Tool sharpener with multi-angle adjustment

A knife sharpener, multi-angle technology, applied in the direction of grinding drive device, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of increasing tool cost, increasing production cost, occupying workshop space, etc. Low, easy to install, good quality of sharpening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below with reference to the drawings and embodiments.

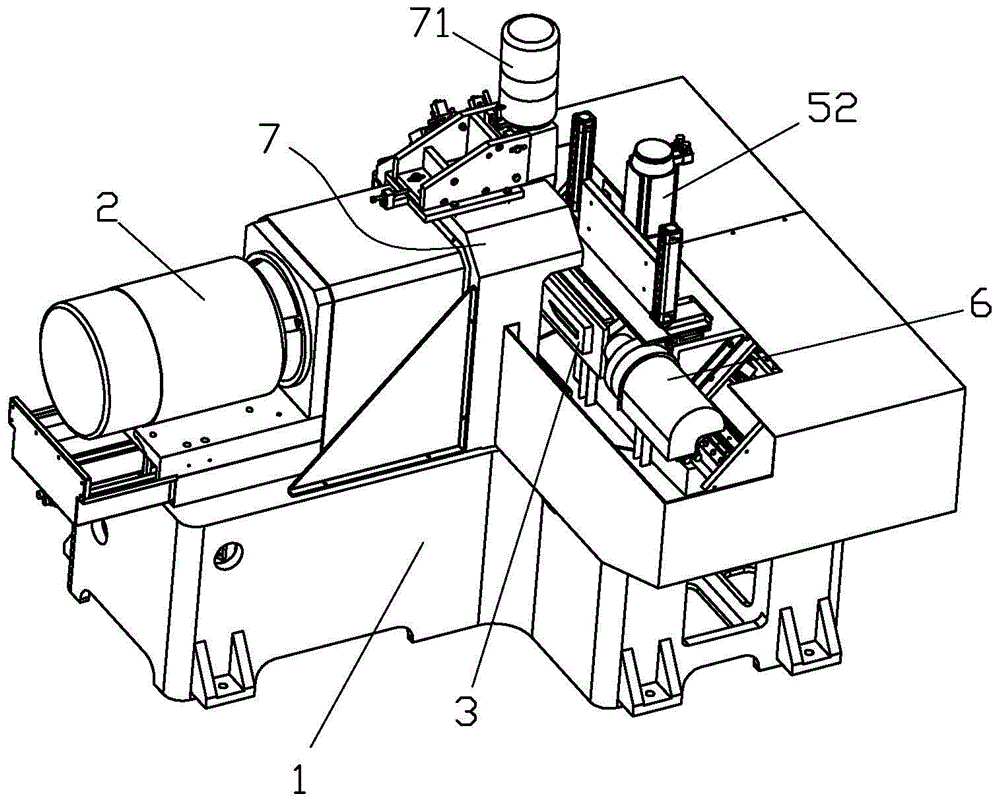

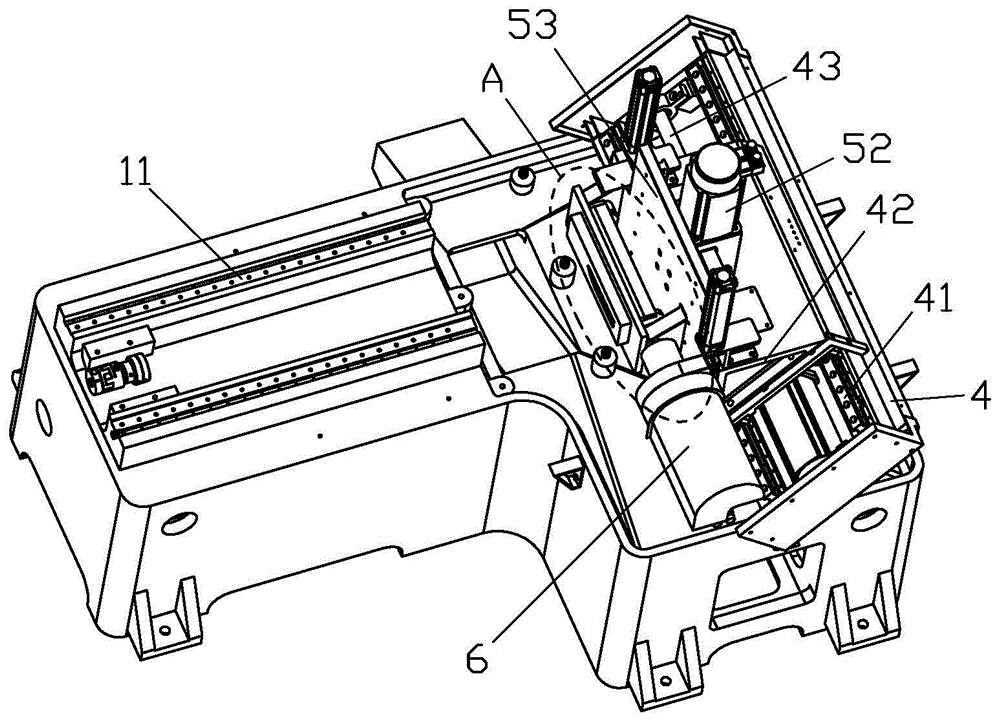

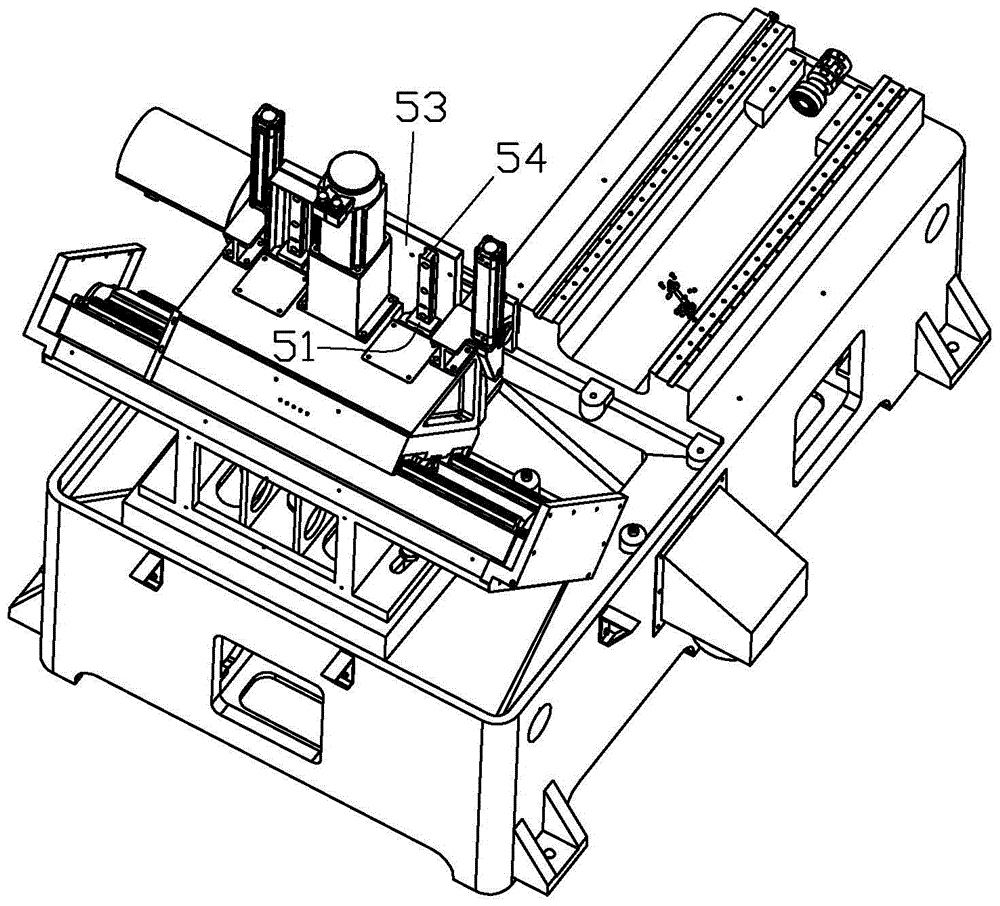

[0022] Reference Figure 1~Figure 9 , A multi-angle adjustable knife grinder of the present invention includes a base 1, a first guide rail 11 is provided on the base 1, and a grinding wheel drive motor 2 is installed on the first guide rail 11. A grinding wheel is installed at the end of the base 1, a tool holder 3 is arranged on the base 1 close to the grinding wheel, an inclined bracket 4 is fixed on the base 1, and a second guide rail 41 is provided on the inclined bracket 4. 41 is provided with a first sliding block 42 that can slide back and forth. The first sliding block 42 is driven by a screw rod 43 installed on the inclined bracket 4. The vertical side and top of the first sliding block 42 are respectively provided with a first Two sliders 51 and a second motor 52. A third slider 53 is connected to the screw at the output end of the second motor 52. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com