Magnetic powder detection device for omnibearing detection of steel structure

A magnetic particle detection, all-round technology, applied in the direction of material magnetic variables, etc., can solve the problems of inconvenient use, low magnetization efficiency, and inability to magnetize workpieces of different sizes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

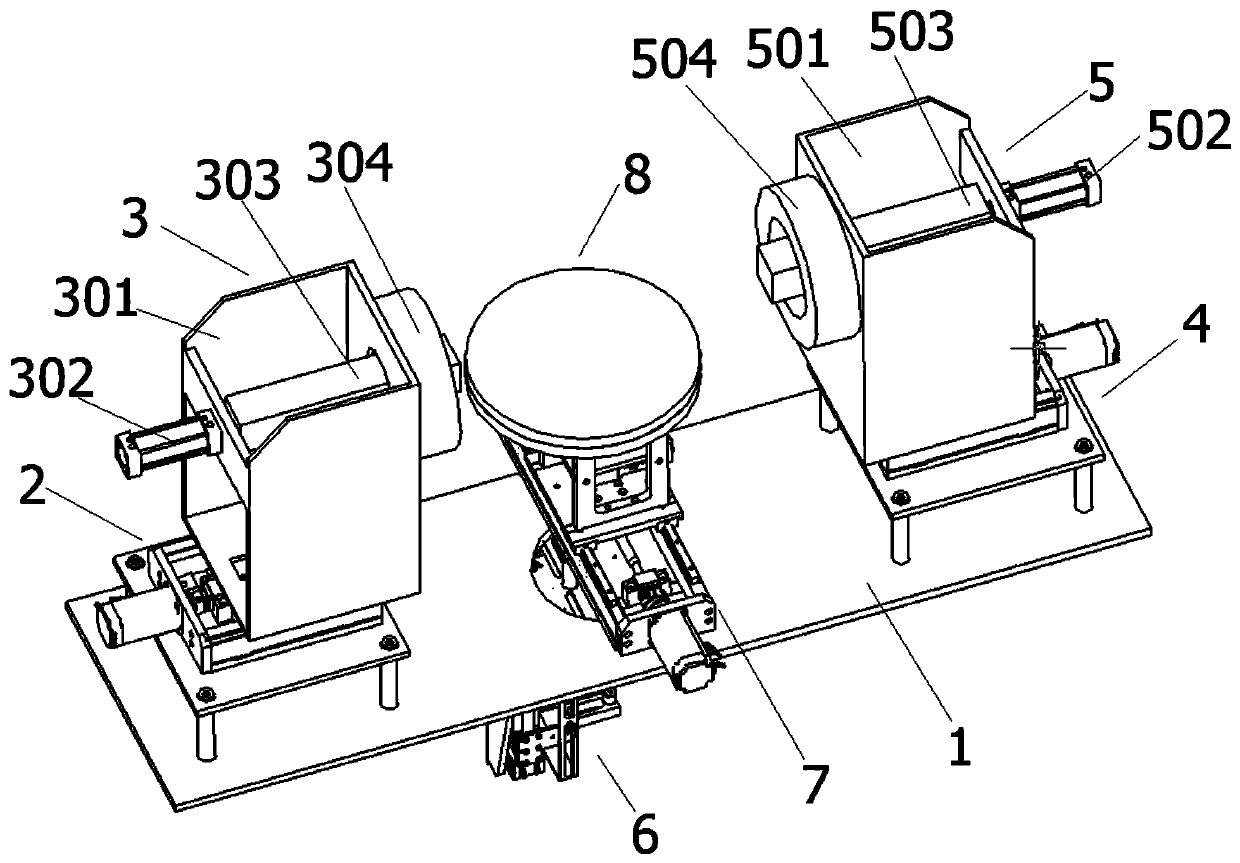

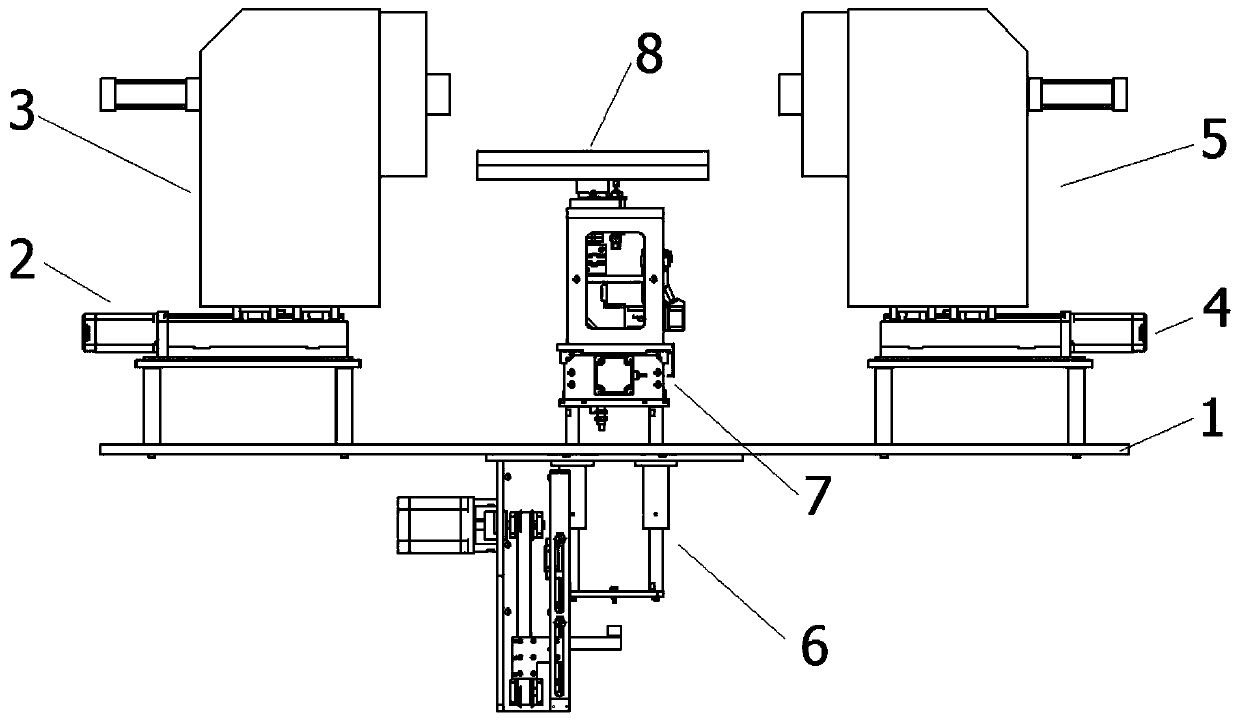

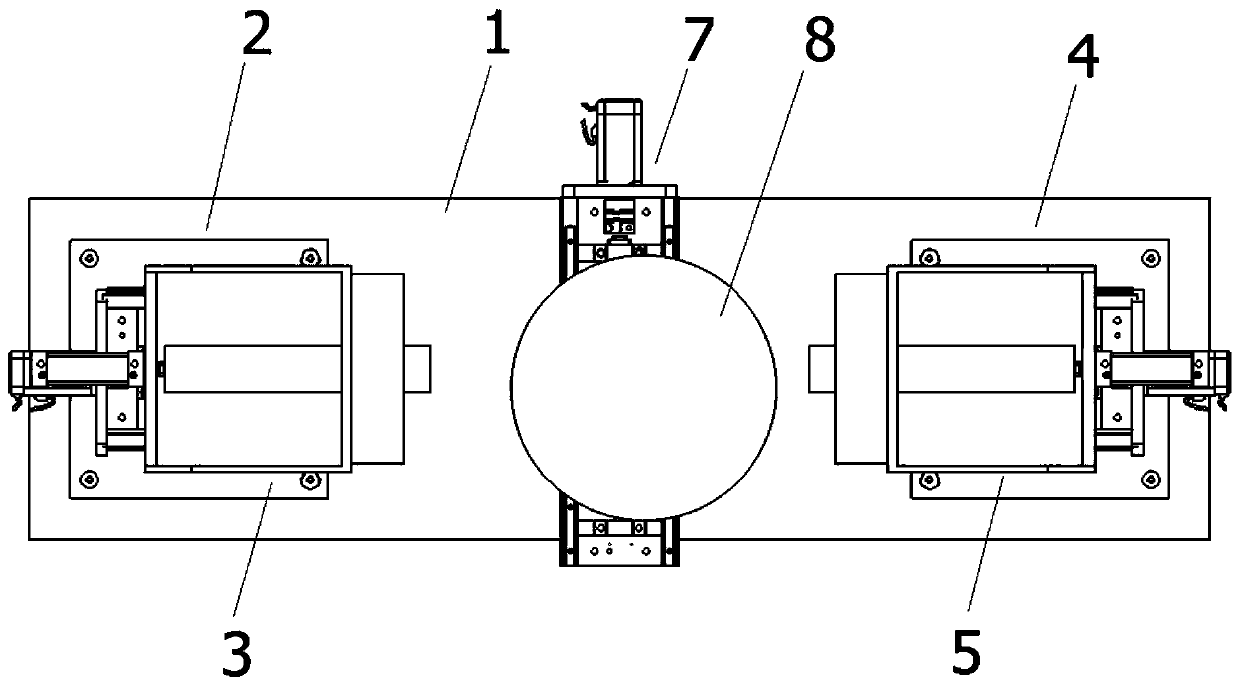

[0036] see Figure 1-8, in an embodiment of the present invention, a magnetic particle inspection device for all-round inspection of steel structures includes a fixed large base plate 1, and a left X-axis driving mechanism 2 is fixed on the left side of the upper end surface of the fixed large base plate 1 by screws. For flaw detection in the X-axis direction of the workpiece, a left magnetic particle flaw detection mechanism 3 is fixed above the left X-axis drive mechanism 2 by screws for flaw detection on the left side of the workpiece. The right X-axis drive mechanism 4 is used for flaw detection in the X-axis direction of the workpiece. The right magnetic particle flaw detection mechanism 5 is fixed above the right X-axis drive mechanism 4 by screws for flaw detection on the right side of the workpiece. The fixed large base plate 1 The middle part of the lower end surface is connected with a Z-axis driving mechanism 6 by screws for flaw detection in the Z-axis direction of...

Embodiment 2

[0046] The rotary platform 8 includes a rotating support plate 801 connected to the upper end surface of the Y-axis moving plate 706 by screws, the upper end surface of the rotating support plate 801 is connected to the upper mounting plate 802 by screws, and the middle part of the upper mounting plate 802 is connected to the bearing seat C803 is connected by screws, and the bearing seat C803 is slidingly connected with the shaft flange 804 to play a role of stable rotation. The lower end of the shaft flange 804 is connected with the reducer 805 through a coupling, and the reducer 805 provides the workpiece The power to rotate in the axial direction, the reducer 805 and the lower end surface of the lower mounting plate 806 are connected by screws, the lower mounting plate 806 is fixed on the inner wall of the rotating support plate 801 by screws, and the upper end surface of the rotating shaft flange 804 is connected to the rotating platform 807 is connected by screws, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com