Automatic shaft measuring machine

A technology of automatic measurement and measurement mechanism, applied in the direction of measurement devices, instruments, etc., can solve the problems of low inspection efficiency, high missed detection and false detection rate, large workload of inspection personnel, etc., and achieve convenient, fast and accurate inspection. Easy integration and high detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

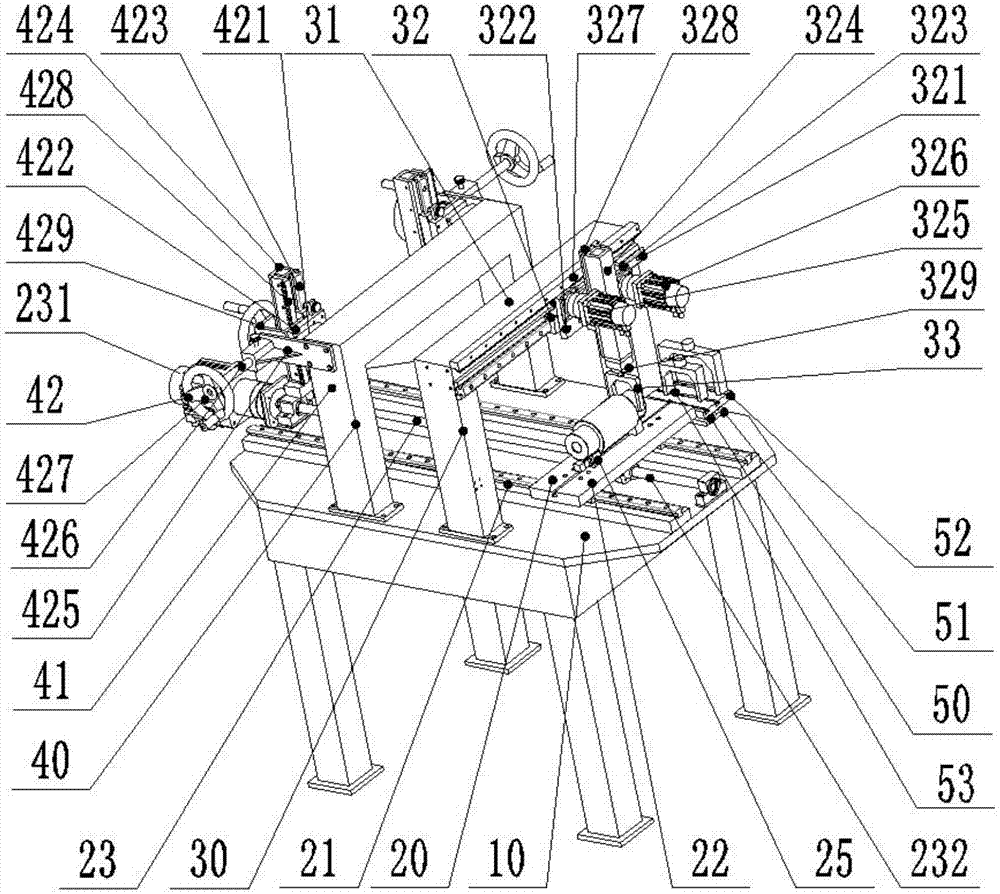

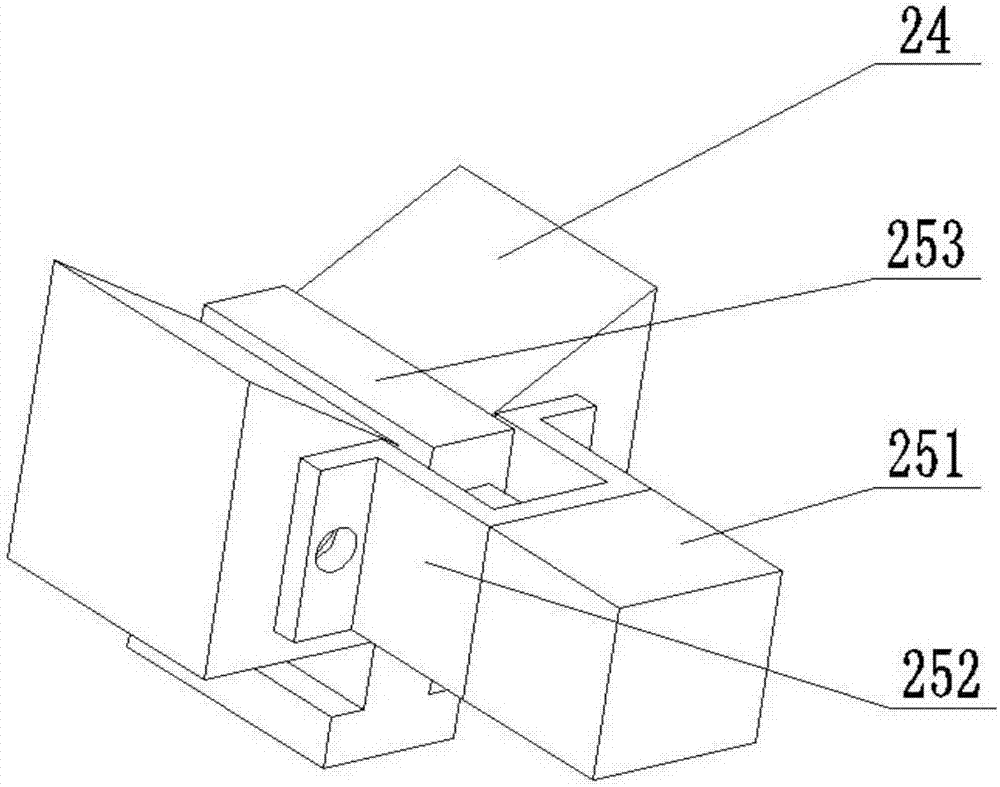

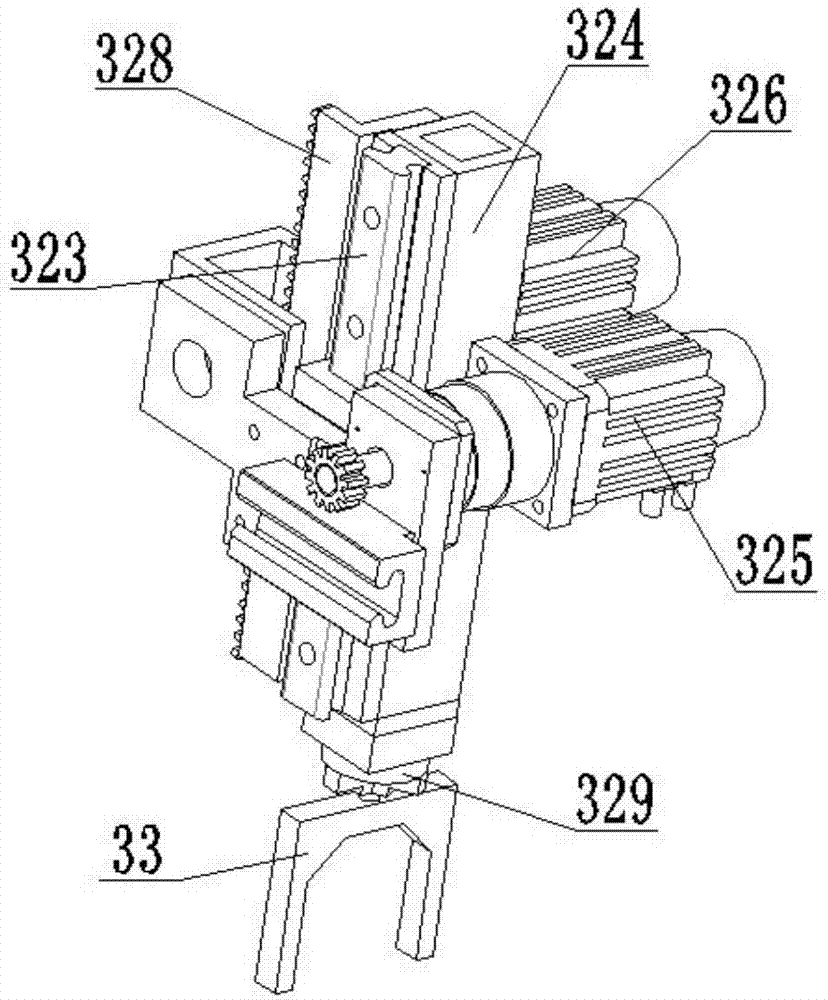

[0029] See figure 1 with Figure 5 , figure 1 It is a schematic diagram of the structure of the shaft automatic measuring machine of the present invention, Figure 5 It is a schematic diagram of the electronic pneumatic measuring instrument and output terminal. The shaft automatic measuring machine of the present invention includes a base 10, a clamping mechanism 20, an outer diameter measuring mechanism 30 and an inner hole measuring mechanism 40, a measuring instrument library assembly 50, an electronic pneumatic measuring instrument 60 and an output terminal 70. The clamping mechanism 20 is fixed on the base 10, and the clamping mechanism 20 is used to place and drive the test piece to move; the outer diameter measuring mechanism 30 and the inner hole measuring mechanism 40 are arranged above the clamping mechanism 20, and the outer diameter measuring mechanism 30 And the inner hole measuring mechanism 40 are respectively used to measure the outer diameter and inner hole of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com