Integrated temperature thin film pressure sensor

A thin-film pressure and sensor technology, which is applied in the field of thin-film pressure sensors and thin-film pressure sensors with integrated temperature measurement functions, can solve problems such as inability to perform relatively accurate compensation, simplify installation and debugging, improve measurement accuracy, and improve dynamic response speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The content of the present invention will be further described below in conjunction with the accompanying drawings, but the specific implementation forms of the present invention are not limited to the following embodiments.

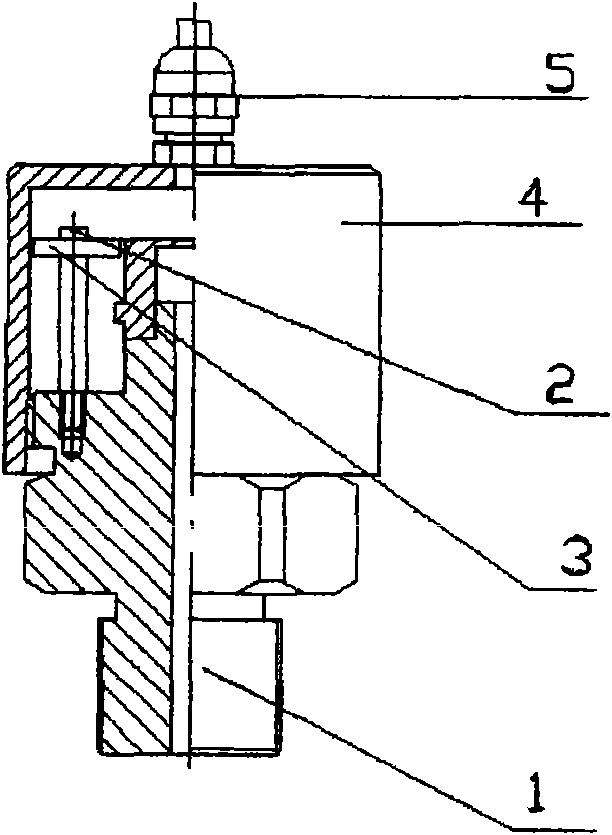

[0030] Referring to accompanying drawing, the structure of the membrane pressure sensor of integrated temperature of the present invention is as follows figure 1 As shown, it consists of a pressure introduction connecting pipe 1 with threads and a sealing ring, a sensitive component 2, an external circuit board 3, a housing 4 and a connector 5.

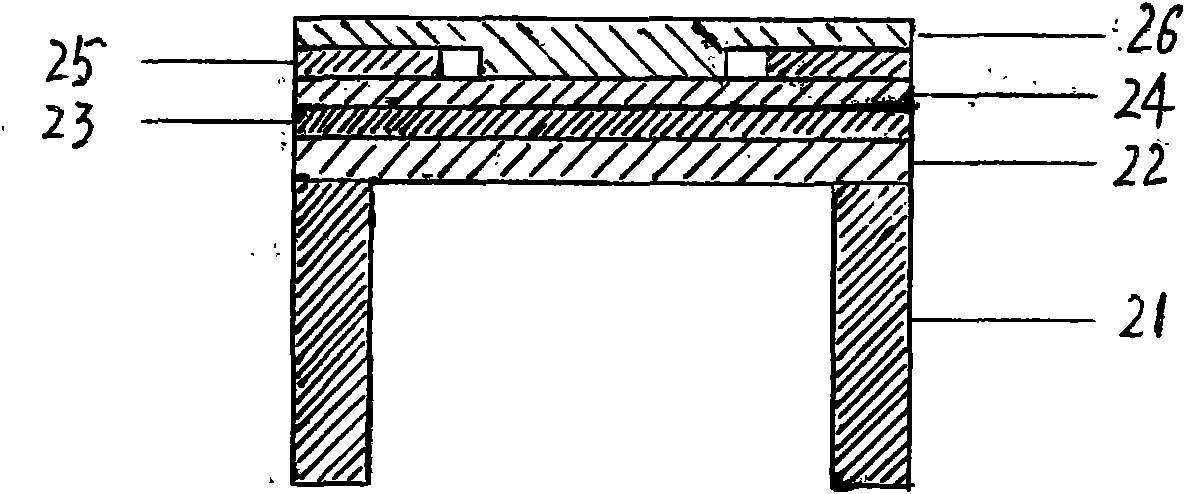

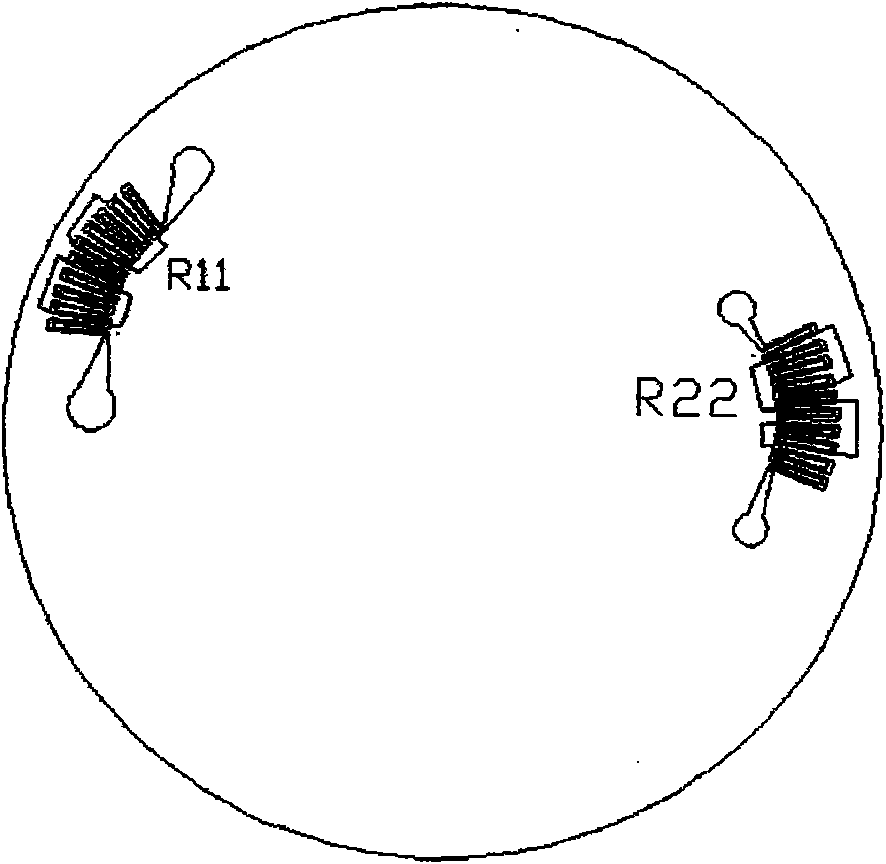

[0031] The structure of the sensitive component 2 in the thin film pressure sensor is as follows figure 2 As shown, it has a hollow sensitive elastic body 21 made of stainless steel 17-4PH material whose lower part is welded on the pressure connecting pipe 1. The upper bottom surface of the sensitive elastic body 21 is a strain deformation zone. A transition layer 22 , an insulating layer 23 , a resista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com