Patents

Literature

79results about How to "Easy processing and maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

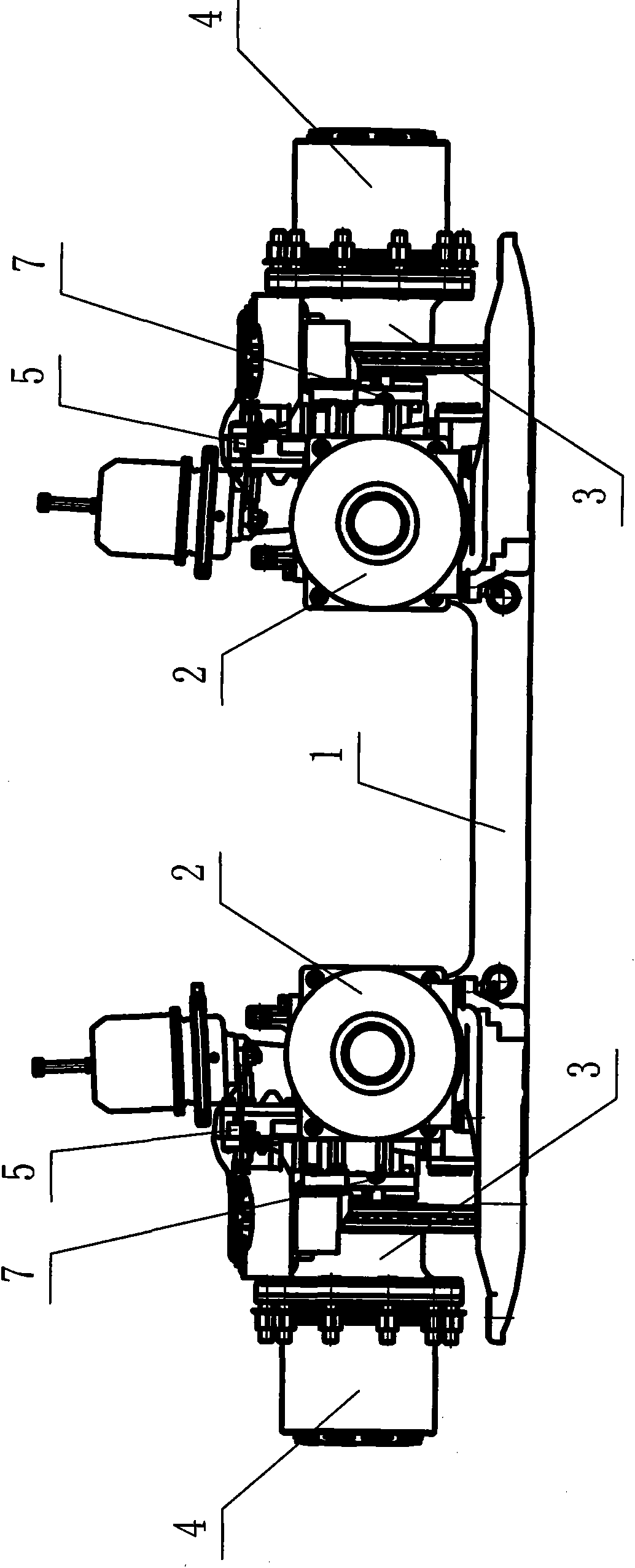

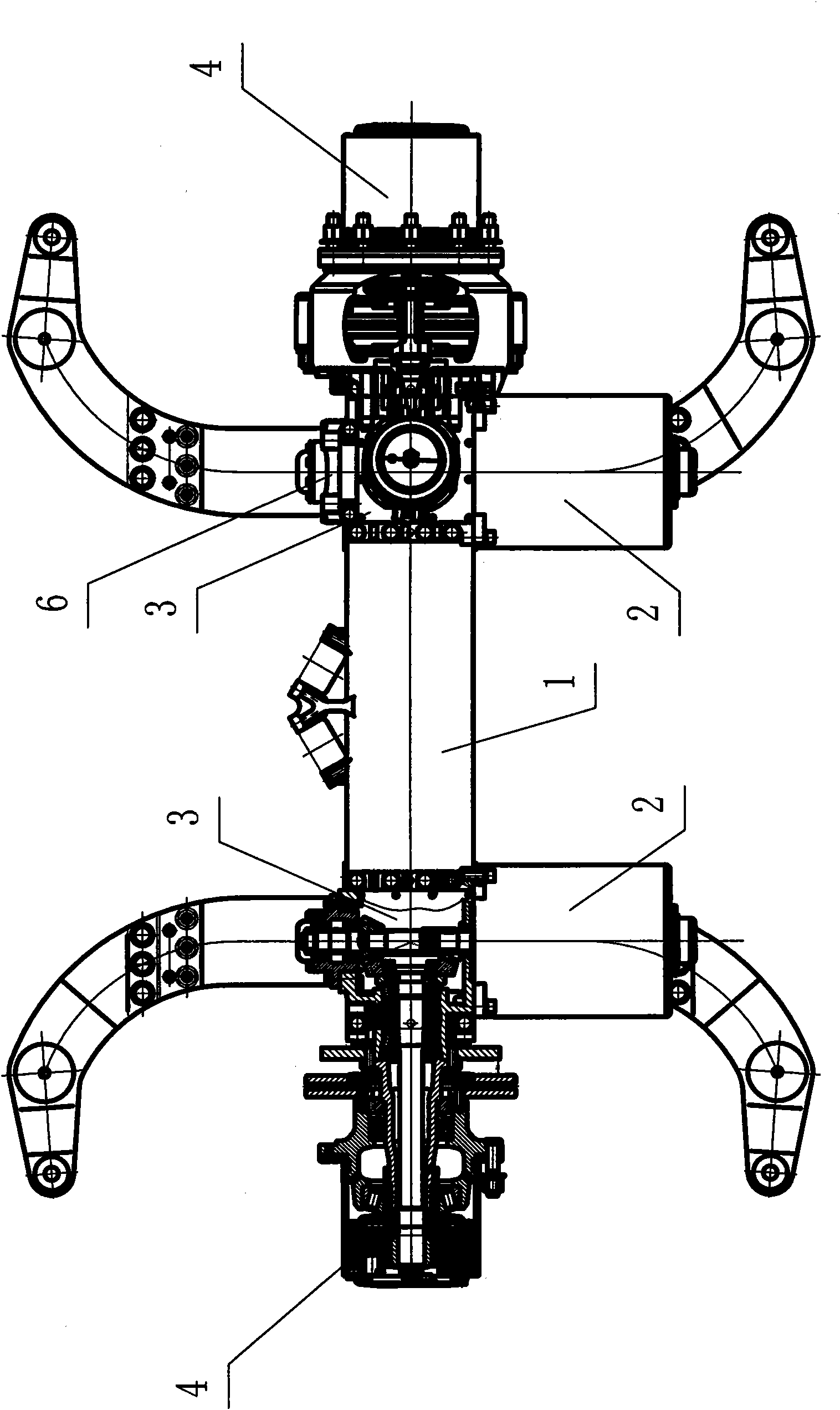

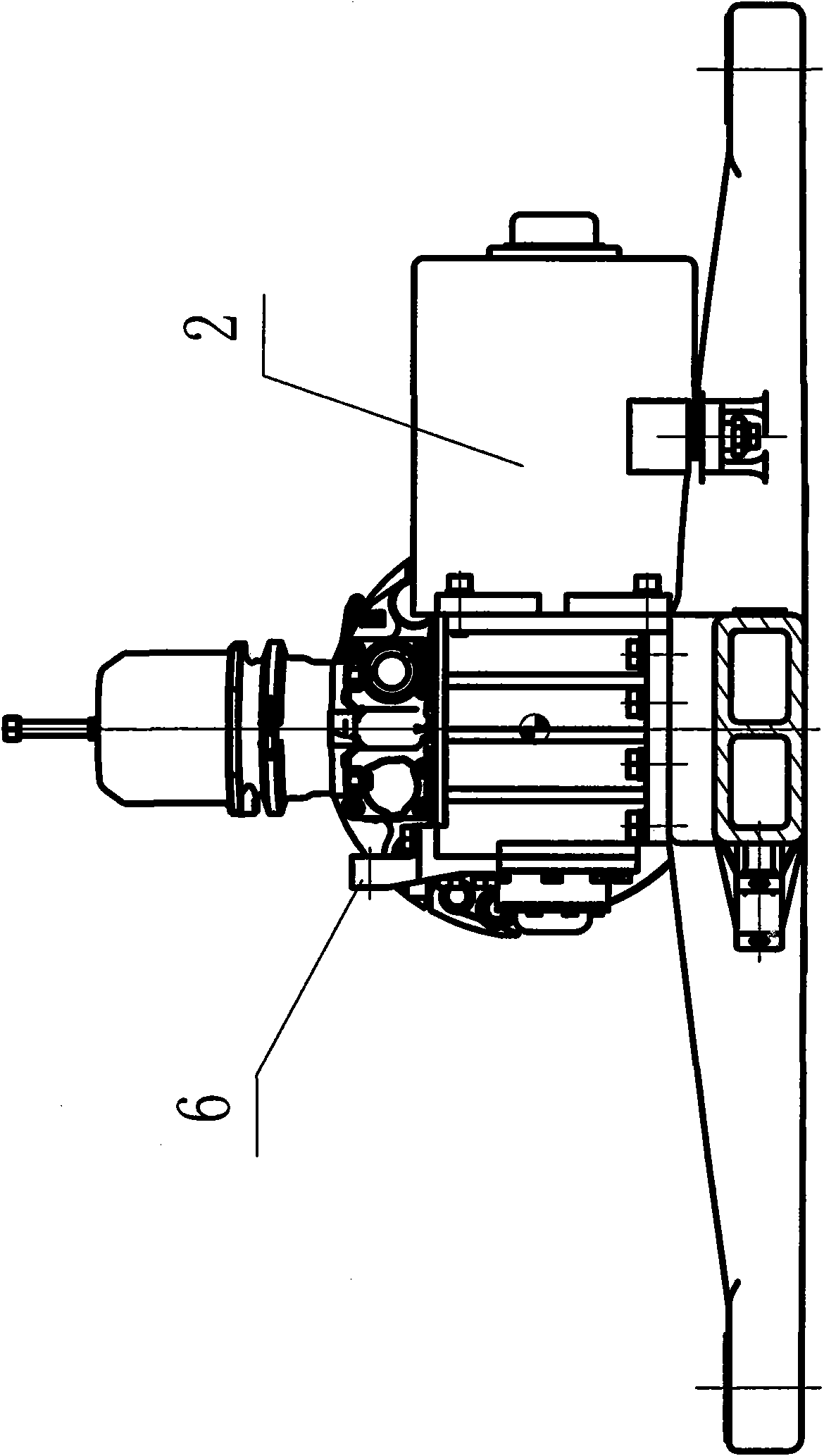

Wheel-rim electric axle

InactiveCN101830172AReduce use costLow costBraking element arrangementsElectric propulsion mountingReduction driveHigh torque

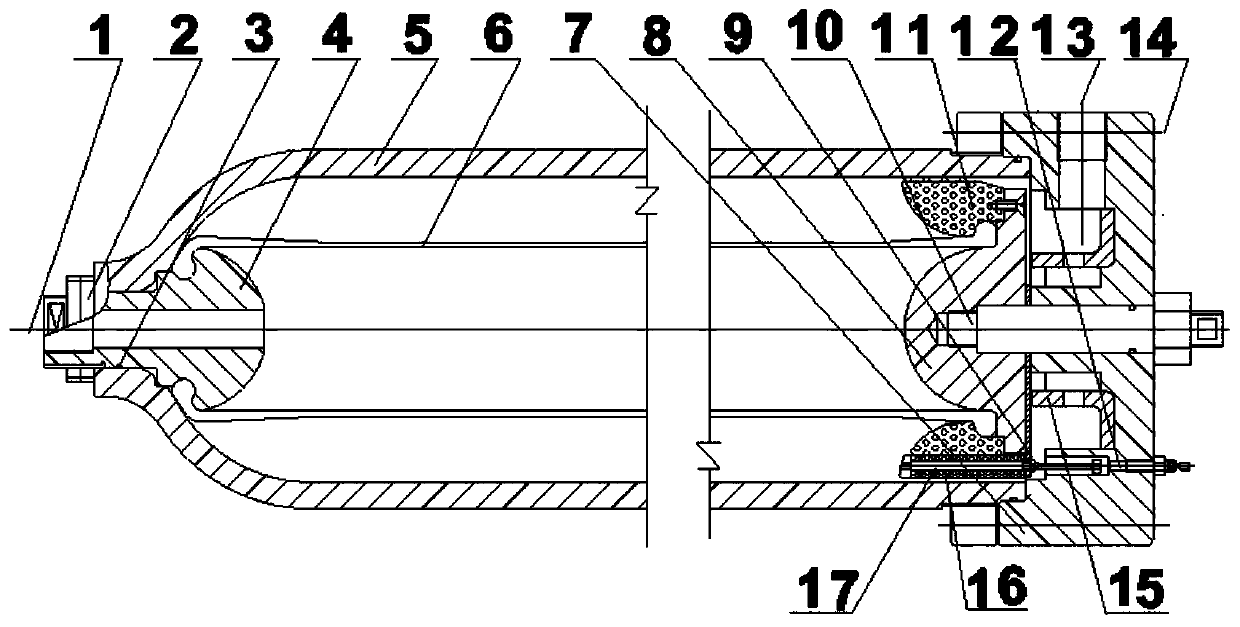

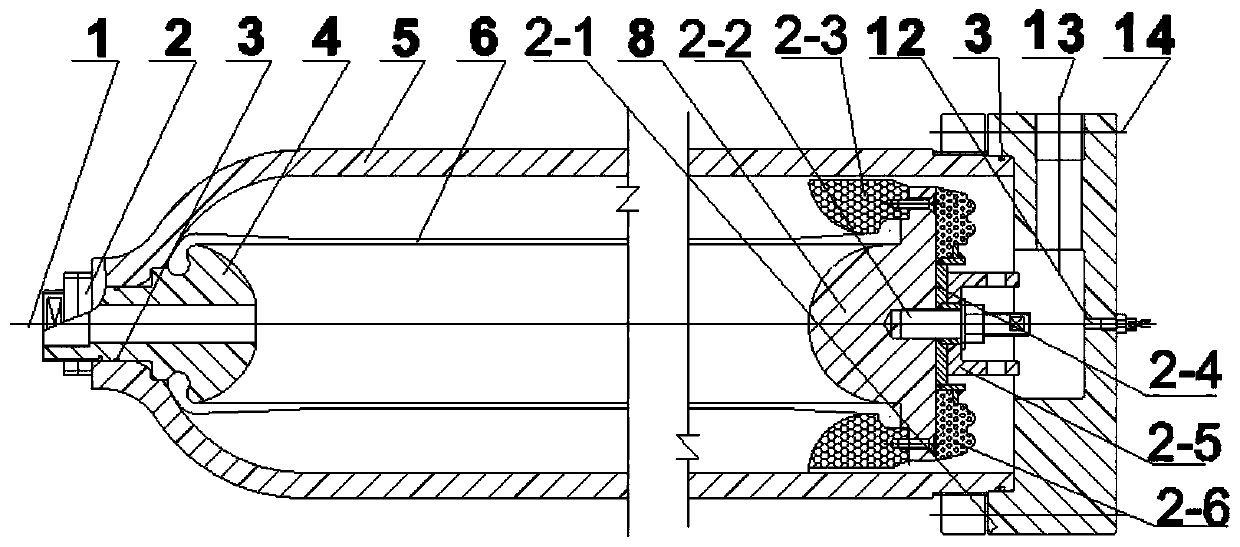

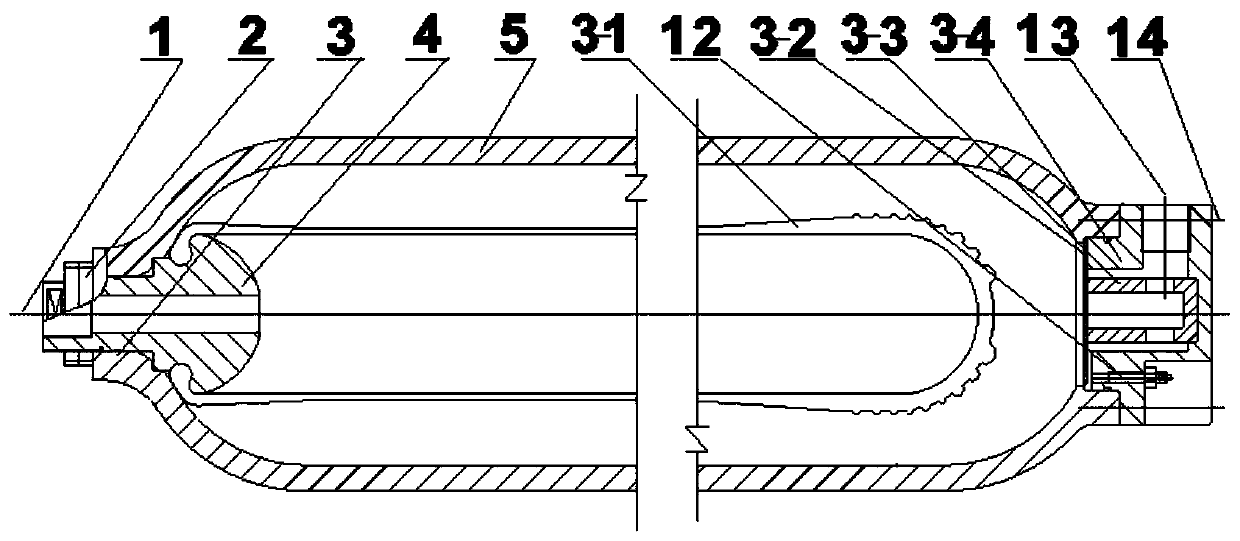

The invention relates to a wheel-rim electric axle for an electric automobile, belonging to the technical field of motor-driven rear axle assemblies of passenger car chassises. The wheel-rim electric axle comprises a rear axle shell assembly, two water-cooling brushless direct-current permanent magnet motors, two rear axle main reducing gear assemblies, two rear axle wheel-rim reducing gear assemblies and the like. The invention changes the transmission direction and enlarges the torque to achieve the purpose of first-stage speed reduction by using the two high-torque water-cooling brushless direct-current permanent magnet motors to simultaneously drive the left and right rear axle main reducing gear assemblies, achieves the purpose of second-stage speed reduction by the rear axle wheel-rim reducing gears, and drives the entire wheel part by using a planetary wheel to drive the wheel-rim reducing gear shell and the rear wheel hub. The wheel-rim electric axle is applicable to various large electric passenger cars, achieves high transmission efficiency, omits the transmission case and the transmission shaft, can simultaneously realize the middle-engine rear-drive, and omits the electro-hydraulic controlled articulated driving device and the automatic gearbox. Besides, the invention overcomes the problems that the axle of the existing electric automobile has low transmission efficiency and the hub motor transmission structure can be only used for small cars such as sedans.

Owner:HUBEI AXLE

Plastic alloy

Plastic alloy of the present invention is prepared through conventional process and with the materials including polypropylene, high-density polyethylene, thermoplastic elastomer, calcium carbonate, antioxidant, lubricant, stabilizer, coupling agent, plasticizer, uvioresistant agent, and nano montmorillonoid or clay or ceramic powder. It has high strength, high toughness, and is anticorrosive, high temperature resistance, non-toxic, easy to machine and maintain and long in service life, and may be used in industry, agriculture, building, medicine and other fields.

Owner:刘建中

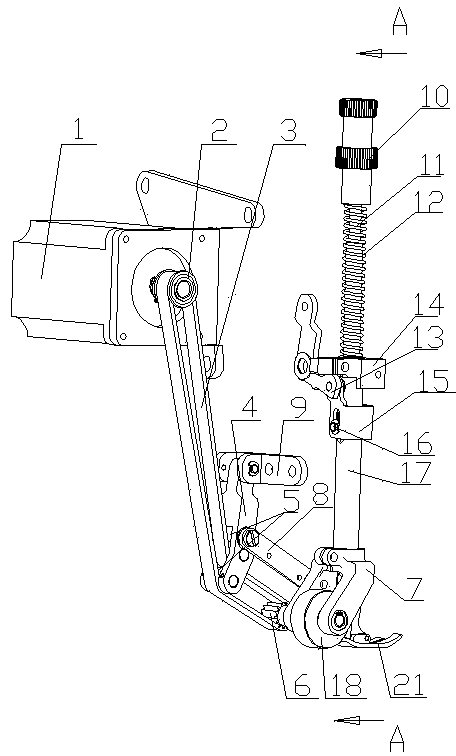

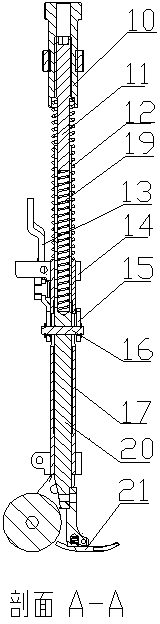

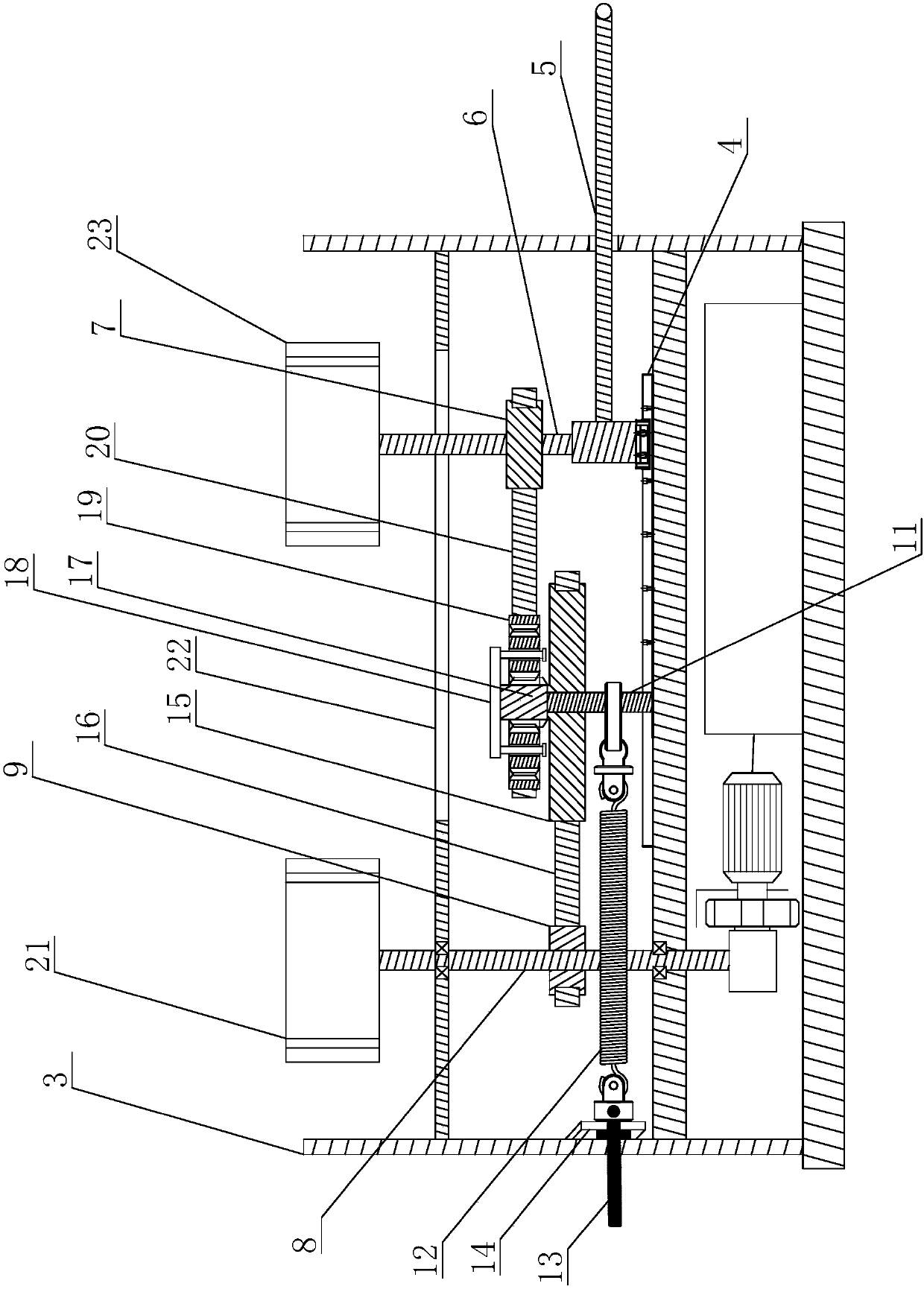

Electronic back-pulling mechanism

The invention relates to the technical field of sewing machines, in particular to an electronic back-pulling mechanism, and solves the problems that the structure is complex, the sewing feeding is unsmooth, and the production efficiency is low in the prior art. The technical scheme is as follows: the electronic back-pulling mechanism comprises a motor, a first synchronous pulley, a second synchronous pulley, a synchronous belt, a synchronous belt tensioning mechanism, a cloth tug component and a presser foot mechanism, wherein one end part of an oscillating bar adopts a double fork structure; the oscillating bar is connected with the synchronous belt, the other end part of the oscillating bar is hinged to an oscillating bar seat; a connecting rod is hinged between the middle of the oscillating bar and a tug rack; an external voltage-regulating screw component adopts an internal thread voltage-regulating structure; an internal voltage-regulating screw rod is in threaded connection with the external voltage-regulating screw; the lower end of the internal voltage-regulating screw rod is pressed onto the upper end of an internal pressing rod spring; the internal pressing rod spring and the internal pressing rod are glidingly sleeved with an external pressing rod; the outer side of the upper part of the external pressing rod is fixedly connected with an upper-raising guide frame; a connecting ring is arranged above the upper-raising guide frame and outside the external pressing rod; and the cloth tug component is fixedly connected with the lower part of the external pressing rod.

Owner:XIAN TYPICAL IND

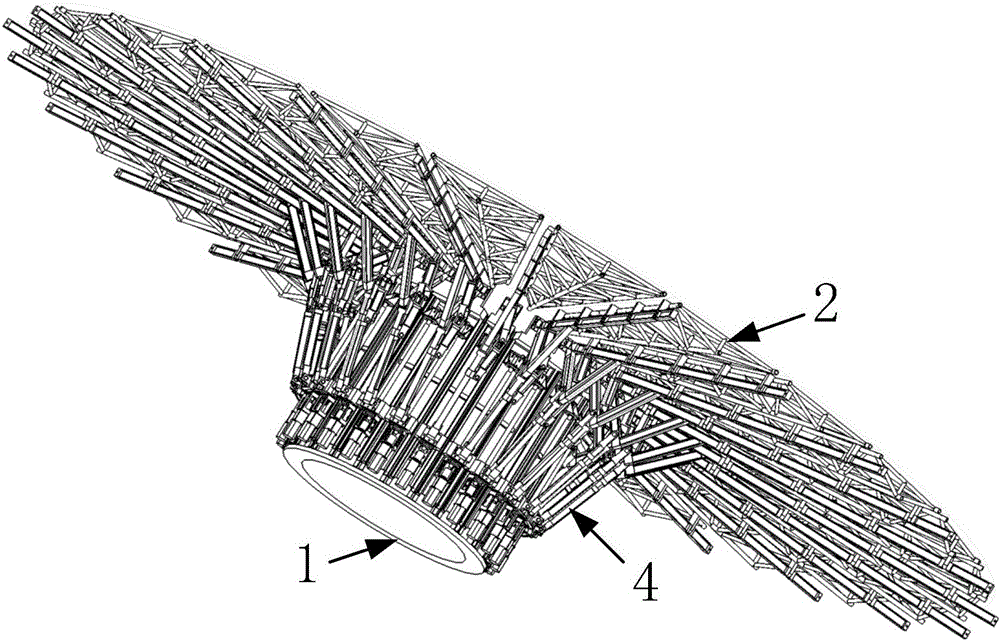

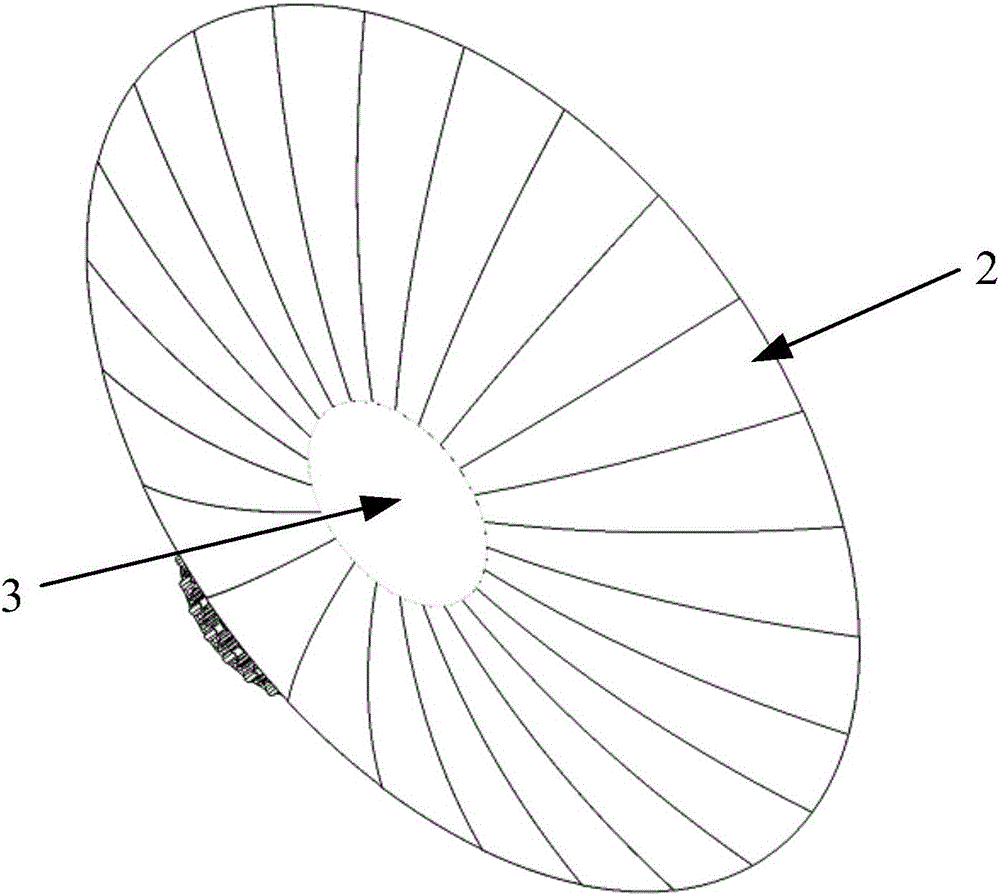

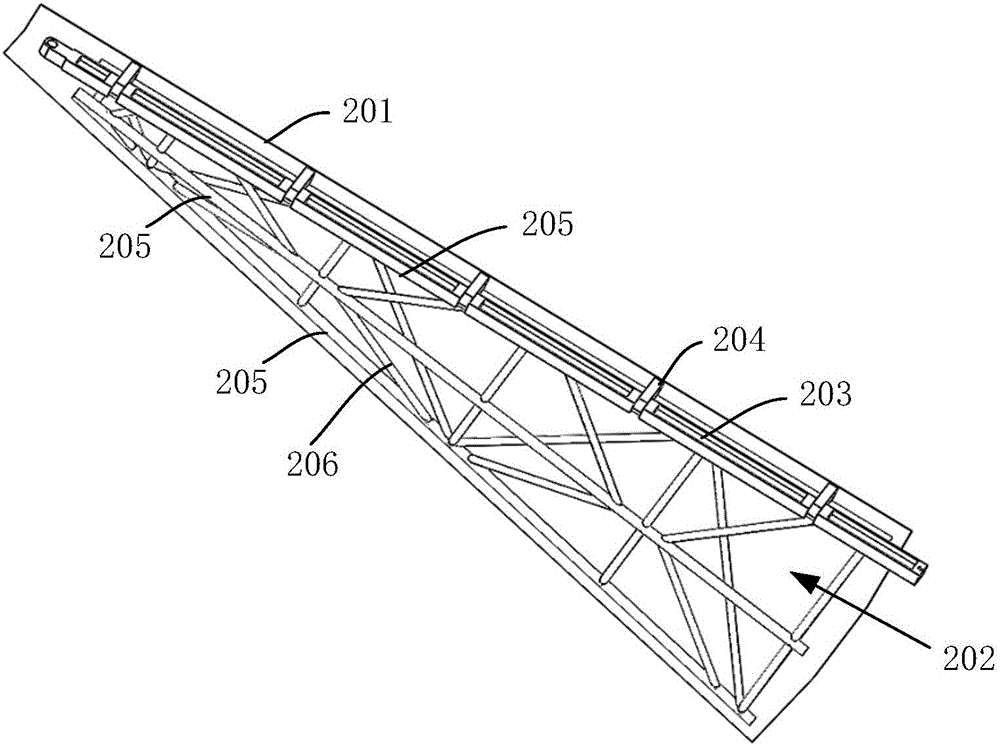

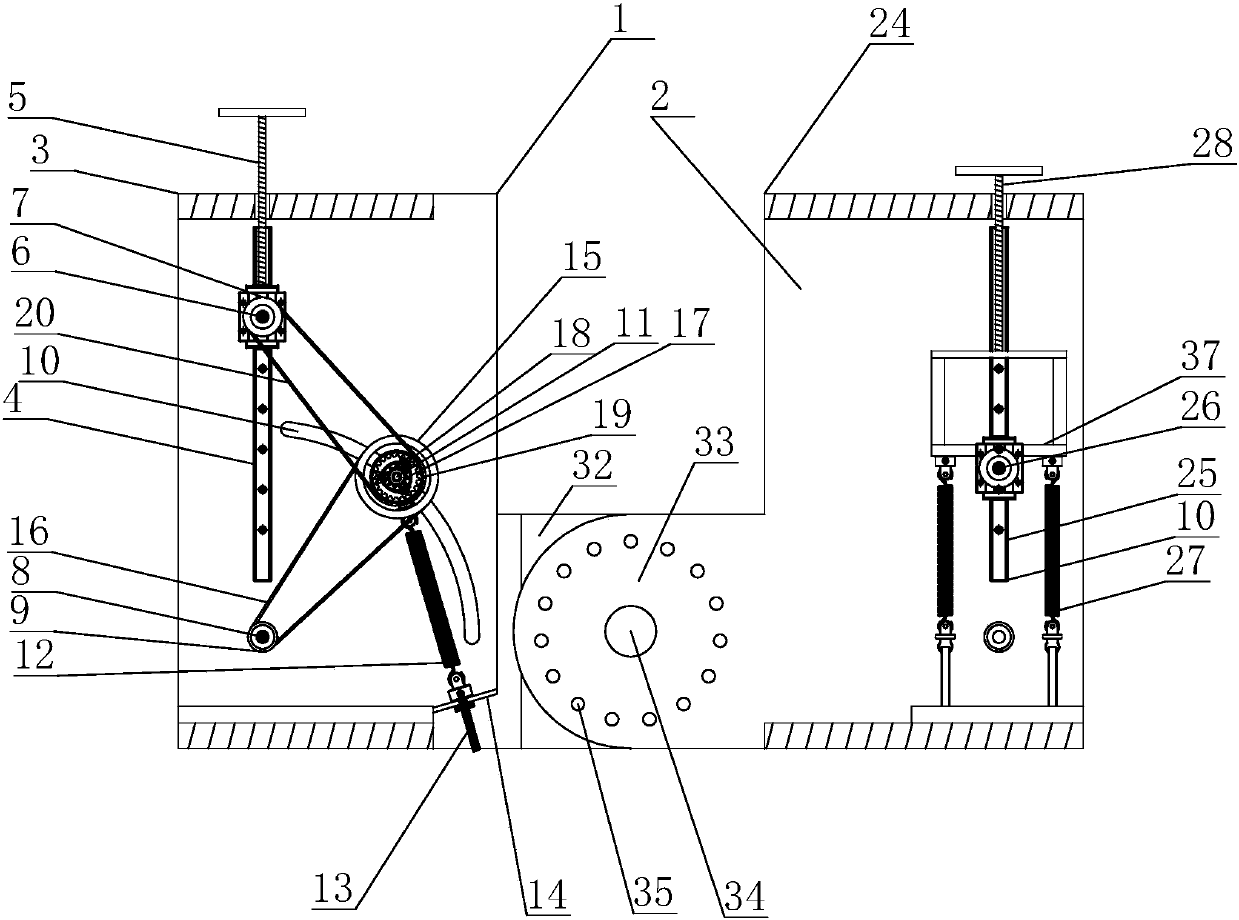

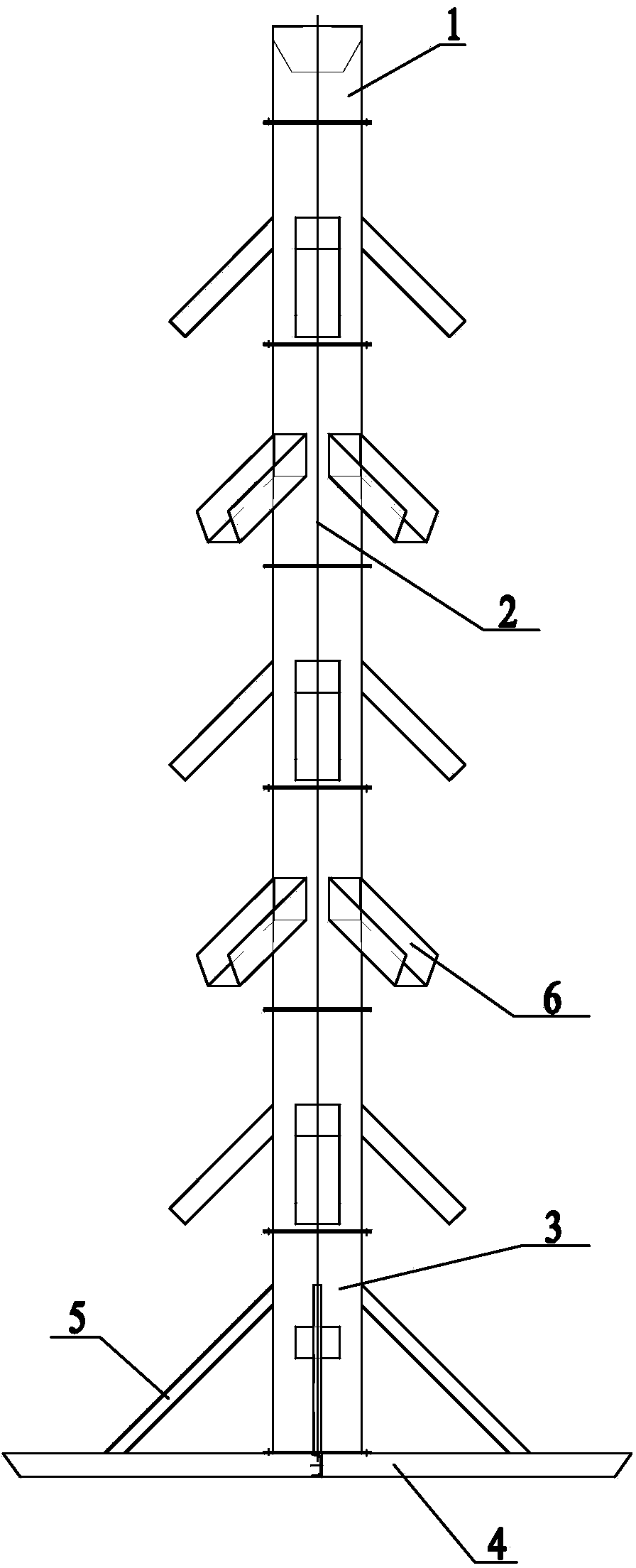

Large-sized foldable parabolic antenna

InactiveCN106450790ALarge shrinkage ratioImprove space utilization and work efficiencyCollapsable antennas meansParabolic antennaEngineering

The invention discloses a large-sized foldable parabolic antenna, and solves the problem that high-contraction-ratio unfolding and folding of the existing large-sized parabolic antenna cannot be realized due to large occupied space. The large-sized foldable parabolic antenna comprises a base body, fan-shaped parabolic modules, a parabolic center and mechanical connecting rod mechanisms, wherein the multiple mechanical connecting rod mechanisms are uniformly mounted on the outer wall of the base body circumferentially; each mechanical connecting rod mechanism is used for driving one corresponding fan-shaped parabolic module to be opened and folded; meanwhile, the parabolic center is mounted on the top of the base; when n fan-shaped parabolic modules are opened, the n fan-shaped parabolic modules and the parabolic center jointly form the overall parabolic structure; and when the n fan-shaped parabolic modules are folded, the mechanical connecting rod mechanisms also control the corresponding fan-shaped parabolic modules to turn circumferentially so as to enable the adjacent fan-shaped parabolic planes to be mutually overlaid and vertically arranged on the circumferential direction of the base body. The large-sized foldable parabolic antenna has the advantages of capability of realizing quick and automatic folding and extension, high contraction ratio, and capability of ensuring the parabolic plane precision.

Owner:BEIHANG UNIV

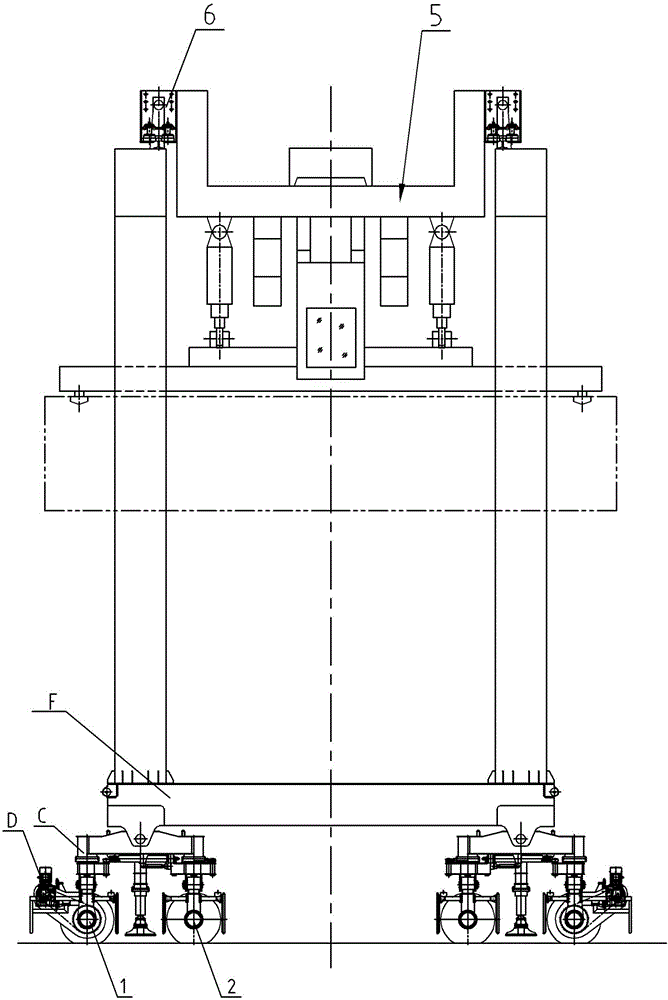

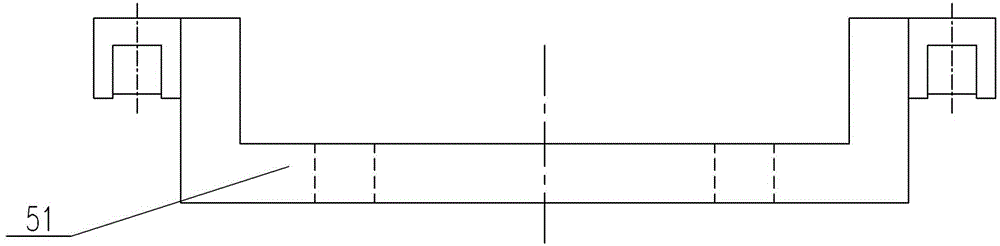

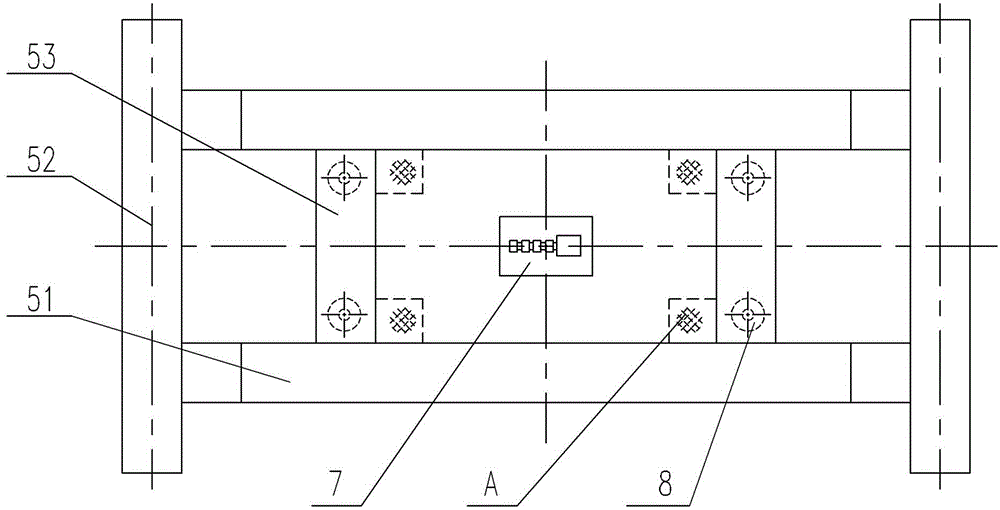

Rubber tire container gantry crane

ActiveCN104085798AExtended useful lifeGuaranteed uptimeTrolley cranesTravelling gearHydraulic cylinderVehicle frame

The invention discloses a rubber tire container gantry crane. The hoisting mechanism of the rubber tire container gantry crane is composed of a hydraulic pump station and four multistage hydraulic oil cylinders, wherein the hydraulic pump station and the hydraulic oil cylinders are respectively mounted on the upper and lower sides of a trolley frame, synchronous telescoping of each hydraulic oil cylinder is controlled by the hydraulic valve of the hydraulic pump station, and a sling is cooperatively used so as to realize loading and unloading of containers. According to the invention, usage of a traditional hoisting mechanism above the trolley frame is discarded; a series of electrical control components and parts for electrical control are not used, so a structure is substantially simplified, weight is decreased and cost is reduced; the driving axle of a cart travel mechanism of the crane is connected with a driving mechanism through a chain connected with the sprocket wheel of a transmission shaft so as to provide power for running of the whole machine, the driving axle is connected with a driving vehicle frame through a bearing pedestal on the transmission shaft so as to support the whole machine, and the driving axle is connected with the rim of a wheel through a rim flange on the transmission shaft so as to transmit power of the driving mechanism to the wheel, thereby realizing operation of the whole machine; traditional complex axle housing and axle package structures are not used, and corresponding defects caused by the axle housing and axle package structures are overcome.

Owner:湖南中铁五新重工有限公司

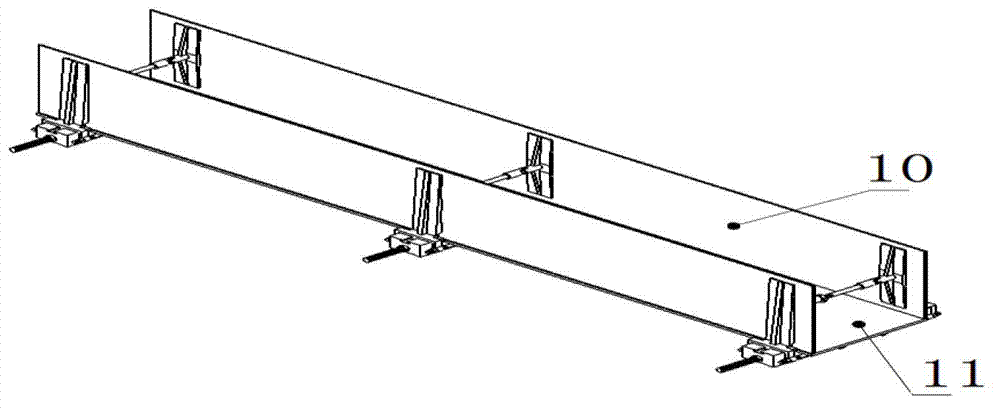

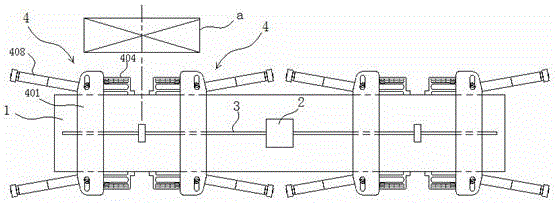

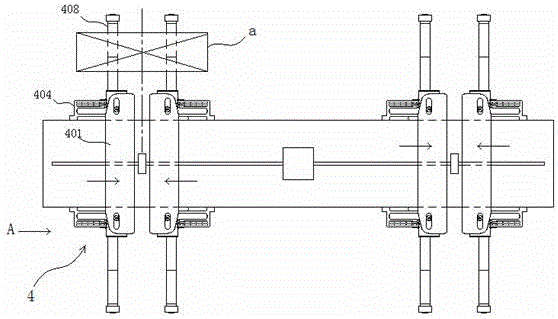

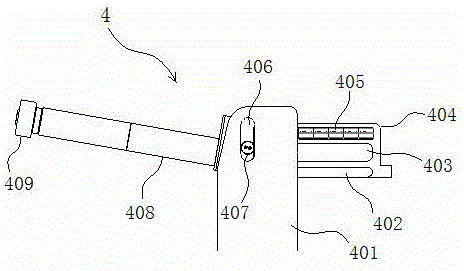

Universal adjustable box beam splicing and welding device

ActiveCN102756232AEasy to assembleEasy to weldWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFlange

The invention discloses a universal adjustable box beam splicing and welding device, comprising a web inner clamping device, a web positioning device, and a flange plate positioning and clamping device. The web positioning device comprises clamping boards of a bottom part and an upper part, which are connected with each other; a T-shaped boss is arranged at the center of the bottom part; through holes II are formed at the both sides of the bottom part; the flange board positioning and clamping device comprises clamping blocks; a through hole I and a T-shaped groove are formed on each clamping block; the T-shaped boss is matched with the T-shaped grooves to form double-rectangular sliding rail fit; the two clamping blocks are connected with a screw rod III through the through holes I; an outer extending lug plate is arranged at the outer side of each clamping block; connection holes are formed on the lug plates; the connection holes are connected with a screw rod II; the through hole II 1 is connected with the screw rod II; the screw rod II is matched with a nut II; the web inner clamping device comprises two inner splints; the two inner splints are connected through the screw rod I; and the inner splints are matched with the clamping blocks in position. The universal adjustable box beam splicing and welding device is applicable to assembling and pairing box beams with various sizes, so that the splicing precision and the welding speed of the box beams can be improved.

Owner:SHANDONG FENGHUI EQUIP TECH

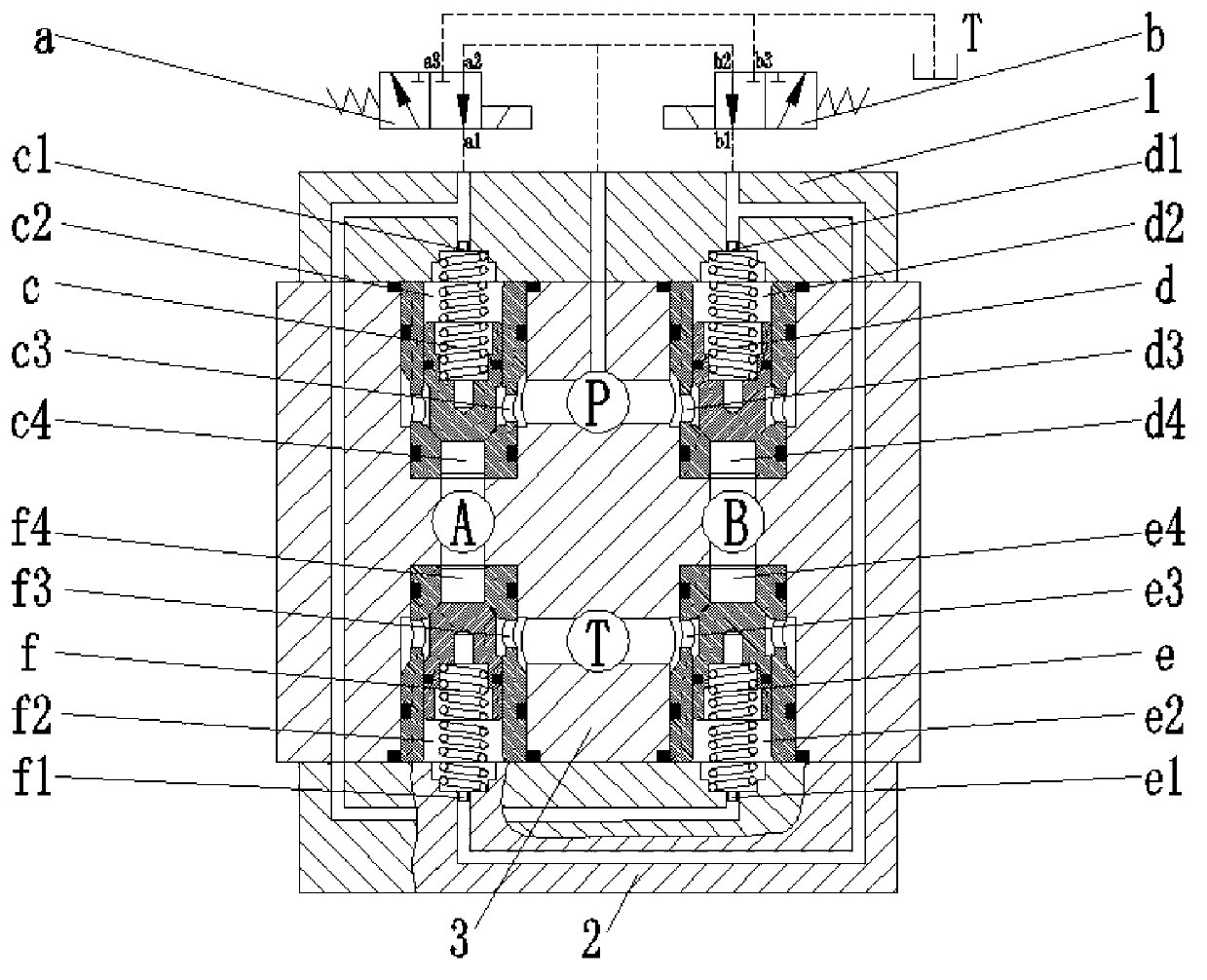

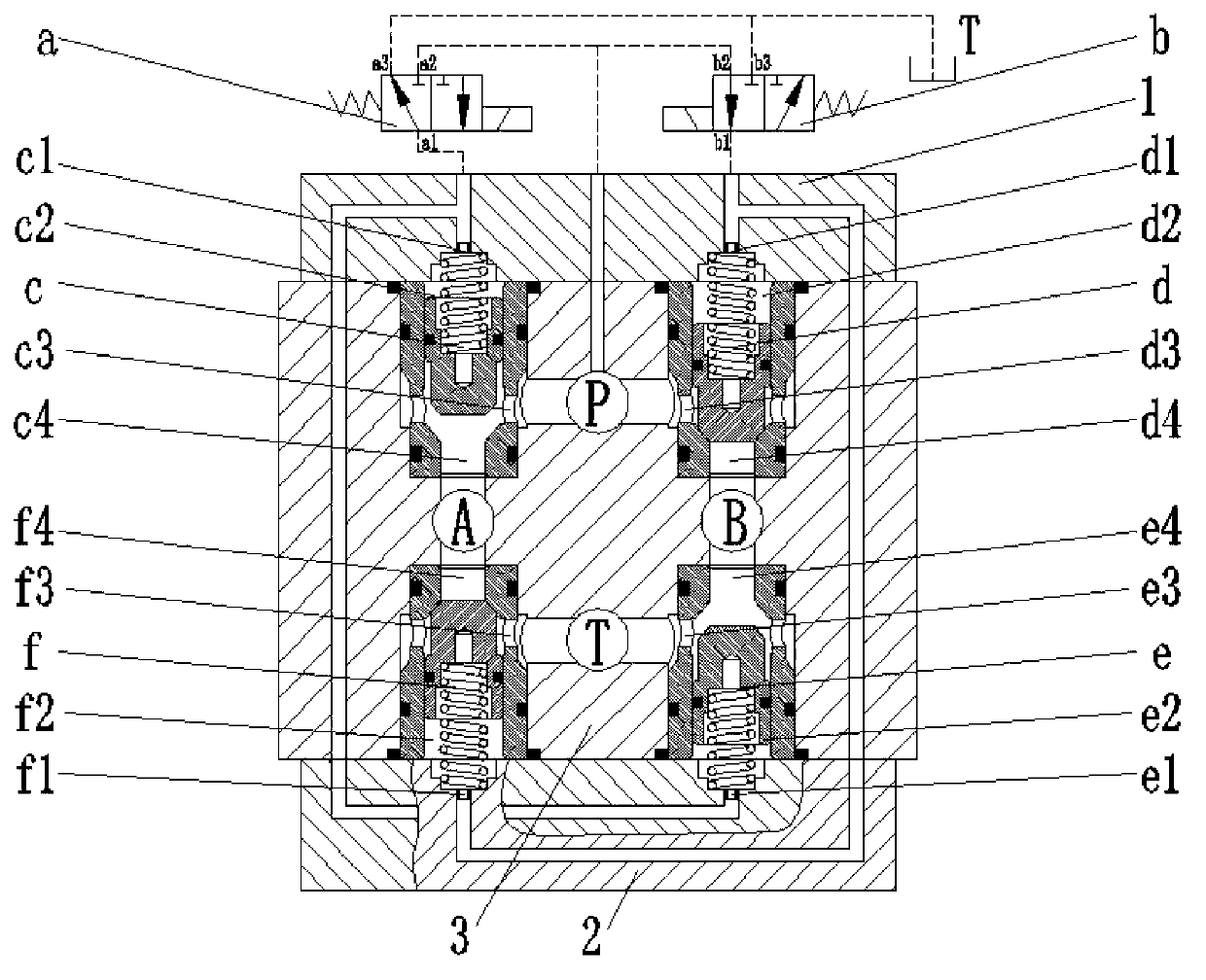

Three-position four-way water pressure magnetic exchange valve used in deep sea

ActiveCN103104569AReduce corrosionOvercome the problem that the effective positioning of the actuator cannot be completedServomotor componentsMagnetic exchangeEngineering

The invention provides a three-position four-way water pressure magnetic exchange valve used in a deep sea and relates to a component which controls a liquid flow direction in a hydraulic system. The three-position four-way water pressure magnetic exchange valve used in the deep sea is composed of two guide control valves, four sets of insertion components, two control cover plates and an insertion block. Each set of insertion component comprises a valve core, a valve sleeve, a spring and a sealing piece combination. Four sets of cone-valve-shaped two-way insertion components which are in the same structure are mutually communicated through ducts which are formed in the inner portion of a valve body by utilizing a method of plug-in mounting plus cover plates. The guide control valves control the opening or closing of each valve opening of each insertion component, and therefore a communication mode of four valve openings including a P valve opening, an A valve opening, a B valve opening and a T valve opening of the three-position four-way magnetic exchange valve is changed, and reversing function is achieved. The three-position four-way water pressure magnetic exchange valve used in the deep sea is suitable for a liquid flow direction control situation of middle and high pressure aqueous media (fresh sea water, seawater base and the like) and is particularly suitable for being used in a deep-sea mass-flow water hydraulic transmission system.

Owner:BEIJING UNIV OF TECH

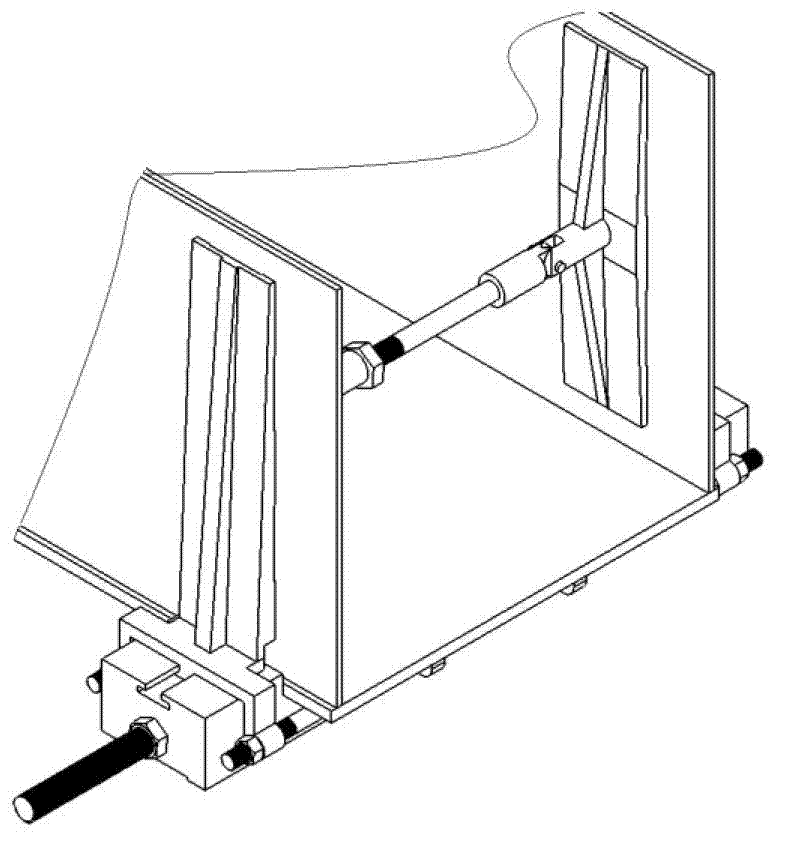

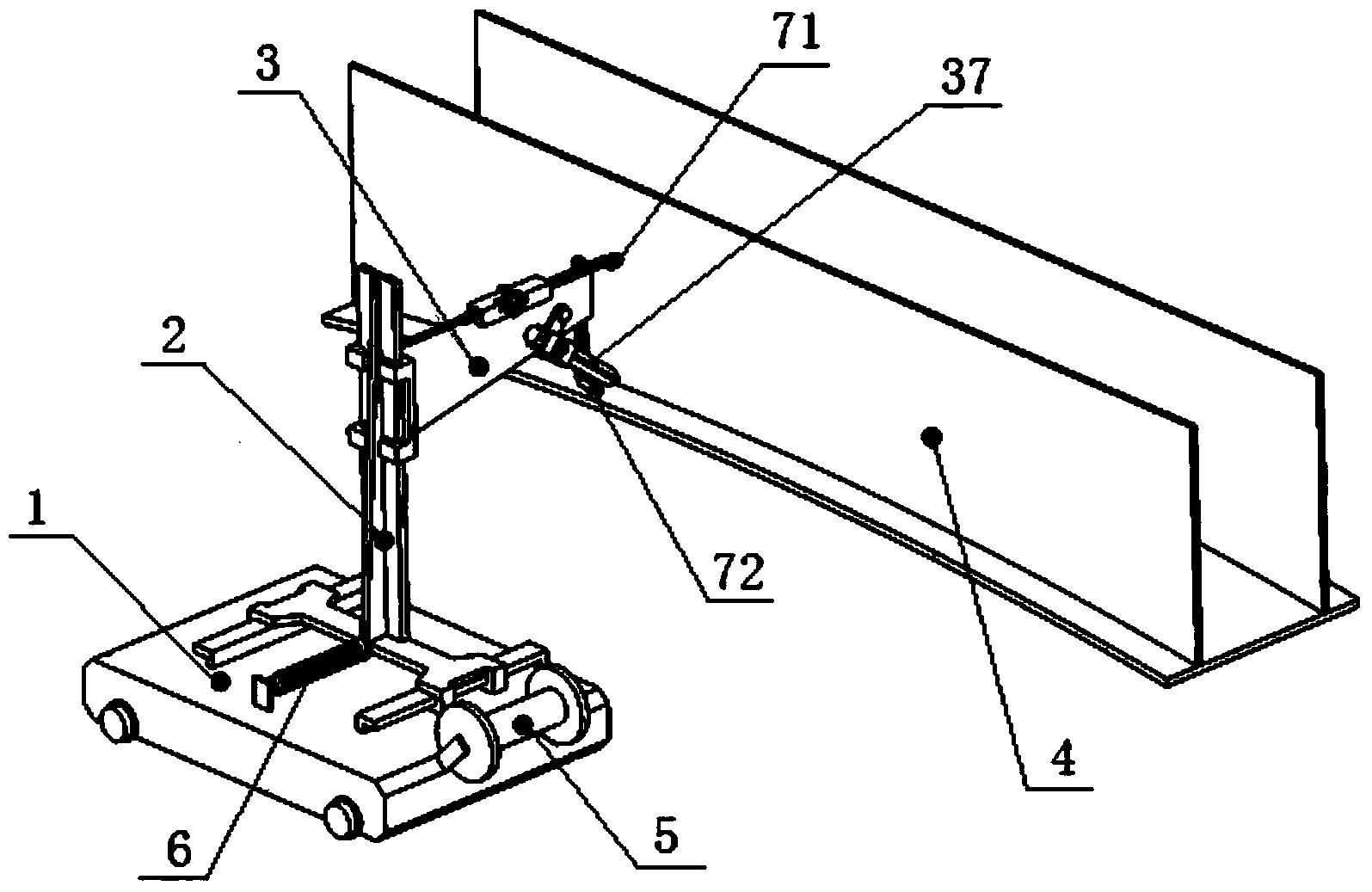

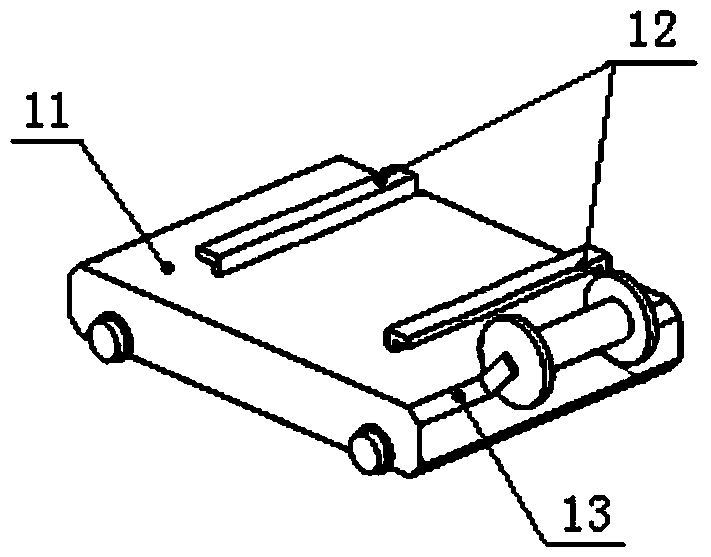

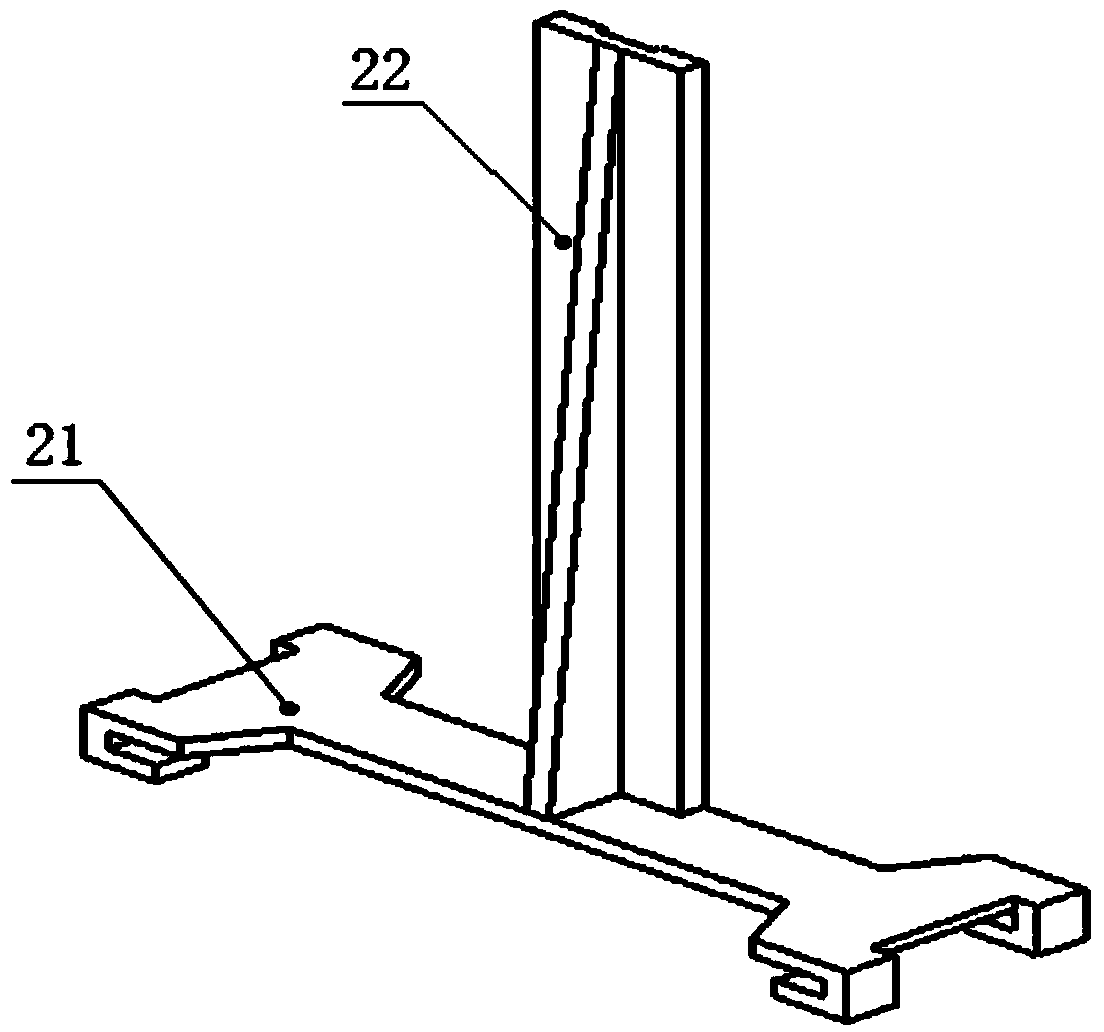

Device and method for automatically welding box beam

ActiveCN104175038AFacilitate automatic weldingReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFlange

The invention discloses a device and method for automatically welding a box beam. The device comprises a walking trolley, a main support, a welding gun supporting arm and a welding gun. The welding gun is arranged on the welding gun supporting arm through a hinge shaft, and the welding gun supporting arm is arranged on a vertical rectangular guide rail of the main support. The main support is matched with a horizontal rectangular guide rail of the walking trolley through a rectangular guide rail groove below the main support, and the welding gun can move along the horizontal rectangular guide rail and the vertical rectangular guide rail. In the welding process, the height and the angle of the welding gun are well adjusted according to the camber of the box beam and the positions of a flange plate and a box beam web, and therefore automatic welding can be achieved. According to the device and method for automatically welding the box beam, the structure is simple, adjustment is easy, box beams of various sizes can be conveniently and automatically welded, the labor intensity of welding personnel is lowered, rigidity is high, the bearing capability is high, machining and maintaining are easy, and cost is saved. The box type beam is automatically welded, besides, H-shaped steel used in a steel structure workshop can be automatically welded, and the accuracy of a profiling outline can be effectively ensured.

Owner:SHANDONG FENGHUI EQUIP TECH

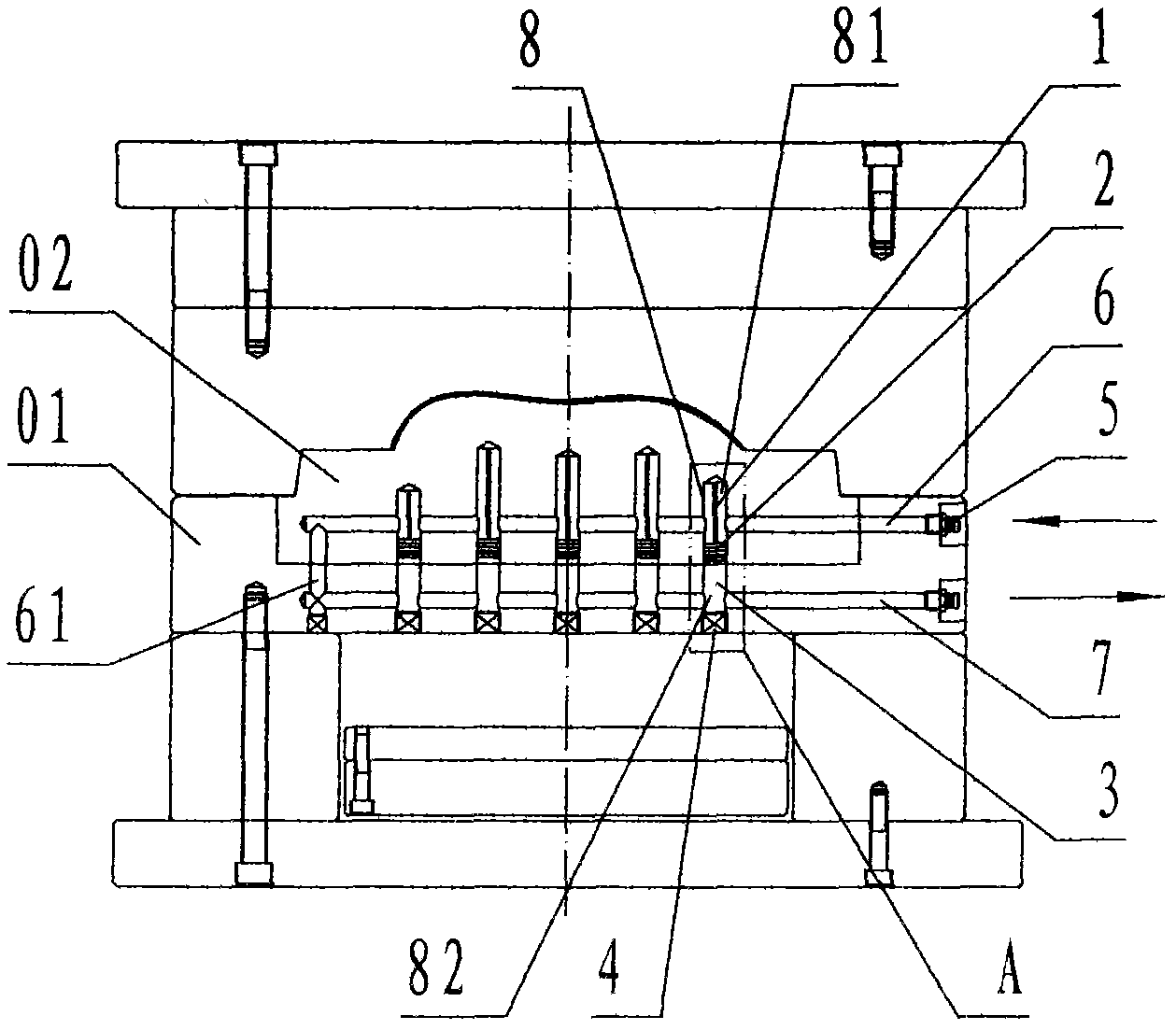

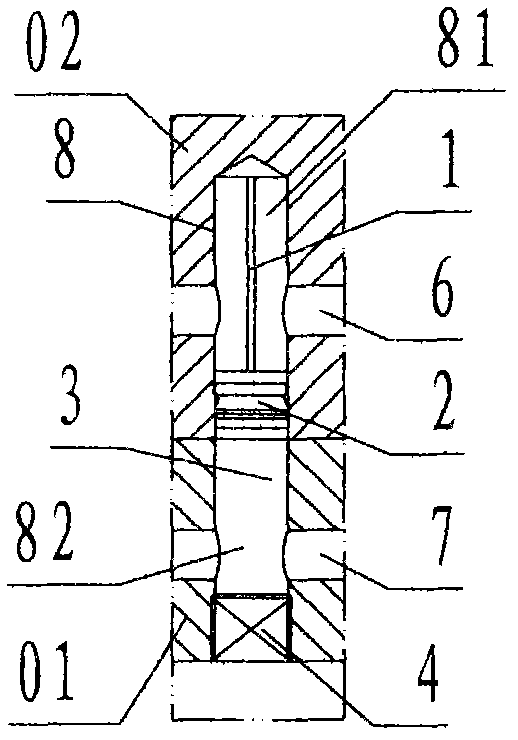

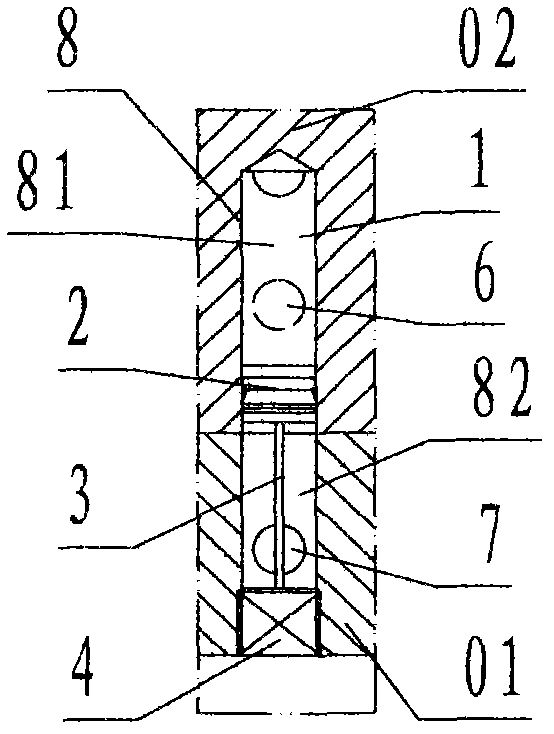

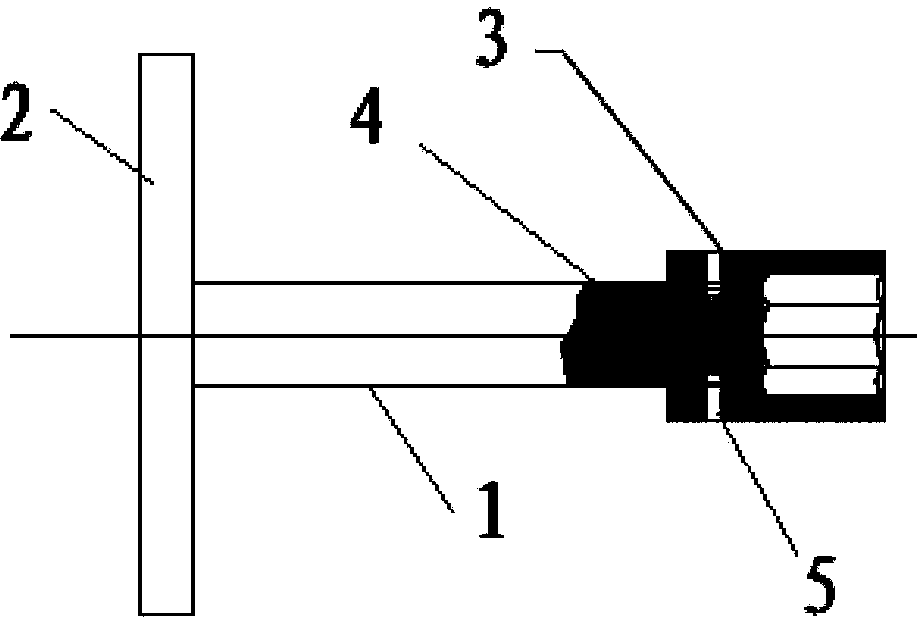

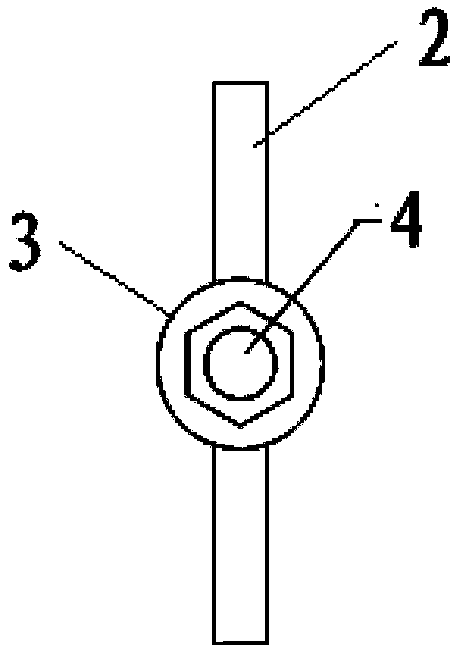

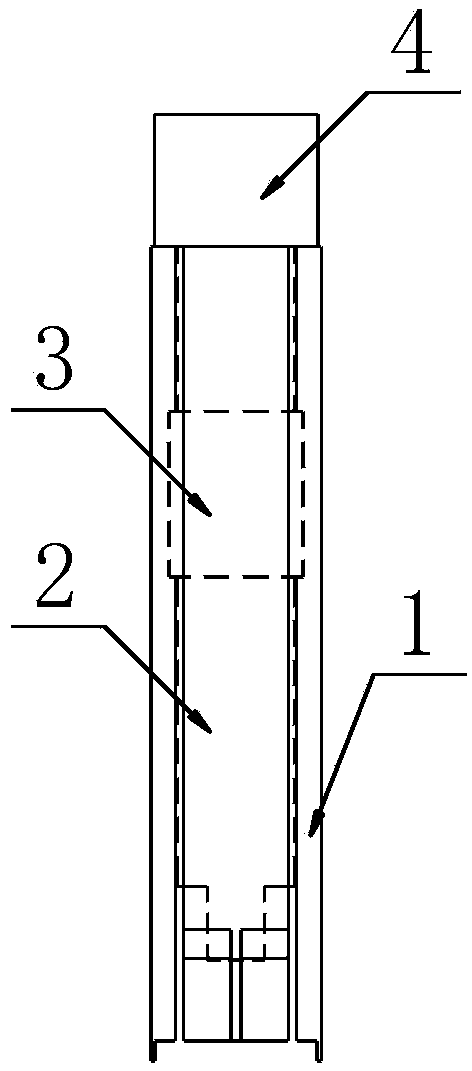

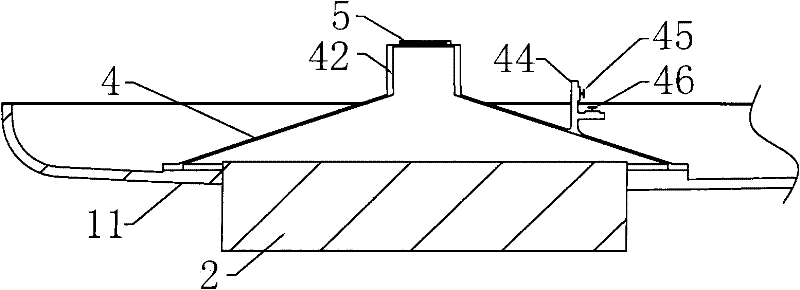

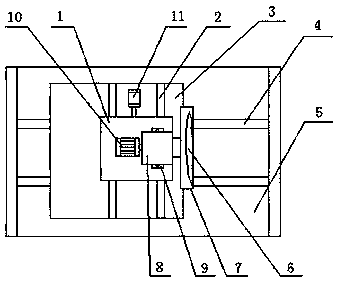

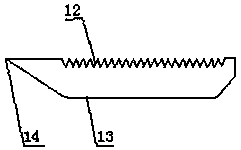

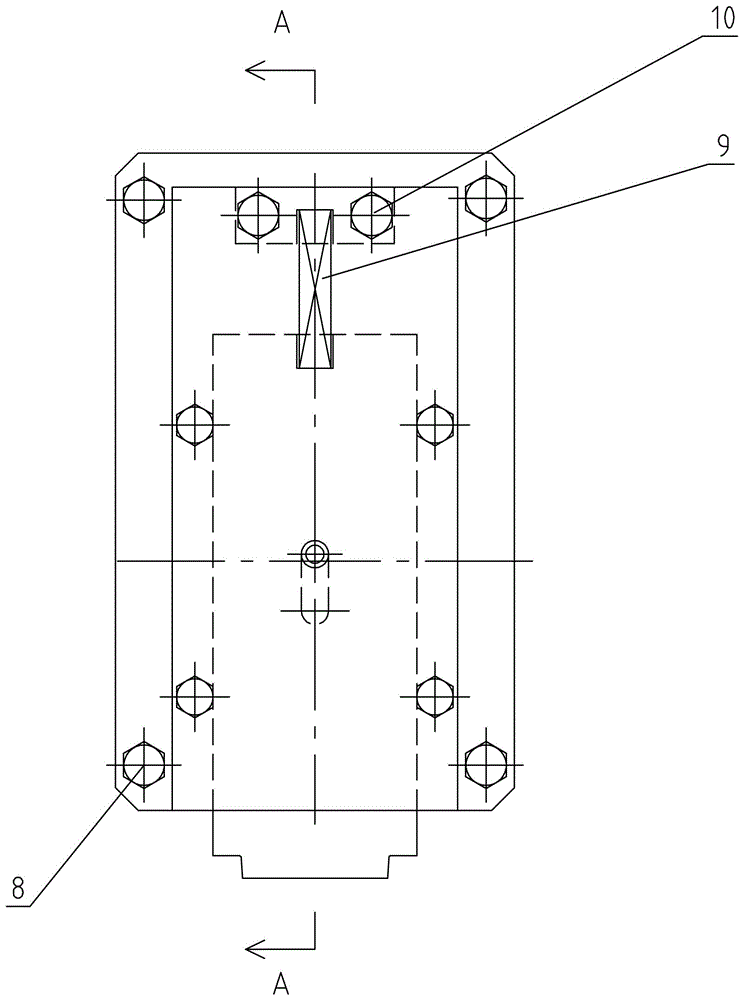

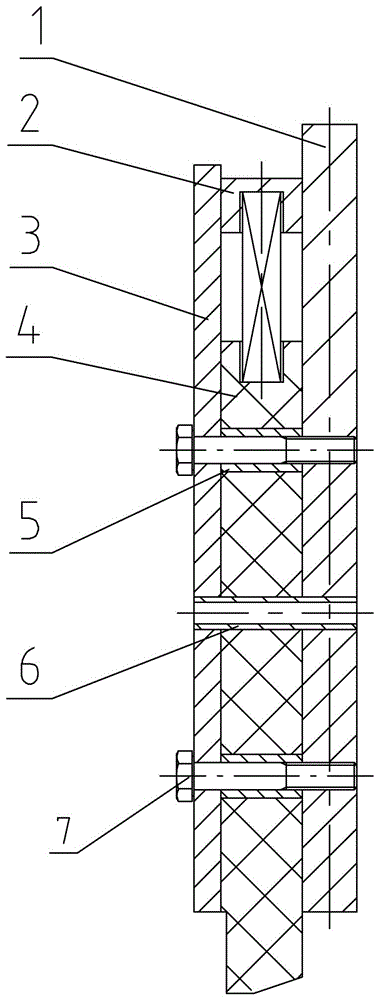

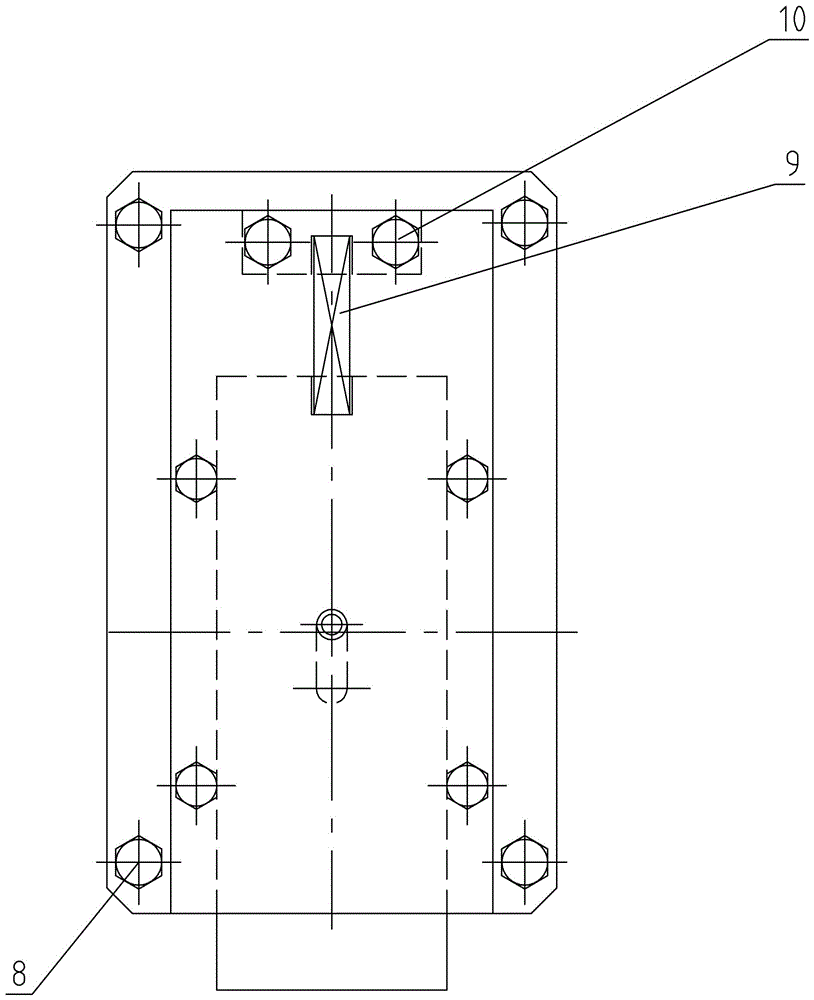

Circuit device of injection mold with single-side inlet and outlet cooling water

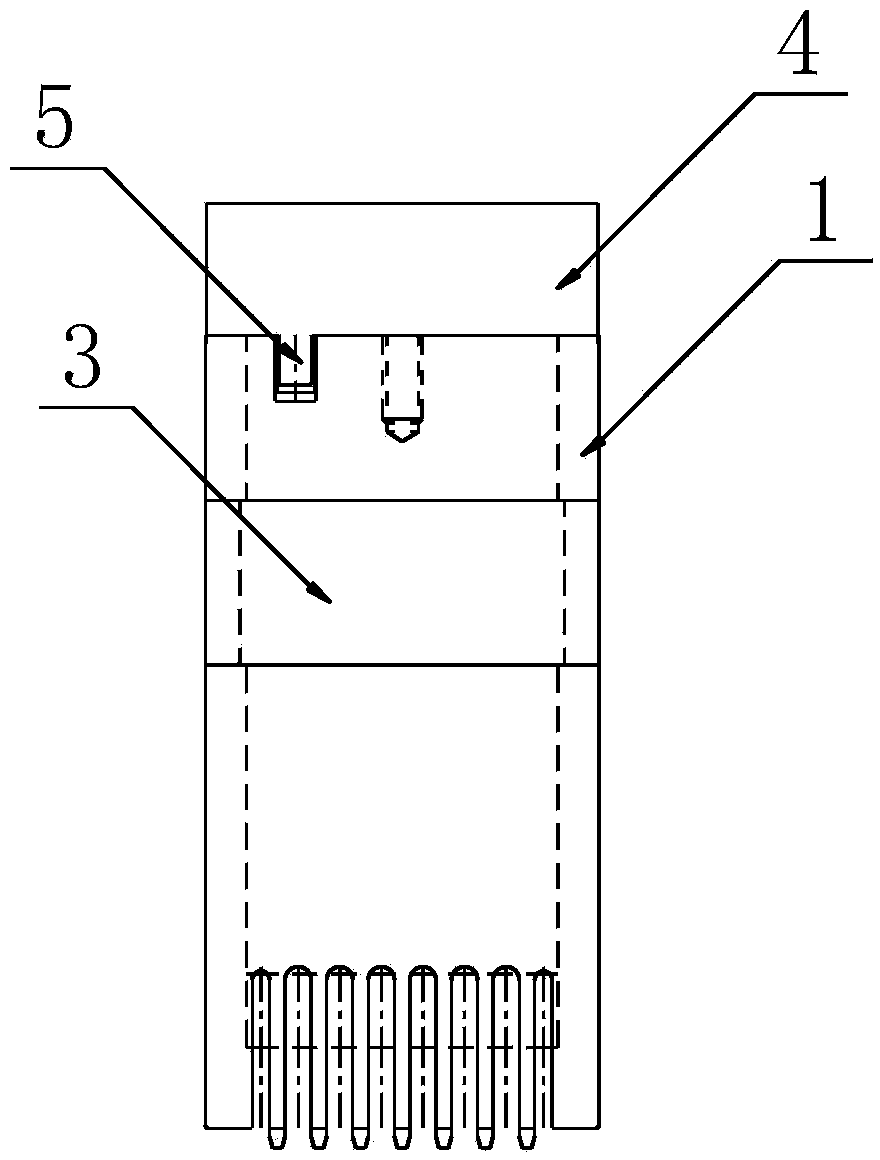

The invention discloses a circuit device of an injection mold with single-side inlet and outlet cooling water, which comprises a water-stop plate (1), a water faucet (2), a support plate (3), a plug (4), a water inlet channel (6), a folded-back channel (61), a water outlet channel (7), and a water-turning cooling hole (8). The present invention adopts such a technical scheme of cooling water circuit that the water-turning cooling hole consisting of several straight blind holes is arranged in the mold, an isolating device consisting of the water-stop plate, the water faucet and the support plate partitions the water-turning cooling hole into a water turning chamber and a water returning chamber from top to bottom; the water inlet channel and the water outlet channel provided with the straight holes are respectively communicated with the water turning chamber and the water returning chamber and then respectively connected with them by the folded-back channel of the straight hole, and the inlet and the outlet are arranged on the same outer side of the mold. By using the water faucet for partitioning the water inlet and the water outlet channels and the processing convenience of straight hole, the injection mold has inlet and outlet water on the single side, the purposes of simplifying structure, reducing processing cost, no restrict and improving cooling effect are achieved.

Owner:宁海县第一注塑模具有限公司

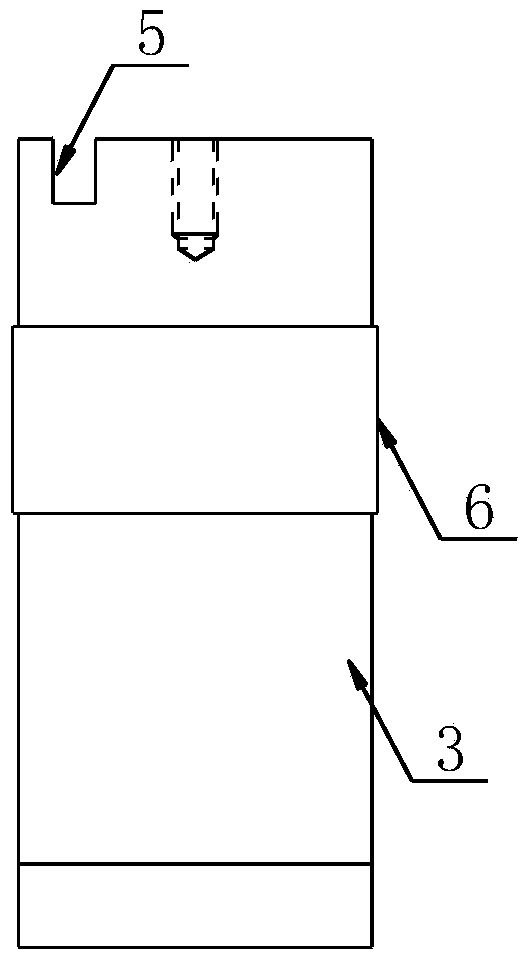

Detachable magnetic type nozzle socket wrench and method for preventing nozzle from dropping

The invention discloses a detachable magnetic type nozzle socket wrench and a method for preventing a nozzle from dropping. An operating handle is connected with a rod body, and a socket is connected with the other end of the rod body. A magnet is arranged on the connecting portion between the rod body and the socket and connected in the socket through a fixing pin. The method for preventing the nozzle from dropping includes sleeving the socket of the detachable magnetic type nozzle socket wrench on the nozzle, screwing the nozzle, sucking the nozzle through the magnetism, and taking out the nozzle and the detachable magnetic type nozzle socket wrench. The practical detachable magnetic type nozzle socket wrench has the advantages that a safe operating environment is provided for preventing operating staffs from failing to mount the nozzle so as to prevent the nozzle from falling into a nozzle sleeve, and accordingly unnecessary loss caused by a series of linked operating mistakes is avoided; the detachable magnetic type nozzle socket wrench is simple in structure, rapid to operate, convenient to process and maintain, low in cost, ; the nozzle is prevented from dropping from the socket wrench and falling into the nozzle sleeve, and thus, normal production of the oil well is guaranteed.

Owner:PETROCHINA CO LTD

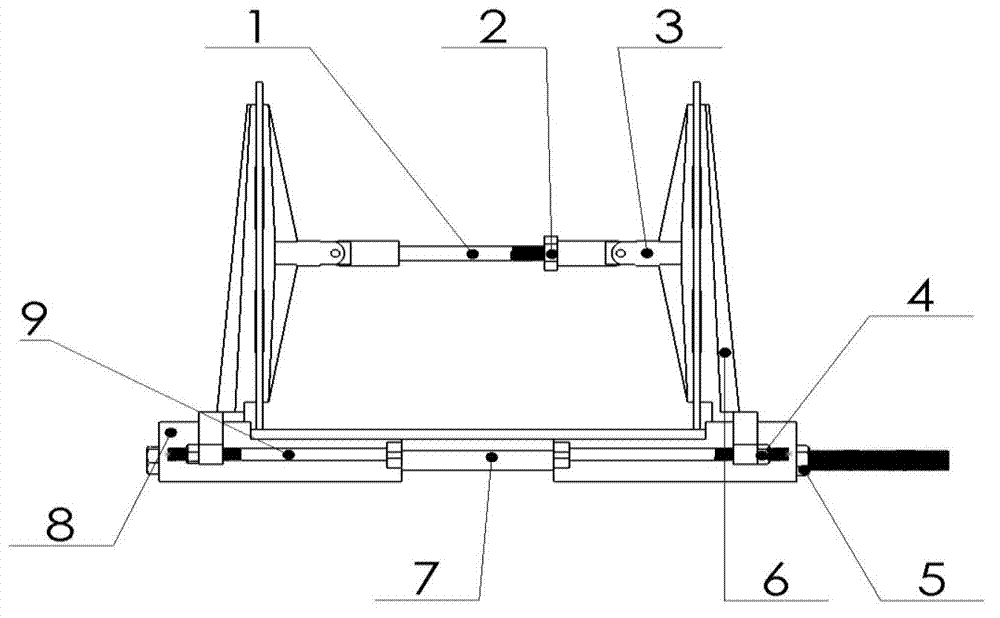

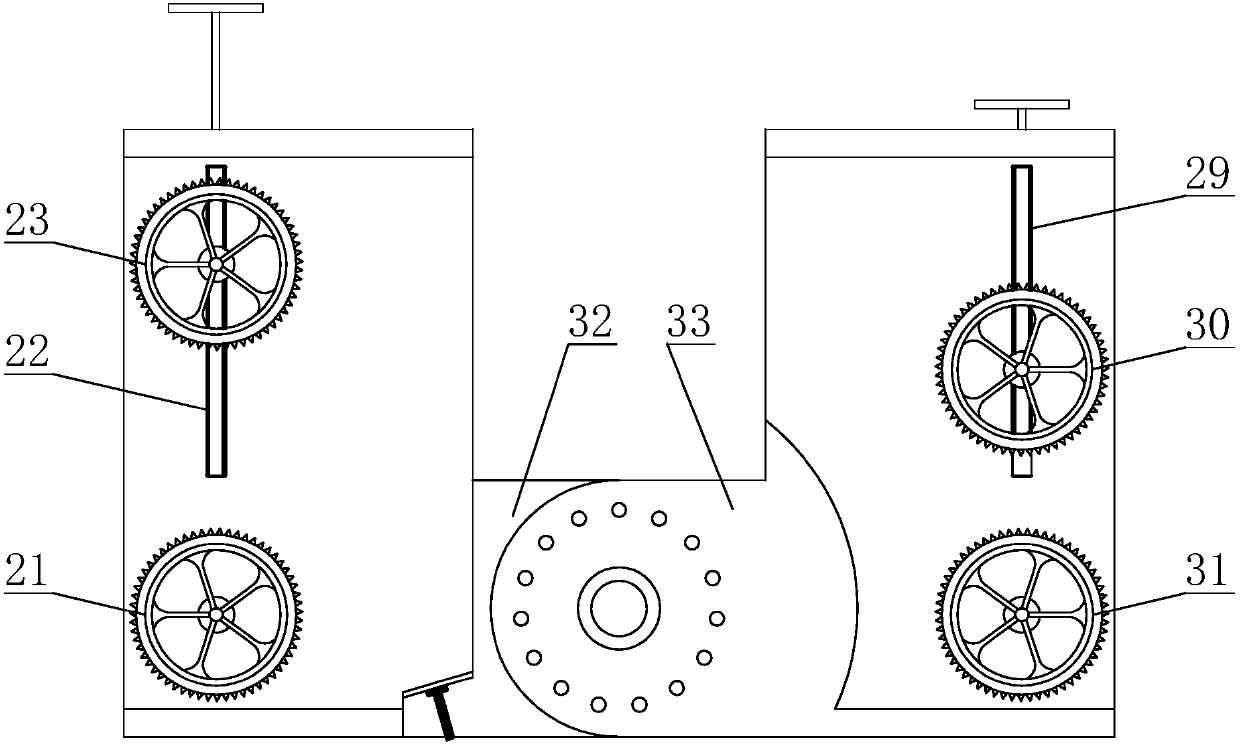

Adjustable automatic wire feeding device

InactiveCN105947779AReduce construction costsGood clamping effectFilament handlingFinish lineWheel drive

The invention discloses an adjustable automatic wire feeding device, and mainly relates to the field of power construction facilities. The adjustable automatic wire feeding device comprises a drive mechanism and a driven mechanism. The drive mechanism is connected to one side of the driven mechanism in a hinged manner, and a limiting pin used for fixing the hinge angle is arranged at the hinged position. The drive mechanism is provided with a power wheel driven by a motor, and a first clamping wheel in reverse transmission through a planetary wheel set so that a cable can be clamped and conveyed, and the driven mechanism is provided with a fixed wheel and a second clamping wheel matched with the fixed wheel so that the turning angle can be assisted. The adjustable automatic wire feeding device has the beneficial effects that the adjustable automatic wire feeding device can be easily matched with various complex power transmission lines to finish line conveying, and meanwhile the cable can be well protected.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO PINGYUAN POWER SUPPLY CO +1

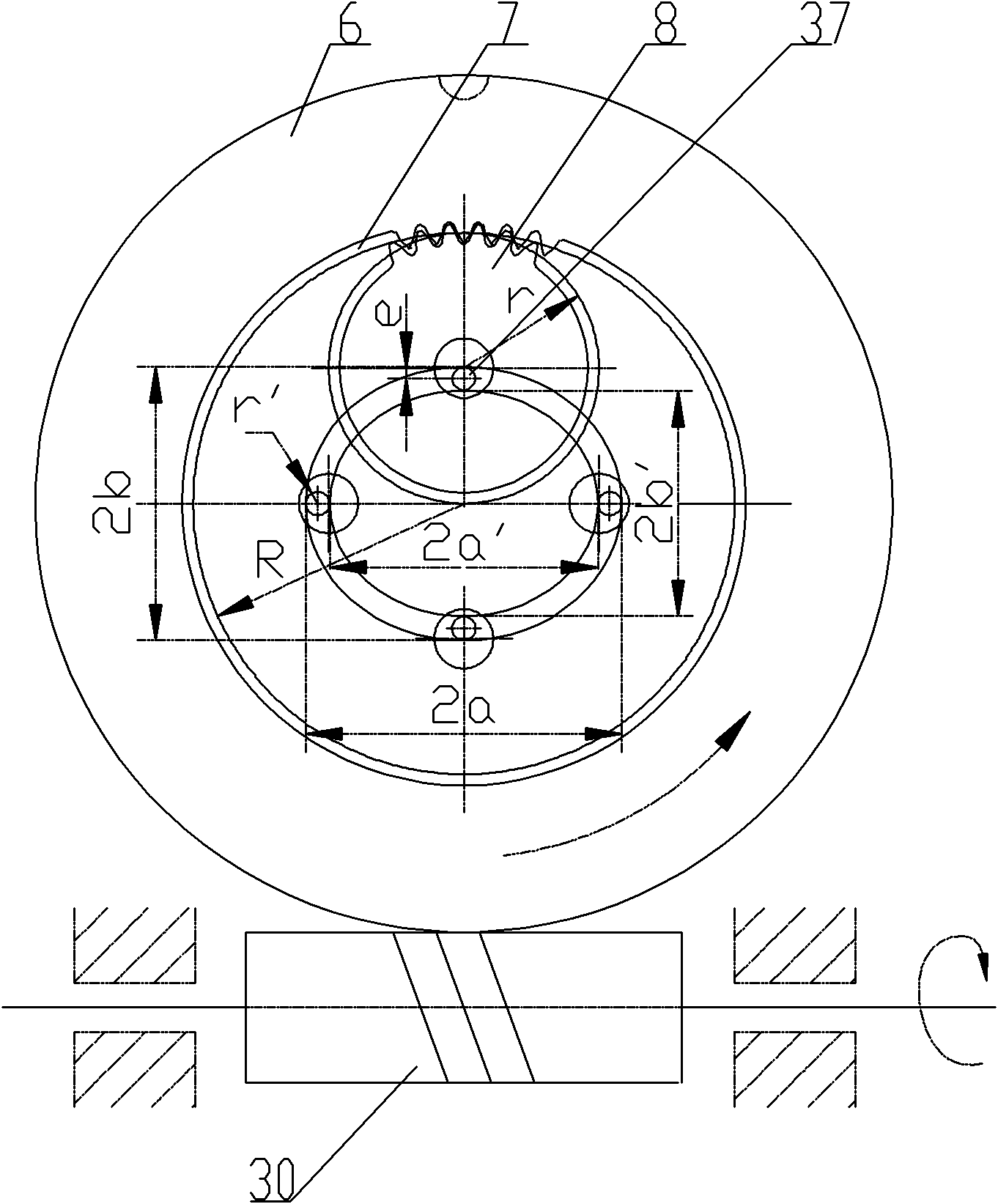

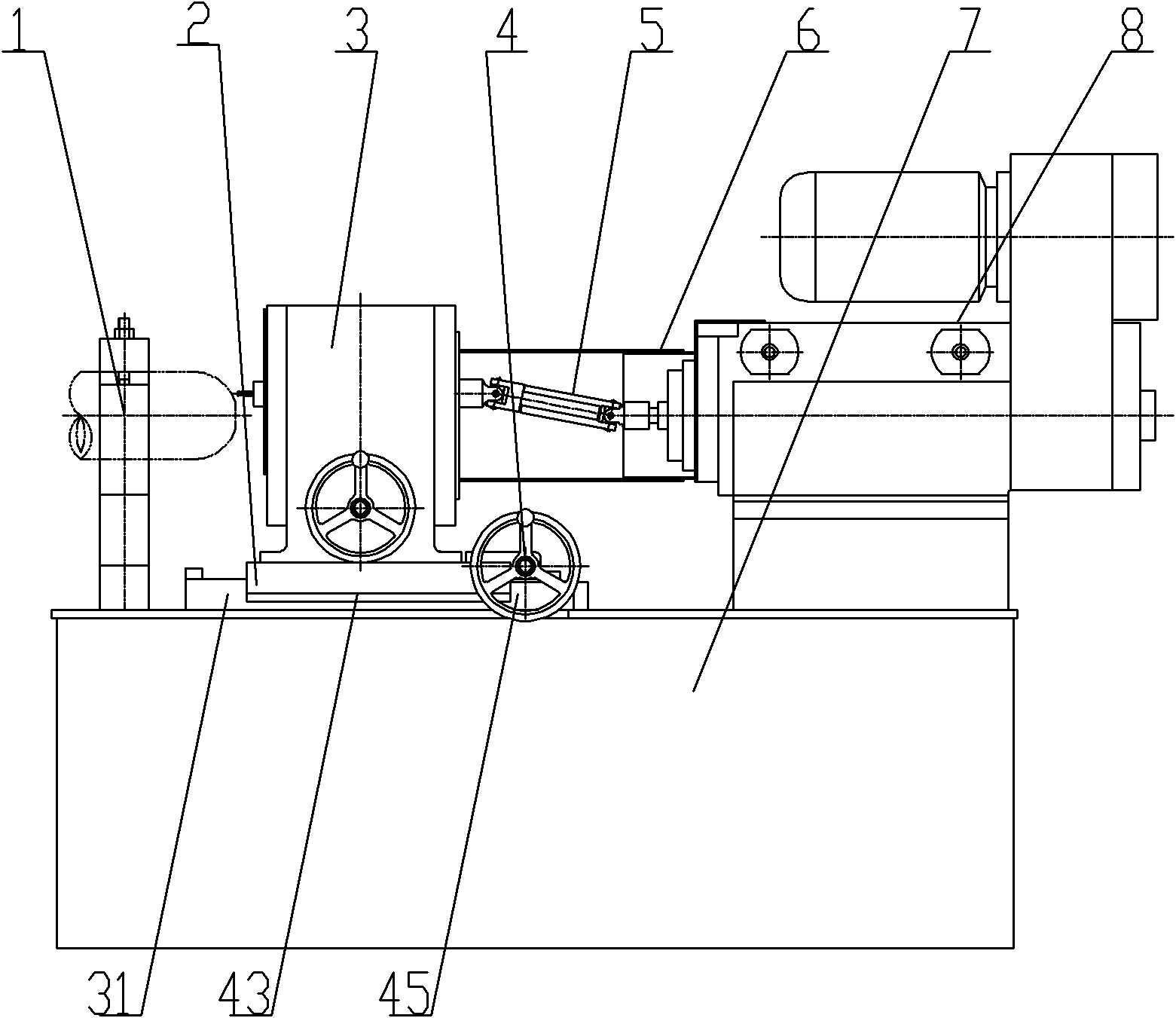

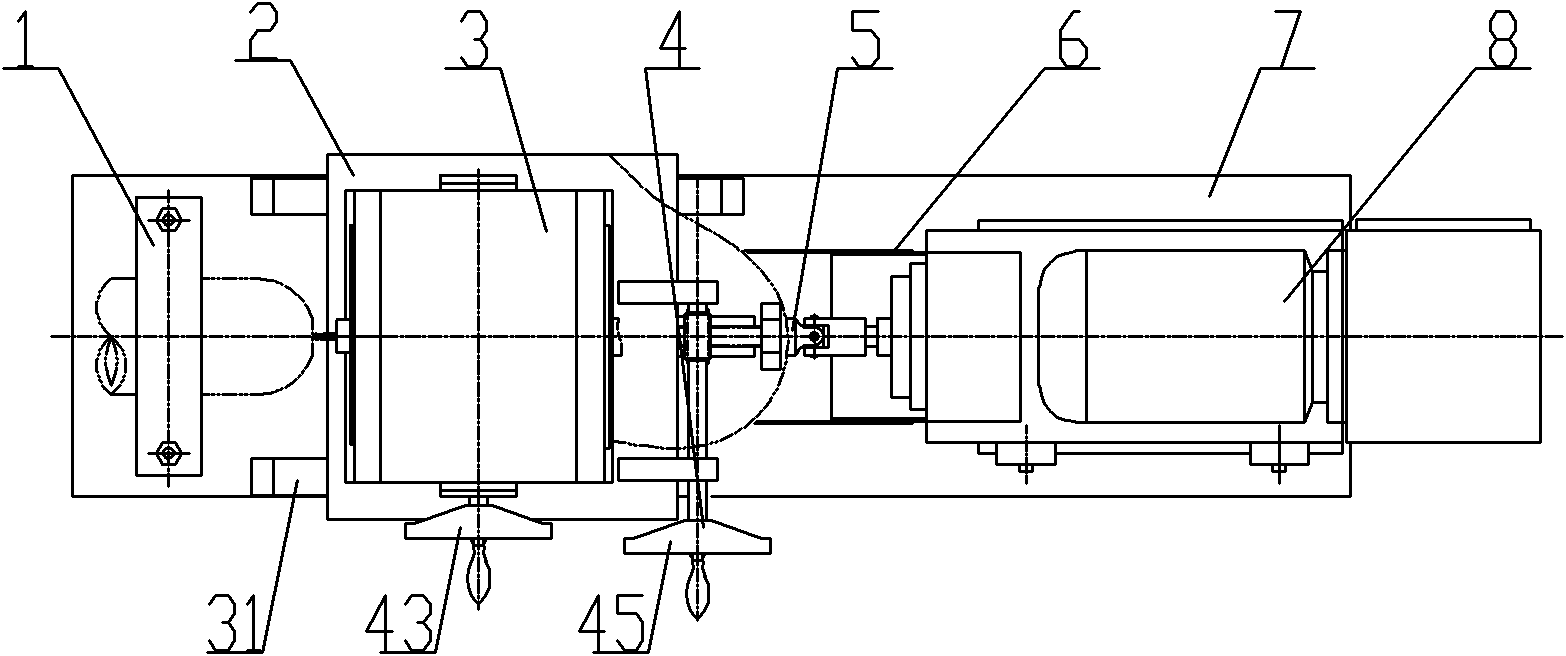

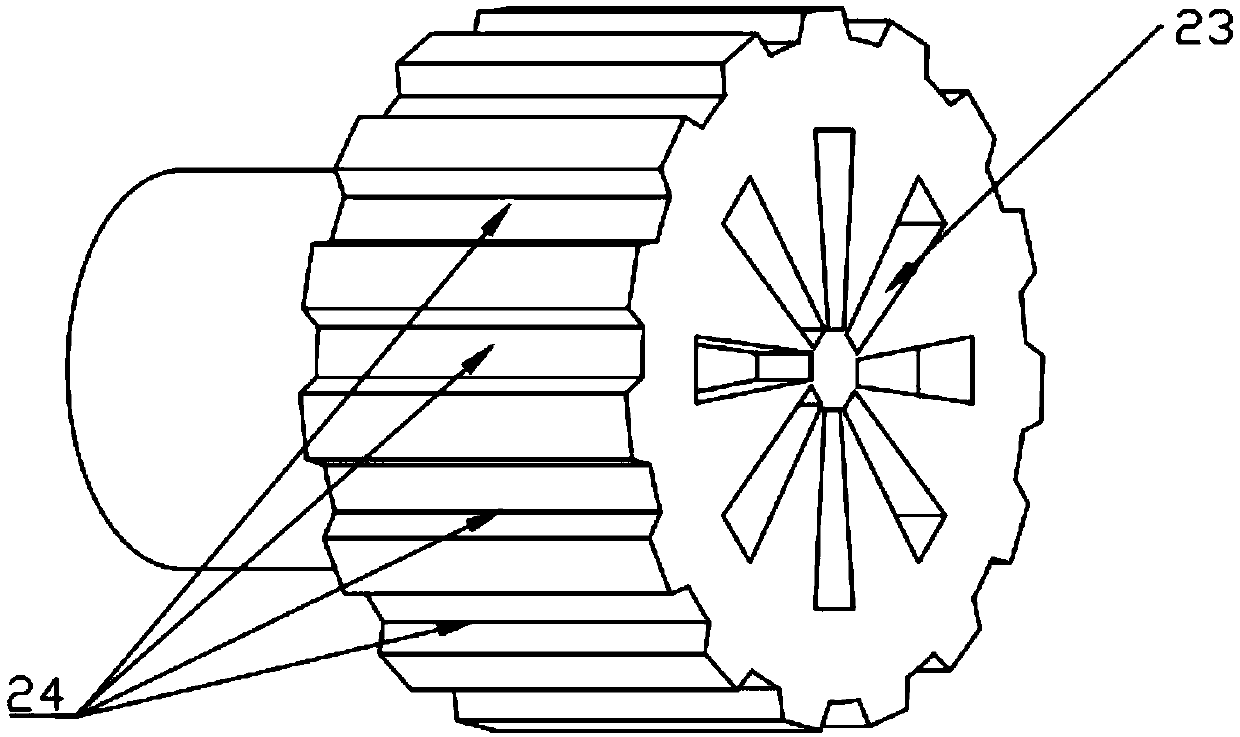

Elliptical hole machining device

ActiveCN101941092AConvenient in placeAccurateFeeding apparatusMilling equipment detailsCouplingDiameter ratio

The invention relates to an elliptical hole machining device. A workpiece clamping device, a spindle box and a power head are arranged on a seat frame; the spindle box is arranged above a longitudinal feeding device; a hollow worm wheel spindle, a circumferential feeding worm wheel and a circumferential feeding worm spindle are arranged inside the box; a first eccentric axial through hole is formed on the hollow worm wheel spindle; a hollow shaft is arranged in the first eccentric axial through hole; the two ends of the hollow shaft are fixedly connected with pinions respectively; the pinions are meshed with internal gears which are fixedly connected at the two ends of the box; the gear ratio and the pitch diameter ratio of the internal gears and the pinions are both 2:1; second eccentric axial through holes are formed on the two pinions; a cutter spindle is arranged in the second eccentric axial through holes; one end of the cutter spindle is provided with a cutter; and the other end of the cutter spindle is connected with the power head through a telescopic universal coupling. The elliptical hole in the invention has a smooth formed surface, accurate dimension and high quality, and the elliptical hole machining device can meet batch machining of different elliptical holes with low machining cost.

Owner:WUXI HUAGUANG IND BOILER

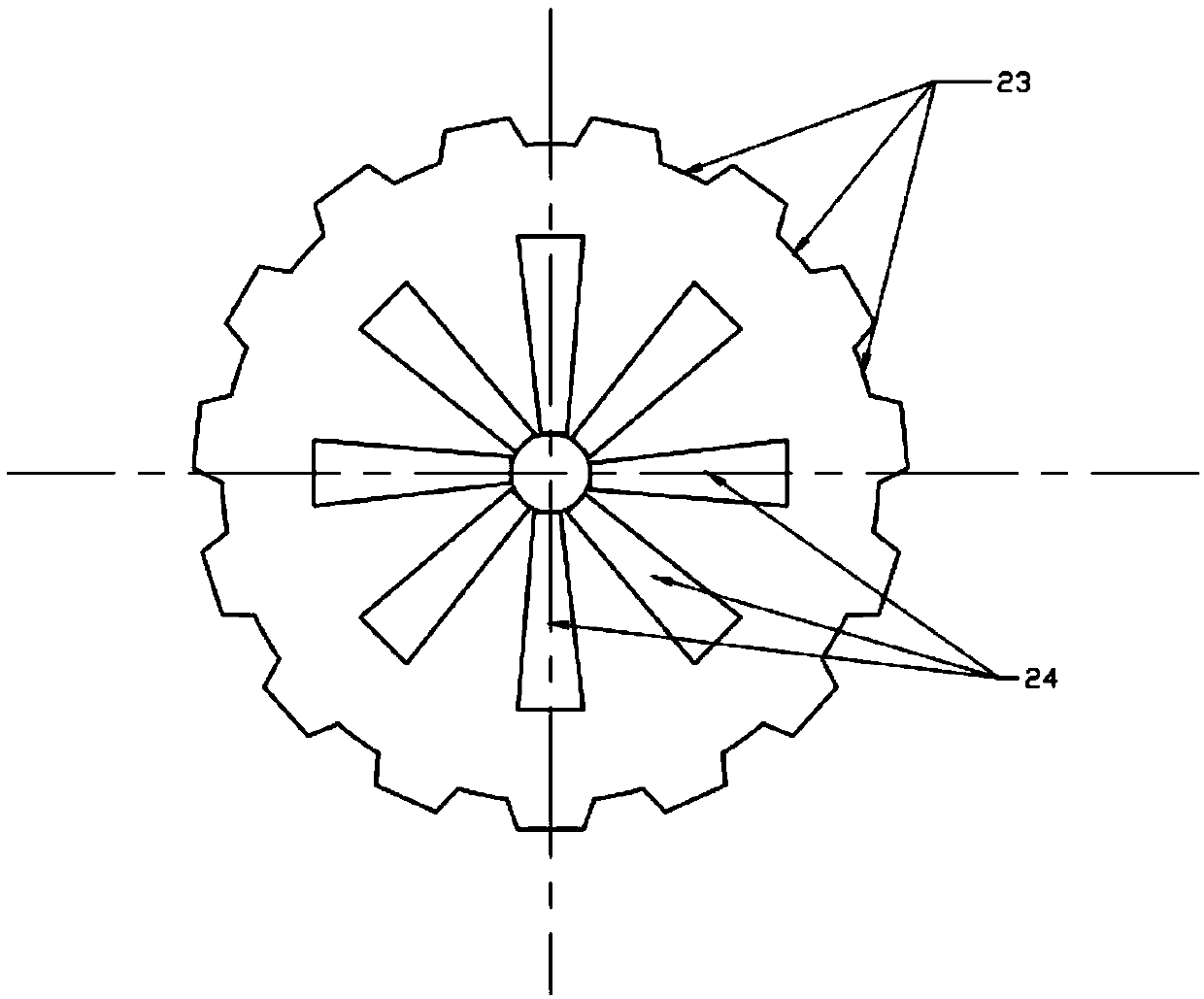

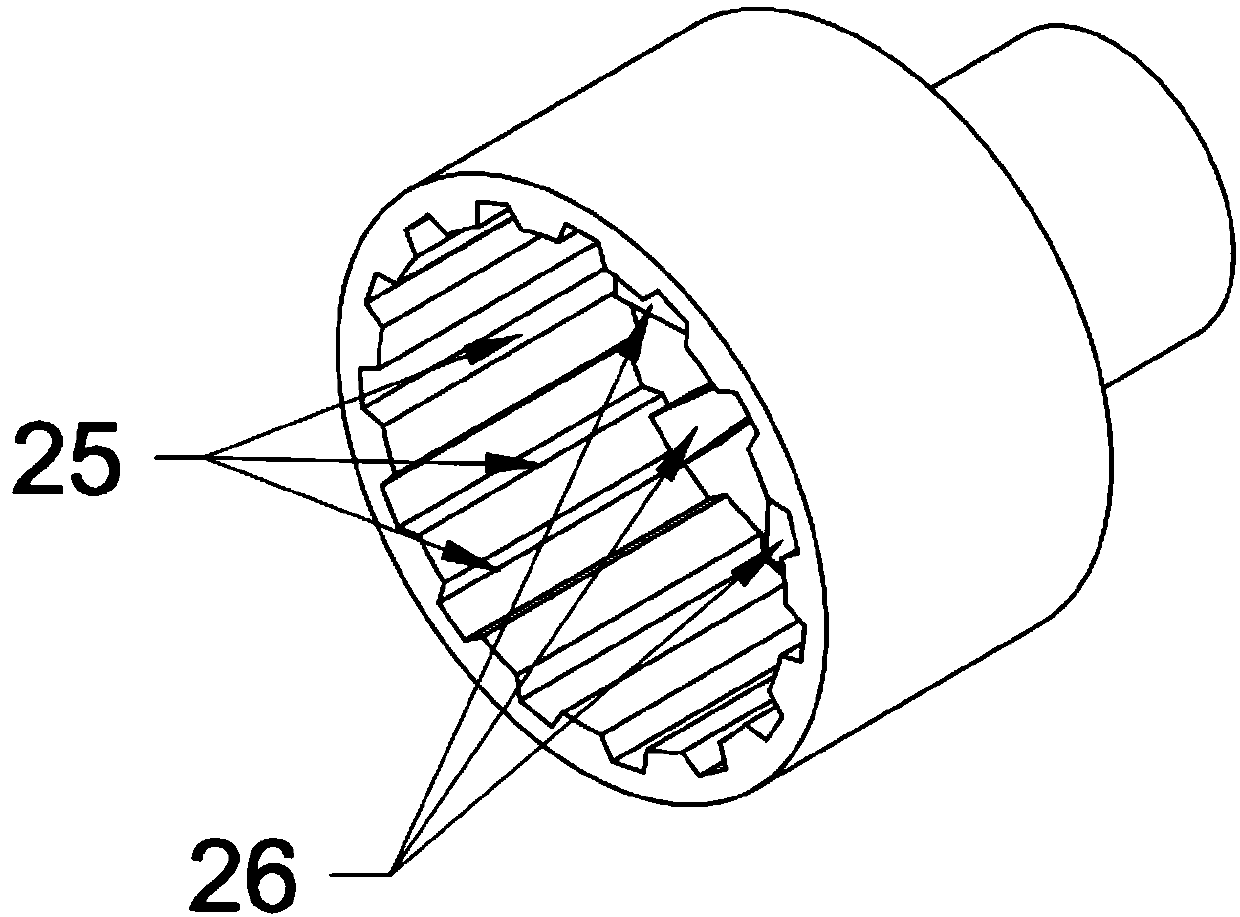

Trapezoidal inner wall cylindrical coupling based on magnetorheological fluid

ActiveCN109578460AImprove the vibration isolation effectReduce vibrationFluid clutchesConvex structureMagnetic current

The invention relates to a trapezoidal inner wall cylindrical coupling based on a magnetorheological fluid, which consists of an input group and an output group, wherein the input group comprises an input shaft, an input end shell, an electromagnetic coil and the like; and the output group comprises an output shaft, a spring, an output end shell and the like. a groove structure at the tail end ofthe input shaft is matched with a convex structure at the tail end of the output shaft; trapezoidal teeth at the outer circumference of the input shaft are matched with trapezoidal grooves at the inner circle side of the output shaft; the matching surfaces are all filled with magnetorheological fluid, and the input end shell and the output end shell are connected and sealed. The coupling providedby the invention is provided with a trapezoidal teeth - trapezoidal grooves structure; the spring is added at the axial direction so as to increase the horizontal vibration isolation effect and reducethe vibration and noise when the coupling works; meanwhile, the coupling has the advantages of simple structure, convenient processing and maintenance, etc. , so the coupling is suitable for non-high-power places and can achieve good vibration isolation effect without precise design and processed components. The coupling provided by the invention solves the problems of vibration and noise generated by mechanical contact the automobile coupling during the process of transmitting force and moment.

Owner:JILIN UNIV

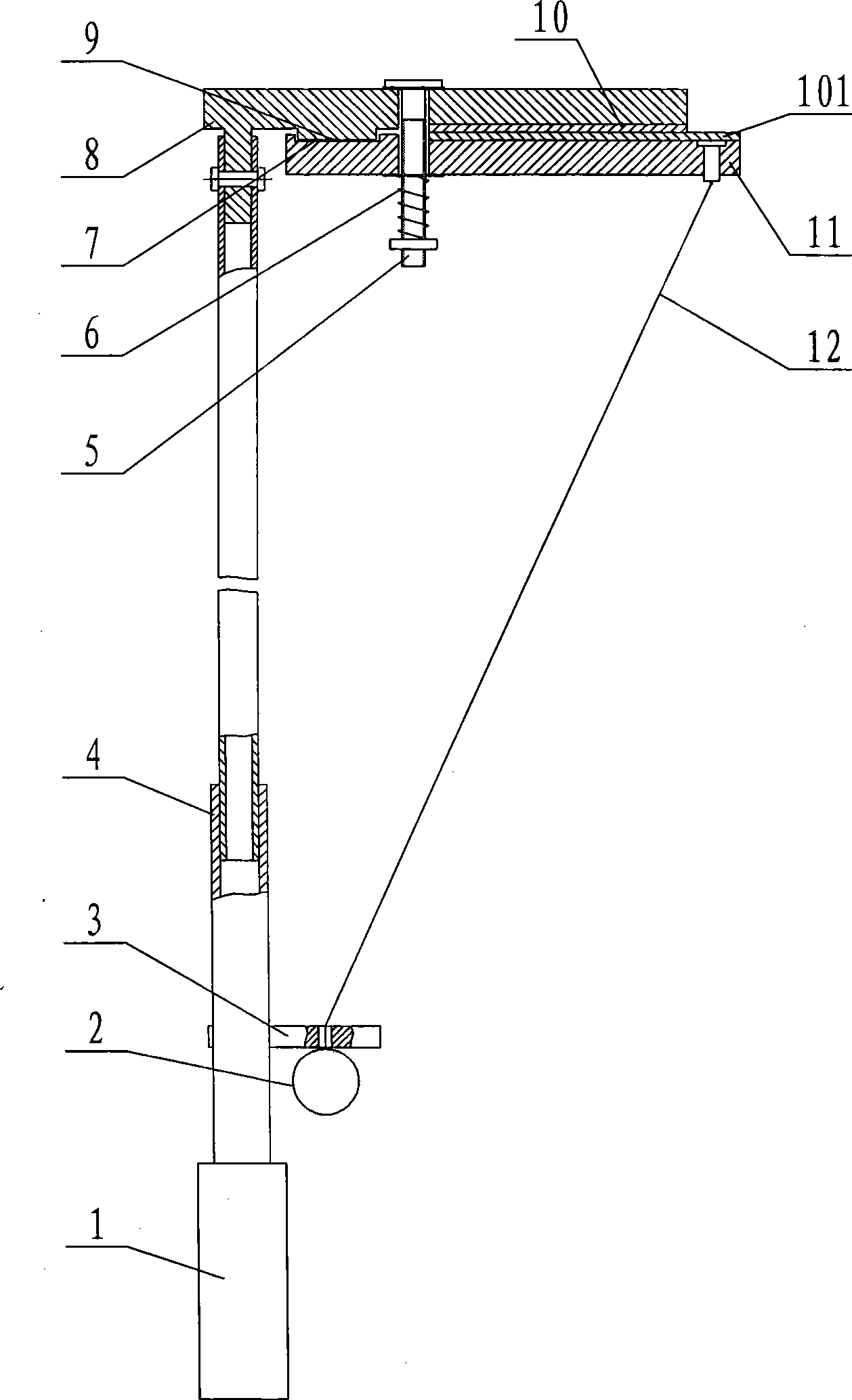

Seedling transplantation device

InactiveCN101390461AEasy to transplantWide range of transplantsTransplantingEngineeringUltimate tensile strength

The invention relates to a seedling transplanter; the seedling transplanter comprises a telescopic rod (4); one end of the telescopic rod is provided with a handle (1), while the other end is provided with a transplanting mechanism; the seedling transplanter is characterized in that the transplanting mechanism comprises a fixed splint (8), a movable splint (11), a pin (5) and a pull cord (12); the fixed splint is fixedly connected on the telescopic rod (4); the movable splint is movably connected with the fixed splint through the pin (5); a reset spring (6) is sleeved on the pin; and one end of the movable splint is connected with the pull cord (12). The device controls the separation and assembling between the movable splint and the fixed splint through the pull cord so as to achieve seedling transplanting; besides, the device is light and flexible and has simple structure, low cost, wide transplanting range, high efficiency of transplantation and low labor intensity, which can be conveniently and rapidly operated on the ridge with one hand.

Owner:丁培然

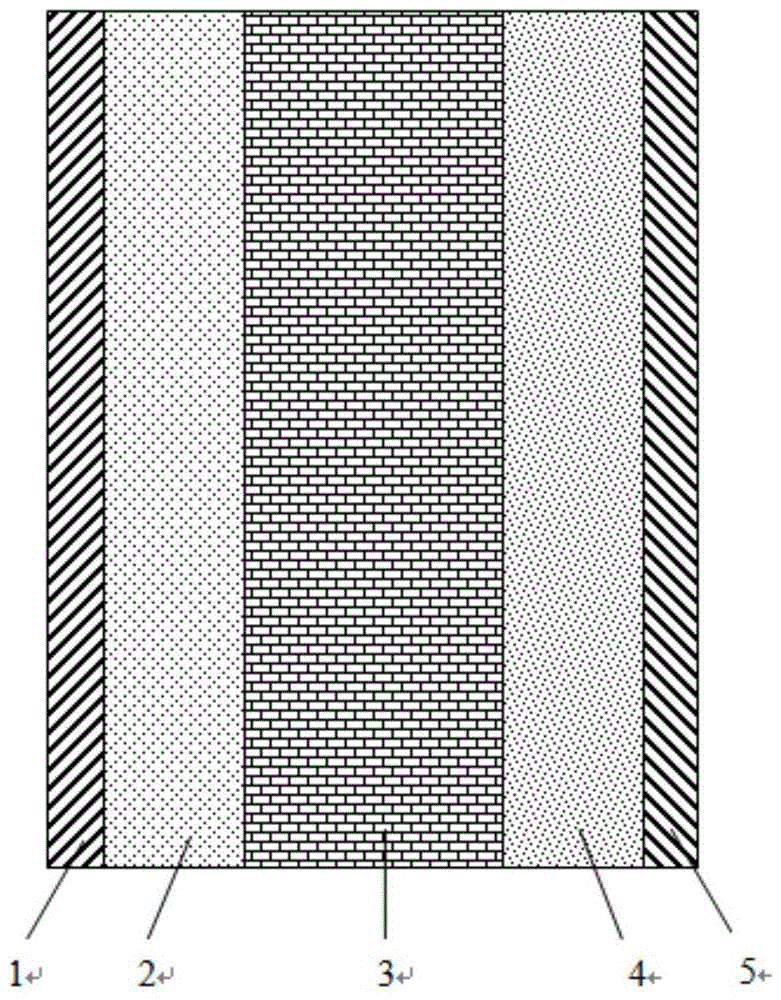

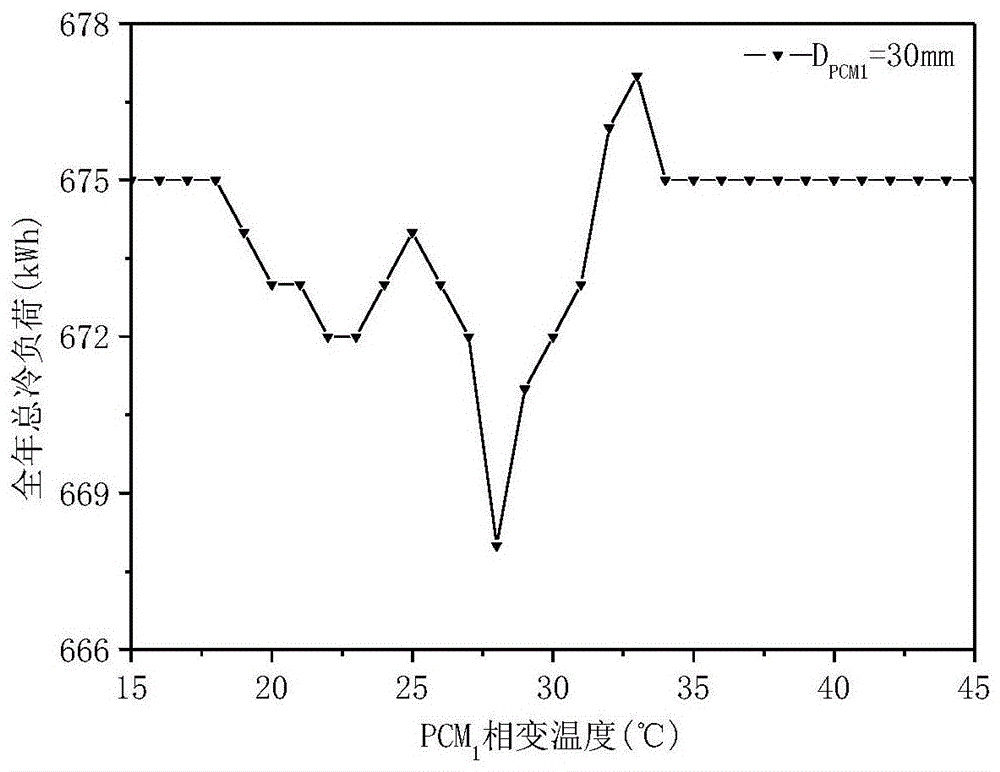

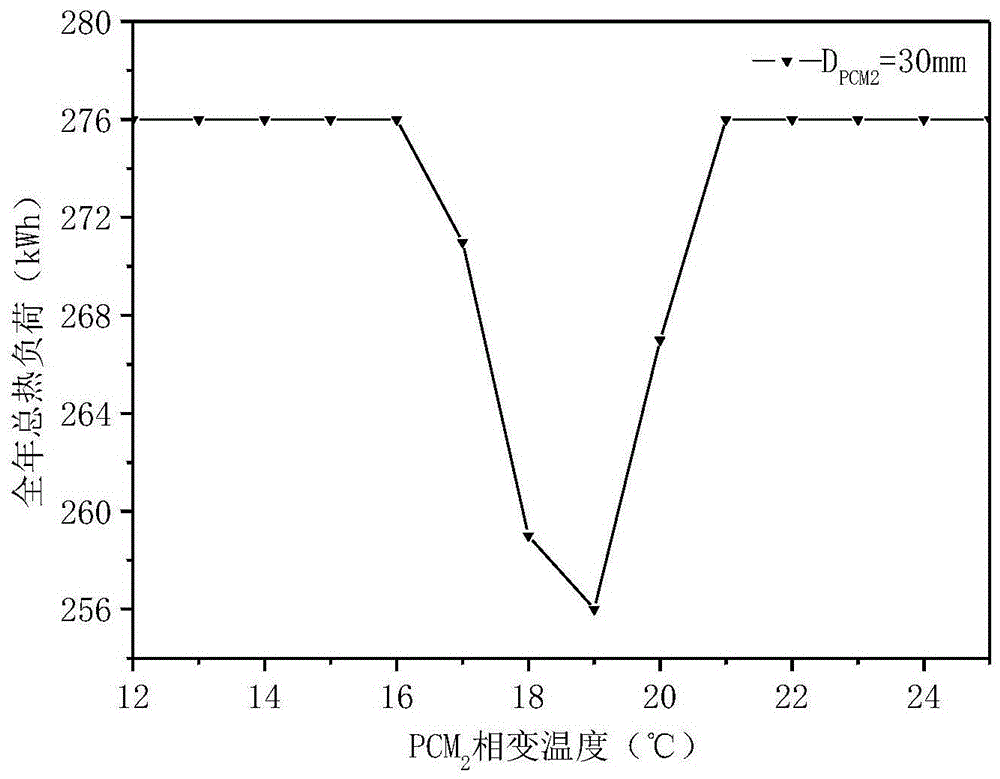

A building exterior wall structure with double-layer stereotyped phase-change material layers

InactiveCN104674978BLarge latent heatEasy processing and maintenanceWallsHeat-exchange elementsThermal insulationAmorphous phase

The invention discloses a building outer wall structure with double shaping phase change material layers. The building outer wall structure sequentially comprises the outer shaping phase change wall board layer, a first thermal insulation layer, a wall body layer, a second thermal insulation layer, the inner shaping phase change wall board layer from outside to inside, wherein the outer shaping phase change wall board layer and the inner shaping phase change wall board layer are respectively made of phase change materials of phase change temperatures of Tm1 and Tm2, the phase change temperature Tm1 is set to be minimum in cold load all year round in the expositing environment of the phase change temperature Tm1, and the solid phase change materials melt into liquid phase change materials when the wall board layer temperature is equal to or higher than Tm1; the phase change temperature Tm2 is set to be minimum in heat load all year round in the exposing environment of the phase change temperature Tm2, and the solid phase change materials melt into liquid phase change materials when the wall board layer temperature is equal to or higher than Tm2. The invention further designs the components and proportion of the phase change materials of the two shaping phase change wall board layers. By the building outer wall structure which is compact, high in adaptability, convenient to manufacture and maintain later, and the like, outer wall cold load and heat load can be lowered effectively, and overall energy consumption is lowered evidently.

Owner:HUAZHONG UNIV OF SCI & TECH

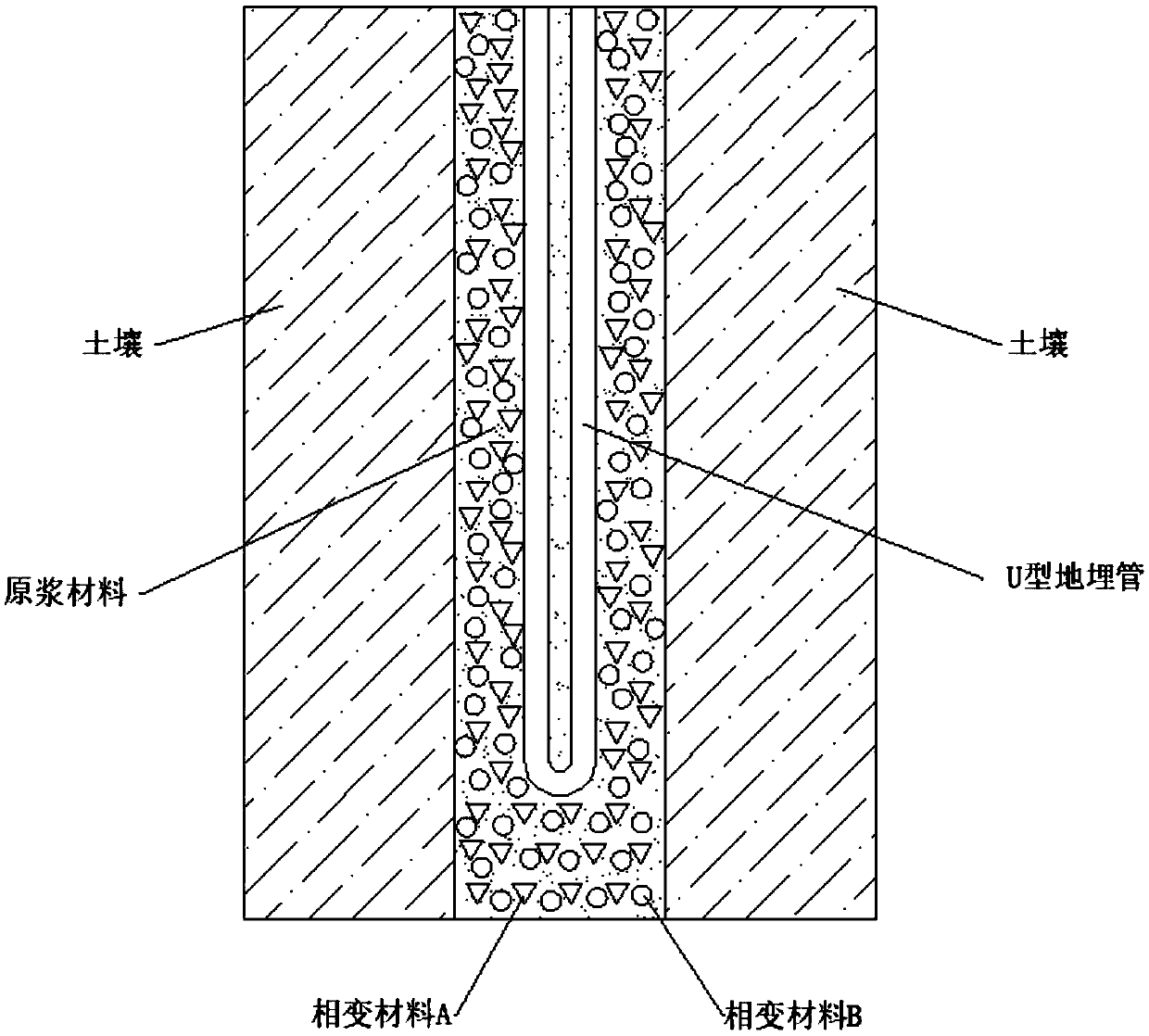

Ground heat exchanging system capable of operating all year round

InactiveCN109539612AImplement storageAchieve releaseHeat storage plantsGeothermal collectorsThermal energy storageEngineering

The invention belongs to the field of renewable energy sources and phase change thermal energy storage application, and particularly relates to a ground heat exchanging system capable of operating allyear round. The heat exchanging system comprises a U-shaped buried pipe and backfill materials, and the U-shaped buried pipe and the backfill materials are buried in soil; the backfill materials comprise a phase change material A, a phase change material B and a normal backfill material, wherein the phase change temperature of the phase change material A is higher than the temperature of the soilin summer and is lower than the temperature of water at an inlet of the buried pipe during operating in summer; and the phase change temperature of the phase change material B is lower than the phasechange temperature of the phase change material A, lower than the temperature of the soil in winter, and higher than the temperature of the water at the inlet of the buried pipe during operating in winter. According to the ground heat exchanging system capable of operating all year round, composition and proportions of two microcapsule phase change materials are further designed. According to theground heat exchanging system capable of operating all year round, the backfill diameter and pipe burying depth can be effectively reduced, the system operation COP can be improved, integral energy consumption is significantly reduced, and meanwhile, the ground heat exchanging system capable of operating all year round has the characteristics that the structure is compact, the adaptability is high, and the use period is long.

Owner:HUAZHONG UNIV OF SCI & TECH

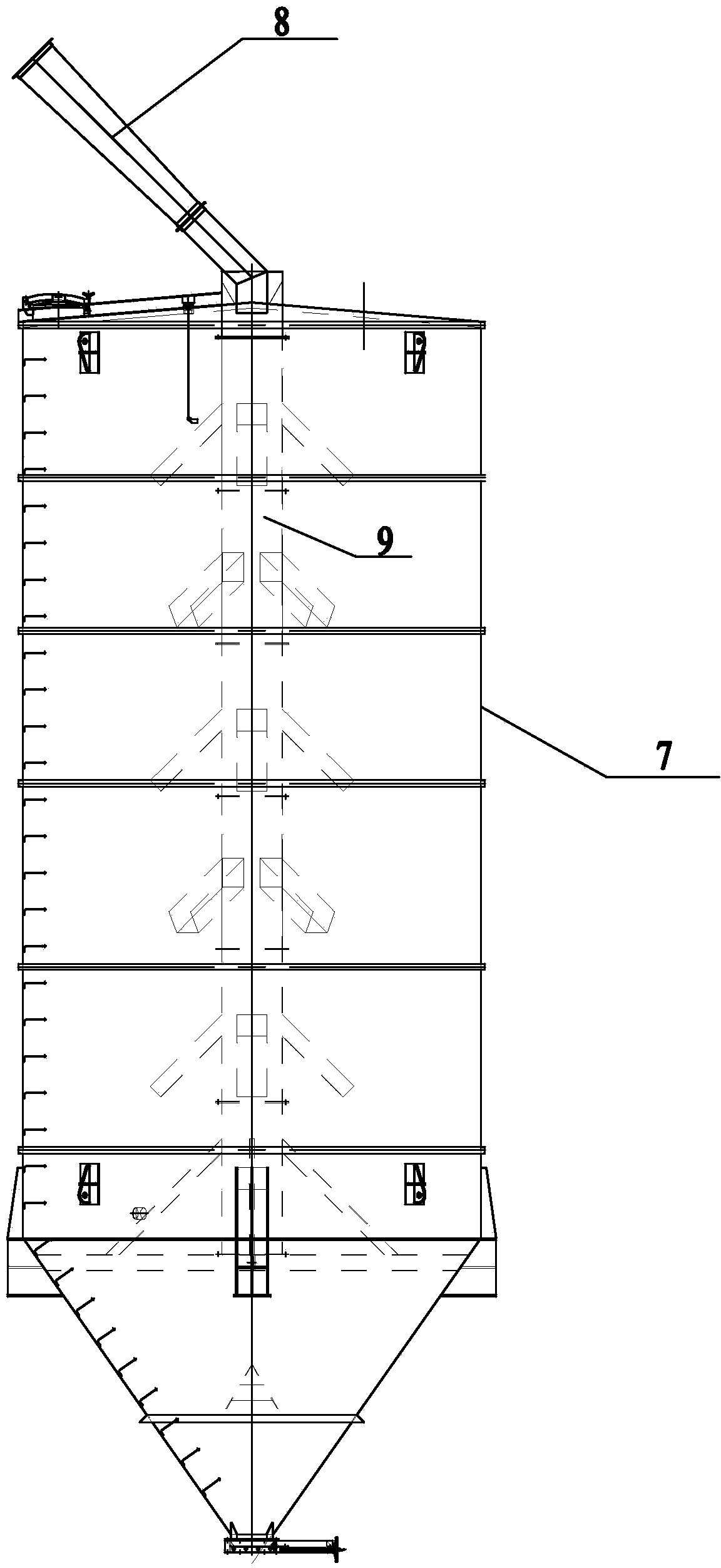

Anti-segregation device of shunt type finished product warehouse

InactiveCN103538148AReduce segregationLow costClay processing apparatusIngredients storageShunt typesEngineering

The invention relates to an anti-segregation device, in particular relates to an anti-segregation device of a shunt type finished product warehouse, belonging to the technical field of processing of ready mixed mortar. According to the technical scheme provided by the invention, the anti-segregation device of the shunt type finished product warehouse comprises a shunting cylinder, wherein a plurality of shunting-discharging pipes, which are staggered, are arranged in the length direction of the shunting cylinder; the shunting-discharging pipes are communicated with the shunting cylinder; the shunting cylinder is formed by in-series connection of a connection top cylinder, an anti-segregation cylinder and a connection bottom cylinder; the shunting-discharging pipes on the anti-segregation cylinder in the shunting cylinder are staggered; a multi-layer anti-segregation cylinder can be used for layering, buffering and discharging, so that the segregation phenomenon is greatly reduced; the anti-segregation device is simple and compact in structure, convenient to process and maintain, low in cost, safe and reliable.

Owner:WUXI XITONG ENG MACHINERY +2

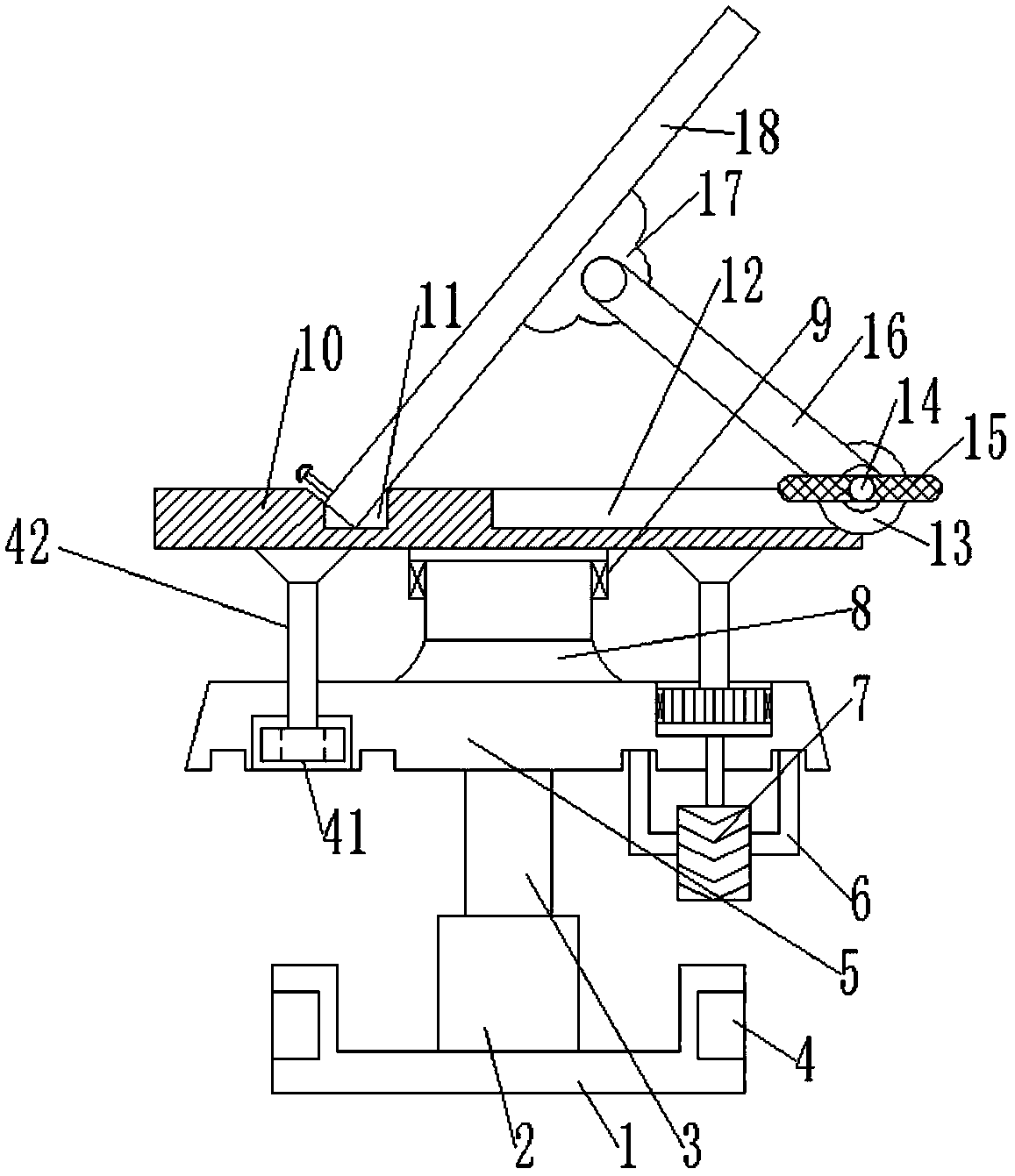

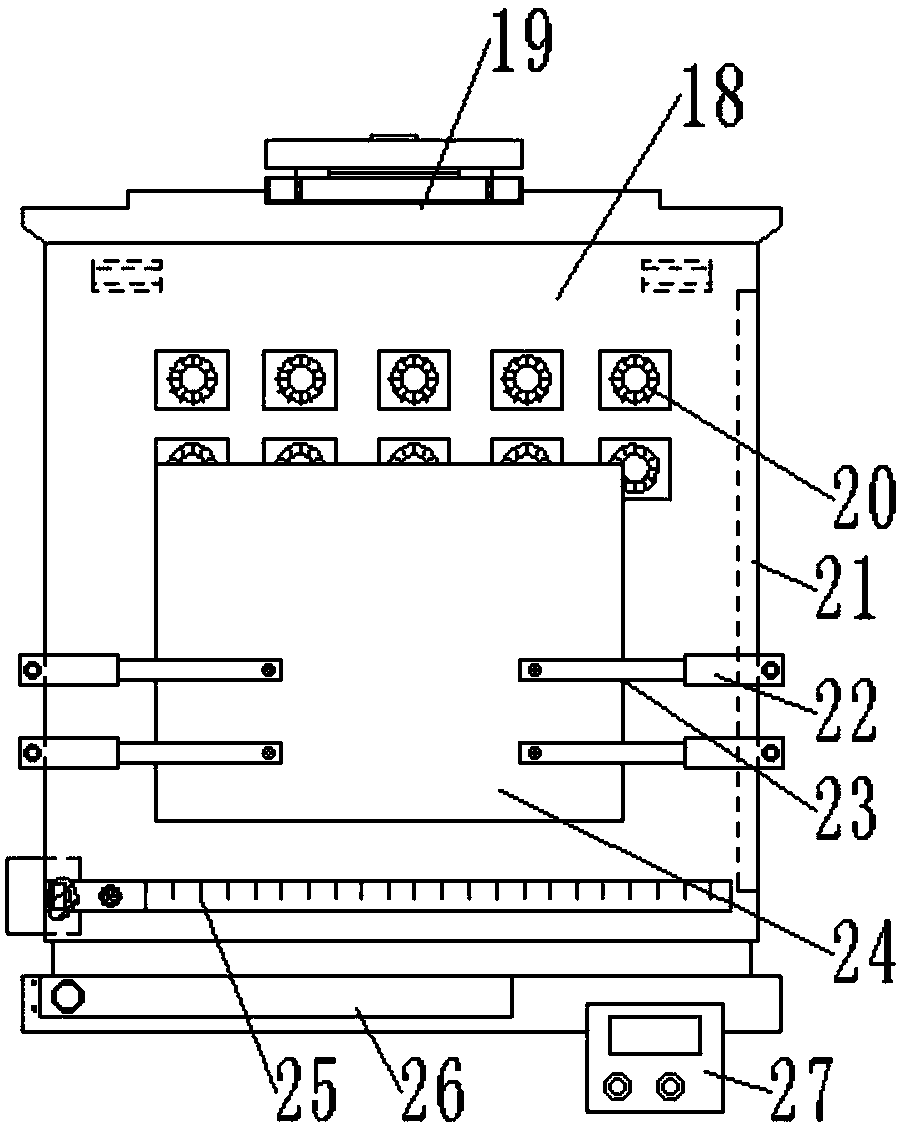

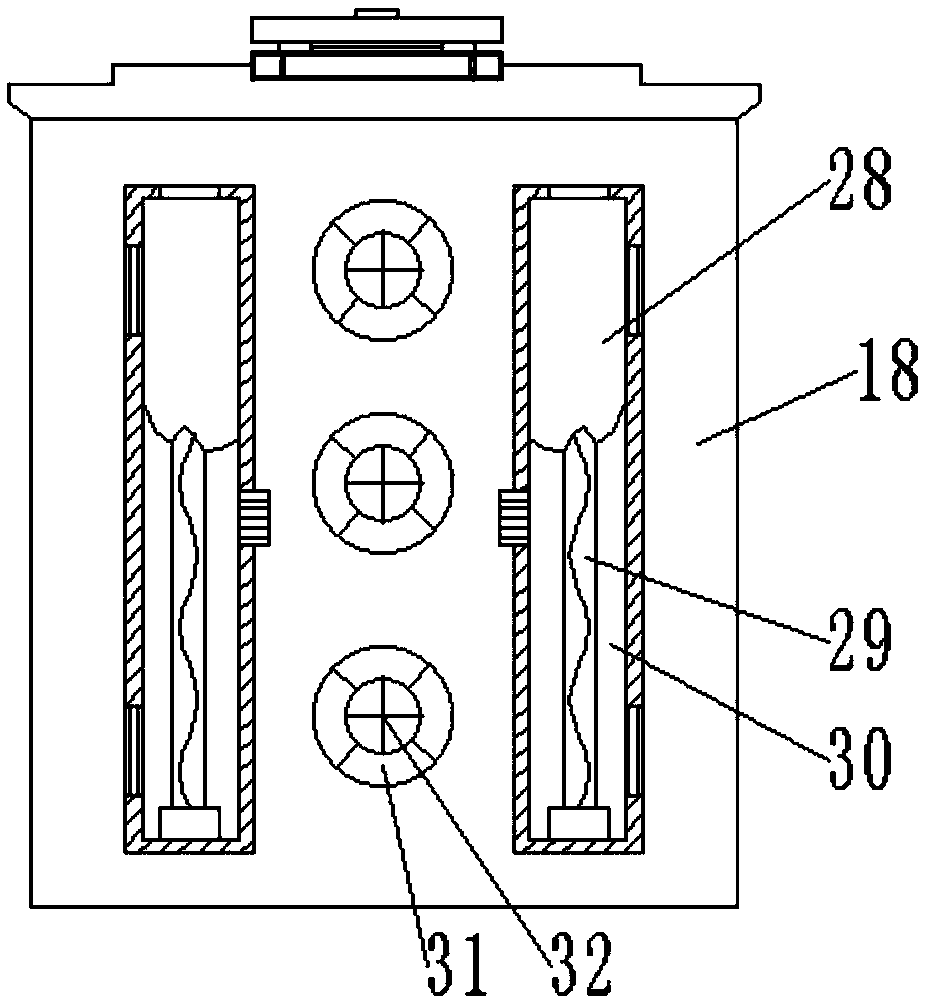

Clamping-fixing device used for electronic product maintenance and convenient to adjust

InactiveCN108672995ARealize multi-angle adjustmentEasy processing and maintenanceWelding/cutting auxillary devicesAuxillary welding devicesTemperature controlFree rotation

The invention belongs to the technical field of electronic products, and particularly discloses a clamping-fixing device used for electronic product maintenance and convenient to adjust. The followingscheme is put forward with regard to the problems that convenient adjustment cannot be carried out on electronic products in a maintenance clamping process, maintenance for the electronic products isnot facilitated, and constant-temperature control cannot be carried out on a welding temperature because a welding manner is generally adopted for the electronic products, so that the maintenance quality of the electronic products is influenced: the clamping-fixing device comprises a fixed base, wherein a fixed barrel is welded to the middle position of the inner wall of the top of the fixed base; and a lifting rod is inserted into the inner wall of the top of the fixed barrel, and slide connection is formed between the lifting rod and the fixed barrel. The clamping-fixing device disclosed bythe invention is capable of realizing multi-angle adjustment for a workbench, and realizing free rotation of a fixed top plate, thereby rotating the workbench; and the movement and fixed support of the device can be facilitated, the workbench can be located in a constant-temperature state, and fixing and accurate location for the electronic products can be realized.

Owner:ZHENGZHOU GERUITA ELECTRONICS INFORMATION TECH CO LTD

Bladder type energy accumulator of various structures and with external air source and oil level control function

PendingCN111396379ANo excessive bendingPlay a sealing roleFluid-pressure actuator testingAccumulator installationsGas supplyEnergy storage

The invention provides a bladder type energy accumulator which is of five structures and has an external air source and an oil level control function. The energy accumulator can horizontally stretch or retreat to deform to store energy, can allow a bladder to be taken out integrally for in-situ replacement, can horizontally or vertically deform to store energy, or has a pull-rod fixed-capacity / variable-capacity control function. According to the operating principle, energy storage is realized through horizontal deformation of the bladder or through main horizontal deformation and auxiliary vertical deformation. According to the structure of the bladder, the diameter of the bladder is half that of a cylinder, the two ends of the bladder are fixed and are open, or one end of the bladder is closed, and the bladder becomes thinner gradually from the two ends to the middle. Oil and gas are separated by the bladder, gas is guided into the bladder, oil is injected outside the bladder, energyconversion is achieved by means of gas pressure changes caused by alternate changes of the volume of oil and the volume of gas, and thus, the purposes of energy storage and release are realized. An automatic alarm device is arranged for oil shortages. Inlet oil can be magnetically filtered. The bladder type energy accumulator has the advantages that the structure is simple, the manufacturing costis lower, machining, manufacturing and maintenance are convenient, and responding is more sensitive; and intelligent control can be achieved, and the bladder type energy accumulator is suitable for alarge-capacity energy storage and closed-loop hydraulic balance system.

Owner:何学才

Combined type rib cutting convex mold

ActiveCN104325509AReduce manufacturing costLess investmentSemiconductor/solid-state device manufacturingMetal working apparatusEngineeringCushion

The invention discloses a combined type rib cutting convex mold. The combined type rib cutting convex mold comprises a rib cutting convex mold set unit and a convex mold fixing plate, wherein the rib cutting convex mold set unit mainly comprises a vertical middle rib cutting convex mold, a bottom rib cutting convex mold, a convex mold pressing block and a rectangular convex mold cushion block; the side edges of the middle rib cutting convex mold and the bottom rib cutting convex mold are sequentially connected to form a rectangular cavity; the convex mold pressing block is positioned in the cavity; the upper end of the convex mold pressing block is fixedly connected with the bottom surface of the convex mold cushion block; annular bosses are arranged on the convex mold cushion block; fixed grooves matched with the bosses are formed in the middle rib cutting convex mold and the bottom rib cutting convex mold; the bosses are positioned in the fixed grooves. Compared with the prior art, for the combined type rib cutting convex mold, the production cost of an integrated circuit product is reduced; the production efficiency is improved; the structure of the rib cutting convex mold of the integrated circuit product rib cutting process is improved; the combined type rib cutting convex mold is simple in structure and convenient to process and maintain; the production efficiency is doubled; the mold investment is reduced; the combined type rib cutting convex mold has the necessity of popularization, implementation and application.

Owner:CHENGDU SHANGMING IND

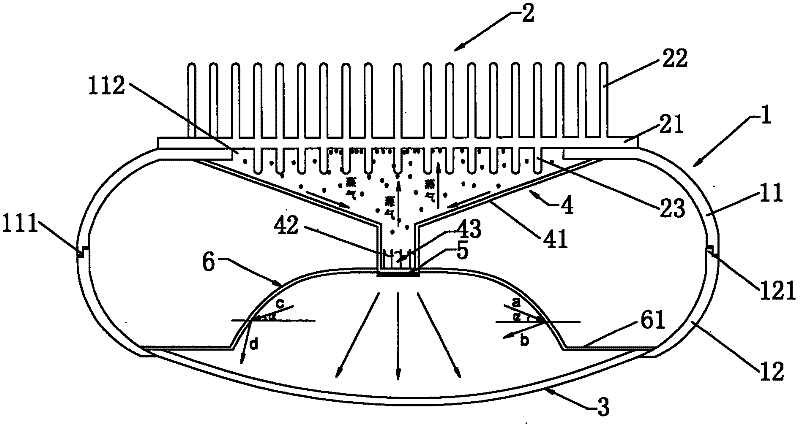

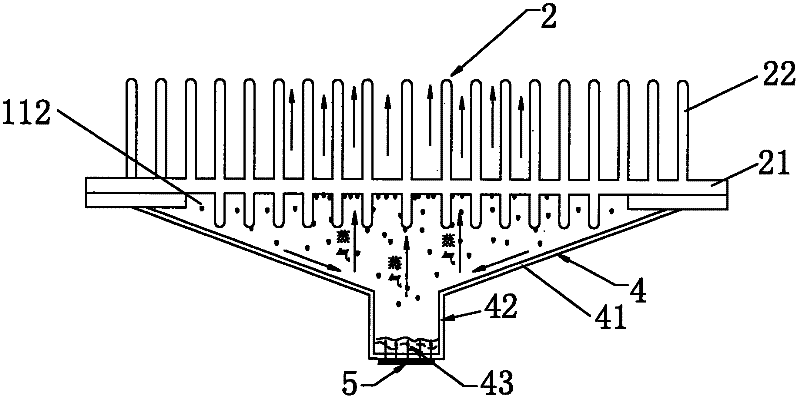

LED street lamp

InactiveCN101598282BControl temperature riseGuaranteed service lifePoint-like light sourceSemiconductor/solid-state device detailsBoiling pointVaporization

Owner:深圳市阳光富源科技有限公司

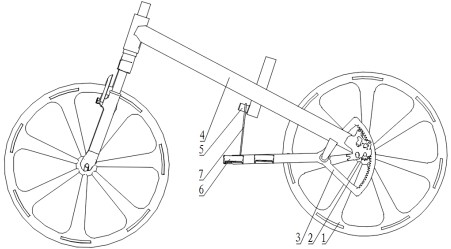

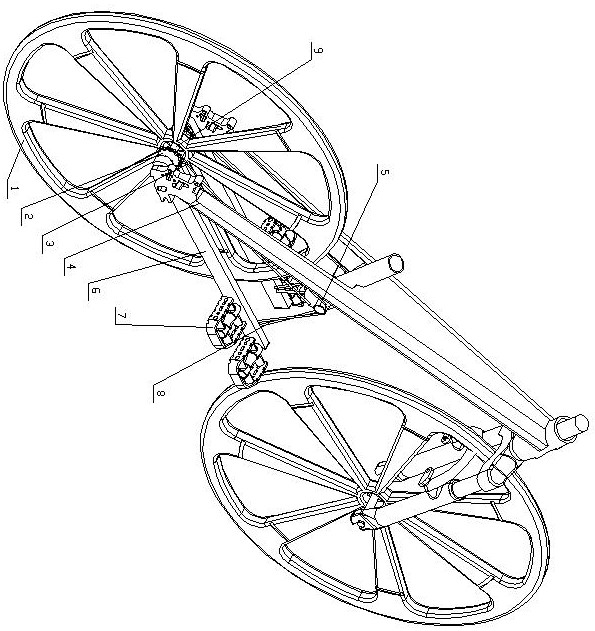

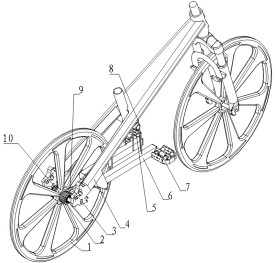

Bicycle gear transmission mechanism

InactiveCN112874688AGuaranteed linkageAchieve variable speedWheel based transmissionRider propulsionRatchetGear drive

The invention provides a bicycle gear transmission mechanism. The bicycle gear transmission mechanism comprises a double-ratchet rear wheel, pinions, fan-shaped inner gears, a rack, a fixed pulley, pedals and a rope. The two pinions are arranged on the double-ratchet rear wheel and then are respectively meshed with the fan-shaped inner gears. The fan-shaped inner gears are arranged on mandrels on two sides of the lower part of a frame. The pedals are installed on lever arms at the front ends of the fan-shaped inner gears, the length of a force arm can be changed by stepping on different positions of the pedals, and speed changing is achieved. The lever arms at the front ends of the two fan-shaped inner gears are wound around the fixed pulley installed on the rack through the rope to be connected together, and pedal linkage is guaranteed. Circumferential motion is replaced by vertical reciprocating motion during riding, work can be done by means of the gravity of a human body, the force exerting function of the human body structure is exerted to the maximum extent, unnecessary force exerting of the human body is reduced, the comfort of a rider is improved, the number of parts is small, design is reasonable, machining and maintenance are easy, transmission protection and sealing lubrication are easy, and large-scale popularization is easy.

Owner:辛永升

Electronic direct current conversion device, printed circuit board (PCB) and electronic direct current conversion method

InactiveCN102739039AReal-time speed adjustmentThe overall structure is simple and reliableApparatus without intermediate ac conversionPrinted circuitsCapacitanceElectrical resistance and conductance

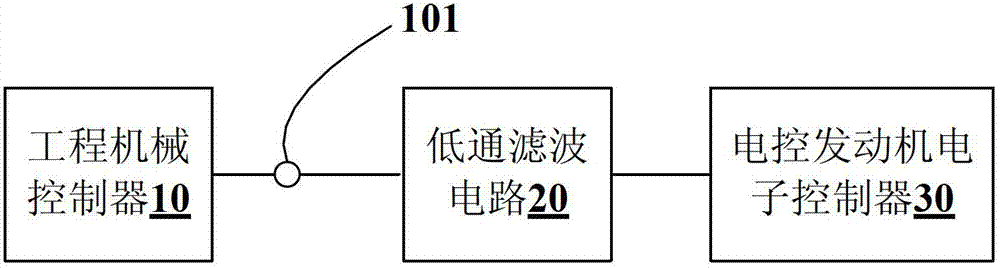

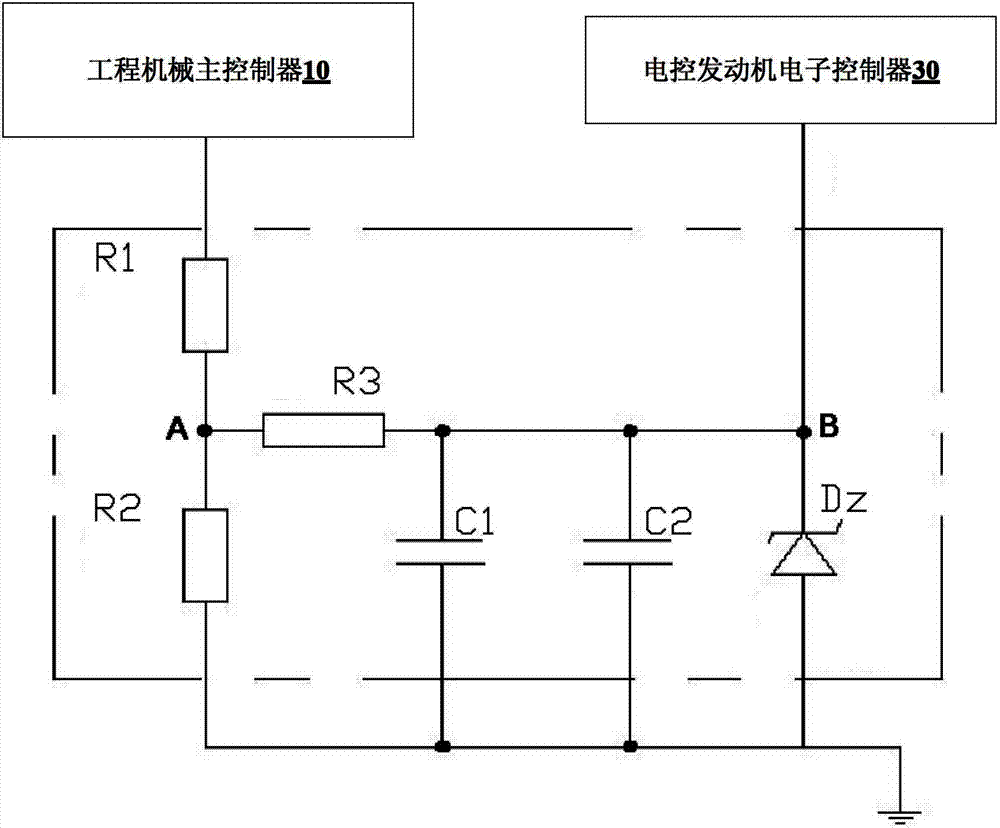

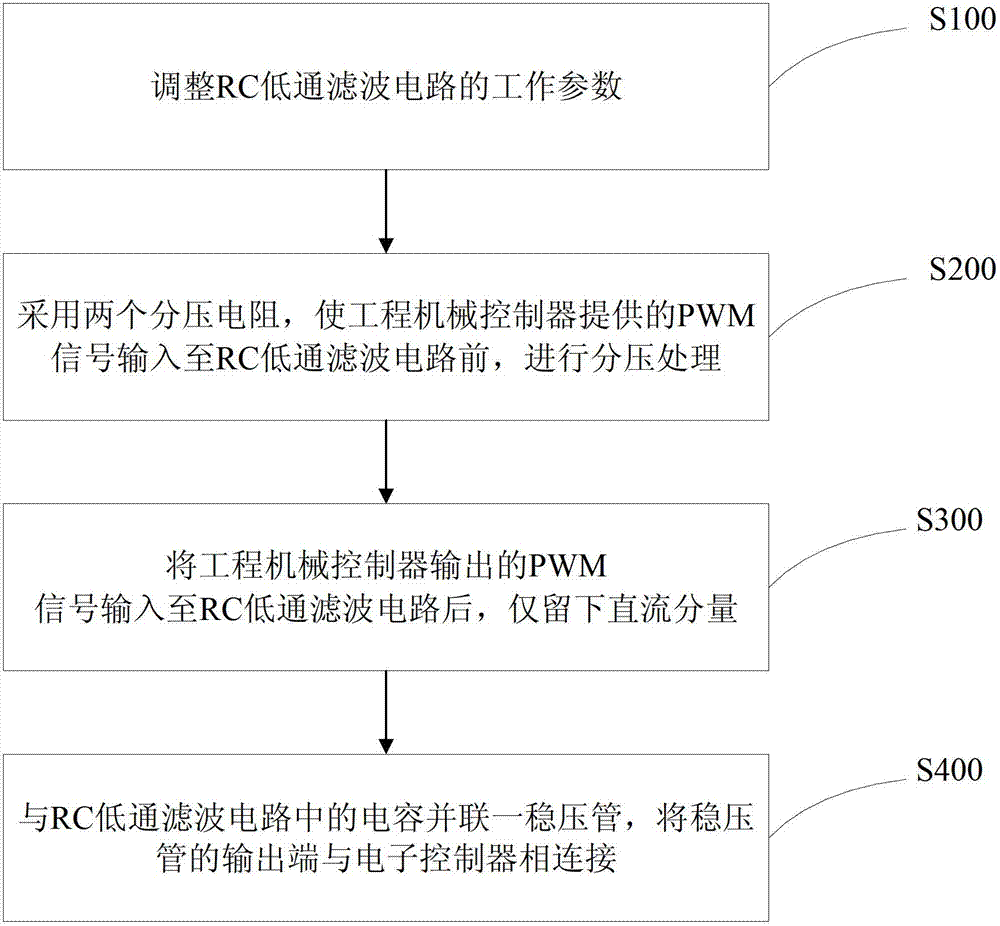

The invention discloses an electronic direct current conversion device, a printed circuit board (PCB) and an electronic direct current conversion method. The electronic direct current conversion device is used for supplying direct current voltage to an electronic controller of an engineering machinery electronic control engine and comprises a low-pass filter circuit, wherein the low-pass filter circuit comprises a filter resistor and a filter capacitor, which are connected with each other; one end of the filter resistor is connected with a pulse width modulation (PWM) signal output end of an engineering machinery controller; and an output end of the filter capacitor is connected with the electronic controller. By the invention, a PWM signal which is output by the engineering machinery controller can be converted into the direct current voltage, and the rotating speed of the engine is regulated in real time.

Owner:SANY HEAVY MACHINERY

A profile and pipe cutting machine

ActiveCN106313160BImprove flatnessIncrease production capacityMetal working apparatusEngineeringKnife blades

The invention provides a cutting machine for profiles and pipes. The cutting machine comprises a first base, a second base and a cutting machine body. A sliding rod is arranged on the first base. The second base can slide leftwards and rightwards on the sliding rod. The second base is provided with a sliding groove used for forward and backward sliding of the cutting machine body, and a positioning air cylinder. The positioning air cylinder is connected with the cutting machine body. A sliding block which is in sliding fit with the sliding groove in the second base is arranged at the bottom of the cutting machine body. A machine head is arranged on the cutting machine body. Lifting air cylinders are arranged on the two sides of the machine head. Two blades and a rotating motor used for driving the blades to rotate are arranged on the machine head. A flat cutting edge and a sawtooth type cutting edge are formed on two corresponding sides of each blade correspondingly. A single-blade or double-blade sharp knife is arranged at one end of each blade. The two blades are fixedly arranged on a rotary shaft with the included angle between the two blades being 180 degrees, and the identical cutting edges of the two blades are in the same direction. A U-shaped silencing structure is arranged at the front end of the machine head. The cutting machine for profiles and pipes is simple in structure, capable of reducing cost, high in cutting capacity and low in nose, and little sawdust is generated.

Owner:CHANGSHA KENBEI TECH

Press moving table rail cleaner

ActiveCN104399683BLight structureEasy processing and maintenanceCleaning using toolsMachine pressEngineering

The invention discloses a press mobile workbench guide rail cleaner, which includes a front pressure plate and a rear pressure plate. An upper support is installed between the upper ends of the front pressure plate and the rear pressure plate. A scraper is installed between the front pressure plate and the rear pressure plate. The front pressure plate is fixed by The bolts and guide bolts are installed on the rear pressure plate, and the rear pressure plate is installed on the mobile workbench through fixed bolts. One end of the adjustment spring is installed on the scraper, and the other end of the adjustment spring is installed on the upper support. Compared with the existing technology, the guide rail cleaner has a lighter structure, not only does the cleaning effect meet the requirements, but also has good economic effects.

Owner:JIER MACHINE TOOL GROUP

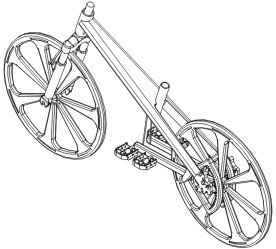

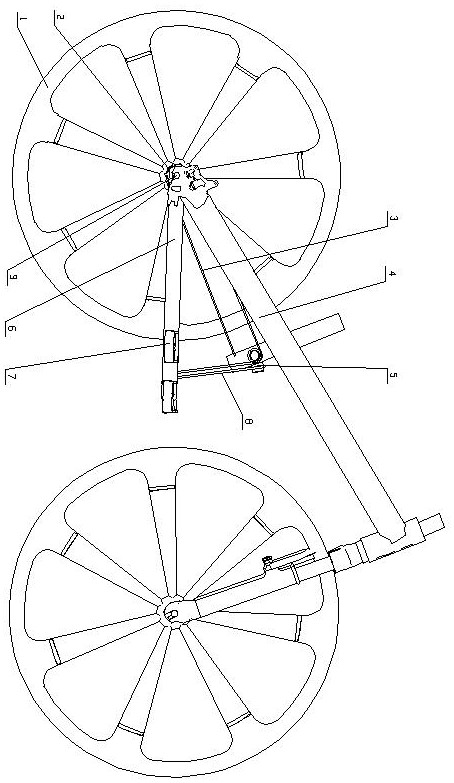

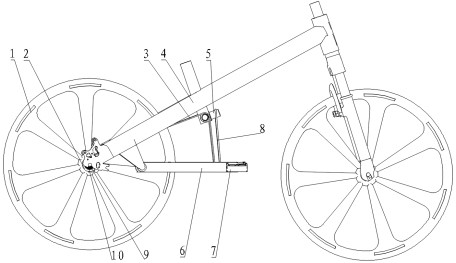

Reciprocating type bicycle and rickshaw transmission mechanism

PendingCN113799904AReduce in quantityConform to the physiological structureRider propulsionRatchetReciprocating motion

The invention provides a reciprocating type bicycle and rickshaw transmission mechanism. The reciprocating type bicycle and rickshaw transmission mechanism comprises a double-ratchet-wheel rear wheel, flywheels, a transmission chain (transmission rope), a rack, a fixed pulley, connecting rods, pedals, a linkage rope and a rear wheel shaft. The two flywheels are installed on the two sides of the double-ratchet-wheel rear wheel, the transmission chain (transmission rope) is of a sectional type, and the rear section has large elasticity. The elastic end of the transmission chain (transmission rope) is fixed on the rack or at the front end of the connecting rod, passes through the flywheel and the fixed pulley, and is finally connected with the corresponding connecting rod; the connecting rod can be mounted on a frame and can also be mounted on a rear wheel shaft; the front ends of the two connecting rods are connected together by winding the fixed pulley on the rack through a linkage rope; and pedals are arranged at the front ends of connecting rod arms. Circumferential motion is replaced by up-down reciprocating motion during riding, work can be done by means of the gravity of a human body, the force exerting function of a human body structure is exerted to the maximum extent, the comfort of a rider is improved, the number of parts is small, machining and maintenance are easy, and large-scale popularization is easy.

Owner:辛永升

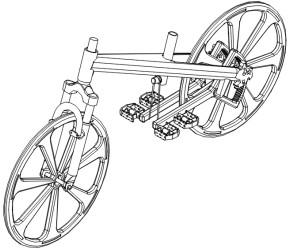

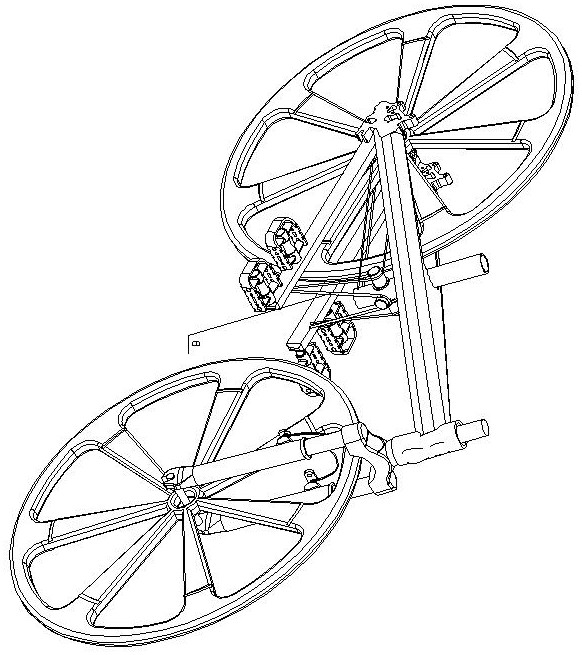

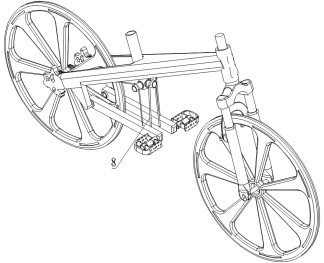

Bicycle rope transmission mechanism

InactiveCN112874691AReduce stiffnessReduce in quantityVehicle transmissionRider propulsionRatchetReciprocating motion

The invention provides a bicycle rope transmission mechanism. The bicycle rope transmission mechanism comprises a double-ratchet-wheel rear wheel, flywheels, a transmission rope, a rack, fixed pulleys, a connecting rods, pedals, a linkage rope, a rear wheel shaft and a volute spiral spring. The two flywheels are installed on the two sides of the double-ratchet-wheel rear wheel, and one end of the transmission rope is fixed to the flywheels, wound on the flywheels for a plurality of circles, then wound around the fixed pulleys installed on the rack and connected with the corresponding connecting rods. A connecting rod mounting shaft can be independently mounted on the rack, and the rear wheel shaft can also be used. The front ends of the two connecting rods are wound around the fixed pulleys installed on the rack through the linkage rope to be connected together, and pedal linkage is guaranteed. One end of the spiral spring is installed on the rear wheel shaft, and the other end is installed on the flywheels to achieve winding recovery of the transmission rope. Circumferential motion is replaced by up-down reciprocating motion during riding, work can be done by means of the gravity of a human body, the force exerting function of the human body structure is exerted to the maximum extent, the comfort of a rider is improved, the number of parts is small, machining and maintenance are easy, and large-scale popularization is easy.

Owner:辛永升

Push plate clamping rod mechanism for garage carrier

The invention discloses a push plate clamping rod mechanism for a garage carrier. The mechanism comprises a toggle plate, a clamping rod and a rail base. Linear rails are arranged on the rail base. Limit steps which are shorter than the linear rail are arranged at the side along the linear rail, of the rail base. A slide column which coordinates with the linear rail on the rail base and a stress column which coordinates with the toggle plate are separately arranged at the bottom and upper portion of the clamping rod. A linear edge which coordinates with the limit steps is arranged at the end portion. According to the push plate clamping rod mechanism for the garage carrier, the clamping rod is driven to coordinate with the linear rails and the limit steps on the rail base through the motion of the toggle plate, and the tire clamping function is achieved through the rotating opening and linear motion of the clamping rod. The mechanism is simple in structure, easy to process and maintain, and capable of reducing production and maintenance cost.

Owner:HUNAN DISHENG IND EQUIP

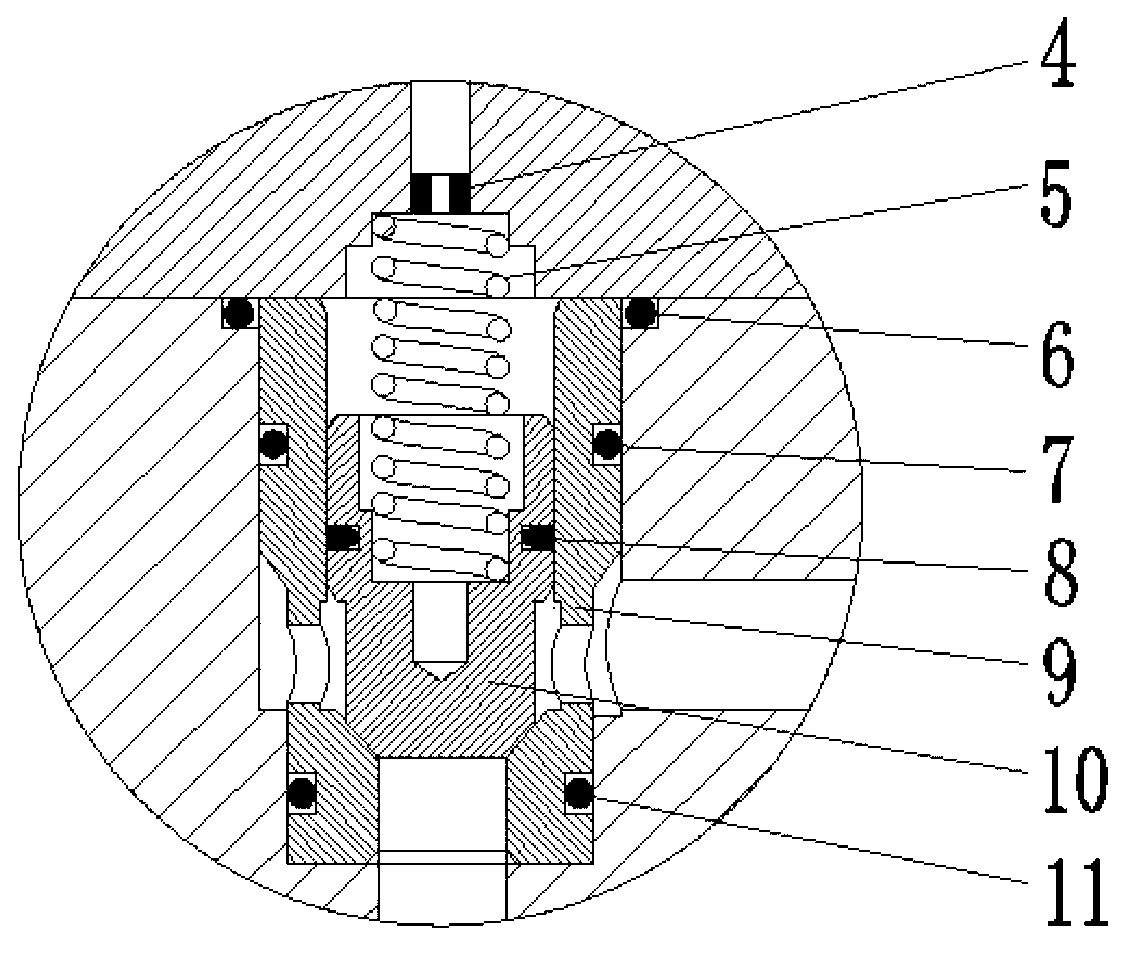

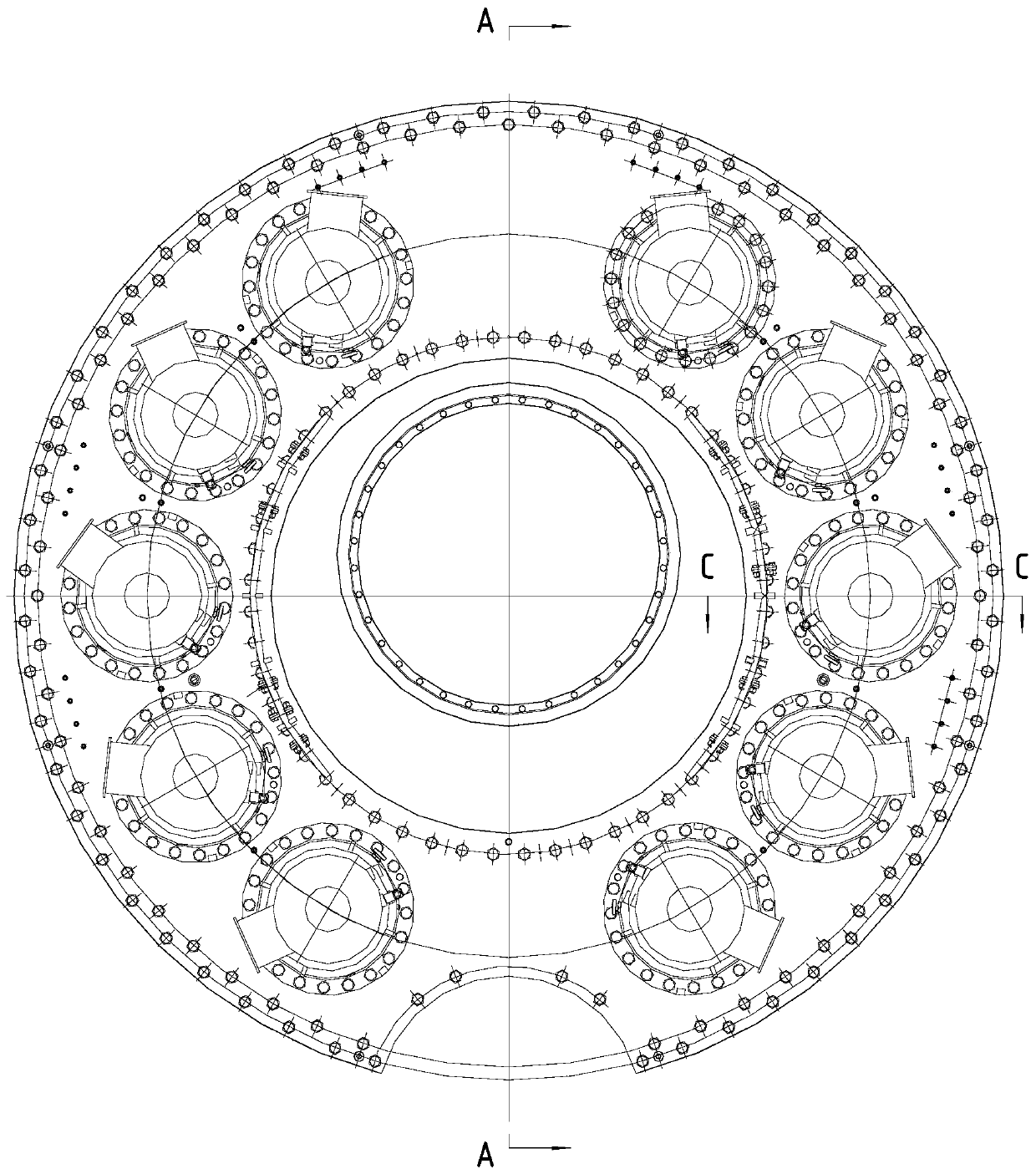

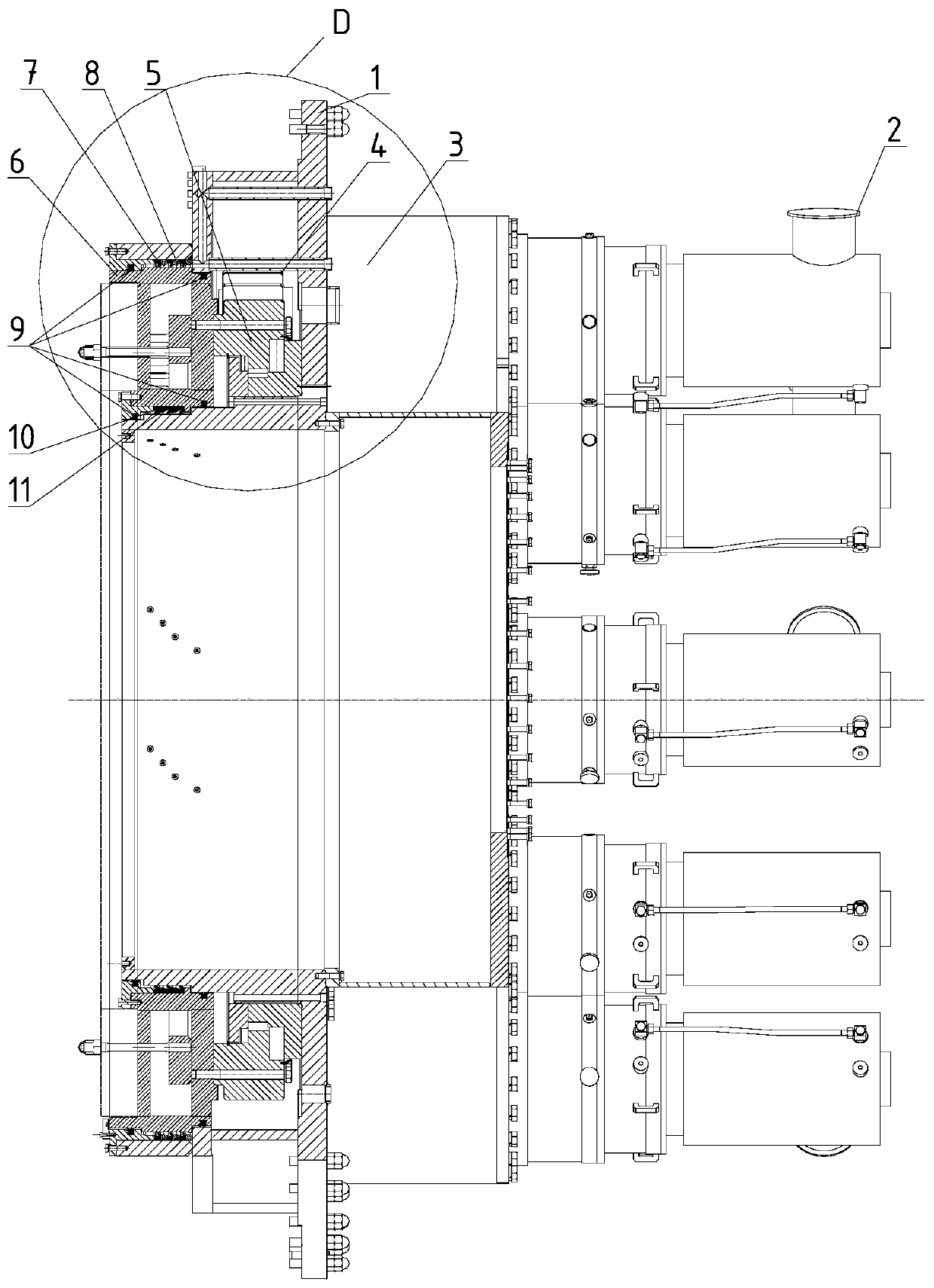

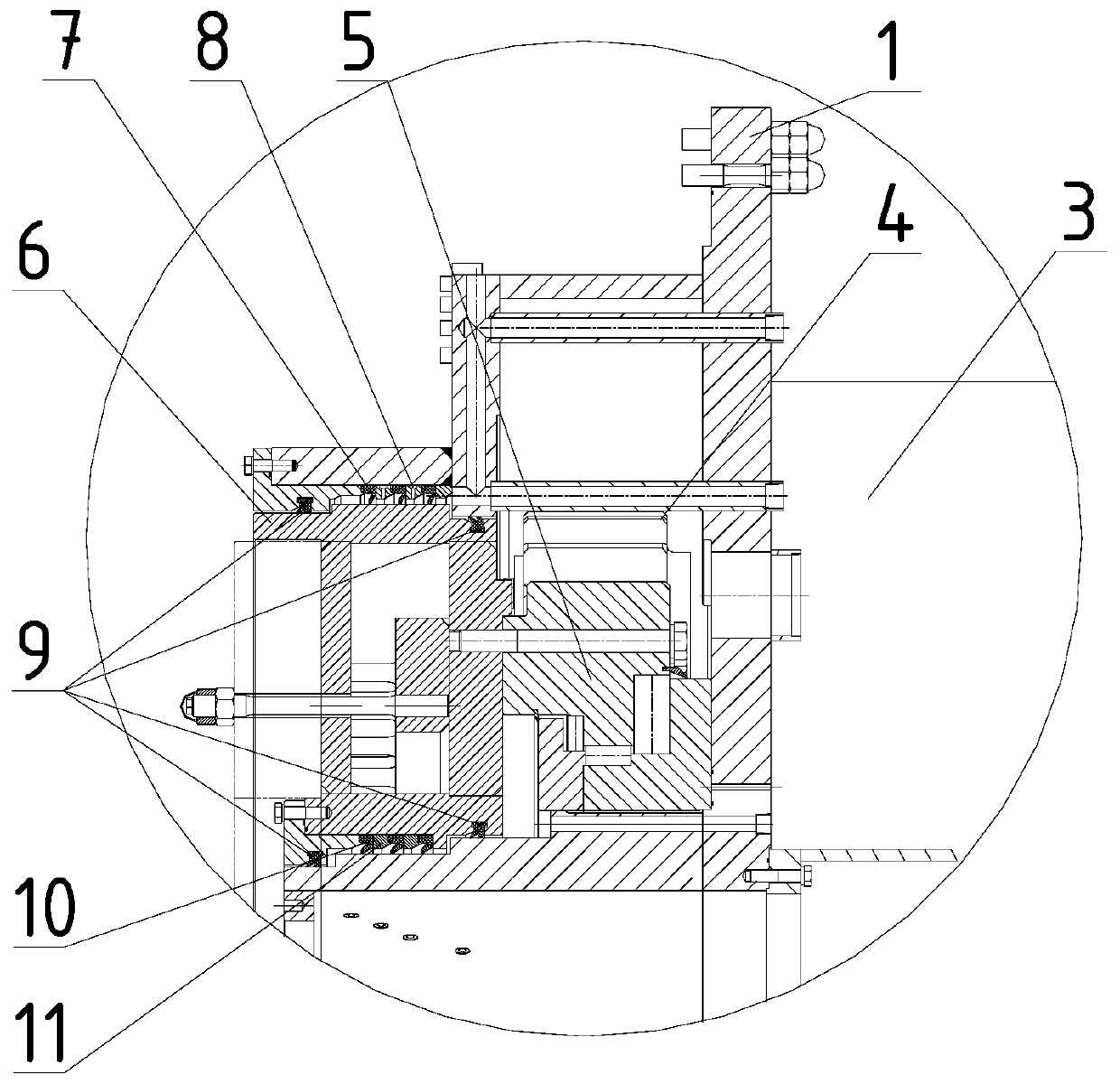

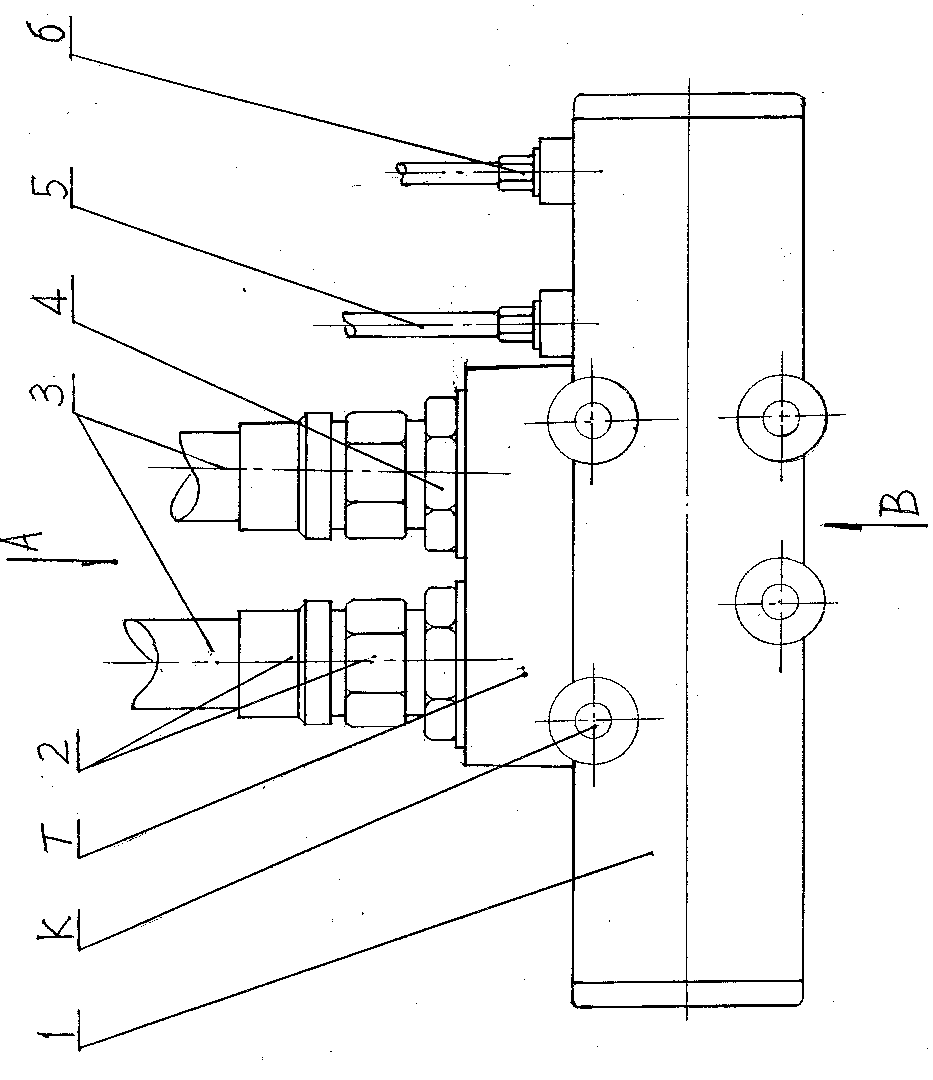

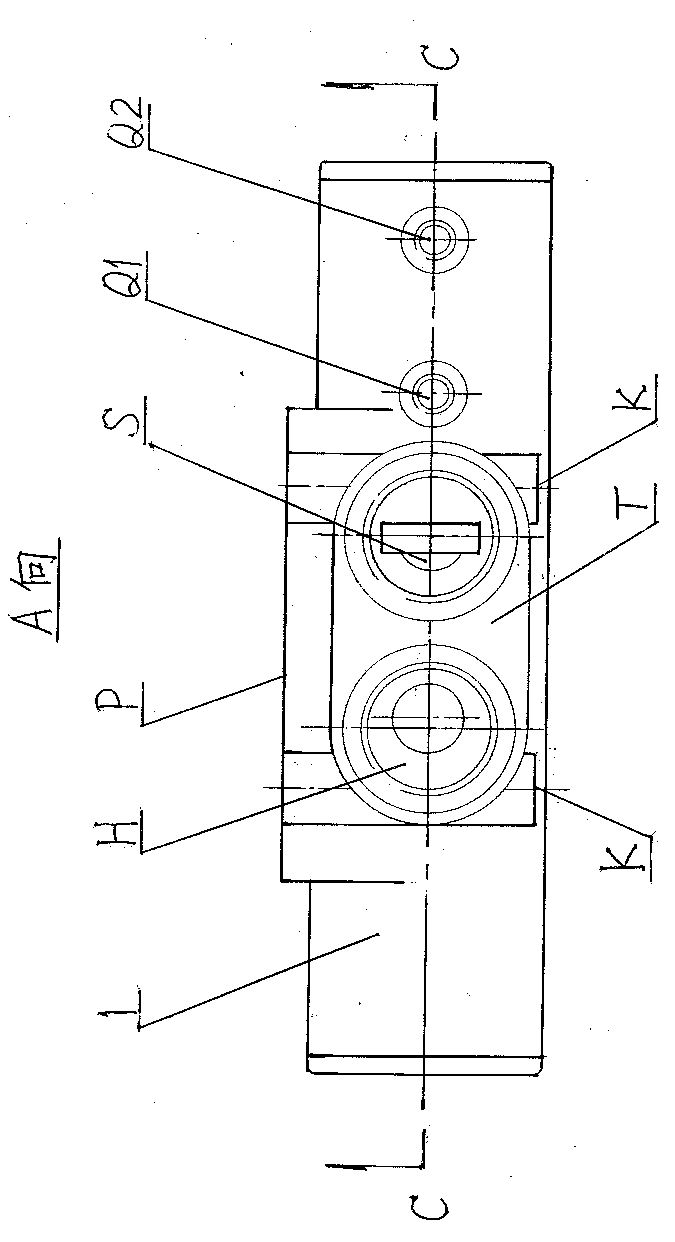

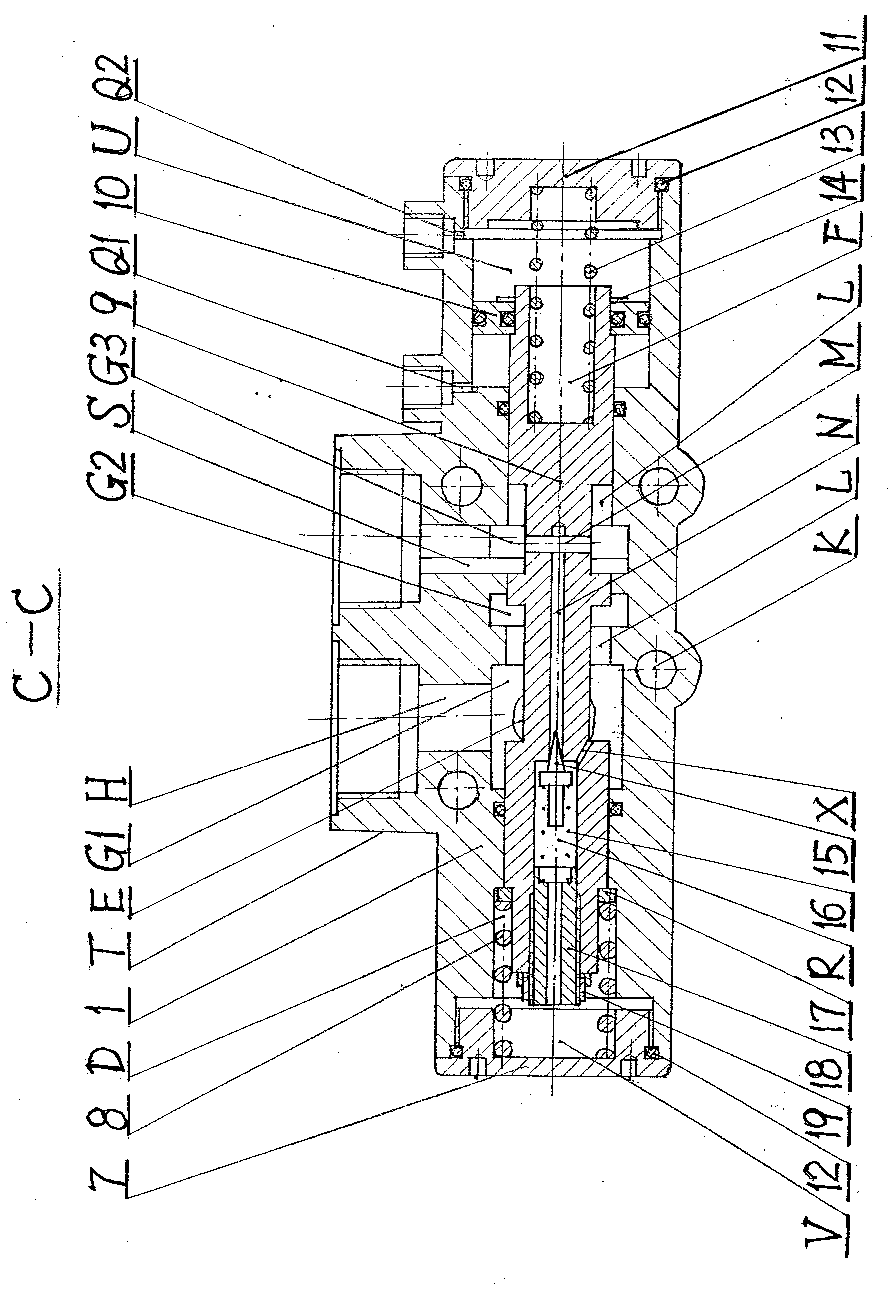

Main drive device for shield tunnelling machine

The invention relates to the technical field of culvert tunnel excavating equipment drive devices, in particular to a main drive device for a shield tunnelling machine with the diameter being 5 to 7 m. The main drive device comprises a shell, driving devices, main bearings, a cutter disc support and a seal structure; the shell is provided with the multiple driving devices and the main bearings which are correspondingly connected, the cutter disc support is arranged in the shell, and is connected with the main bearings through bolts in an occlusal manner, the seal structure is arranged betweenthe cutter disc support and the shell, and a cutter disc is arranged on the cutter disc support; each driving device comprises a motor and a speed reducer, the speed reducer is arranged on the shell in an occlusal manner, and the motor is connected with the speed reducer; small gears on the output ends of the speed reducers are engaged with teeth on outer rings of the main bearings; and through the technical scheme, the problems that in the prior art, the structure is complex and particular, the size is large, bearing is large, and purchasing maintaining cost is high can be solved.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com