Temperature and pressure integrated transmitter and manufacture method thereof

A technology for temperature and pressure transmitters, which is applied in the field of temperature and pressure integrated transmitters and its production, can solve the problems of slow temperature response and low measurement accuracy, and achieve less production processes, high temperature measurement accuracy, and reduced volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

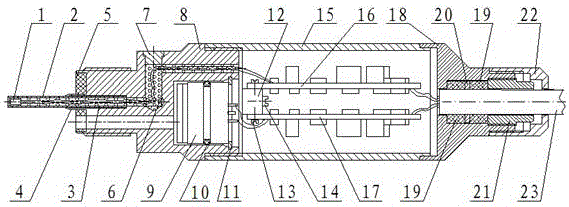

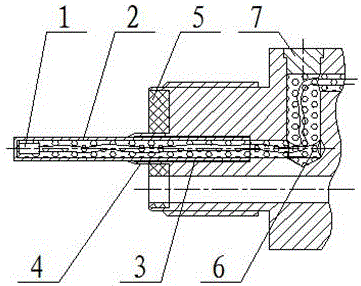

[0024] see figure 1 , figure 2 , a temperature and pressure integrated transmitter, including a joint 8 and a sleeve 15, a through hole is provided above the joint 8, which is convenient for the transmission temperature signal wire to pass through in the Z direction, and a plug 7 is embedded in the through hole to ensure the transmitter's Tightness; the front end of the joint 8 is embedded with a polytetrafluoroethylene gasket 5; the mouth of the front end of the joint 8 is sealed with a PT100 platinum resistance 1, and the cavity set eccentrically at the rear of the joint 8 is provided with a diffusion silicon oil injection core 9. A temperature transmission board 16 and a pressure transmission board 17 are fixedly installed in the cavity at the front of the sleeve 15; the temperature transmission board 16 is connected to the PT100 platinum resistance 1 through a Z-shaped temperature signal line, and the pressure changes The sending plate 17 is connected with the diffusion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com