Bladder type energy accumulator of various structures and with external air source and oil level control function

A technology of bladder accumulator and oil level control, applied in liquid balance, energy saving, hydraulic, electromechanical, can solve the problems of limited use, and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

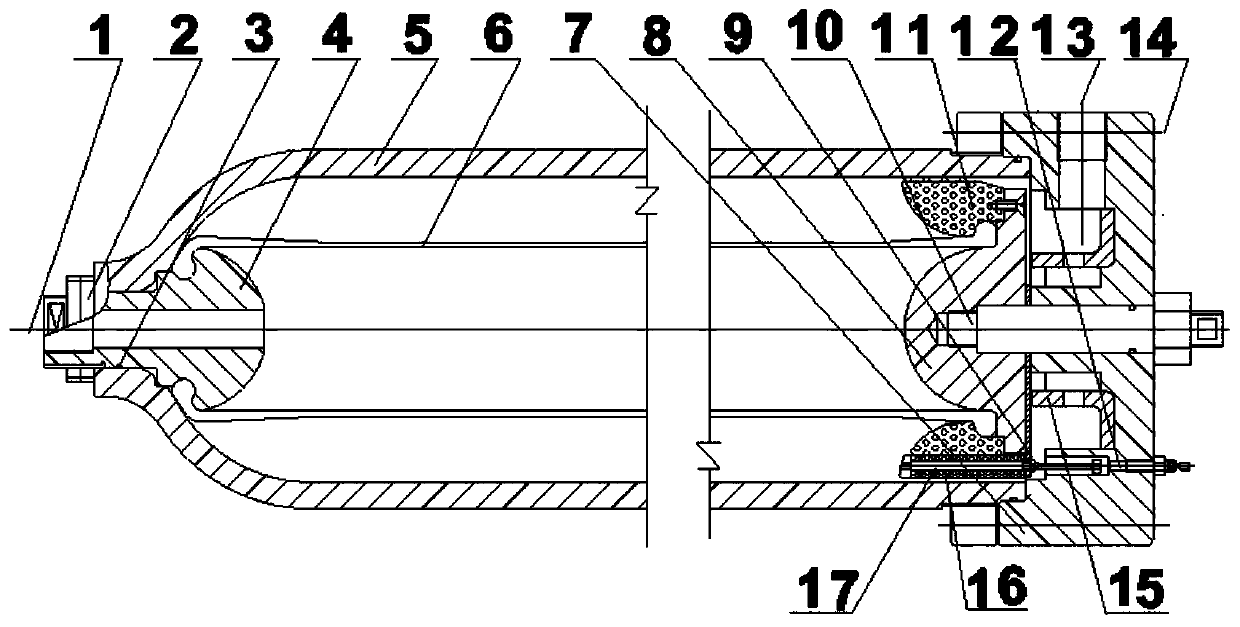

[0065] Such as figure 1 As shown, the embodiment discloses an accumulator with external gas supply source capsules with fixed lateral telescopic deformation at both ends to store energy and oil level control. The inner surface is smooth, which is beneficial to processing. The outer surfaces of the two open ends of the capsule 6 all have spherical blocks, and several annular spherical bumps are also provided on the inclined surface near the spherical blocks.

[0066] The spherical body round piece at the opening end of the capsule 6 at the air inlet end is pressed and embedded in the notch of the ventilation assembly 4; the diameter of the capsule 6 is about half of the inner diameter of the canister 5, and its two ends are made with thicker ports, gradually moving towards the middle at a certain distance Thinning is beneficial to realize lateral deformation energy storage and improve the use efficiency of the bladder accumulator; a sealing ring and a retaining ring 3 are insta...

Embodiment 2

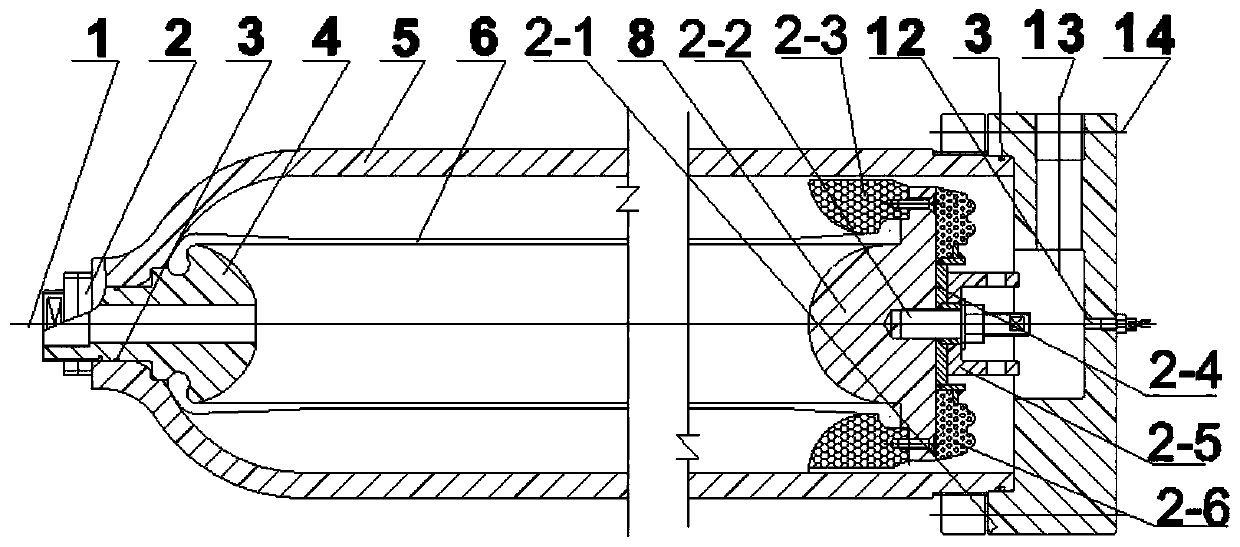

[0069] Such as figure 2 As shown, this embodiment discloses a bladder-type accumulator with openings at both ends of the capsule with an external air supply source, a cushion pad, which can be stretched and deformed horizontally and vertically to store energy and has oil level control. 5 capsules 6 at both ends; the inner surface of the capsule 6 is smooth, which is beneficial to processing, and the outer surfaces of the two open ends of the capsule 6 all have spherical body circles, and several annular spherical protrusions are also provided on the inclined surface near the spherical body circles.

[0070] The spherical body round block at the opening end of the air inlet capsule 6 is pressed and embedded in the notch of the ventilation assembly 4; It is thin, which is beneficial to realize lateral deformation energy storage and improve the use efficiency of the bladder accumulator; a sealing ring and a retaining ring 3 are installed on the outer peripheral surface of the ve...

Embodiment 3

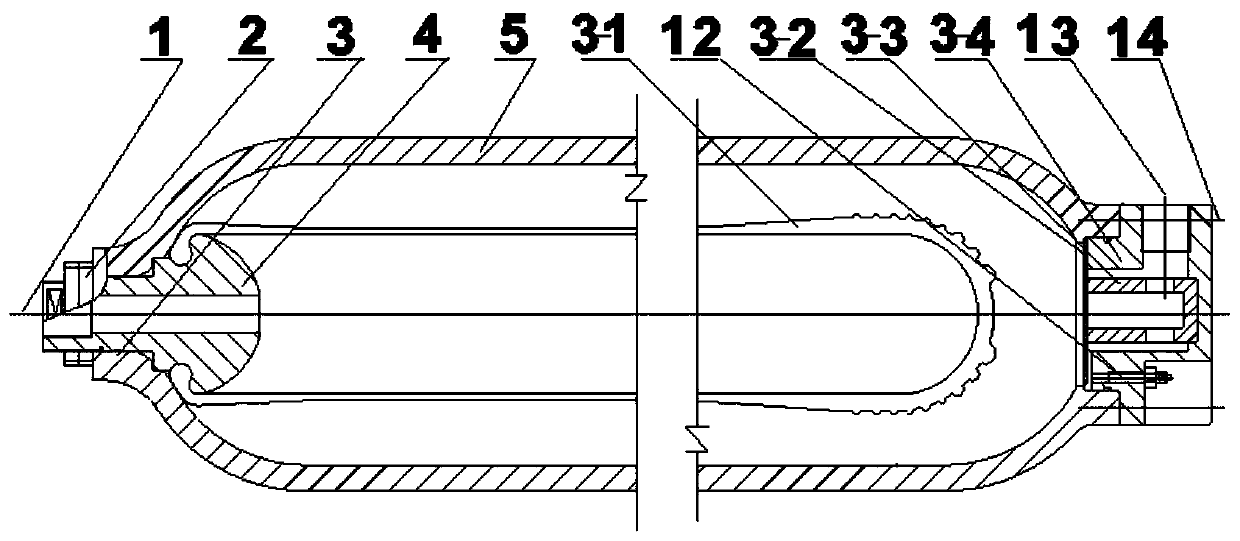

[0073] Such as image 3 As shown, one end of the capsule with an external air supply source disclosed in this embodiment is open and the other end is closed. The hemispherical capsule accumulator with buffer energy, horizontal and vertical telescopic deformation, energy storage and oil level control includes an air intake end. Open capsule 3-1, the bottom of the capsule 3-1 at the other end is closed semi-spherical, and its inner surface is smooth, which is beneficial to processing.

[0074]The spherical body round block at the opening end of the air inlet capsule 3-1 is pressed and embedded in the notch of the ventilation assembly 4; The distance is thinned toward the middle, which is conducive to the realization of lateral deformation energy storage, and improves the use efficiency of the bladder accumulator; the outer circumferential surface of the ventilation assembly 4 is equipped with a sealing ring and a retaining ring 3; The nut 2 compresses the ventilation assembly 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com