Electric pulse rock-breaking dill bit and experimental facility thereof

An experimental device and electric pulse technology, which is applied to the drilling driving device, drill bit, measuring device and other directions in the wellbore, can solve the problems of application range and performance impact, difficult construction, and high drilling cost, and achieve high energy utilization efficiency, The effect of avoiding electromagnetic interference and high device reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

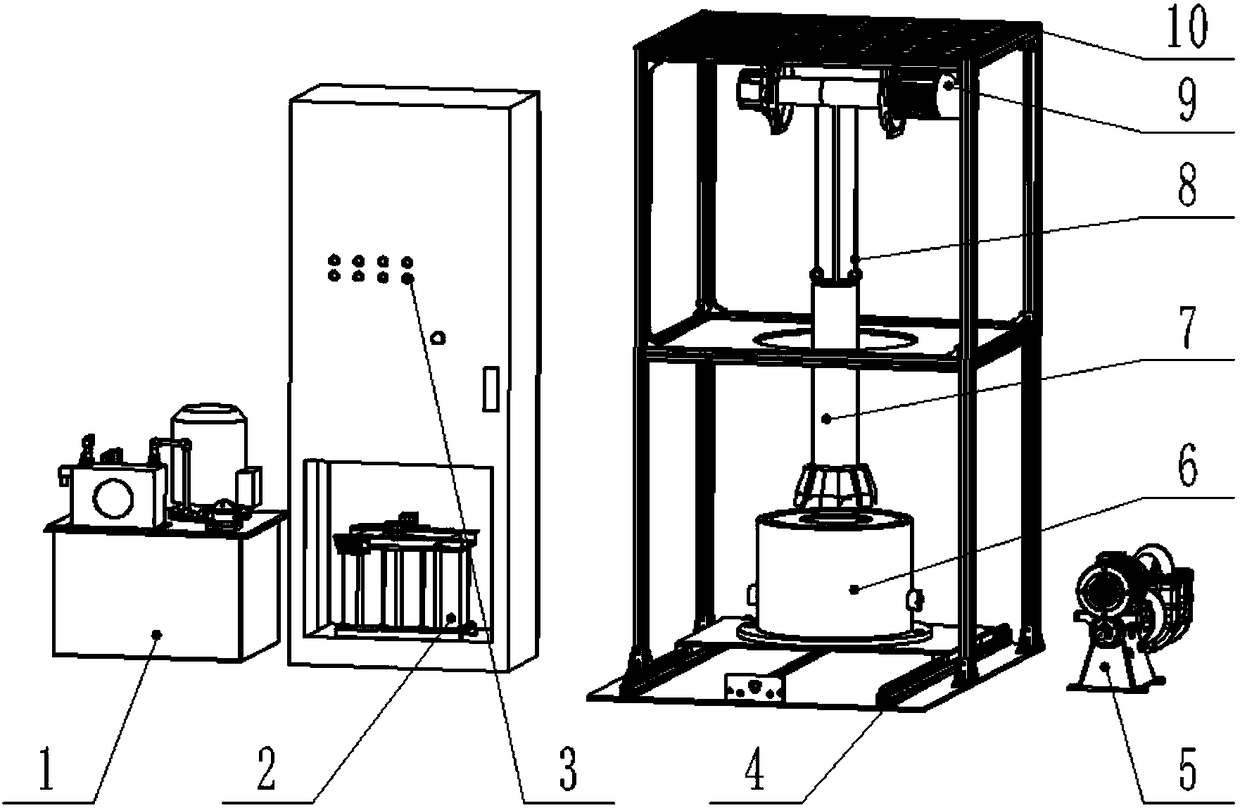

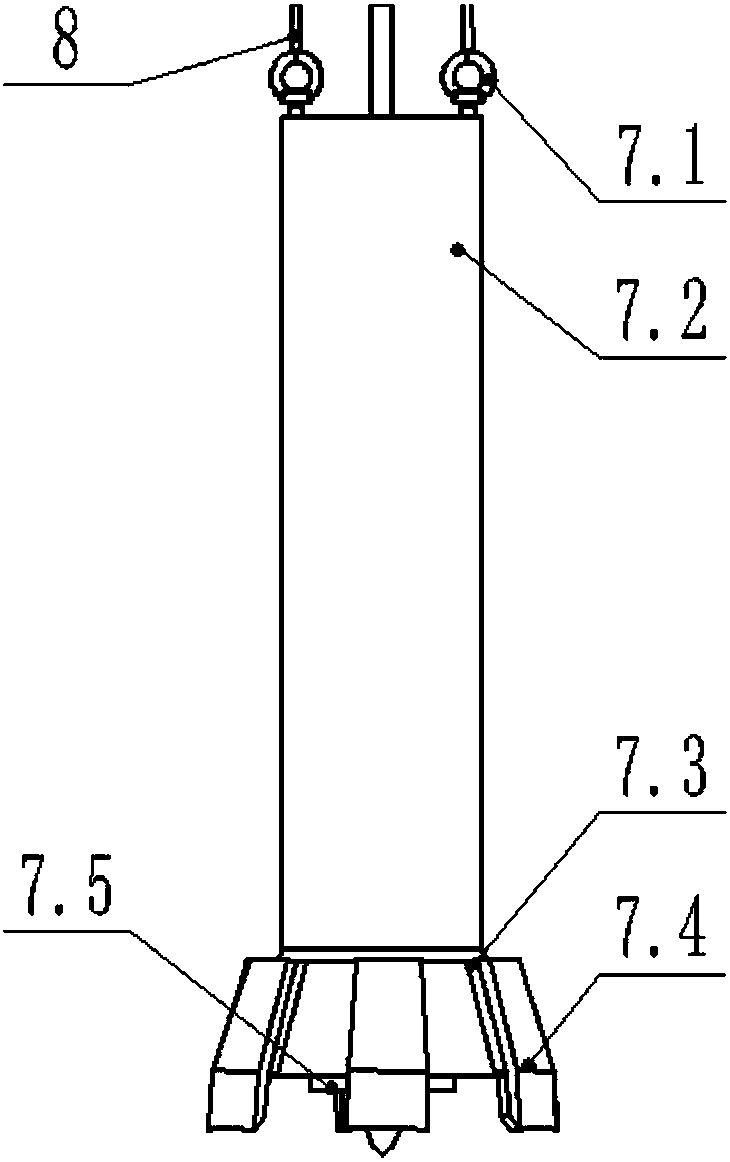

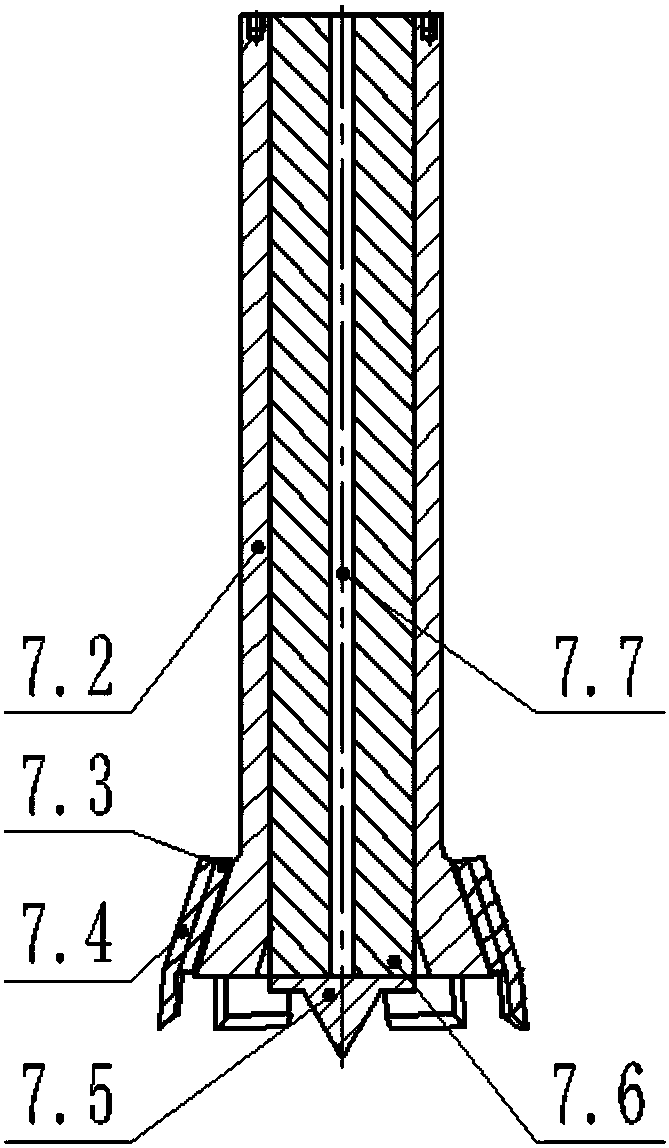

[0032] Example 1: An electric pulse rock breaking drill bit and its electric pulse rock breaking experimental device according to the present invention, its structure is as follows figure 1 , 2 , 3 and 4, including confining pressure pump station 1, pulse power supply 2, PLC control device 3, confining pressure cylinder horizontal movement device 4, inlet and outlet water pump 5, confining pressure cylinder assembly 6, electric pulse rock breaking bit 7, steel wire rope 8 , Rope hoist 9, aluminum profile bracket 10. Confining pressure pumping station 1, mainly provides high-pressure oil for the confining cylinder assembly 6 to simulate the high-pressure environment of the rock through the confining cylinder assembly 6; the pulse power supply 2 is to obtain high-voltage pulse electricity after the high-voltage high-frequency power is boosted and rectified. , Provides high-voltage pulse electricity for the electric pulse rock breaking bit 7; PLC control device 3, mainly controls t...

Embodiment 2

[0035] Example 2: An electric pulse rock breaking drill bit and an electric pulse rock breaking experimental device of the present invention have the same structure as Example 1. The electric pulse rock breaking drill bit 7 contacts the surface of the rock sample 6.3, and the pulse power supply 2 supplies the low voltage electrode 7.4 and the high voltage Electrode 7.5 is powered. When certain conditions are met, the breakdown voltage of the rock is lower than that of ionized water. The high-voltage electric pulse first breaks down the rock, generating a plasma channel for discharge inside the rock, and the energy of the high-voltage electric pulse is released to the plasma The plasma channel is heated and expands and does work on the surrounding rock mass. When the stress exceeds the stress intensity of the rock, the rock breaks. The electric pulse rock breaking bit 7 contains a plurality of low voltage electrodes 7.4. The high voltage electrode 7.5 simultaneously generates di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com