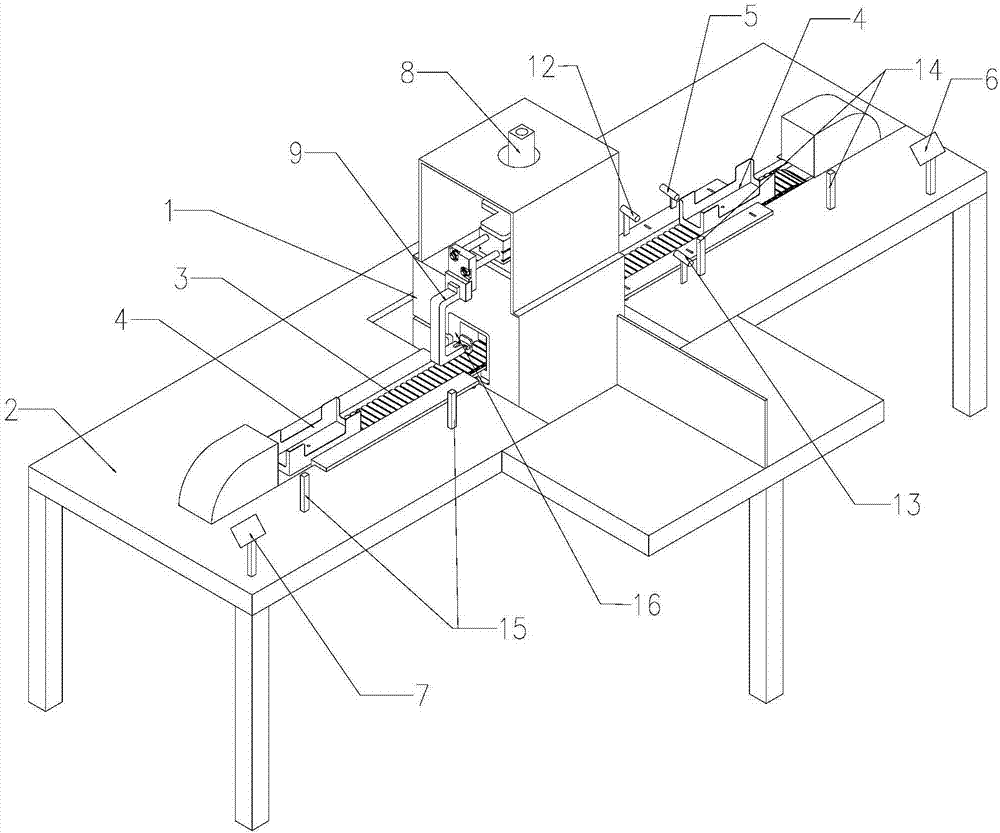

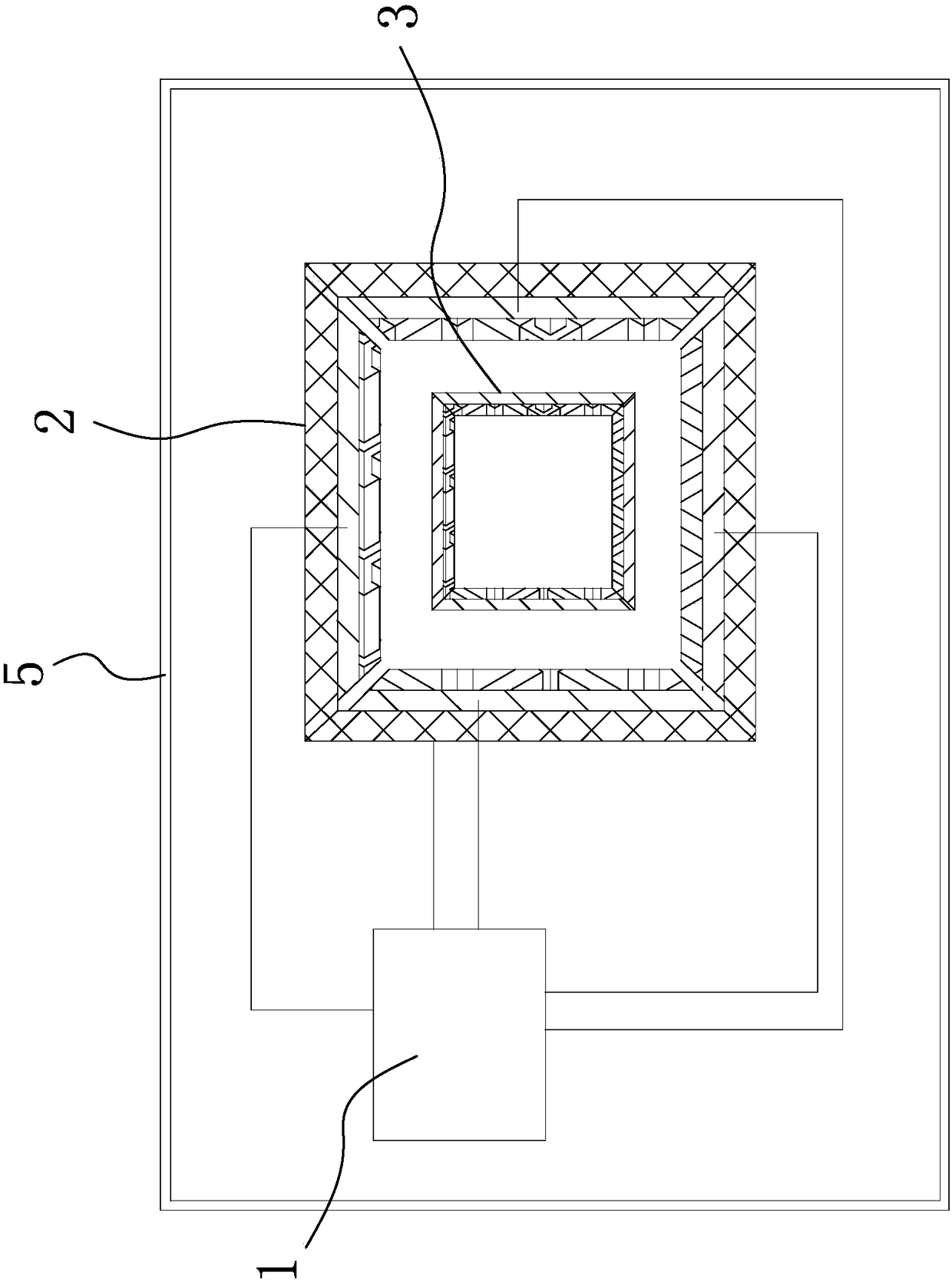

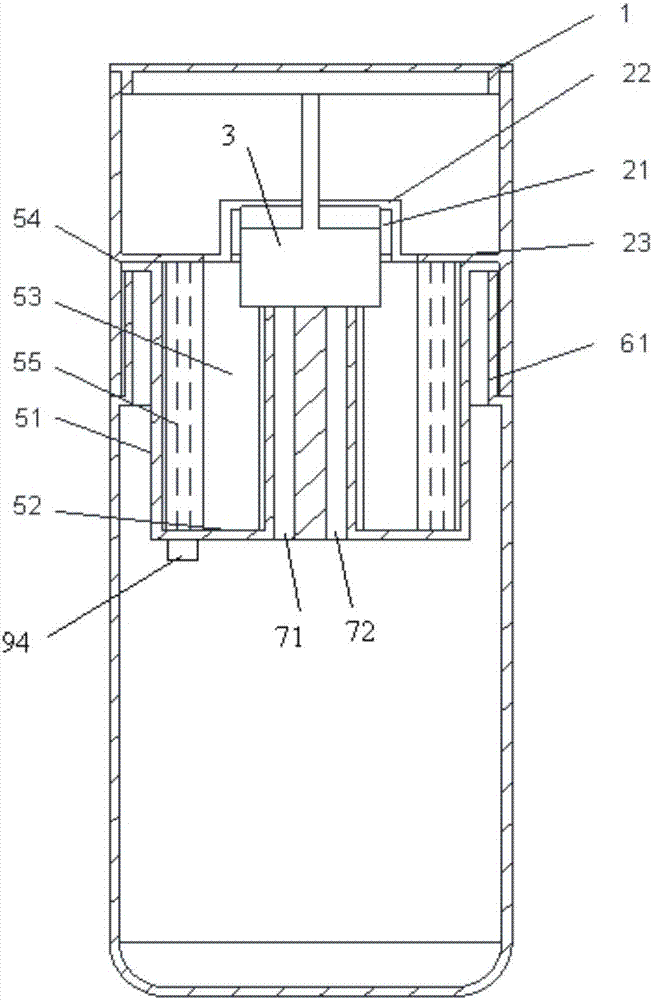

Magnetizing and checking integrated equipment

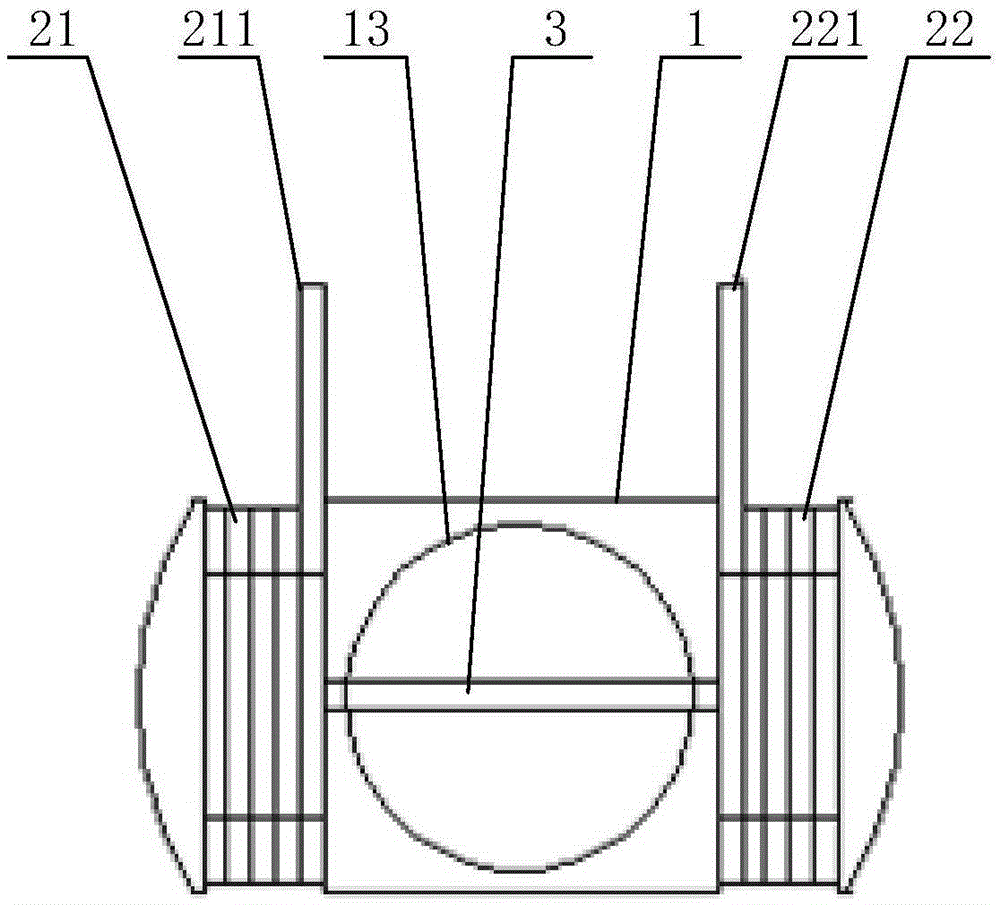

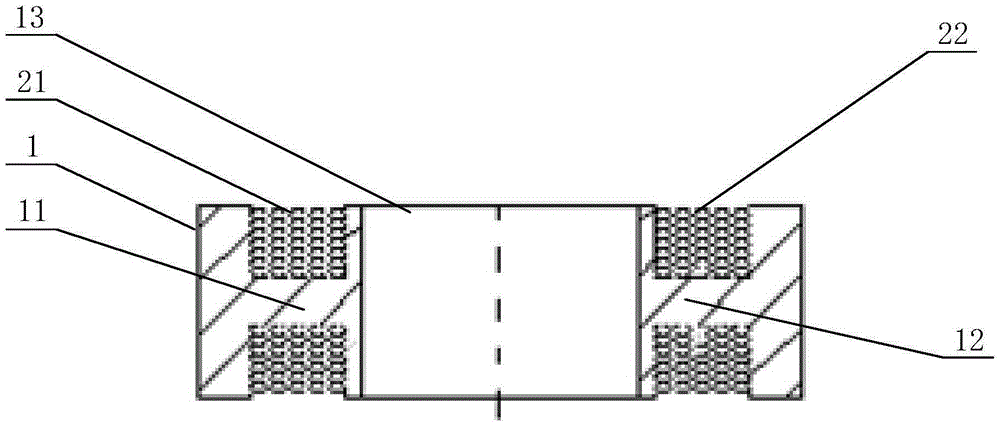

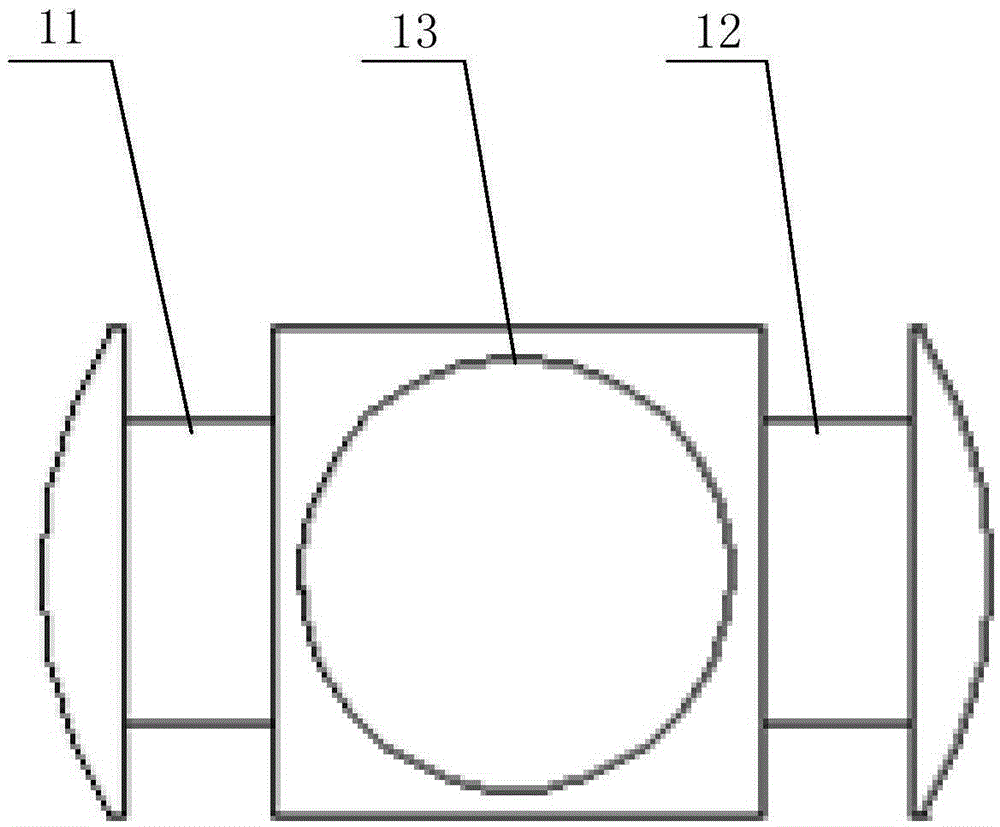

PendingCN109731809AHigh degree of automationImprove magnetization efficiencyMagnetic bodiesMagnetic property measurementsEngineeringMagnetic flux

The invention discloses magnetizing and checking integrated equipment. The magnetizing and checking integrated equipment comprises a machine base (1), a feeding mechanism (2), a magnetizing machine (3), a magnetic flux detection device (4) and a mechanical arm assembly (5), the feeding mechanism (2) is arranged on one side of the machine base (1), a mounting groove (6) is formed in the machine base (1), the magnetizing machine (3) is fixed in the mounting groove (6), a placement groove A (7) is formed in front of the magnetizing machine (3), the magnetic flux detection device (4) is arranged in the middle of the machine base (1) and is located on one side of the magnetizing machine (3), the top of the magnetic flux detection device (4) is provided with a placement groove B (8), a distinguishing device (9) is further arranged on the side, far away from the magnetizing machine (3), of the magnetic flux detection device (4), a machine frame (10) is further arranged on the machine base (1), a machine shaft (11) is fixed on the machine frame (10), and the mechanical arm assembly (5) is installed on the machine shaft (11). According to the magnetizing and checking integrated equipment, the labor intensity of workers is reduced, and the magnetizing efficiency is improved.

Owner:CHENGDU TO NAN ELECTRONICS

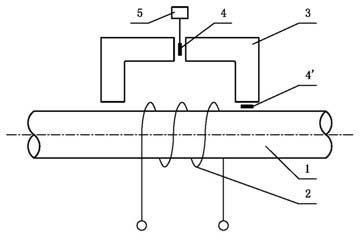

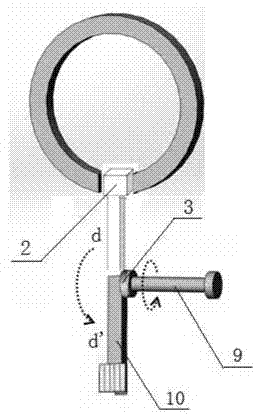

Residual magnetism flaw detection method and device for piston rings based on series-connection closed type magnetization

ActiveCN104764800AImprove magnetization efficiencyAvoid space magnetic field interferenceMaterial magnetic variablesPhysicsMagnetic noise

The invention relates to a residual magnetism flaw detection method and a residual magnetism flaw detection device for piston rings based on series-connection closed type magnetization. The N pole and the S pole of single permanent magnet 2 and a piston ring 1 form an annular magnetic loop, the penetrating-through magnetization in a circumferential direction is realized by the maximum magnetic energy density, a workpiece is scanned by multiple space sensitivity scale magnetic-sensing detection units 4' in a circumferential direction after the magnet is separated, a leakage magnetic field generated by a flaw is picked up and is converted into an electrical signal, and whether a flaw exists in the piston ring or not is judged through signal mutation. According to the residual magnetism flaw detection method, different opening gaps and a trans-scale flaw in irregular cross section of the piston ring 1 can be detected through the array type magnetic-sensing detection units 4' surrounding the piston ring 1, and the flaw detection rate is high; and besides, the problems of magnetic noise and the blind flaw detection end part in magnetic flux leakage detection of the piston ring 1 are solved and the automatic flaw detection of the piston ring 1 can be realized.

Owner:WUHAN HUAYUYIMU TESTING EQUIP CO LTD

Indirect matrix transformation multi-phase multi-level permanent magnet motor system and its control method

ActiveCN105896856BImprove torque rippleMeet the requirements of compact designElectronic commutation motor controlAC motor controlThree levelPermanent magnet synchronous motor

The invention discloses an indirect matrix transformation type multi-phase multi-level permanent magnet motor system. The indirect matrix transformation type multi-phase multi-level permanent magnet motor system includes a double-stator multi-phase composite permanent magnet synchronous motor, wherein two independent five-phase three-level inverters supplies power for stator winding ports of the motor respectively; an independent controllable rectifier supplies power for each five-phase three-level inverter; the two controllable rectifiers can share one set of LC filter at the power grid side; the LC filter includes a three-phase grid-connected inductor and a three-phase filter capacitor which is connected with the three-phase grid-connected inductor in parallel; and the first five-phase three-level inverter and the second five-phase three-level inverter are respectively connected with the two stator winding ports of the double-stator multi-phase composite permanent magnet synchronous motor. The invention also discloses a control method of the indirect matrix transformation type multi-phase multi-level permanent magnet motor system. The indirect matrix transformation type multi-phase multi-level permanent magnet motor system and the control method thereof can significantly improve reliability, power density, torque smoothness and operation efficiency of the motor driving system, and can lay the foundation of solving the technical difficulty that a high capacity motor traction driving system requires compact designs, reliable operation and energy-efficient aspects.

Owner:SOUTHEAST UNIV

Magnetization device

InactiveCN105405572AImprove magnetization efficiencyReduce manufacturing costMagnetic bodiesMagnetizationEngineering

The invention relates to the technical field of electromagnetism, in particular to a magnetization device. The magnetization device comprises a base body, a first winding coil and a second winding coil, wherein the matrix comprises a first winding segment and a second winding segment, which are arranged at two ends respectively; the first winding coil is wound on the first winding segment; the second winding coil is wound on the second winding segment; and the first winding coil and the second winding coil are opposite in winding direction. Through the structure arrangement, the magnetization device can simultaneously carry out magnetization on two to-be-magnetized parts at the first winding segment and the second winding segment, so that the work efficiency is significantly improved; and meanwhile, the cost is reduced.

Owner:CHONGQING WUFU TECH

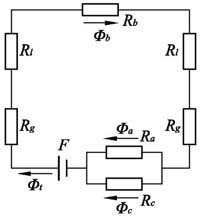

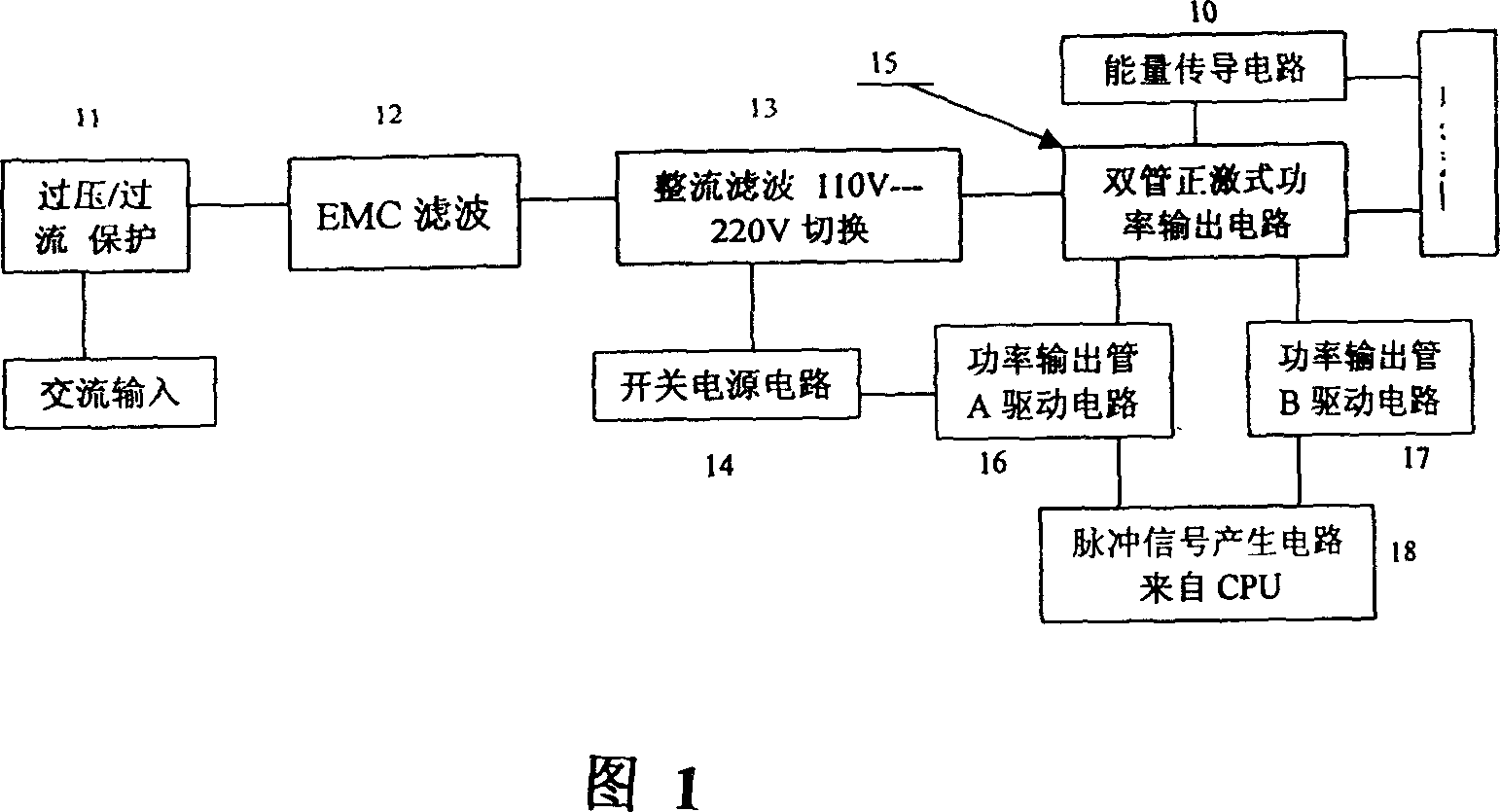

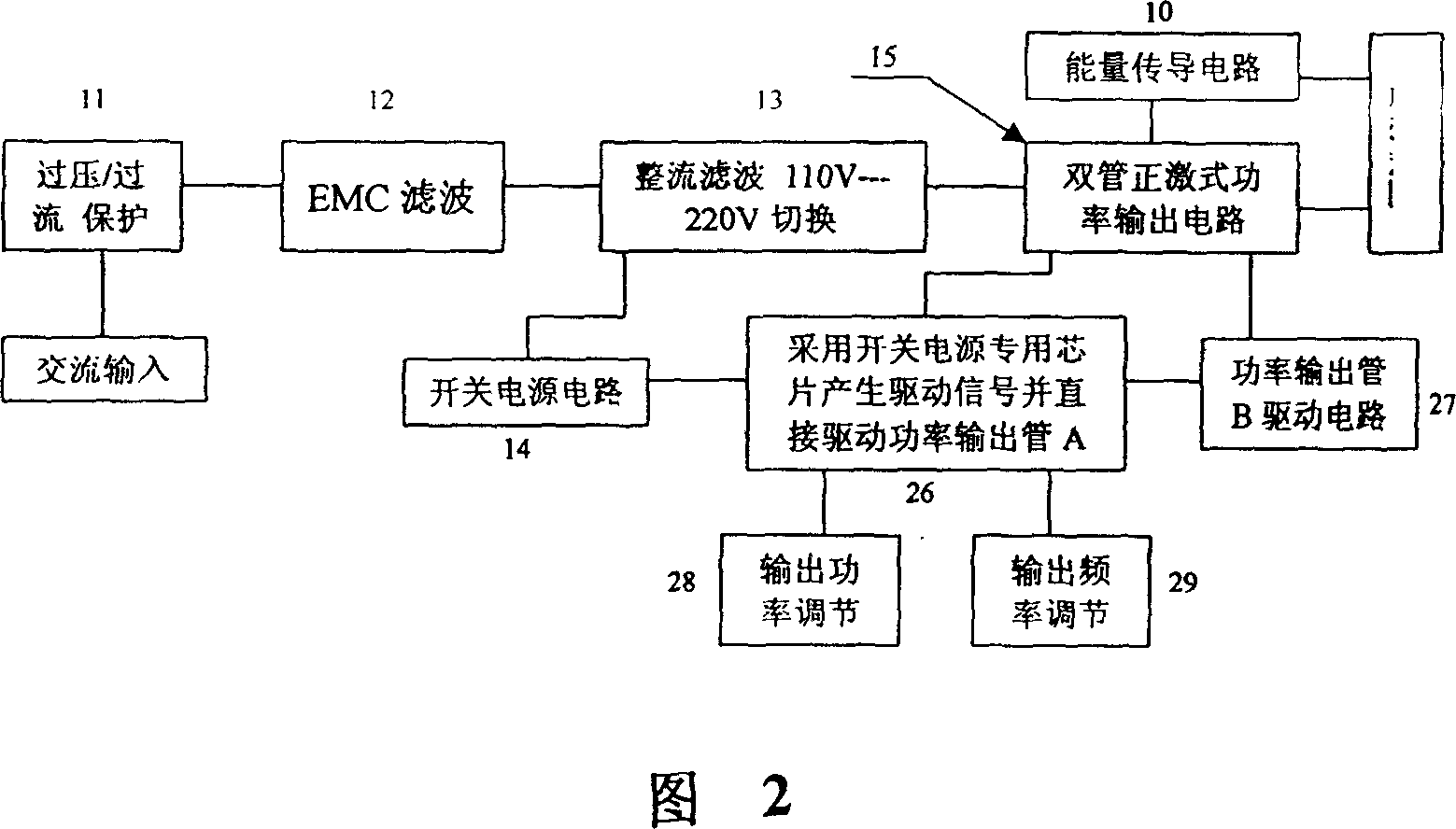

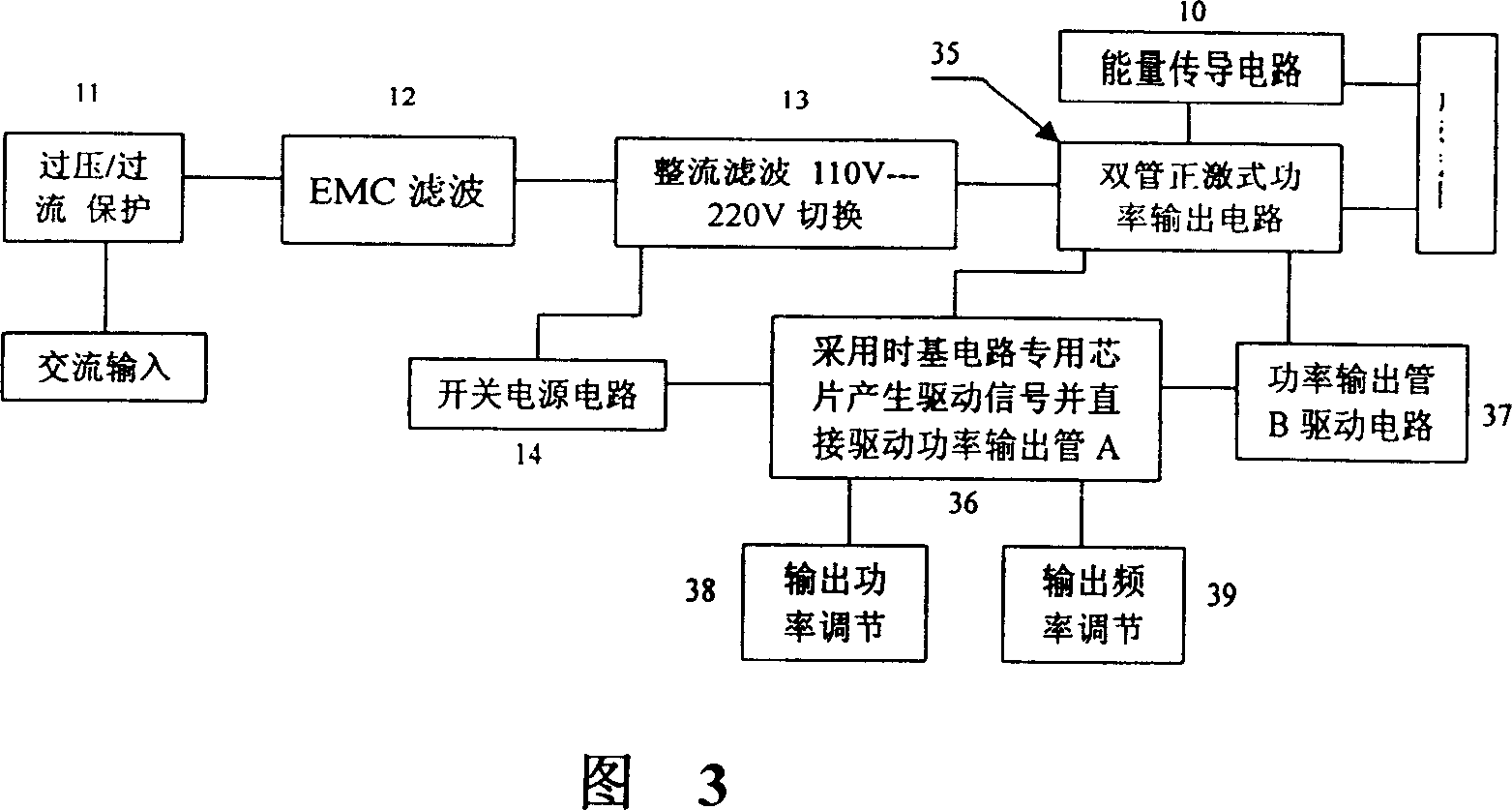

Control circuit of magnetized liquid device

InactiveCN1966417AAvoid offsetImprove magnetization efficiencyWater/sewage treatment by magnetic/electric fieldsCapacitanceDriver circuit

The invention is about a pilot circuit of liquid magnetizing device which includes rectifying and filter circuit, switch circuit, energizing circuit and energy-conducting circuit. The switch circuit contains at least one power transistor, every power transistor works in on and off state, during the period when the power transistor is broken-over; the pulse power source is exerted to the magnet exciting coil. The characteristic of the circuit: when the power transistor changes from break-over to cut-off, the energy stored in the magnetic field goes back to the filtering capacitance, when the power transistor is broken-over again, the electric charges is utilized again to become the magnetic energy in the coil so the invention has quite little energy expenditure. The advantages of the invention: the pulse magnetic field in the invention can improve the magnetizing efficiency and decrease the energy expenditure; the control circuit in the invention can decrease the consumed power in pilot circuit, extend the service life of the pilot circuit as well as decrease the cost.

Owner:蔡志峰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com