Control circuit of magnetized liquid device

A technology of magnetizing liquid and control circuit, applied in the fields of magnetic field/electric field water/sewage treatment, etc., can solve the problems of easy damage of control circuit components, affecting the cost of magnetizing liquid, shortening the life of magnetizing liquid device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

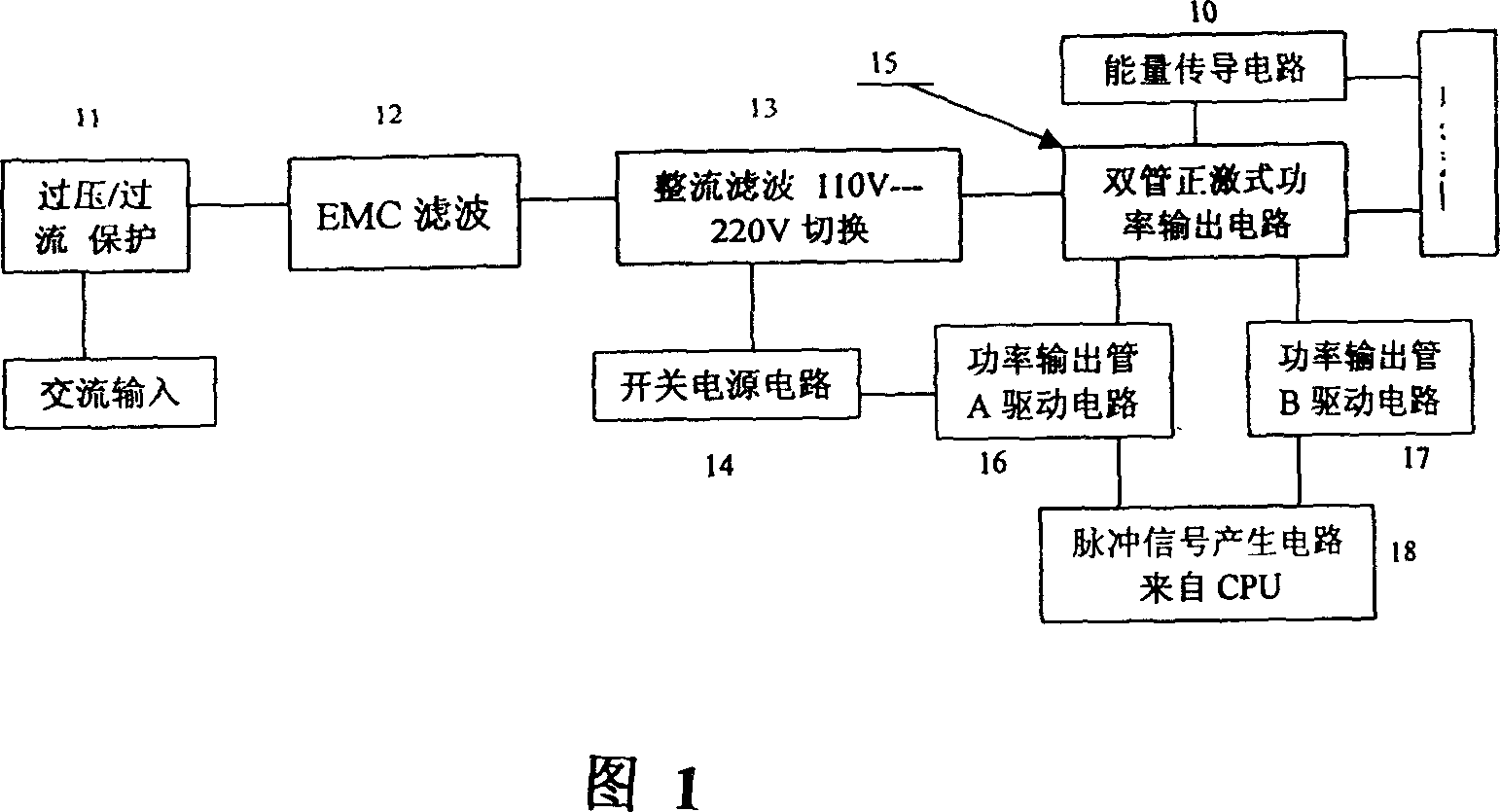

[0041] Please refer to FIGS. 1 and 5, which respectively show a block diagram and a schematic circuit diagram of an embodiment of a control circuit using a CPLD (Programmable Logic Device) chip to drive a two-transistor forward inverter according to the present invention.

[0042] In Fig. 1, the AC power of 110V or 220V is input to the overcurrent / overvoltage protection circuit 11, passed through the electromagnetic compatibility (EMC) filter circuit 12, and then applied to the rectification and filter circuit 13 to convert the input AC power into DC power, The rectification and filtering circuit 13 further includes a 110V / 220V switching switch, so that the input AC power can be switched to 220V or 110V.

[0043] Figure 5 shows that the overcurrent / overvoltage protection circuit 11 can be composed of a fuse (fuse) and a voltage sensitive element (ZMR), the EMC filter circuit 12 can be composed of capacitors C1 and C2 and a choke coil (choke) L1, and a rectification and filter c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com