Torque optical fiber sensor

A fiber optic sensor and sensor technology, which is applied in the field of testing technology and fiber optic sensors, can solve the problems of troublesome testing, complexity, and low accuracy, and achieve the effects of simple structure, anti-electromagnetic interference, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

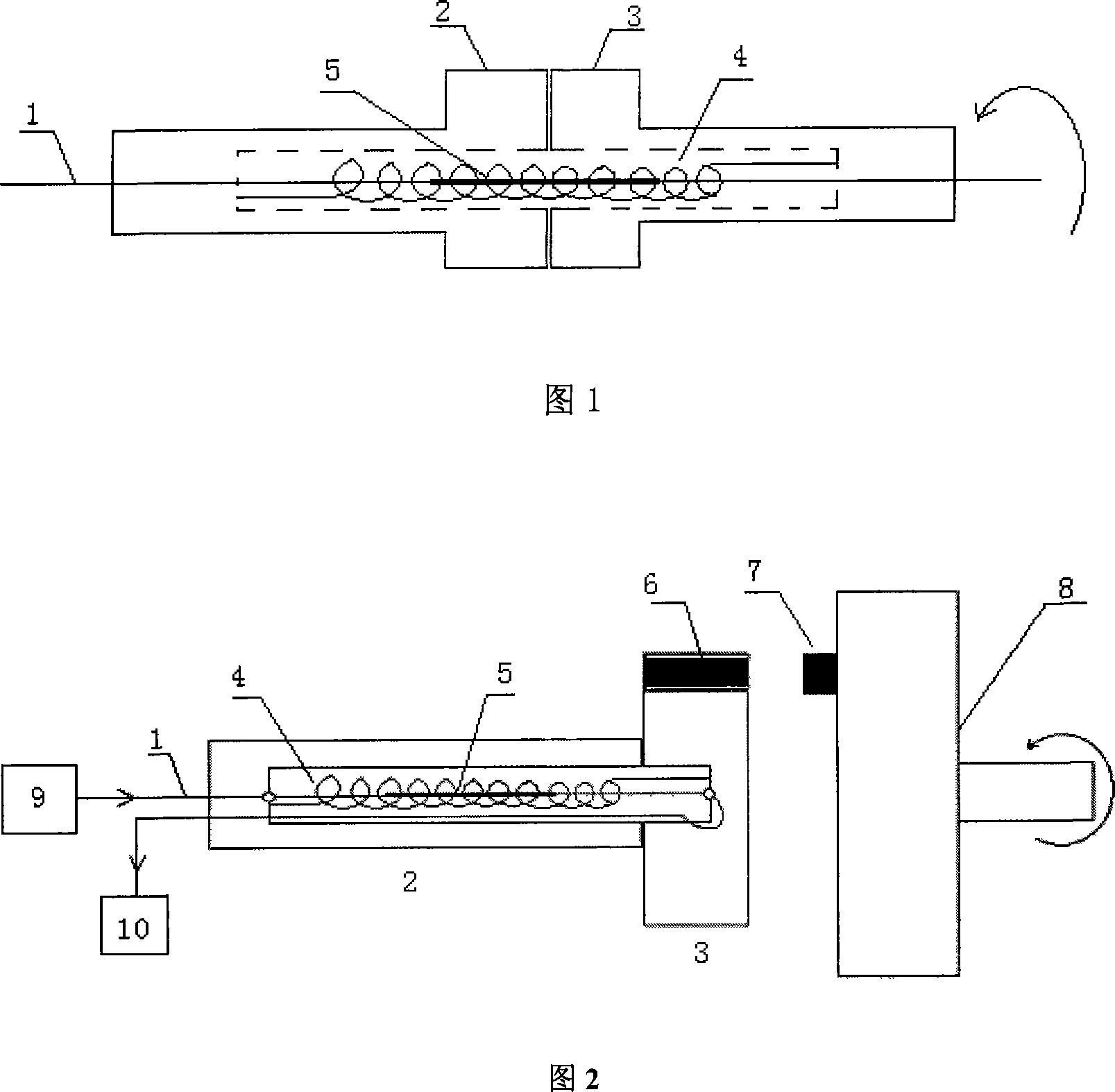

[0019] A novel torque fiber optic sensor of the present invention includes a guide fiber 1, two torsion bars 2, 3, a long-period fiber grating or fused cone fiber 5, and a spring 4. The torsion bar 2 is connected to the torsion bar 3 through a spring 4, and the sensing optical fiber passes through the central axis of the two torsion bars and is respectively fixed at the ends of the two torsion bars. Among them, two torsion bars are connected by springs. The role played by the spring is not only the connection function, but also the reset function, that is, when there is no relative rotation between the two torsion bars, the spring can ensure that the two torsion bars are in the initial position. see picture 1. ,

[0020] In the embodiment shown in FIG. 2 , the light emitted by the light source 9 enters the optical fiber 1 , passes through the sensing optical fiber 5 , and is received by the optical detector 10 . A permanent magnet 6 is installed at the end of the torsion ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com