Multi-pole magnetic ring magnetizing equipment with full-automatic feeding, discharging and magnetizing functions

A technology of multi-pole magnetic rings and magnetizing equipment, which is applied in the direction of conveyors, magnetic objects, conveyor objects, etc., can solve the problems of large labor costs, low magnetization efficiency, and insufficient automation of enterprises, so as to reduce labor costs and improve The effect of magnetizing efficiency and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

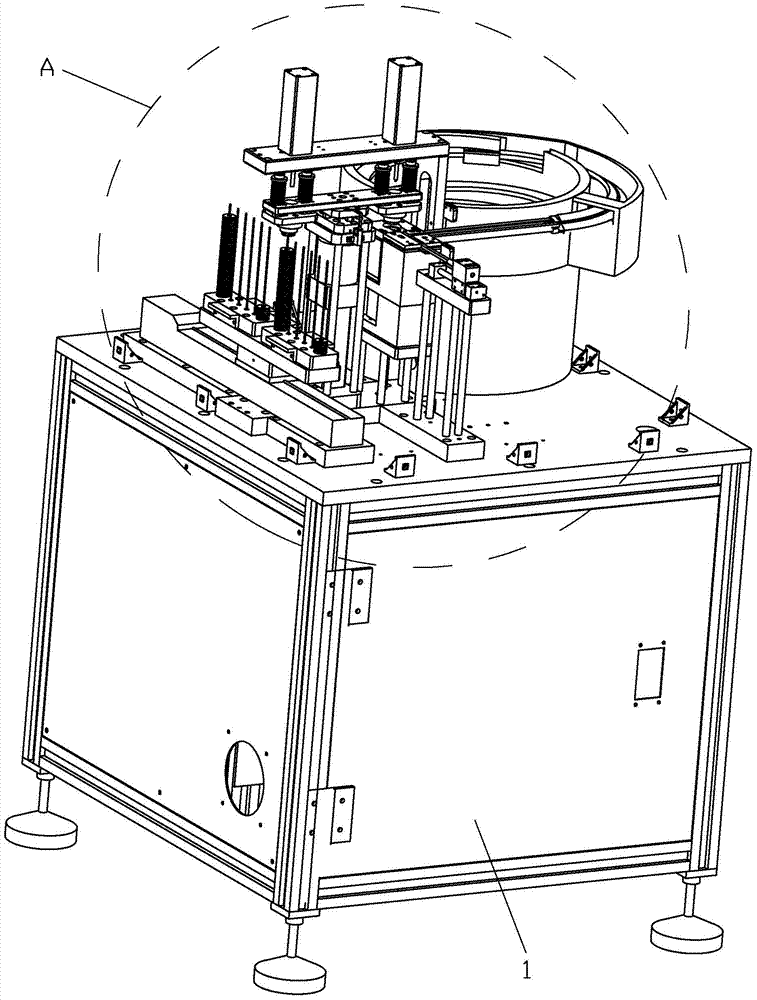

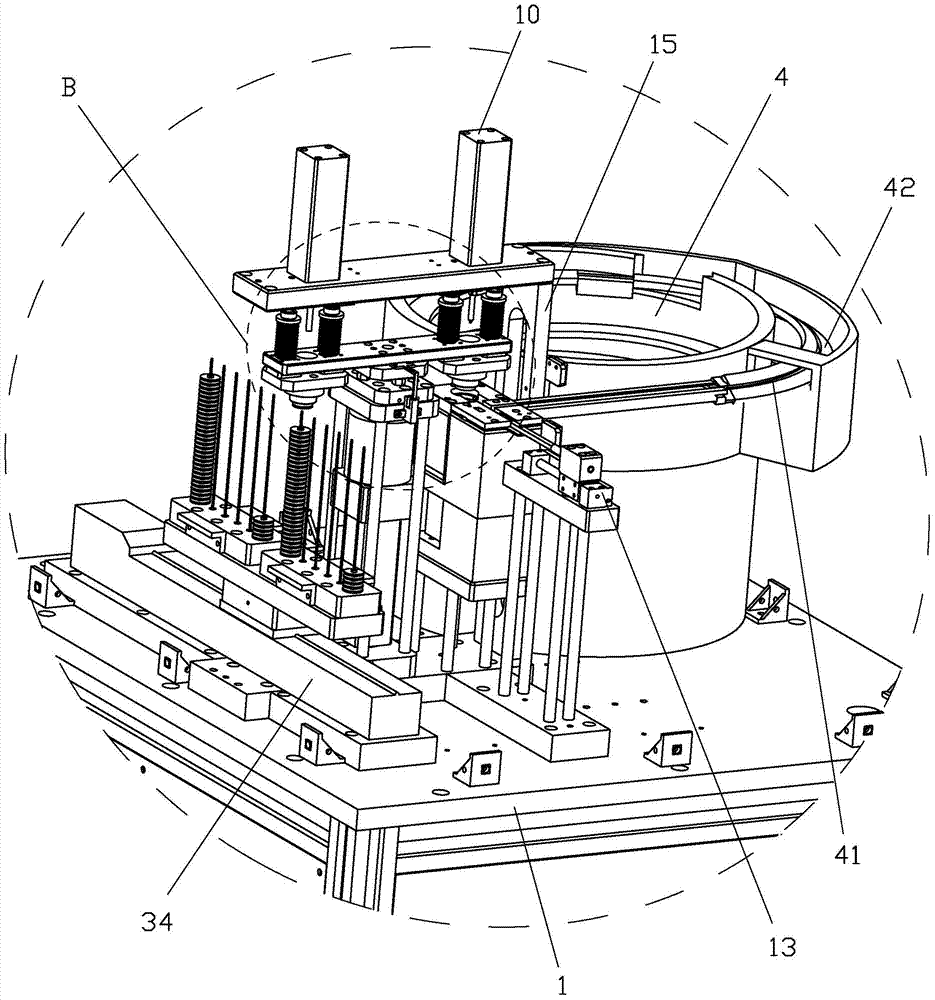

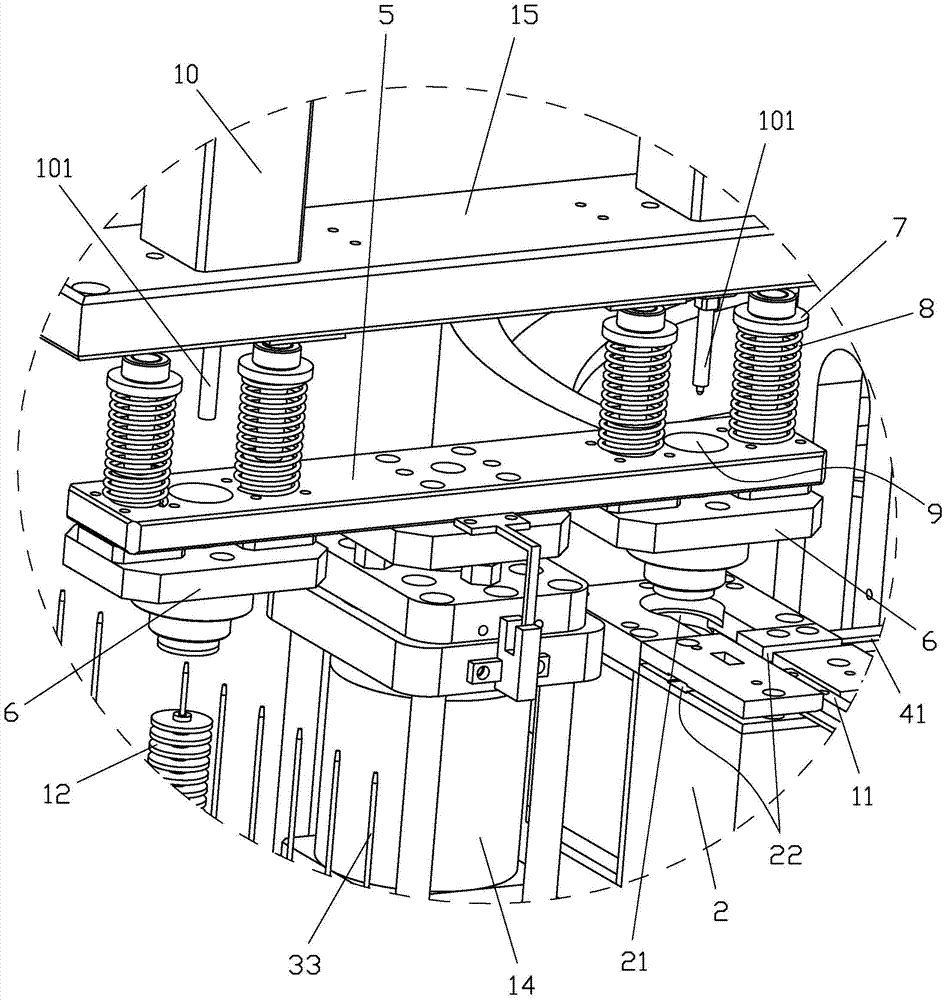

[0020] refer to Figure 1~Figure 4 , a kind of feeding, blanking and magnetizing automatic multi-pole magnetic ring magnetization equipment of the present invention comprises a base 1, a magnetization base 2 and a material receiving table 3 are arranged on the base 1, and the magnetization base 2 is A magnetizing hole 21 for accommodating the magnetic ring 12 and magnetizing the magnetic ring 12 is provided. The base 1 is also provided with a vibrating feeder 4, and the vibrating feeder 4 is provided with a spiral feeding groove rail 41. The vibrating feeder 4 with the spiral feeding groove rail 41 is a known technology in the feeding field, and its specific structure will not be described in detail here; Through the docking of the groove 22, the magnetic ring 12 on the feeding groove rail 41 pushes each other, so that the magnetic ring 12 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com