Patents

Literature

119results about How to "Simple, reasonable and compact structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

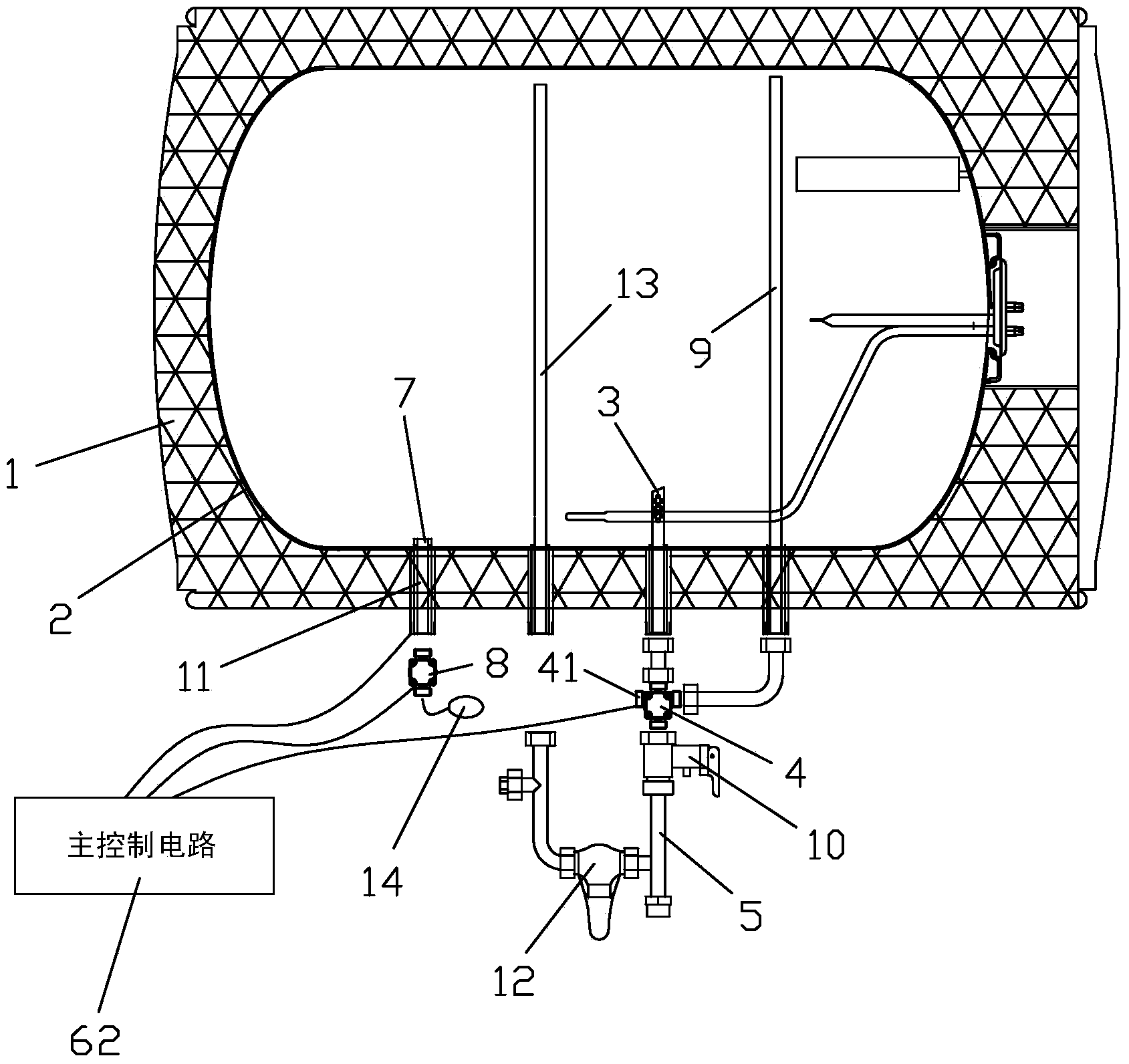

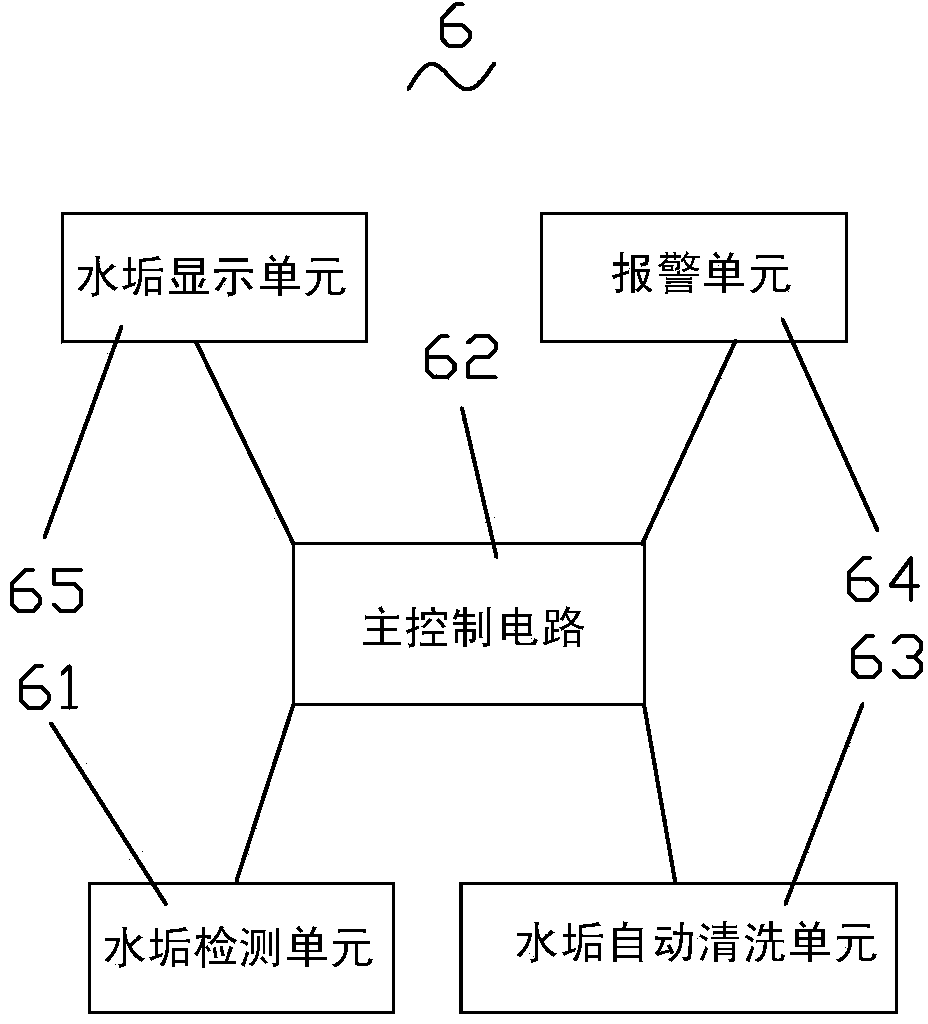

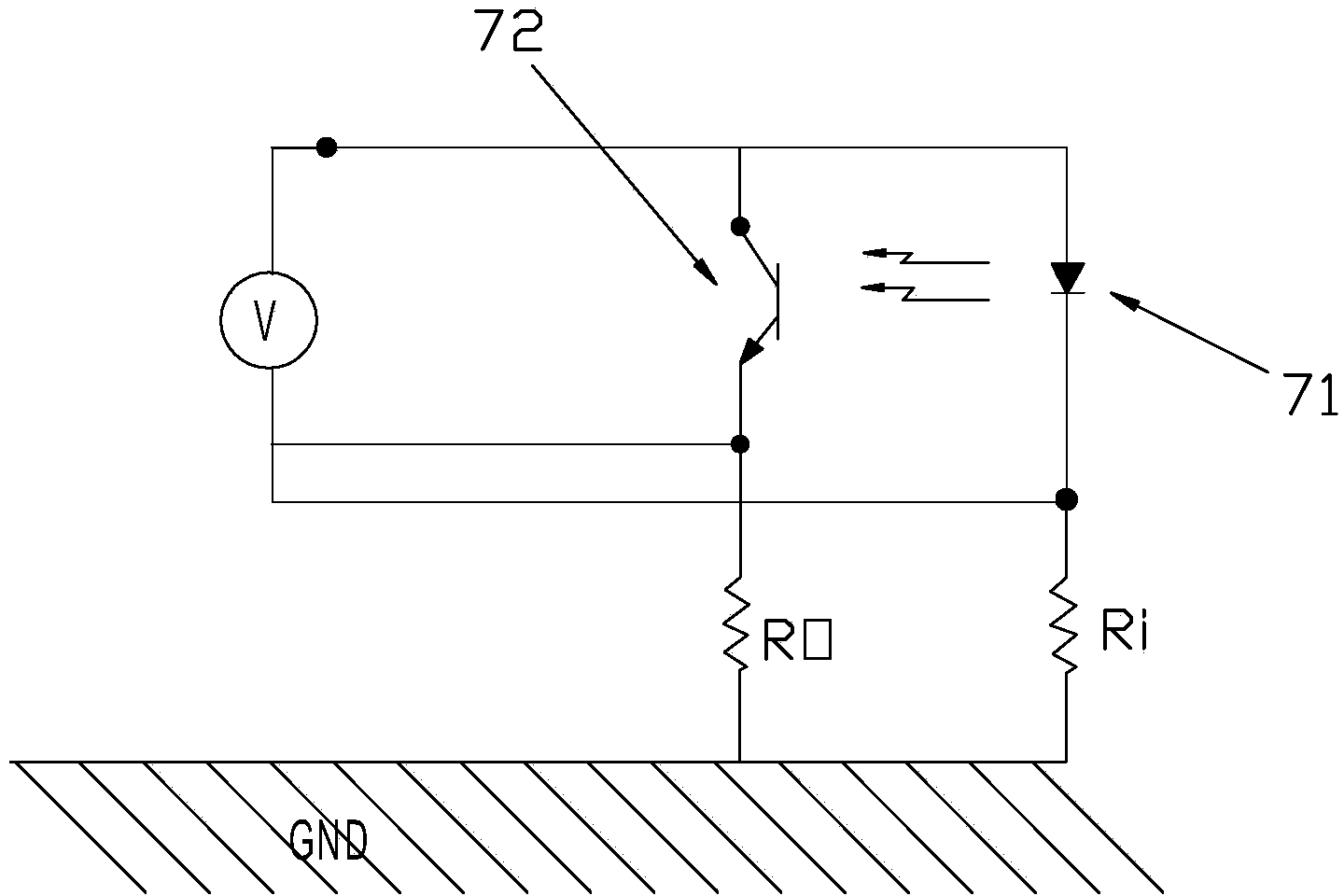

Electric water heater with water scale detecting function, alarming function and automatic cleaning function

InactiveCN103759408ASimple, reasonable and compact structureEasy to installWater heatersControl circuitWater pipe

The invention discloses an electric water heater with a water scale detecting function, an alarming function and an automatic cleaning function. The electric water heater comprises a shell, an inner container and a control circuit, wherein a water feeding pipe is arranged in the inner container, and is connected with a water feeding valve after penetrating out of the shell; the water feeding valve is connected with a cold water pipe; the control circuit comprises a water scale detecting unit, a master control circuit and an automatic water scale cleaning unit; a signal input end of the water scale detecting unit is a water scale detector arranged in the inner container; a signal output end of the water scale detecting unit is connected with the master control circuit; a signal input end of the automatic water scale cleaning unit is connected with the master control circuit; a signal output end of the automatic water scale cleaning unit comprises an electromagnetic dirt discharging valve and a water feeding valve; the electromagnetic dirt discharging valve is arranged on a dirt discharging outlet on the electric water heater; the dirt discharging outlet is communicated with the shell and the inner container; and the master control circuit is also connected with an alarming unit. The shortcoming that the traditional electric water heater does not have a precipitated dirt detecting function, a precipitated dirt alarming function or an automatic precipitated dirt cleaning function is overcome; and the electric water heater provides healthful hot water for users.

Owner:法罗力热能设备(中国)有限公司

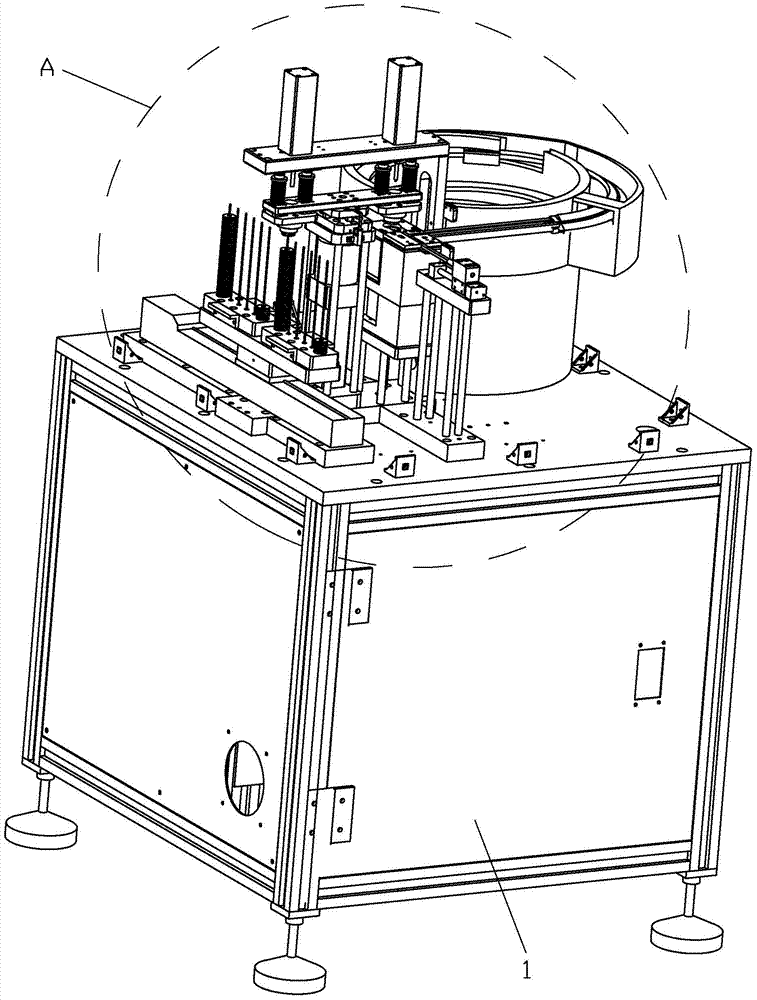

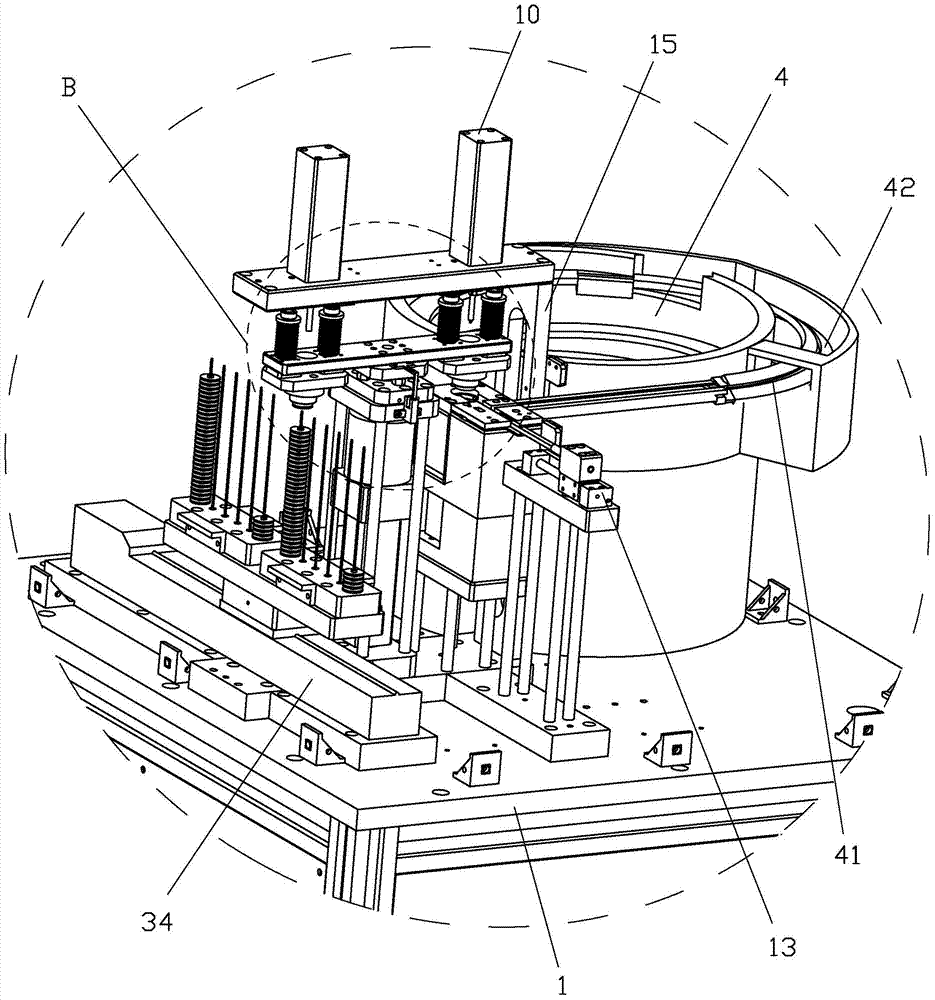

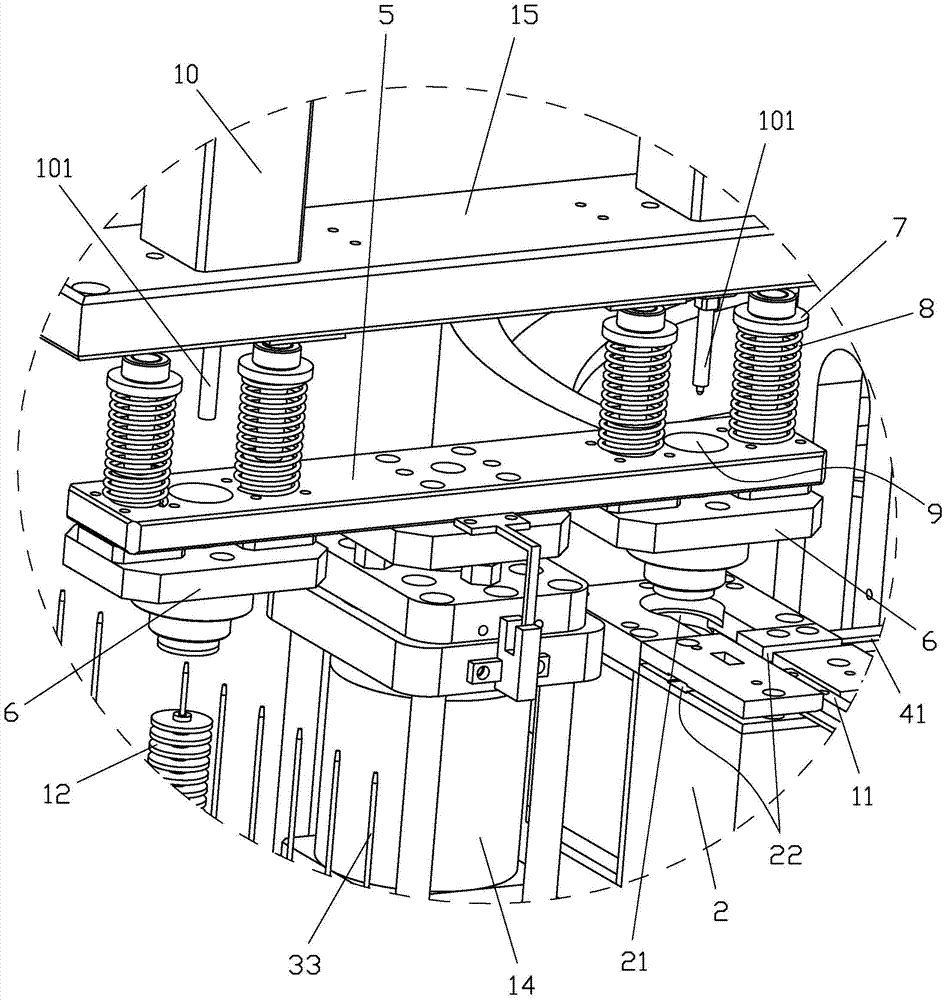

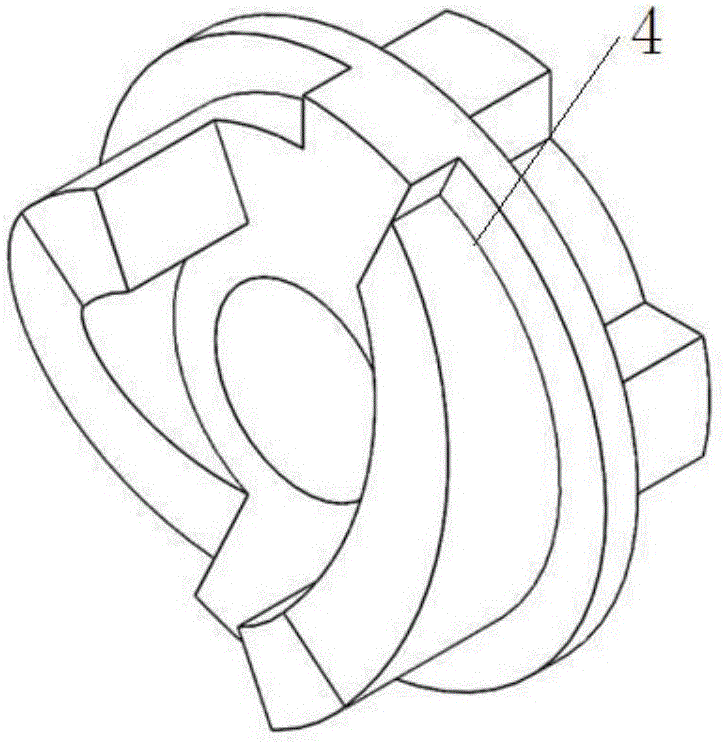

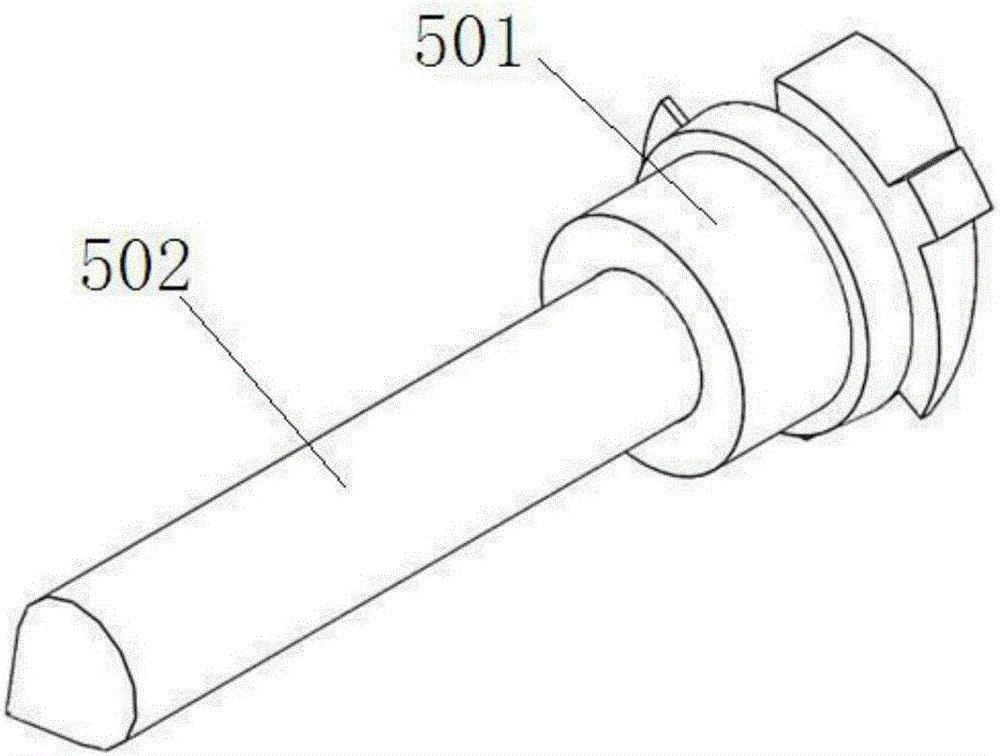

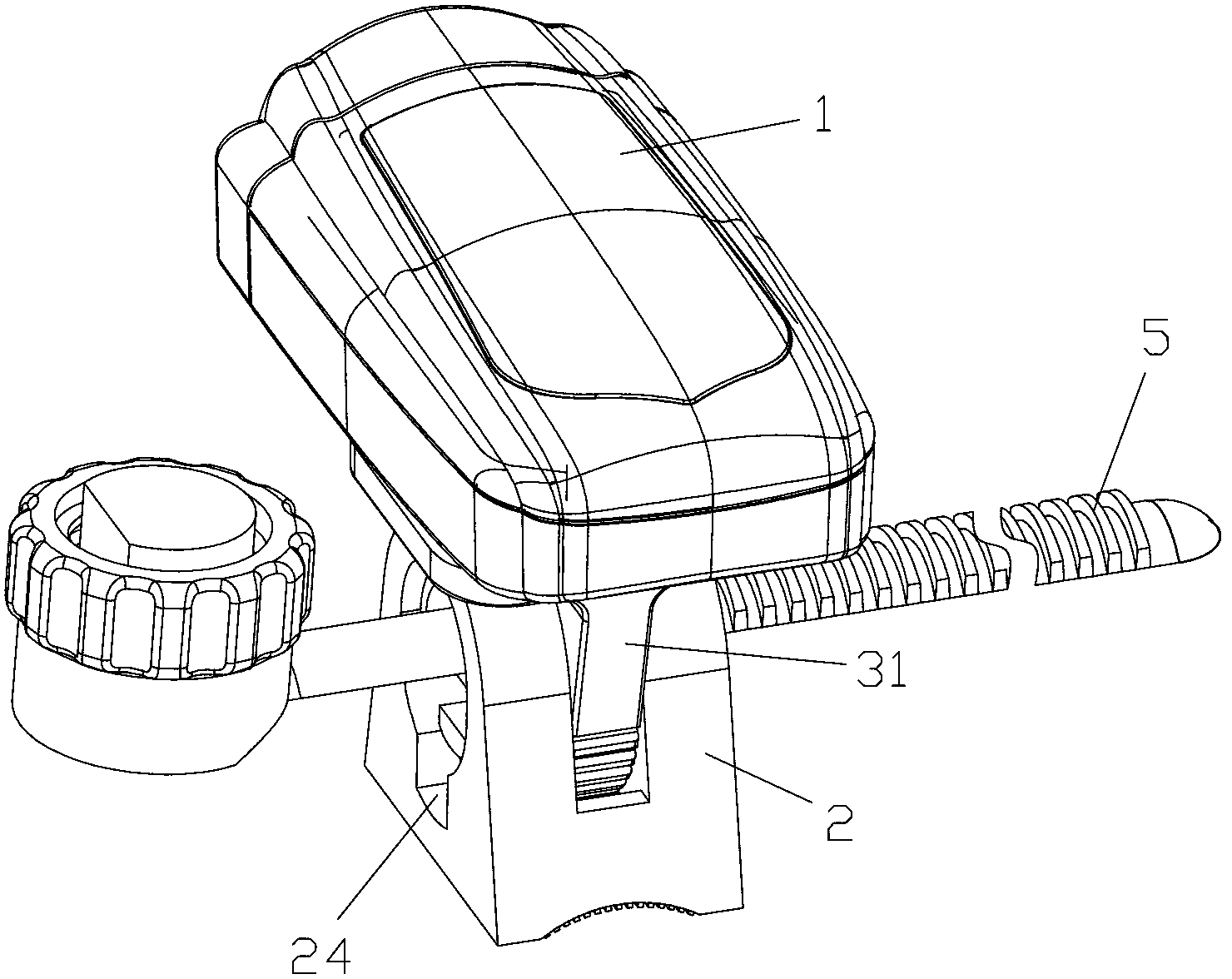

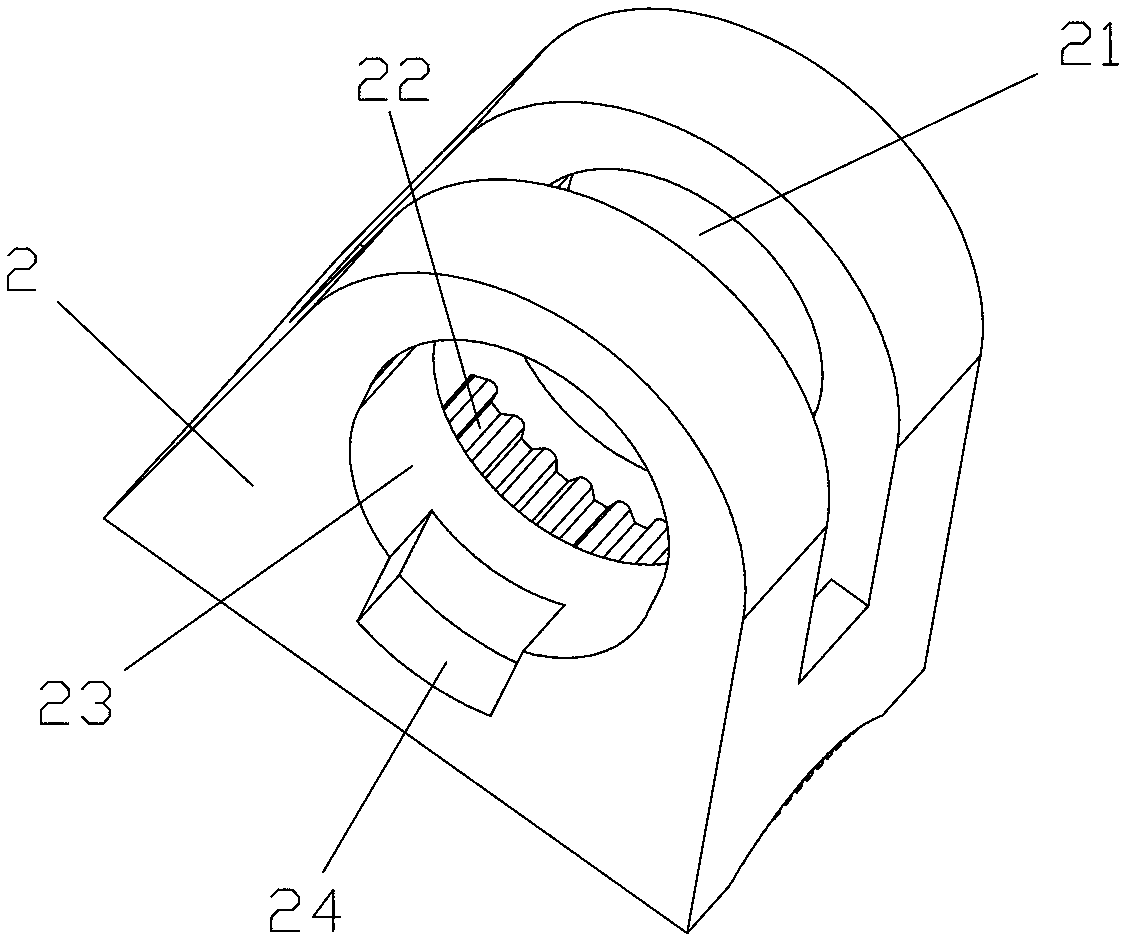

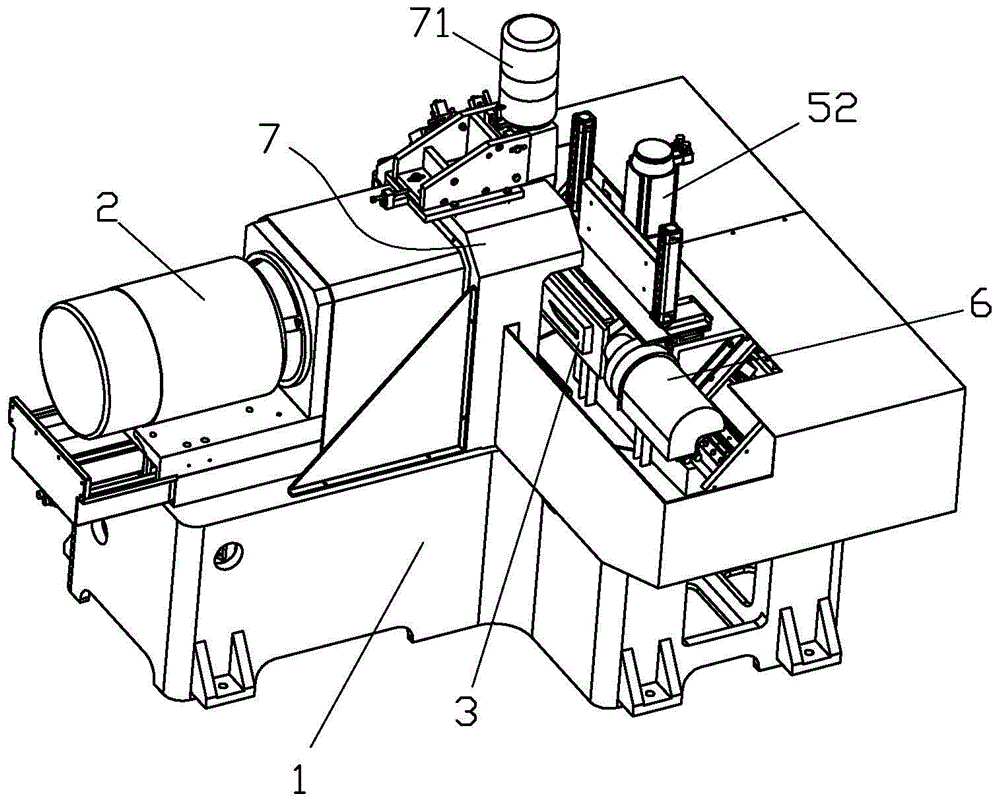

Multi-pole magnetic ring magnetizing equipment with full-automatic feeding, discharging and magnetizing functions

InactiveCN103680810ARealize automatic feedingFully automatedMagnetic bodiesJigging conveyorsEngineeringWork force

The invention discloses a set of multi-pole magnetic ring magnetizing equipment with the full-automatic feeding, discharging and magnetizing functions. A magnetic ring can be automatically fed through a vibrating feeding machine, through the arrangement of a rotating plate and a pushing oil cylinder, when a magnetizing head is made to be located above a magnetizing hole, after a push rod of the pushing oil cylinder acts to penetrate through a through hole in the rotating plate, the magnetizing head is pushed to fall into the magnetizing hole, the magnetic ring in the magnetizing hole can be magnetized automatically, meanwhile, after the push rod of the pushing oil cylinder located above a material collecting table acts to penetrate through the through hole of the rotating plate and a through hole in the magnetizing head, the magnetic ring attracted to the bottom end of the magnetizing head is pushed away from the magnetizing head, and thus automatic discharging is achieved. The manual feeding, magnetizing and discharging method in the traditional technology is abandoned, full-automatic feeding, magnetizing and discharging of the magnetizing equipment are achieved, the magnetizing efficiency is greatly improved, and labor cost is reduced. The multi-pole magnetic ring magnetizing equipment is simple, reasonable and compact in structure, convenient to install and easy to implement and can meet industry development requirements better.

Owner:江门协立磁业高科技有限公司

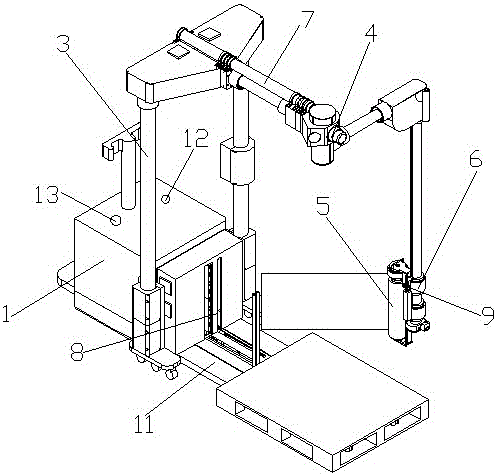

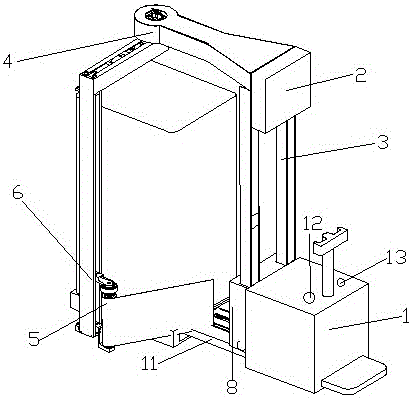

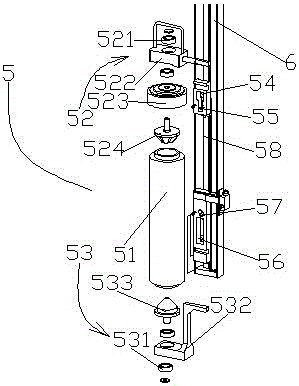

Movable type thin film packaging robot

ActiveCN106314846AHigh market recognitionSimple, reasonable and compact structureWrapping material feeding apparatusWeb rotation wrappingThin membraneMovable type

The invention discloses a movable type thin film packaging robot. The movable type thin film packaging robot comprises a forklift body, an electric control box, a fixed support frame, a power transmission rotating mechanism, a thin film tension control mechanism, a thin film winding and elevating mechanism, a stabilization balancing rod and a thin film cutting and pressing mechanism. The power transmission rotating mechanism is arranged at the tail end of one side of the fixed support frame. The thin film winding and elevating mechanism is movably connected to the tail end of the power transmission rotating mechanism. The thin film tension control mechanism is fixedly arranged on the thin film winding and elevating mechanism. One end of the stabilization balancing rod is fixedly connected with the fixed support frame, and the other end of the stabilization balancing rod is fixedly connected with the power transmission rotating mechanism. The thin film cutting and pressing mechanism is arranged on the fixed support frame and located between a pair of forking teeth. By improving the power transmission mechanism and the thin film winding and elevating mechanism, the movable type thin film packaging robot is simpler, more reasonable and compacter in structure, lower in cost, smaller in occupied space, more reasonable in designed layout, good in overall aesthetic performance and high in customer market recognition degree; and better upgrading improvement is achieved for an old type product.

Owner:北京小棉医药有限公司

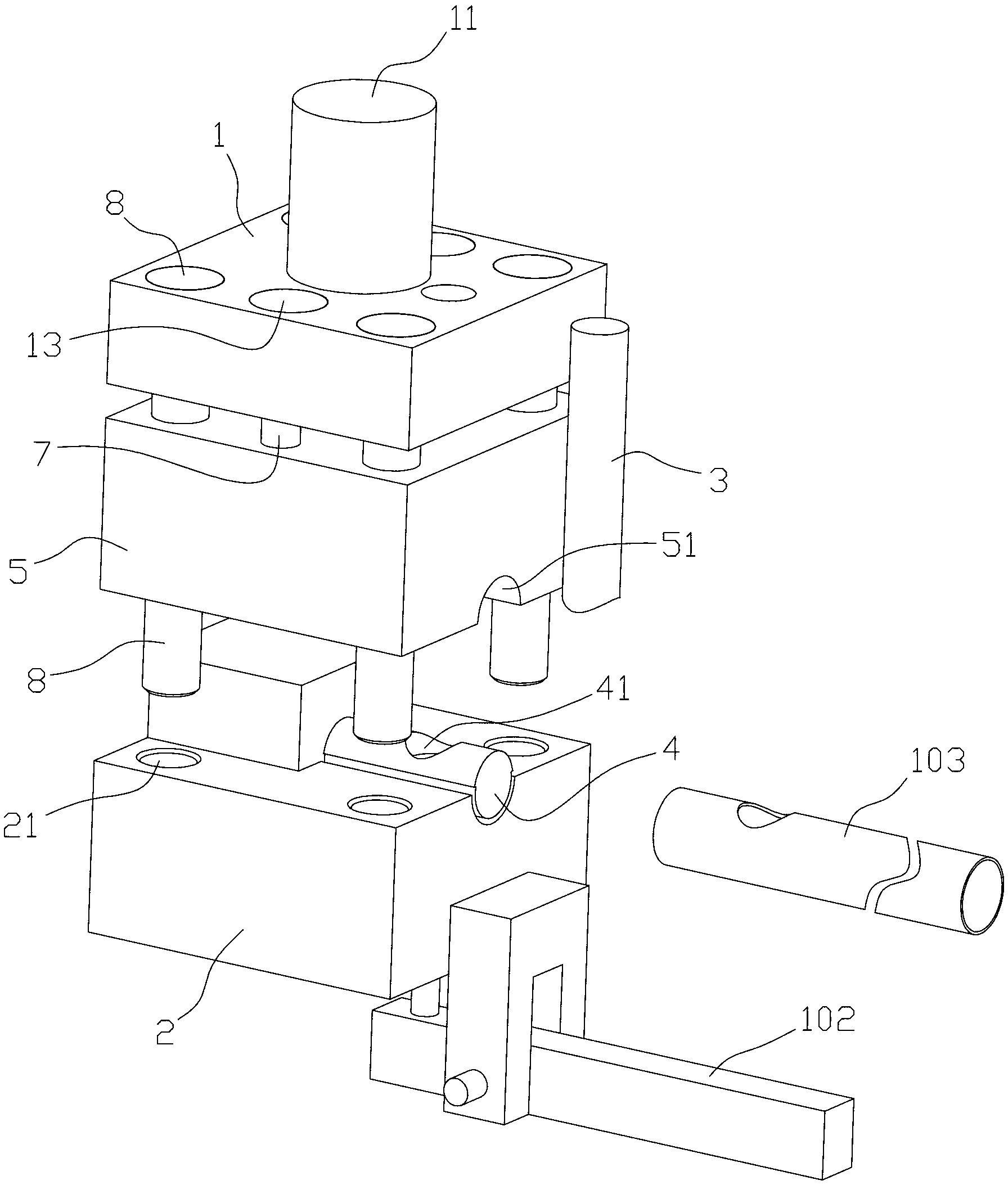

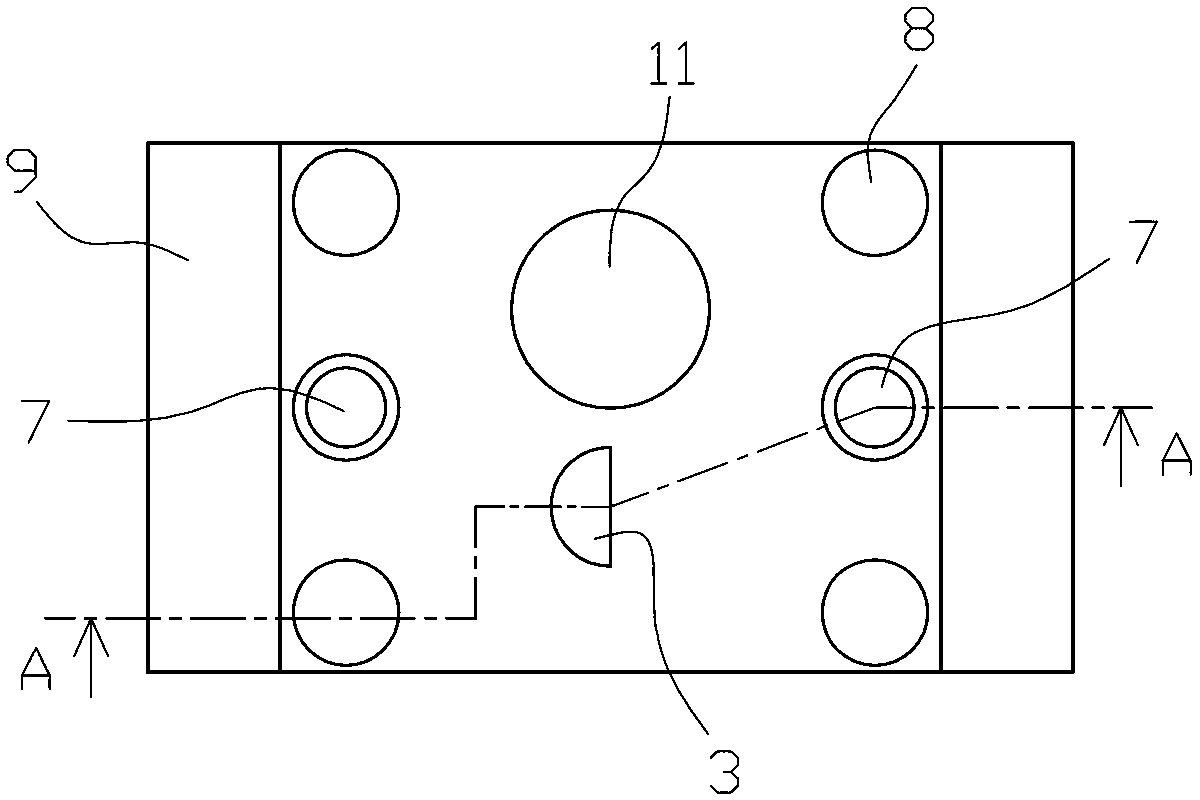

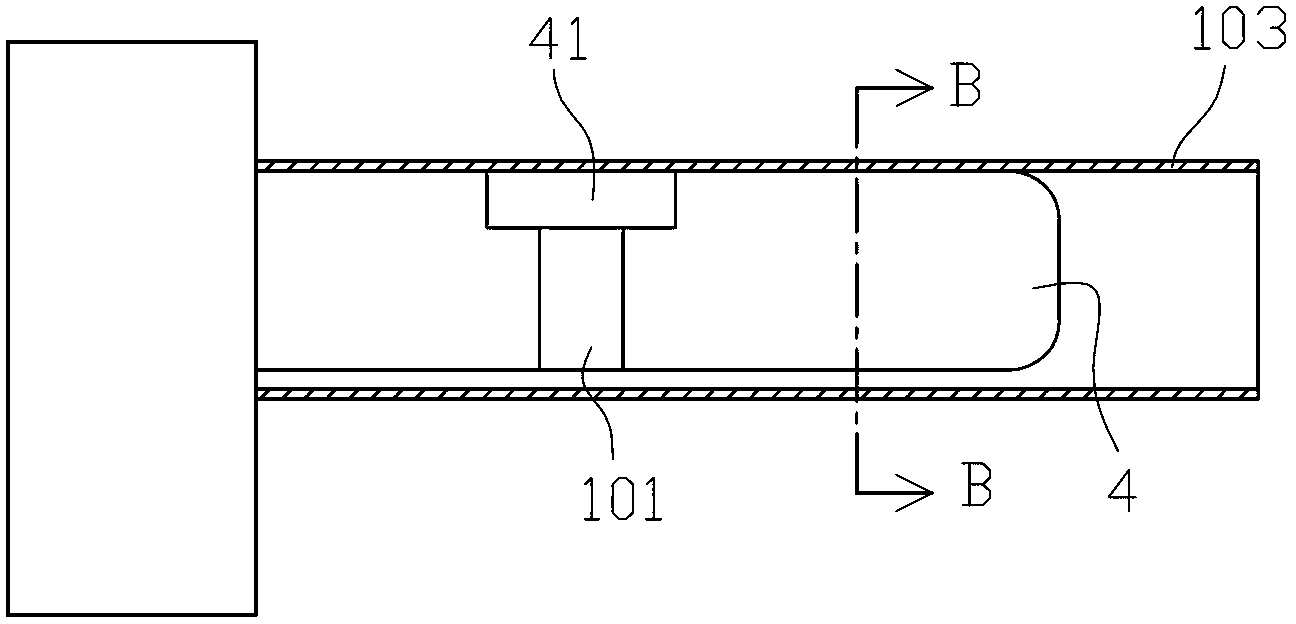

Blank pipe fitting lateral surface punching die

The invention discloses a blank pipe fitting lateral surface punching die and abandons the structure that in the prior art, a punched hole on a sleeve die core is a through hole and the sleeve die core is in loose fit with a blank pipe fitting. The inner walls of a sleeve die core and a blank pipe fitting are partially abutted against each other; the blank pipe fitting lateral surface punching die adapts to slight deformation of the blank pipe fitting in the punching process; and the blank pipe fitting lateral surface punching die is matched with a movable pressure pipe die plate and an elastic device, so that when a side hole is punched, the movable pressure pipe die plate descends to compress the blank pipe fitting and then an upper die continuously descends to squeeze the elastic device to enable a punching die core to slide downwards in a slideway on the movable pressure pipe die plate and efficiently compete the punching action. The punched big side hole of the blank pipe fitting is not deformed; in the punching process, the sleeve die core is difficult to break; the service life of each part of the punching die is prolonged; and the blank pipe fitting lateral surface punching die has the characteristics of high efficiency, no deformation, suitability for punching various sizes of side holes and the like.

Owner:何祺晃

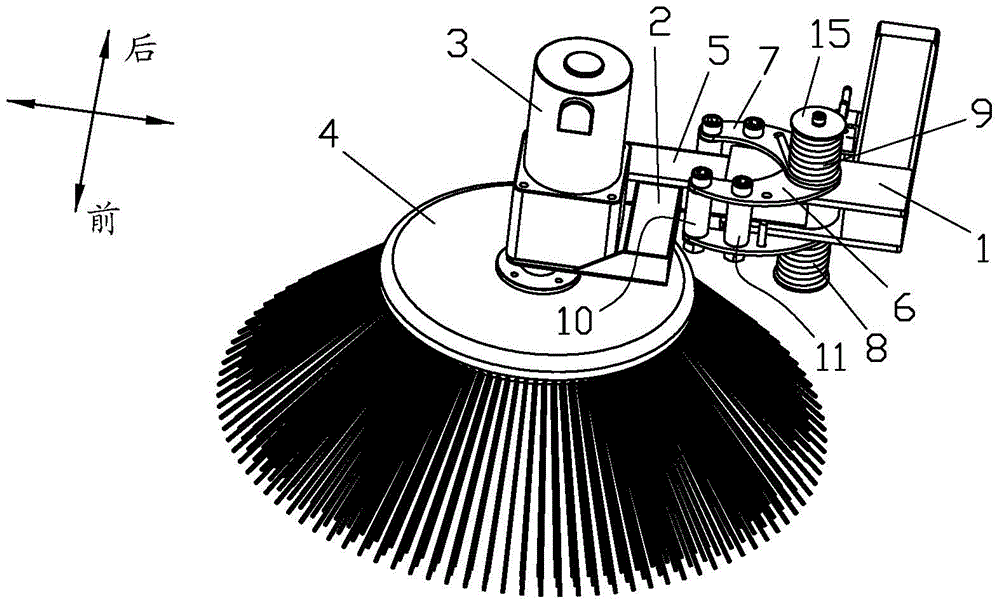

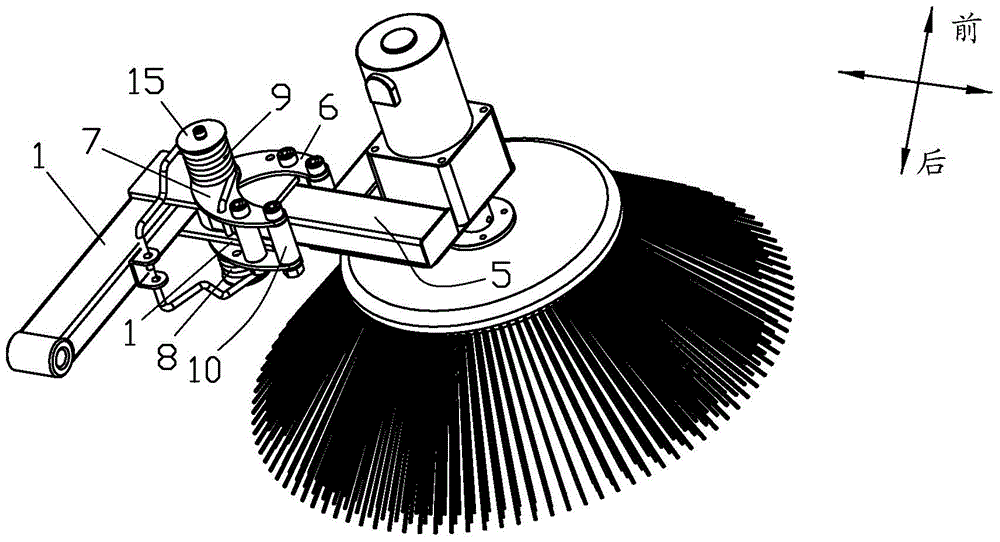

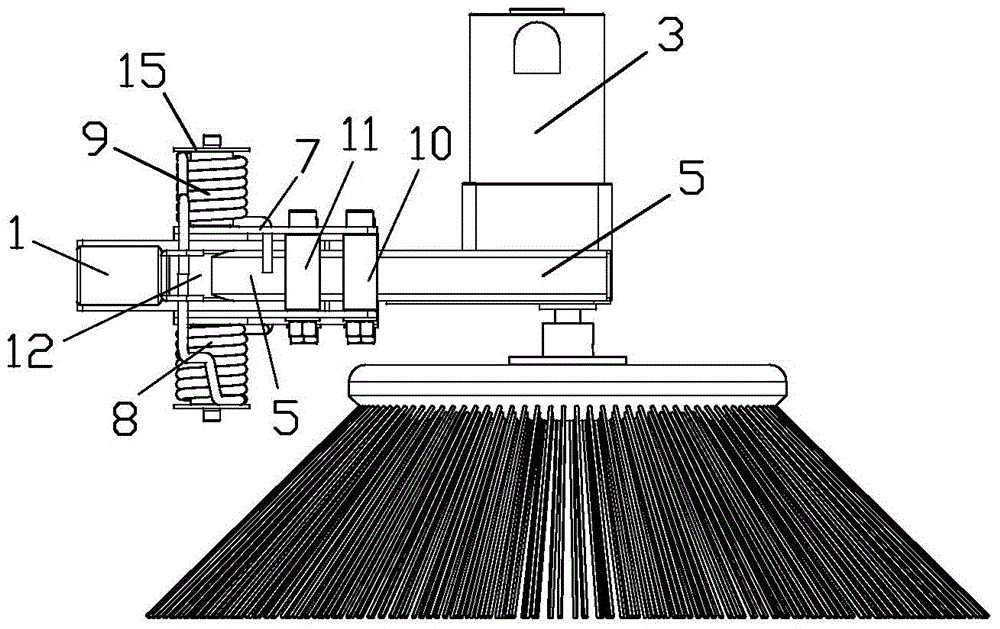

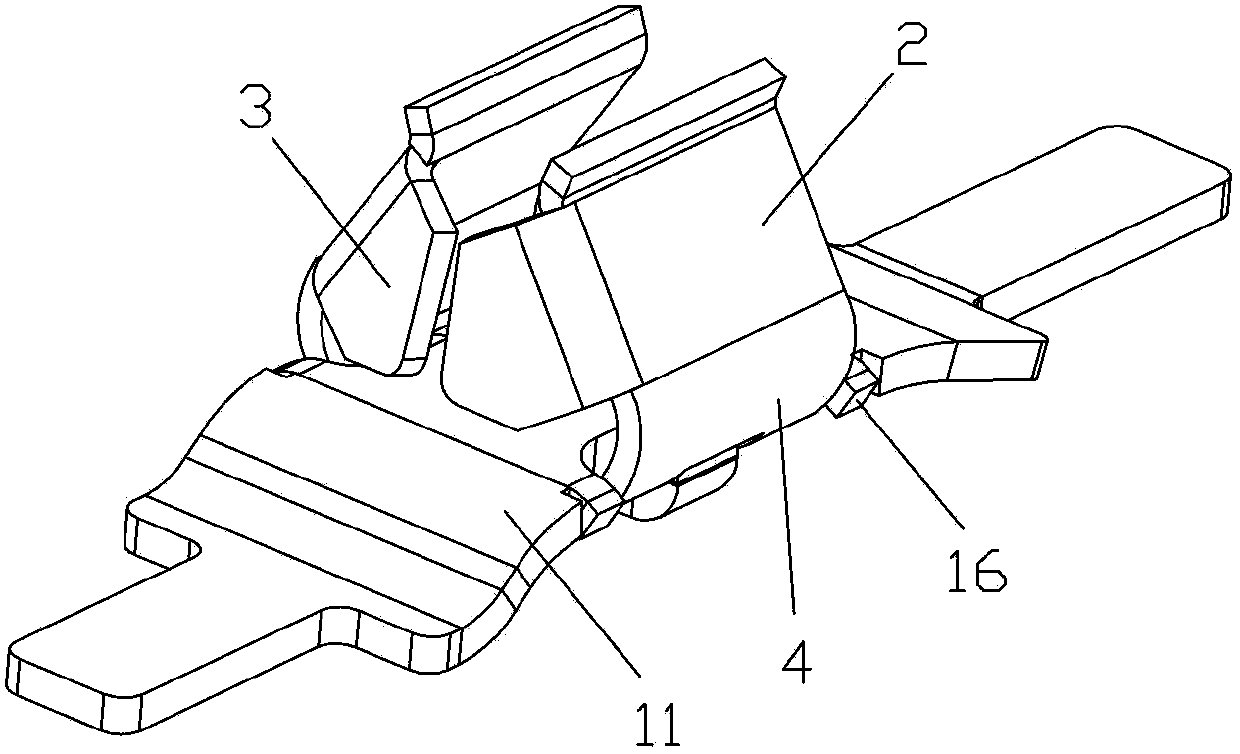

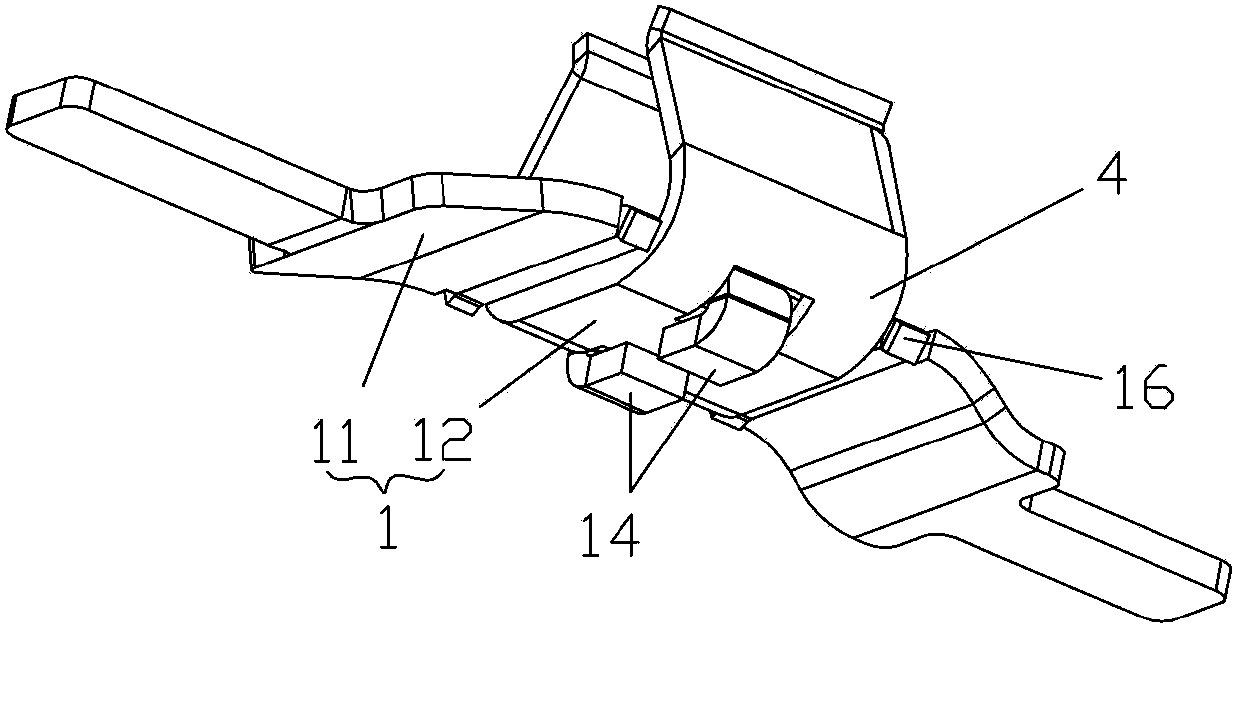

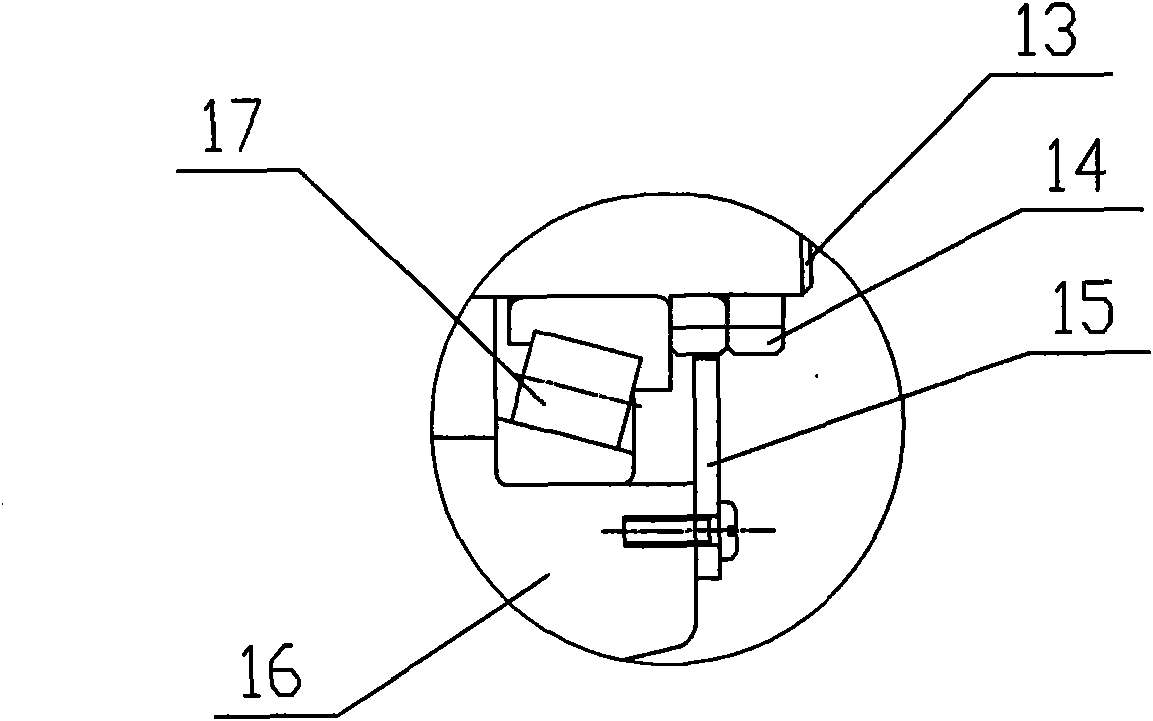

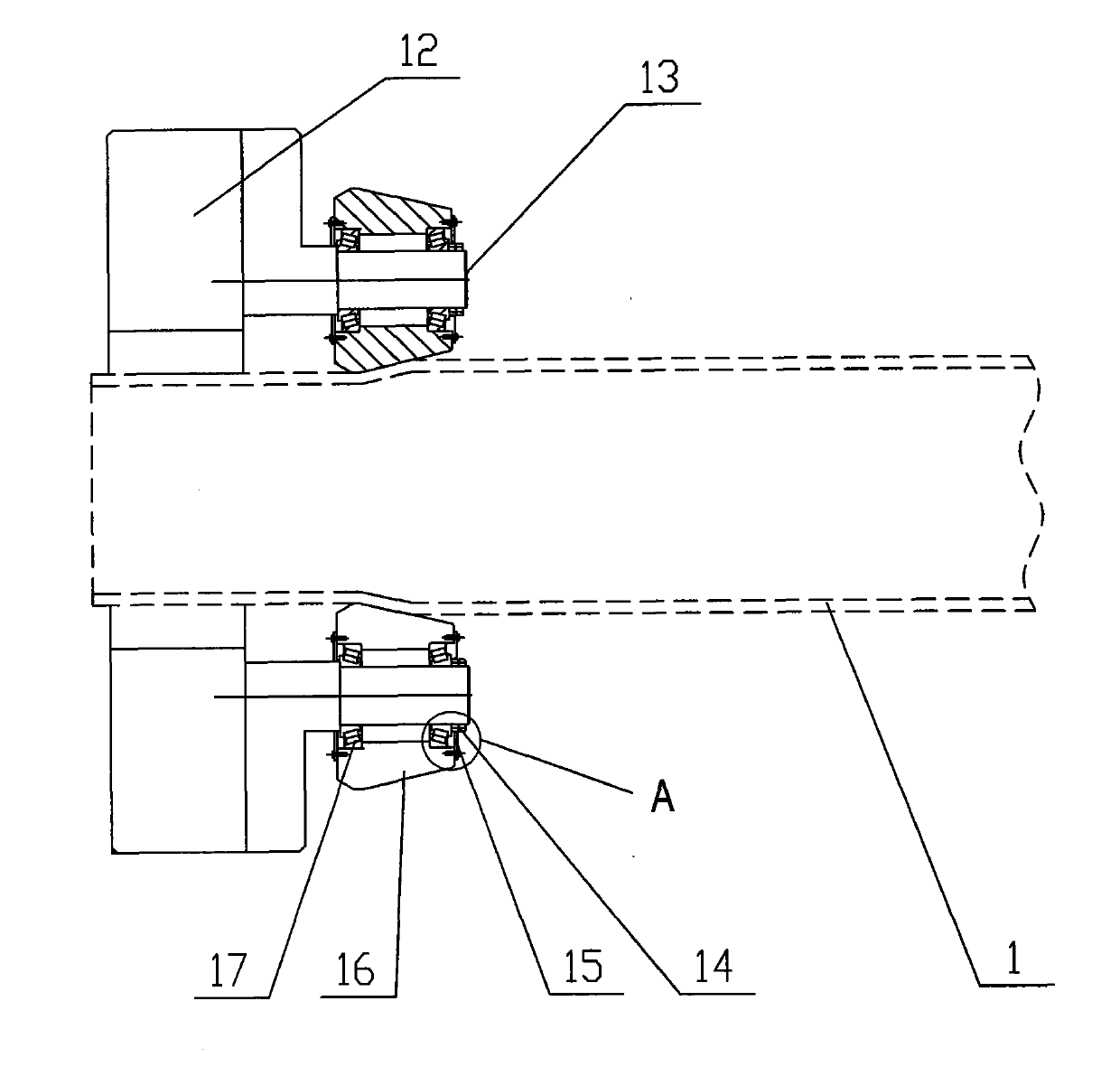

Bidirectional anticollision structure of sweeper side brush

The invention discloses a bidirectional anticollision structure of a sweeper side brush. The bidirectional anticollision structure comprises a side brush support rod of which the end part is provided with a side brush motor mounting seat, wherein a side brush motor is arranged on the side brush motor mounting seat; the output end of the side brush motor is connected with the side brush. The bidirectional anticollision structure is characterized in that a side brush movable rod is connected to the side brush motor mounting seat; the side brush movable rod is hinged to the side brush support rod; a front press claw and a rear press claw are also hinged to the side brush support rod; the side brush support rod is provided with a first pressure spring of which one end part is connected with the front press claw and enables the front press claw to have backward rotation trend and a second pressure spring of which one end part is connected with the rear press claw and enables the rear press claw to have forward rotation trend; the other ends of the first pressure spring and the second pressure spring are connected to the side brush support rod; a front section spacer bush and a middle section spacer bush are respectively arranged on the front press claw and the rear press claw; the front section spacer bush tightly leans on the side brush movable rod; the middle section spacer bush tightly leans on the side brush support rod. The bidirectional anticollision structure of the sweeper side brush has the characteristic that reliable avoiding performance can be realized during the advancing and reversing of a sweeper.

Owner:牛力机械制造有限公司

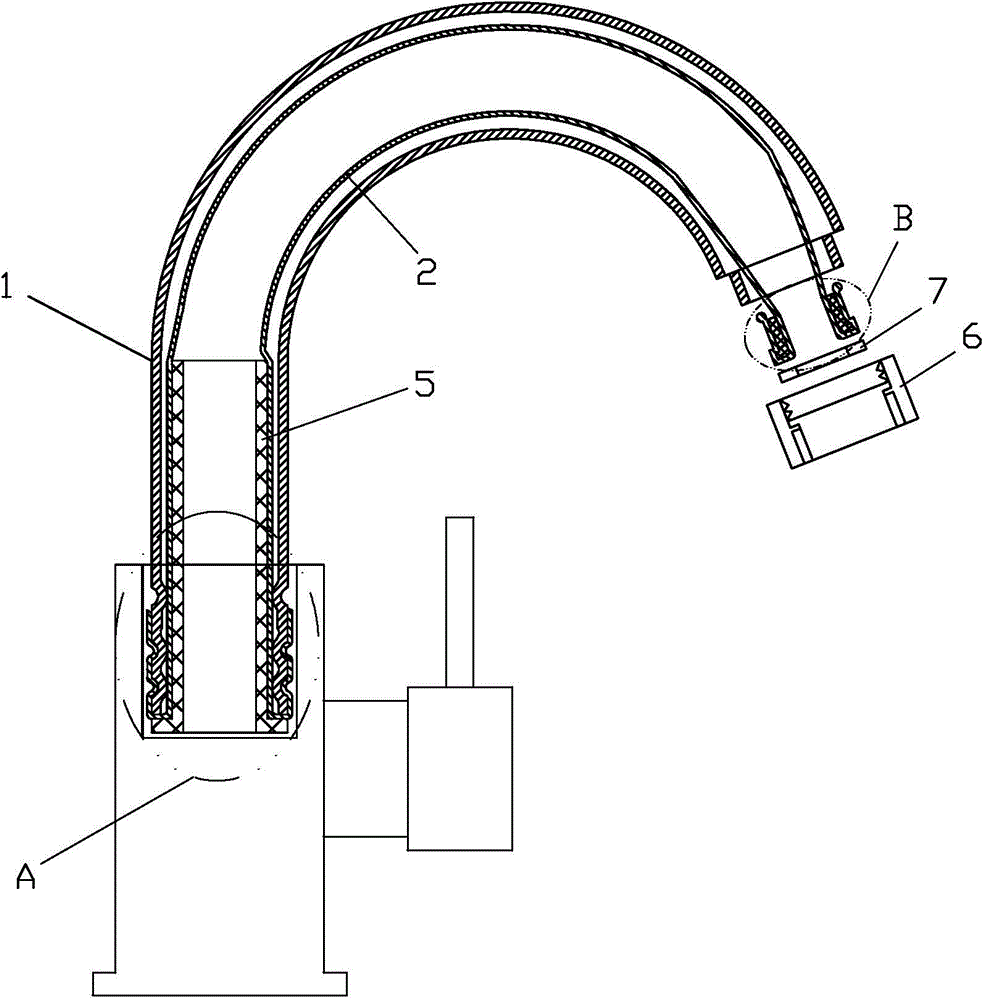

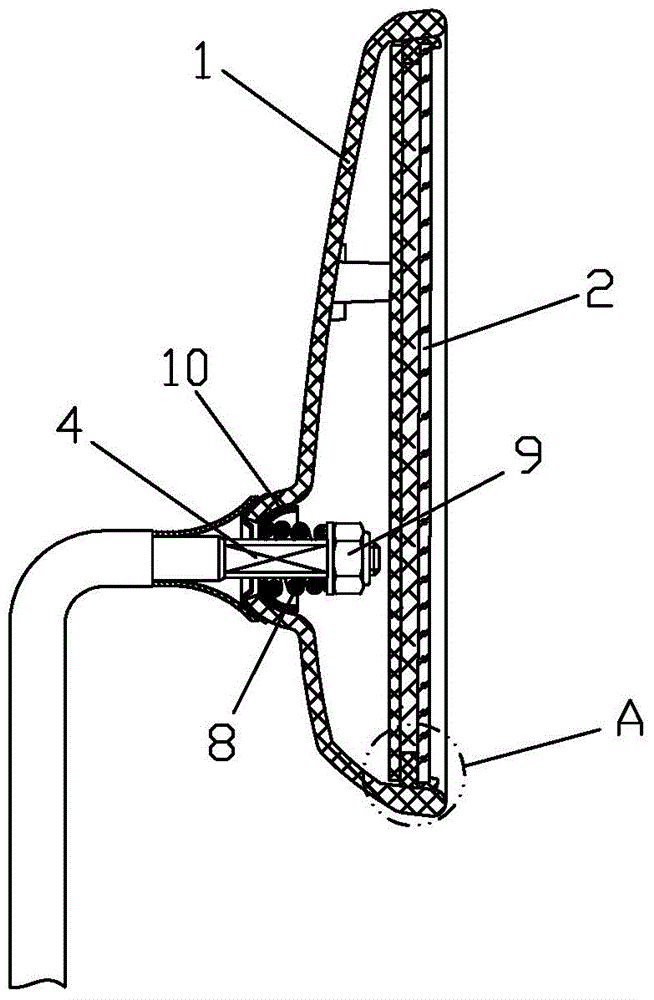

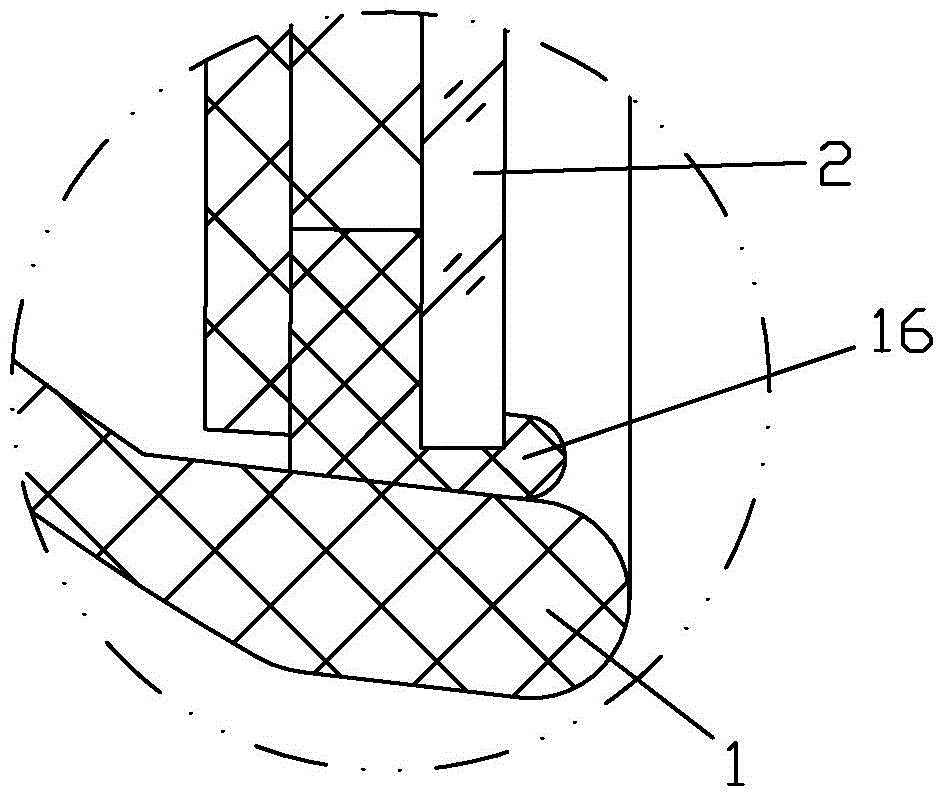

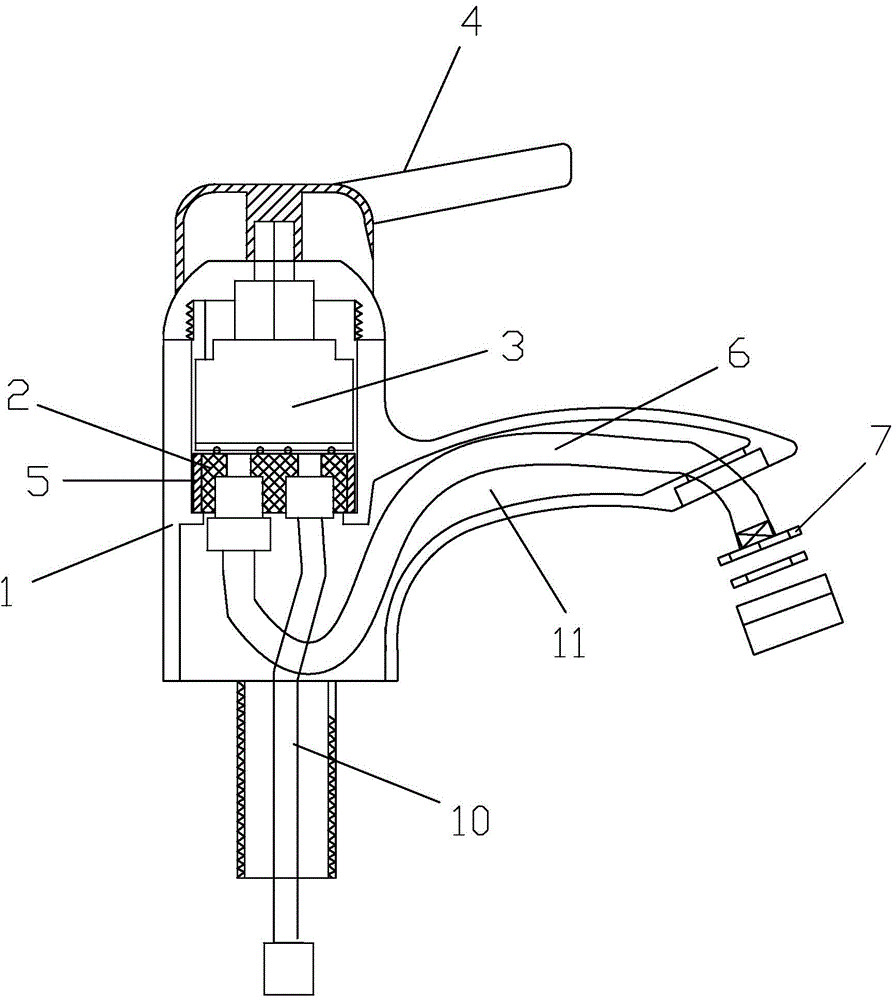

Safe, non-toxic, water-tight and non-scale water outlet pipe structure of faucet

ActiveCN104154291AAvoid health effectsNot easy to cause water leakageValve housingsLimescaleWater flow

The invention discloses a safe, non-toxic, water-tight and non-scale water outlet pipe structure of a faucet. The safe, non-toxic, water-tight and non-scale water outlet pipe structure comprises a water outlet pipe of the faucet and a rubber film pipe. The rubber film pipe is inserted in the water outlet pipe of the faucet, one end of the rubber film pipe extends out of a water inlet of the water outlet pipe of the faucet and then sleeves the water outlet pipe of the faucet in an outwardly turned manner, the other end of the rubber film pipe extends out of a water outlet of the water outlet pipe of the faucet and then is connected with a T-shaped sleeve, and one end of the T-shaped sleeve is clamped at the water outlet of the water outlet pipe of the faucet after the other end of the T-shaped sleeve is arranged in the water outlet pipe of the faucet; sealing grooves are formed in the outer wall of the water outlet pipe of the faucet, and the rubber film pipe extends out of the water inlet of the water outlet pipe of the faucet and then sleeves the sealing grooves in an outwardly turned manner. The safe, non-toxic, water-tight and non-scale water outlet pipe structure has the advantages that when water flows into the safe, non-toxic, water-tight and non-scale water outlet pipe structure, the water outlet pipe, which is of a metal structure, of the faucet is not in contact with the water, accordingly, safe, non-toxic, water-tight and non-scale effects can be realized, and the like.

Owner:KAIPING QILONG SANITARY WARE TECH CO LTD

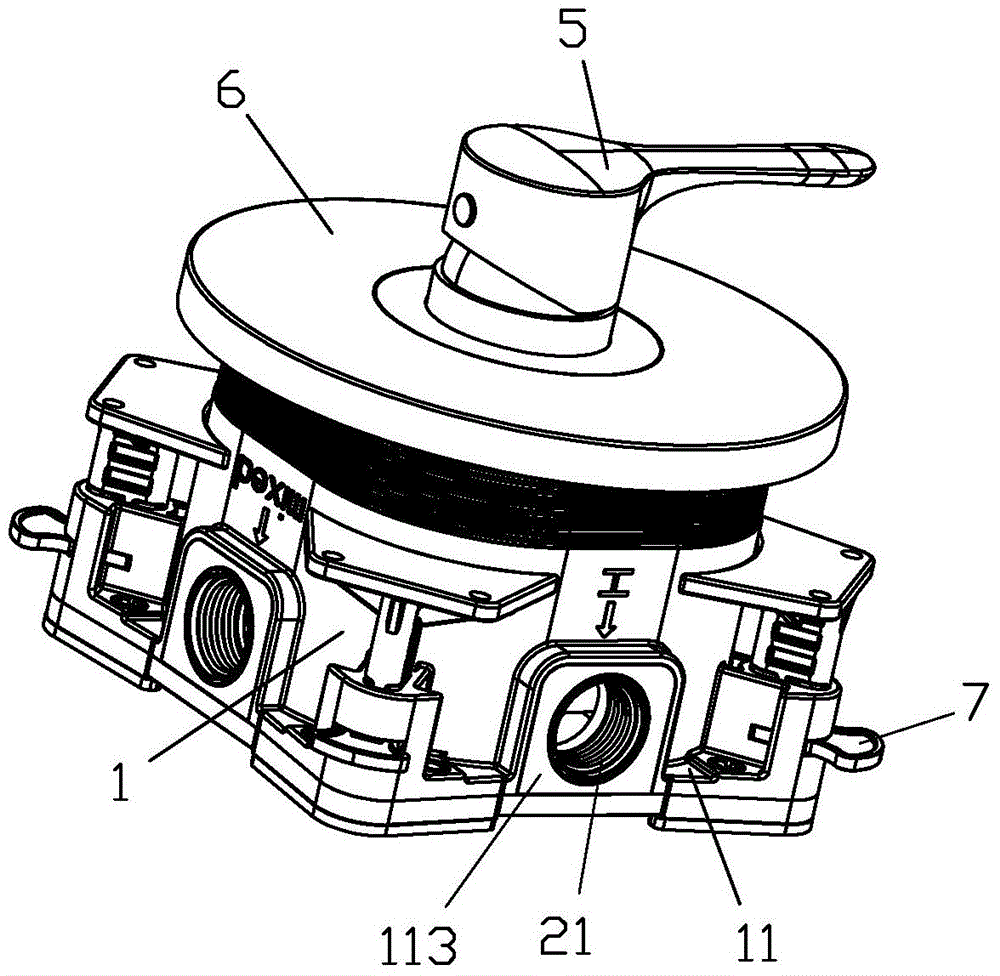

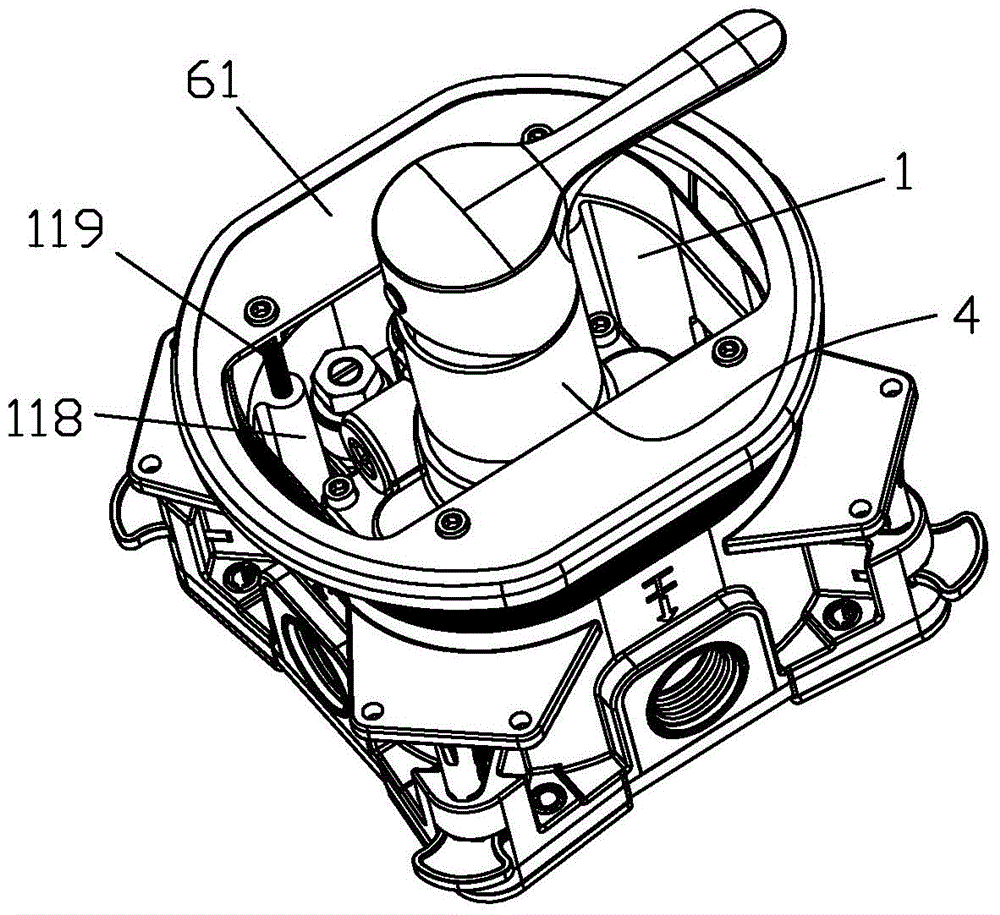

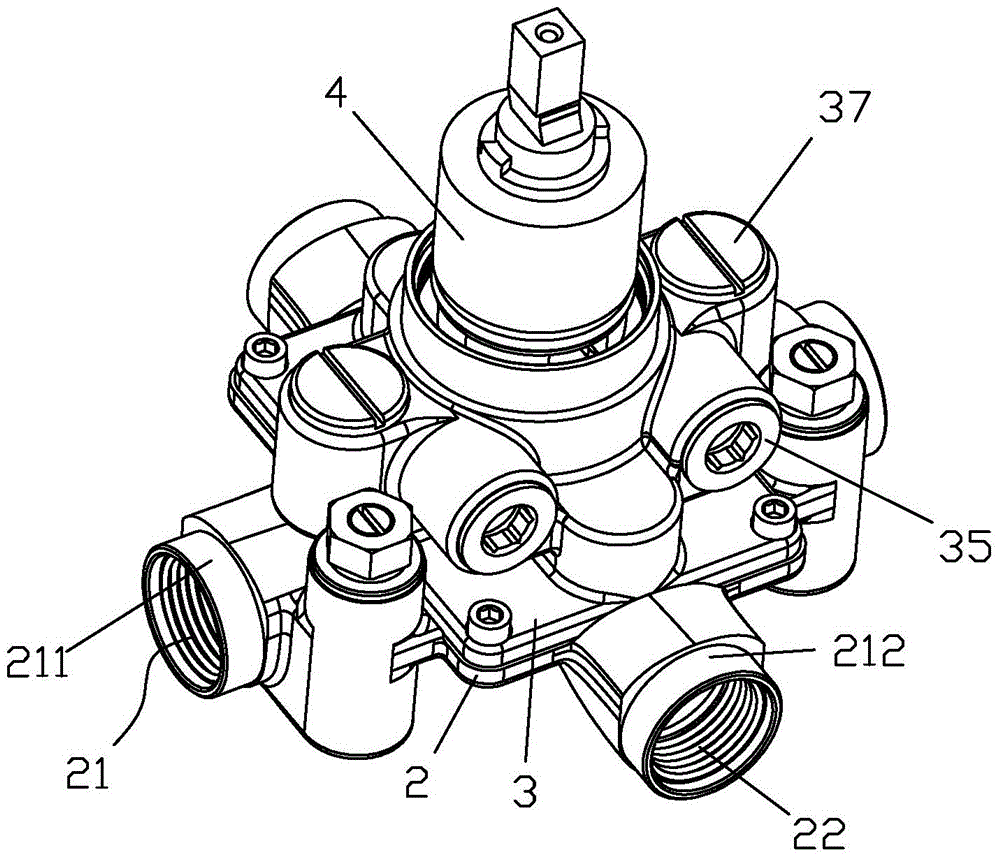

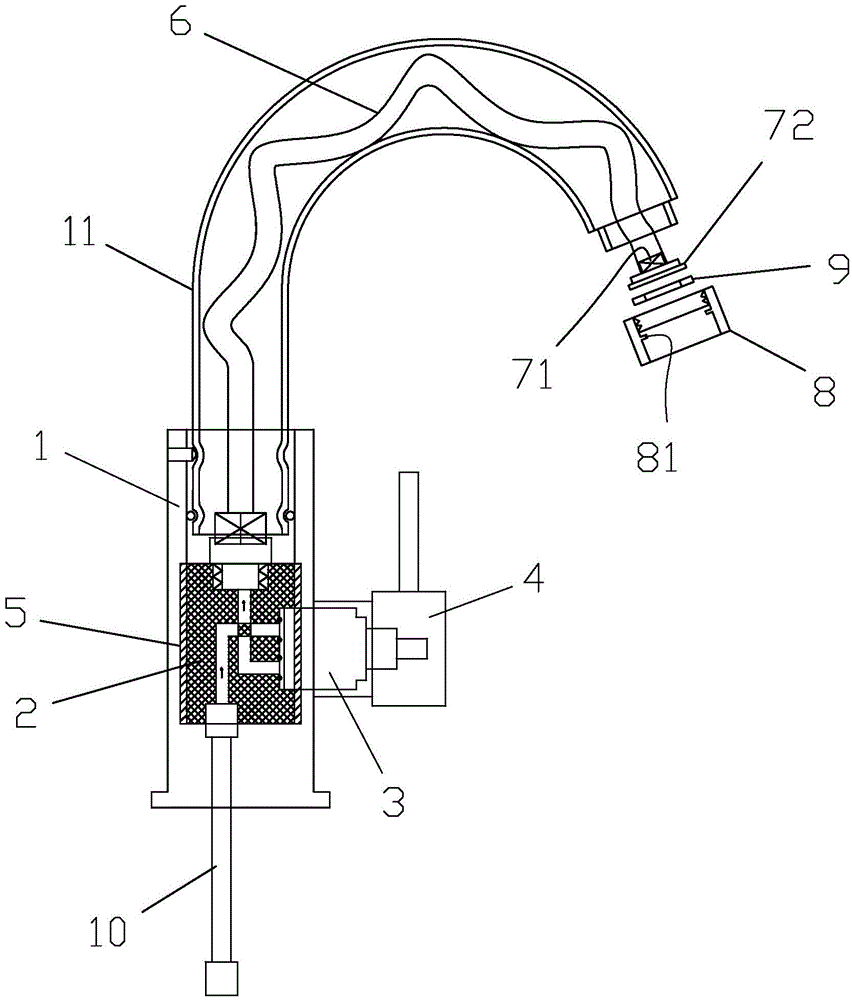

Embedded faucet structure assembly

ActiveCN103953785AWill not affect normal useWill not affect normal water useValve members for absorbing fluid energyDomestic plumbingInlet channelMechanical engineering

Owner:开平市瑞霖淋浴科技有限公司

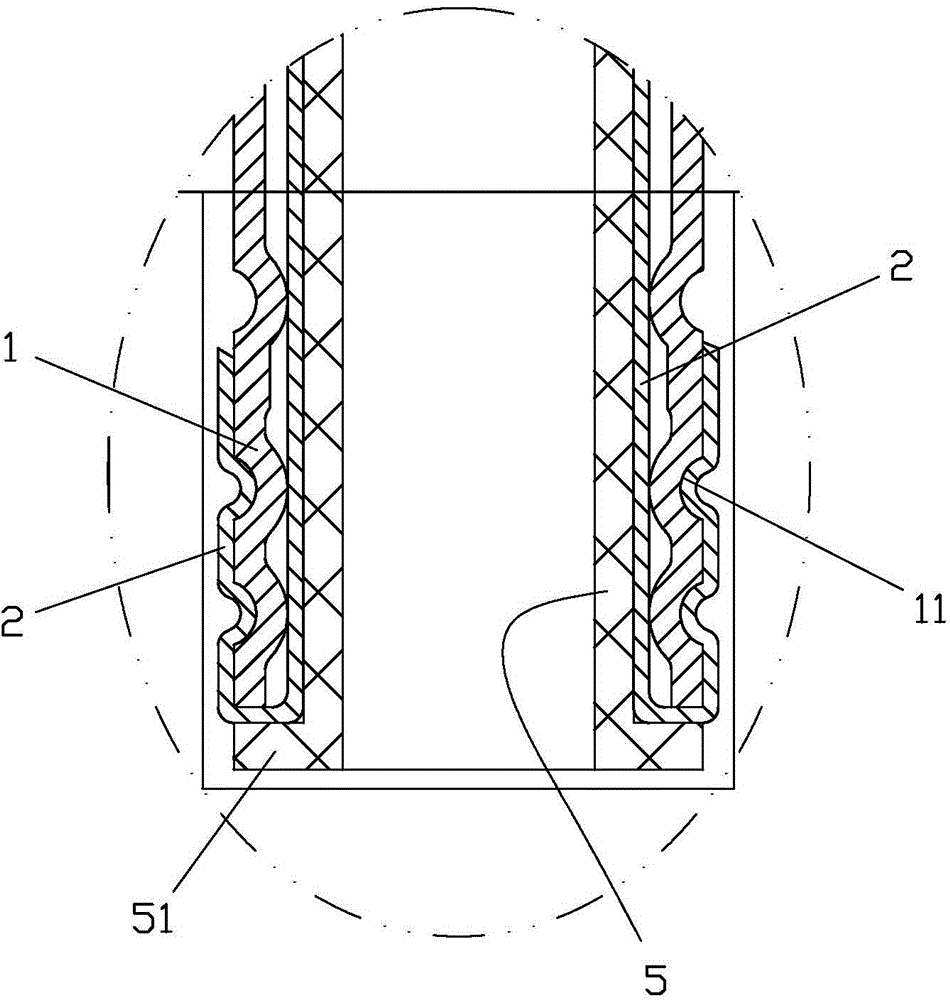

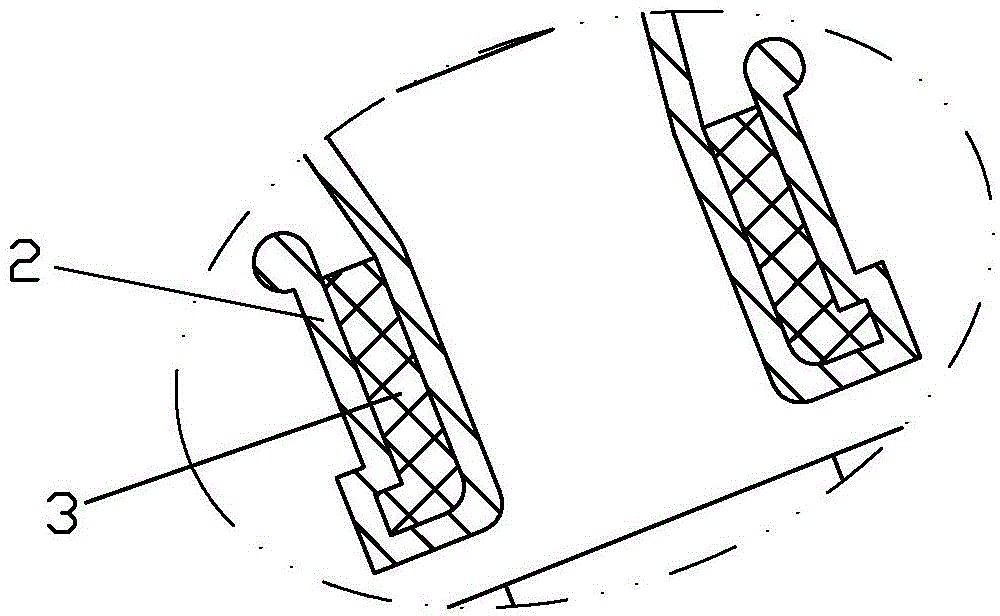

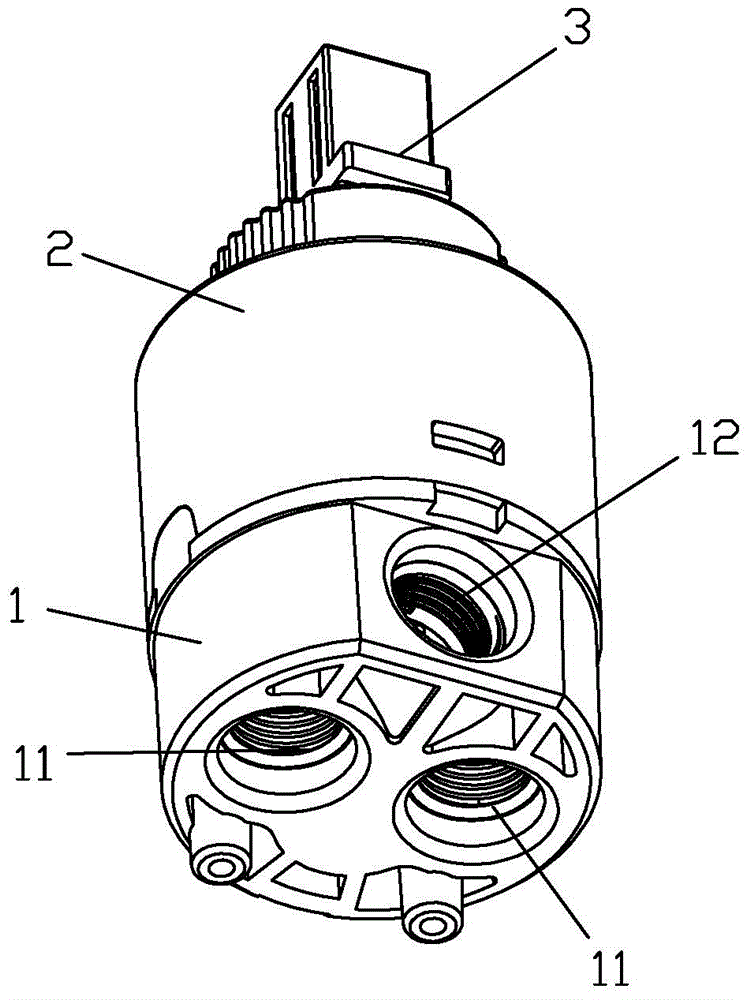

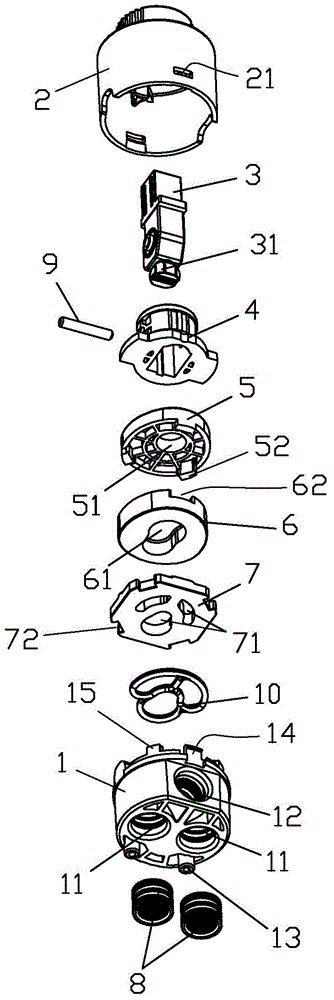

Faucet valve core

The invention discloses a faucet valve core which comprises a valve core body, a rotary rod, a movable valve plate and a stationary valve plate, wherein the rotary rod, the movable valve plate and the stationary valve plate are mounted in the valve core body sequentially from the top down; the movable valve plate is fixed at the bottom end of the rotary rod; a waterstop rubber ring is arranged at the bottom end of the valve core body; a mounting thread part and a water outlet are arranged on and formed in a side wall of the valve core body; an O-shaped sealing ring is arranged above the mounting thread part; the position of the water outlet on the valve core body is unchanged; the axial height of the mounting thread part is unchanged; the position of the O-shaped sealing ring relative to the mounting thread part is unchanged; the mounting thread part is moved down to allow the water outlet to be located on the mounting thread part; a structure that the water outlet is formed below the mounting thread part in the prior art is abandoned; the valve body length of the valve core is reduced; a valve core mounting position matched with the valve core is designed to be shallow certainly; the gorgeous and attractive decoration effect can be reached under the condition that an entire main body of a faucet is not required to be large; the material consumption is reduced; and the cost is lowered.

Owner:KAIPING SEDAL TAP COMPONENTS

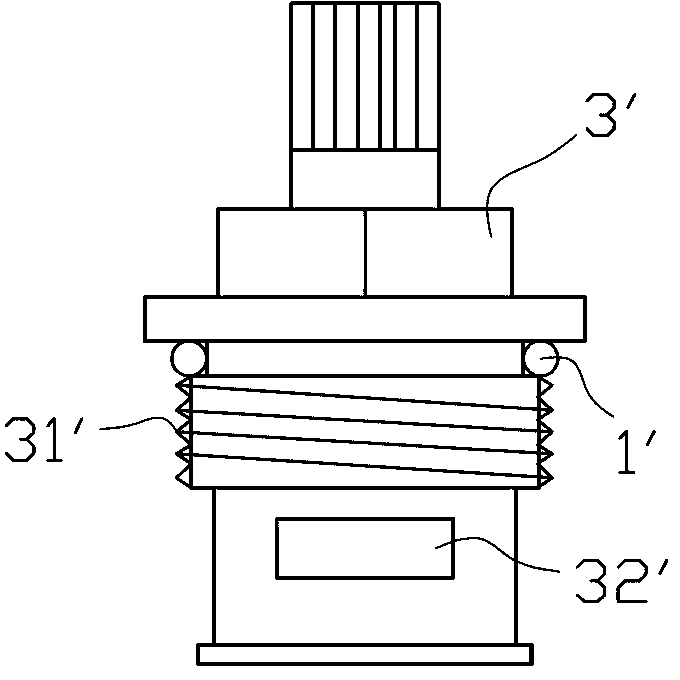

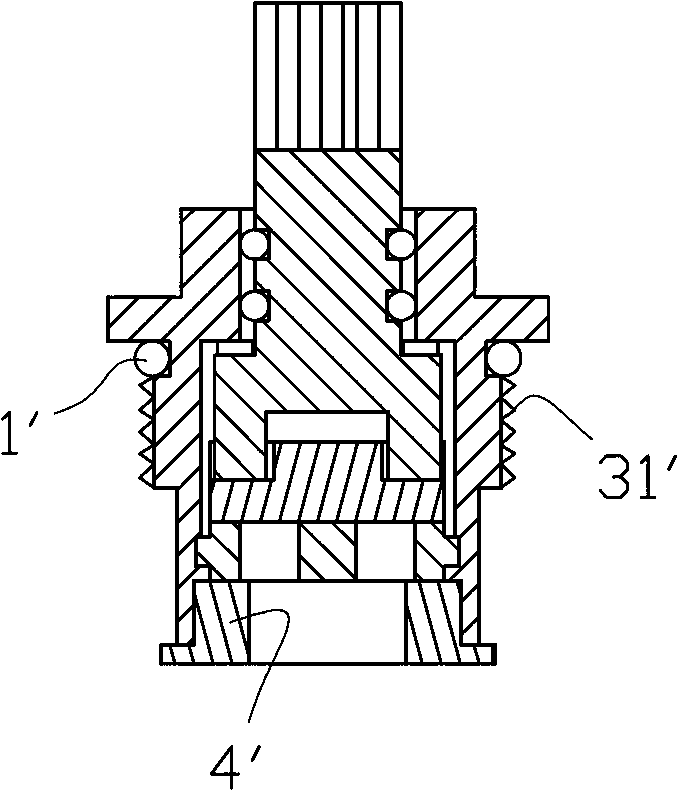

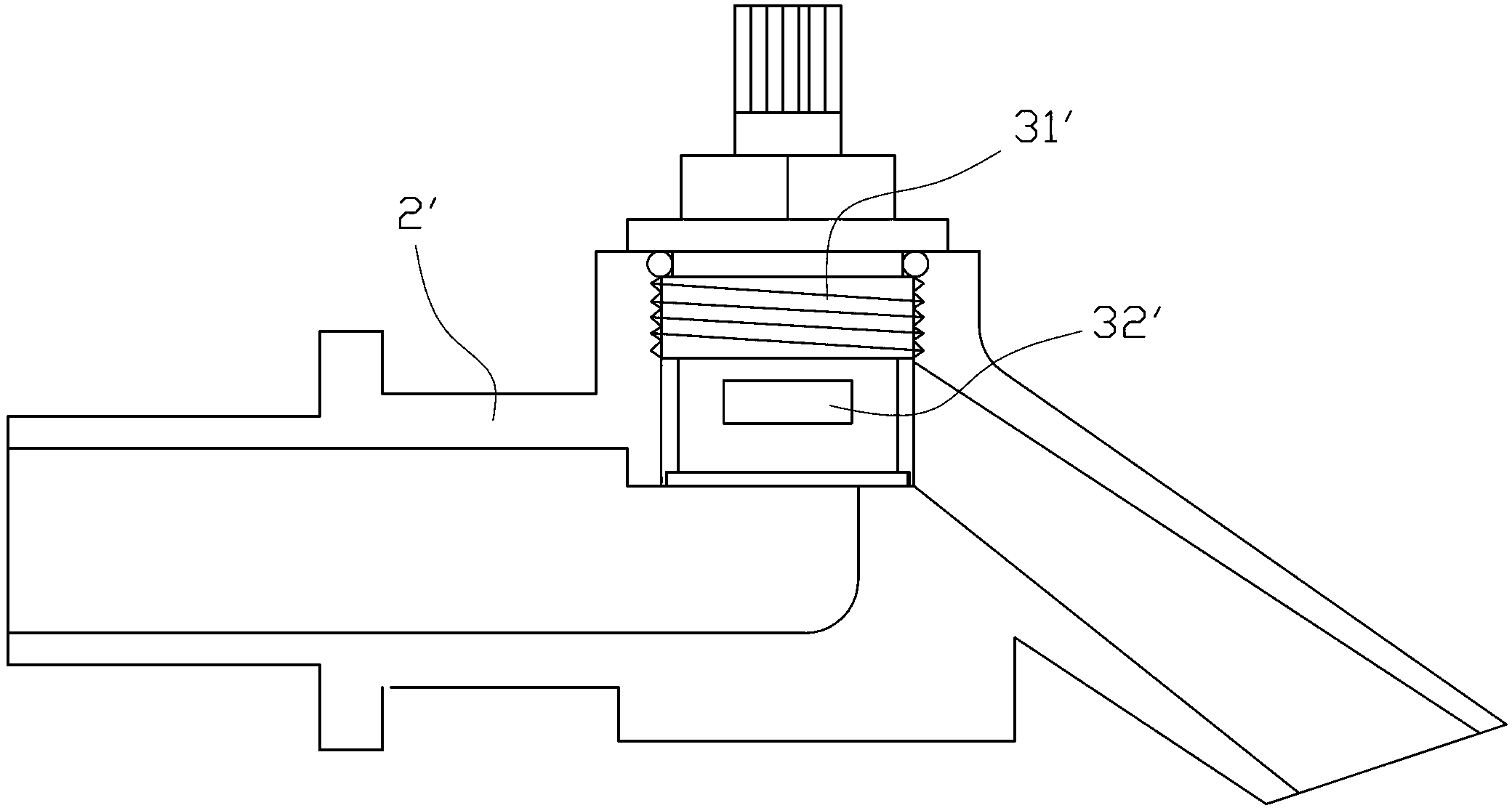

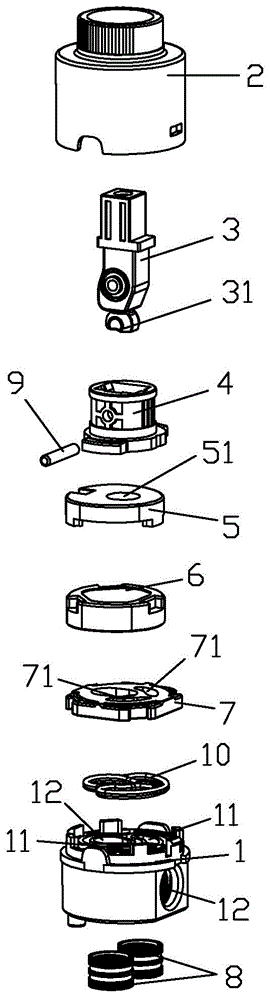

Poking rod control type valve core

InactiveCN104565414AReduce material requirementsThe main structure is simpleSlide valveWater flowScrew thread

The invention discloses a poking rod control type valve core. The poking rod control type valve core comprises a base and a valve body, wherein a poking rod, a support, a poking disc, a ceramic rotor plate and a ceramic stator plate are sequentially arranged in the valve body from top to bottom, a containing hole is formed in the poking disc, the ceramic rotor plate is fixedly connected with the poking disc, the ceramic stator plate is fixed on the base, the bottom end surface of the base is provided with two water inlet passages which axially penetrate through the base, the side wall of the base is provided with a water outlet passage which stretches to the upper end surface of the base, water holes which correspond to the water inlet passages and the water outlet passage are formed in the ceramic stator plate, and a concave cavity which corresponds to the water holes in the ceramic stator plate is formed in the ceramic rotor plate; the poking rod is connected to the support in a pivoting way, the lower end of the poking rod stretches into the containing hole of the poking disc, the ceramic rotor plate is driven to move through the poking disc by the poking rod, and communicating or opening and closing states between the concave cavity in the ceramic rotor plate and the water holes can be realized; water inlet pipe connectors which are provided with threads are embedded into the water inlet passages, and the water outlet passage is a plastic threaded hole which is connected with a standard hose, so that water flow cannot pass through a faucet main body, and the requirement on the faucet main body is low.

Owner:GUANGDONG HENT TECH

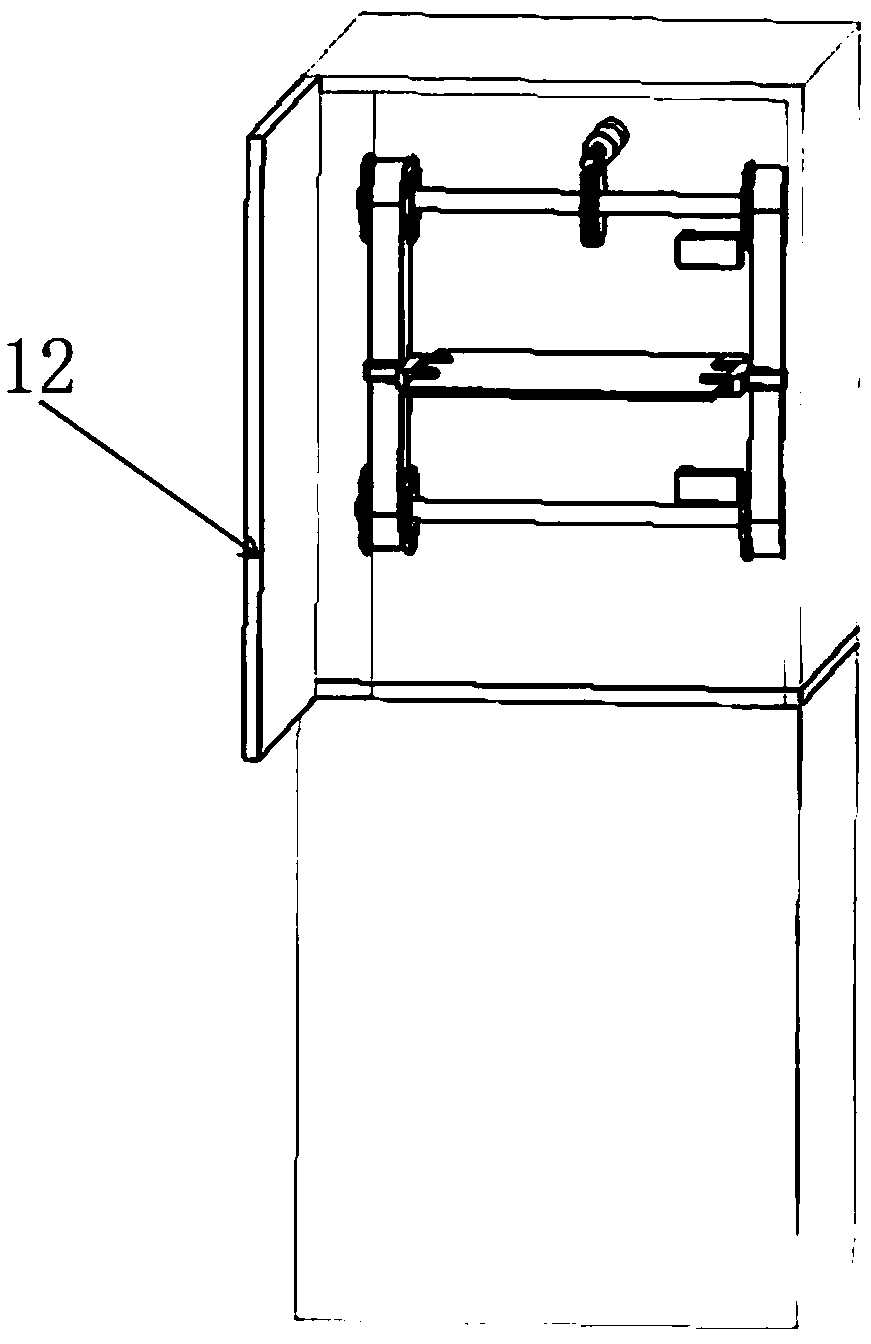

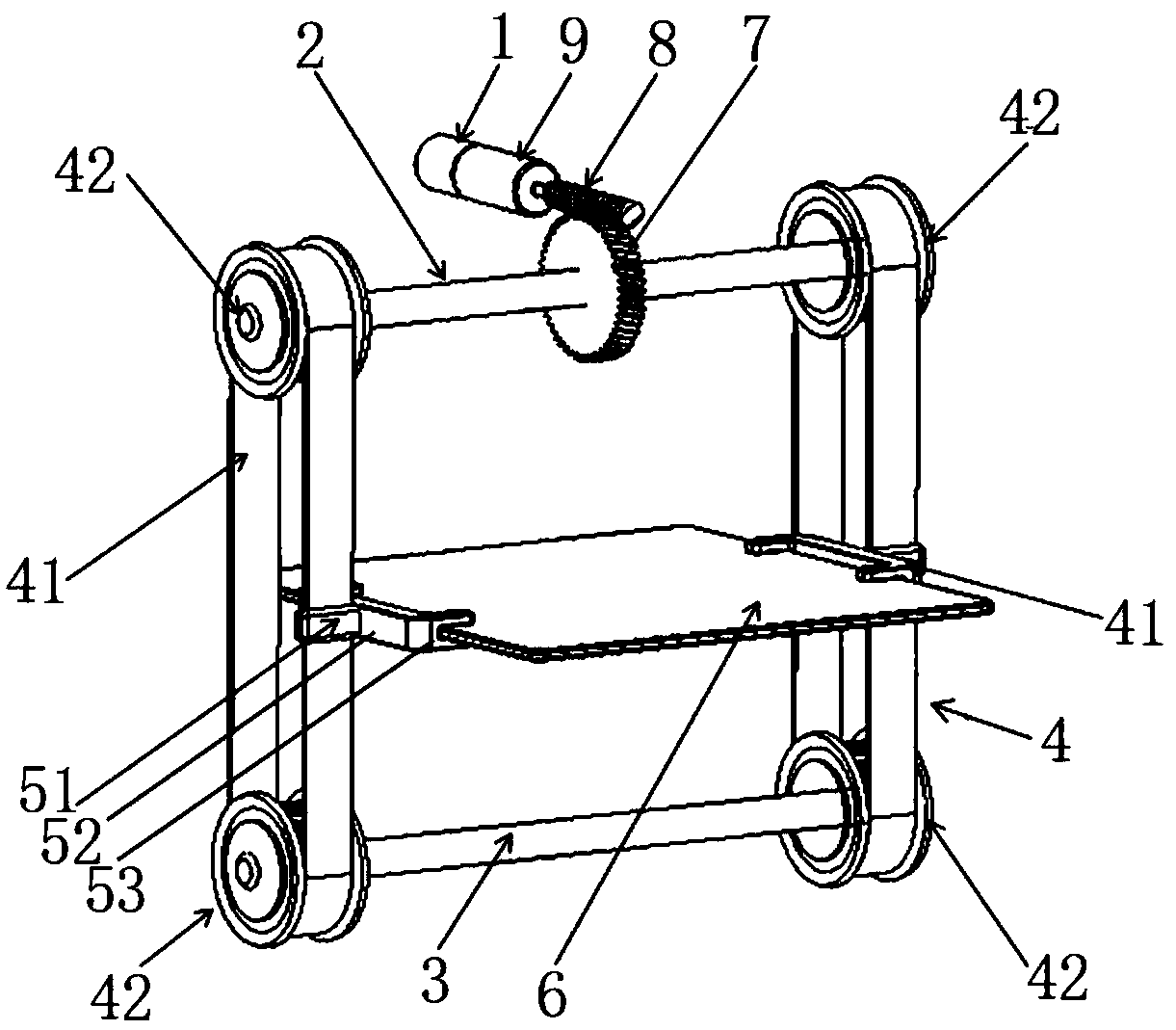

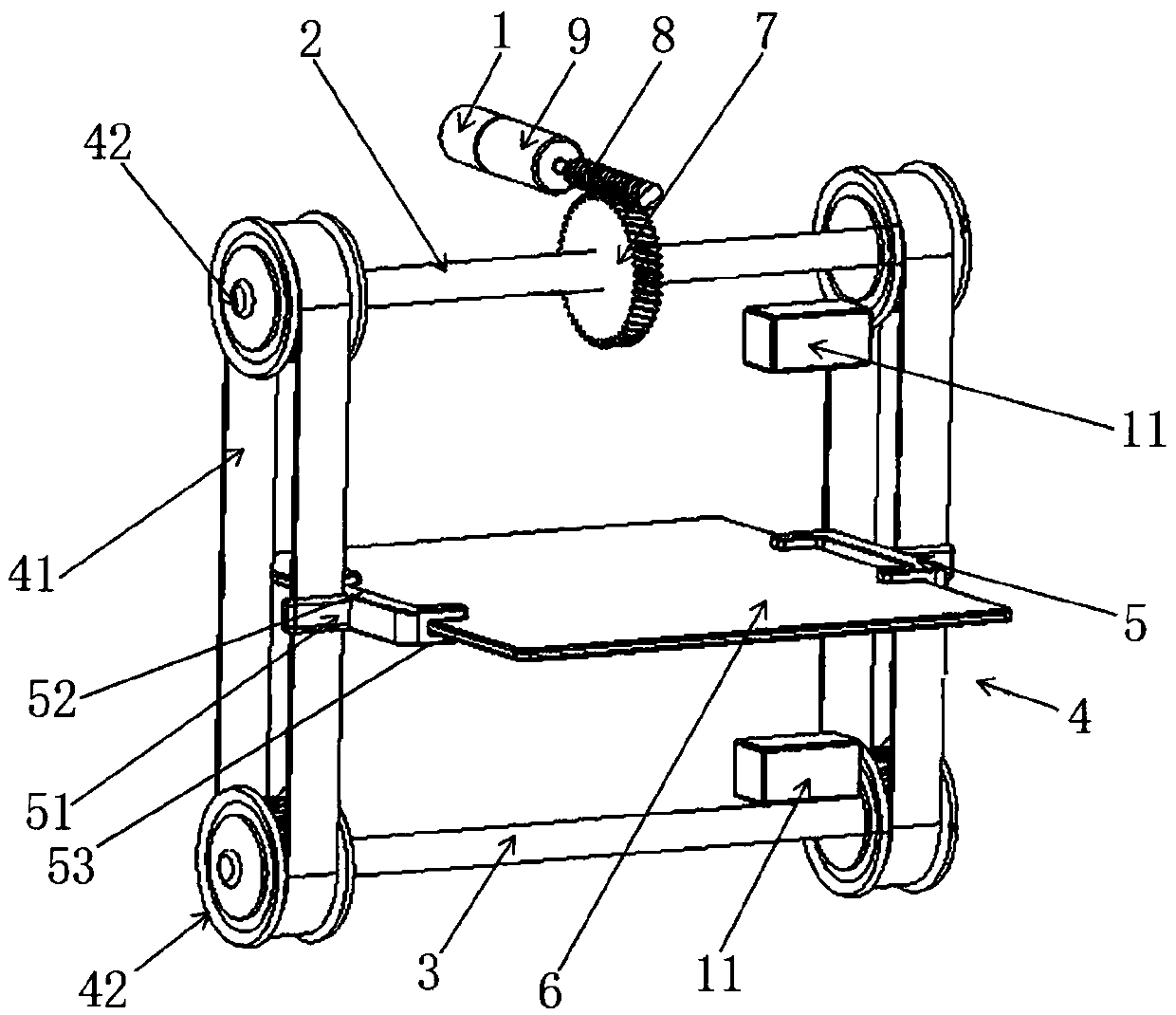

Self-locking lifting device for refrigerator cold storage interval and working method thereof

PendingCN109520201ASimple, reasonable and compact structureSmall footprintLighting and heating apparatusSupportMotor driveSelf locking

The invention relates to a self-locking lifting device for a refrigerator cold storage interval and a working method thereof. The lifting device comprises a motor, an upper connecting rod, a lower connecting rod, driving mechanisms, connecting mechanisms and a clapboard, wherein the upper connecting rod and the lower connecting rod are connected with the two driving mechanisms; a bevel gear is arranged in the middle of the upper connecting rod; a worm rod is arranged on a main shaft of the motor; the bevel gear meshes with the worm rod; the connecting mechanisms are arranged on the two drivingmechanisms; and the clapboard is arranged between the connecting mechanisms and is fixed. The self-locking lifting device for the refrigerator cold storage interval provided by the invention is reasonable and compact in structure and small in space occupation; the motor drives the driving mechanisms to drive the clapboard to realize an up-and-down lifting function; and the automatic clapboard lifting device has a self-locking function, so that the clapboard can be fixed at the designated position without the need for additionally arranging a locking device.

Owner:OECHSLER PLASTIC PROD TAICANG

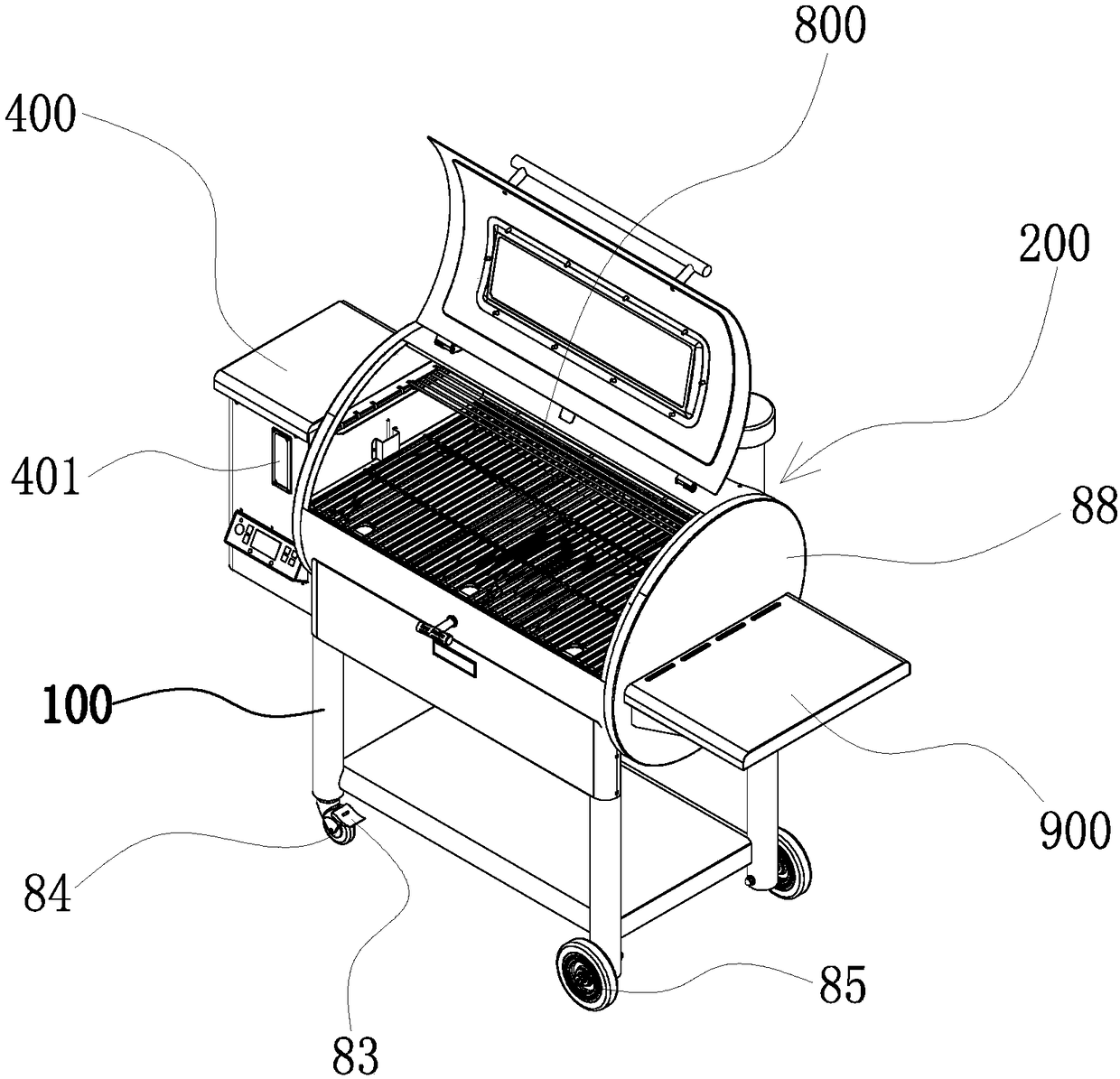

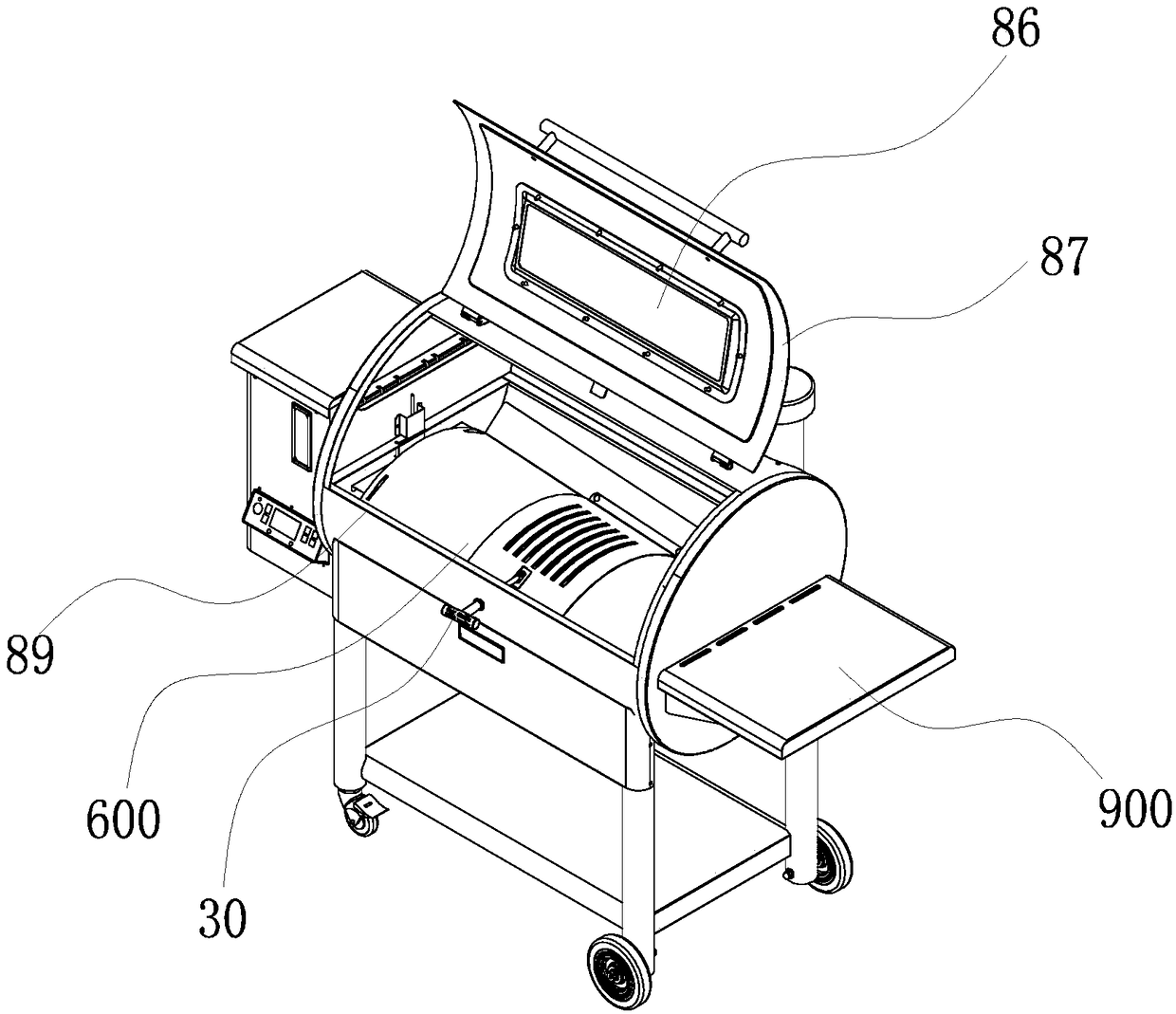

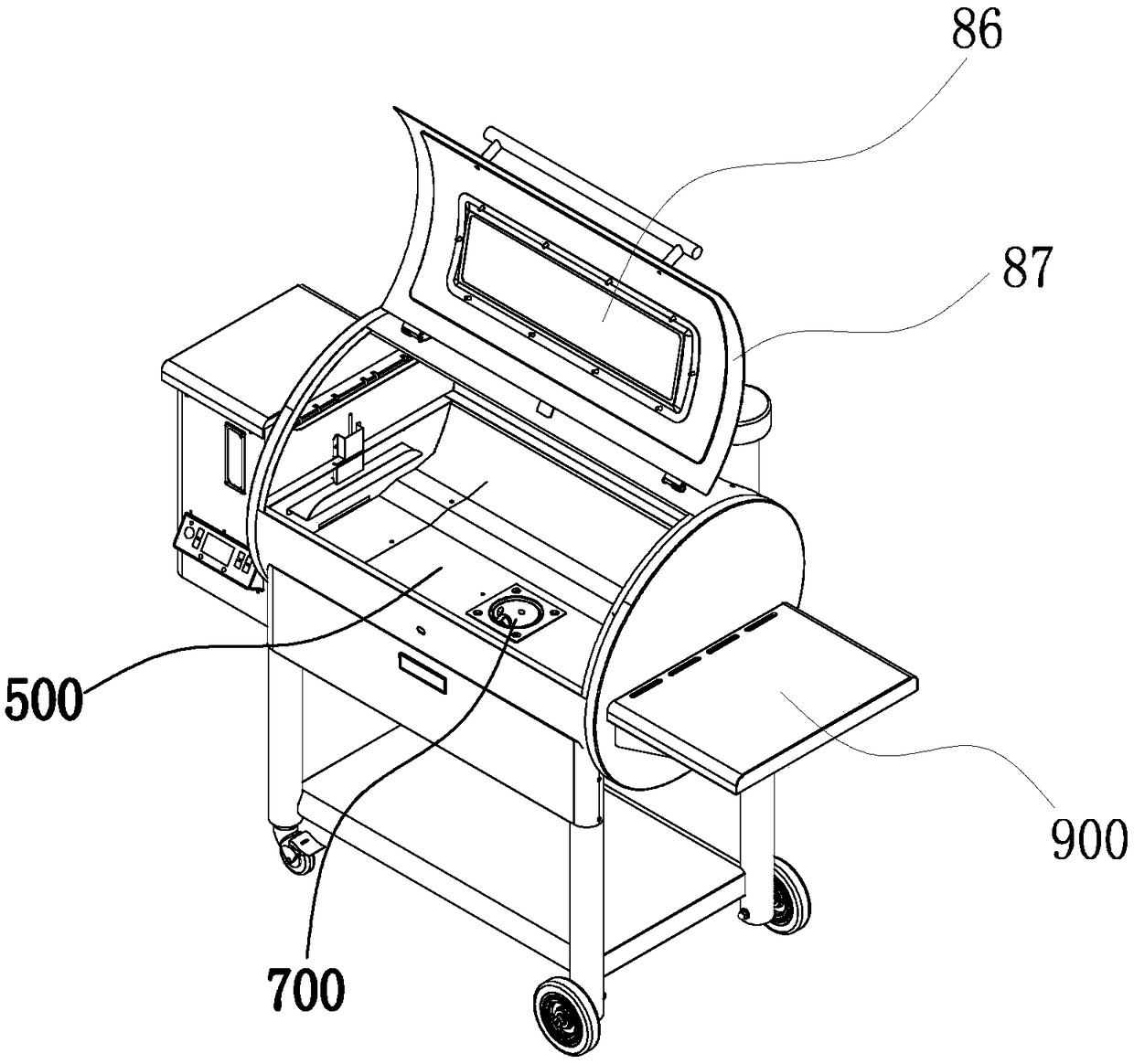

Fuel barbecue grill

PendingCN109363526AIncrease the grilling areaReal-time observation of barbecue statusFood scienceEngineeringFeeding observations

Owner:ZHEJIANG GIANT TECH CO LTD

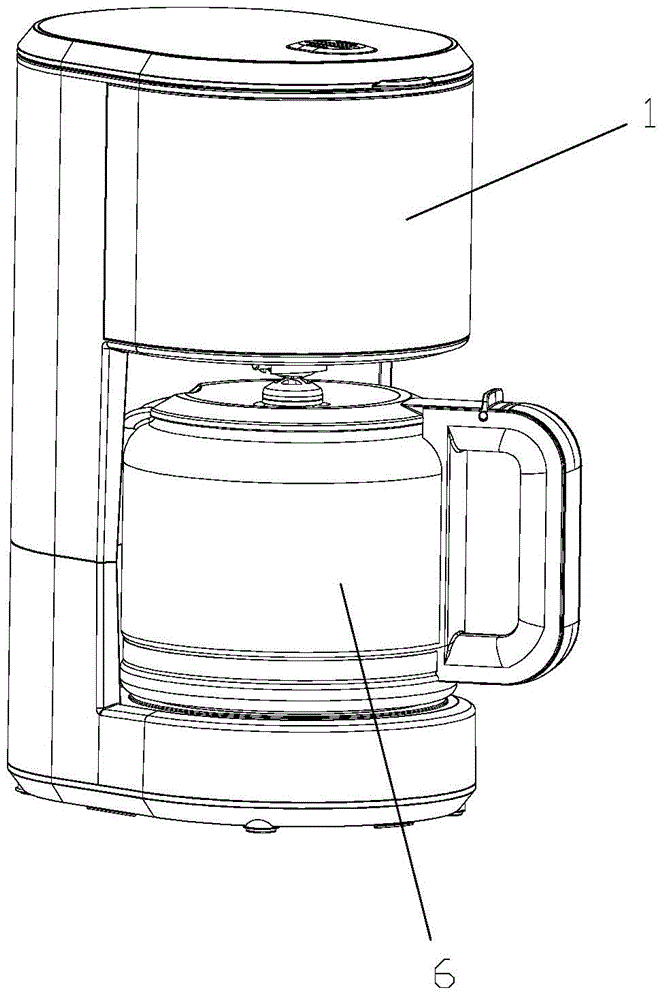

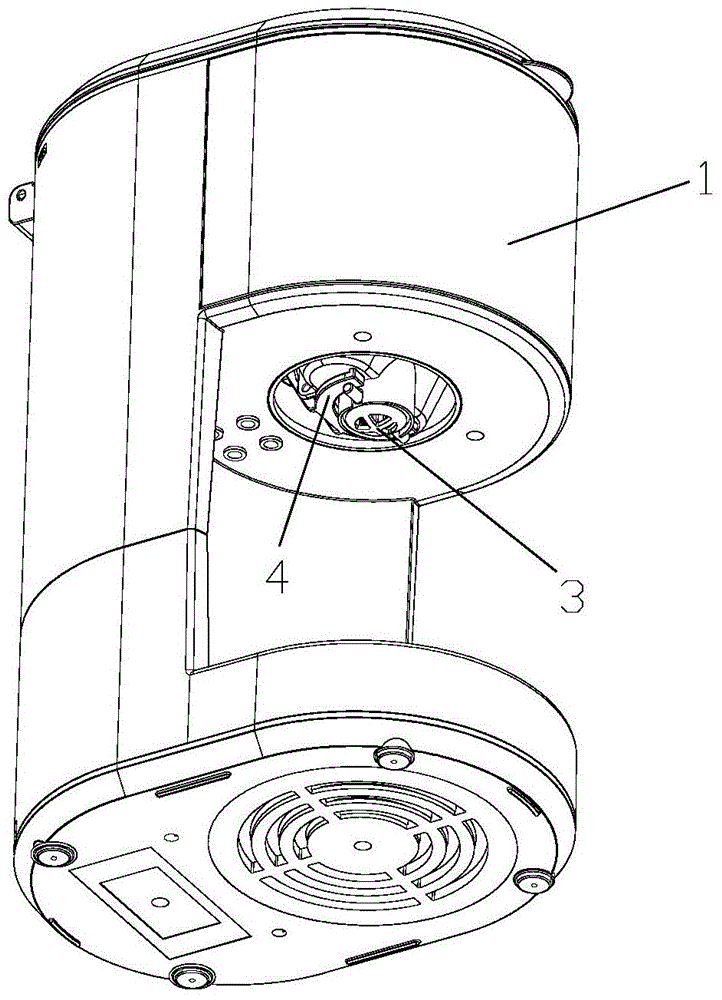

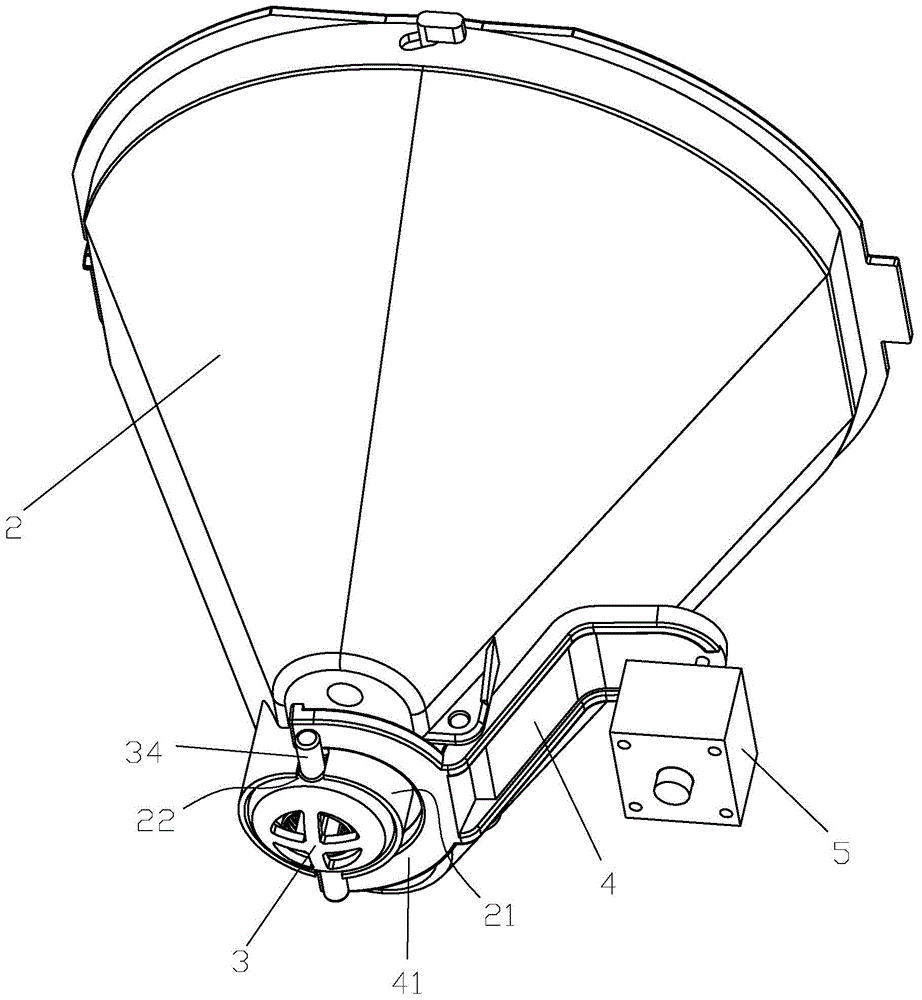

Dripping coffee maker

Owner:KINWING ELECTRIC IND

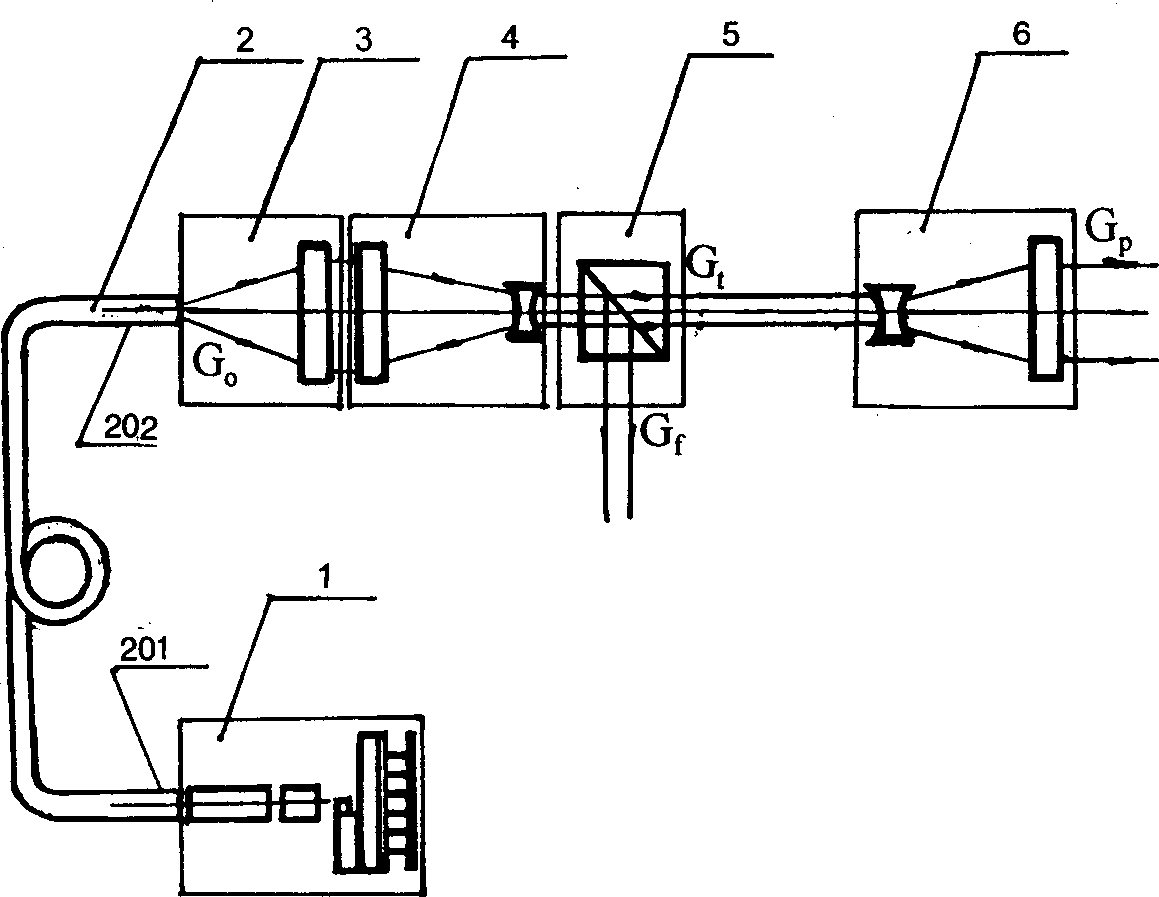

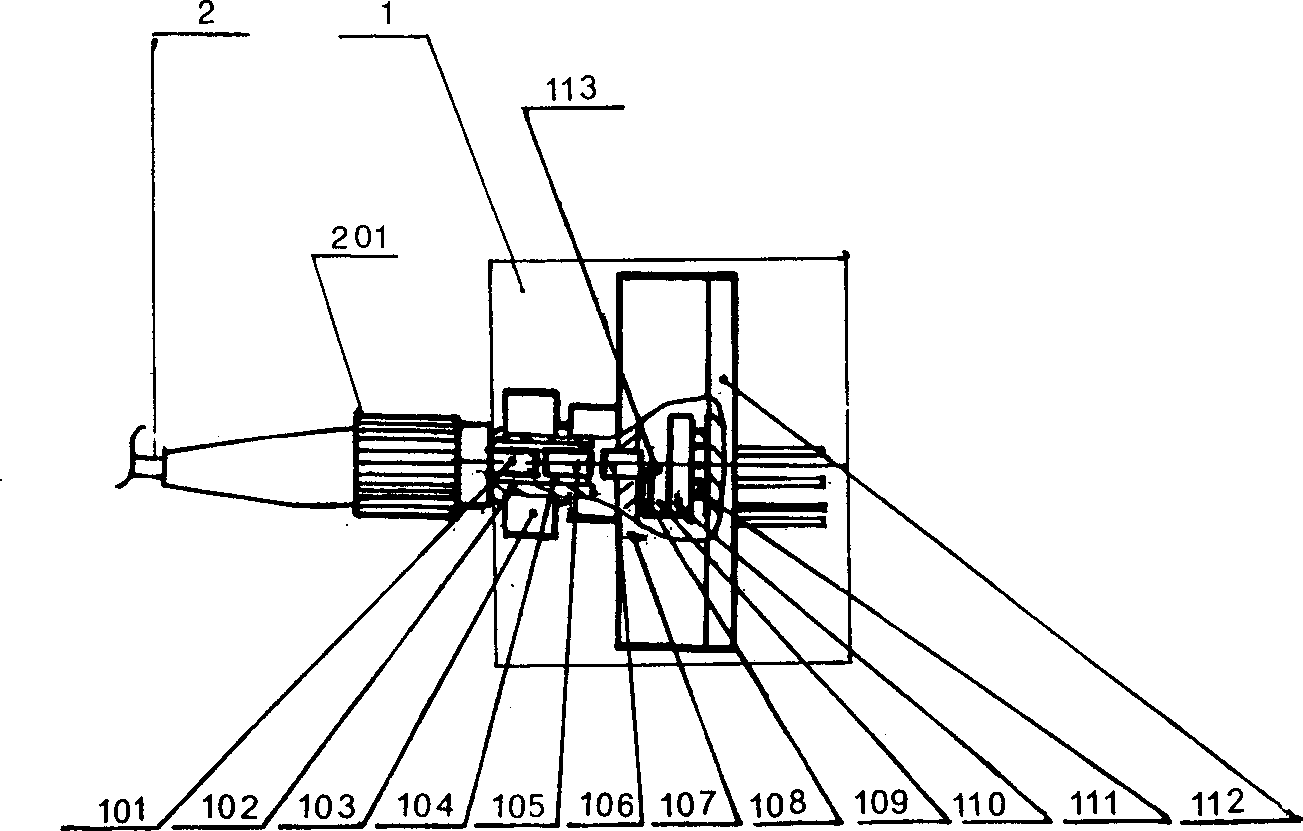

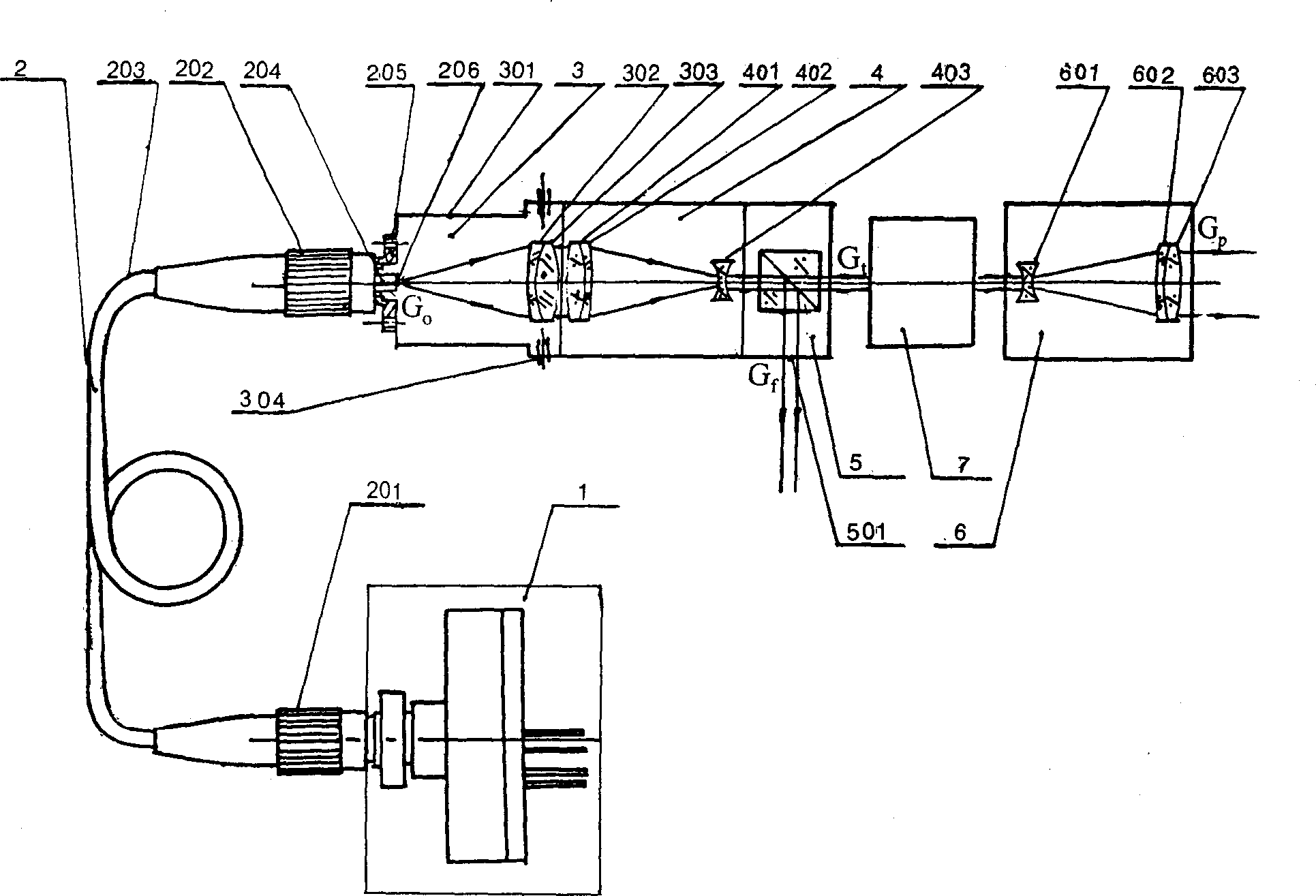

Semiconductor laser light resource for projection apparatus

InactiveCN1359175ASimple, reasonable and compact structureEasy to operateLaser detailsSemiconductor lasersLaser lightSingle mode fiber coupling

The semiconductor laser light source mainly is applicable to laser projection, alser etching, printing and measurement equipments, and is characterized by that its semiconductor laser component is coupled with monomode fibre to output a laser beam, said laser beam is passed through a collimating element and collimated, and beam-splitted to obtain two beans of light, one beam of light can be directly outputted, its beam orifice is smaller, can be provided for use, another beam of light is expanded by means of beam-expanding element, then a parallel beam with larger beam orifice can be outputted for use. Said invention is simple in structure, its coupling efficiency is about 70%.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

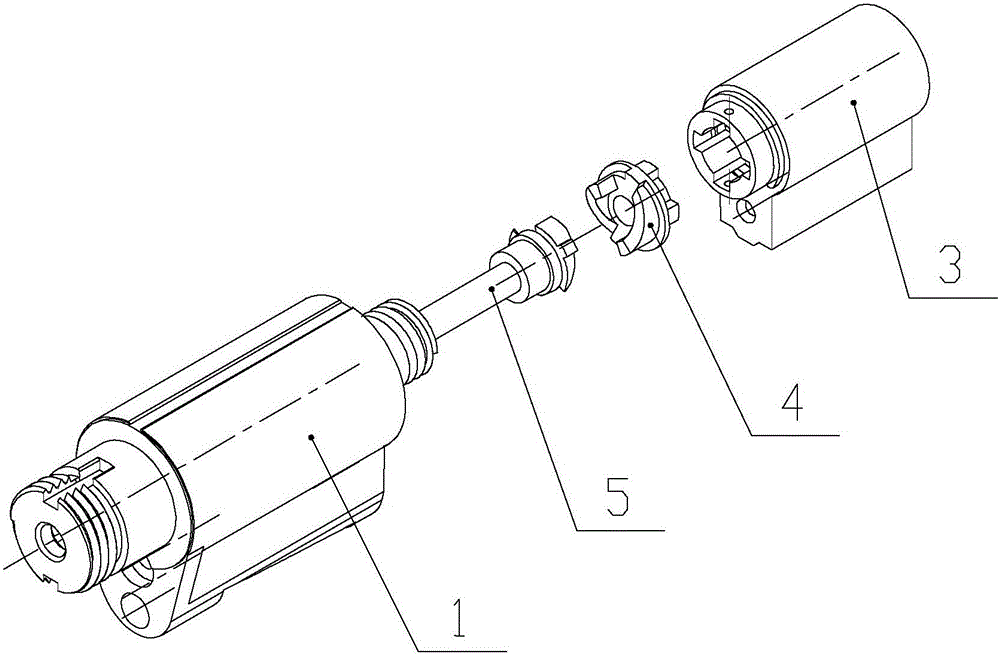

Lock core mechanism

ActiveCN105971408ASimple, reasonable and compact structureSimple mechanical transmission connectionNon-mechanical controlsLock casingsLinear motionEngineering

The invention discloses a lock core mechanism. The lock core mechanism comprises a lock chamber shell and a clutch part, wherein a lock chamber, a cam positioned inside the lock chamber, and a clutch ejector part which are sequentially connected are arranged inside the lock chamber shell; the clutch ejector part comprises a clamping end which is combined with the cam in a clamping manner and an ejector shaft; a reset spring is arranged on the ejector shaft in a sleeving manner, and stretches into the clutch part; a dowel is arranged in the clutch part; and when a key is inserted into the lock chamber and drives the cam to rotate, the cam pushes the clutch ejector part to perform axial linear motion in a clutch manner to eject the dowel to achieve unlocking. According to the lock core mechanism, the rotating motion of the key is converted into the linear motion of the ejector shaft through the combined structure of the cam and the clutch ejector part, and the ejector shaft ejects the dowel to achieve unlocking; and the rotating motion of the key is converted into the linear motion of the ejector shaft, so that the mechanical transmission connection of the lock core mechanism is more simple, efficient and reliable, and the safety of the lock core mechanism is improved.

Owner:NANJING EASTHOUSE ELECTRIC CO LTD

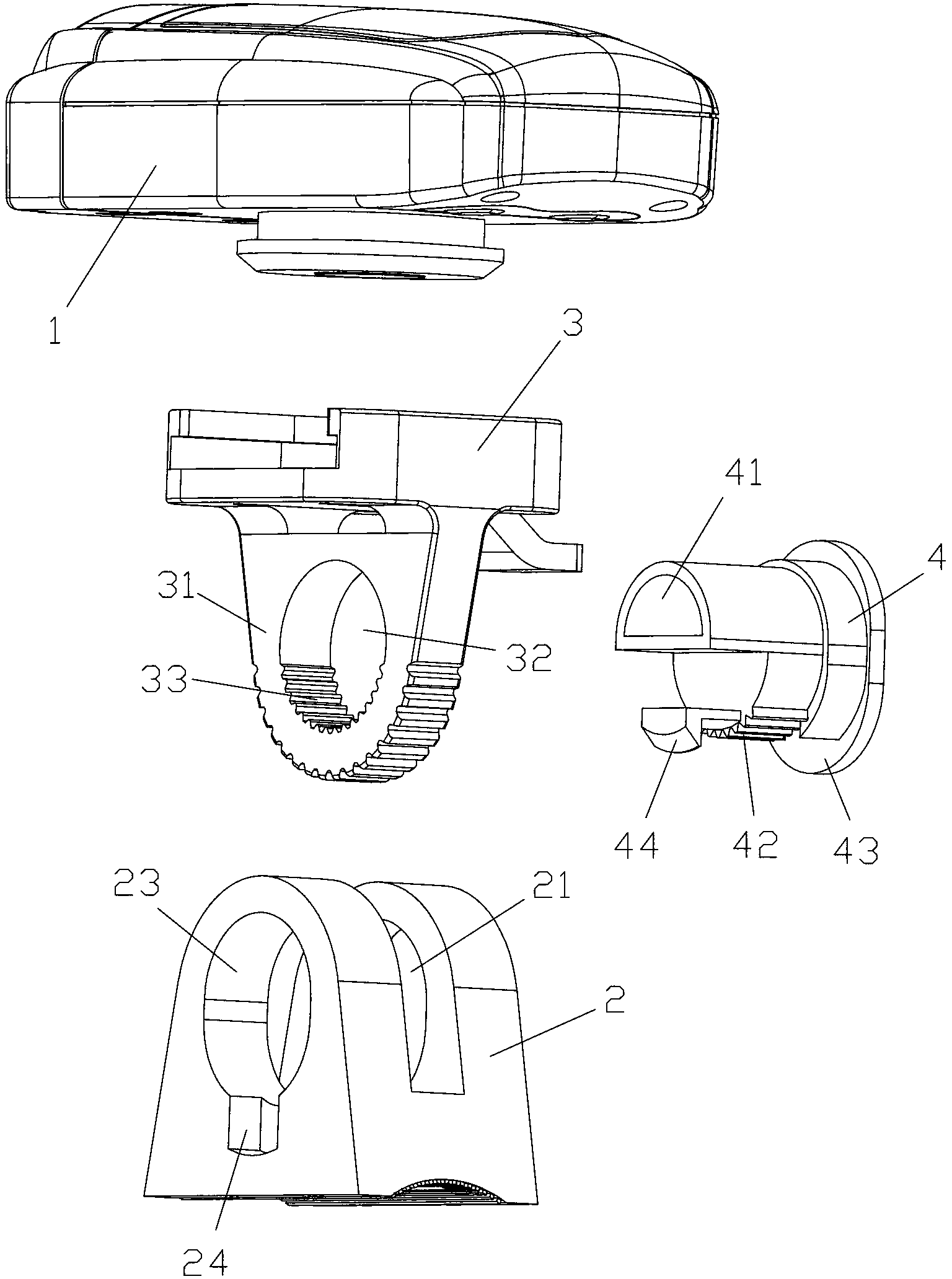

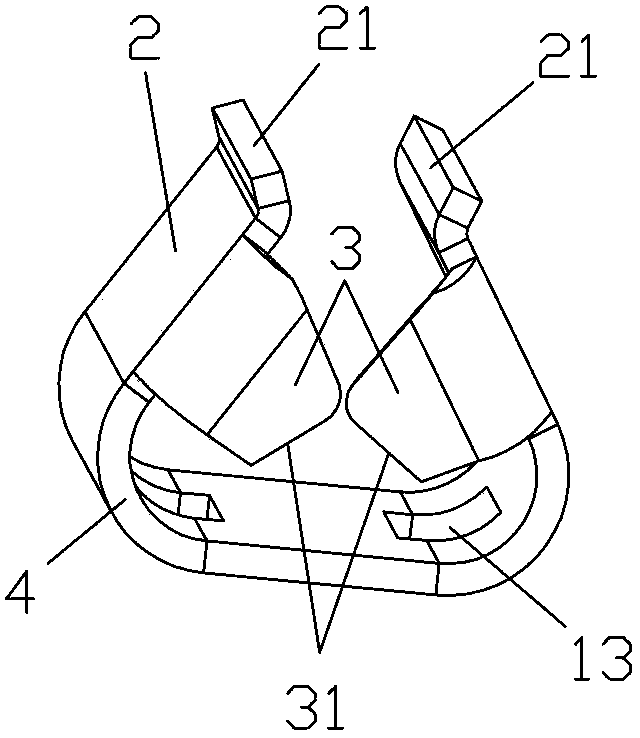

Body-angle-adjustable projection laser tail lamp for outdoor cycling

InactiveCN103322530AAccurate and stable angular positionSimple, reasonable and compact structureLighting support devicesOptical signalBody angleEngineering

The invention discloses a body-angle-adjustable projection laser tail lamp for outdoor cycling. The body-angle-adjustable projection laser tail lamp for outdoor cycling comprises a lamp body, a base, and a connecting block. The lamp body is fixed on the connecting block. The lower portion of the connecting block is a gear structure. The base is provided with a notch matching with the lower portion of the connecting block. The bottom surface of the notch is provided with gear teeth corresponding to the gear on the lower portion of the connecting block. The lower portion of the connecting block is inserted into the notch before the gear on the lower portion of the connecting block is meshed with the gear teeth on the bottom surface of the notch. The base is provided with a through hole coaxial with the lower portion of the connecting block, the connecting block is fixed on the base through a pin which passes through the through hole and a shaft hole in the lower portion of the connecting block, the pin is in loose fit with the shaft hole in the lower portion of the connecting block, and the pin is fixedly connected with the base. The form that the lamp body and the base are fixed in a non-rotatable structure in the traditional art is abandoned, and angle adjustment of the lamp body is facilitated.

Owner:余德锐

Conductive connecting body structure of connector

The invention discloses a conductive connecting body structure of a connector. The conductive connecting body structure of the connector comprises a connecting body. Two opposite side edges of the connecting body are respectively provided with an elastic clamping edge; the two elastic clamping edges are configured in a manner that the two elastic clamping edges are closer as the two elastic clamping edges goes up; each elastic clamping edge is provided with a fixture block; each fixture block is provided with a bevel connection or a notch used for clamping leads; the two elastic clamping edges are strutted; the leads can pass through below the bevel connections or the notches; the two elastic clamping edges are reset; the leads are clamped by the bevel connections or the notches of the fixture blocks, and therefore, the direct insertion and direct stripping of lead disassembly and assembly are realized while a manner adopted all the time that the leads are compressed by adopting structures, such as bolts, rivets and the like is abandoned; after the leads are clamped by the bevel connections or the notches of the fixture blocks, the leads are not easy to loose and fall under the unwariness condition; the clamping forces of the fixture blocks to the leads are stable. Moreover, the conductive connecting body structure of the connector disclosed by the invention is simple, reasonable and compact in structure, simple to operate and low in implementation cost.

Owner:JIANGMEN KREALUX ELECTRICAL APPLIANCES

Waterproof structure of motorcycle rearview mirror

InactiveCN103950488AEasy to adjustImprove waterproof performanceCycle mirrorsArchitectural engineeringRear-view mirror

The invention discloses a waterproof structure of a motorcycle rearview mirror. The waterproof structure comprises a mirror shell and a mirror piece installed in the mirror shell, wherein the back face of the mirror piece is provided with an explosion-proof tape; a mirror rod through which the mirror shell is installed on a motorcycle handle is installed in the mirror shell in a penetrating way; annular waterproof convex ribs protrude on the internal bottom wall of the mirror shell; the waterproof convex ribs closely abut against the explosion-proof tape; a waterproof space is formed among the waterproof convex ribs, the internal bottom wall of the mirror shell and the explosion-proof tape; the mirror rod is located in the waterproof space. The waterproof structure abandons the waterproof structure in the prior art, and has the characteristics of good waterproof effect, simple rational compact structure and the like.

Owner:JIANGMEN DACHANGJIANG GROUP CO LTD

Tool sharpener with multi-angle adjustment

InactiveCN104526476ARealize multi-angle adjustmentReduce equipment costsGrinding wheel securing apparatusGrinding drivesVertical edgeEngineering

The invention discloses a tool sharpener with multi-angle adjustment. The tool sharpener with the multi-angle adjustment comprises a base. The base is provided with a first guide rail. A grinding wheel driving motor is installed on the first guide rail. A grinding wheel is installed on the end of the grinding wheel driving motor. The position, close to the grinding wheel, on the base is provided with a knife part clamp. A tilted support is fixed on the base. The tilted support is provided with a second guide rail. A first sliding block capable of sliding forth and back is arranged on the second guide rail. The first sliding block is driven by a screw rod installed on the tilted support. The vertical edge and the top of the first sliding block are provided with a second sliding block and a second motor respectively. The screw rod of an output end of the second motor is connected with a third sliding block. A third guide rail is arranged on the third sliding block in the vertical direction, and the third guide rail is matched with the second sliding block. A third motor is horizontally installed on the third sliding block in the axial direction. An output shaft of the third motor is connected with a rotating block. The knife part clamp is installed and fixed on the rotating block. According to the tool sharpener, the front and back, the up and down and the multi-angle adjustment can be achieved, so that the tool sharpening requirement of various tools is met.

Owner:江门杰能刀剪装备科技有限公司

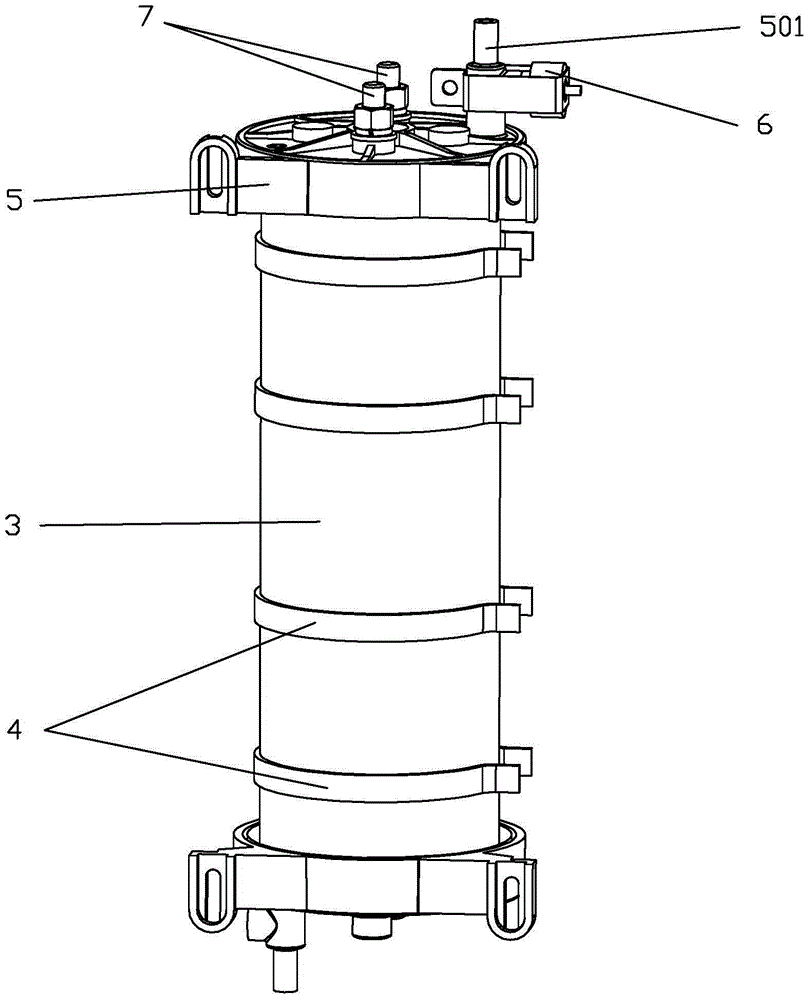

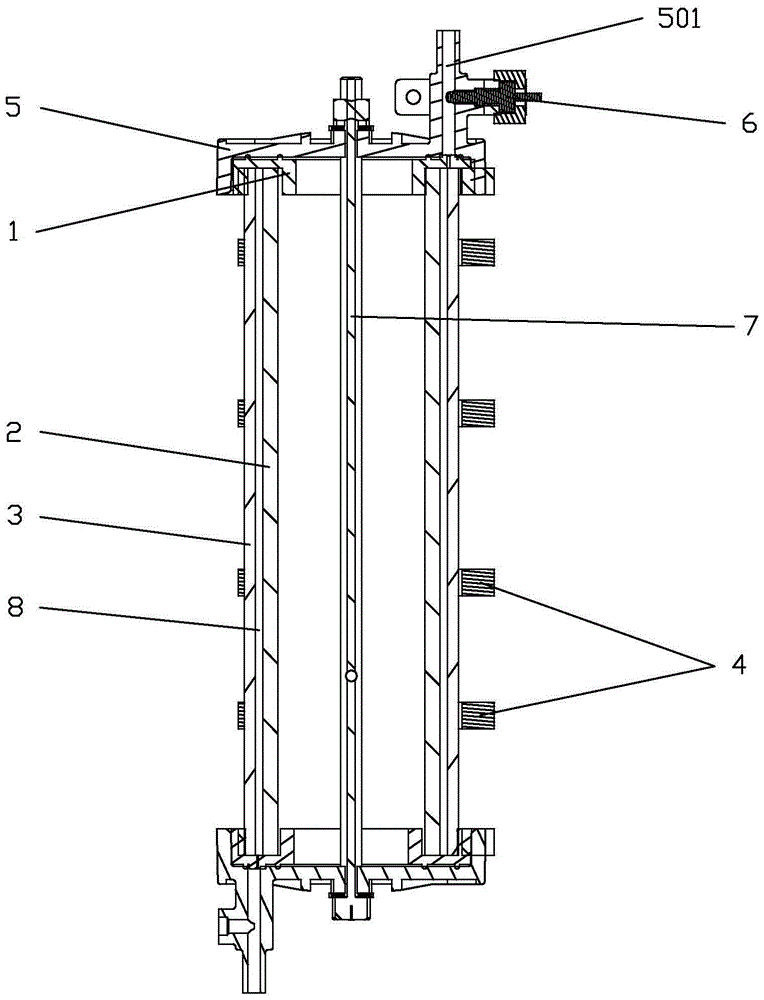

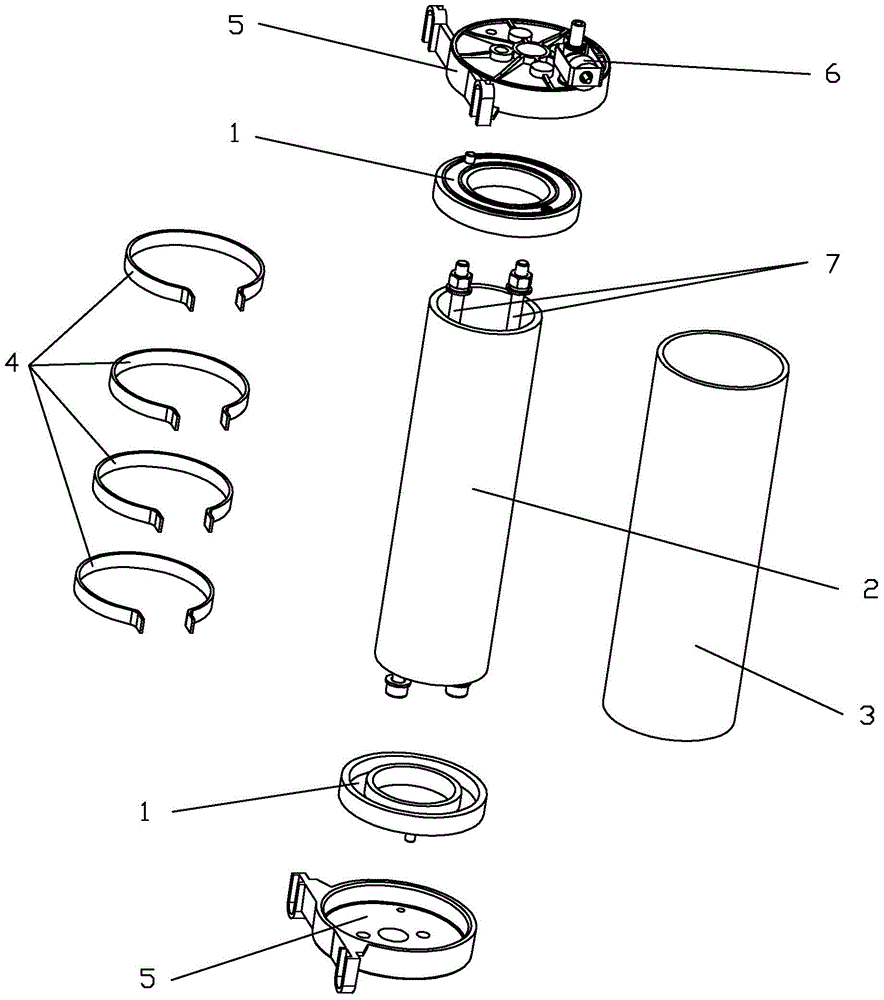

Heating pipe with internal and external heating function

InactiveCN105188166AShorten delivery timeSimple structureHeating element shapesWater heatersWater dischargeWater flow

The invention discloses a heating pipe with an internal and external heating function. The heating pipe comprises a glass pipe and end covers positioned at two ends of the glass pipe, wherein the two end covers are fixed by locking bolts and nuts; the end covers are provided with grooves matched with the glass pipe; the glass pipe comprises an inner pipe and an outer pipe; a gap is formed between the inner pipe and the outer pipe, so that a water flow channel is formed; water-passing holes communicated with the water flow channel are formed in the two end covers; heating sheets are arranged on the outer surface of the outer pipe; the heating sheets are arc-shaped and are clung to the outer wall of the outer pipe; and a nano resistance heating film is arranged on the inner surface of the inner pipe. The heating pipe has the advantages of quickness for water flow medium heating, uniformity for heating, high water discharge, convenience for assembly, low cost and the like.

Owner:KINWING ELECTRIC IND

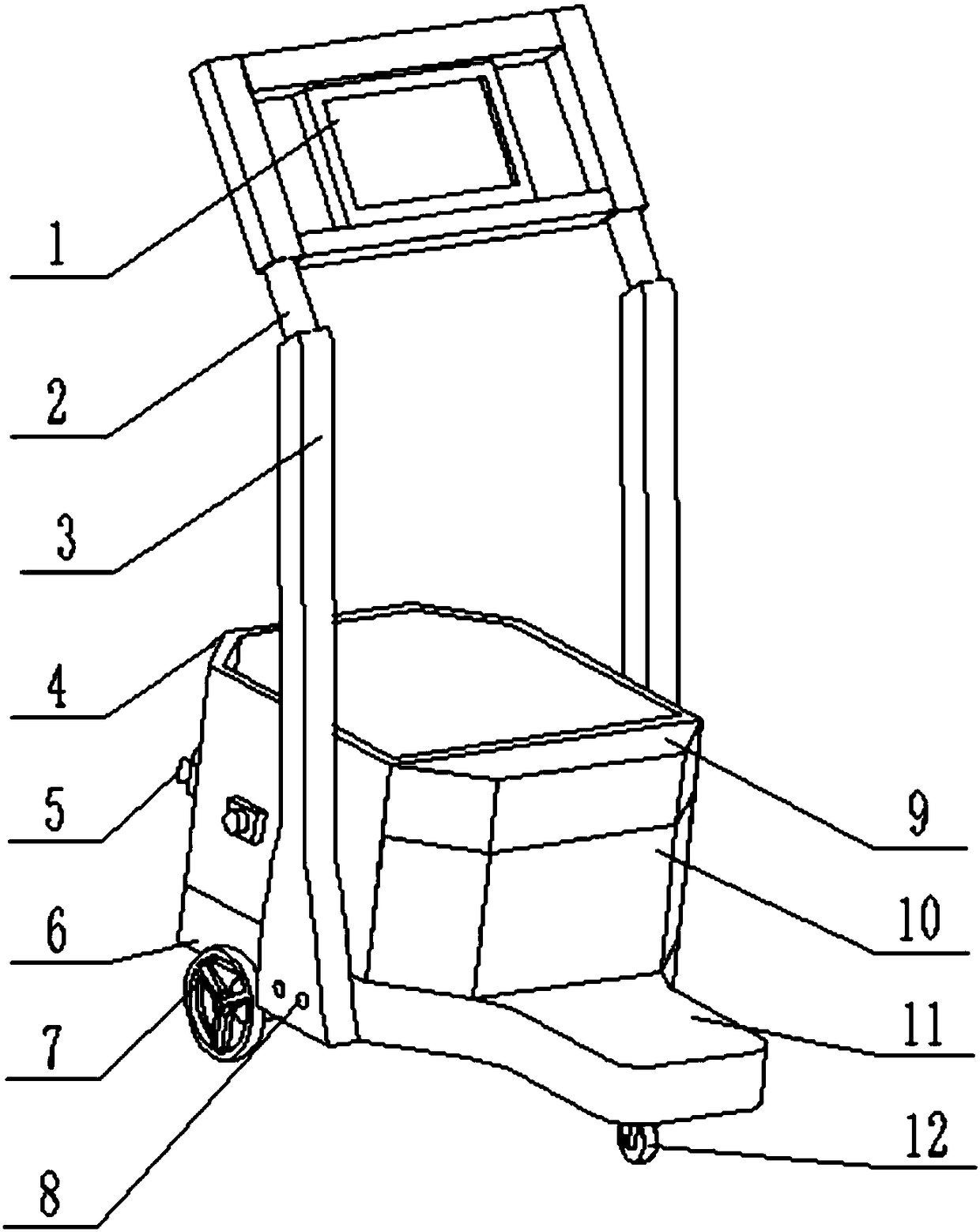

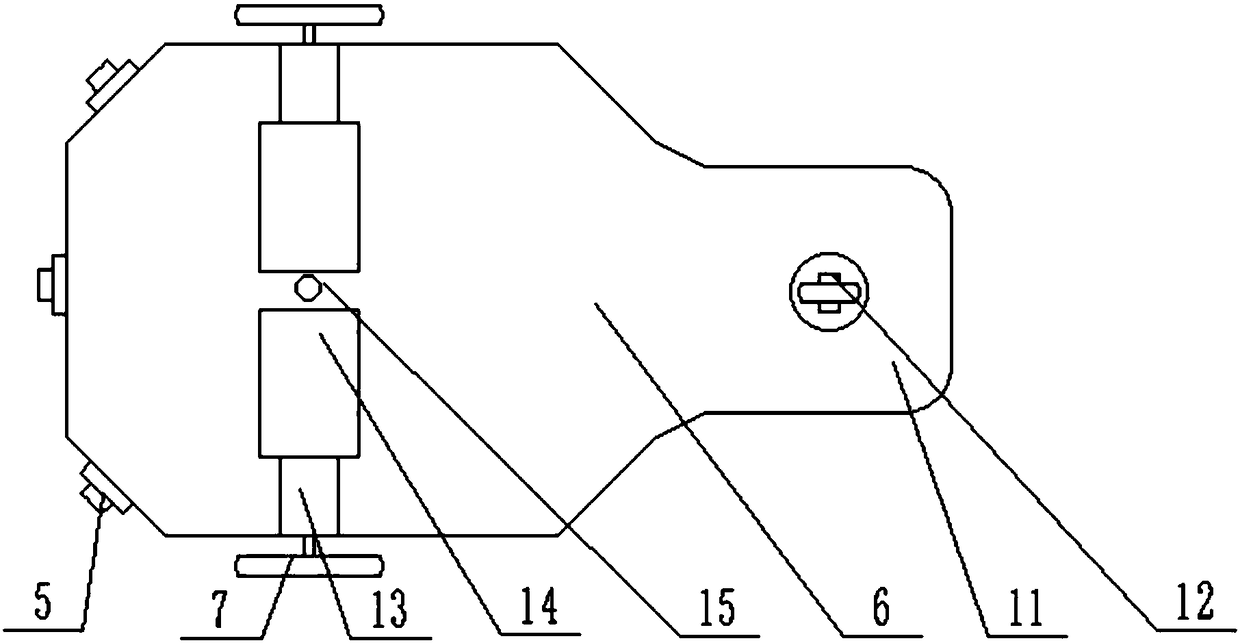

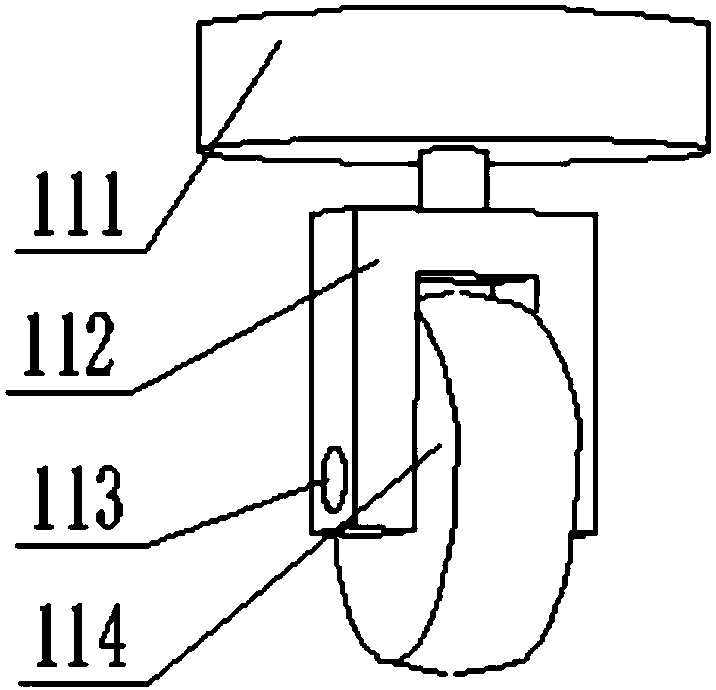

Automatic-navigation people and article loading supermarket shopping guiding robot

InactiveCN108106618AImprove shopping experienceNovel structureNavigational calculation instrumentsTarget-seeking controlLithiumDrive wheel

The invention discloses an automatic-navigation people and article loading supermarket shopping guiding robot which is composed of a vehicle body, a walking system, a controlling system and a sensingsystem, wherein the vehicle body is composed of an accommodating bottom plate, an accommodating basket, a pedal plate and an supporting arms; the walking system is composed of a driving wheel, drivenwheels and a driving device, the driving wheel is a front wheel and is arranged under the accommodating bottom plate, and the driven wheels are rear wheels and are arranged under the pedal plate; thecontrolling system is composed of a control panel arranged above the supporting arms and a control unit fixed behind the accommodating basket; a power system is a lithium storage battery and is arranged behind the accommodating basket and above the control unit; a steering system is arranged under the accommodating bottom plate and is connected with the driving device; the sensing system is composed of an obstacle avoiding device, a speed collecting device and a sensing handle. The shopping guiding robot has the advantages of simple, reasonable and compact structure, ability in assisting customers to choose and purchase goods more conveniently, efficiently and safely and wide application to all supermarkets and shopping places.

Owner:曾正扬

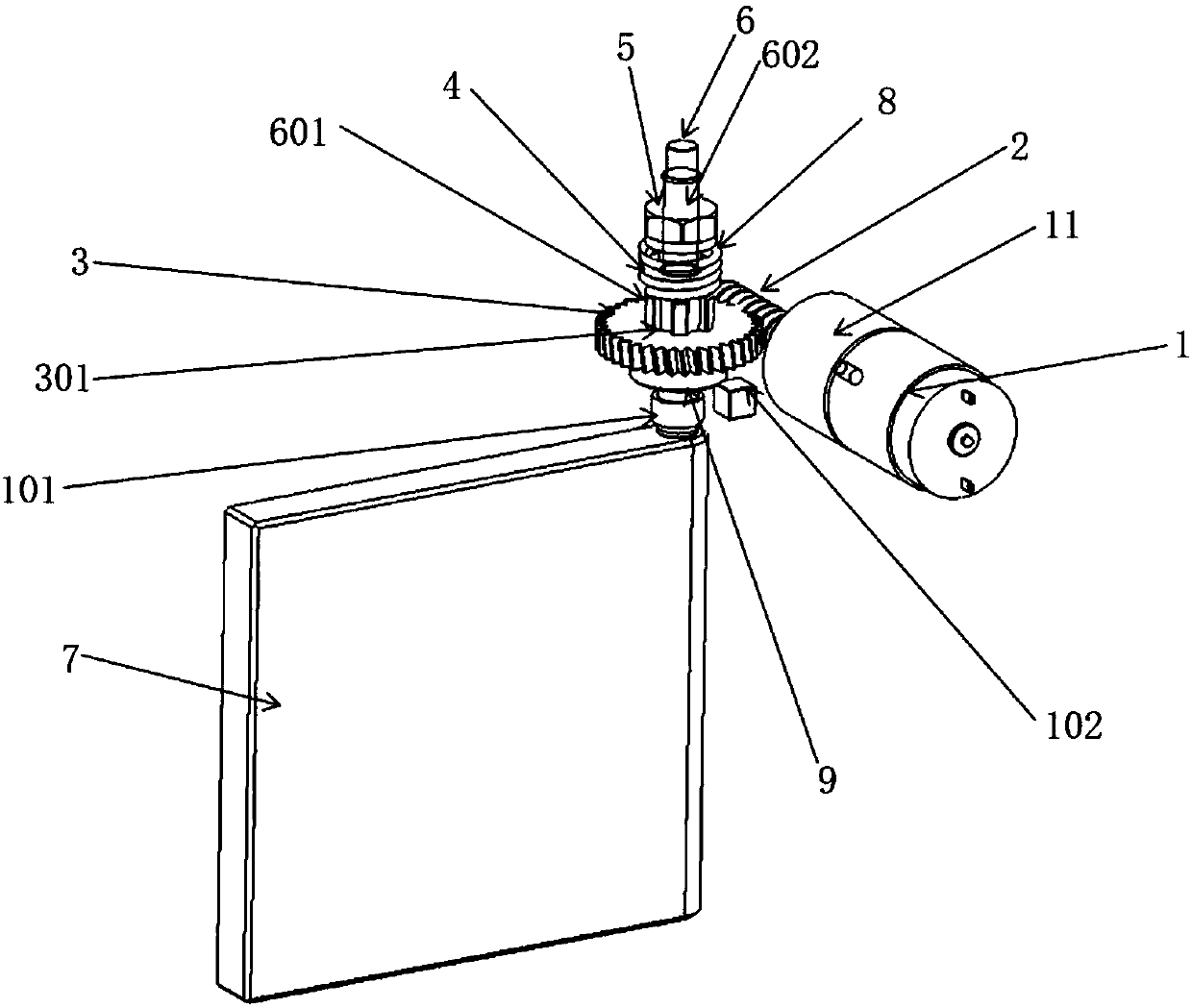

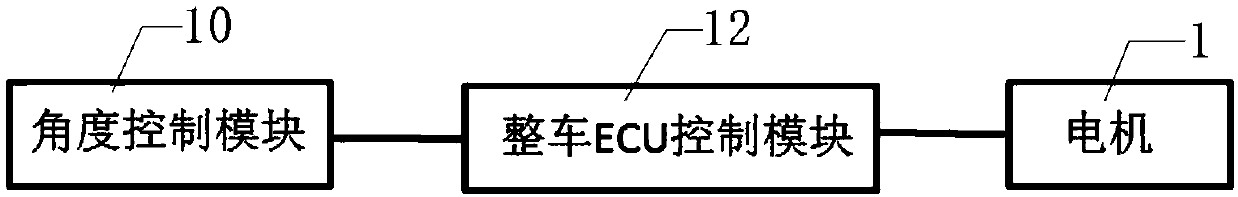

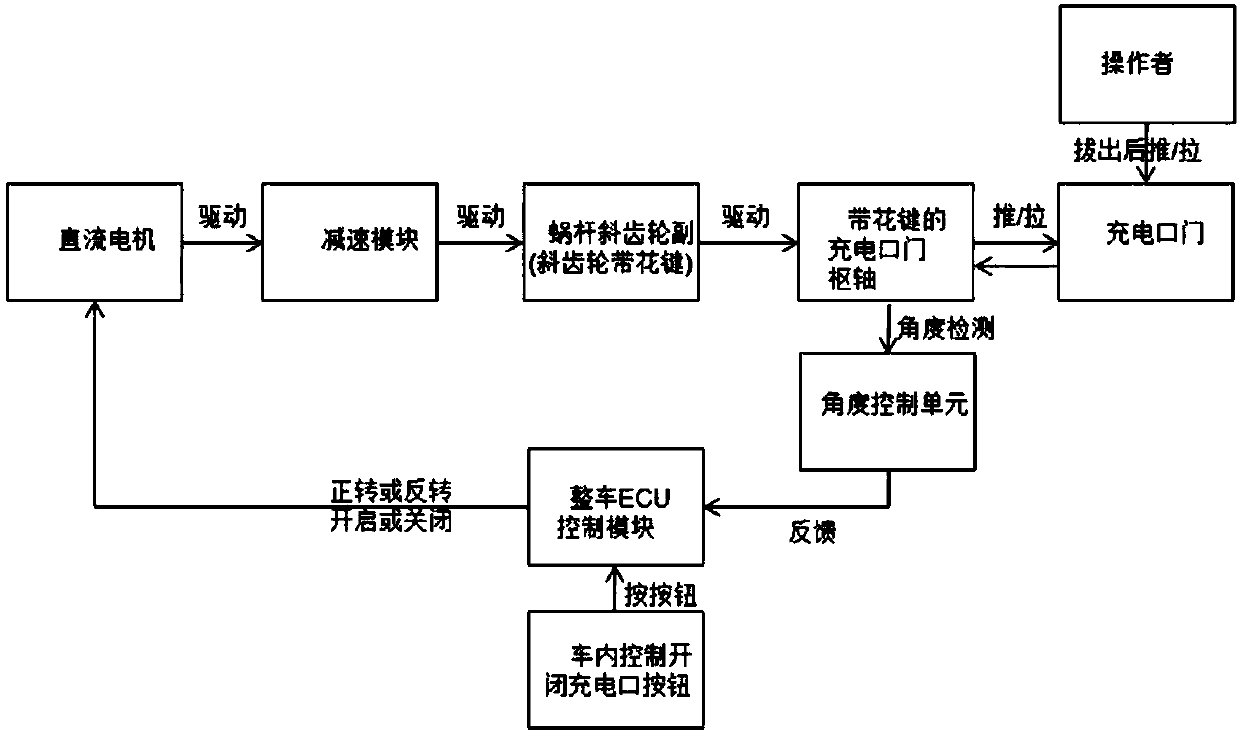

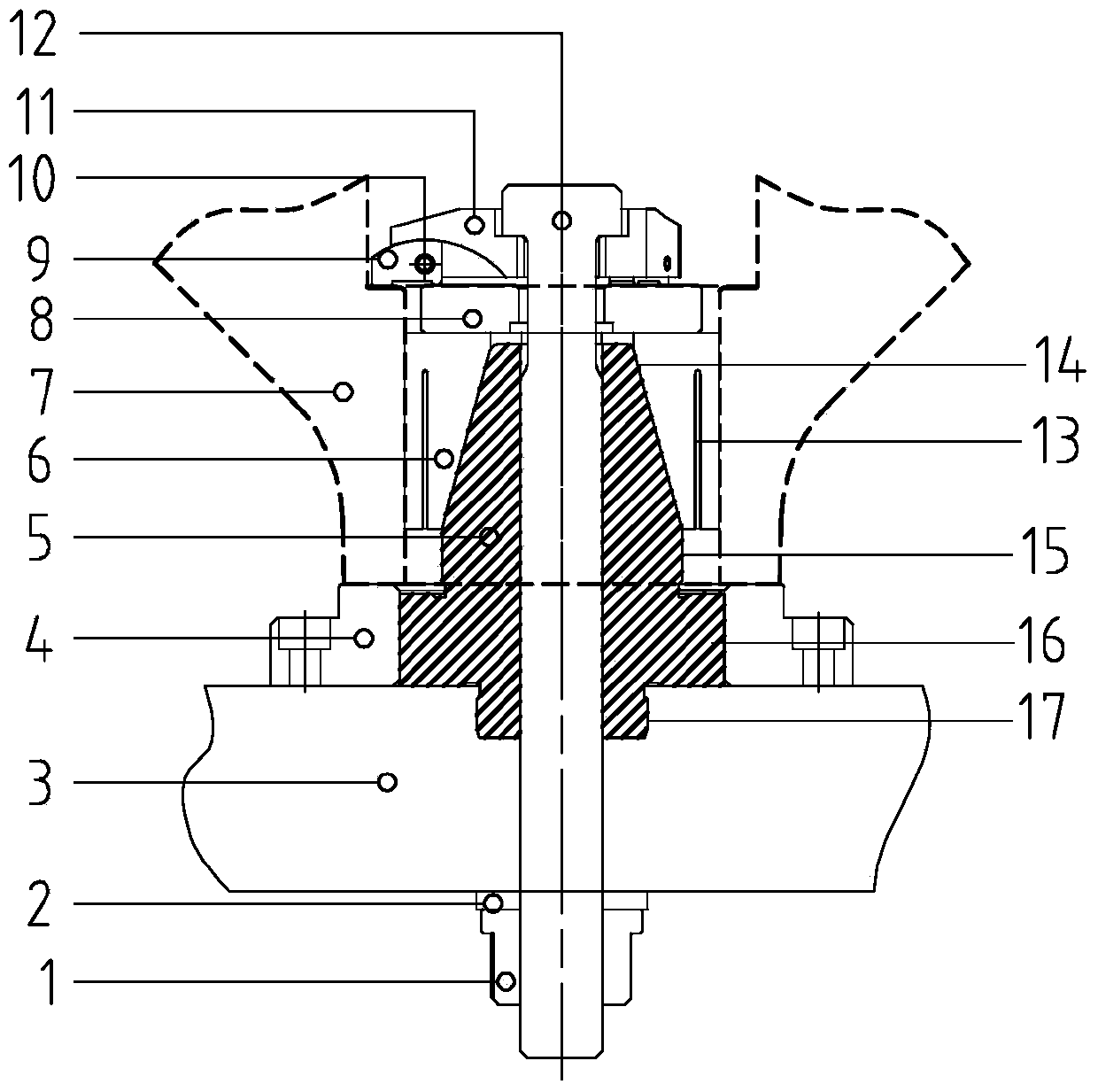

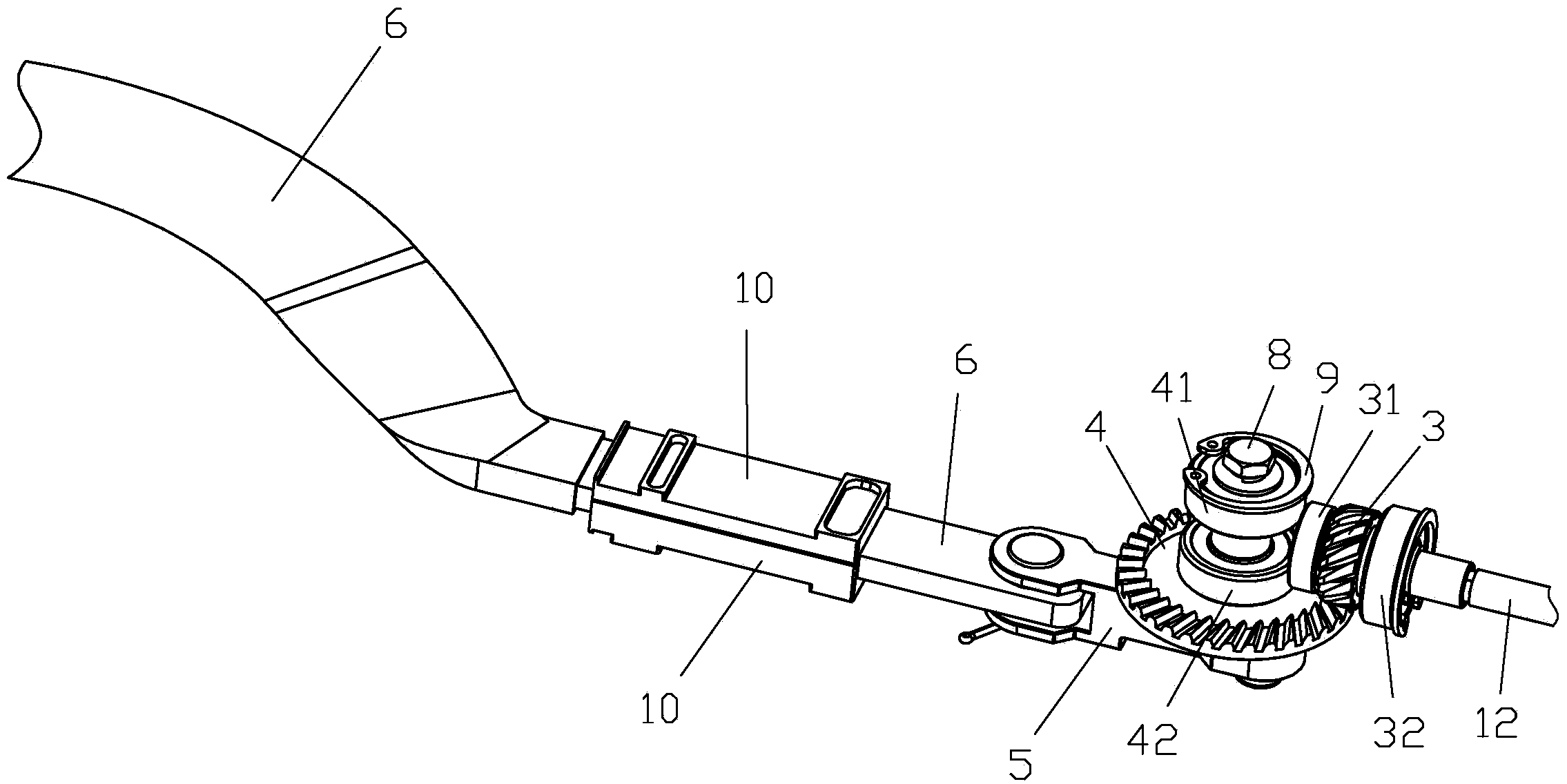

Convenient manually-operable automatic opening and closing device for electric vehicle charging port door

PendingCN107719484AImprove the sense of operationConvenient manual work processSuperstructure subunitsElectric machineGear wheel

A convenient manually-operable automatic opening and closing device for an electric vehicle charging port door comprises a motor, a worm, a bevel gear, a spring, a nut, a charging port door spindle and a charging port door. The charging port door spindle is arranged in the charging port door, a group of external splines are arranged on the upper portion of the charging port door spindle, an external thread is arranged at the top of the charging port door spindle, the bevel gear is arranged on the charging port door spindle, and a group of internal splines are arranged in the bevel gear and engaged with the external splines. A spring is arranged on the bevel gear and fixed onto the charging port door spindle by the nut, and the worm is arranged on a rotating spindle of the motor and engagedwith the bevel gear. The device is simple, reasonable and compact in structure, the direct-current motor drives an actuating mechanism to push the charging port door to open and close, the electric opening and closing mode of the vehicle charging port door replaces an existing manual opening and closing mode, the device has a manual mode, and a user can select an automatic mode or the manual modeaccording to using habits in a normal usage state.

Owner:OECHSLER PLASTIC PROD TAICANG

Expansion sleeve linkage compression mechanism

ActiveCN103737372AFast positioningEasy and fastExpansion mandrelsPositioning apparatusArchitectural engineeringSpare part

The invention relates to an expansion fixture for locating hole type spare parts, in particular to an expansion sleeve linkage compression mechanism. The expansion sleeve linkage compression mechanism comprises a fixture board; a rotary support block is fixed above the fixture board; a conical post is mounted in an inner hole of the support block; an expansion sleeve is sleeved on the upper conical surface of the conical post; the upper plane of the expansion sleeve is higher than the upper plane of the conical post; an expansion sleeve compression block is mounted at the upper head face of the conical post; the expansion sleeve compression block is provided with a compression press plate; a floating press plate is mounted between the arc surface of the bottom of the compression press plate and the surface of the outer circle of the expansion sleeve compression block; the upper surface of the floating press plate is circular arc-shaped transitional surface; the circular arc-shaped transitional surface is jointed at the arc surface of the bottom of the compression press plate; the fixture board, the conical post, the expansion sleeve compression block and the compression press plate are formed with through holes which are connected with each other. The expansion sleeve linkage compression mechanism is simple, reasonable and compact in structure, is low in production and manufacturing cost, and is capable of expanding and locating the workpieces effectively and quickly.

Owner:无锡倍安杰机械科技有限公司

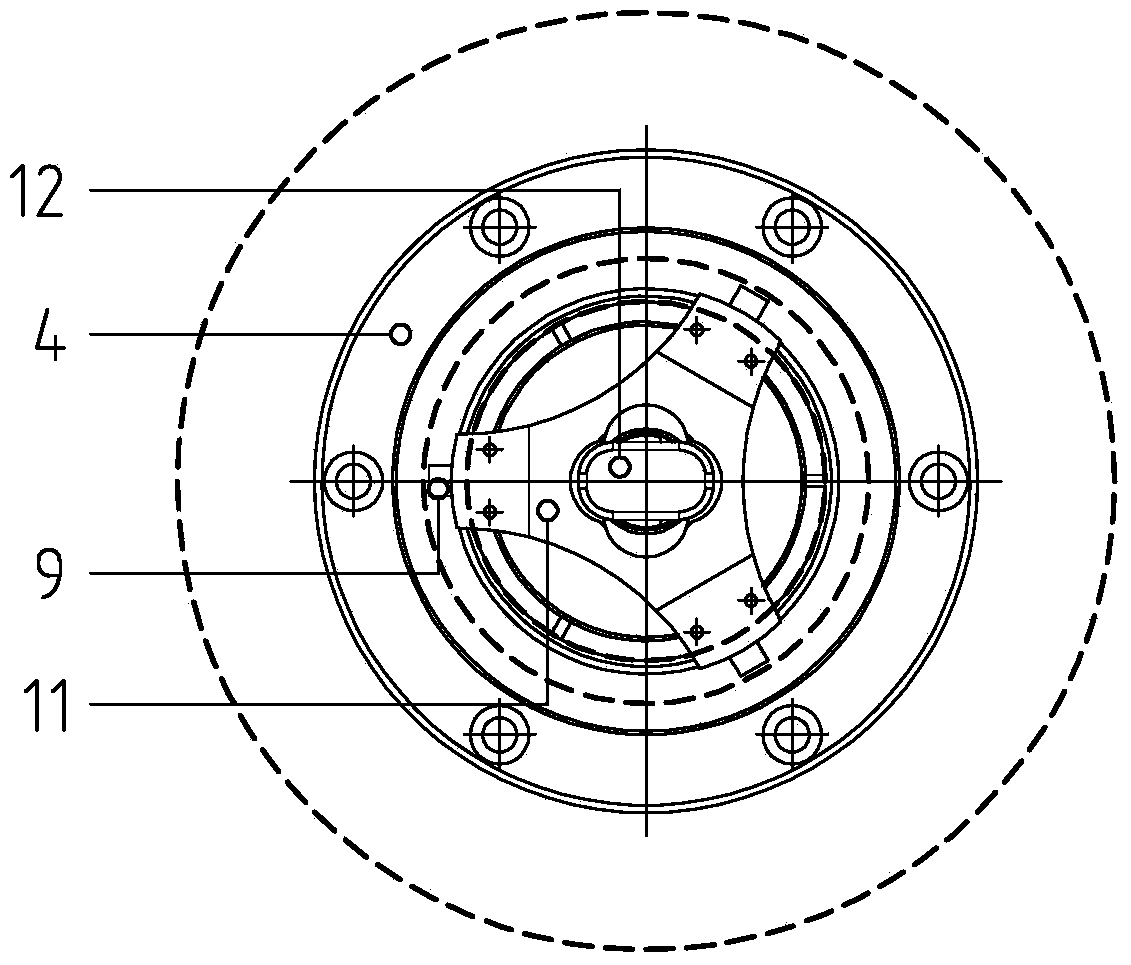

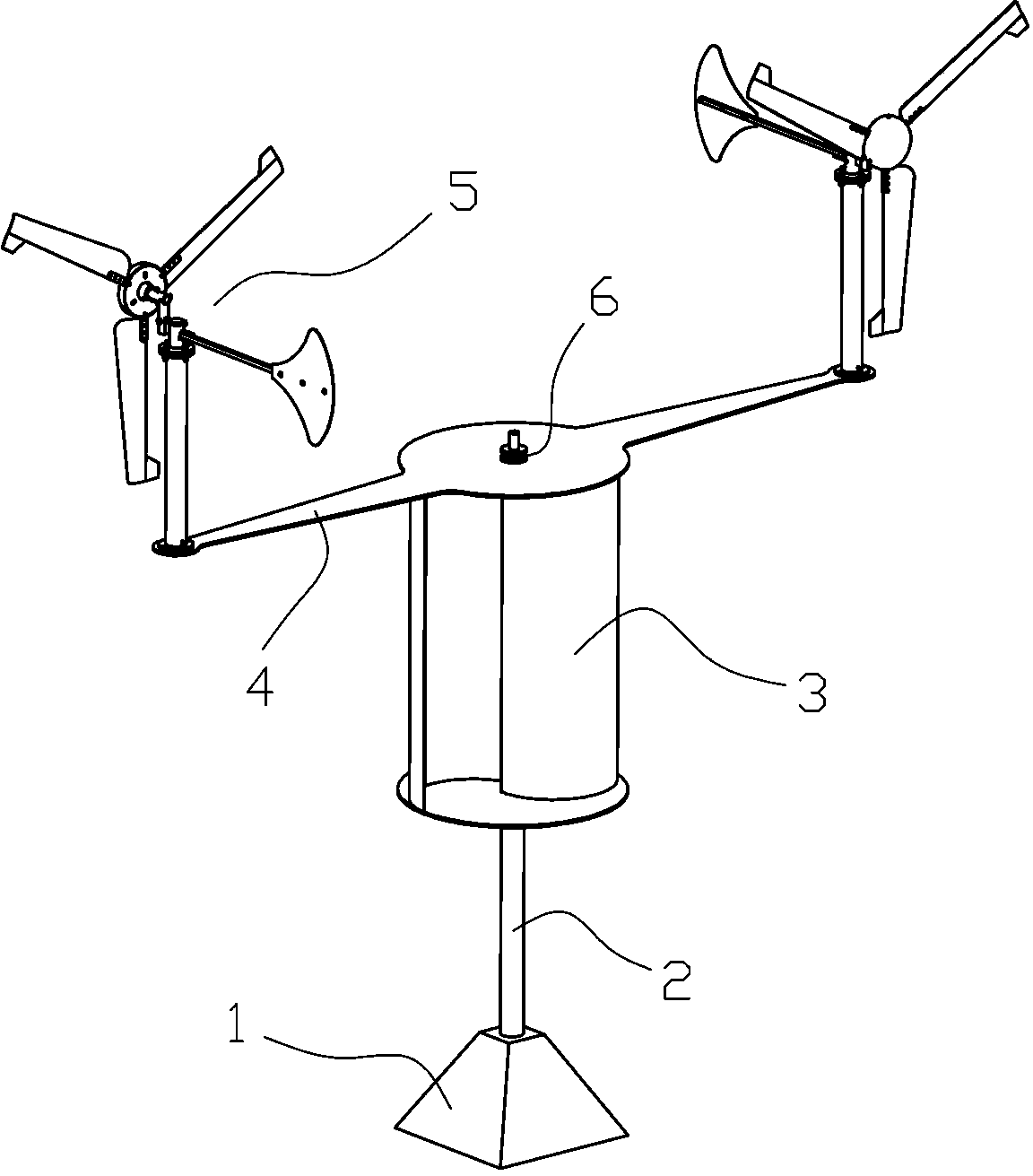

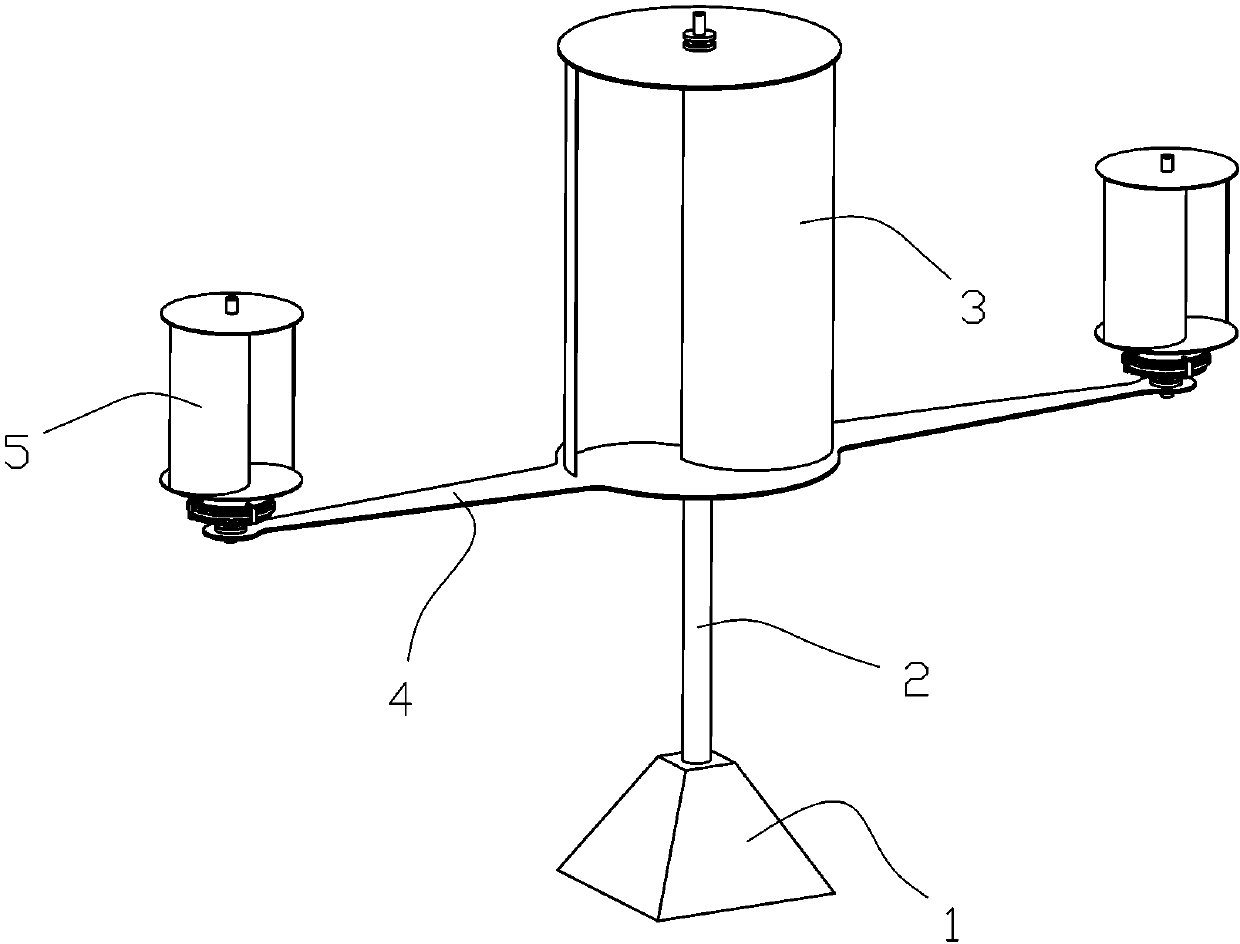

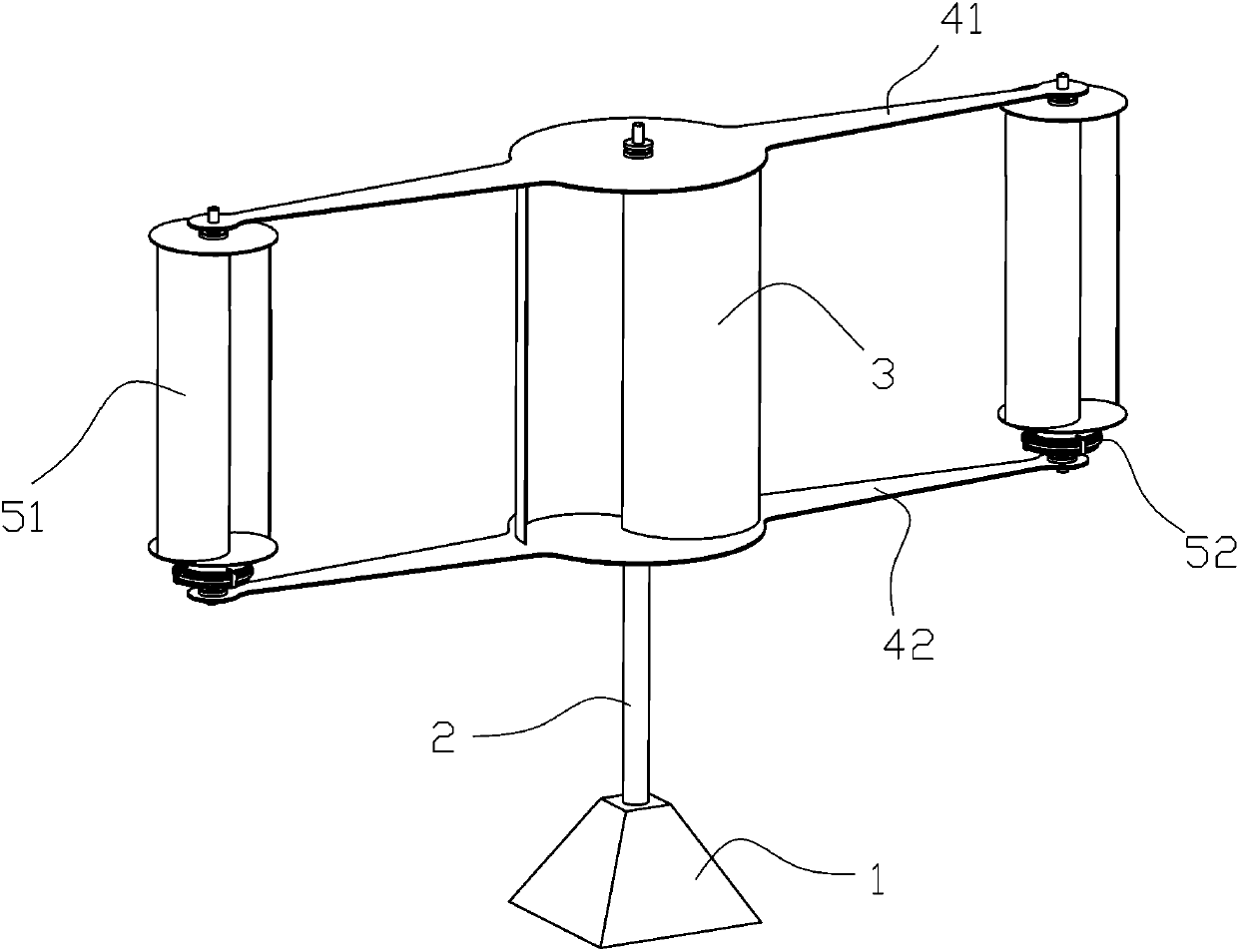

Planetary accelerating wind turbine vertical shaft wind power generator

InactiveCN103726991AIncrease line speedIncrease power generationRenewable energy generationMachines/enginesGear wheelEarth surface

The invention discloses a planetary accelerating wind turbine vertical shaft wind power generator which comprises a base. A vertical shaft is fixedly connected on the base, a vertical shaft wind turbine is pivoted on the vertical shaft, a magnetic levitation device is mounted on an axial end portion of the vertical shaft wind turbine, at least one axial end portion of the vertical shaft wind turbine is fixedly connected with horizontal connecting rods, more than two horizontal connecting rods are arranged for each axial end portion of the vertical shaft wind turbine, the horizontal connecting rods are uniformly arranged peripherally on the vertical shaft wind turbine, and a wind power generator body is mounted at the tail end of each horizontal connecting rod. A gearbox-type speed increaser structure in conventional technology is abandoned, so that the planetary accelerating wind turbine vertical shaft wind power generator is obvious in accelerating effect, simple, reasonable and compact in structure, convenient to mount and low in implementation cost; even if the wind power generator is arranged at a place where wind speed is low or there is no high wind on the earth surface, as long as the vertical shaft wind turbine rotates, rotating speed of the wind power generator bodies at the tail ends of the horizontal connecting rods can easily reach design requirements, so that the wind power generator is enabled to realize normal power generation within a wide wind speed span.

Owner:WINDPOWER ENERGY CO LTD SHUNDE

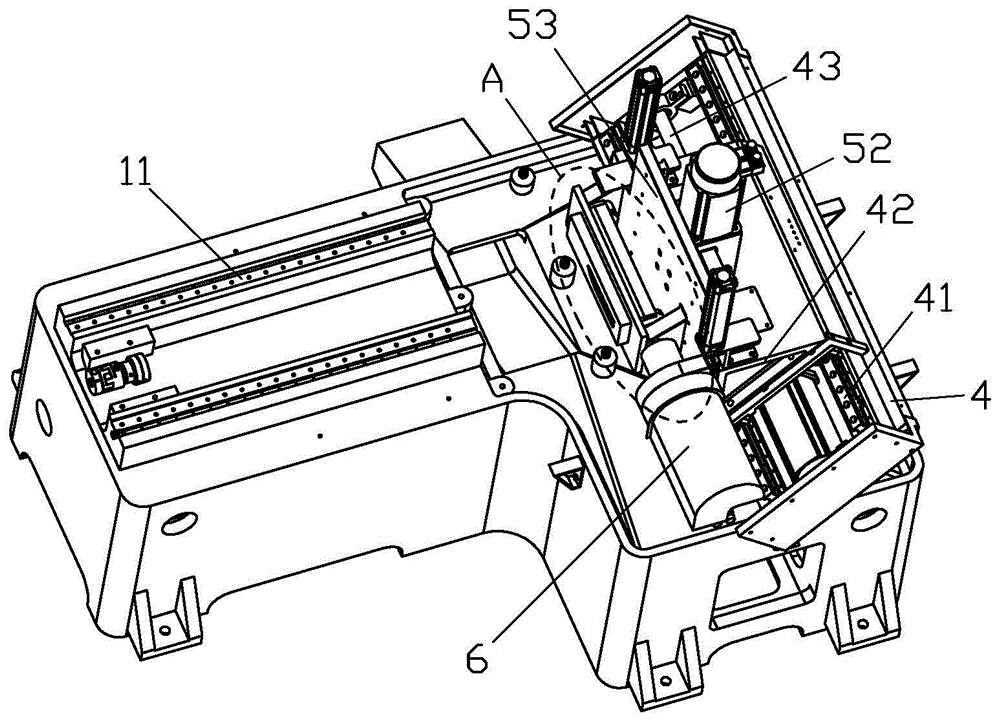

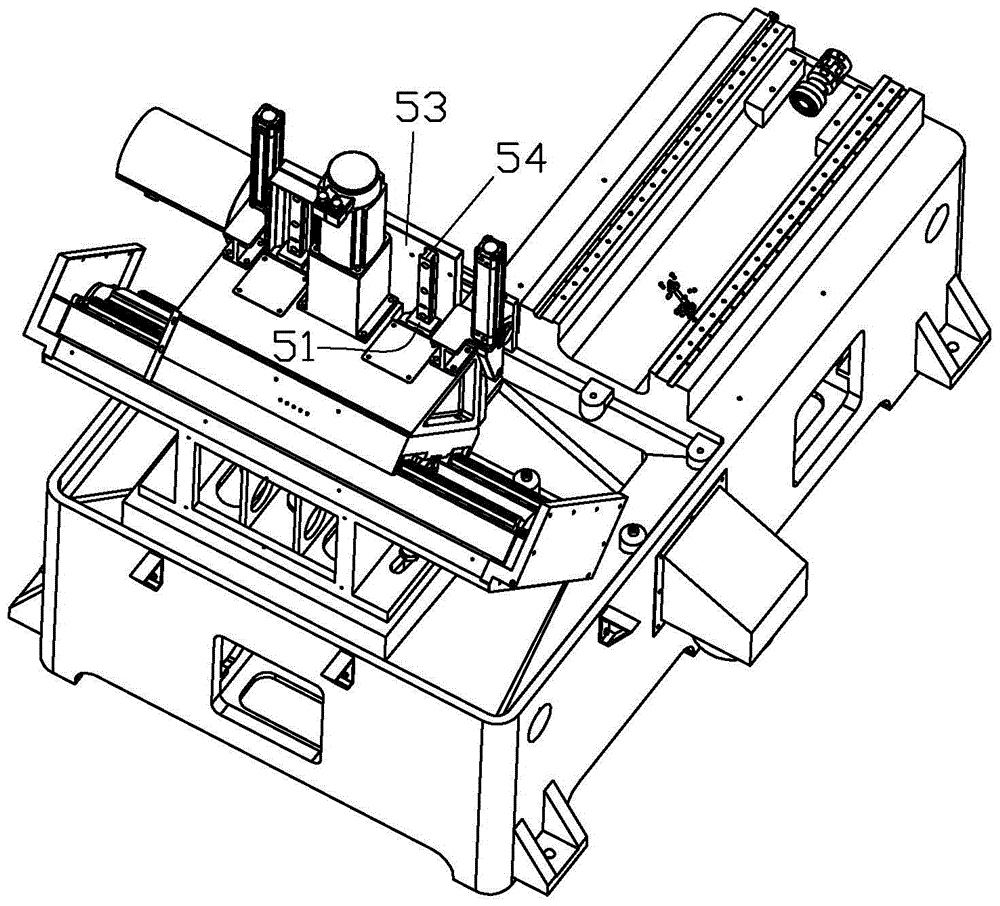

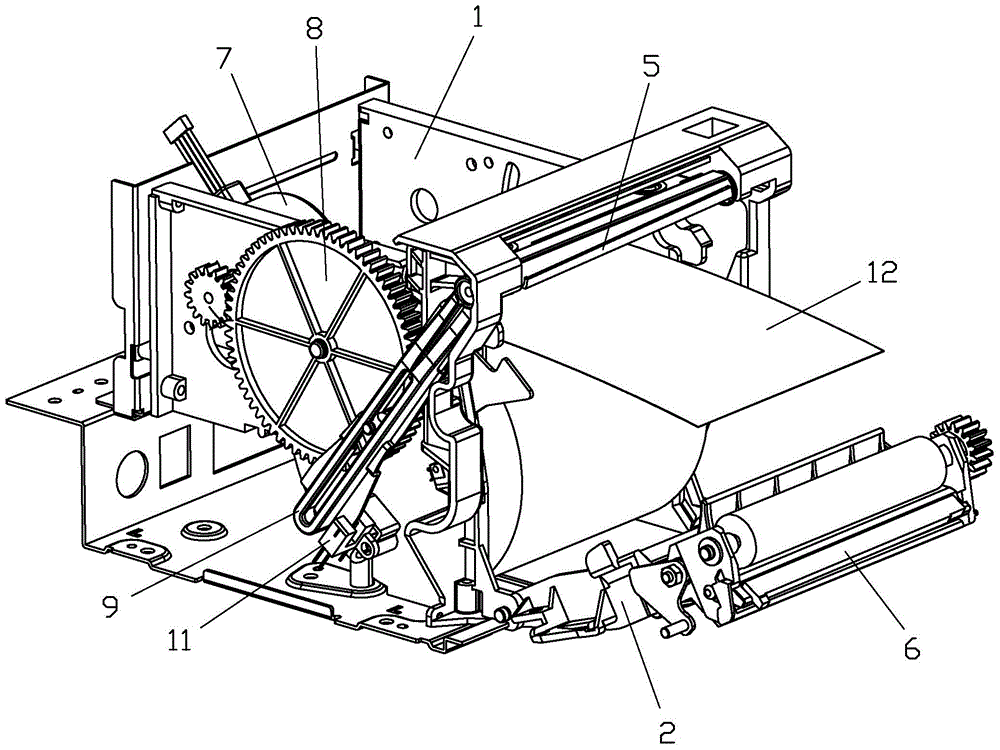

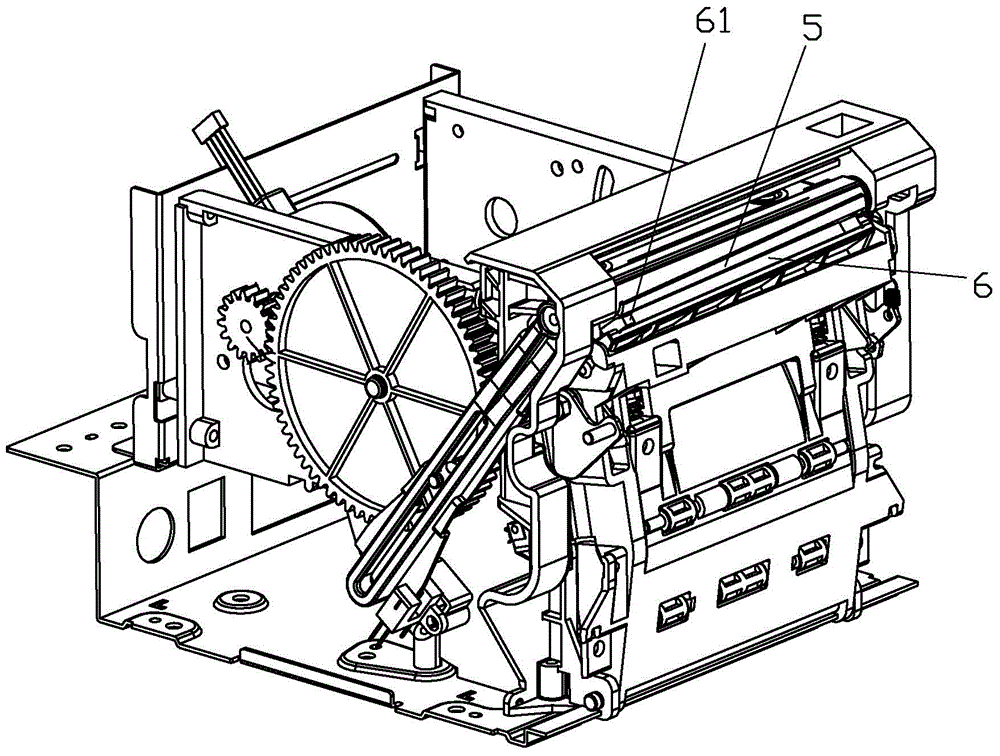

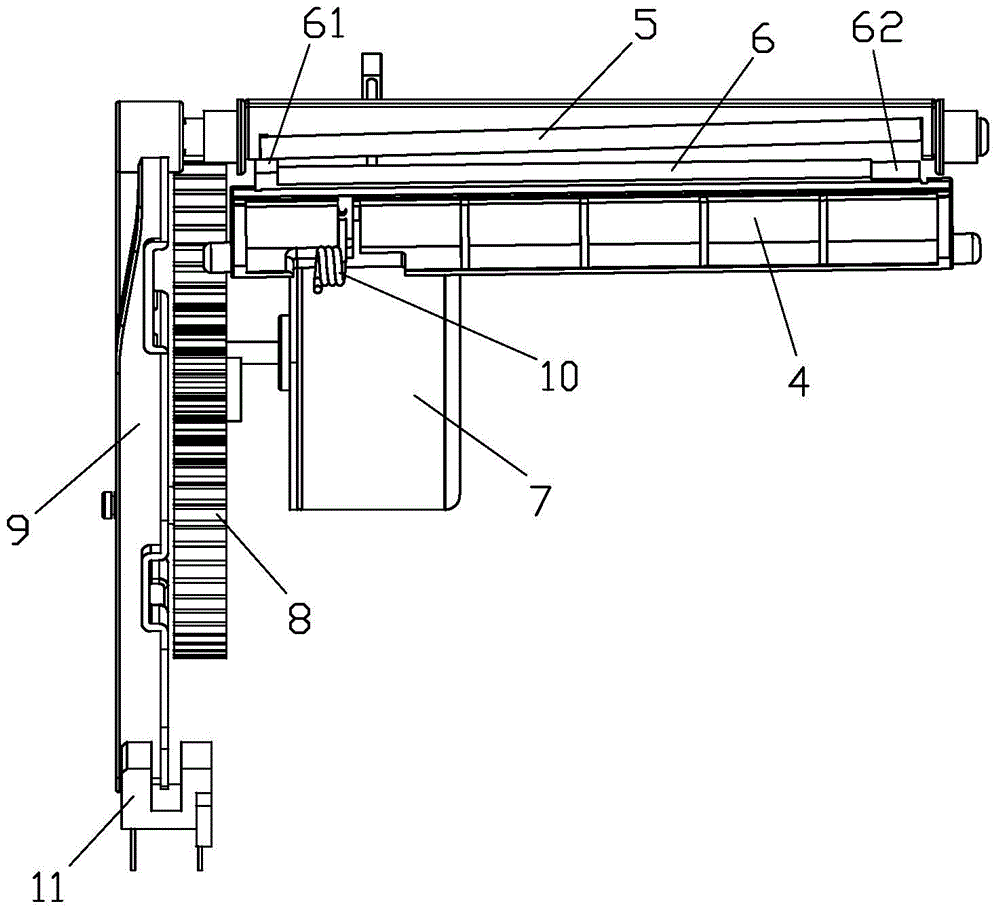

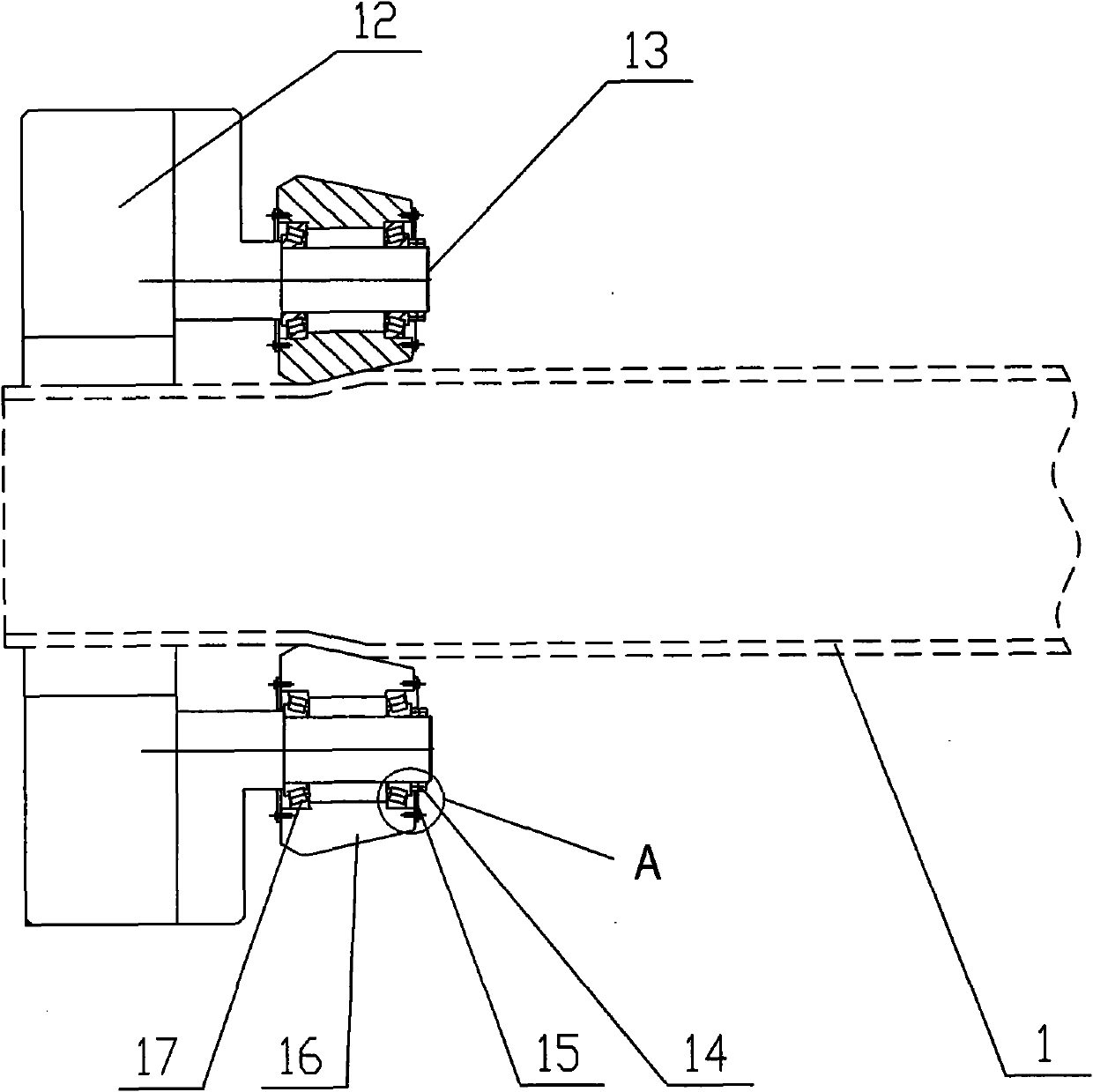

Printer with built-in hob paper cutting device

InactiveCN104859317AExtended service lifeReduce frictionOther printing apparatusGear driveGear wheel

The invention discloses a printer with a built-in hob paper cutting device. The printer includes a machine core assembly and a paper feeding roller fixing frame assembly which are pivoted with a moving blade fixing frame and a fixed blade fixing frame respectively; the moving blade fixing frame and the fixed blade fixing frame are provided with a moving blade and a fixed blade respectively; the machine core assembly is provided with a stepping motor and a cutter gear driven by the stepping motor; the cutter gear is connected with a cutter driving arm which is driven by the cutter gear so as to swing in a reciprocating manner; one end of the cutter driving arm is fixedly connected with the moving blade fixing frame so as to drive the moving blade to move in a reciprocating manner; the fixed blade is provided with a guide arm used for guiding the moving blade; the paper feeding roller fixing frame assembly is provided with a torsional spring used for driving the fixed blade to rotate towards the moving blade; the two cutting edges of the moving blade and the fixed blade are arranged obliquely in a manner that the closer the two cutting edges are to the guide arm, the smaller the interval between the cutting edges is; and the cutting edge of the moving blade is a plane curve. The printer of the invention is simple and compact in structure. The appearance design and miniaturization design of the printer can be benefitted, and the service life of the paper cutting device is long.

Owner:KONG YUE ELECTRONICS & INFORMATION IND XIN HUI

Roller spinning device for steel tube pointing machine

InactiveCN101947590ASimple, reasonable and compact structureEasy to manufactureShaping toolsSteel tubeEngineering

The invention discloses a roller spinning device for a steel tube pointing machine, which relates to a steel tube pointing machine, particularly a roller spinning device for a pointing machine. The roller spinning device comprises a three-jaw self-centering chuck, wherein one side of the three-jaw self-centering chuck is connected with three clamping jaws, and each clamping jaw is respectively connected with a roller. The invention has the advantages of simple, reasonable and compact structure, easy production and manufacturing and high precision. The invention enhances the precision and efficiency of cold-drawn steel tube pointing, can be widely used for pointing of medium / large diameter cold-drawn seamless steel tubes, is especially suitable for large-tonnage hydraulic drawbenches to produce seamless steel tubes, and has high popularization value.

Owner:江苏诚德钢管股份有限公司

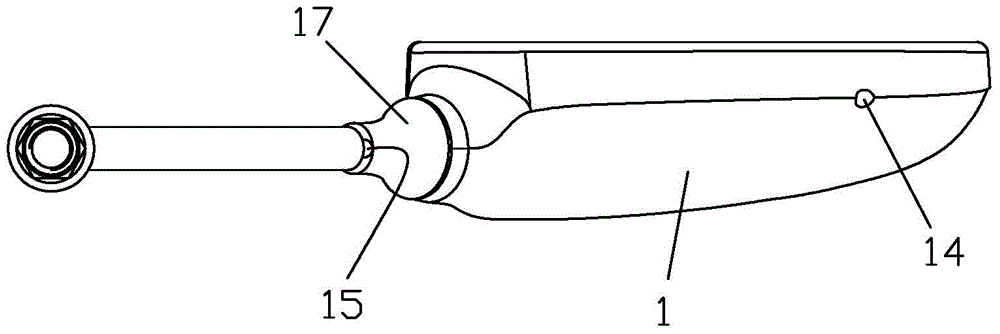

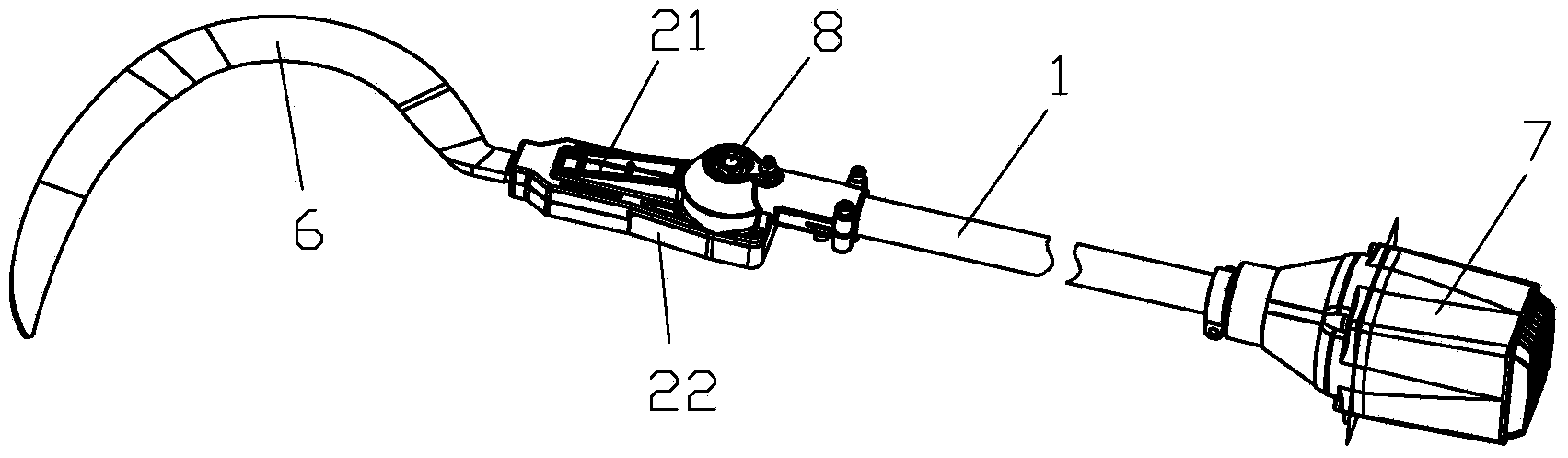

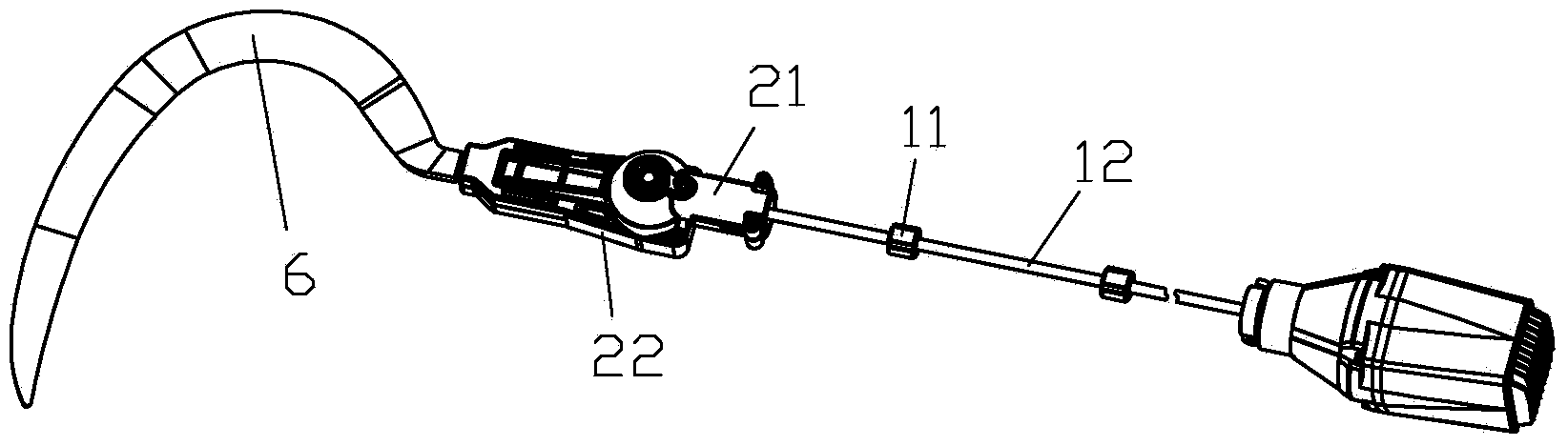

Electric palm picking machine

The invention discloses an electric palm picking machine which comprises a high branch tube and a main shell arranged at the front end of the high branch tube. The main shell is formed by an upper shell and a lower shell, a transverse tube part enabling the high branch tube to be mounted is arranged at the rear end of the upper shell, a driving bevel gear and a driven bevel gear are arranged on the upper shell, the driving bevel gear and the driven bevel gear are meshed with each other, a connecting rod is in eccentric connection with the bottom end of the driven bevel gear, a sickle is hinged to the front end of the connecting rod, the driving bevel gear is driven by a motor, a notch avoiding the driven bevel gear is formed in the transverse tube part, a front end bearing of a rotating shaft of the driving bevel gear is arranged in a hole site which is in front of the notch and corresponds to the transverse tube part, and a rear end bearing of the rotating shaft of the driving gear is located in the transverse tube part. The structure that bearings are arranged on one side of the driving bevel gear in the traditional technology is avoided, the fact that a cantilever end is formed by the driving bevel gear is avoided, the stress imbalance of unilateral stress gears and the bearings is prevented from being formed, and a whole rotating mechanism is made to run more stably.

Owner:JIANGMEN CHAOYANG PRECISION MFG

Simple durable hygienic faucet

InactiveCN104154320AGuaranteed service lifePrevent rustPlug valvesValve housingsEngineeringControl valves

The invention discloses a simple durable hygienic faucet comprising a main shell. A faucet body core is mounted in the main shell and connected with a cold- and hot-water control valve spool driven by a handle. The main shell is provided with a water outlet pipe, the faucet body core is a plastic core, a metal shell wraps the outer surface of the faucet body core, the faucet body core is provided with a water inlet and a water outlet end, the water outlet end of the faucet body core is connected with a plastic water outlet pipe disposed in the water outlet pipe and extending to a water outlet of the water outlet pipe, and a steel wire gauze is knitted on the surface of the plastic water outlet pipe. The faucet body core is not easily damaged by environment temperature, so that the faucet is long in service life, simple, durable and hygienic.

Owner:何祺晃

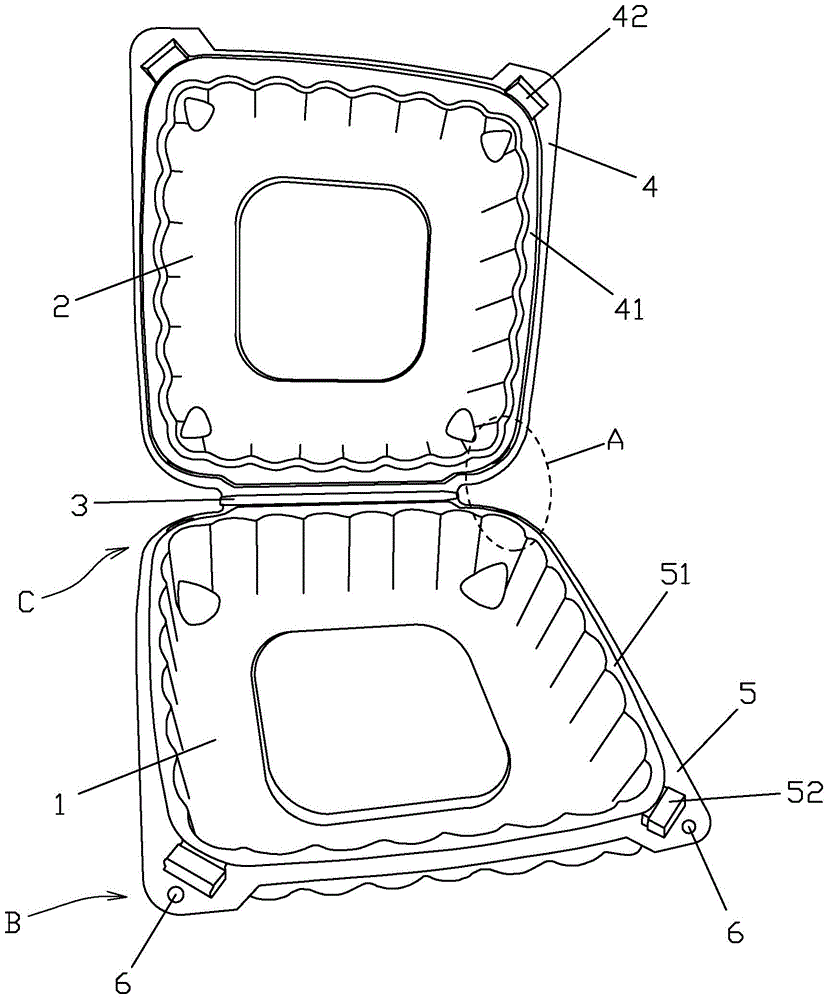

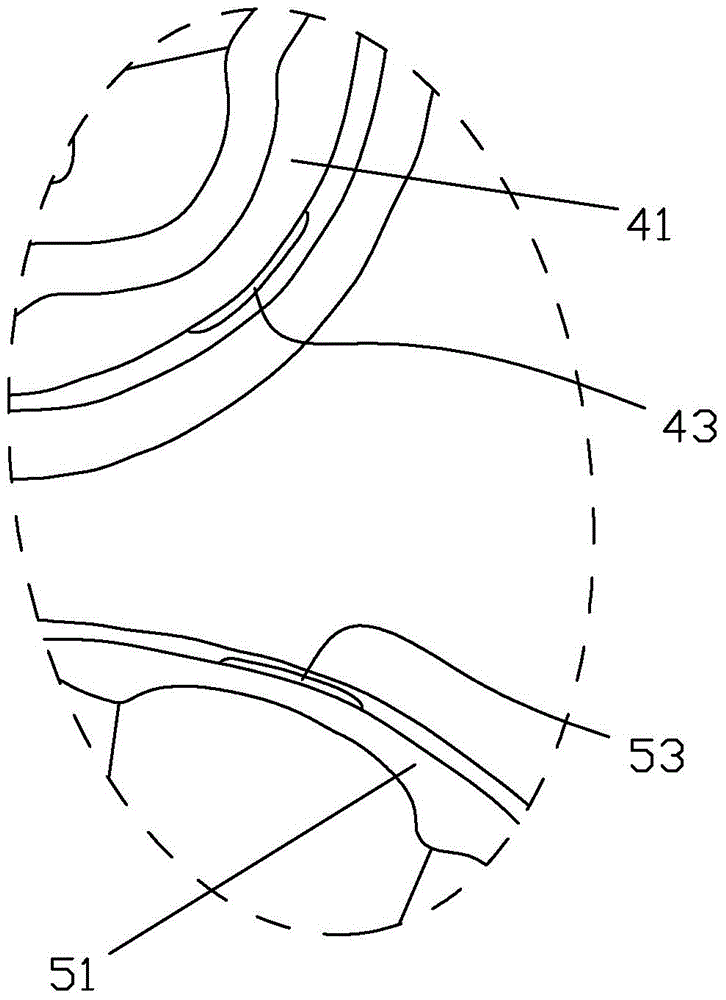

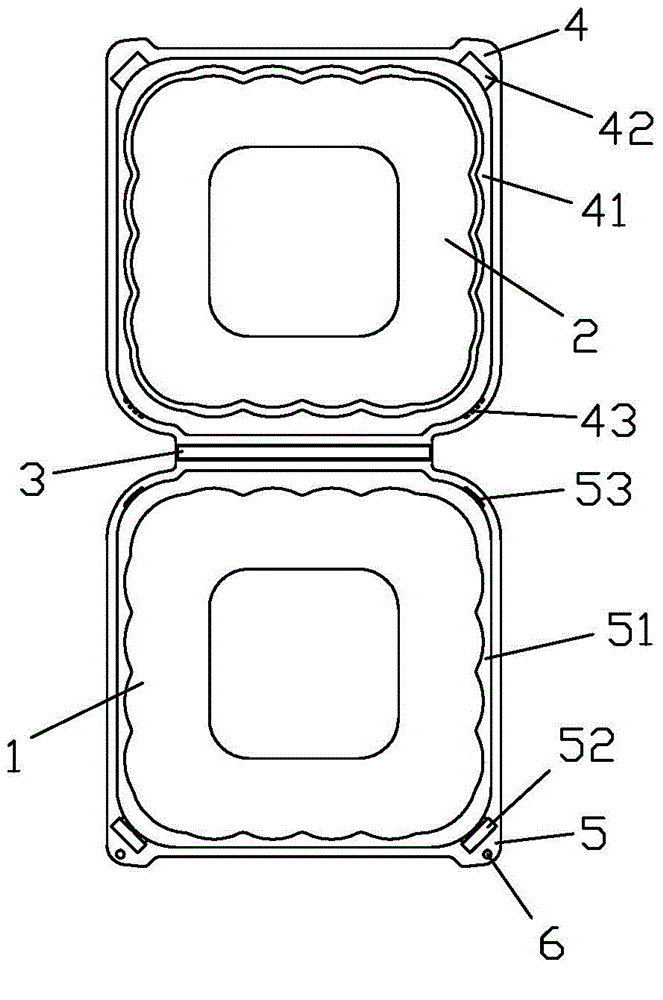

Fast food box convenient to open

InactiveCN104082936ASimple, reasonable and compact structureEasy to implementOther accessoriesFlangeEngineering

The invention discloses a fast food box convenient to open. The fast food box comprises a box body and a box cover which are made of a plastic or foam material, wherein the box body is connected with the box cover through a flexible connector; the box cover can turn over relative to the box body through the flexible connector so as to cover or open the box body; the box body and the box cover are provided with a clamping groove and a clamping bump corresponding to each other; when the box body is covered by the box cover, the clamping groove is matched with the clamping bump so as to tightly couple the box body with the box cover; an upper thin flange and a lower thin flange are formed on the peripheral sides of the box cover and the box body, respectively; bumps are arranged on the lower surface of the upper thin flange and / or the upper surface of the lower thin flange; by virtue of the bumps, the upper and lower thin flanges is spaced at an interval and are not in contact with each other when the box body is covered by the box cover. The fast food box disclosed by the invention enables a diner to conveniently open the box cover with little force, and is simple and compact in structure and low in implementation cost.

Owner:余锦安

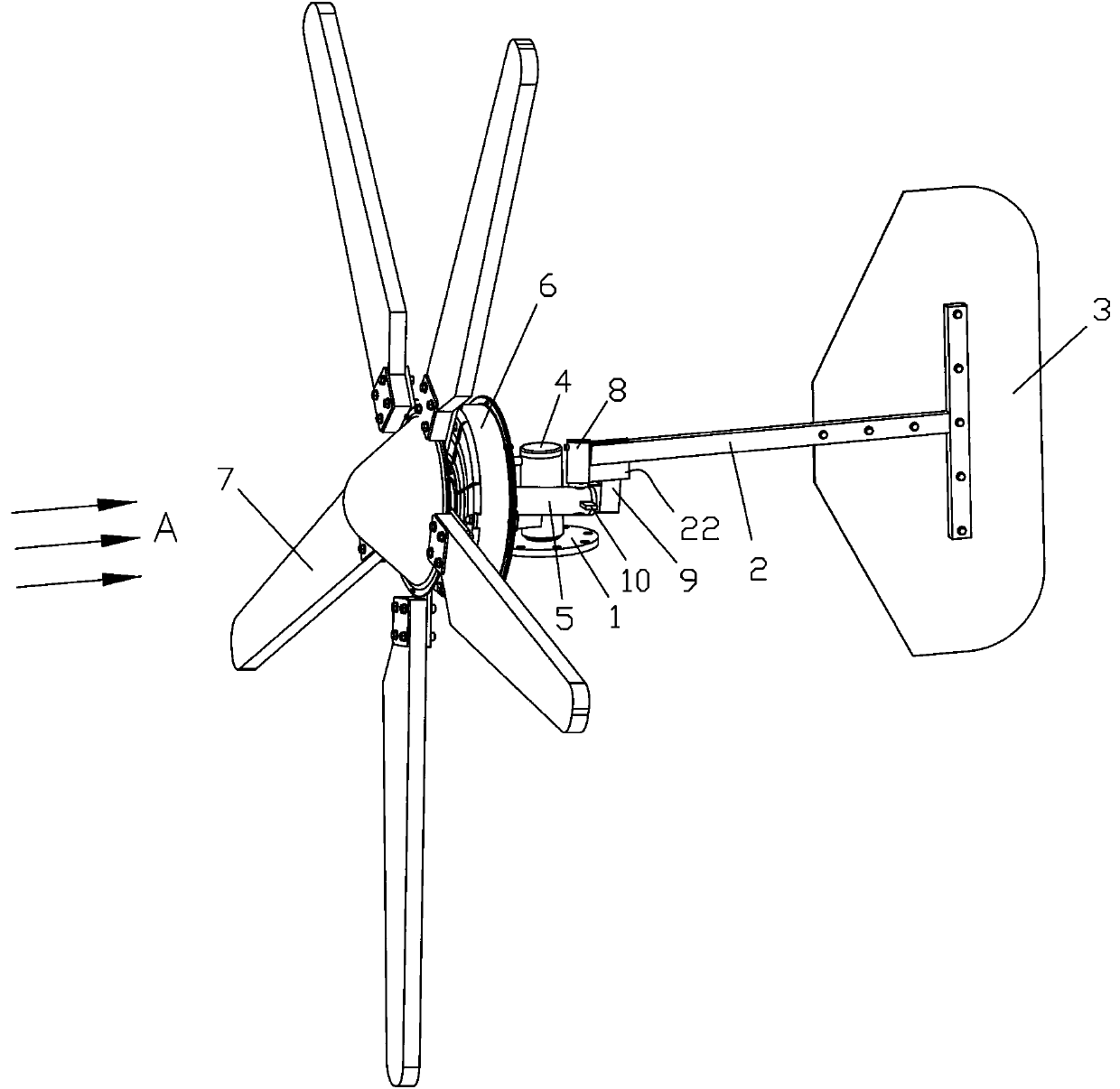

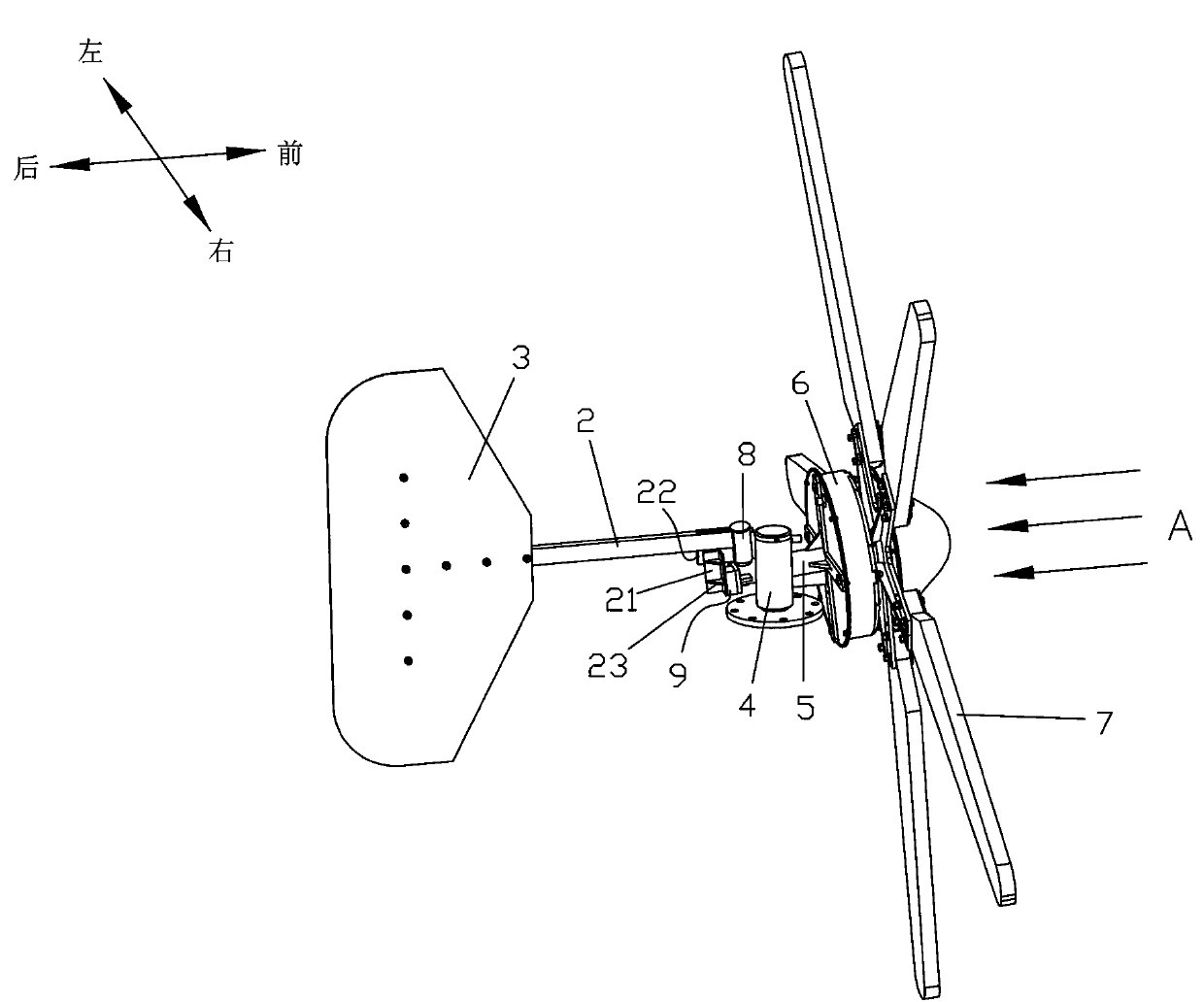

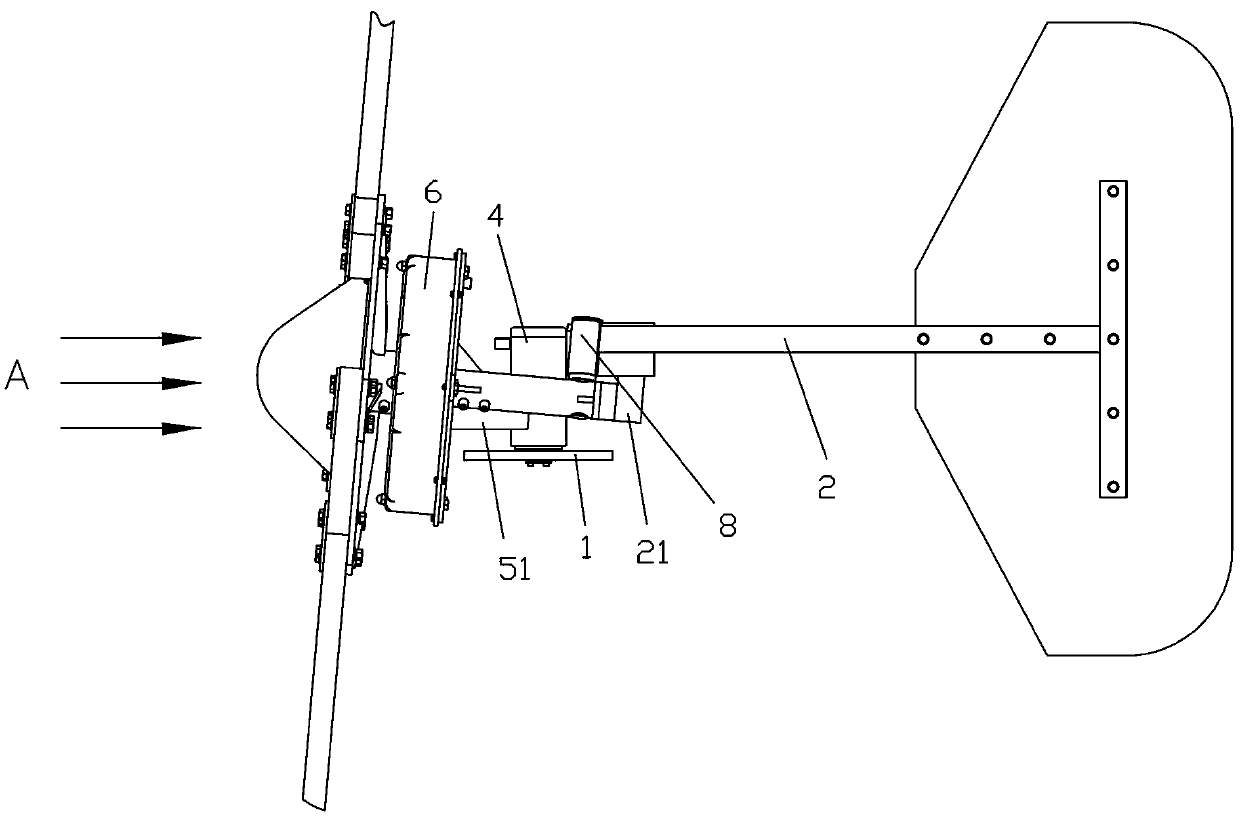

Wind driven generator yawing device capable of effectively withstanding strong wind attack

InactiveCN103726994AReduce the windward areaReduce the stress areaFinal product manufactureWind energy generationWind drivenAir velocity

The invention discloses a wind driven generator yawing device capable of effectively withstanding strong wind attack. A connection arm is eccentrically mounted relative to a yawing rotary seat, a tail vane rotary sleeve is rotatably connected onto the connection arm and positioned behind the yawing rotary seat, and the tail vane rotary sleeve is in a tilted arrangement in a way that the higher the tail vane rotary sleeve is, the closer the tail vane rotary sleeve approaches to the side of the yawing rotary seat. A tail vane rod is fixed onto the tail vane rotary sleeve, a first limiting block and a second limiting block are positioned on two sides of the tail vane rod respectively and arranged on the connection rod, and a limiting plate is arranged on the tail vane rod. A tail vane plate is perpendicular to a vane rotation surface when the first limiting block and the limiting plate are in abutted connection. The tail vane plate is parallel to the vane rotation surface when the connection arm rotates relative to the tail vane rod to drive the second limiting block to be in abutted connection with the limiting plate. The wind driven generator yawing device has the advantages of simplicity, reasonability and compactness in structure, convenience in installation, low implementation cost, capability of automatically adjusting vane rotation speed according to wind speed, avoidance of galloping and the like.

Owner:WINDPOWER ENERGY CO LTD SHUNDE

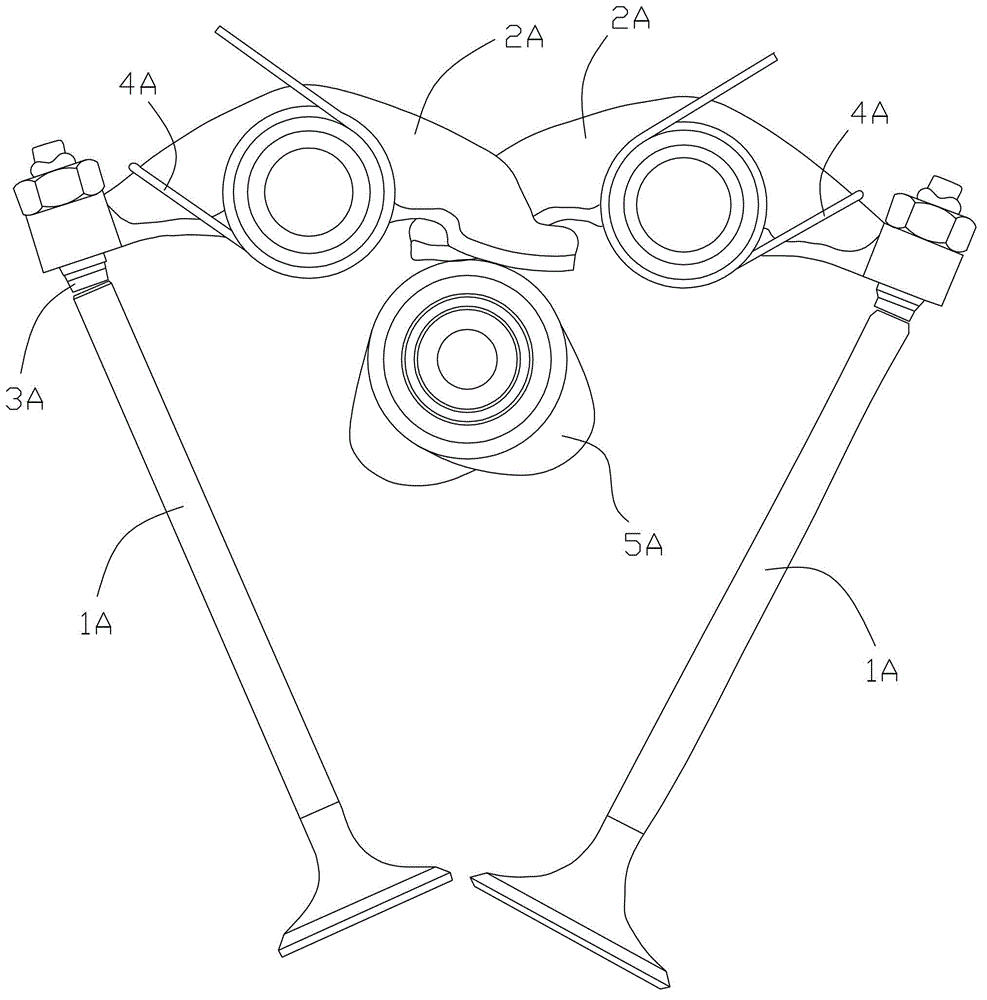

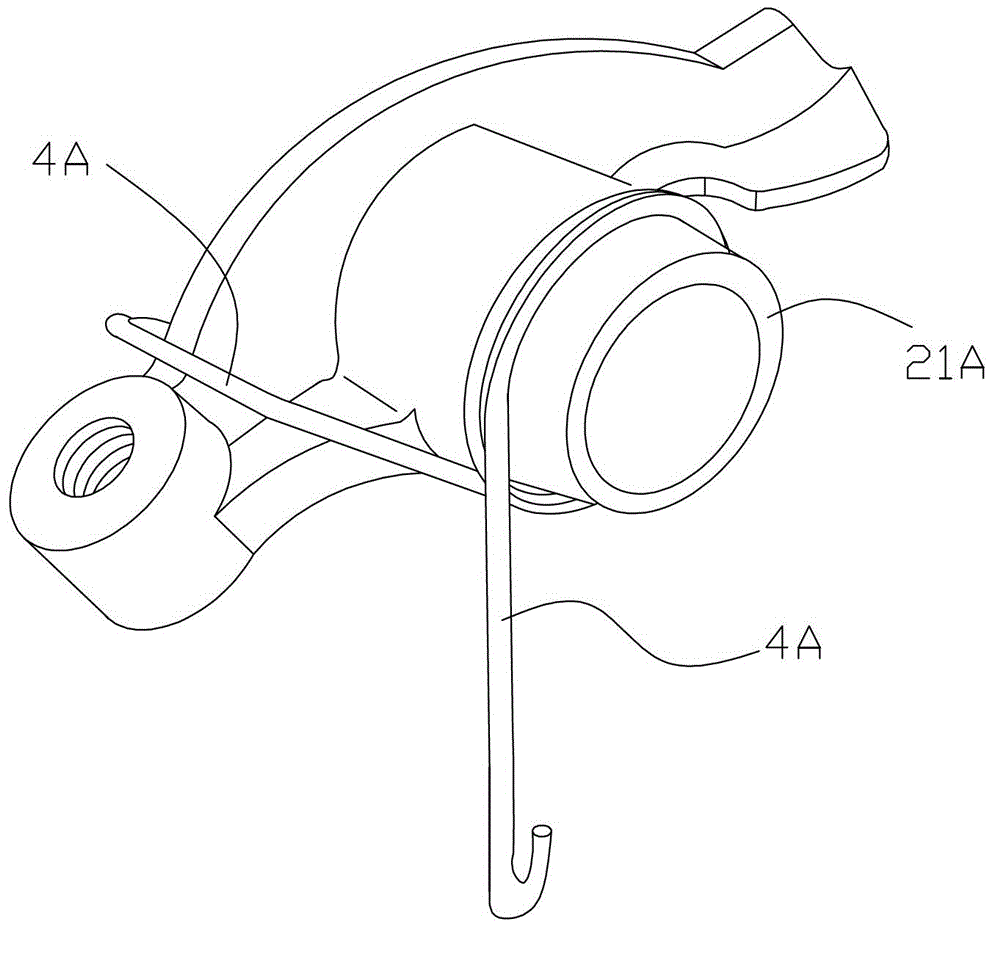

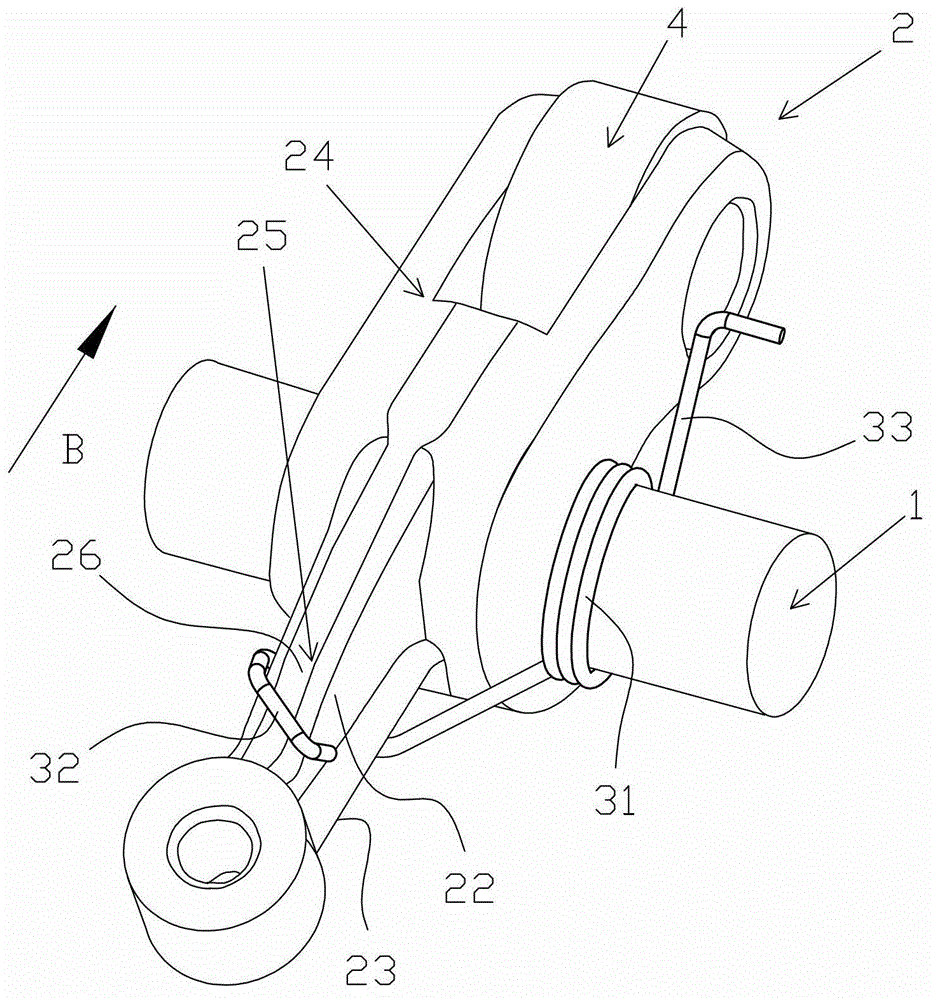

Low-noise valve rocker assembly of motorcycle engine

ActiveCN103061838AGuaranteed uptimeFirmness makes the rocker arm run more smoothlyValve arrangementsMachines/enginesLow noiseCylinder head

The invention discloses a low-noise valve rocker assembly of a motorcycle engine. The low-noise valve rocker assembly comprises a rocker which is assembled on a rockshaft of a cylinder head and a torsion spring which applies preload to the rocker, wherein the rocker includes a left side surface and a right side surface and the torsion spring includes a spiral section. A spring hook at one end of the torsion spring which is a rocking end is connected with the rocker in a lap joint mode, and a spring hook at the other end of the torsion spring which is a fixed end is connected with the cylinder head in a lap joint mode. The spiral section of the torsion spring is positioned on the left side surface or the right side surface of the rocker, and the rocking end of the torsion spring crosses the left side surface or the right side surface of the rocker to be connected with the rocker in a lap joint mode. The rocking end and the spiral section of the torsion spring are respectively positioned on the left side surface and the right side surface of the rocker, so that axial component force which is generated by the moving torsion spring to enable the rocker to move axially is avoided, abnormal sound produced due to the fact that the axially-moving rocker knocks the cylinder head is eliminated, loosening and position changing of the torsion spring and the rocker due to rocker forging die difference, torsion spring manufacturing error and the like cannot occur, and the firmly connection of the torsion spring and the rocker enables the rocker to run more steadily and quietly.

Owner:JIANGMEN DACHANGJIANG GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com