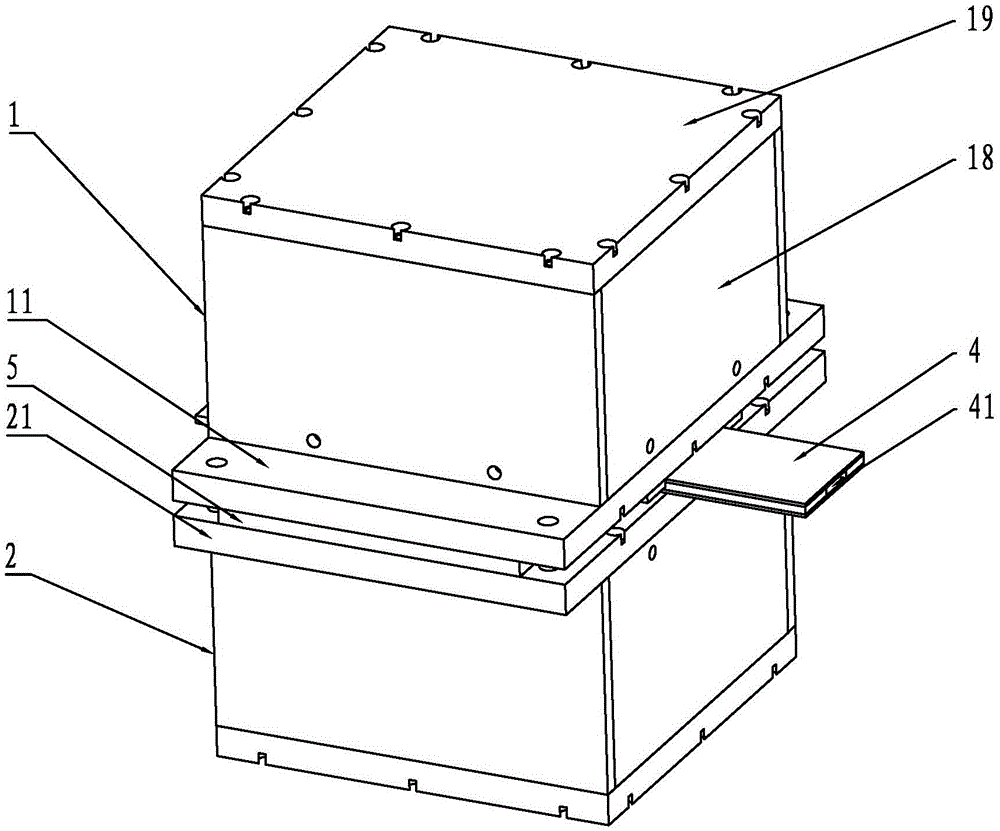

Magnetostatic field magnetizing device and method at normal temperature

A magnetizing device, a technology of static magnetic field, applied in the direction of magnetic objects, transportation and packaging, conveyor objects, etc., can solve the problems of unsuitable long-term, frequent use, large area of magnetization equipment, and high instantaneous current, so as to improve the charging efficiency. Magnetic efficiency, reduce production energy costs, and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

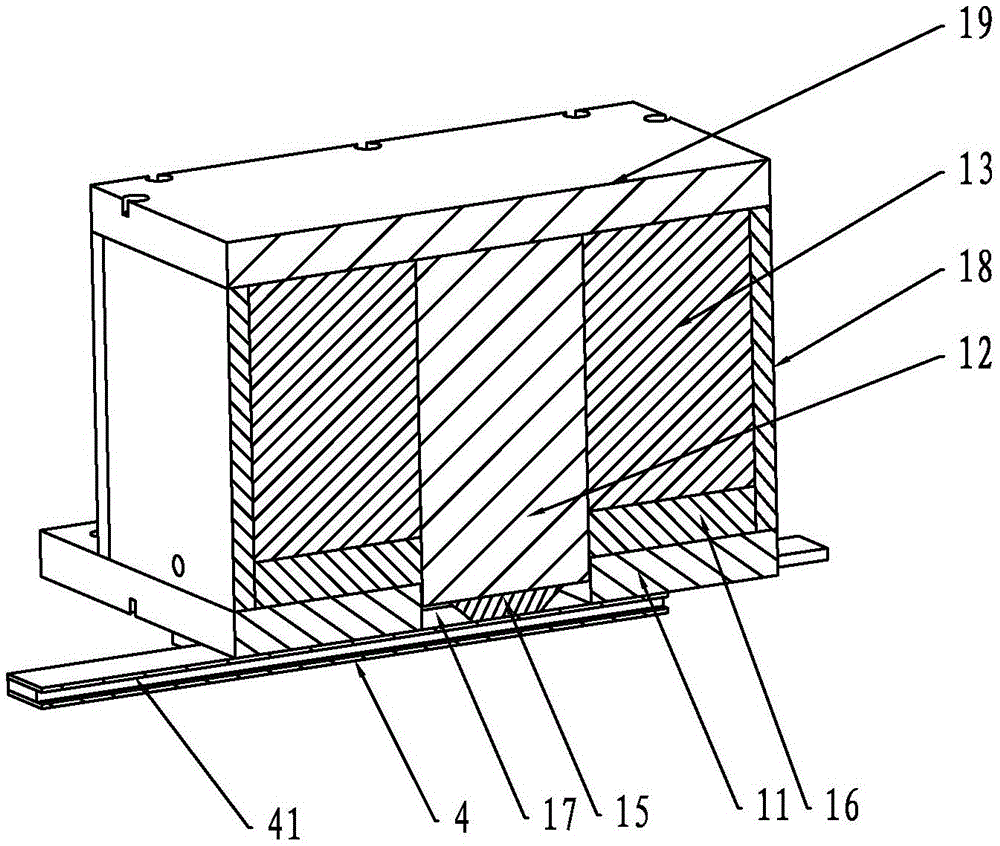

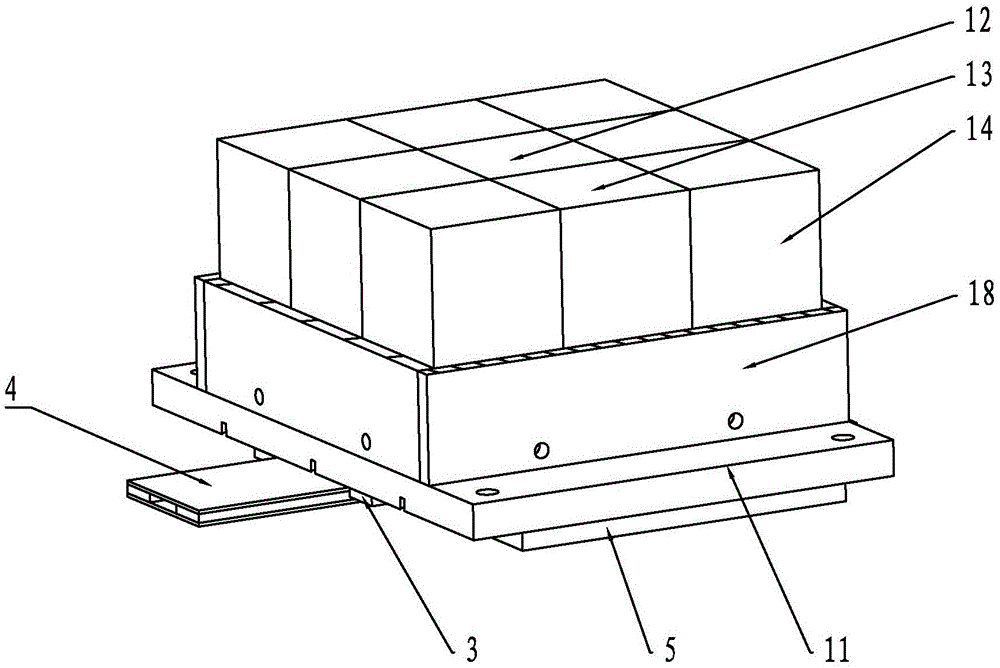

Method used

Image

Examples

Embodiment 1

[0045] The sample is a sintered Nd-Fe-B magnet with commercial grade N50H. The magnet performance is: Br=14.0KGs; Hcb=12.9kOe; Hcj=16kOe; Hk / Hcj=0.7; (BH)m=48MGOe; commercial grade is N42UH The sintered Nd-Fe-B magnet, the magnet properties are: Br=13.0KGs; Hcb=12kOe; Hcj=25kOe; Hk / Hcj=0.6; (BH)m=40MGOe. The dimensions of the magnets of the above two brands are both cuboids of 45×11.5×2 mm, and the orientation direction of the magnets is the direction of 2 mm.

[0046] In the experiment, the above two different brands of NdFeB permanent magnets were magnetized in a static magnetic field, and the magnets were sent into the material guide channel of the magnetization part by the automatic feeding part, so that the magnets corresponded to the positions of the magnetization heads, and the magnetization The direction is consistent with the direction of the magnetic field, and they stay for 5 seconds and 10 seconds respectively. The results are shown in Table 1. As can be seen from...

Embodiment 2

[0048] The sample adopts a ferrite magnet whose commercial grade is Y35, and the magnet properties are: Br=4.1KGs; Hcb=2.35kOe; Hcj=2.5kOe. The size of the magnet is a cuboid of 44.5×15×3mm, and the orientation direction of the magnet is the direction of 3mm.

[0049] Send the magnet into the material guide channel of the magnetization part, make the magnet correspond to the position of the magnetization head, the magnetization direction is consistent with the magnetic field direction, and stay for 8 seconds. The results are shown in Table 1. It can be seen from Table 1 that the magnetic flux of the ferrite magnet after magnetization is consistent with the pulse magnetization flux at normal temperature, indicating that the present invention can saturate and magnetize the ferrite magnet in a static magnetic field under normal temperature.

[0050] Magnetic flux comparison after the magnetization of the pulse magnetizer and the magnetization of the present invention after the ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com