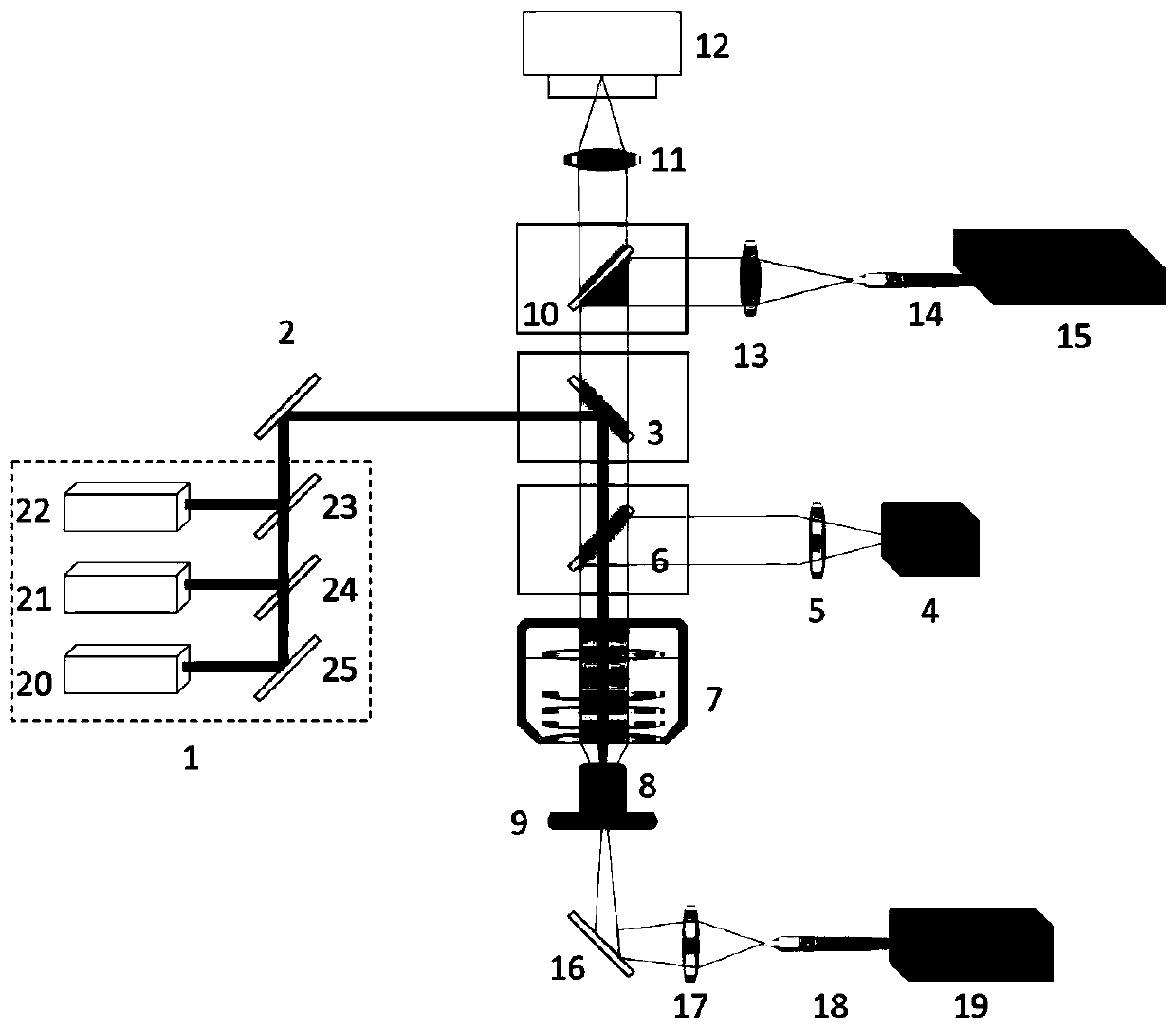

Patents

Literature

48results about How to "Realize integrated measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

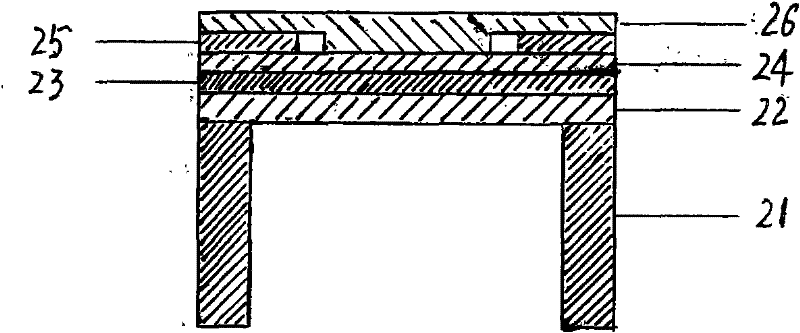

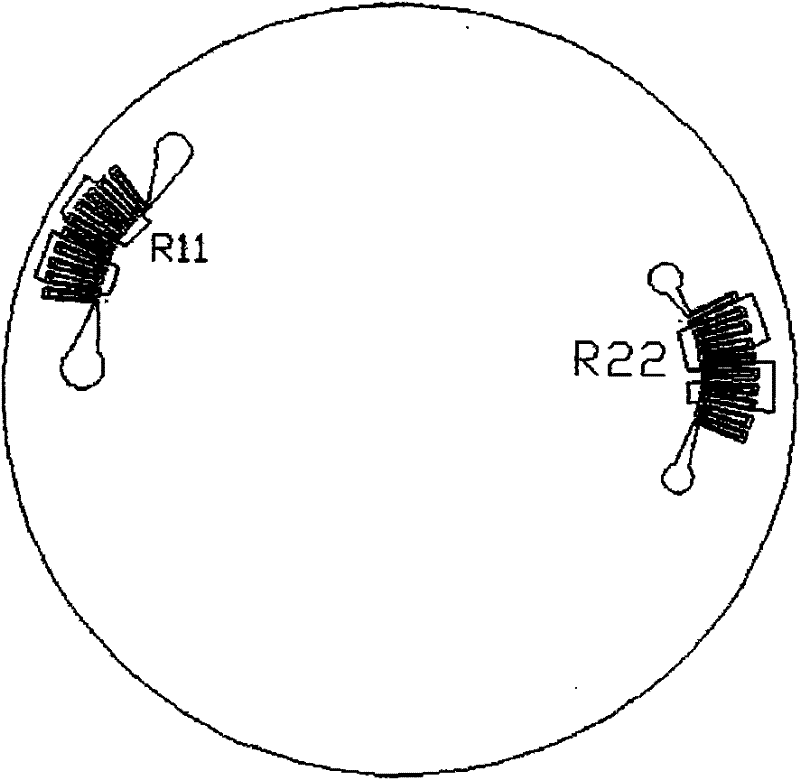

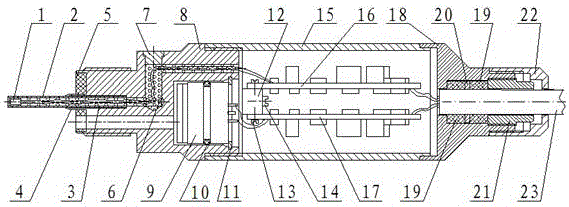

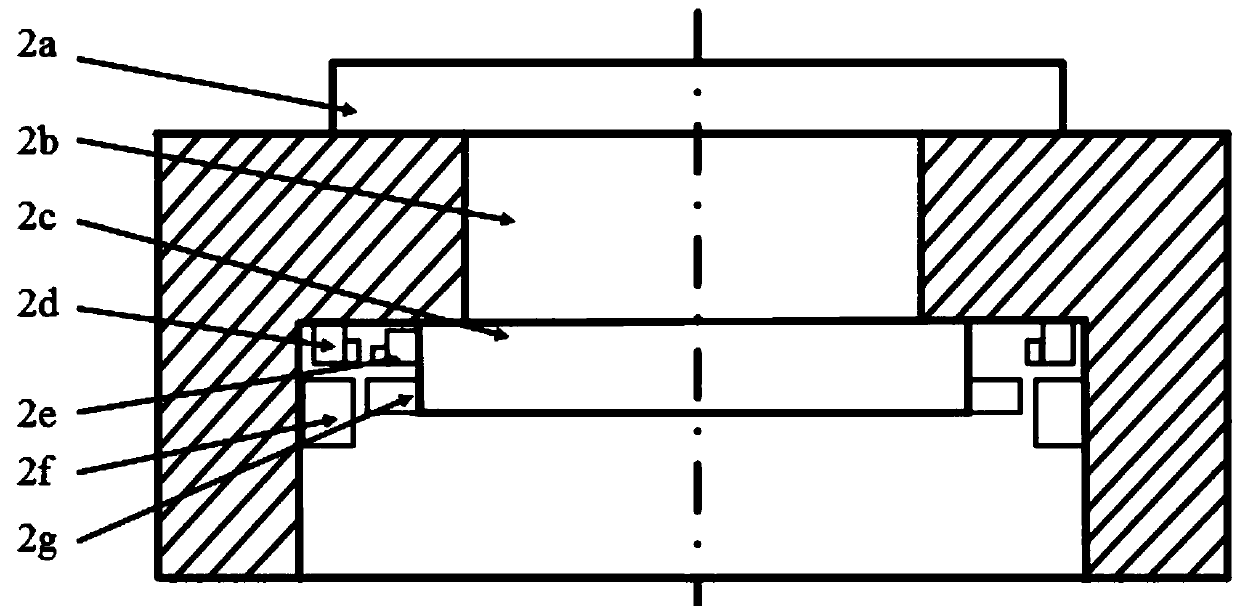

Integrated temperature thin film pressure sensor

InactiveCN101566514AHigh measurement accuracyRealize integrated measurementFluid pressure measurement using ohmic-resistance variationThermometers using electric/magnetic elementsElastomerTemperature sensitive

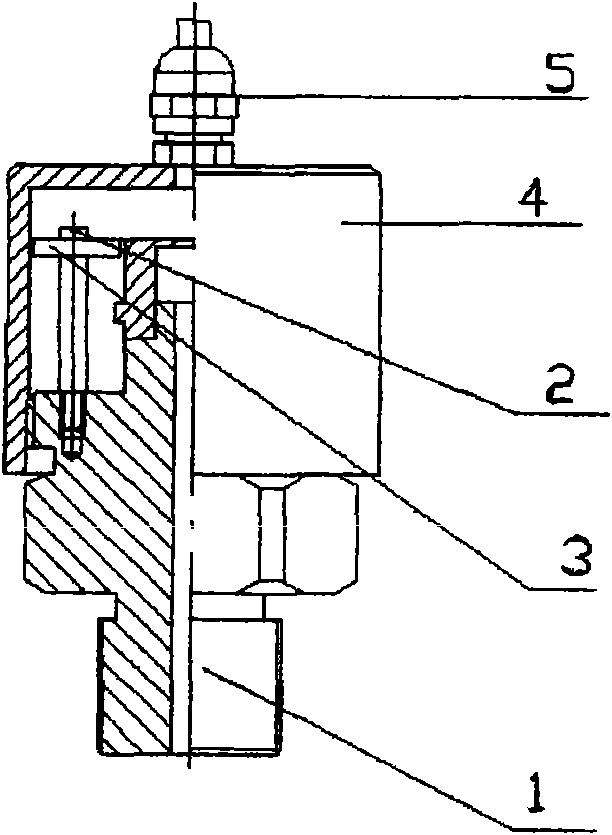

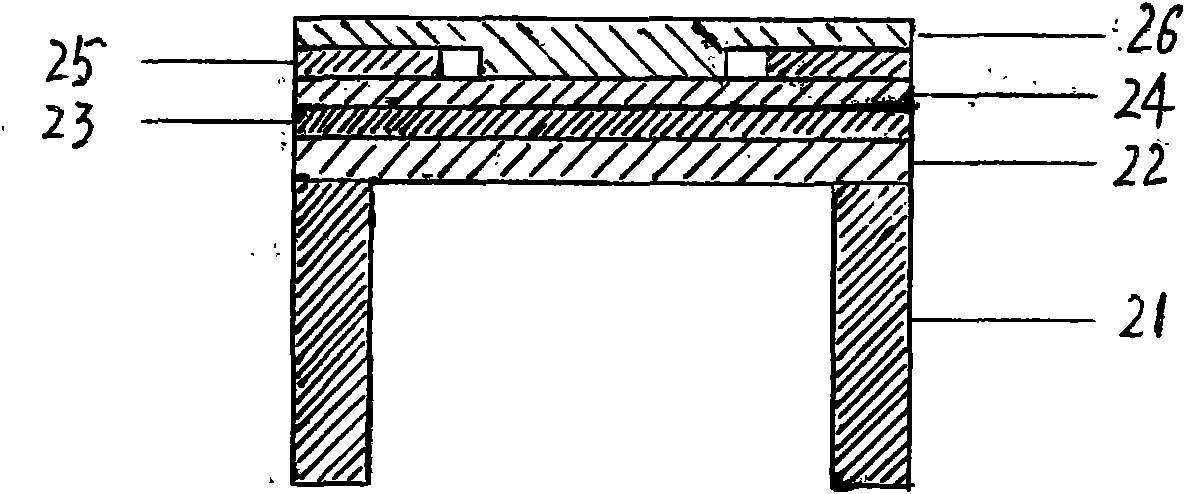

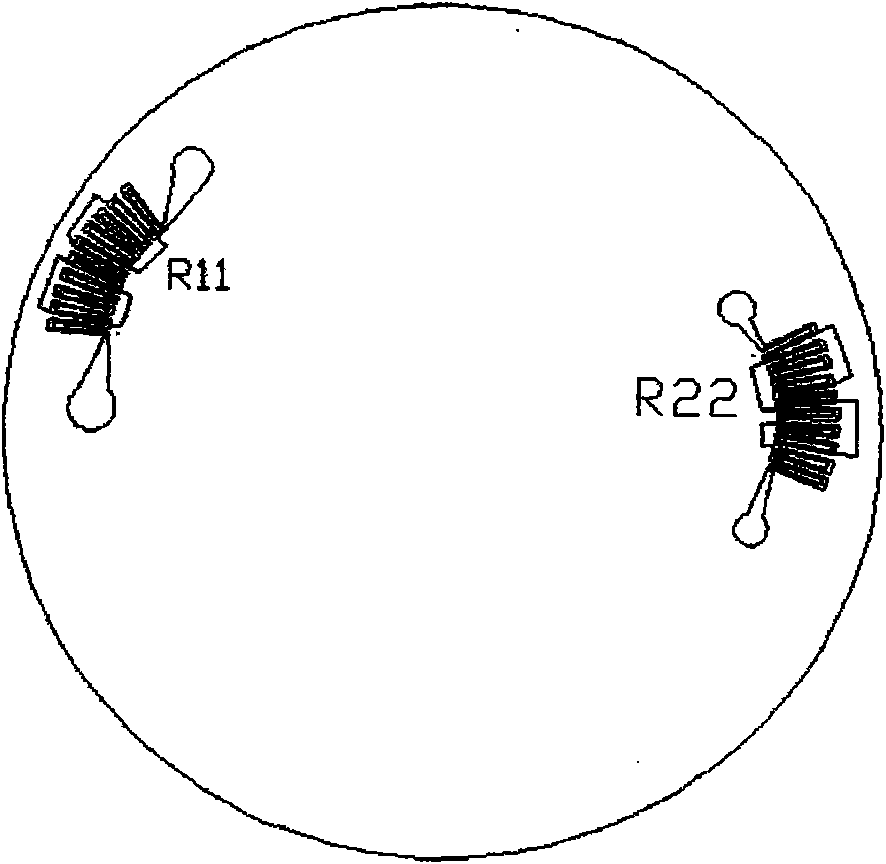

The invention relates to an integrated temperature thin film pressure sensor, which consists of a suction pressure connecting pipe with threads and a seal ring, a sensitive component, an external circuit board, a shell and a socket connector. A sensitive elastomer is provided with a transition layer, an insulating layer, resistive layers (including a strain resistive layer and a temperature sensitive resistive layer), a welding layer and a passivation protective layer, wherein the resistive layers are connected with the external circuit board through conducting wires. The insulating layer of the sensor is formed by superimposing SiO2 and Ta2O5 or superimposing the SiO2 and Al2O3, the strain resistive layer is formed by photoetching a NiCr alloy layer, the temperature sensitive layer is formed by photoetching Ni metal, and the temperature sensitive layer not only can solve the problem of actual temperature measurement, but also can compensate the temperature sensitivity more precisely so that the pressure measurement is more accurate. The integrated temperature thin film pressure sensor adopts an ion beam sputtering process, thus the long-term stability of the sensor is good, the temperature zero drift is minimum and the comprehensive precision is high.

Owner:SHAANXI ELECTRICAL APPLIANCE RES INST

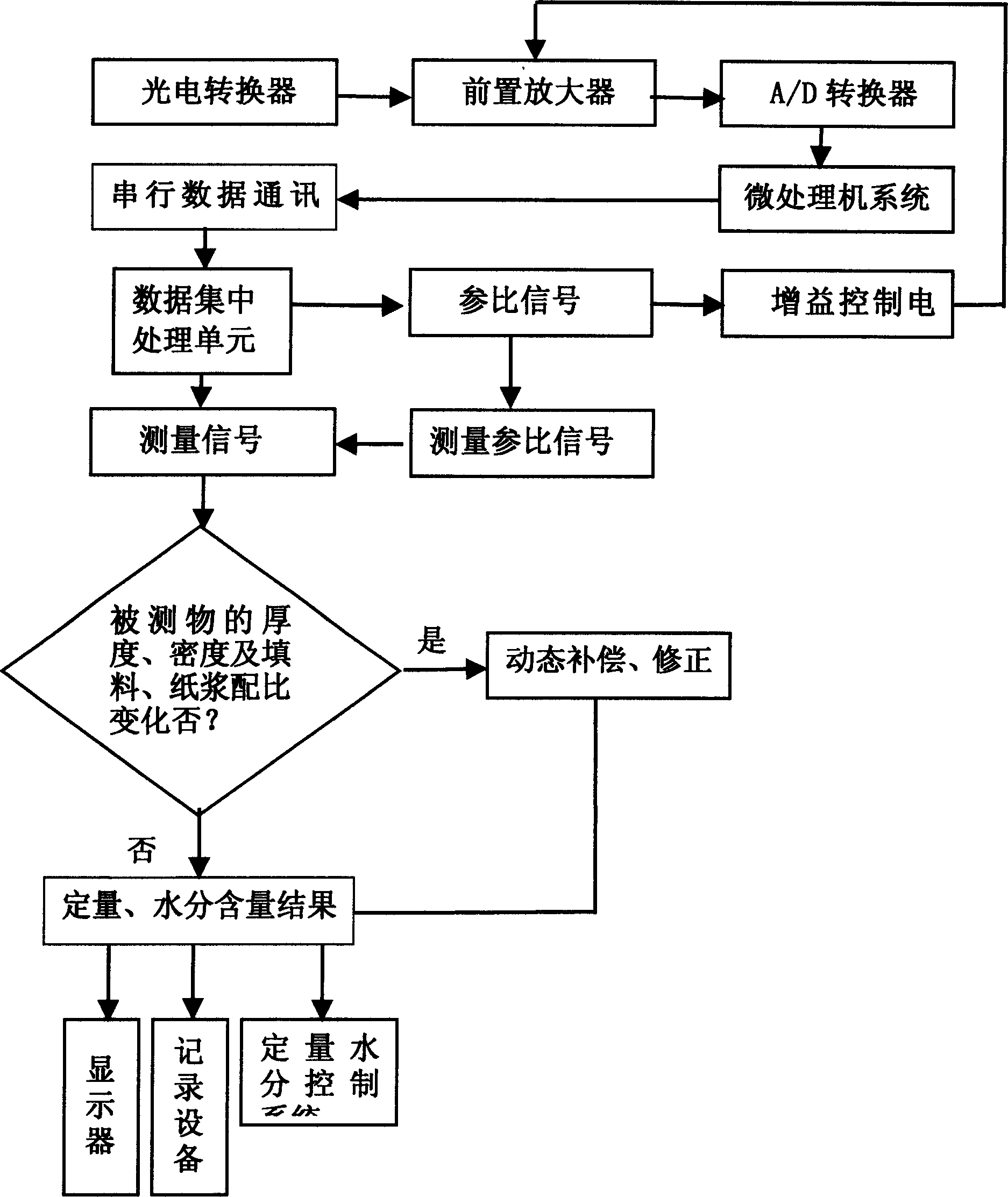

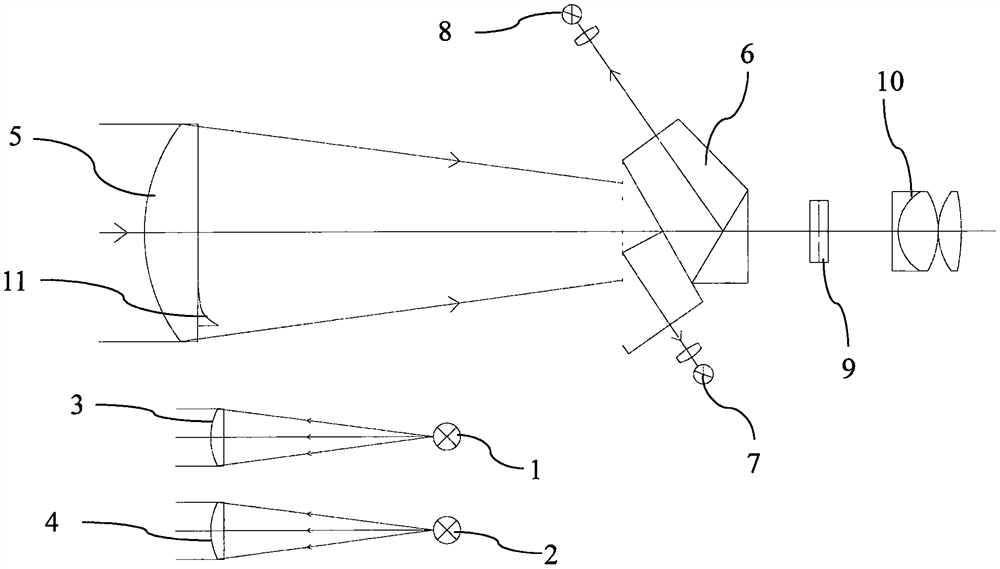

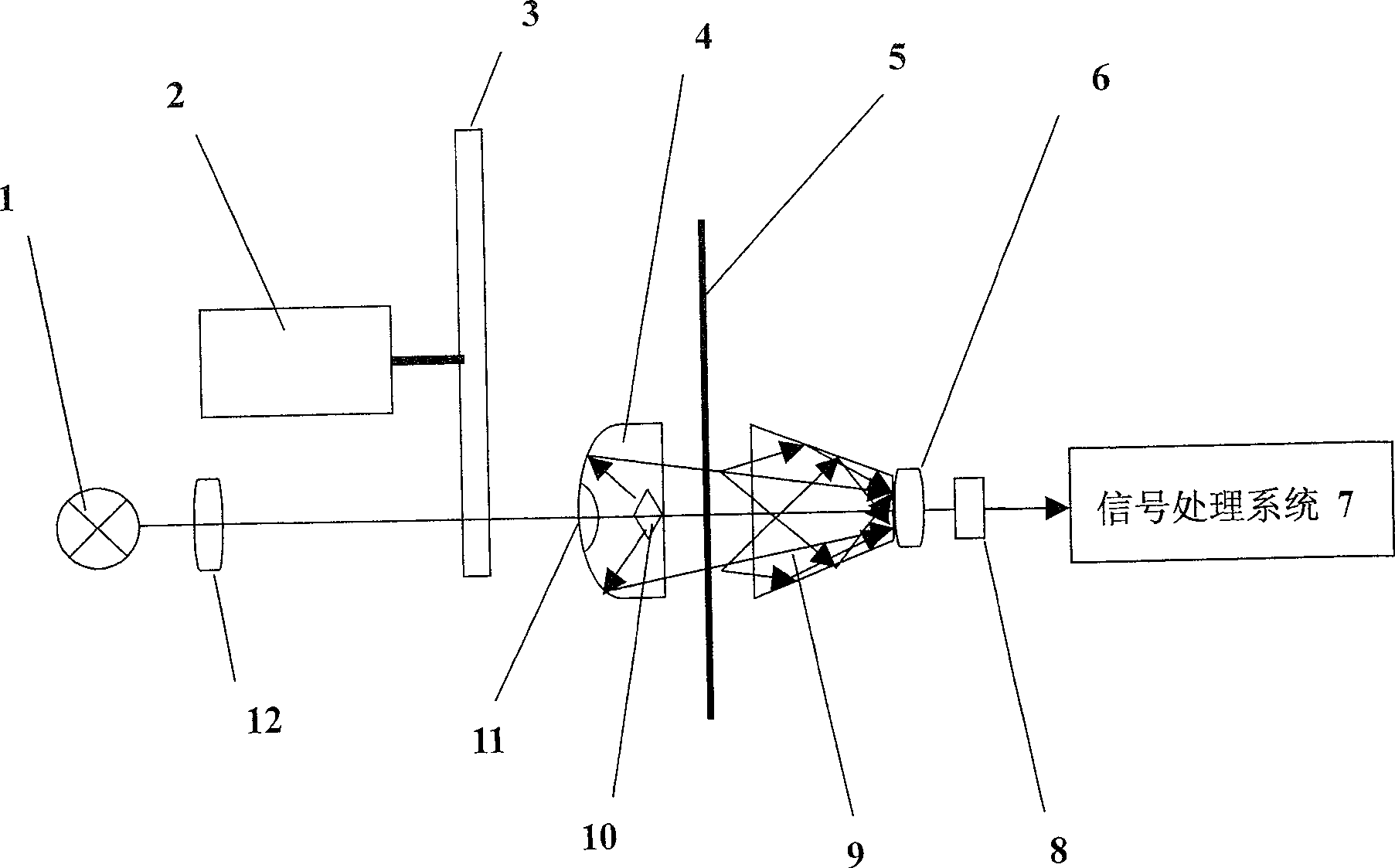

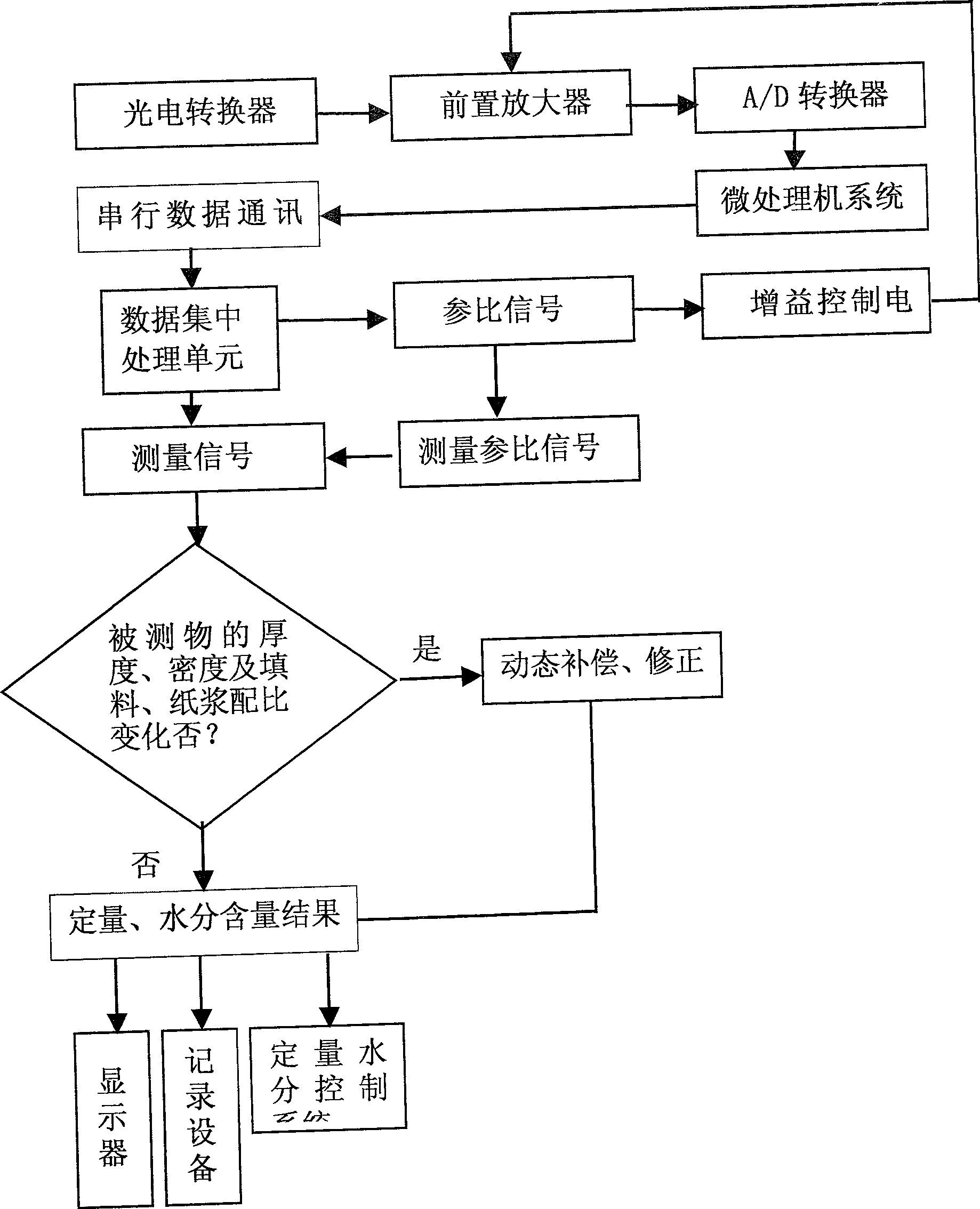

Near infrared quantitative water content measurement method for paper

ActiveCN1800825AEnables real-time process detectionNo radioactive contaminationColor/spectral properties measurementsAudio power amplifierEngineering

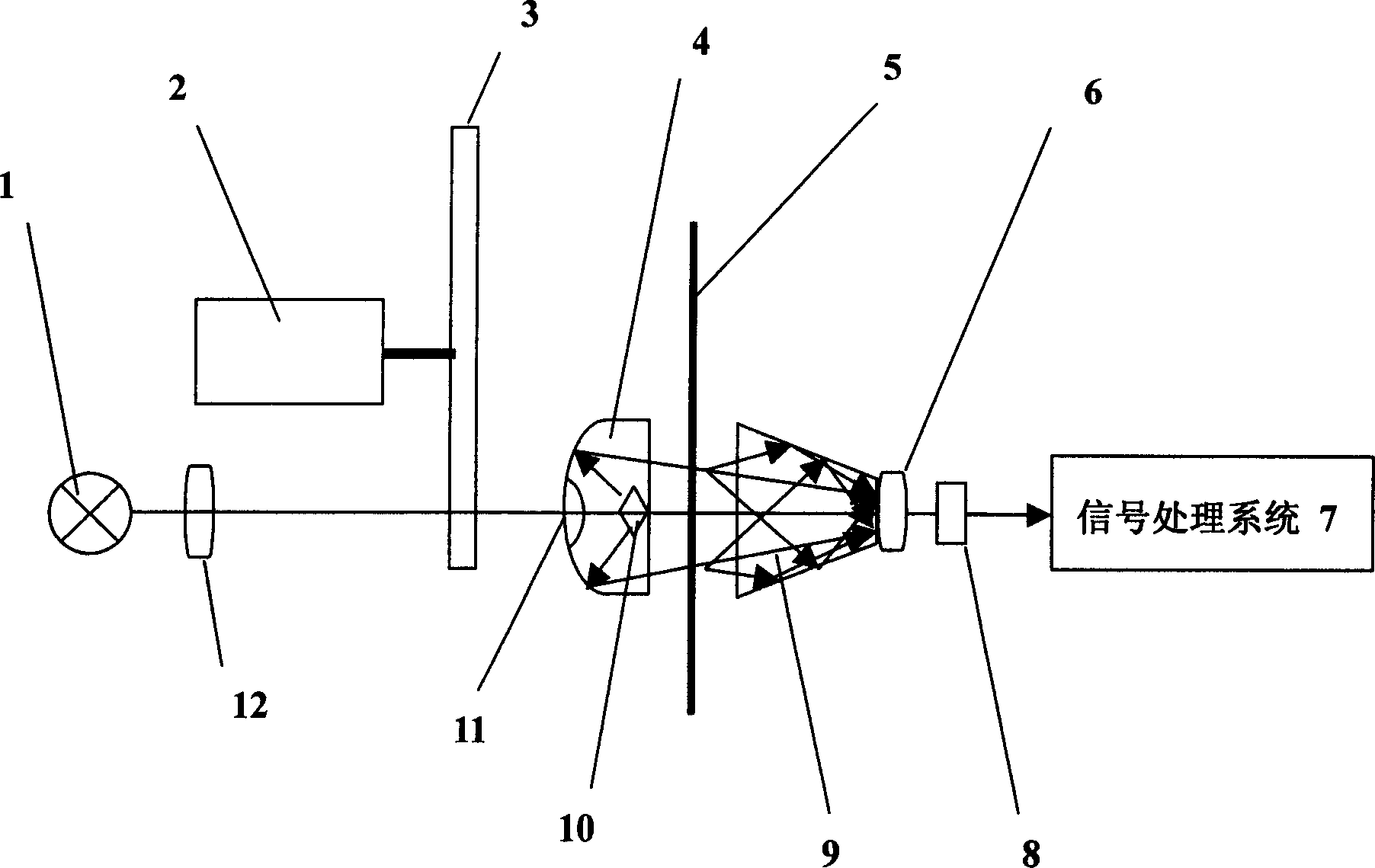

The quantitative moisture measurement method for near infrared paper comprises: modulating the infrared light into near infrared lights with different wavelength and arranged as chronological order to reflect with a reflector to the emission integral semisphere to reflect and cross the paper to focus on a optical-electrical converter, sending the converted electric signal to microprocessor for pretreatment; then, transmitting into a data centralized processing unit to recognize and divide into reference signal with one path to control front amplifier and another path as the reference signal and measurement signal; calculating in the processing unit to obtain quantitative moisture content. This invention realizes online measurement with high accuracy and low cost.

Owner:西安力源光电科技有限责任公司

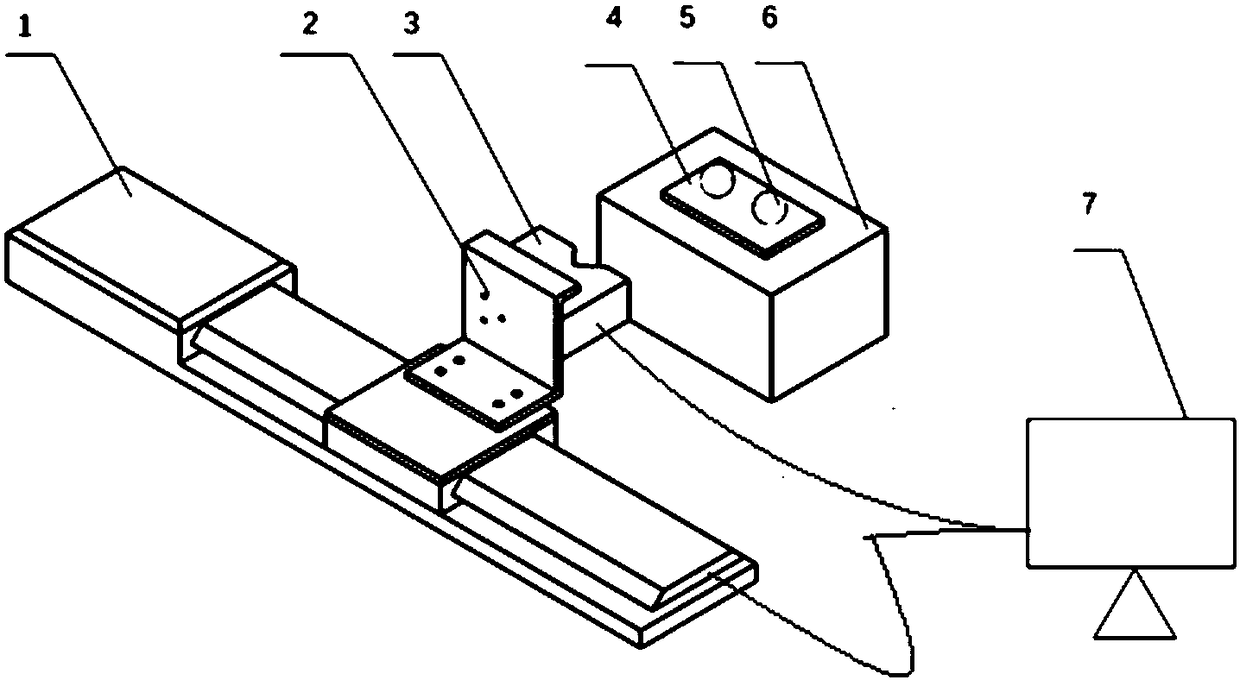

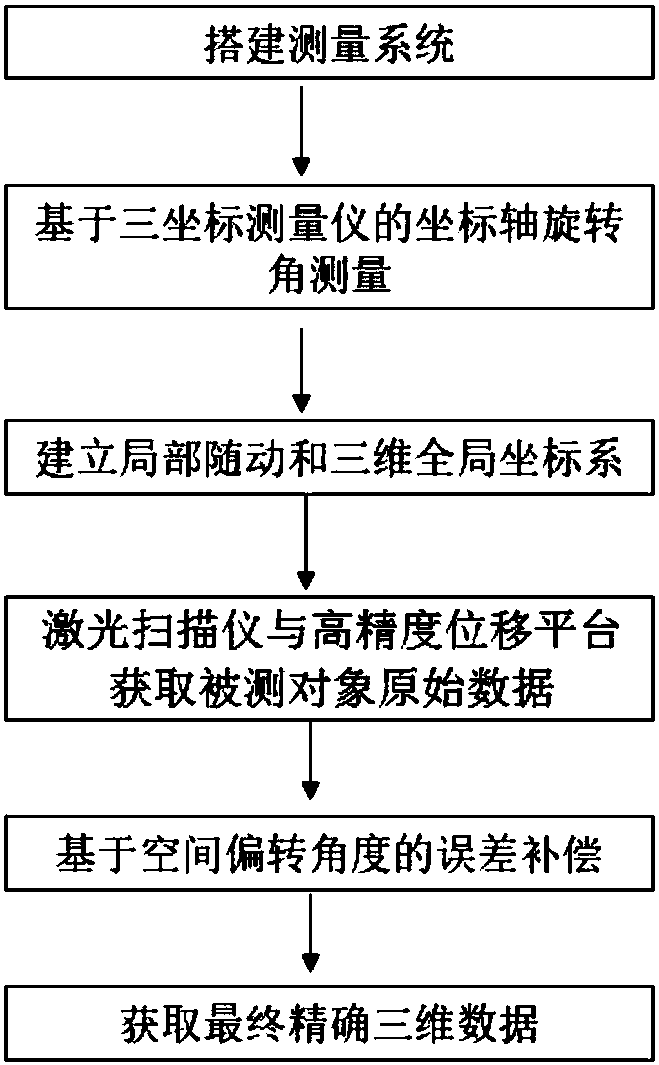

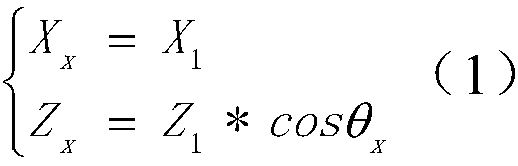

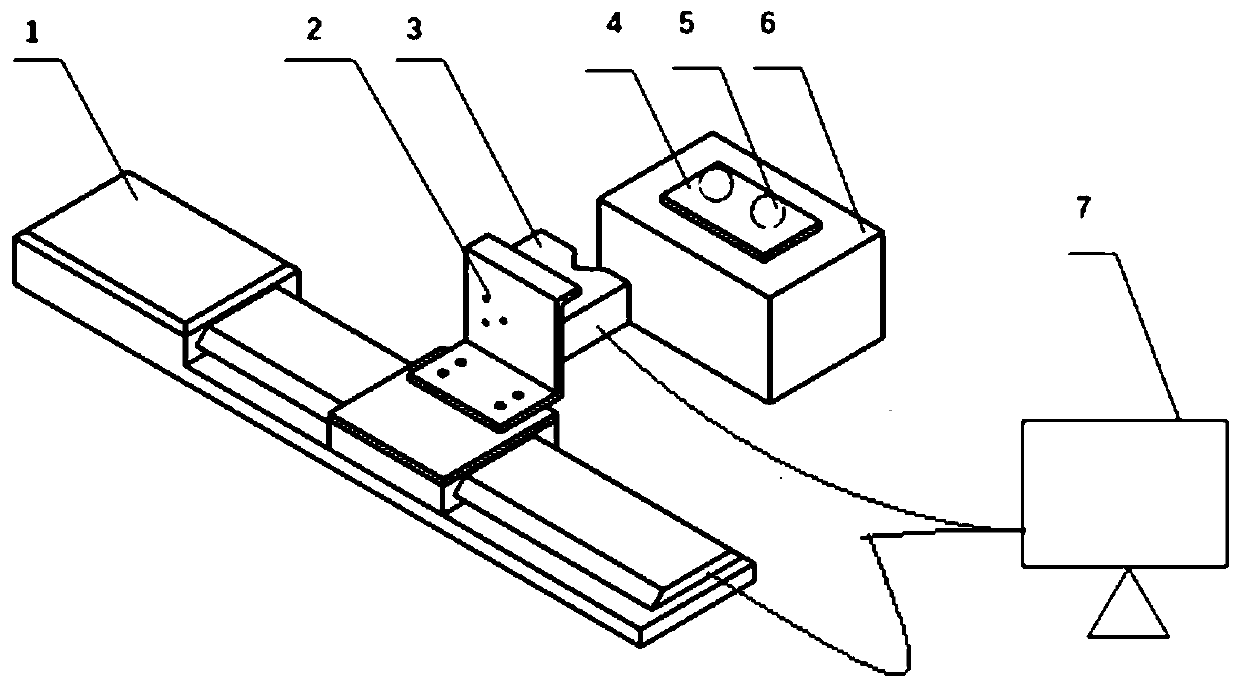

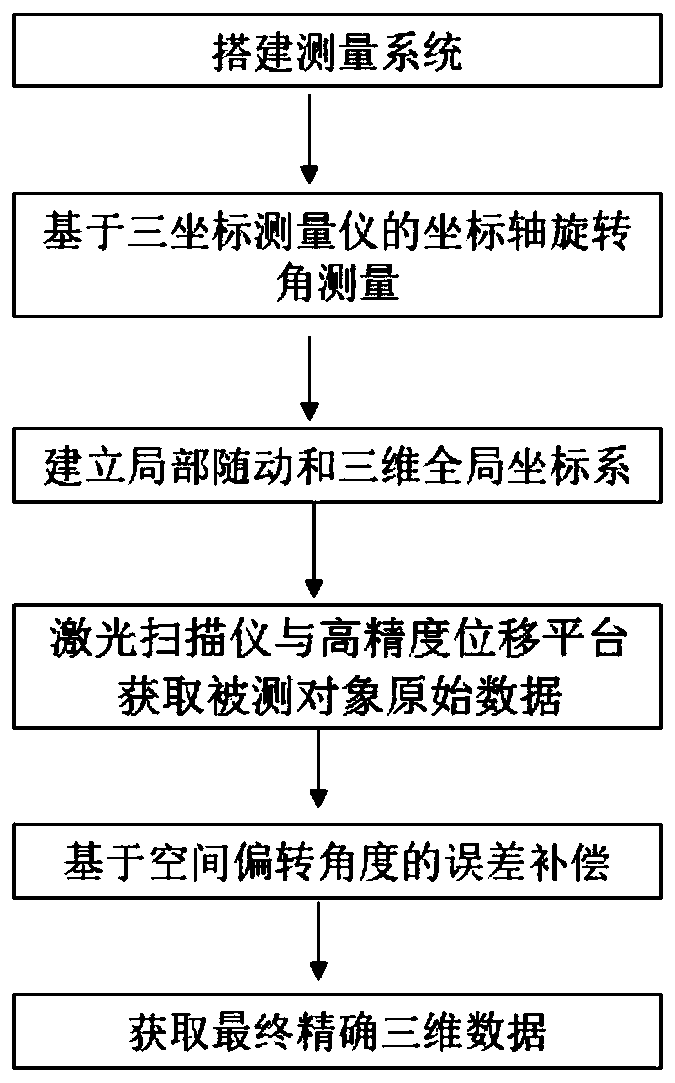

Method for obtaining three-dimensional accurate data by adopting two-dimensional linear laser scanner

ActiveCN108507466ARealize high-precision measurementThe problem of achieving high-precision acquisition of three-dimensional information of the measured objectUsing optical meansObservational errorLaser scanning

The invention provides a method for obtaining three-dimensional accurate data by adopting a two-dimensional linear laser scanner and belongs to the field of reverse engineering and three-dimensional measurement. According to the method, a two-dimensional local coordinate system is established based on the linear laser scanner, a high-precision electrically controlled movable platform is adopted toprovide third-dimensional coordinates, and dimension raising of two-dimensional position information to three-dimensional position information of measured workpieces is achieved. For correcting three-dimensional coordinate deviations caused by clamp installing errors and manufacturing errors, a space angle compensation method is adopted to calculate a converting torque between a theoretical measurement coordinate system and an actual measurement coordinate system, thus measurement errors brought by angle deviations are eliminated, and accurate reestablishment of three-dimensional informationis achieved. The problem of high-precision measurement in the machining process of aerospace parts is effectively solved by adopting the method, the method is flexible, efficient and good in robustness, and integral measurement of non-contact and high-precision machining process is achieved.

Owner:DALIAN UNIV OF TECH

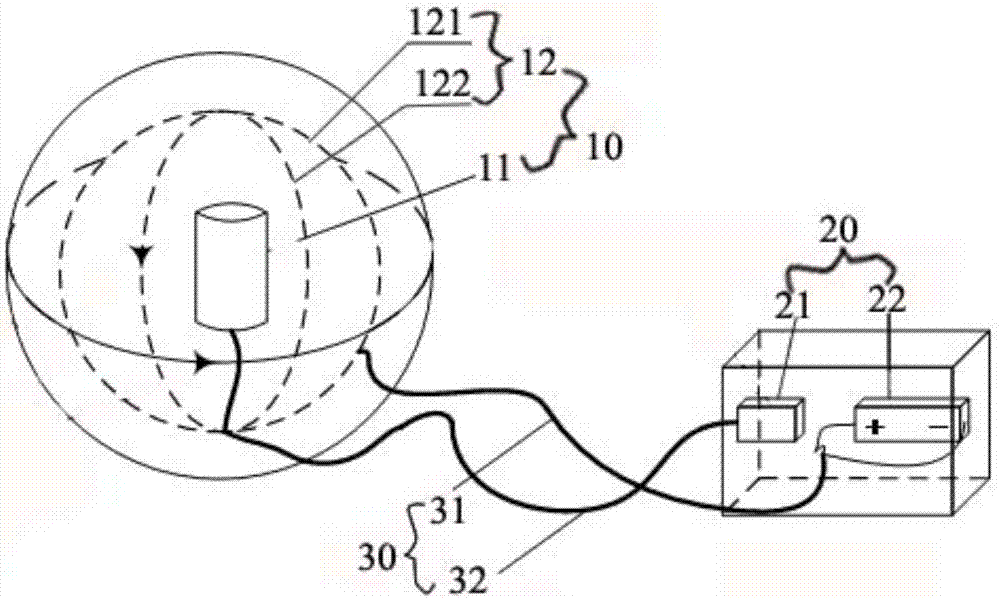

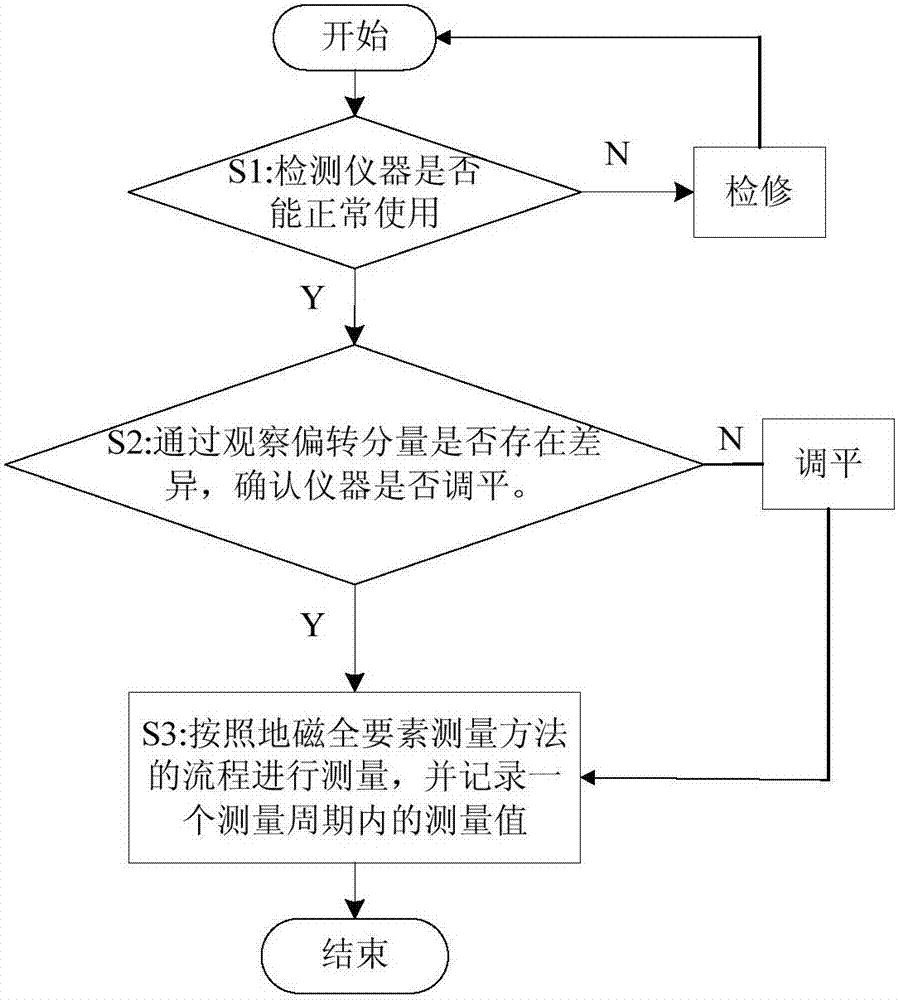

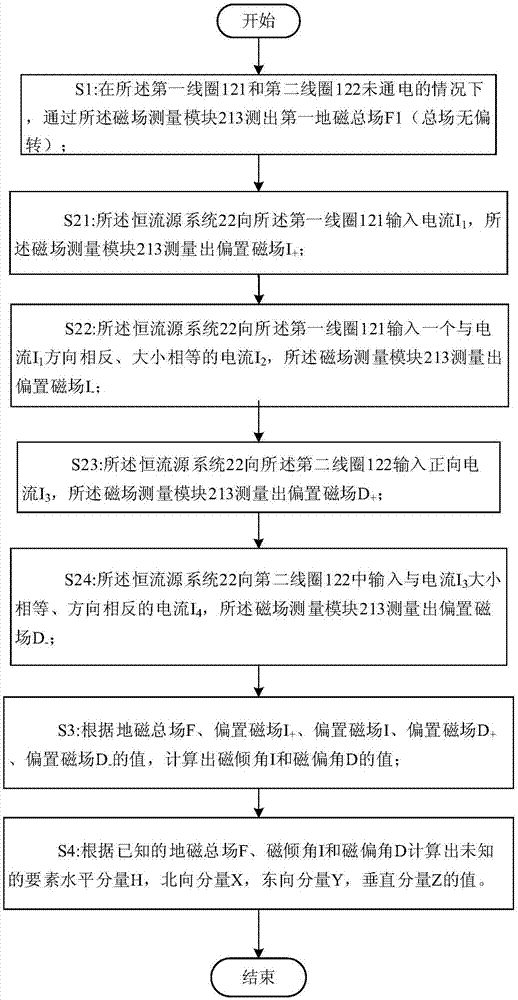

Measuring system and method of total geomagnetic elements

ActiveCN107340545ARealize integrated observationMiniaturizationWater resource assessmentElectric/magnetic detectionSignal conditioningEngineering

The invention provides a measuring system and method of total geomagnetic elements. The measuring system of the geomagnetic elements comprises a geomagnetic element sensor, an element magnetometer host and a connecting unit, wherein the geomagnetic element sensor comprises a total field sensor and a uniform magnetic field generator; one end of the total field sensor is fixed in the center on the inner side of the uniform magnetic field generator in a clamping manner; the other end of the total field sensor is connected with the uniform magnetic field generator; the element magnetometer host comprises a measuring module and a constant current source system; the measuring module comprises an excitation source, a signal conditioning module and a magnetic field measuring module; the excitation source drives the total field sensor to send a signal; the connecting unit comprises a signal transmission line and a power supply cable; the signal transmission line is connected with the total field sensor and the measuring module; the power supply cable is connected with the uniform magnetic field generator and the constant current source system; the constant current source system supplies power for the uniform magnetic field generator via the power supply cable.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

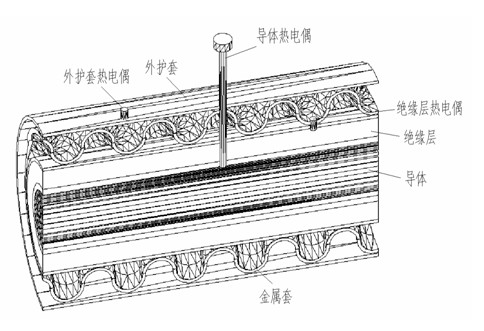

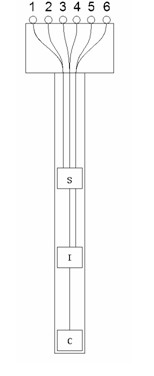

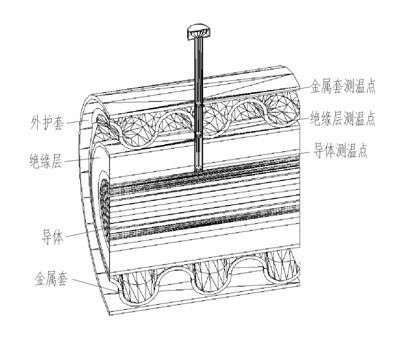

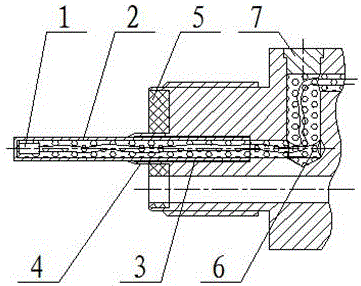

Temperature thermocouple for high-voltage and ultrahigh-voltage power cable

InactiveCN102494793AReduce workloadImprove synchrony and accuracyThermometers using electric/magnetic elementsUsing electrical meansCross-linked polyethyleneTemperature measurement

The invention relates to a temperature thermocouple for a cable, belonging to the research field of cable tests. For detecting the temperatures of a conductor, an insulating layer and an outer sheath of a cable and ensuring the detection synchronism, the invention provides a needle-shaped thermocouple which can be used for detecting the temperatures of the conductor, the insulating layer and the outer sheath of the cable at the same time after being installed for one time; therefore one-point synchronous temperature detection can be realized, workload of the temperature detecting process is reduced, and the synchronism and the accuracy of the temperature detection are enhanced. The temperature thermocouple can be used for detecting temperature of each structural layer of a simulated cable in a high-voltage and ultrahigh-voltage XLPE (Cross Linked Polyethylene) power cable type test and preverification, can realize the effect of one-time installation and one-time detection and can avoid temperature detection deviation caused by difference among different thermocouples.

Owner:STATE GRID ELECTRIC POWER RES INST

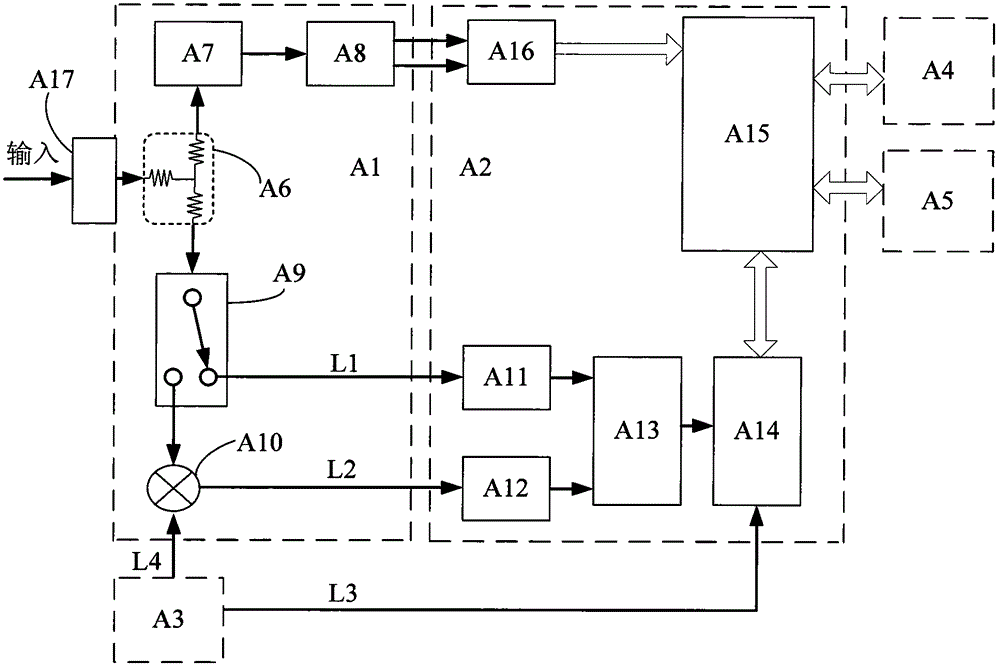

Integrated frequency and power measurement device and method based on RFID antenna transmission

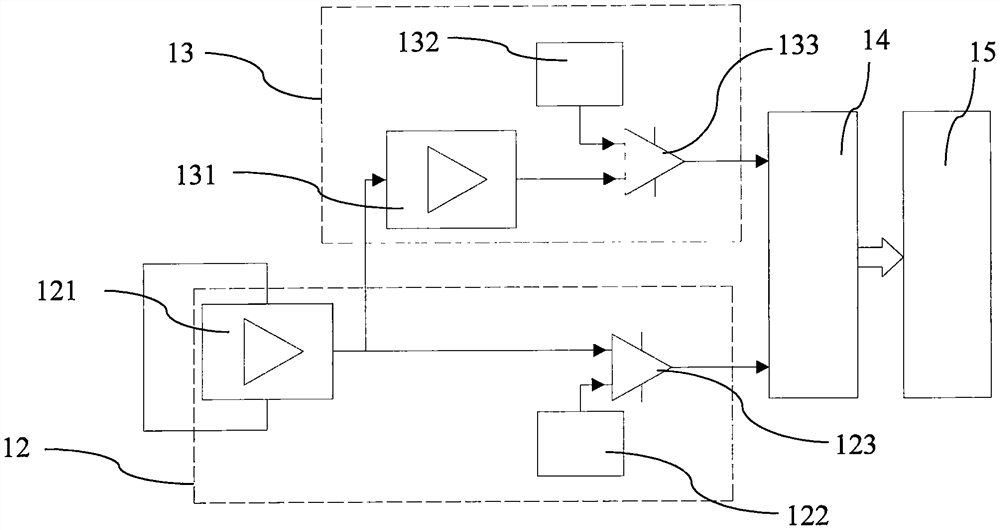

InactiveCN104535837ARealize integrated measurementRealize monitoringPower measurement by digital techniqueFrequency to pulse train conversionTest efficiencyMicrowave

The invention provides an integrated frequency and power measurement device based on RFID antenna transmission. The integrated frequency and power measurement device comprises a sampling detection microwave assembly, an integrated frequency and power measurement circuit, a time base reference and local oscillator generating circuit and an RFID circuit module. Input signals enter the sampling detection microwave assembly. In the sampling detection microwave assembly, a power divider distributes the signals, a path of signals are used for power measurement, and a path of signals are used for conducting frequency measurement. The integrated frequency and power measurement device based on RFID antenna transmission has the advantages that a testing instrument is small in size, convenient to carry and capable of being used in a narrow space, single-port input and integrated measurement of frequency and power can be achieved, the testing efficiency is high, a wireless testing system is convenient to establish, the limitation of the position where a tested device is located is avoided, the testing instrument can be controlled through an upper computer, and the testing efficiency is greatly improved.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP +1

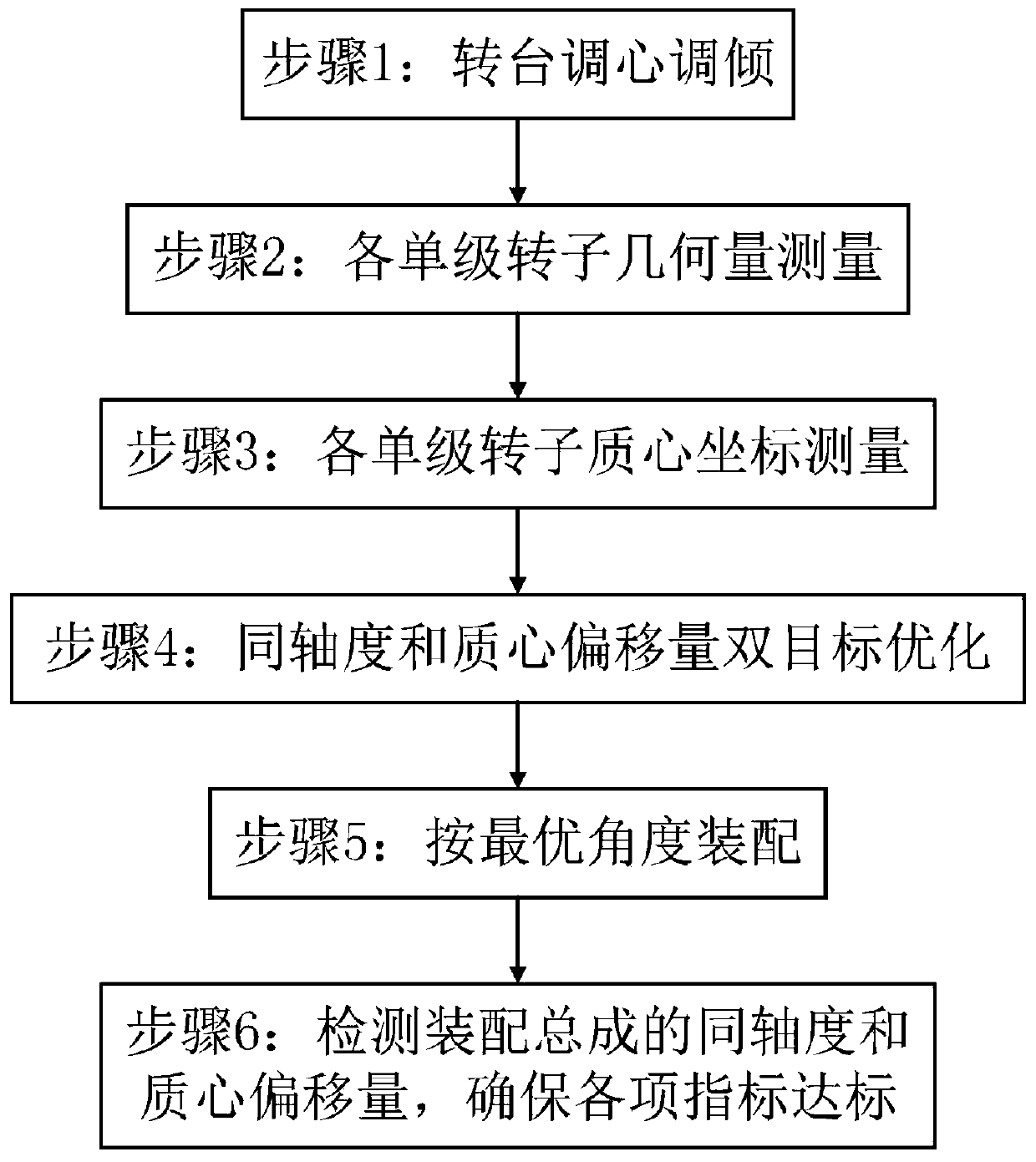

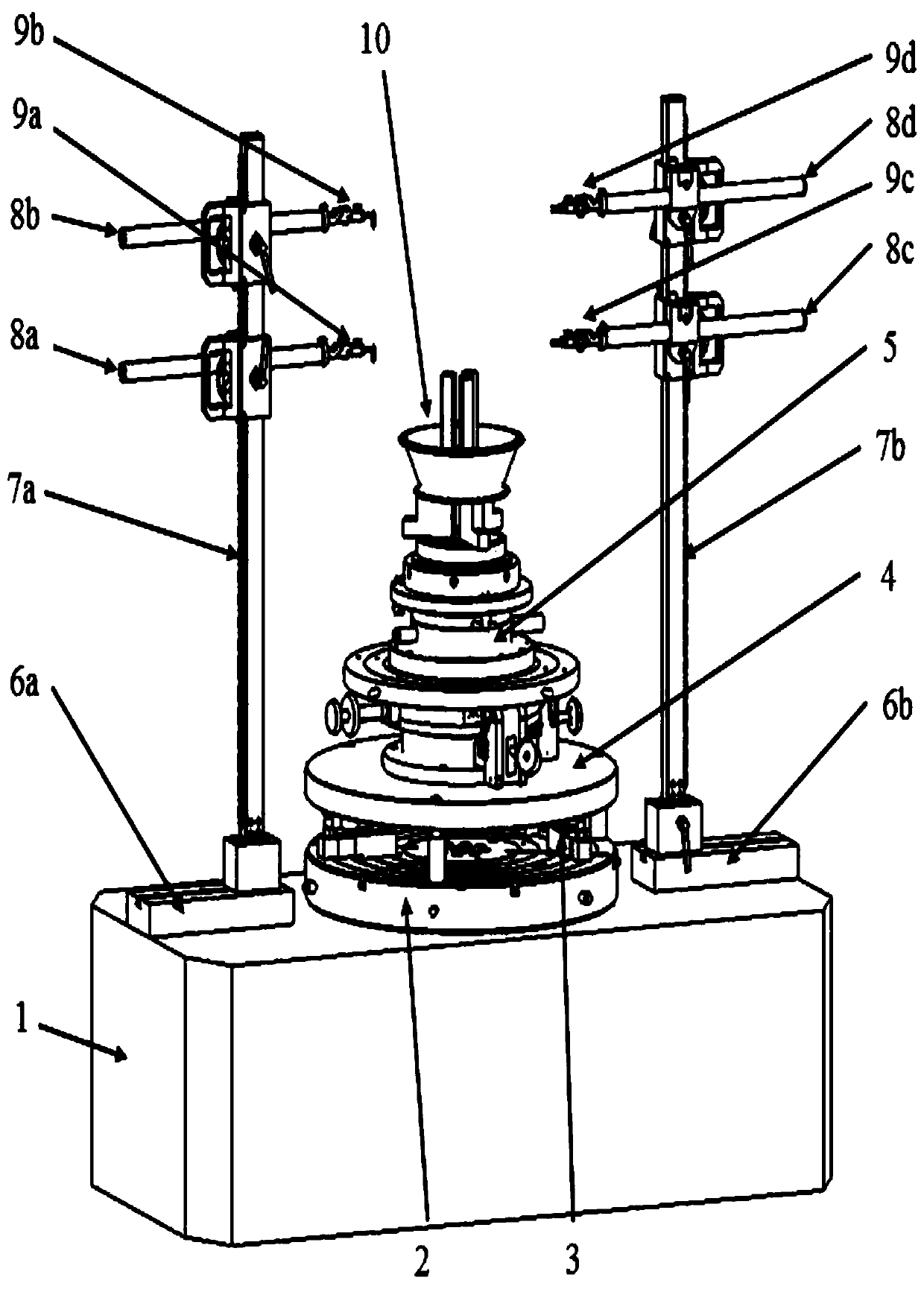

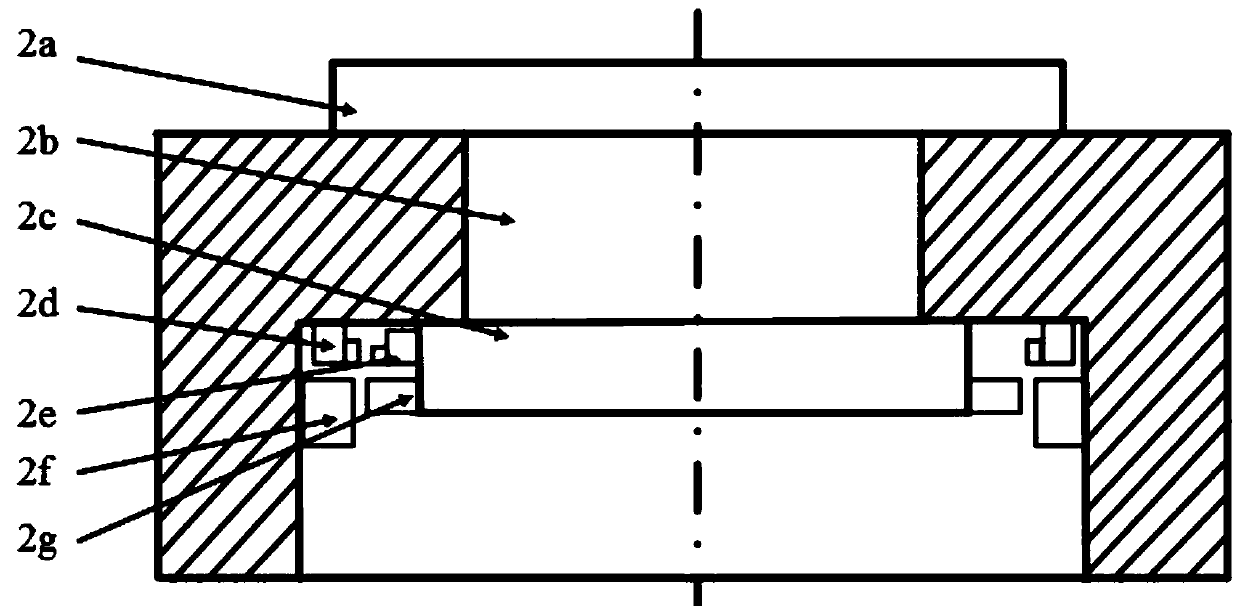

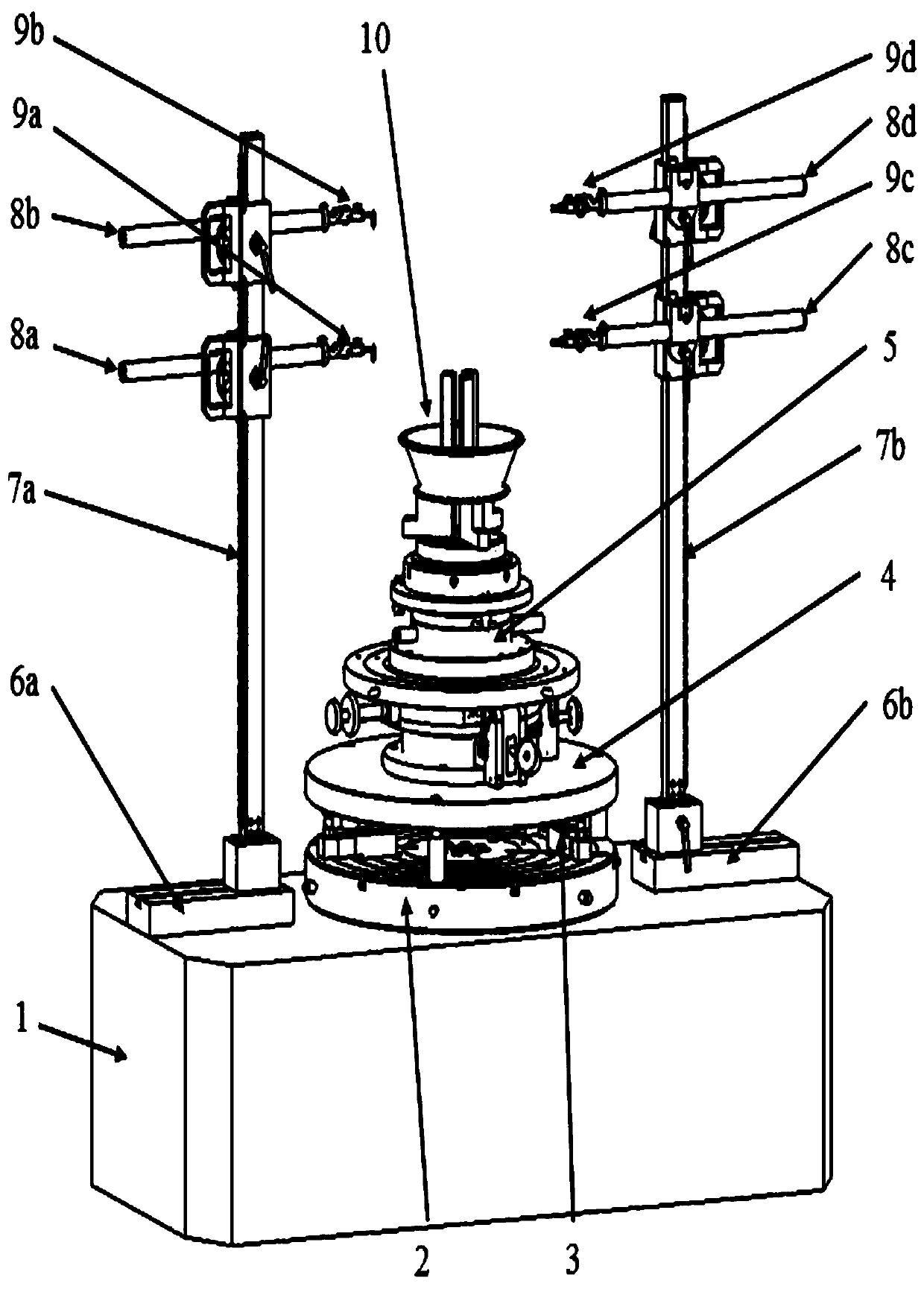

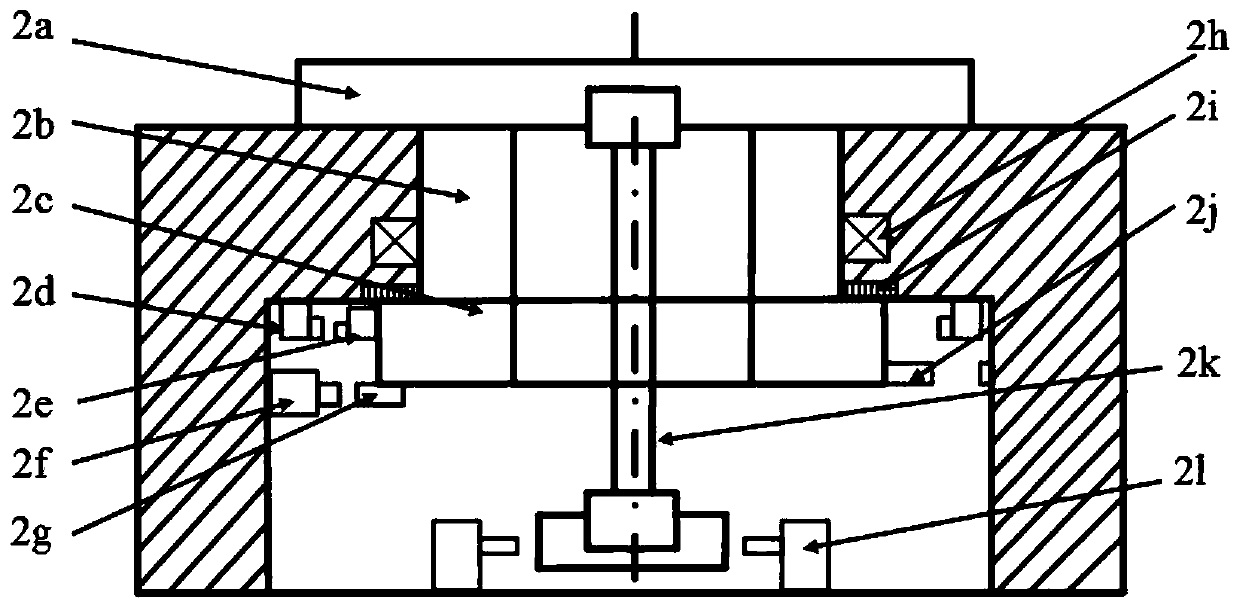

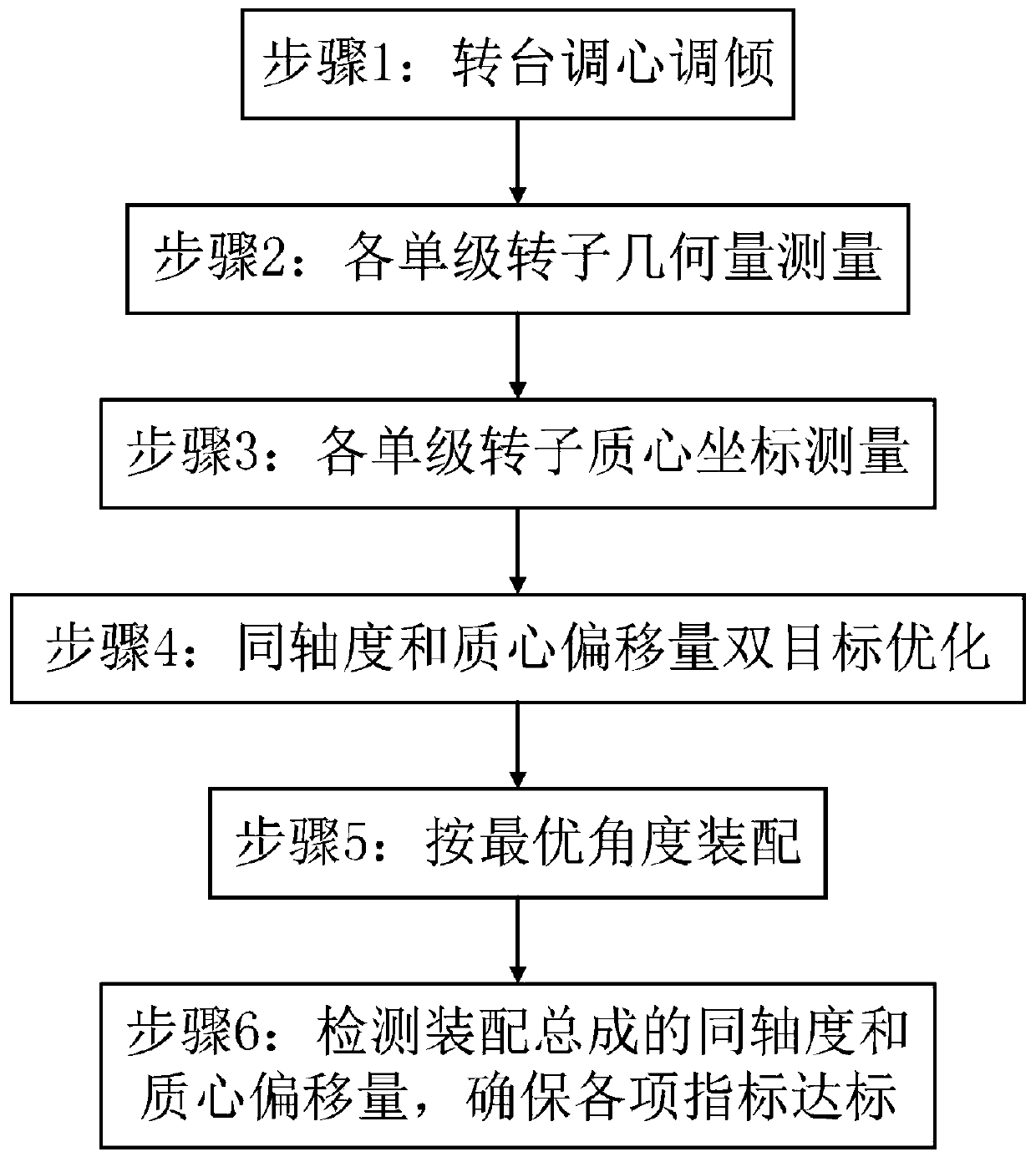

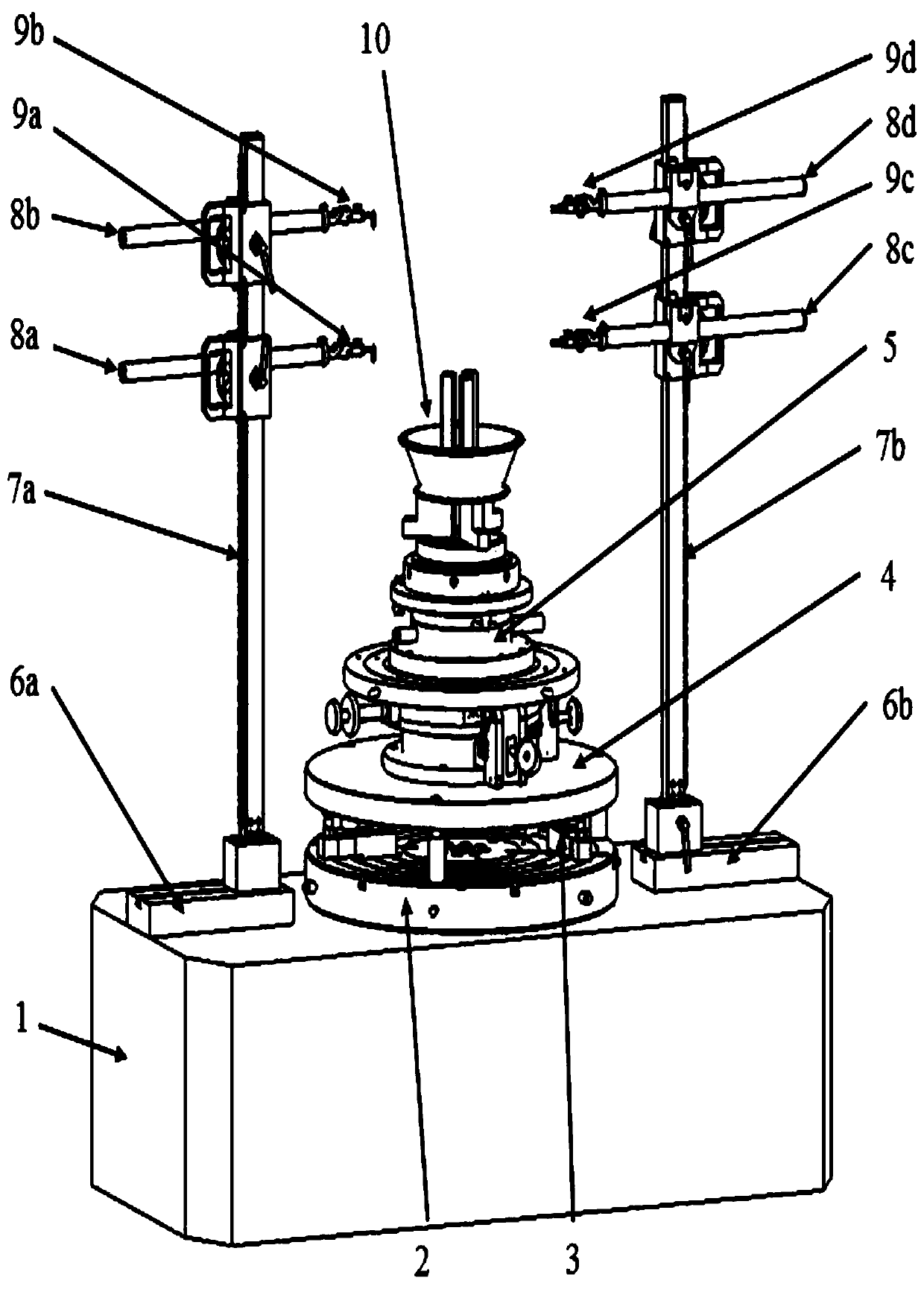

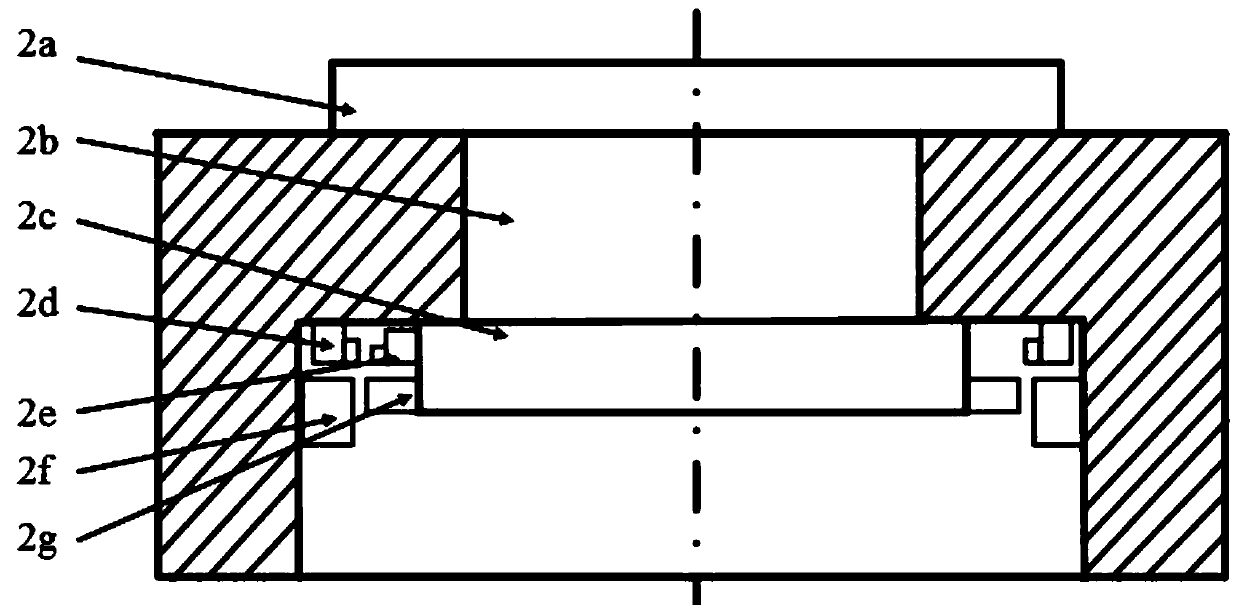

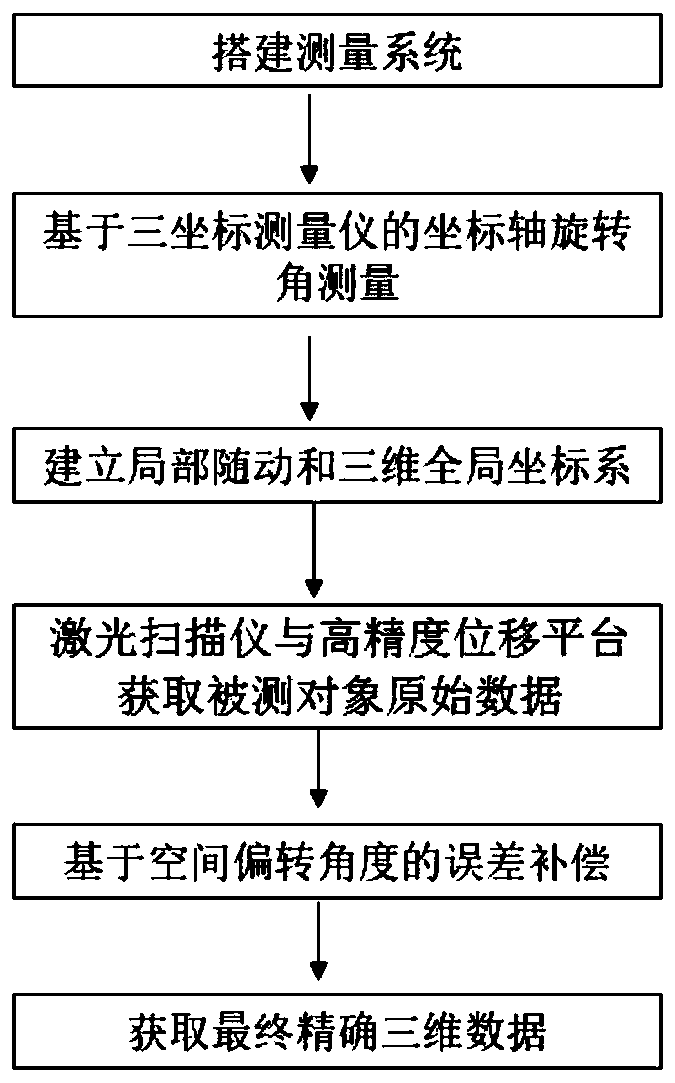

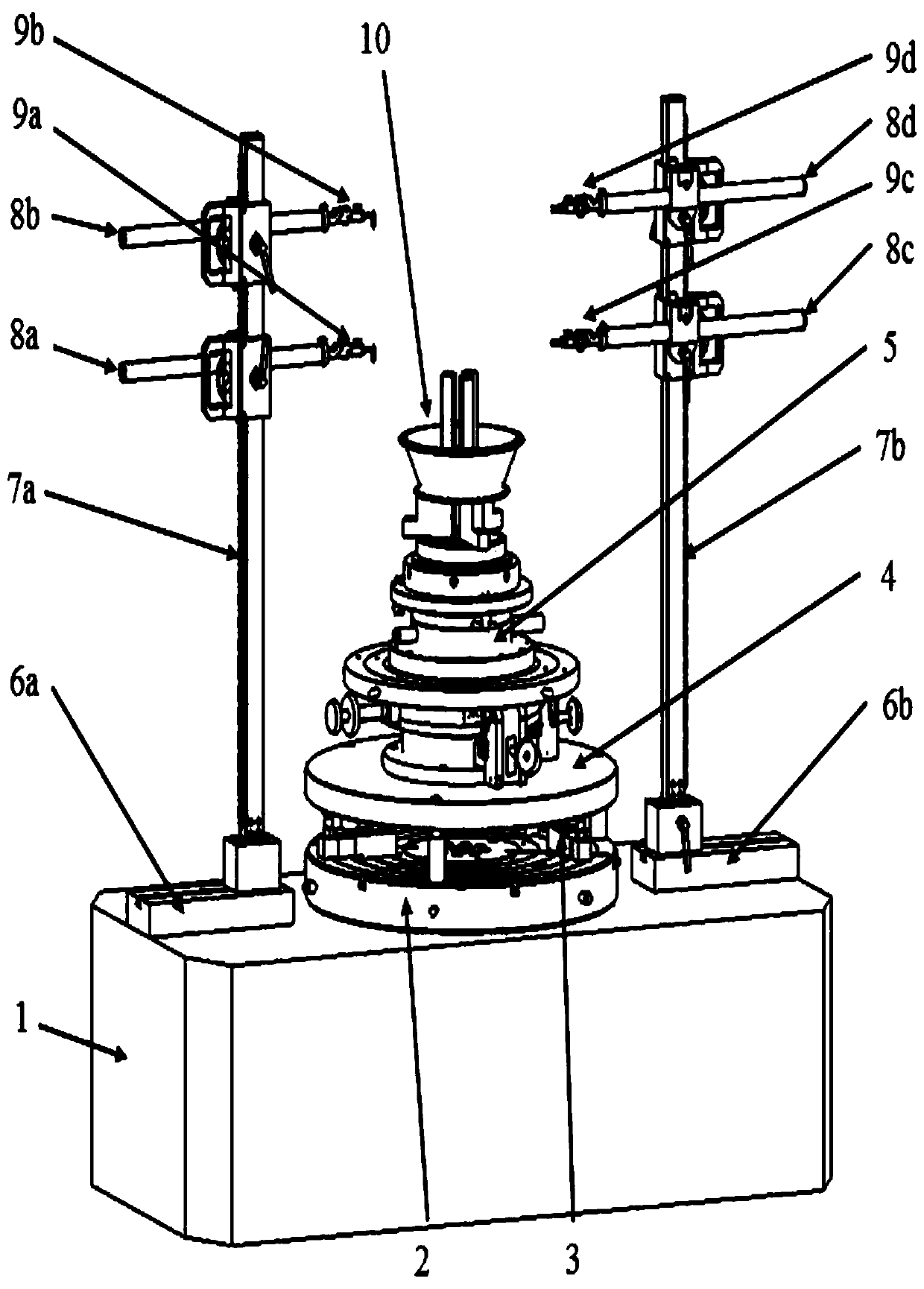

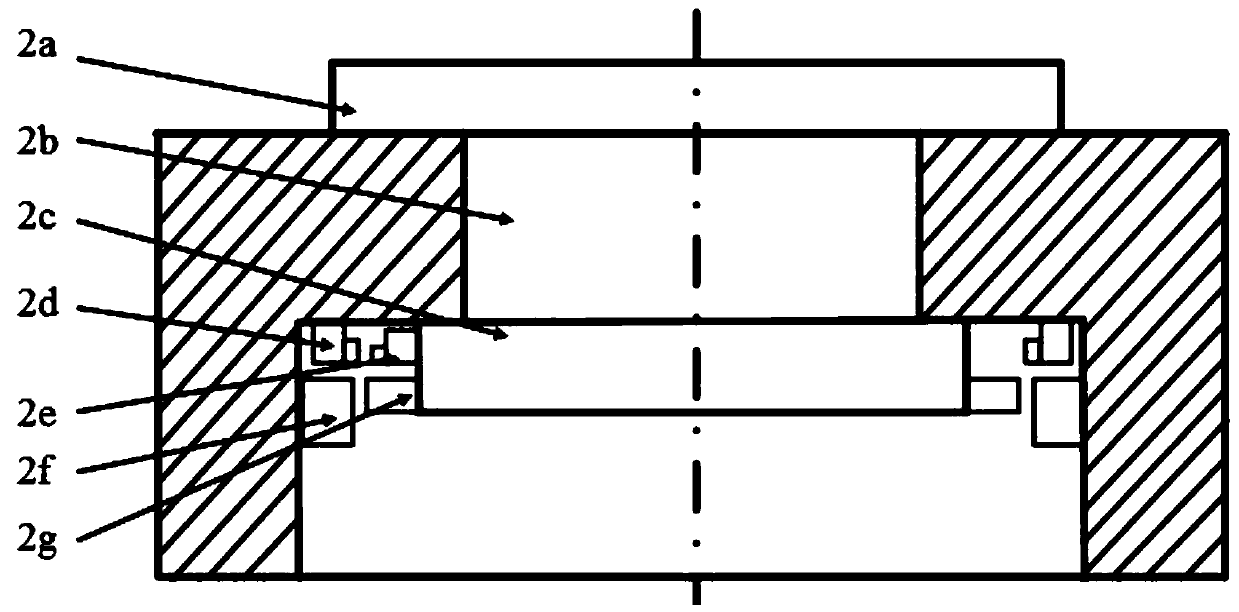

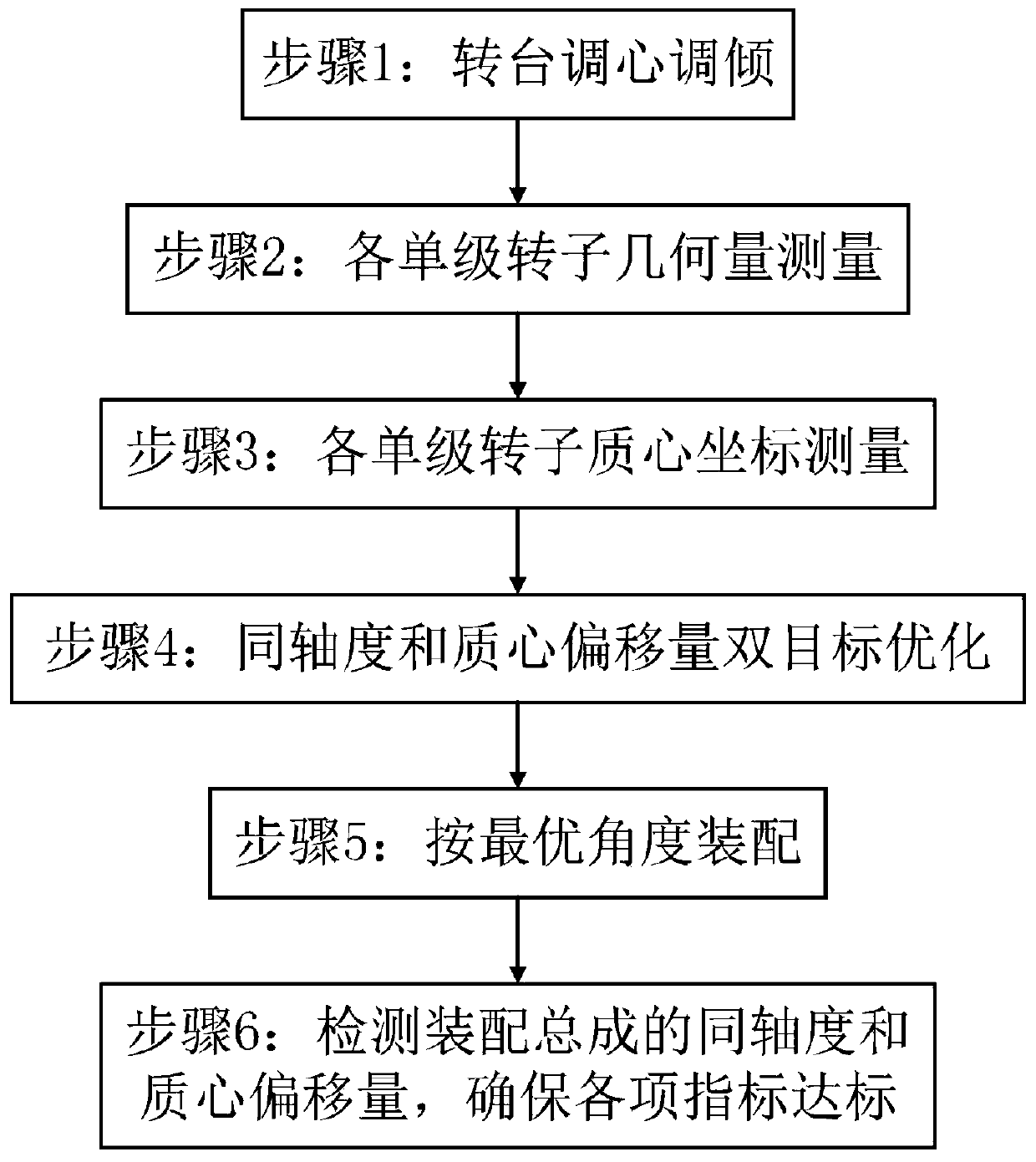

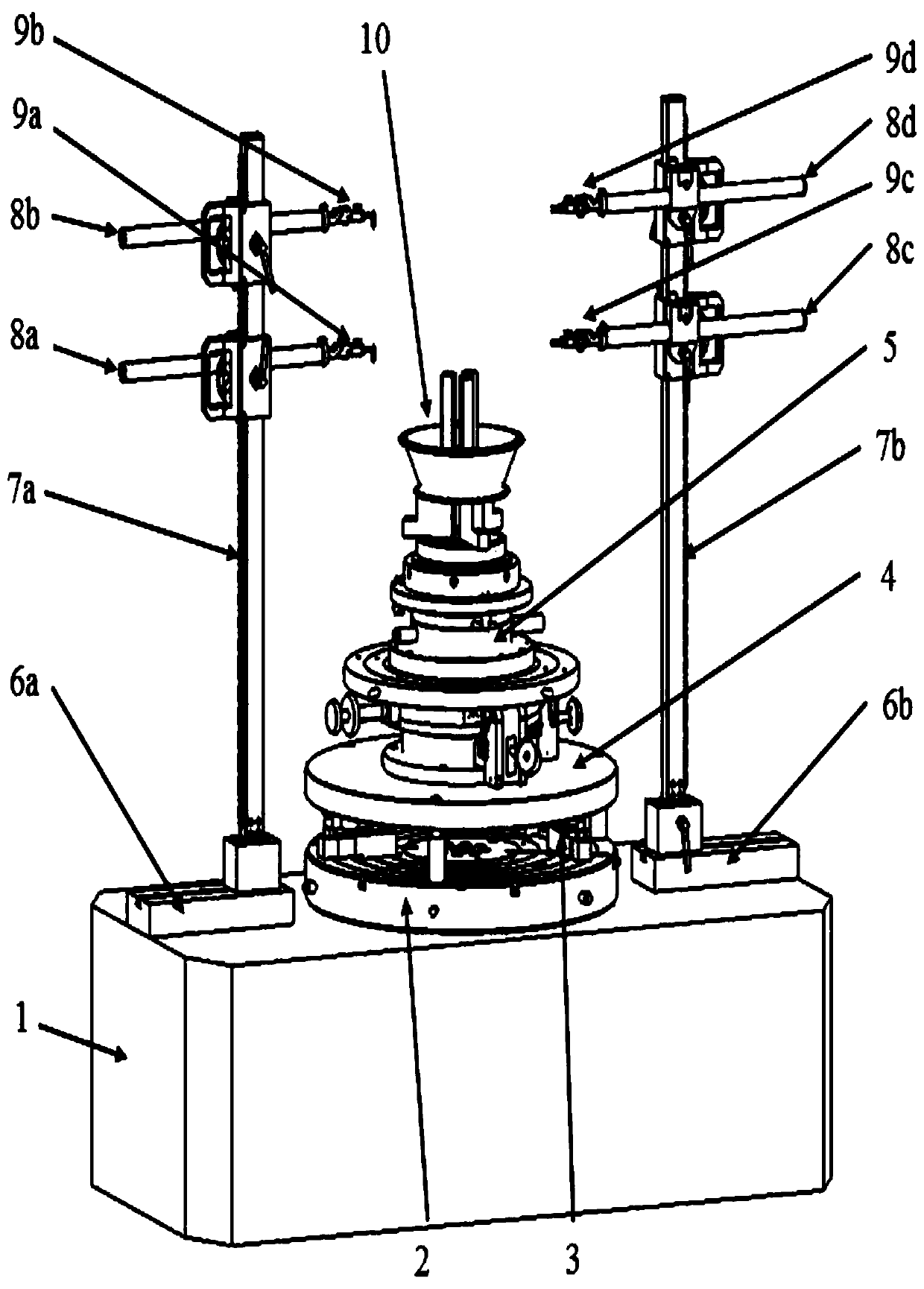

Aircraft engine rotor assembly measuring device based on three-point weighing and double-objective optimization method

InactiveCN110608668AImprove coaxialityControl unbalanceStatic/dynamic balance measurementUsing electrical meansAviationTransfer model

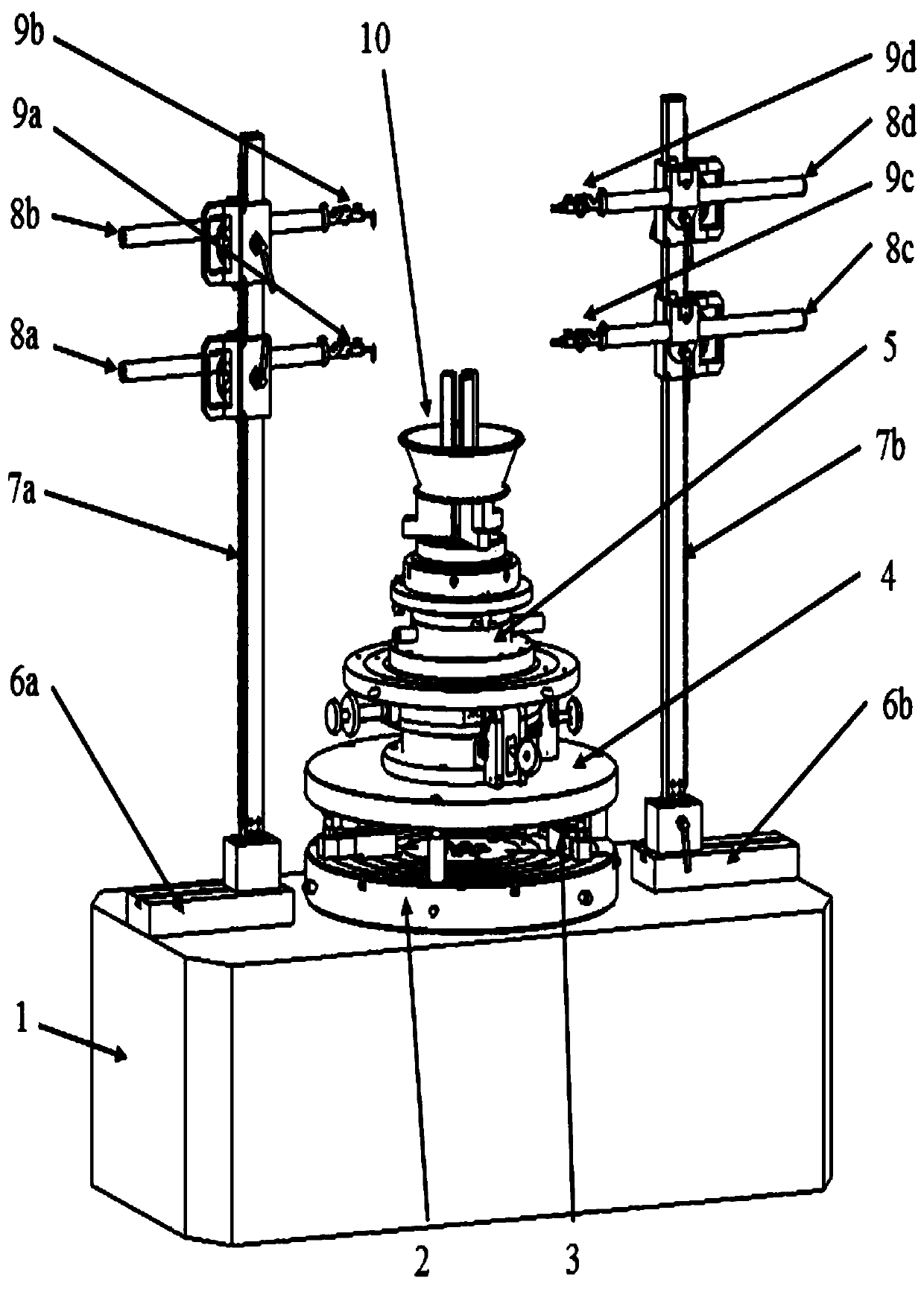

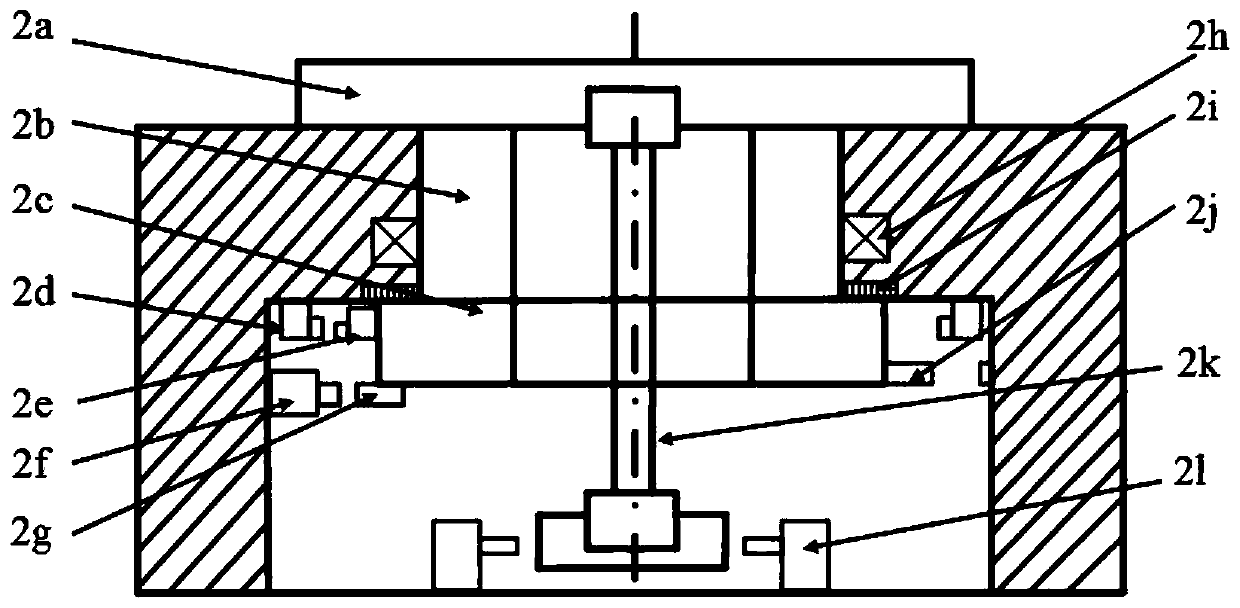

The invention discloses an aircraft engine rotor assembly measuring device based on three-point weighing and a double-objective optimization method. The double-objective optimization method comprisesthe following steps: determining the angle positioning of a rotary table based on a circular grating; ensuring the measurement and assembling of the concentricity, the parallelism and the center-of-mass coordinate of a measured rotor under the same reference based on an aligning and inclination adjusting device; based on a four-probe measuring device, respectively extracting concentricity errors of radial assembly surfaces and parallelism errors of axial assembly surfaces of all levels of rotors; based on a three-point weighing measuring device, respectively extracting radial coordinates of the mass centers of all levels of rotors; based on a rotor assembly pose transfer model, taking the coaxiality and center-of-mass offset of a rotor assembly as double optimization objectives, and obtaining the optimal assembly angle of each level of rotor through genetic optimization. The method can effectively solve the problem that coaxiality and an unbalance value exceed standard after the rotorof the aircraft engine is assembled, and has the characteristics of integrated measurement of the geometric and quality characteristics of the rotor, high one-time assembly qualification rate and reduction of engine vibration.

Owner:HARBIN INST OF TECH

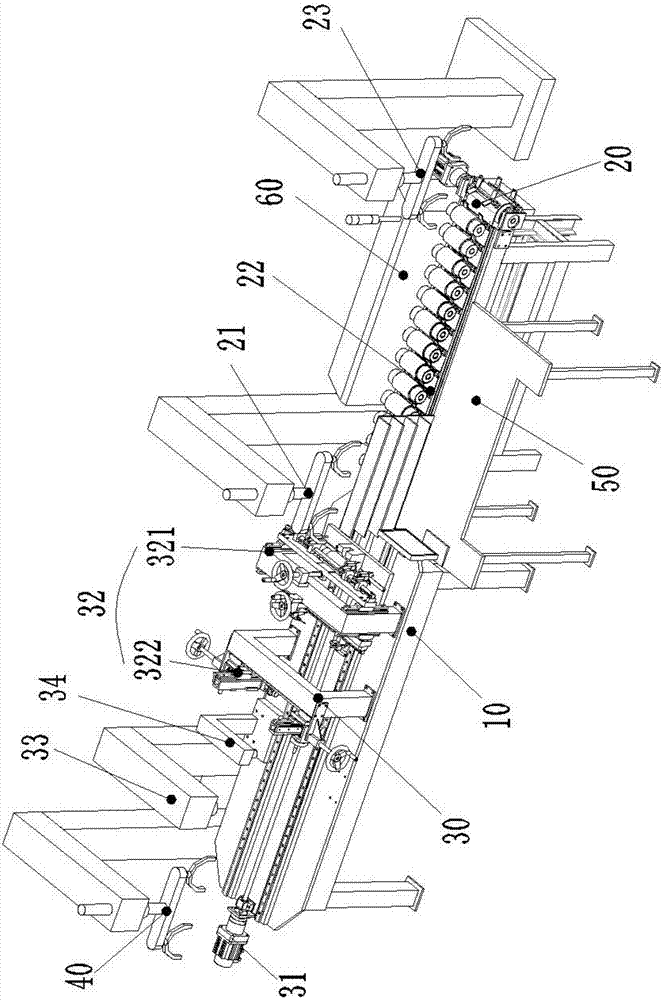

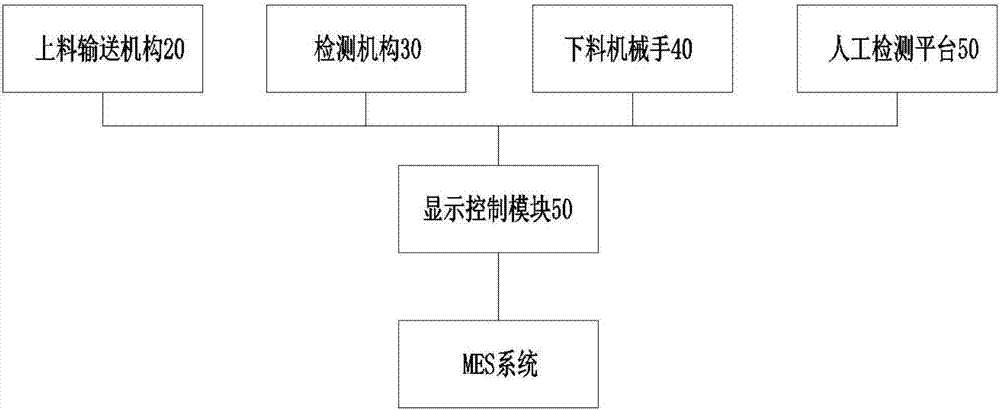

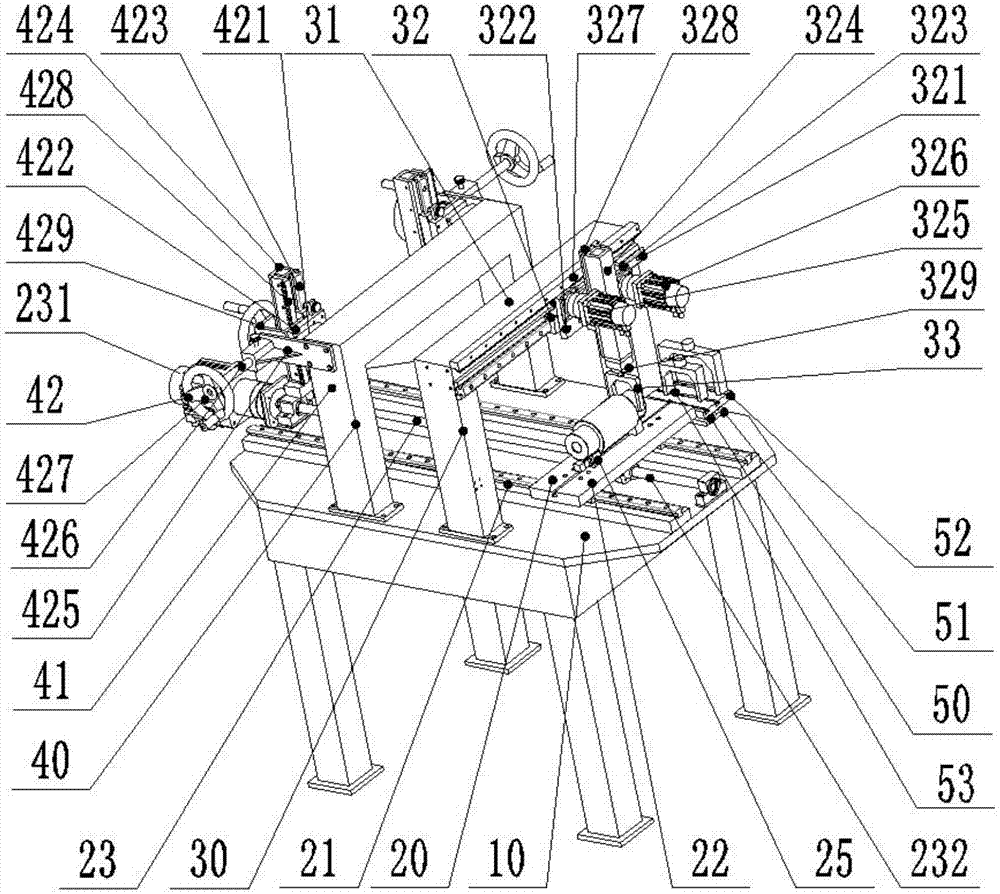

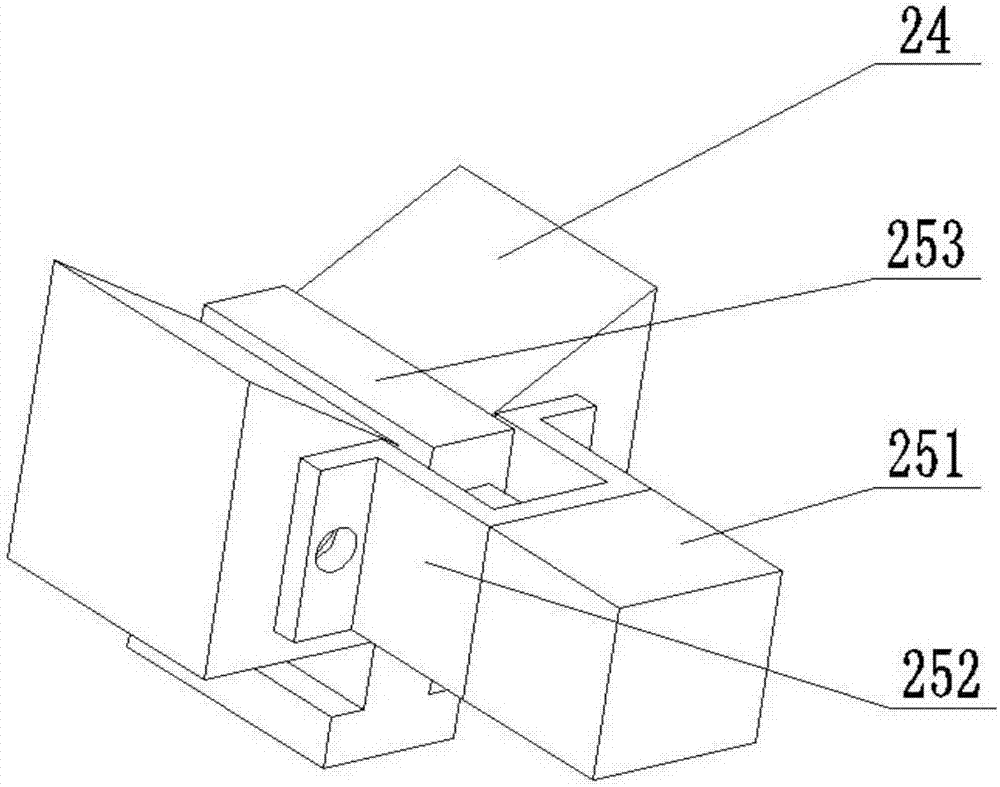

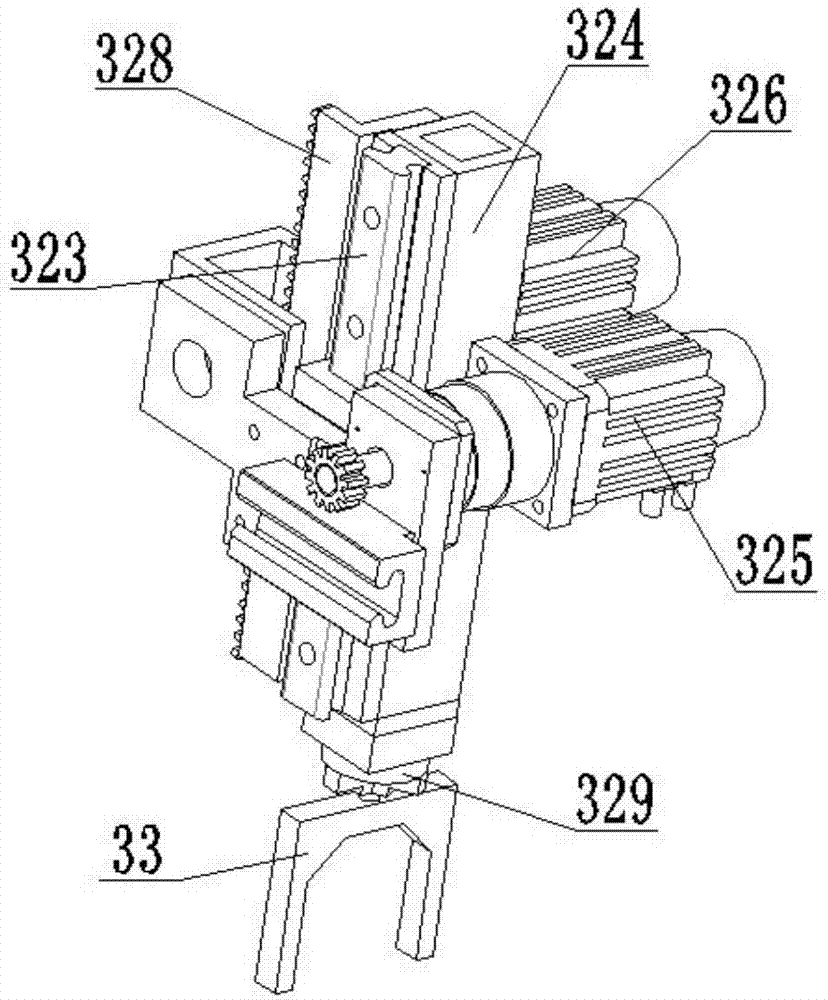

Automatic detection line for mechanical parts

PendingCN107957242ARealize integrated measurementImprove detection efficiencyUsing optical meansManipulatorEngineering

The invention discloses an automatic detection line for mechanical parts, including a base and a feeding and conveying mechanism and a detection mechanism arranged on the base in sequence. The feedingand conveying mechanism includes a detection feeding manipulator. The detection mechanism includes a detection transmission unit, a size detection unit and a code printer. The size detection unit andthe code printer are arranged in sequence along the detection transmission unit. The size detection unit is disposed between the detection feeding manipulator and the code printer. The detection feeding manipulator is used for feeding parts to the detection transmission unit. The detection transmission unit, the size detection unit and the code printer are respectively used for transmitting parts, detecting the sizes of parts and marking parts with codes. According to the automatic detection line for mechanical parts, through the feeding and conveying mechanism and the detection mechanism, integrated measurement of the length, inner hole and projection of a mechanical part is realized, and qualified products can be marked with codes by laser. Mechanical parts can be detected on a large scale. Compared with manual detection, detection is more efficient, and detection is more convenient, quicker and more accurate.

Owner:KEDA INDUSTRIAL GROUP CO LTD

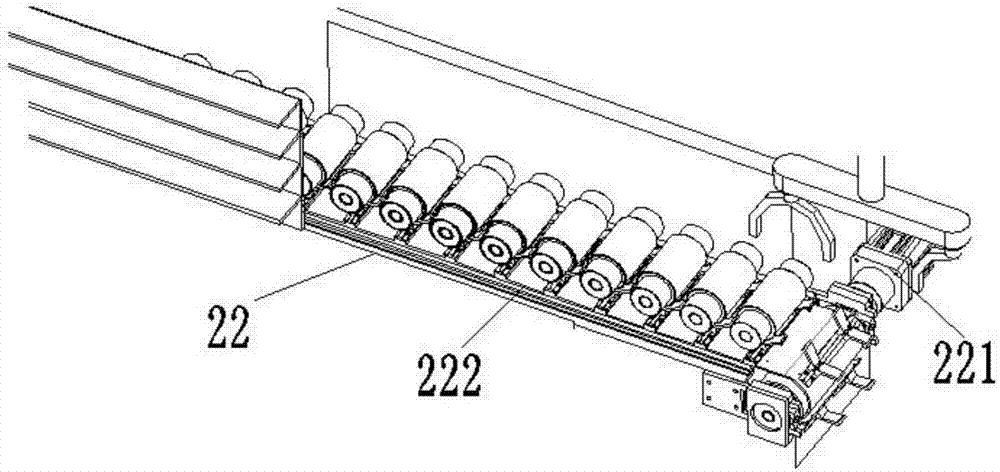

Online detection system for combustible gas detector

PendingCN111830201AGas concentration is continuously adjustableRealize integrated measurementMaterial analysisAir velocityThermodynamics

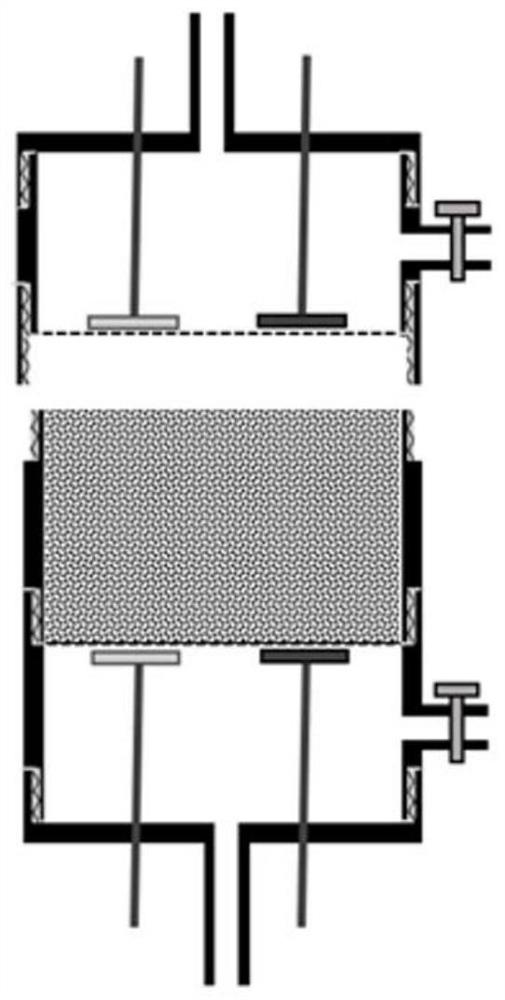

The invention relates to an online detection system for a combustible gas detector. The online detection system comprises an annular box, a gas distribution and gas concentration analysis monitoring system, a wind speed monitoring and control system, an orientation test intelligent control system and a temperature and humidity monitoring and control system. The annular box is a closed annular space and is used for providing a simulated industrial field environment for online detection of the gas detector; the gas distribution and gas concentration analysis monitoring system is connected with the annular box; the wind speed monitoring and control system is connected with the annular box; the orientation test intelligent control system comprises an electrical control system and an orientation test bench, wherein the orientation test bench is a three-axis rotation test bench, and the orientation test bench is arranged in the annular box; and the temperature and humidity monitoring and control system is connected with the annular box. According to the invention, the on-line working environment of the combustible gas detector can be simulated, and comprehensive technical evaluation canbe carried out on the combustible gas detector more scientifically and reasonably.

Owner:山西省计量科学研究院

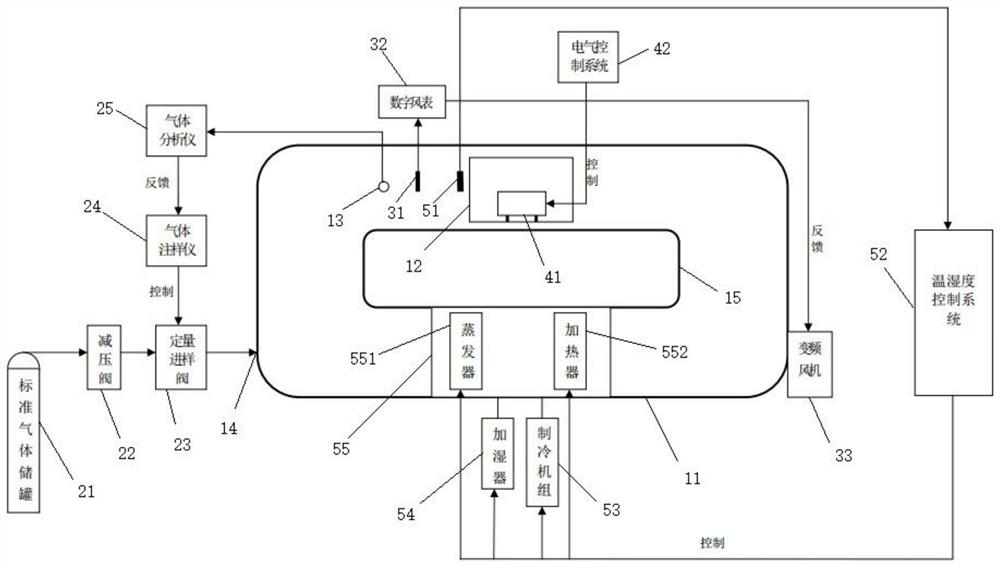

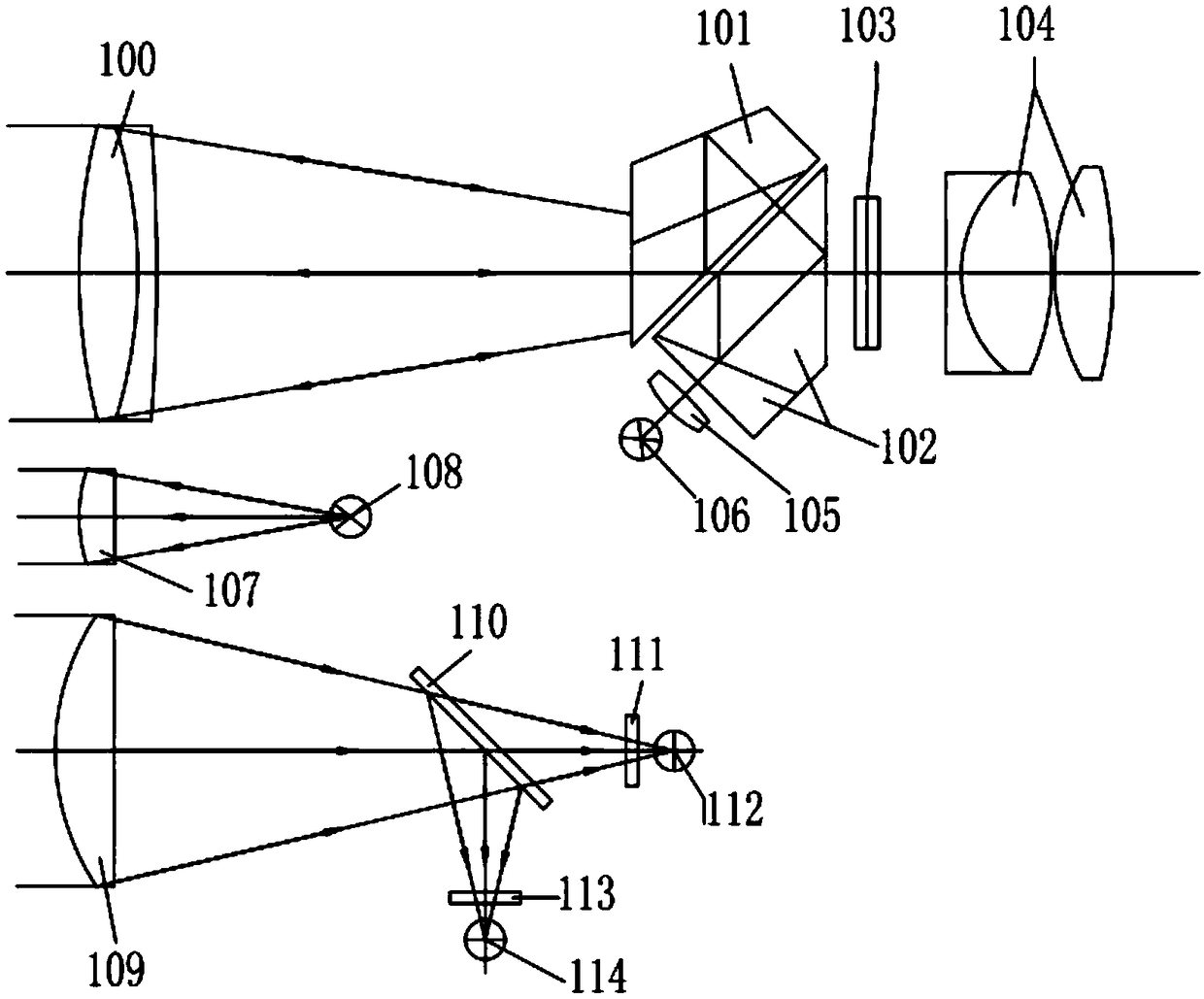

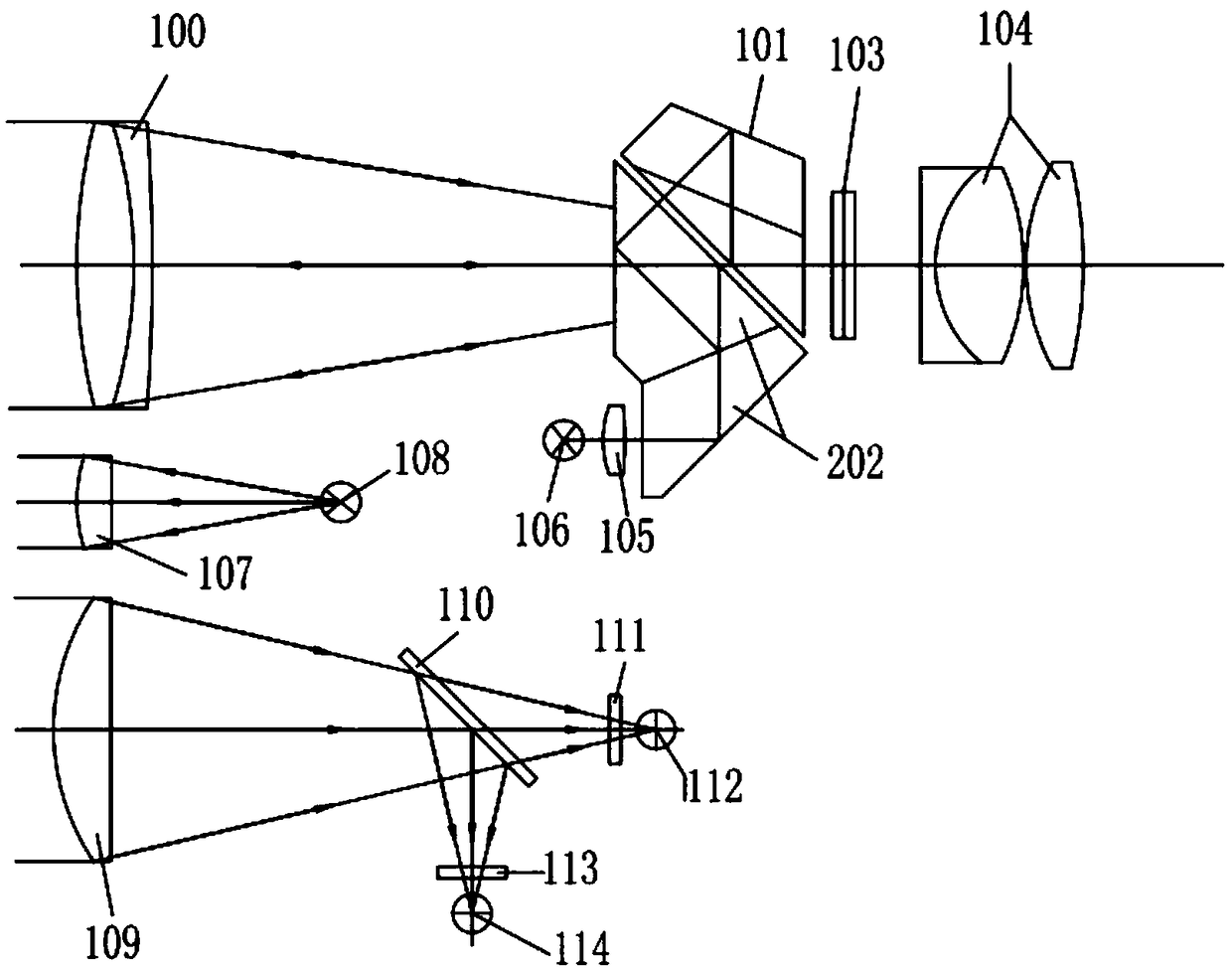

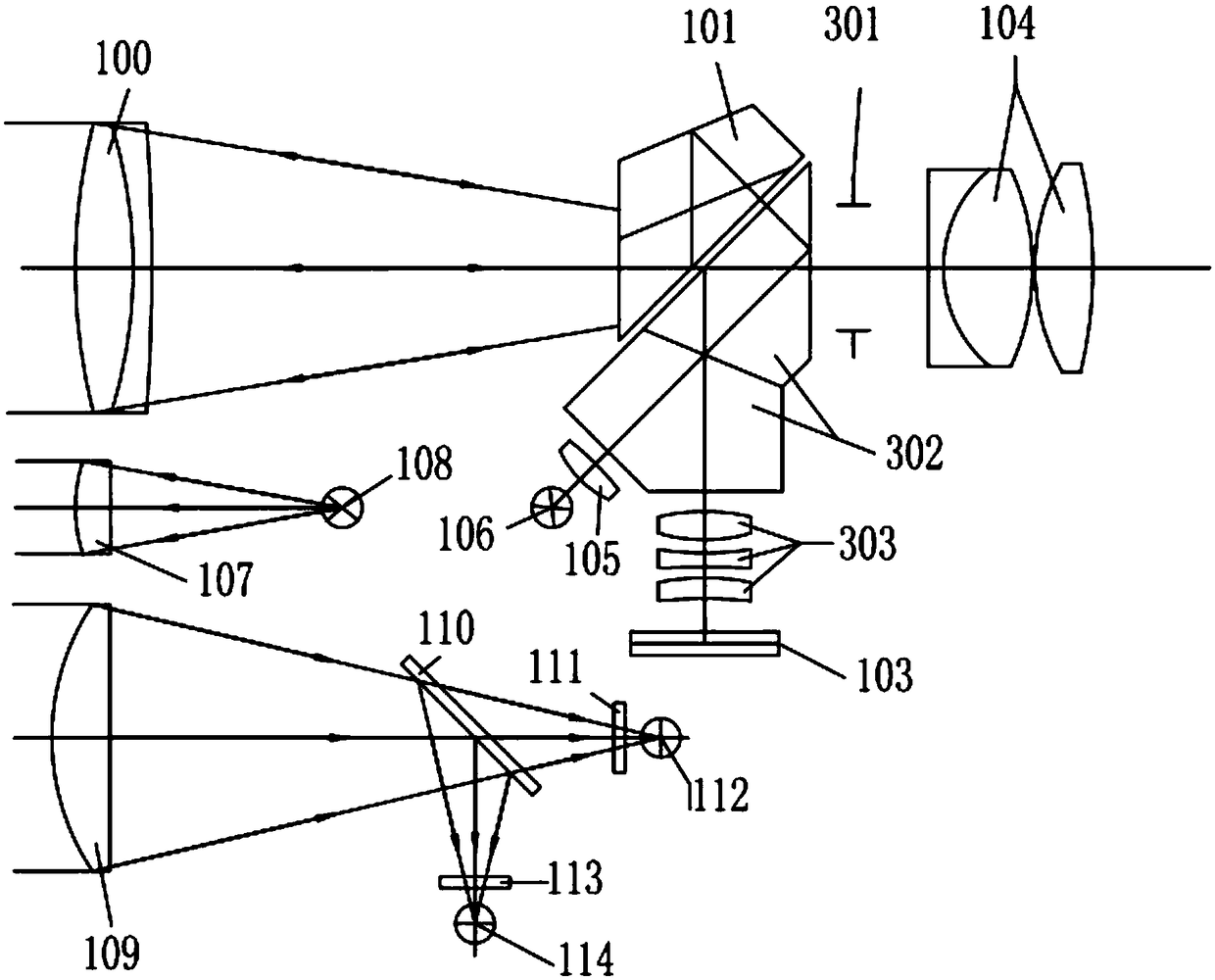

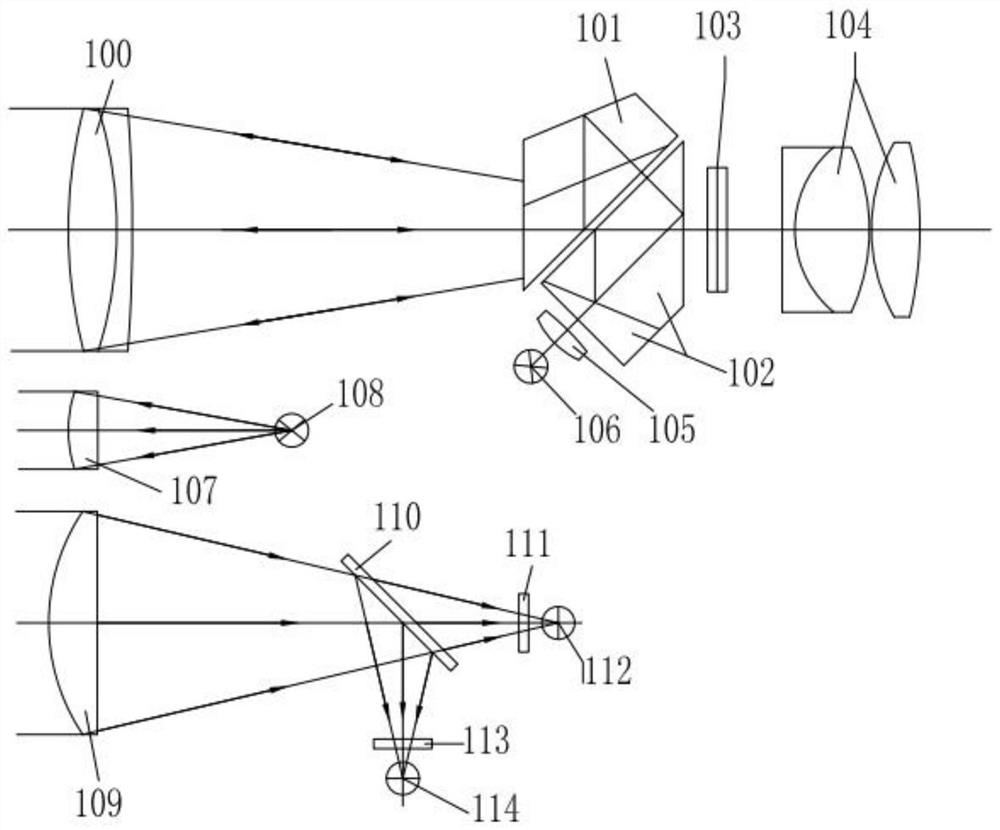

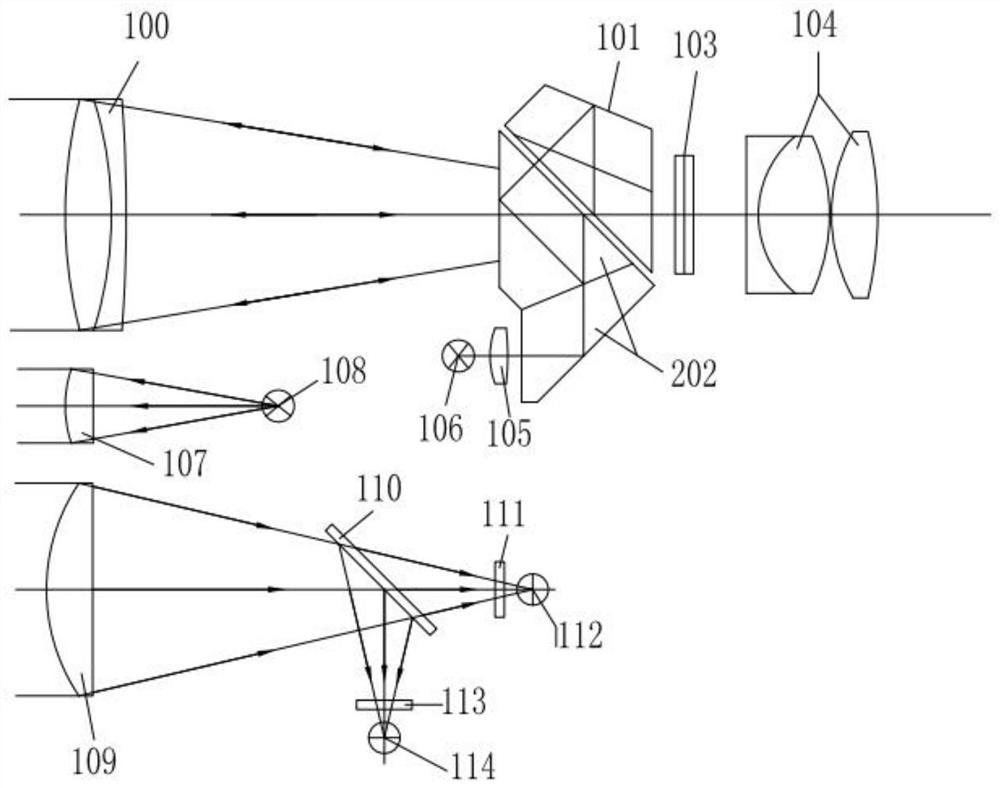

Multifunctional wide-range spectral measurement device for diamond press

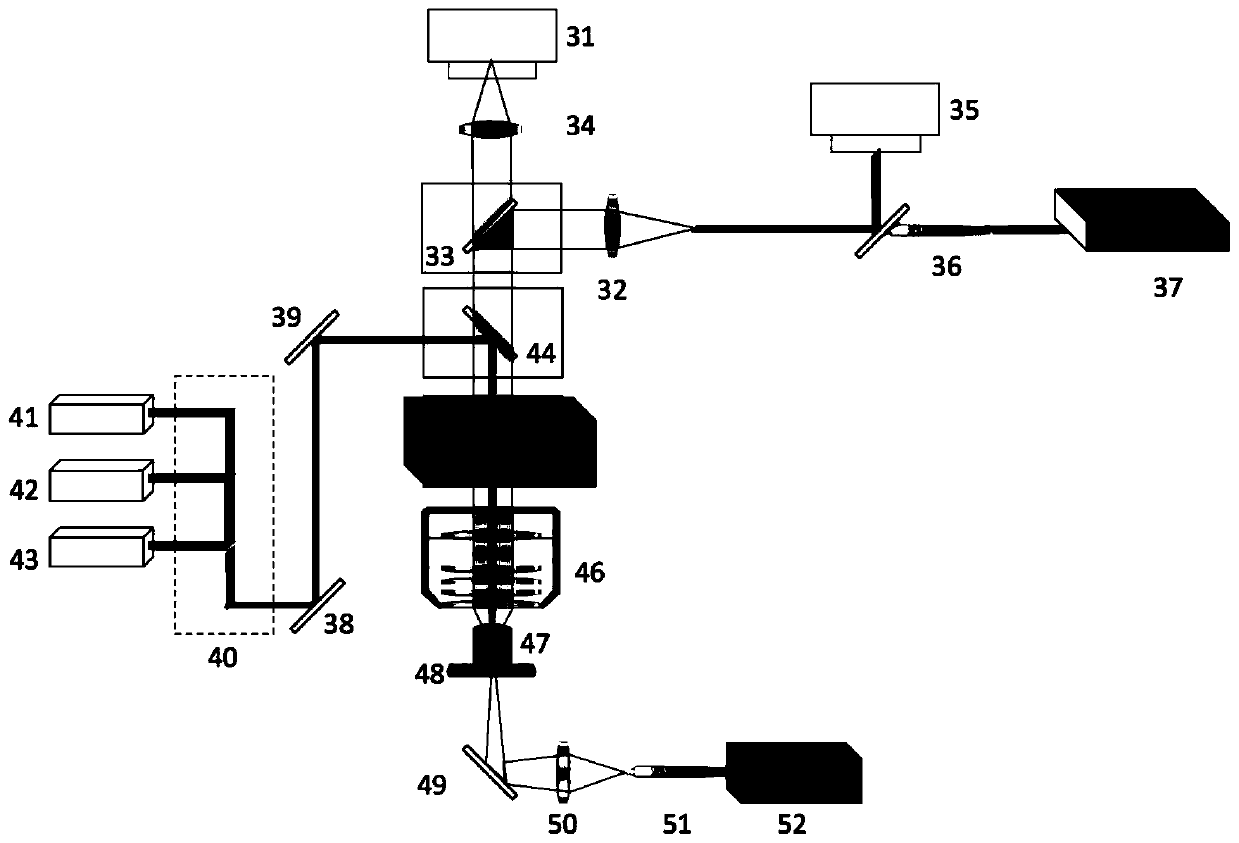

PendingCN110887821ARealize integrated measurementHigh measurement sensitivityFluorescence/phosphorescenceLight equipmentFirst light

The invention relates to a multifunctional wide-range spectral measurement device for a diamond press. The multifunctional wide-range spectral measurement device comprises a transmission incident light source part, a laser incident part, a signal receiving part and a microscopic light path part, wherein the microscopic light path part comprises a first light path switcher, a second light path switcher, fluorescent lighting equipment, an objective lens group, an objective table and a first reflecting mirror; the laser incident part comprises a laser router; the signal receiving part comprises athird light path switcher and at least one spectrograph, and is used for collecting an absorption spectrum, a reflection spectrum, a fluorescence spectrum and an image; and the first light path switcher is connected with the signal receiving part, the second light path switcher is connected with the laser incident part, and the first reflecting mirror is connected with the transmission incident light source part. The multifunctional wide-range spectral measurement device solves the technical problem that the fluorescence spectrum, the fluorescence imaging, the absorption spectrum and the reflection spectrum of a sample in the diamond press under high pressure are difficult to measure at the same time by means of an existing testing device, and realizes integrated in-situ measurement of the sample in the diamond press.

Owner:CENT FOR HIGH PRESSURE SCI & TECH ADVANCED RES

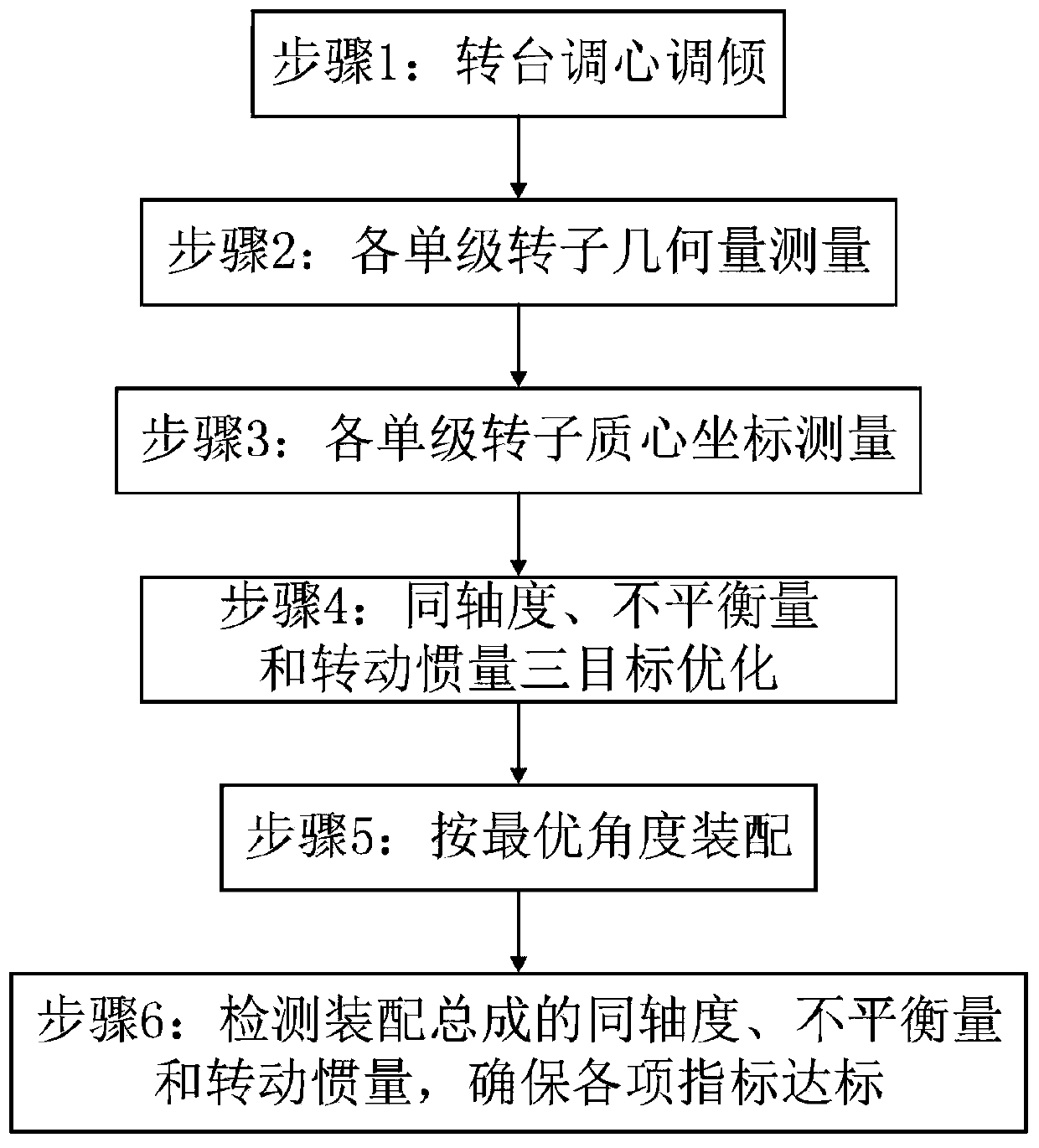

Aero-engine rotor assembly measuring device and three-target optimization method based on three-point weighing

InactiveCN110608667AControl balanceOptimizing for multiple objectivesStatic/dynamic balance measurementUsing electrical meansAviationMeasurement device

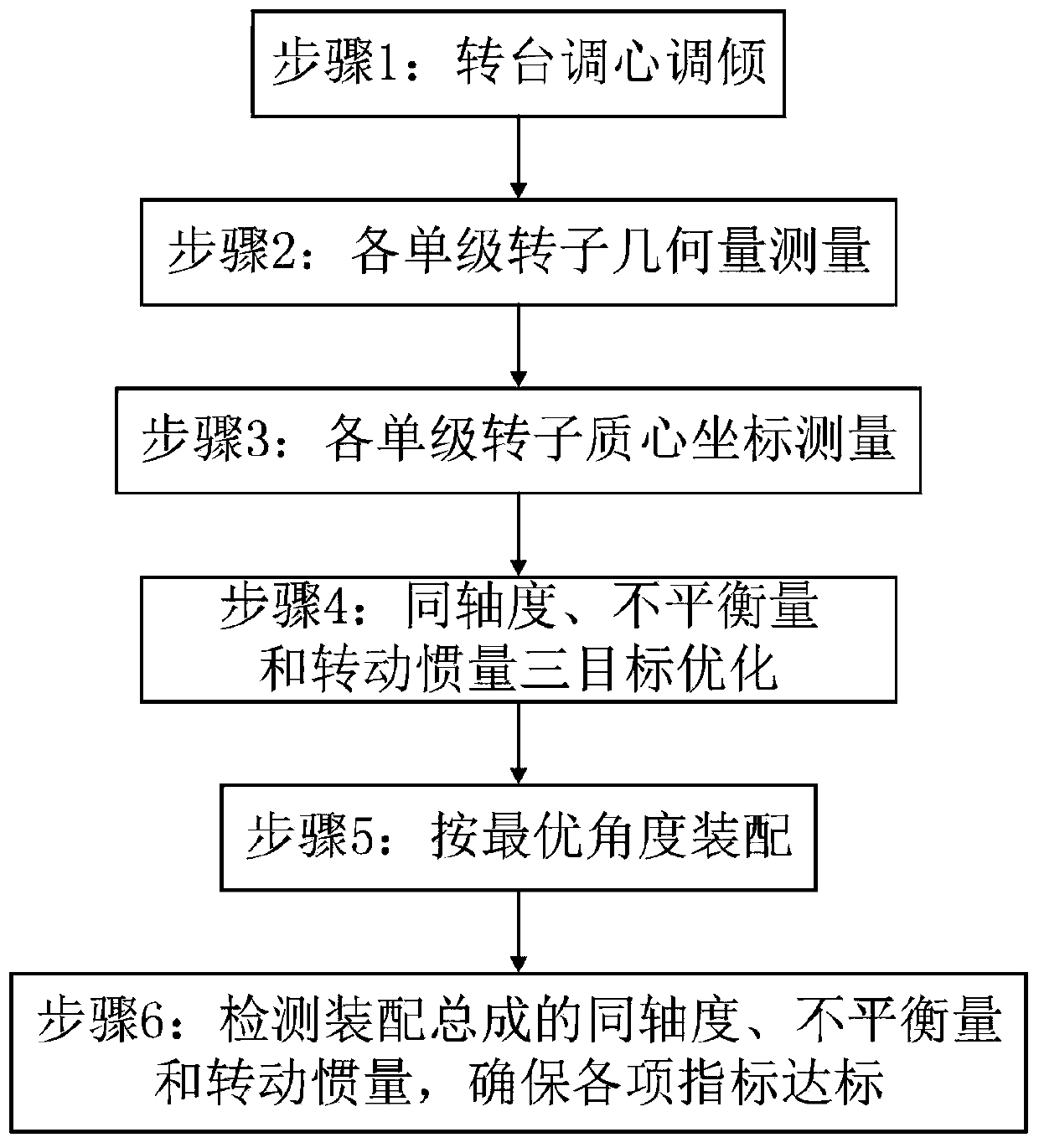

The invention relates to an aero-engine rotor assembly measuring device and three-target optimization method based on three-point weighing. Based on a four-head measuring device, a concentricity errorof the radial assembling surface and a parallelism error of the axial assembling surface of each stage of rotor are extracted; based on a three-point weighing measuring device, radial coordinates ofthe centroid of each stage of rotor are extracted; based on a rotor assembly attitude transmission model, an optimal assembly angle of each stage of rotor is obtained through genetic optimization by taking the coaxiality, the unbalance amount and the rotational inertia of a rotor assembly as three optimization targets; and based on a torsion rod measuring device, the rotational inertia of the longitudinal axis of the assembly is obtained. The device and the method can effectively solve the over-standard problem of the coaxiality, the unbalance amount and the rotational inertia of the assembledaero-engine rotor, and have the characteristics of integrated measurement of rotor geometry and mass characteristics, high one-time assembly qualification rate and reduced engine vibration.

Owner:HARBIN INST OF TECH

Automatic shaft measuring machine

PendingCN107957253AImprove detection efficiencyThe detection is convenient, fast and accurateMeasurement devicesEngineeringPallet

The invention discloses an automatic shaft measuring machine which includes a base, a clamping mechanism, an outer diameter measuring mechanism and an inner hole measuring mechanism. The clamping mechanism includes an X-direction guide rail, a support plate and a support plate driving component. The support plate driving component is connected with the support plate and is used for driving the support plate to slide on the X-direction guide rail. The outer diameter measuring mechanism includes an outer diameter measuring bracket, an outer diameter measuring mobile unit and an outer diameter measurer. The outer diameter measuring mobile unit is used for driving the outer diameter measurer to move in the Y and Z directions. The inner hole measuring mechanism includes an inner hole measuringbracket, an inner hole measuring mobile unit and an inner hole measurer. The inner hole measuring mobile unit is used for driving the inner hole measurer to move in the Y and Z directions. The automatic shaft measuring machine of the invention can be used to detect the critical geometric dimensions of a large batch of shaft parts, and is more efficient than artificial detection. Compared with artificial detection, the detection is more convenient, quicker and more accurate.

Owner:KEDA INDUSTRIAL GROUP CO LTD

Laser distance measuring system for realizing long-distance and short-distance measurement

PendingCN111812664AGuaranteed measurement accuracyImprove ranging abilityElectromagnetic wave reradiationLaser rangingGrism

The invention discloses a laser distance measuring system for realizing long-distance and short-distance measurement. The laser distance measuring system comprises a laser light source, a collimationlight source, a first transmitting lens, a second transmitting lens, a receiving lens, a prism group, an image sensor, a photosensitive element, a distance display unit and an eyepiece; distance measuring light emitted by the laser light source passes through the first emitting lens and then irradiates a measured object, collimation light emitted by the collimation light source passes through thesecond emitting lens and then irradiates the measured object, and the distance measuring light and the collimation light emitted by the measured object pass through the receiving lens and then enter the prism group. Through the prism group, the collimation light and the distance measuring light are separated, the separated collimation light enters the image sensor, the separated distance measuringlight enters the photosensitive element, and natural light sequentially penetrates through the prism group and the distance display unit to enter the eyepiece. The laser distance measuring system issimple in structure, is convenient to use, and can achieve the integrated measurement from the short-distance high-precision measurement to the long-distance measurement of a product.

Owner:LANHAI PHOTOELECTRICITY TECH CO LTD

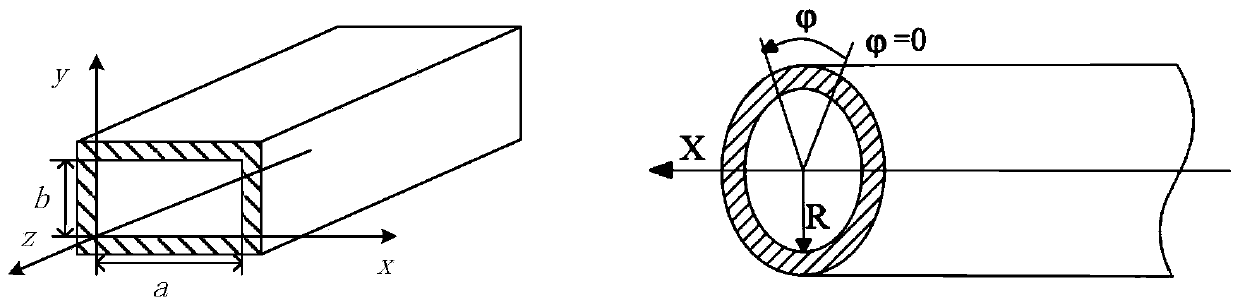

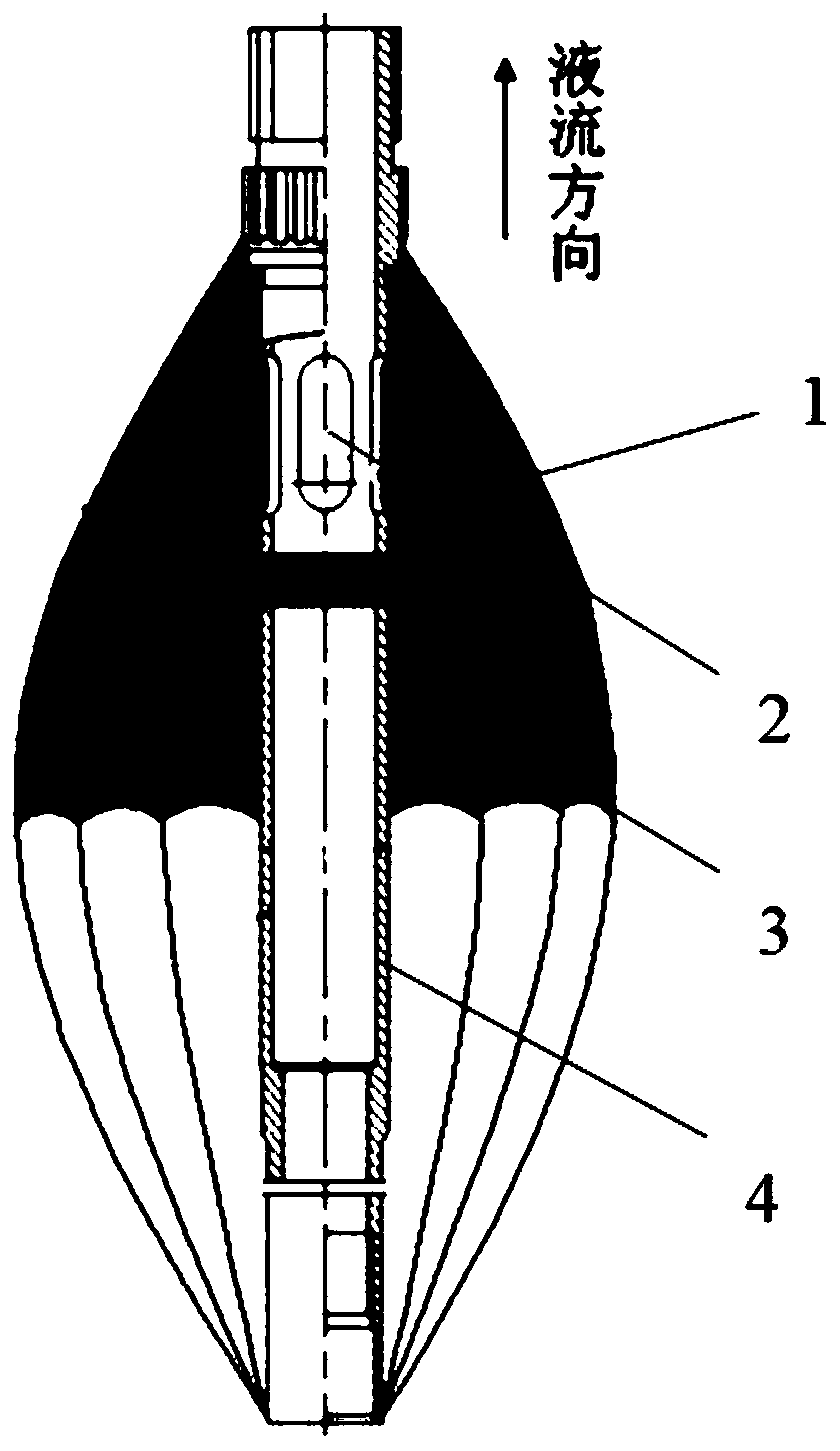

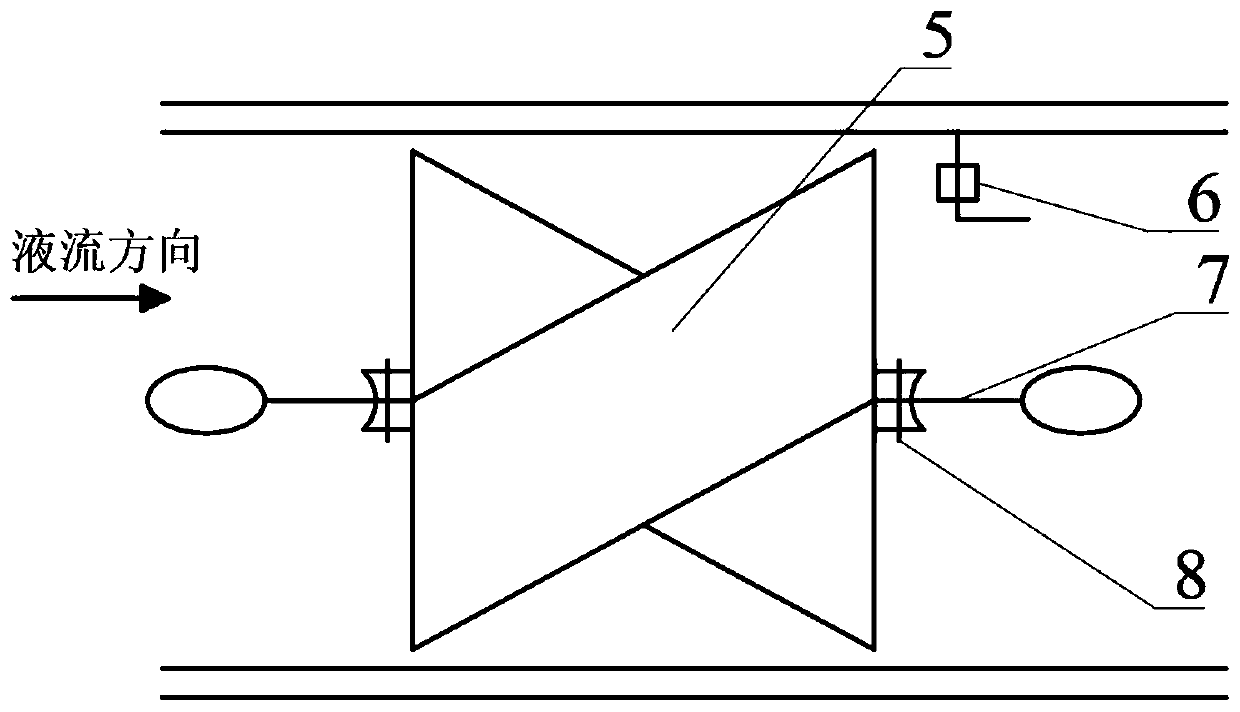

Waveguide phase measurement method and device for water content and flow of oil well

ActiveCN110700811ARealize integrated measurementAvoid shakaSurveyMaterial analysis using wave/particle radiationWell loggingOil water

The invention discloses a waveguide phase measurement method and device for water content and flow of an oil well, and belongs to the technical field of production logging by integrally measuring thewater content and flow of crude oil through a waveguide method. A shell of a logging instrument serves as a waveguide sensor, a plurality of receivers are arranged in a waveguide in sequence in the electromagnetic wave propagation direction, phase characteristics of electromagnetic wave propagation on different waveguide lengths are respectively measured, water content signals measured by the receivers are utilized, and then the flow of a fluid medium is obtained through correlation function processing. According to the technical scheme, the measurement accuracy of the water content of the oil-water medium in the oil well and the success rate of flow measurement can be further improved.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY +1

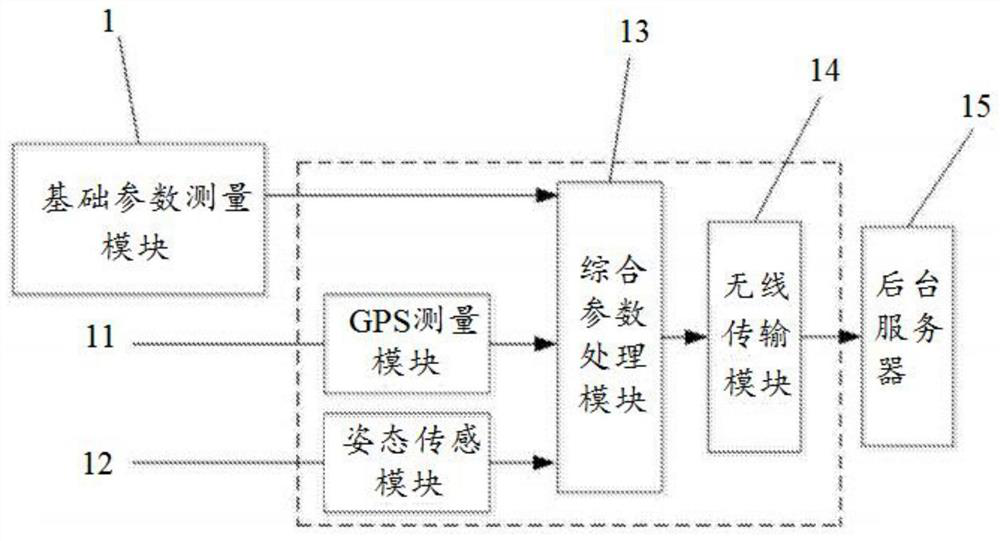

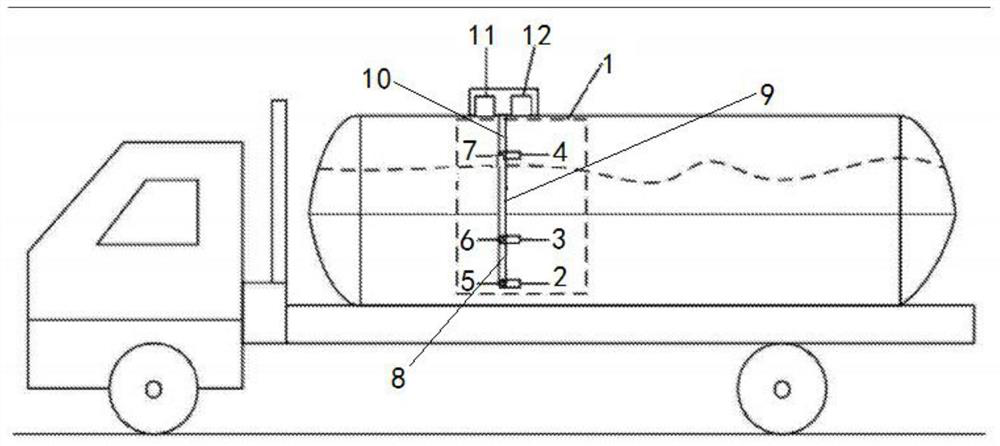

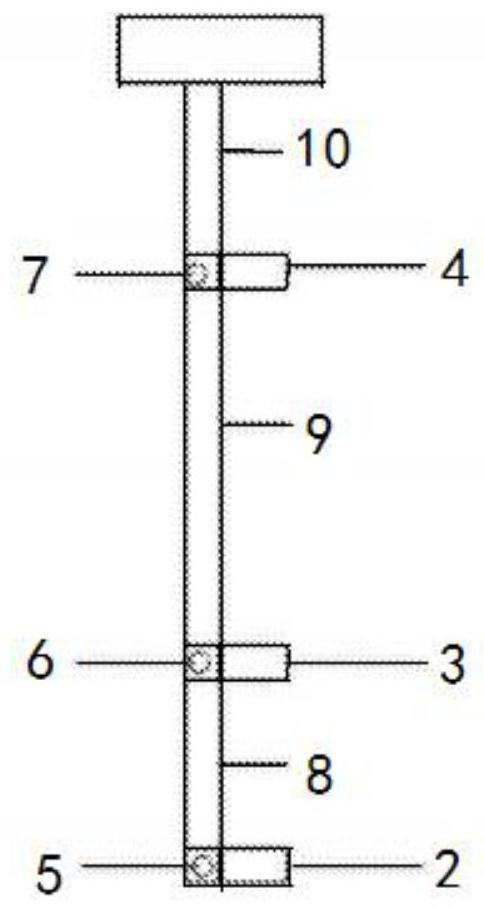

Tank car comprehensive measurement system and method capable of judging leakage

InactiveCN113063465ASolve monitoring problemsRealize integrated measurementMeasurement devicesGps measurementReliability engineering

The invention relates to a tank car comprehensive measurement system and method capable of judging leakage. The system comprises: a basic parameter measurement module which is used for obtaining the temperature information, pressure information, liquid level, density and leakage alarm information of liquid in a tank car; a GPS measurement module used for acquiring tank car positioning information; an attitude sensing module used for acquiring vehicle running state information; a comprehensive parameter processing module used for analyzing and processing the acquired multi-parameter information according to a comprehensive sensor data processing operation mode; and a background server used for displaying the data processed by the comprehensive parameter processing module and judging whether to give an alarm or not according to the liquid leakage alarm information. Therefore, the basic parameter measurement module is introduced while the basic GPS and the attitude sensor are applied, comprehensive parameters of liquid level monitoring can be improved, and key parameter data such as the liquid level, the temperature, the pressure, the density and tank leakage alarm information of dangerous chemical liquid can be measured in a high-precision mode.

Owner:XIAN DINGHUA ELECTRONICS CO LTD

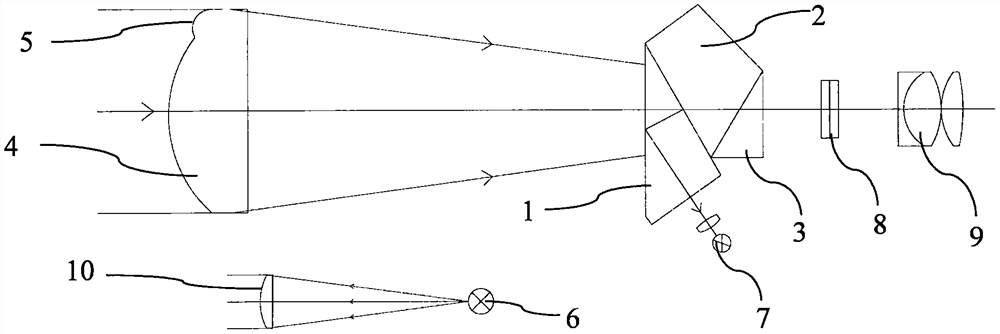

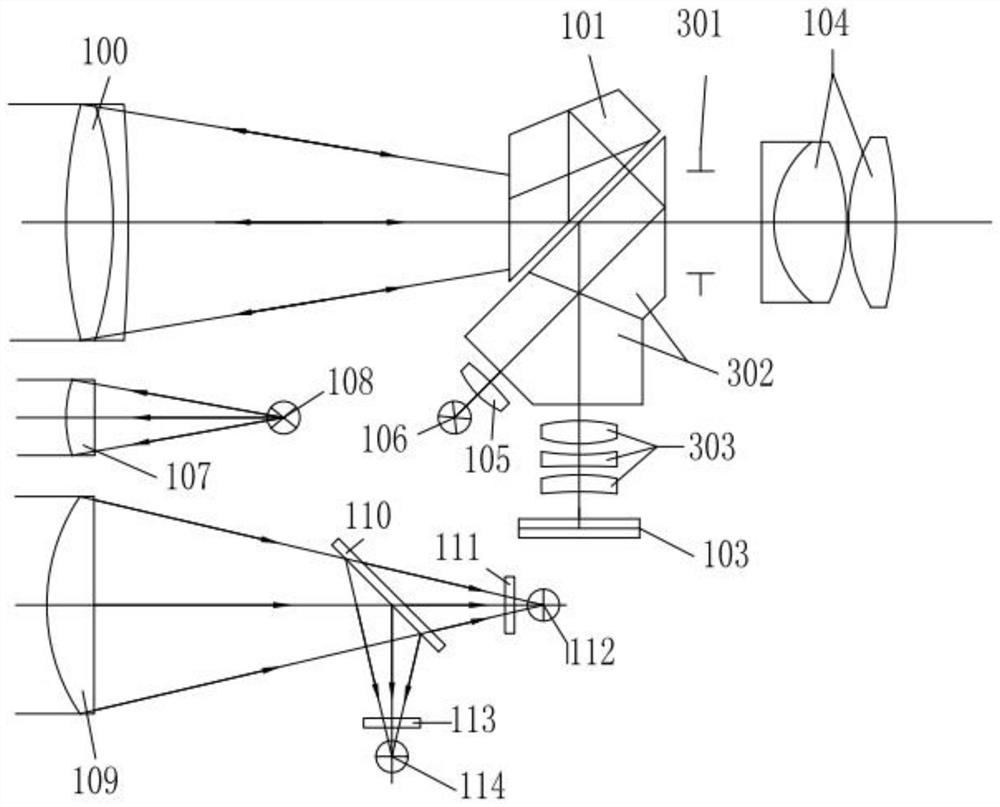

Multifunctional laser range finder

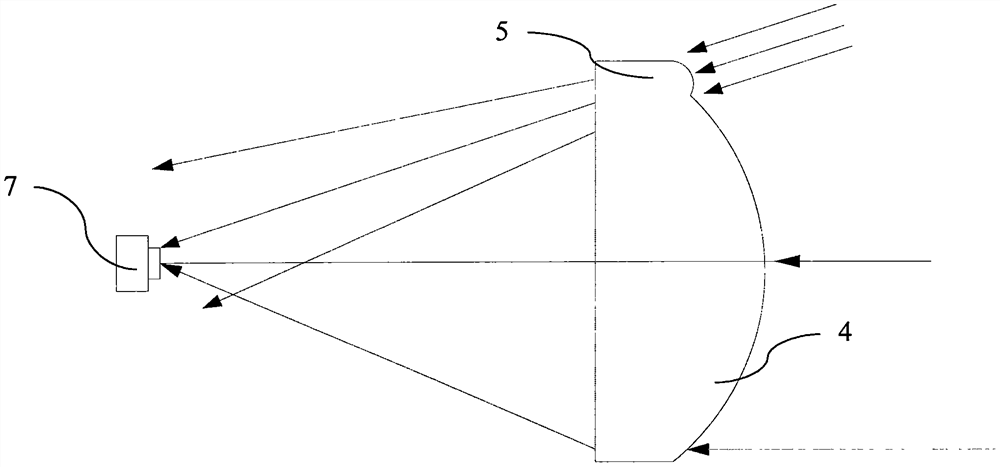

ActiveCN108594246ARealize integrated measurementOvercome the shortcoming of a single requirement for ranging applicationsElectromagnetic wave reradiationLaser rangingLaser light

The invention relates to a laser ranging device and discloses a multifunctional laser range finder comprising a monocular telescope, two laser emitting systems and two laser receiving systems. The monocular telescope is arranged between the laser transmitting systems and the laser receiving systems. The laser emitting systems consist of long-range laser emitting systems and short-range laser emitting systems. The laser receiving systems include long-range laser receiving systems and close-range laser receiving systems. On the basis of combination of the laser pulse with the phase, a novel ranging mode of close-range high-precision laser phase ranging and long-range pulsed laser ranging is realized. According to the invention, integration of pulse ranging and phase ranging modules is realized. Because the ranging principles of the pulse ranging and phase ranging modules do not interfere with each other, the used laser light sources have different wavelengths, so that integrated measurement of high-precision short-range measurement and long-range measurement of the product is realized; various application demands can be satisfied by one product; a defect of single ranging applicationdemand of the previous products is overcome; and the multi-functionalization effect of the product is represented.

Owner:LANHAI PHOTOELECTRICITY TECH CO LTD

Aero-engine rotor assembly measuring device based on four-point weighing and dual-objective optimization method

InactiveCN110608665AImprove coaxialityControl unbalanceStatic/dynamic balance measurementUsing electrical meansAviationTransfer model

The invention discloses an aero-engine rotor assembly measuring device based on four-point weighing and a dual-objective optimization method. The method comprises the steps of determining angular positioning of a turntable based on a circular grating; ensuring that, based on a centering and tilting device, the measurement and assembly of the concentricity, parallelism, and center of mass coordinates of a measured rotor are performed under the same reference; extracting, based on a four-probe measuring device, a concentricity error of a radial assembly surface and a parallelism error of an axial assembly surface of each stage of rotor, respectively; extracting, based on a four-point weighing measuring device, radial coordinates of the center of mass of each stage of rotor; and obtaining, based on a rotor assembly posture transfer model, an optimal assembly angle of each stage of rotor by genetic optimization taking the coaxiality and offset of the center of mass of the rotor assembly asdual optimization objectives. The device can effectively solve the problem that the coaxiality and the imbalance of the aero-engine rotor after assembly are over standards, and has the characteristics of integrated measurement of rotor geometry and quality characteristics, high one-time assembly qualification rate, and reduction of engine vibration.

Owner:HARBIN INST OF TECH

Integrated temperature thin film pressure sensor

InactiveCN101566514BHigh measurement accuracyRealize integrated measurementFluid pressure measurement using ohmic-resistance variationThermometers using electric/magnetic elementsElastomerEngineering

The invention relates to an integrated temperature thin film pressure sensor, which consists of a suction pressure connecting pipe with threads and a seal ring, a sensitive component, an external circuit board, a shell and a socket connector. A sensitive elastomer is provided with a transition layer, an insulating layer, resistive layers (including a strain resistive layer and a temperature sensitive resistive layer), a welding layer and a passivation protective layer, wherein the resistive layers are connected with the external circuit board through conducting wires. The insulating layer of the sensor is formed by superimposing SiO2 and Ta2O5 or superimposing the SiO2 and Al2O3, the strain resistive layer is formed by photoetching a NiCr alloy layer, the temperature sensitive layer is formed by photoetching Ni metal, and the temperature sensitive layer not only can solve the problem of actual temperature measurement, but also can compensate the temperature sensitivity more precisely so that the pressure measurement is more accurate. The integrated temperature thin film pressure sensor adopts an ion beam sputtering process, thus the long-term stability of the sensor is good, the temperature zero drift is minimum and the comprehensive precision is high.

Owner:SHAANXI ELECTRICAL APPLIANCE RES INST

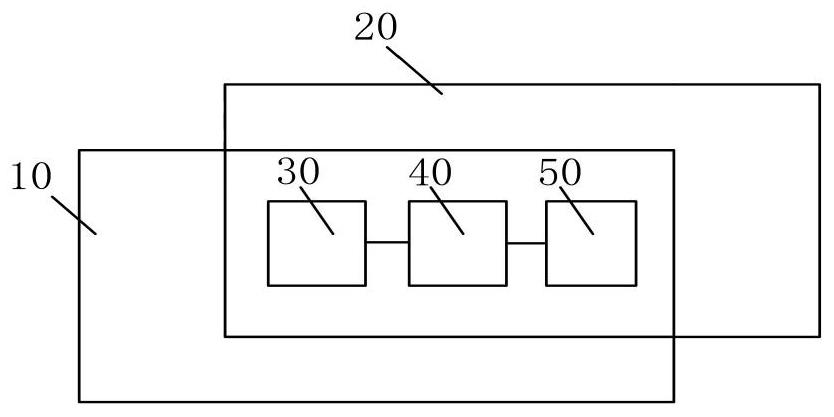

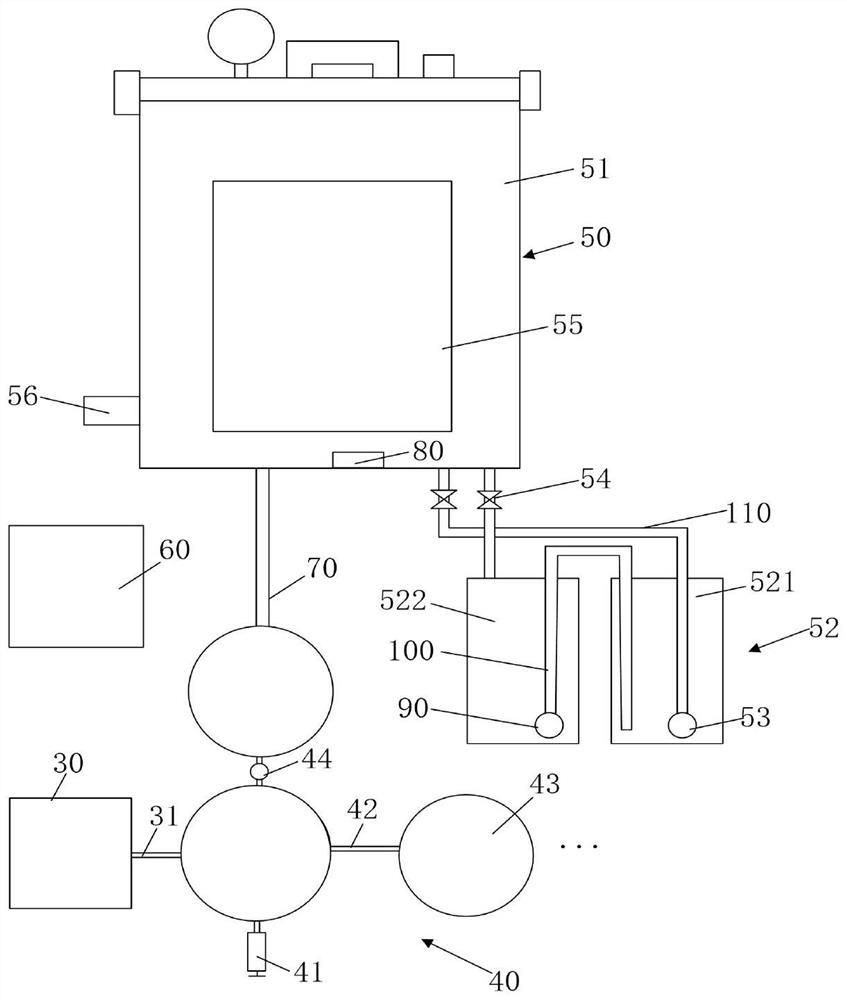

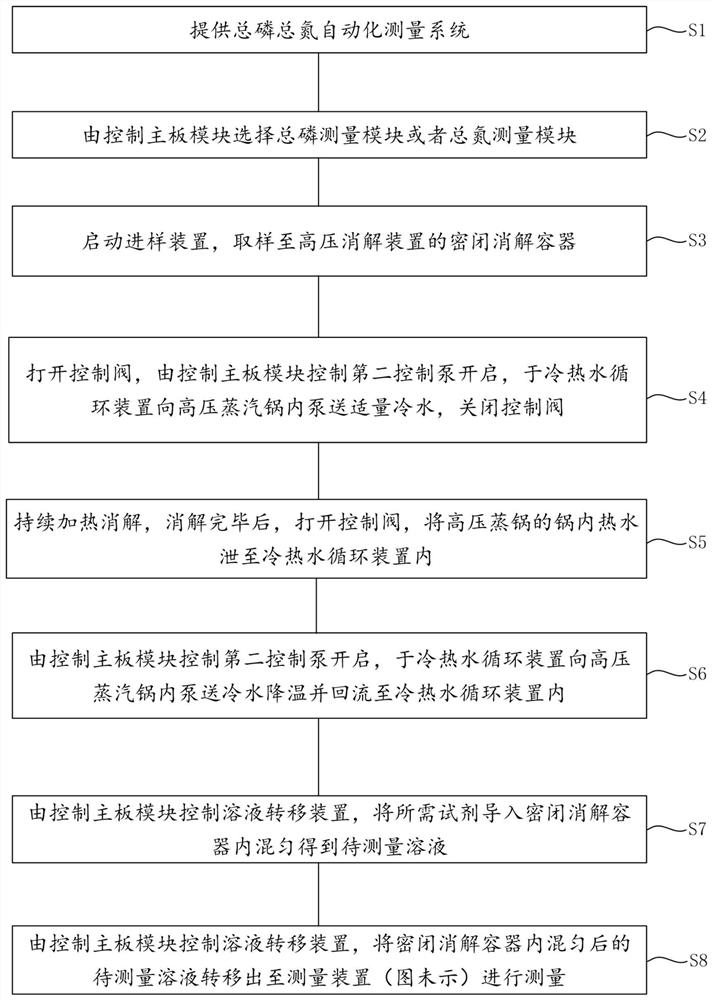

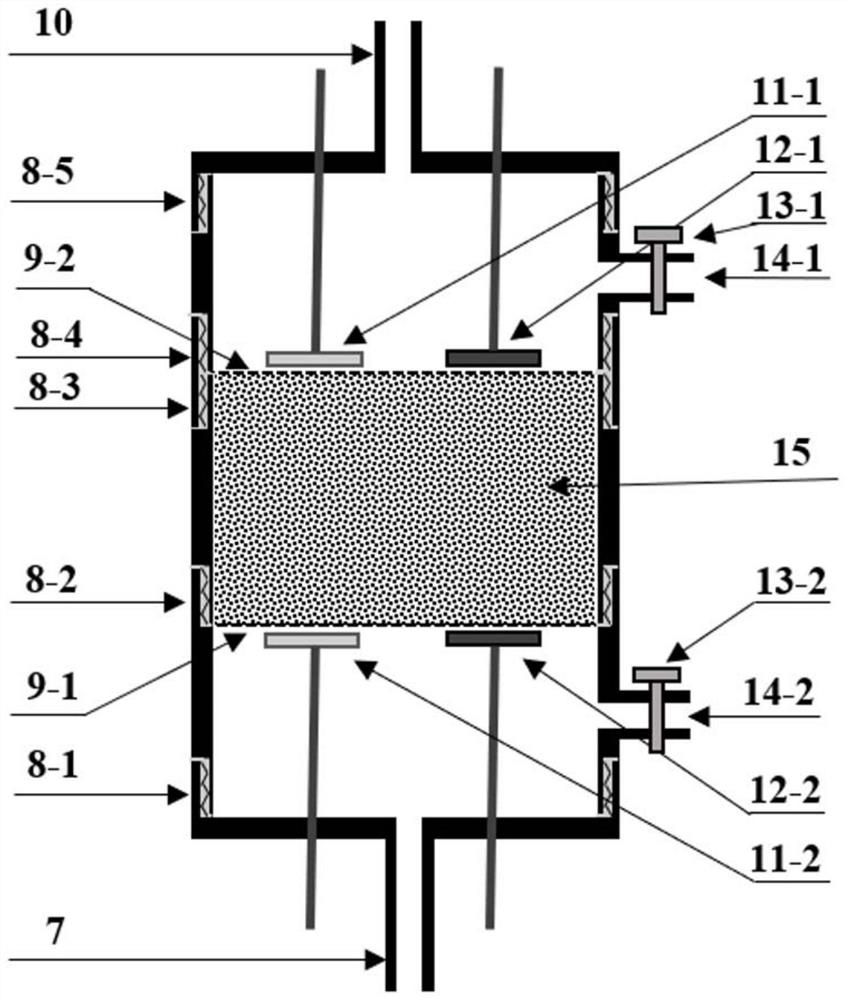

Total phosphorus and total nitrogen integrated and automatic measuring system and automatic measuring method thereof

PendingCN114577588AReduce complex stepsImprove efficiencyNuclear energy generationPreparing sample for investigationTotal phosphorusPhosphorus measurement

The invention provides a total phosphorus and total nitrogen integrated and automatic measurement system and an automatic measurement method thereof, and the system comprises a total phosphorus measurement module, a total nitrogen measurement module, and a control mainboard module which is in communication connection with the total phosphorus measurement module and the total nitrogen measurement module. Each of the total phosphorus measurement module and the total nitrogen measurement module comprises a sample introduction device and a solution transfer device connected with the sample introduction device, and the total phosphorus measurement module and the total nitrogen measurement module share a high-pressure digestion device. The total phosphorus and total nitrogen can be integrally and automatically measured, the problems of article damage, low efficiency, potential safety hazards and the like caused by frequent uncovering of the high-pressure digestion device are avoided, and the contact of operators with related toxic reagents is reduced.

Owner:上海昂林科学仪器股份有限公司

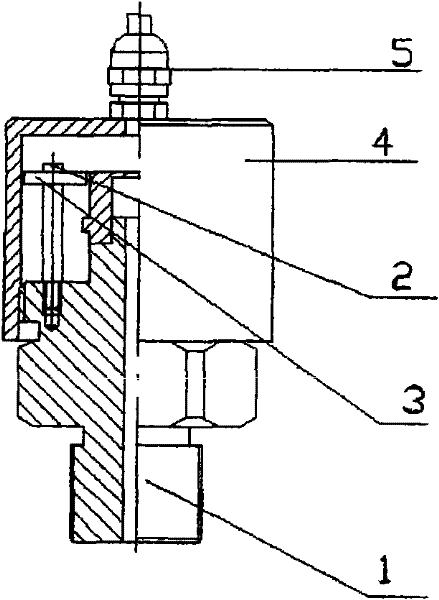

Temperature and pressure integrated transmitter and manufacture method thereof

ActiveCN106595758AReduce volumeFast temperature responseMeasurement devicesSignal linesInstrumentation

The invention relates to a temperature and pressure integrated transmitter and a manufacture method thereof and belongs to the instrument technical field. The temperature and pressure integrated transmitter comprises a connector and a sleeve; a polytetrafluoroethylene gasket is embedded at the front end of the connector; a narrowing opening of the front end of the connector is provided with a PT100 platinum resistor in a sealing manner; a diffused-silicon oil injection core body is arranged in a cavity arranged eccentrically at the rear portion of the connector; a temperature transmission plate and a pressure transmission plate are fixedly arranged at a cavity at the front portion of the sleeve; the temperature transmission plate is connected with the PT100 platinum resistor through a zigzag-wired temperature signal line; the pressure transmission plate is connected with the diffused-silicon oil injection core body; the tail end of the sleeve is provided with a gas communication cable in a sealed manner; the gas communication cable is connected with the temperature transmission plate and the pressure transmission plate; and the rear end of the connector is in sealed and fixed connection with the front end of the sleeve. According to the temperature and pressure integrated transmitter of the invention, a temperature transmitter and a pressure transmitter are designed into an integrated structure, and functions originally completed by the two kinds of transmitters can be completed by one transmitter, and integrated measurement of temperature and pressure can be realized.

Owner:TIANSHUI HUATIAN SENSOR

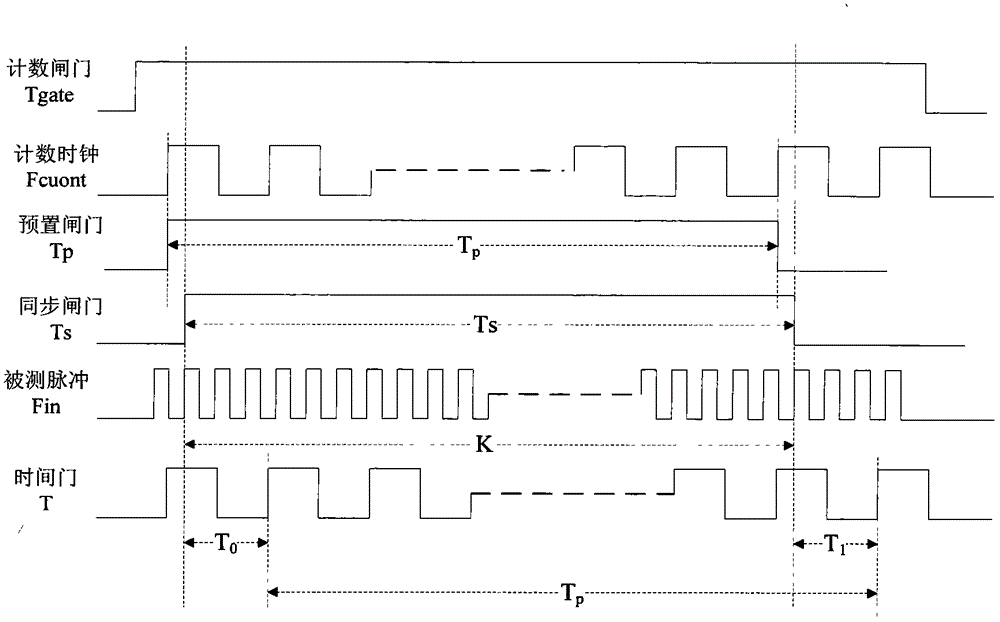

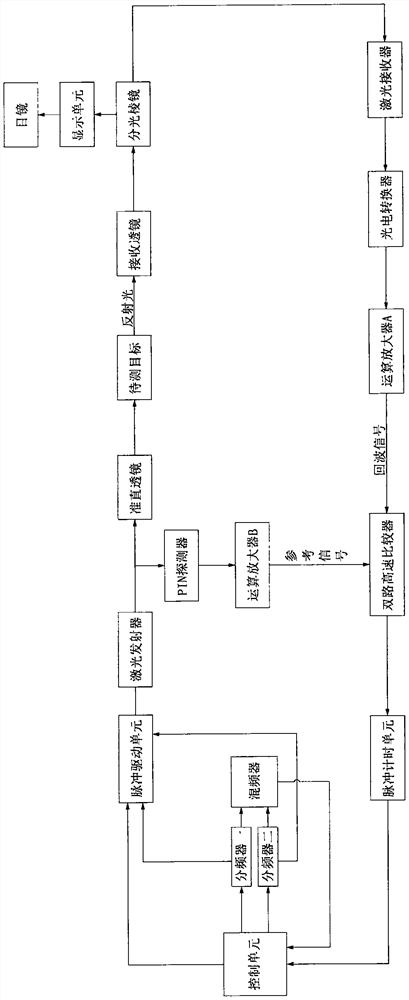

Pulse and phase integrated laser distance measurement device

PendingCN111812665AGuaranteed measurement accuracyImprove ranging abilityElectromagnetic wave reradiationConvertersBeam splitter

The invention discloses a pulse and phase integrated laser distance measurement device. The device comprises a control unit, a pulse driving unit, a laser emitter, a laser receiver, a beam splitter prism, a display unit, an ocular lens, a photoelectric converter, an operational amplifier A, a PIN detector, an operational amplifier B, a double-path high-speed comparator and a pulse timing unit. A laser generator emits pulse laser, the pulse laser is reflected to the beam splitter prism through a to-be-measured target, one path is incident to the ocular lens, the other path is incident to the laser receiver, and the photoelectric converter is connected with the double-path high-speed comparator through the operational amplifier A; the laser generator emits pulse laser to be incident to the PIN detector, the PIN detector is connected with the double-path high-speed comparator through the operational amplifier B, the double-path high-speed comparator is connected with the pulse timing unit, and the pulse timing unit is connected with the control unit. According to the invention, a pulse distance measurement and phase distance measurement combined mode is adopted, so that the product can accurately measure far and near distances and is convenient to operate and simple to use.

Owner:LANHAI PHOTOELECTRICITY TECH CO LTD

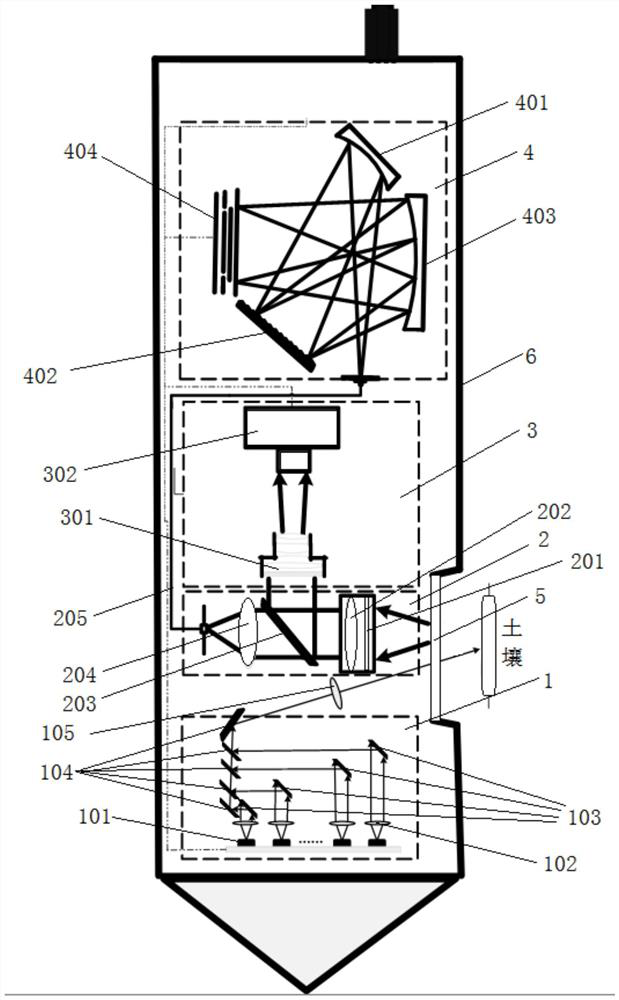

Fluorescence collection device for in-situ monitoring and analysis of organic pollutants in soil

PendingCN114324281ARealize integrated measurementFull accessFluorescence/phosphorescenceThree dimensional fluorescenceOrganopónicos

The invention discloses a fluorescence collection device for in-situ monitoring and analysis of soil organic pollutants, which comprises a shell, and a light source module, a front fluorescence collection module, a fluorescence imaging module and a spectrum detection module which are arranged in the shell from bottom to top in sequence, and an optical window is arranged on the side wall of the shell on one side of the front fluorescence collection module; detected soil is placed on the outer side of the optical window; measurement is easy and convenient, complex operation such as sample collection and laboratory pretreatment is not needed, synchronous collection of fluorescence images and three-dimensional fluorescence spectrums is achieved through combined work of the imaging camera and the optical fiber coupling probe system, integrated measurement of the fluorescence images and the three-dimensional fluorescence spectrums is achieved, spectral feature information of soil organic pollutants is obtained more comprehensively, and the measurement accuracy is improved. And the detection accuracy and reliability are improved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Near infrared quantitative water content measurement method for paper

ActiveCN100501374CEnables real-time process detectionNo radioactive contaminationColor/spectral properties measurementsAudio power amplifierEngineering

Owner:西安力源光电科技有限责任公司

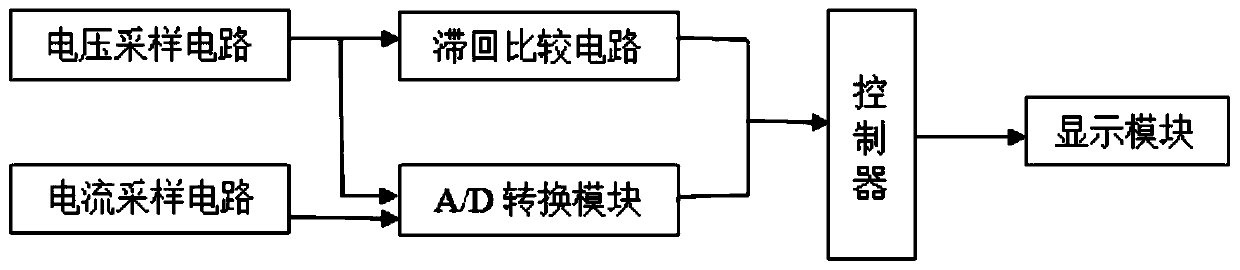

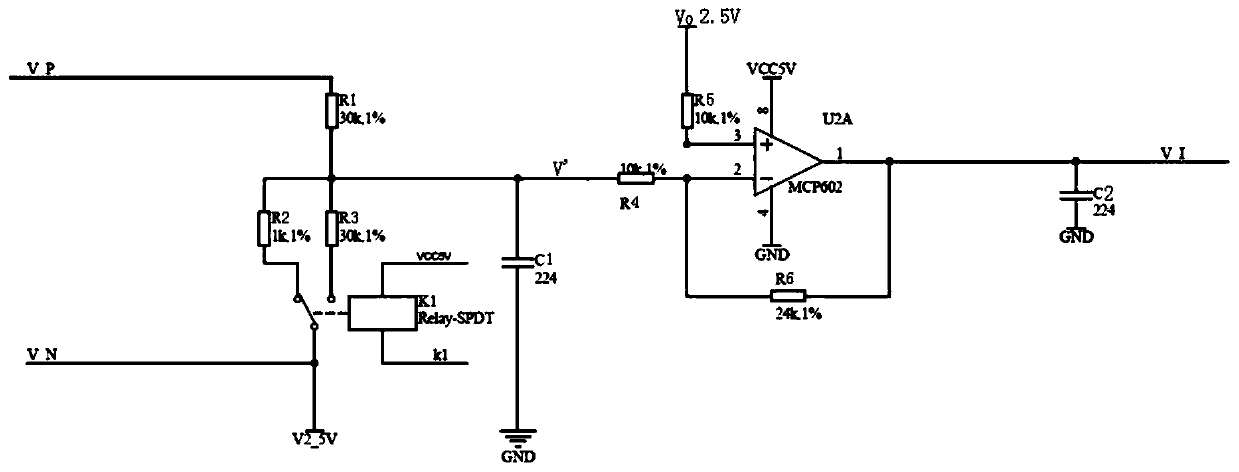

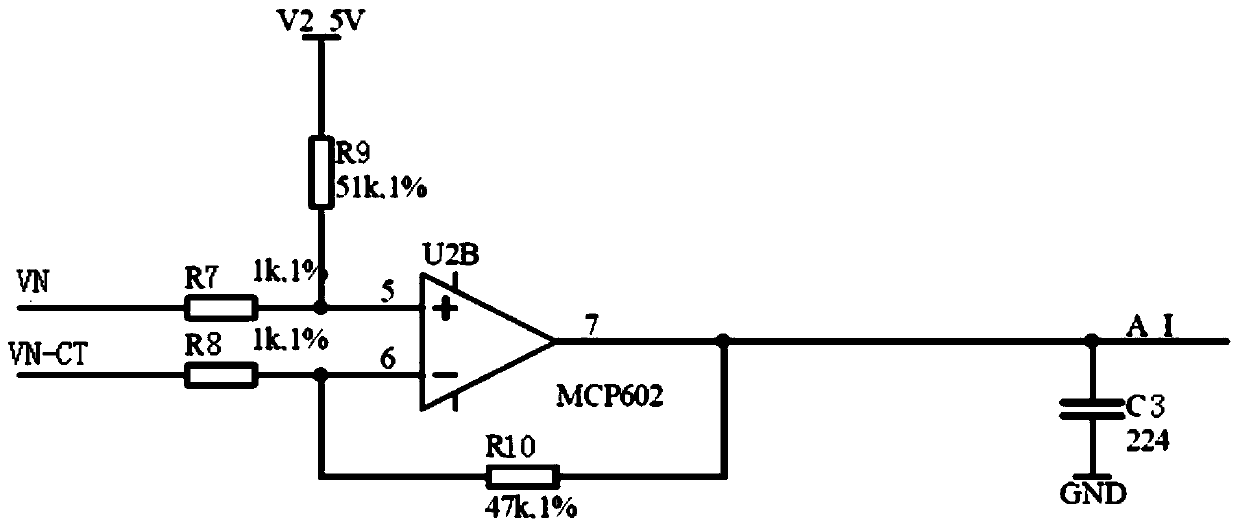

Alternating-current/direct-current signal power integrated measuring device and method

PendingCN109752592ARealize integrated measurementSimple structurePower measurement by digital techniqueHysteresisComputer module

The invention discloses an alternating-current / direct-current signal power integrated measuring device and method, which is used for outputting the power of an input signal which is an alternating-current / direct-current signal. The device comprises a voltage sampling circuit, a current sampling circuit, a hysteresis comparison circuit, an A / D conversion module and a controller; the voltage sampling circuit is used for collecting a voltage signal of the input signal; the current sampling circuit is used for collecting a current signal of the input signal; the hysteresis comparison circuit is used for judging the type of the input signal; the A / D conversion module is used for converting simulated voltage and current signals into digital signals; and the voltage sampling circuit is connectedwith the hysteresis comparison circuit and the A / D conversion module; the current sampling circuit is connected with the A / D conversion module; and the hysteresis comparison circuit and the A / D conversion module are connected with the controller. The voltage and the current of the input signal are sampled, and the hysteresis comparison circuit is adopted to judge the type of the input signal so asto realize the measurement of alternating-current / direct-current signal power.

Owner:NANJING COLLEGE OF INFORMATION TECH

A multifunctional laser rangefinder

ActiveCN108594246BRealize integrated measurementOvercome the shortcoming of a single requirement for ranging applicationsElectromagnetic wave reradiationLaser rangingEngineering

The invention relates to a laser ranging device and discloses a multifunctional laser range finder comprising a monocular telescope, two laser emitting systems and two laser receiving systems. The monocular telescope is arranged between the laser transmitting systems and the laser receiving systems. The laser emitting systems consist of long-range laser emitting systems and short-range laser emitting systems. The laser receiving systems include long-range laser receiving systems and close-range laser receiving systems. On the basis of combination of the laser pulse with the phase, a novel ranging mode of close-range high-precision laser phase ranging and long-range pulsed laser ranging is realized. According to the invention, integration of pulse ranging and phase ranging modules is realized. Because the ranging principles of the pulse ranging and phase ranging modules do not interfere with each other, the used laser light sources have different wavelengths, so that integrated measurement of high-precision short-range measurement and long-range measurement of the product is realized; various application demands can be satisfied by one product; a defect of single ranging applicationdemand of the previous products is overcome; and the multi-functionalization effect of the product is represented.

Owner:LANHAI PHOTOELECTRICITY TECH CO LTD

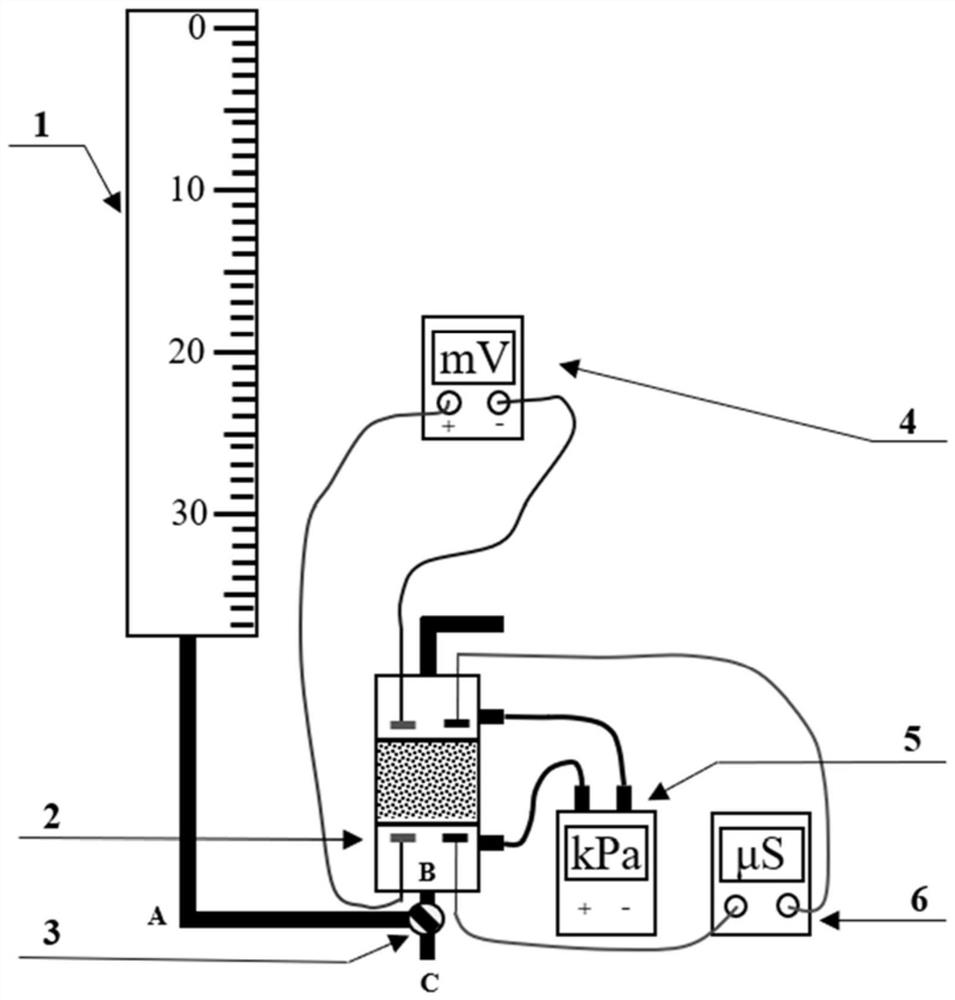

Measuring device and measuring method of flowing potential coefficient and zeta potential

ActiveCN112730570BContinuous measurementImprove measurement efficiencyMaterial analysis by electric/magnetic meansZeta potentialMeasurement device

The invention discloses a measuring device and method for measuring flow potential coefficient and zeta potential. When the time is poor, the liquid in the liquid storage container can flow into the sample addition container by gravity, and both the liquid storage container and the sample addition container can drain through the three-way valve; the sample addition container has a sample addition chamber and a measurement chamber. The present invention relies on gravity to transmit the liquid, without additional pumping device, and the change of the hydraulic pressure difference in the sample container caused by the liquid falling under the action of gravity can be measured through the hydraulic pressure difference measurement interface of the first measurement chamber and the second measurement chamber, then When measuring streaming potential, it is only necessary to know the drop height of the liquid level to know the streaming potential under the measured hydraulic pressure difference, and it is not necessary to maintain a constant pressure difference during the streaming potential measurement process. The measurement process is continuous and efficient, realizing the integrated measurement of streaming potential coefficient and zeta potential.

Owner:SOUTHWEST UNIV

An aeroengine rotor assembly measurement device based on three-point weighing and three-objective optimization method

InactiveCN110608667BControl balanceOptimizing for multiple objectivesStatic/dynamic balance measurementUsing electrical meansAviationEngineering

The invention relates to an aero-engine rotor assembly measuring device and three-target optimization method based on three-point weighing. Based on a four-head measuring device, a concentricity errorof the radial assembling surface and a parallelism error of the axial assembling surface of each stage of rotor are extracted; based on a three-point weighing measuring device, radial coordinates ofthe centroid of each stage of rotor are extracted; based on a rotor assembly attitude transmission model, an optimal assembly angle of each stage of rotor is obtained through genetic optimization by taking the coaxiality, the unbalance amount and the rotational inertia of a rotor assembly as three optimization targets; and based on a torsion rod measuring device, the rotational inertia of the longitudinal axis of the assembly is obtained. The device and the method can effectively solve the over-standard problem of the coaxiality, the unbalance amount and the rotational inertia of the assembledaero-engine rotor, and have the characteristics of integrated measurement of rotor geometry and mass characteristics, high one-time assembly qualification rate and reduced engine vibration.

Owner:HARBIN INST OF TECH

A method of obtaining accurate 3D data by using 2D line laser scanner

ActiveCN108507466BRealize high-precision measurementRealize integrated measurementUsing optical meansObservational errorThree dimensional measurement

Owner:DALIAN UNIV OF TECH

A four-point weighing-based aeroengine rotor assembly measuring device and a dual-objective optimization method

InactiveCN110608665BImprove coaxialityControl unbalanceStatic/dynamic balance measurementUsing electrical meansAviationControl engineering

The invention discloses an aero-engine rotor assembly measuring device based on four-point weighing and a dual-objective optimization method. The method comprises the steps of determining angular positioning of a turntable based on a circular grating; ensuring that, based on a centering and tilting device, the measurement and assembly of the concentricity, parallelism, and center of mass coordinates of a measured rotor are performed under the same reference; extracting, based on a four-probe measuring device, a concentricity error of a radial assembly surface and a parallelism error of an axial assembly surface of each stage of rotor, respectively; extracting, based on a four-point weighing measuring device, radial coordinates of the center of mass of each stage of rotor; and obtaining, based on a rotor assembly posture transfer model, an optimal assembly angle of each stage of rotor by genetic optimization taking the coaxiality and offset of the center of mass of the rotor assembly asdual optimization objectives. The device can effectively solve the problem that the coaxiality and the imbalance of the aero-engine rotor after assembly are over standards, and has the characteristics of integrated measurement of rotor geometry and quality characteristics, high one-time assembly qualification rate, and reduction of engine vibration.

Owner:HARBIN INST OF TECH

A three-point weighing-based aero-engine rotor assembly measurement device and dual-objective optimization method

InactiveCN110608668BImprove coaxialityControl unbalanceStatic/dynamic balance measurementUsing electrical meansAviationControl theory

The invention discloses an aircraft engine rotor assembly measuring device based on three-point weighing and a double-objective optimization method. The double-objective optimization method comprisesthe following steps: determining the angle positioning of a rotary table based on a circular grating; ensuring the measurement and assembling of the concentricity, the parallelism and the center-of-mass coordinate of a measured rotor under the same reference based on an aligning and inclination adjusting device; based on a four-probe measuring device, respectively extracting concentricity errors of radial assembly surfaces and parallelism errors of axial assembly surfaces of all levels of rotors; based on a three-point weighing measuring device, respectively extracting radial coordinates of the mass centers of all levels of rotors; based on a rotor assembly pose transfer model, taking the coaxiality and center-of-mass offset of a rotor assembly as double optimization objectives, and obtaining the optimal assembly angle of each level of rotor through genetic optimization. The method can effectively solve the problem that coaxiality and an unbalance value exceed standard after the rotorof the aircraft engine is assembled, and has the characteristics of integrated measurement of the geometric and quality characteristics of the rotor, high one-time assembly qualification rate and reduction of engine vibration.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com