Rubber tire container gantry crane

A gantry crane and container technology, which is applied in the direction of cranes, trolley cranes, traveling mechanisms, etc., can solve the problems of increased weight of the whole machine, increased weight of the trolley assembly, and high manufacturing costs, and can extend the practical life, reduce the weight of the trolley, and reduce the weight of the trolley. cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

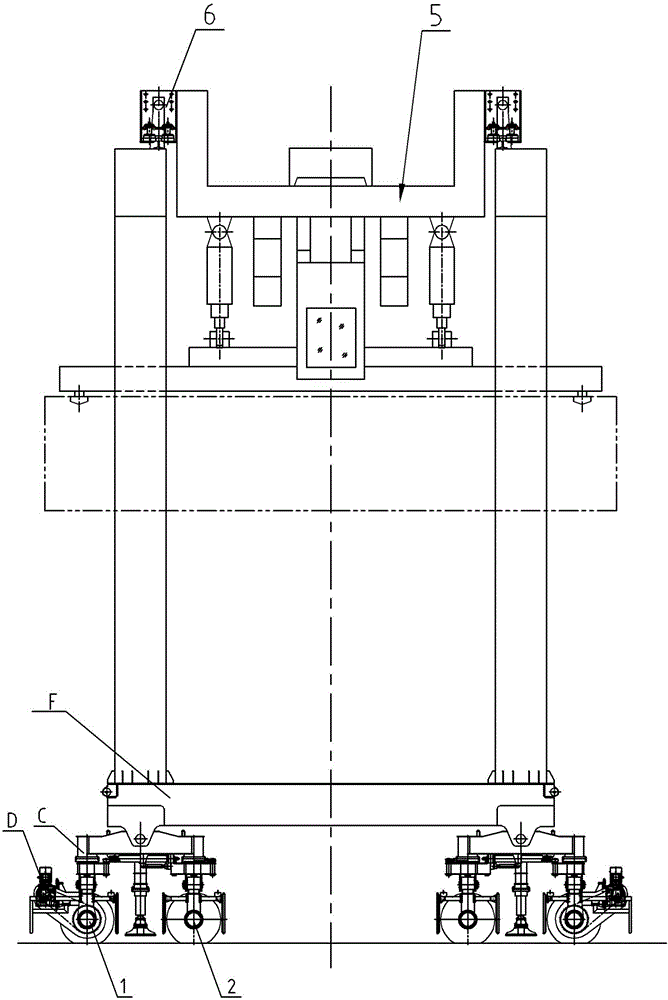

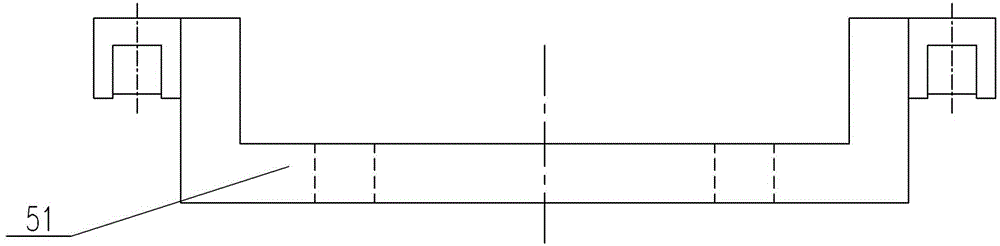

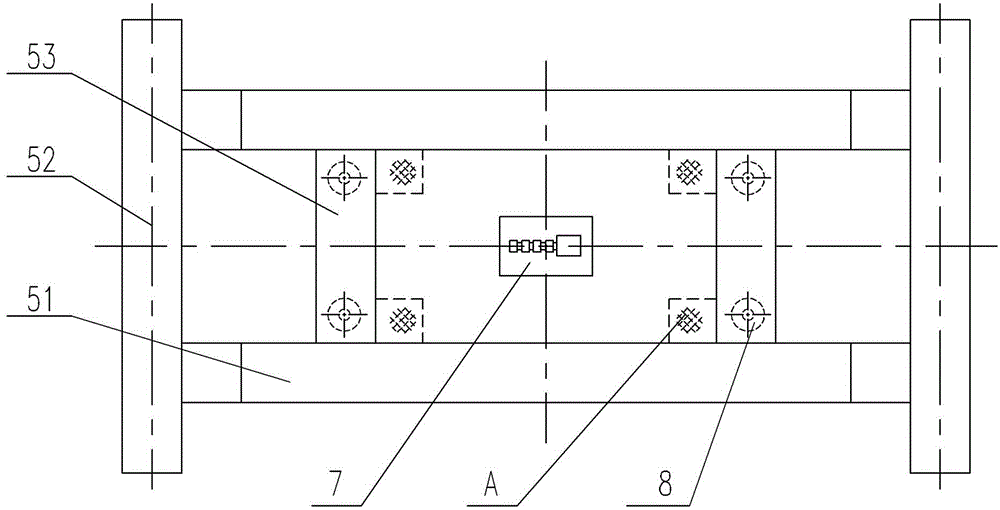

[0022] Such as figure 1 system Figure 6 As shown, the rubber-tyred container gantry crane disclosed in the present invention includes a driving axle 1 and a driven axle 2, outriggers 3, a main girder 4, a trolley frame 5, a trolley running mechanism 6, a hydraulic pump station 7, Multi-stage hydraulic cylinder 8, spreader rack 9, spreader 10, maintenance cage A, cab B. The driving axle 1 and the driven axle 2 form the main components of the cart running mechanism. The trolley frame 5, the trolley running mechanism 6 and the hoisting mechanism composed of a hydraulic pump station 7 and four multi-stage hydraulic cylinders 8 form the main parts of the trolley. There are four supporting legs 2, and a lower beam F is connected between the lower ends of the two supporting legs 2 at the same end, and the main beam 2 is connected between the two supporting legs 2 in the longitudinal direction. Both ends of the lower beam F are connected with the driving frame C, and the driving f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com