Underwater cable protection device

A protection device, underwater cable technology, applied in the direction of electrical components, etc., can solve the problems of underwater cable damage, impact of underwater cable service life, underwater cable bending, etc., to achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

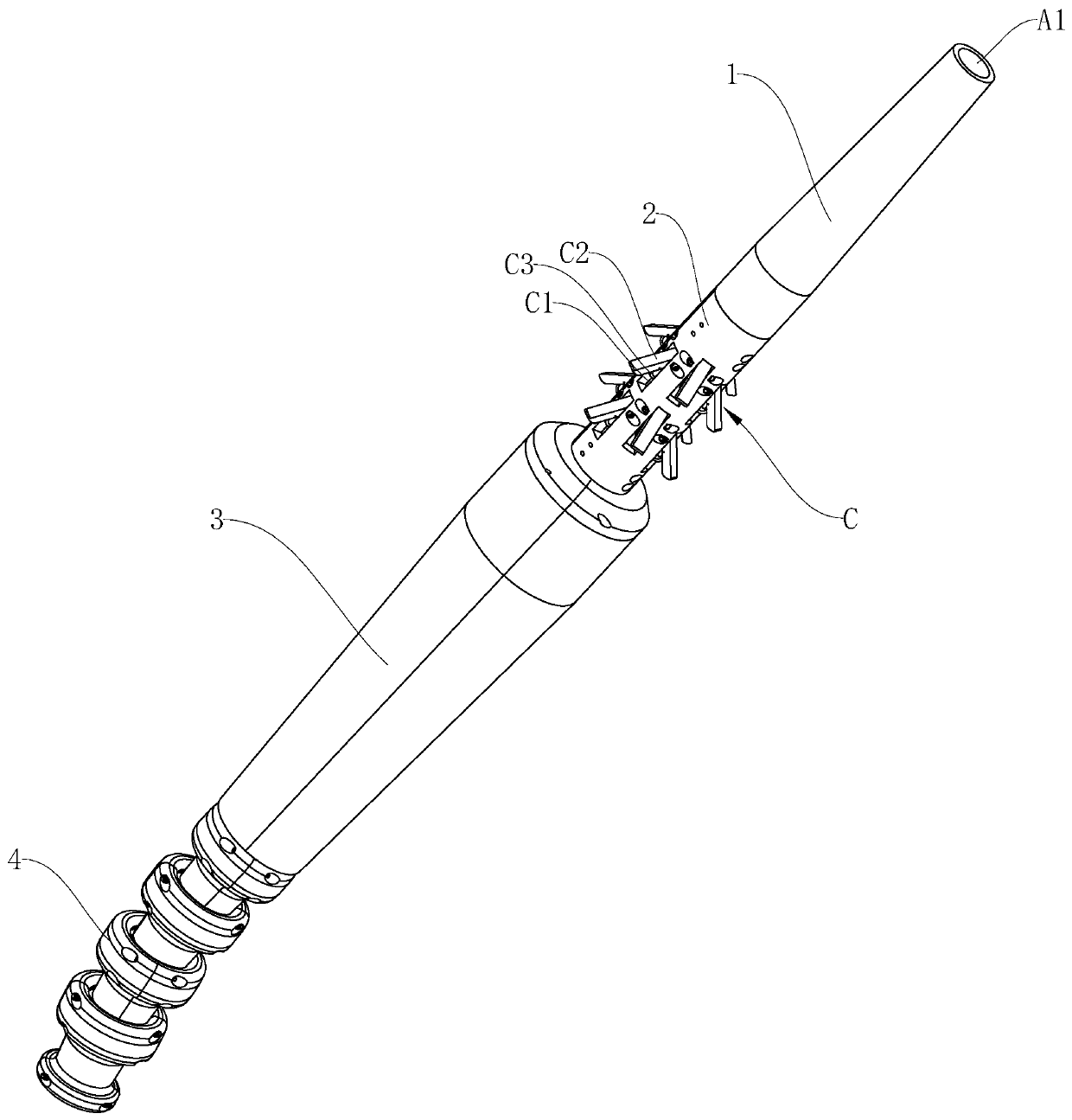

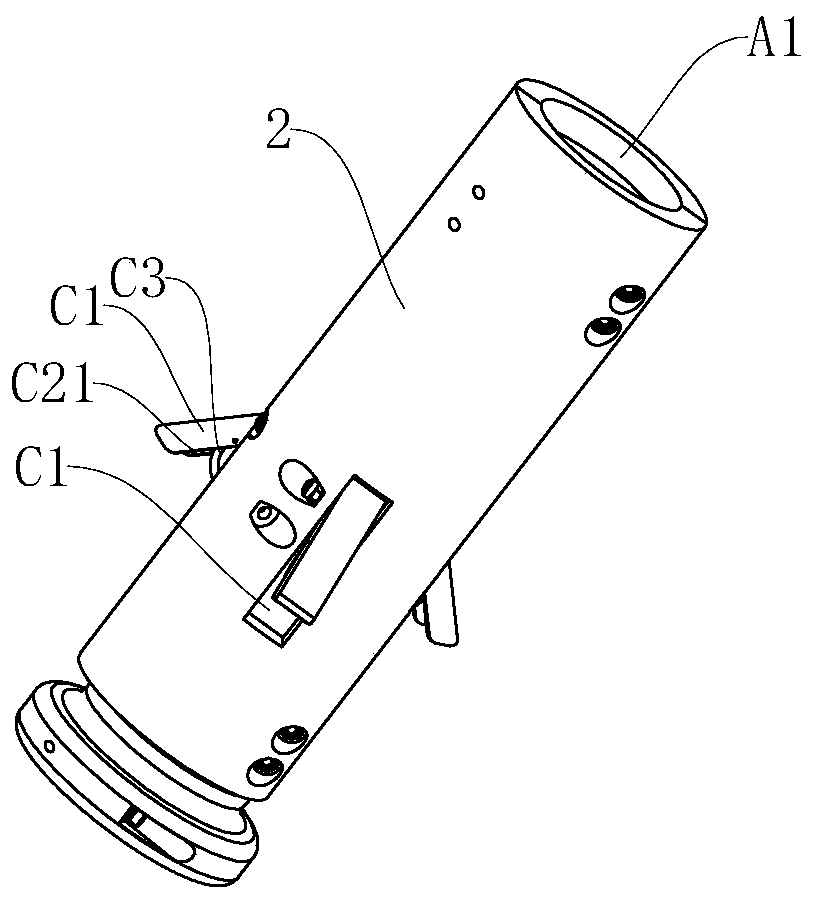

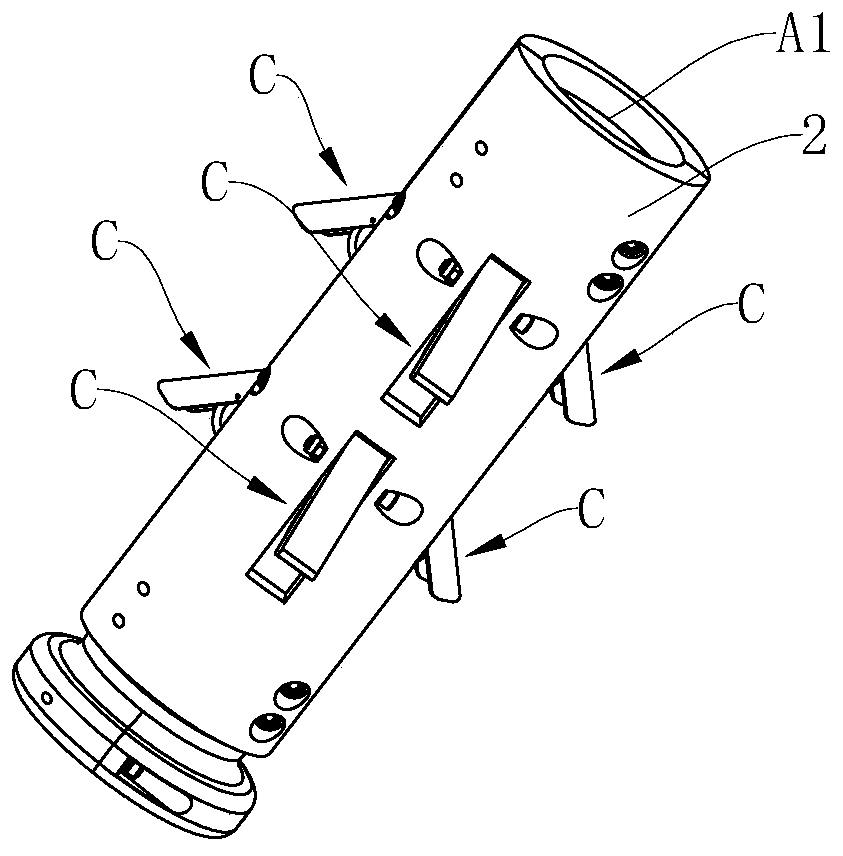

[0045] Embodiment 1: As shown in the figure, an underwater cable protection device includes a protection device body provided with a central through hole A1 for the underwater cable A to pass through the installation. The protection device body includes flexible guides connected sequentially from top to bottom. Tube 1, rigid positioning tube 2 and flexible anti-bending tube 3, the flexible guide tube 1 is a tapered tube with gradually larger outer diameter from top to bottom, and the maximum outer diameter of the flexible guide tube 1 is smaller than the water supply bottom set on the wall of the tower B. The inner diameter of the installation hole B1 where the cable A passes through the installation, the rigid positioning tube 2 is a cylindrical tube with the same outer diameter everywhere, the outer diameter of the rigid positioning tube 2 is equal to the maximum outer diameter of the flexible guiding tube 1, and the flexible guiding tube 1 The anti-bending pipe 3 is a tapere...

Embodiment 2

[0051] Embodiment 2: Other parts are the same as Embodiment 1, the difference is that the elastic support member C3 is a spring, one end of the spring is fixedly installed on the inner end surface of the rigid positioning block C2, and the other end of the spring is fixedly installed on the bottom of the groove C1 end face.

Embodiment 3

[0052] Embodiment 3: other parts are the same as Embodiment 1 or Embodiment 2, the difference is that the positioning mechanism includes multiple sets of positioning components, and multiple sets of positioning components are arranged at intervals up and down.

[0053] In this particular embodiment, there are 2 groups of positioning components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com