A four-point weighing-based aeroengine rotor assembly measurement device and three-objective optimization method

An aero-engine and rotor assembly technology, which is applied to measurement devices, electrical devices, optical devices, etc., can solve the problems of lack of aero-engine rotor assembly, low assembly efficiency, and inability to take into account the optimization of rotor imbalance and moment of inertia.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

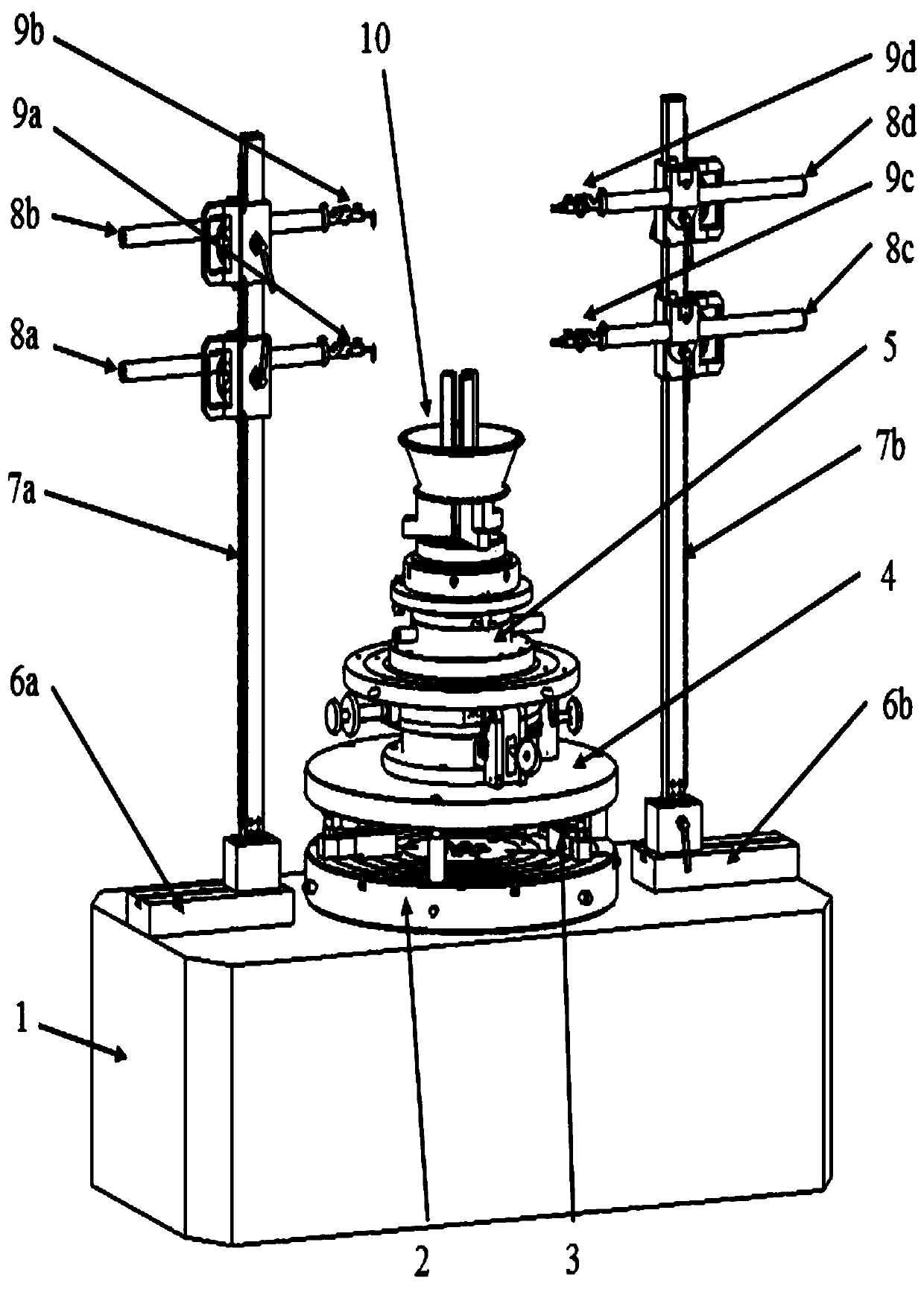

[0078] according to figure 2 and image 3 As shown, the present invention provides an aeroengine rotor assembly measurement device based on four-point weighing, which includes: a base 1, an air bearing shaft system 2, a load cell 3, a leveling and tilting platform 4, a hydraulic clamp Pan 5, left column transverse guide rail 6a, right column transverse guide rail 6b, left column vertical guide rail 7a, right column vertical guide rail 7b, left lower transverse measuring rod 8a, left upper transverse measuring rod 8b, right lower transverse measuring rod 8c, upper right horizontal measuring rod 8d, lower left telescopic inductive sensor 9a, upper left telescopic inductive sensor 9b, lower right lever inductive sensor 9c, upper right lever inductive sensor 9d and the measured rotor 10;

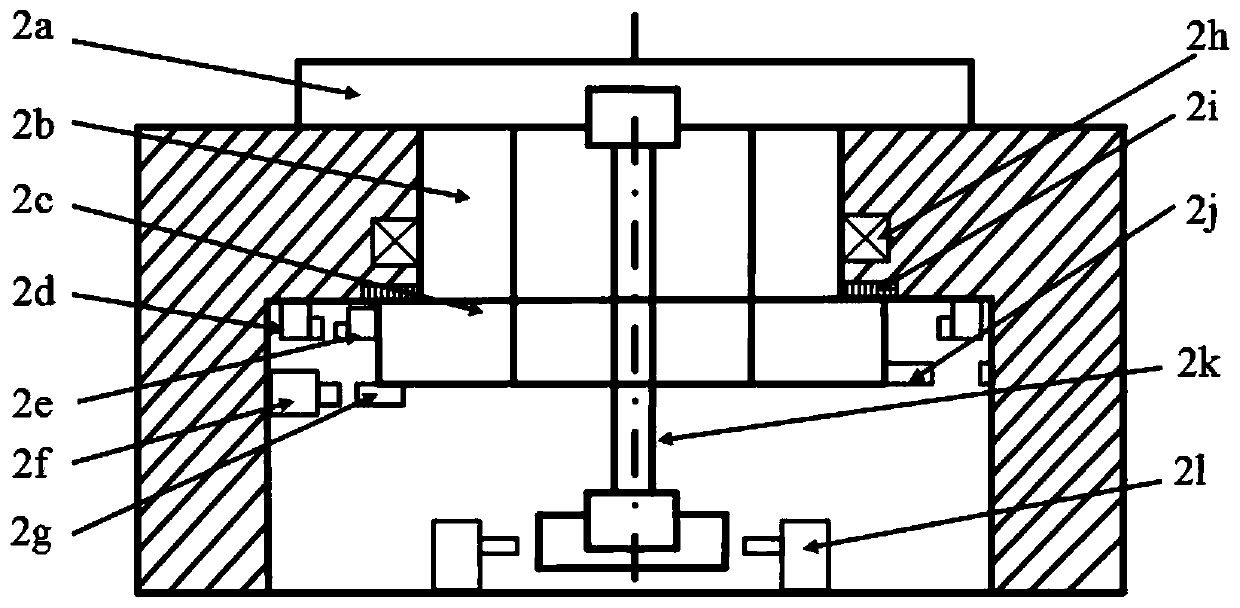

[0079] The air bearing shaft system 2 includes an air bearing upper plate 2a, an air bearing main shaft 2b, an air bearing lower plate 2c, a circular grating ruler 2d, a circular grating readi...

specific Embodiment 2

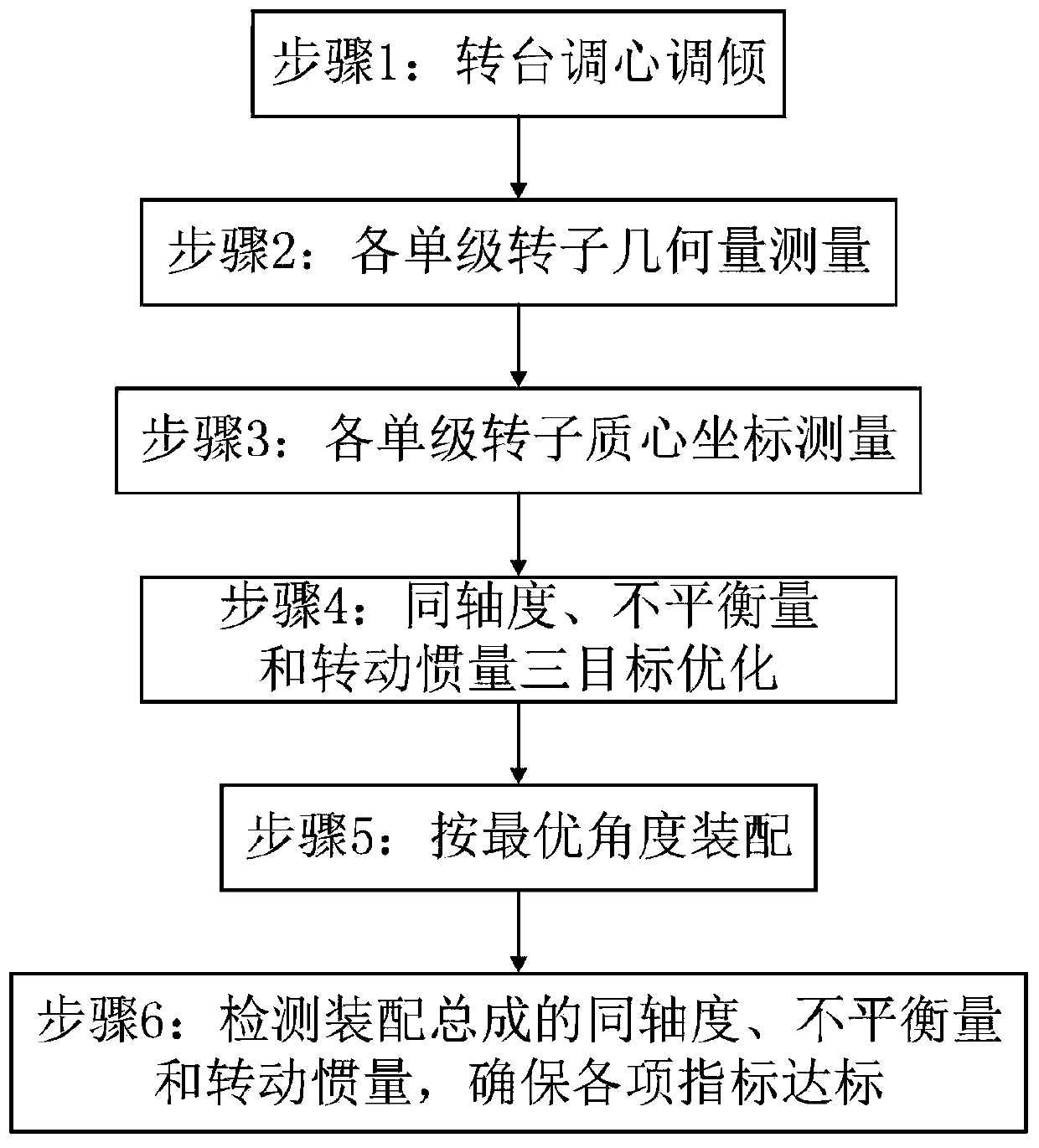

[0085] according to figure 1 As shown, the present invention provides a three-objective optimization method for aero-engine rotor assembly based on four-point weighing, comprising the following steps:

[0086] Step 1: For centering and tilting of the leveling and tilting platform 4, ensure that the centroid of the assembly reference plane is concentric with the rotation axis of the 4-axis system of the leveling and tilting platform, and ensure that the assembly reference plane is parallel to the plane of the leveling and tilting platform 4, so that The assembly reference is the bottom surface of the bottom rotor, the axis of rotation of the air bearing shaft system 2 is the Z axis, the intersection of the axis of rotation and the upper surface of the upper air bearing plate 2a is the origin of coordinates, and a straight line passing through the origin of coordinates and parallel to the base 1 is used is the X-axis, and the Y-axis is a straight line passing through the coordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com