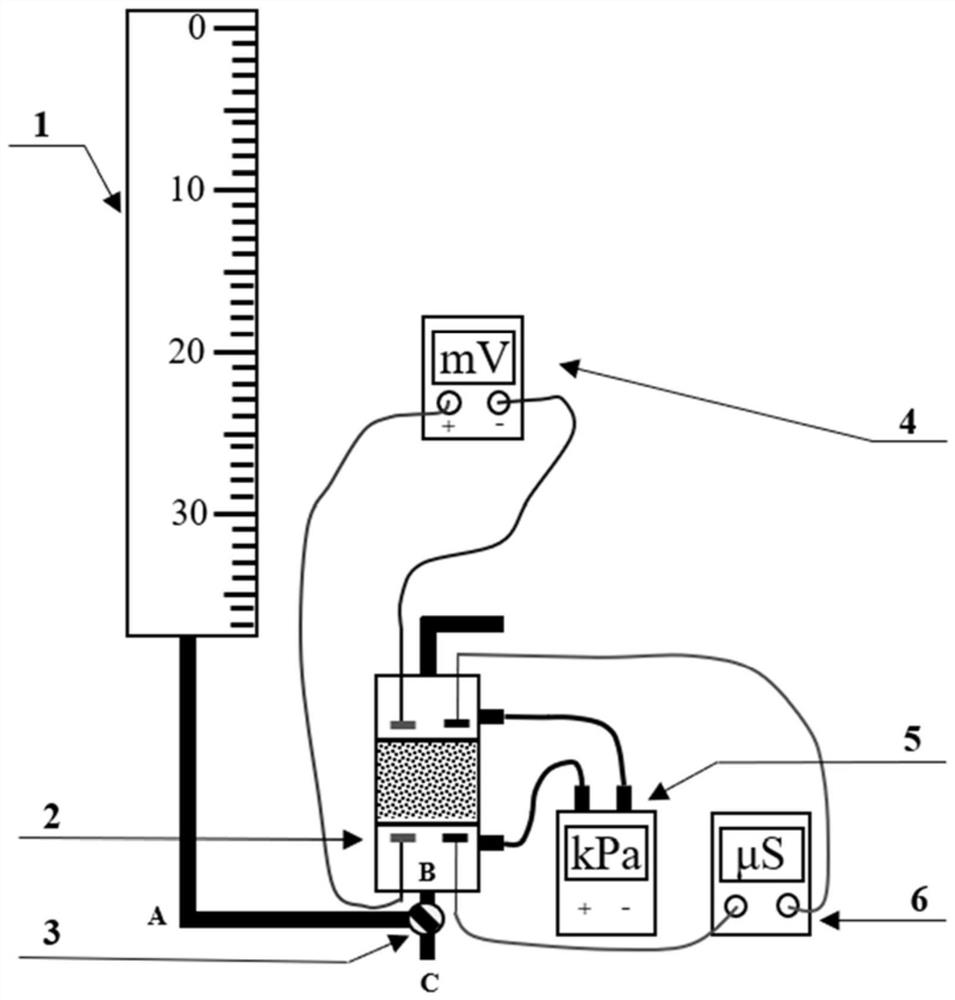

Measuring device and measuring method of flowing potential coefficient and zeta potential

A streaming potential and measuring device technology, applied in measuring devices, material analysis through electromagnetic means, instruments, etc., to achieve the effects of convenient filling, avoiding leakage, and avoiding pressure measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

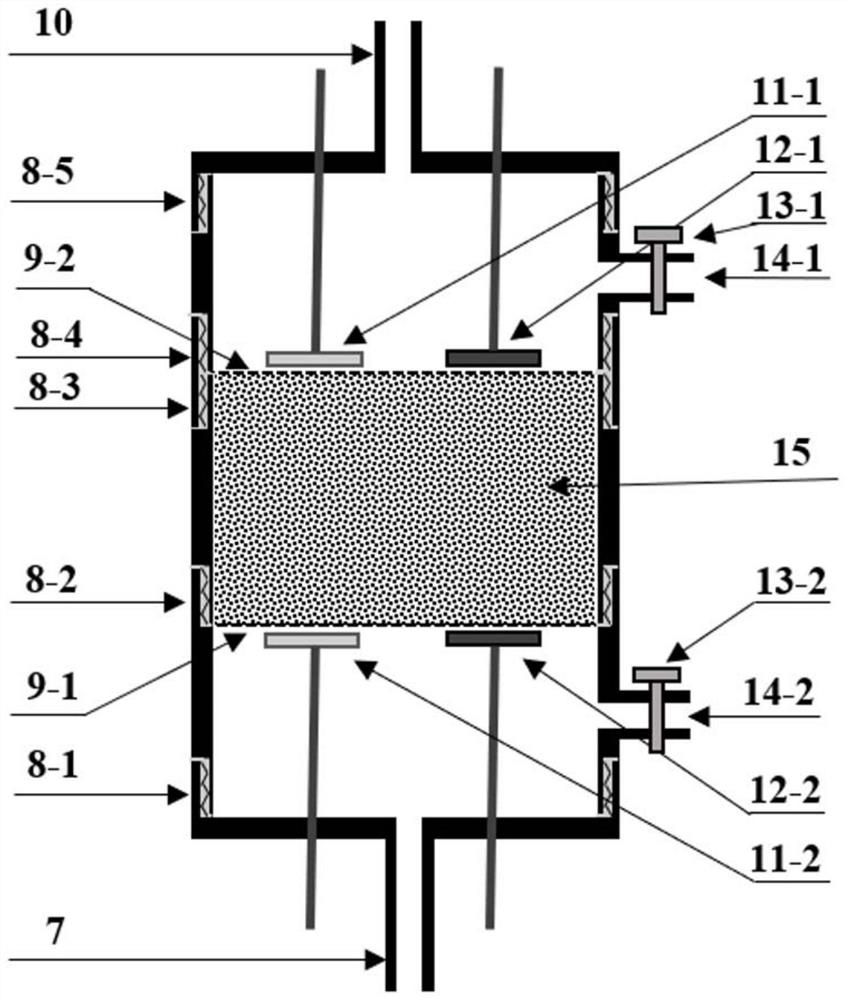

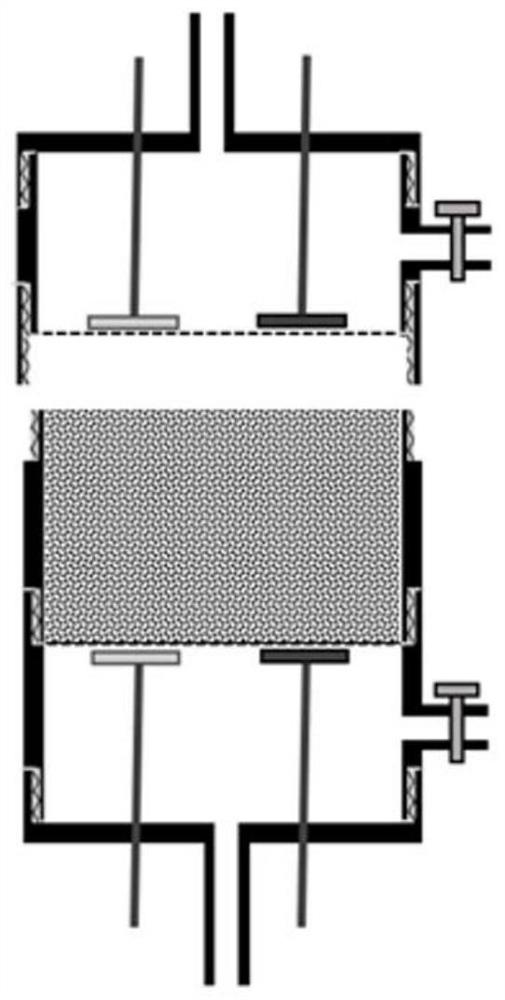

Method used

Image

Examples

Embodiment 1

[0065] Using the device of the present invention, the zeta of quartz sand mineral particles with a particle size of 0.42 to 0.85 mm and surface modified (coated with iron hydroxide) quartz sand mineral particles in different pH electrolyte solutions were measured according to the above-mentioned instrument operation steps. potential. The Fe content per kilogram of iron-coated quartz sand is 4.95g. The sample amount of quartz sand or iron-coated quartz sand required for each measurement is 8.80g. The pH values of the electrolyte solutions used were 4.4, 5.2, 6.1, 6.6, 6.9, 7.7, 8.0, and the conductivity of the solutions were all 20 μS cm -1 . Follow the measurement procedure above for sample measurement. Hydraulic differential correction is performed first, followed by streaming potential measurement, followed by conductivity determination. The zeta potentials of the finally calculated quartz sand and iron-coated quartz sand in electrolyte solutions with different pH valu...

Embodiment 2

[0067] The device of the present invention is used to measure the zeta potential of quartz sand mineral particles with a particle size of 0.42-0.85 mm in electrolyte solutions with different ionic strengths according to the above-mentioned instrument operation steps. The sample amount of quartz sand or iron-coated quartz sand required for each measurement is 8.80g. The electrolyte solutions with different ionic strengths used were 0.01, 0.05, 0.1, 0.5, 1.0, 2.0, 5.0 mmol·L -1 of NaCl solution. Carry out sample measurement according to the above-mentioned measurement steps, first perform hydraulic pressure difference correction, then conduct streaming potential measurement, and then conduct conductivity determination. Finally, the zeta potential of quartz sand in different ionic strength electrolyte solutions is obtained as Figure 5 shown. It can be seen that in electrolyte solutions with different ionic strengths, the measured zeta potential of quartz sand is negative, but...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com