Method for obtaining three-dimensional accurate data by adopting two-dimensional linear laser scanner

A two-dimensional line laser and precise data technology, applied in the direction of optical devices, instruments, measuring devices, etc., can solve the problems of lack of Y-axis position information and inability to form three-dimensional information, and achieve good robustness and high-precision measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The line laser scanner 3 used in this embodiment is the LJ-V7060 type measuring instrument of Keyence Corporation, and its repeatability in the X-axis direction is 5 μm, and the repeatability in the Z-axis direction is 0.5 μm. The high-precision electronically controlled mobile platform 1 adopts the M521.DD model precision mobile platform of PI Company, and its repeated positioning accuracy is 0.1 μm.

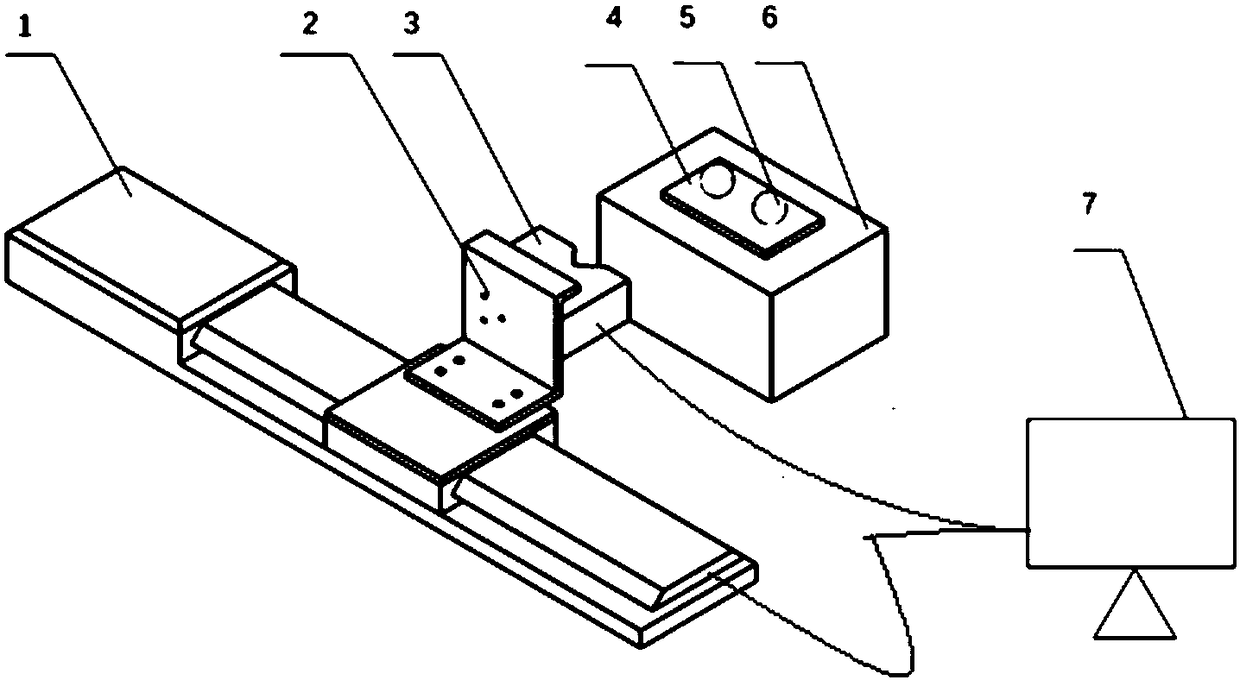

[0041] The present invention adopts the combination of high-precision electric control mobile platform 1 and line laser scanner 3 to realize high-precision measurement in a large size range, such as figure 1 As shown, the system consists of a high-precision electronically controlled mobile platform 1, a right-angle fixture 2, a line laser scanner 3, a standard ball base 4, a standard ceramic ball 5, a backing plate 6, and a computer 7.

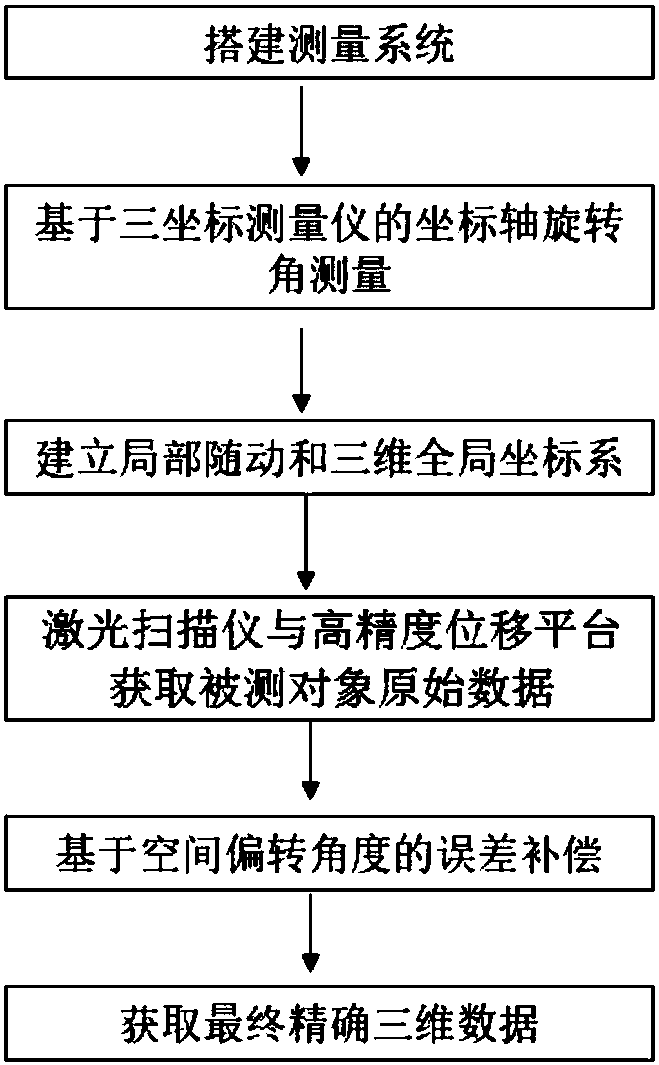

[0042] Data acquisition and data processing flow chart as figure 2 As shown, first, the line laser scanner 3 is installed on the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com