Tank car comprehensive measurement system and method capable of judging leakage

A comprehensive measurement and tanker technology, which is applied in the field of comprehensive measurement systems for multi-parameter high-precision measurement, can solve problems such as poor measurement accuracy, accuracy impact, tank leakage, etc., and achieve cost reduction and product installation complexity, accurate liquid level Monitoring and measurement, to achieve the effect of compensation work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

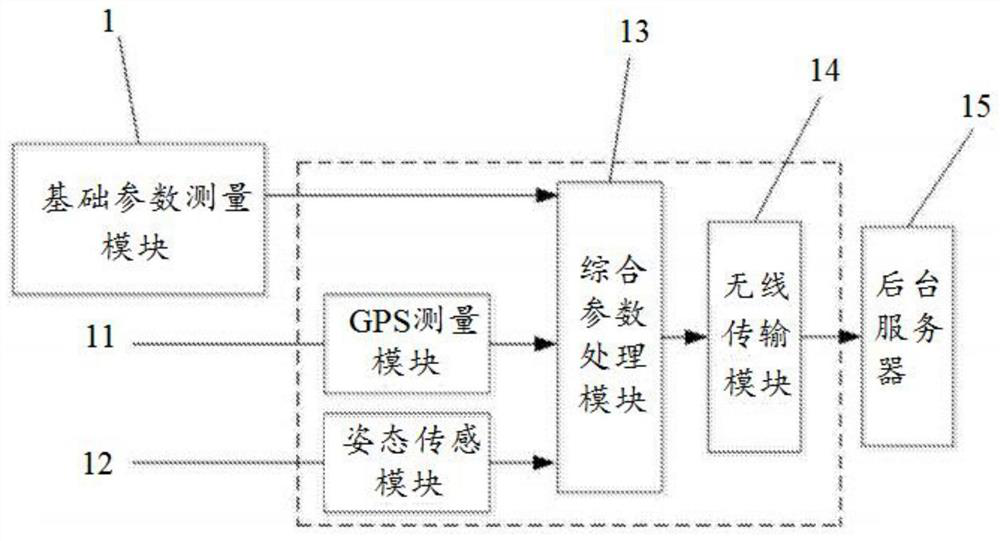

[0034] Such as figure 1 As shown, this embodiment provides a tank car comprehensive measurement system capable of judging leakage, including:

[0035] The basic parameter measurement module 1 installed inside the tank car and the GPS measurement module 11, attitude sensing module 12, comprehensive parameter processing module 13 and background server 15 installed outside the tank car;

[0036] The basic parameter measurement module 1 is connected to the input terminal of the comprehensive parameter processing module 13, and is used to obtain temperature information, pressure information, liquid level, liquid density and liquid leakage alarm information of the liquid in the tanker;

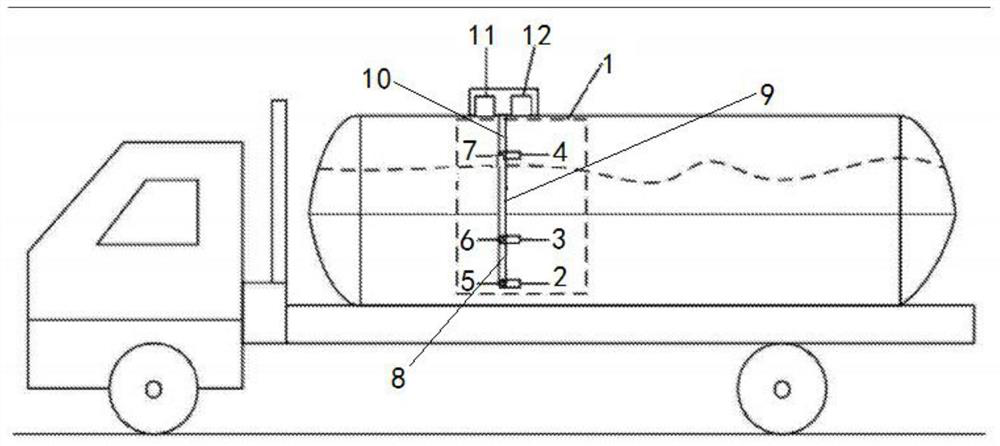

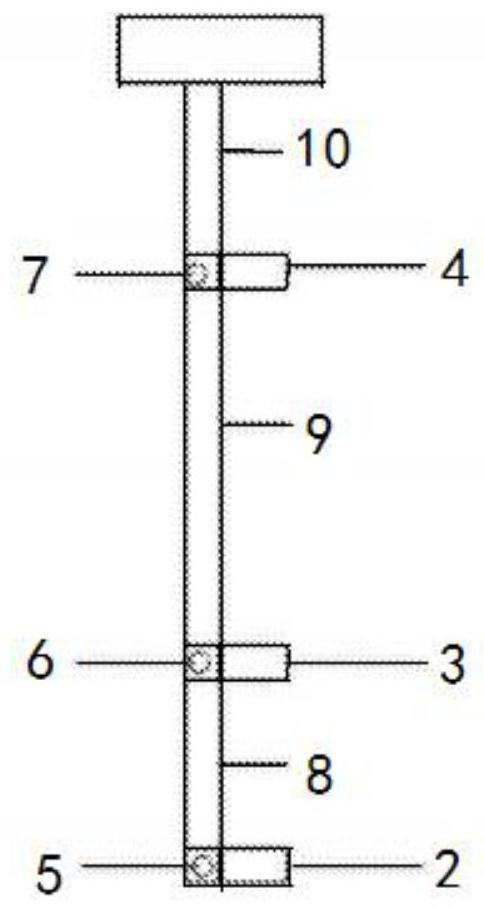

[0037] In order to meet the high-precision measurement requirements of the tank body, the basic parameter measurement module 1 adopts a three-stage structure integrated multi-parameter measurement module, which can comprehensively process parameters and solve the problem of low precision of single p...

Embodiment 2

[0089] Such as Figure 5 As shown, the present embodiment provides a tank car comprehensive measurement method that can judge leakage (work steps when the comprehensive measurement system provided in Embodiment 1 works), including:

[0090] Step S1: Obtain the basic information and vehicle status information in the tanker; the basic information in the tanker includes the temperature, pressure information, liquid level, liquid density and liquid leakage alarm information of the liquid in the tanker; the vehicle status information includes tanker Positioning information and vehicle operating status information;

[0091] Wherein, the first temperature sensor 5 and the first pressure sensor 2, the second temperature sensor 6 and the second pressure sensor 3 are placed in the liquid phase of the dangerous chemical liquid to be measured, the third temperature sensor 7 and the third pressure sensor 4 Placed in the gas phase of the tank containing the dangerous chemical liquid to be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com