Temperature thermocouple for high-voltage and ultrahigh-voltage power cable

A technology of thermocouples and power cables for temperature measurement, applied in the direction of heat measurement, thermometers and thermometers using electric/magnetic elements that are directly sensitive to heat, can solve the problems of inaccurate temperature measurement, inability to measure at the same time, different measurements, etc. Achieve the effects of enhancing synchronization and accuracy, realizing one-time installation, and avoiding temperature measurement deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

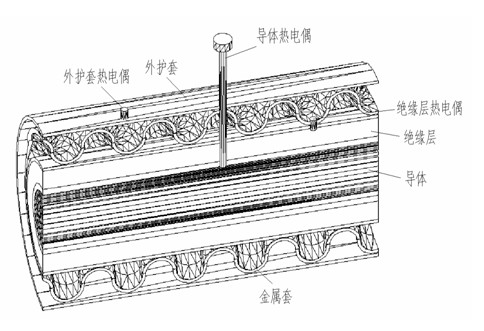

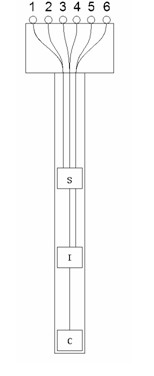

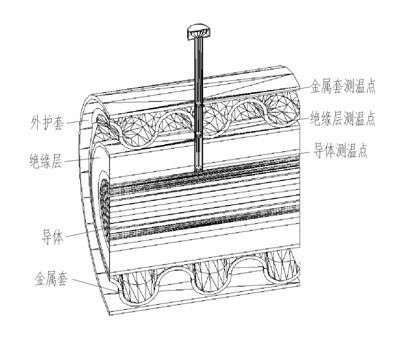

[0014] Explanation of marks in the figure: C-conductor unit, I-insulation layer unit, S-outer sheath unit, 123456-respectively connecting terminals.

[0015] Below in conjunction with accompanying drawing and example the present invention is further described.

[0016] According to the typical structural dimensions of high-voltage and ultra-high-voltage XLPE power cables, the recommended structural dimensions of 110kV, 220kV and 500kV integrated temperature-measuring thermocouples are as follows:

[0017]

[0018]

[0019] For 110kV cables, the distance between the outer sheath temperature measurement unit and the conductor temperature measurement unit is 26mm, and the distance between the conductor temperature measurement unit and the insulation layer temperature measurement unit is 16mm.

[0020] For 220kV cables, the distance between the outer sheath temperature measurement unit and the conductor temperature measurement unit is 36mm, and the distance between the condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com