Patents

Literature

109results about How to "Increase cutting rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slightly alkaline sapphire polishing solution and preparation method thereof

ActiveCN101870853AStrong dilutable ratioImprove stabilityPolishing compositions with abrasivesSURFACTANT BLENDSapphire

The invention provides a slightly alkaline sapphire polishing solution and a preparation method thereof, which relates to the field of sapphire polishing technology. The method comprises the following steps: firstly, suspending nano-silica sol particles of which the particle diameters are 3-300nm in water; adding a complexing agent into the suspension; then, adding a surfactant; and finally, regulating the pH value of the suspension to 7-9.5. The method of the invention is simple and reasonable, easy production and good product stability. The product has high dilution rate, high polishing efficiency, good and strong stability and easy production and can not deposit on the surfaces of polishing machines and polishing materials easily; and because of unique fluid property, the product can not be air-dried on the surface of sapphire easily after being polished, thereby greatly reducing the burden of the subsequent cleaning processes. Different from the traditional sapphire polishing solution, the product of the invention has the advantage that under the condition of regulation of a reasonable formula, the polishing and cutting rate of sapphire increases when the pH (10.5) decreases.

Owner:江苏集萃中以科技产业发展有限公司

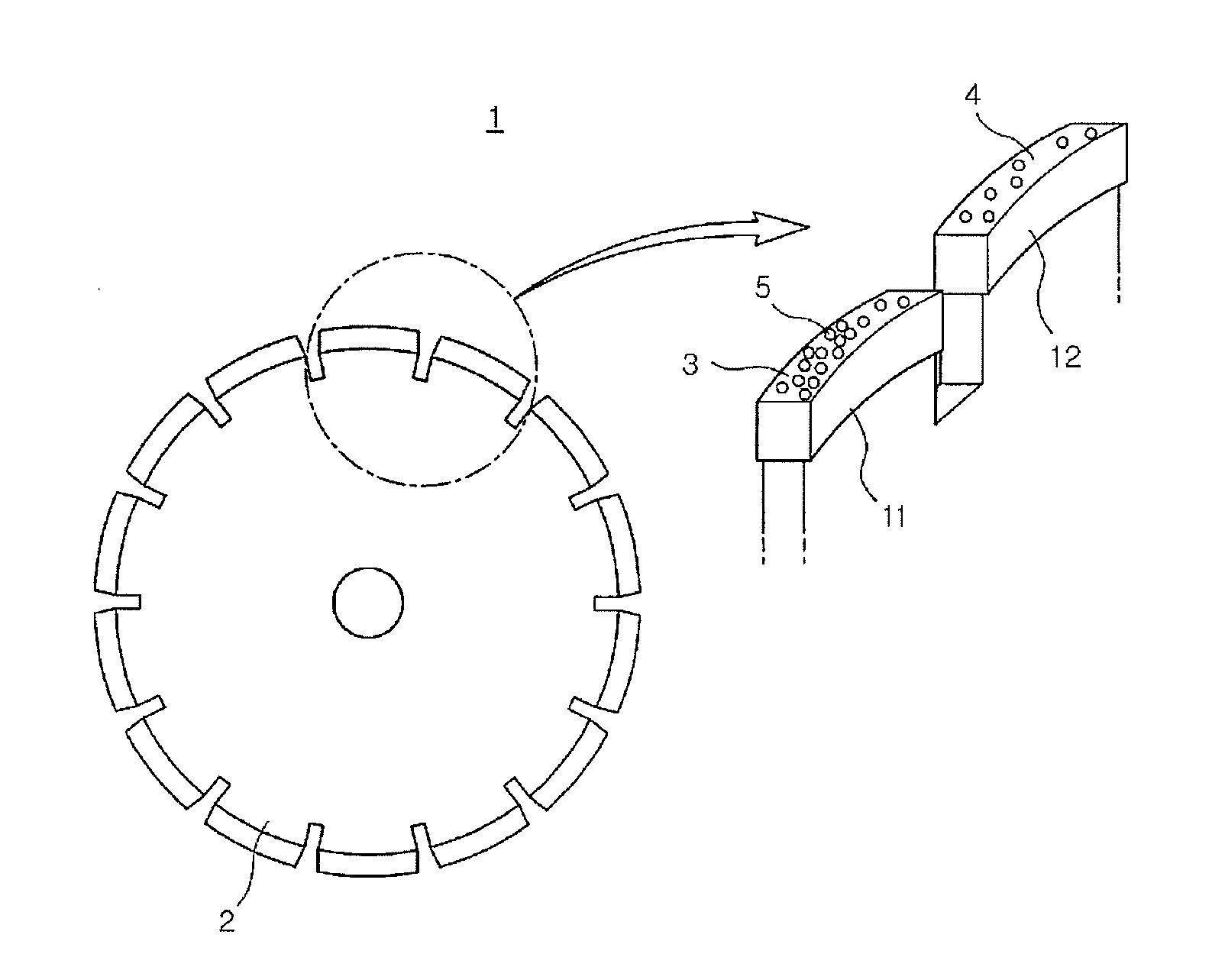

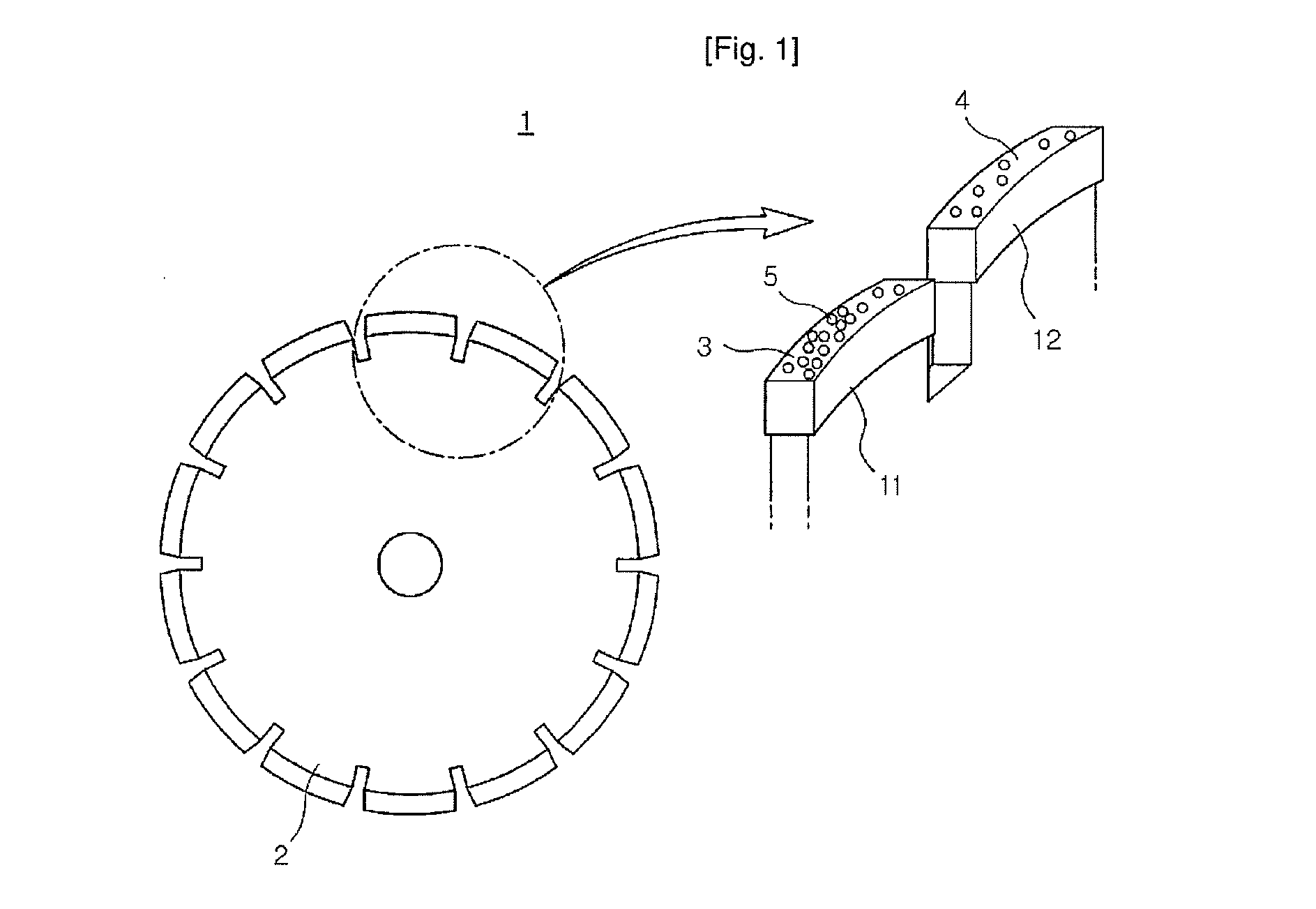

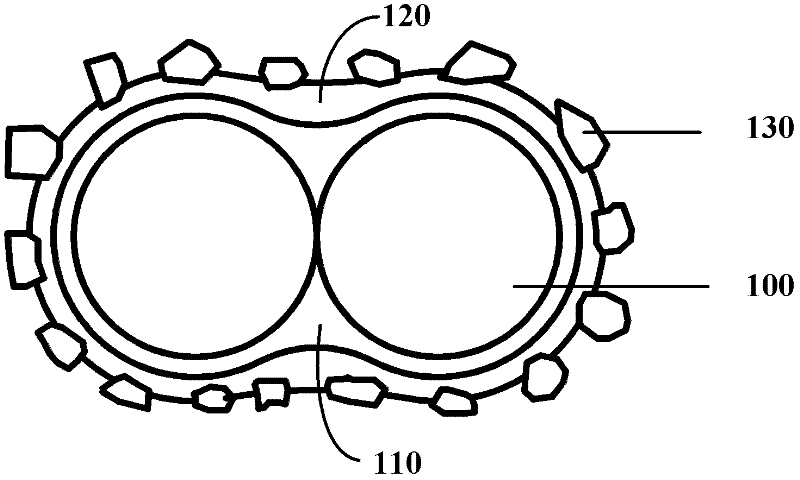

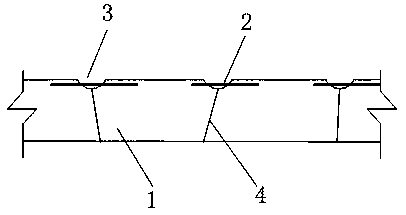

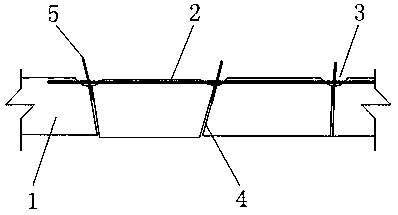

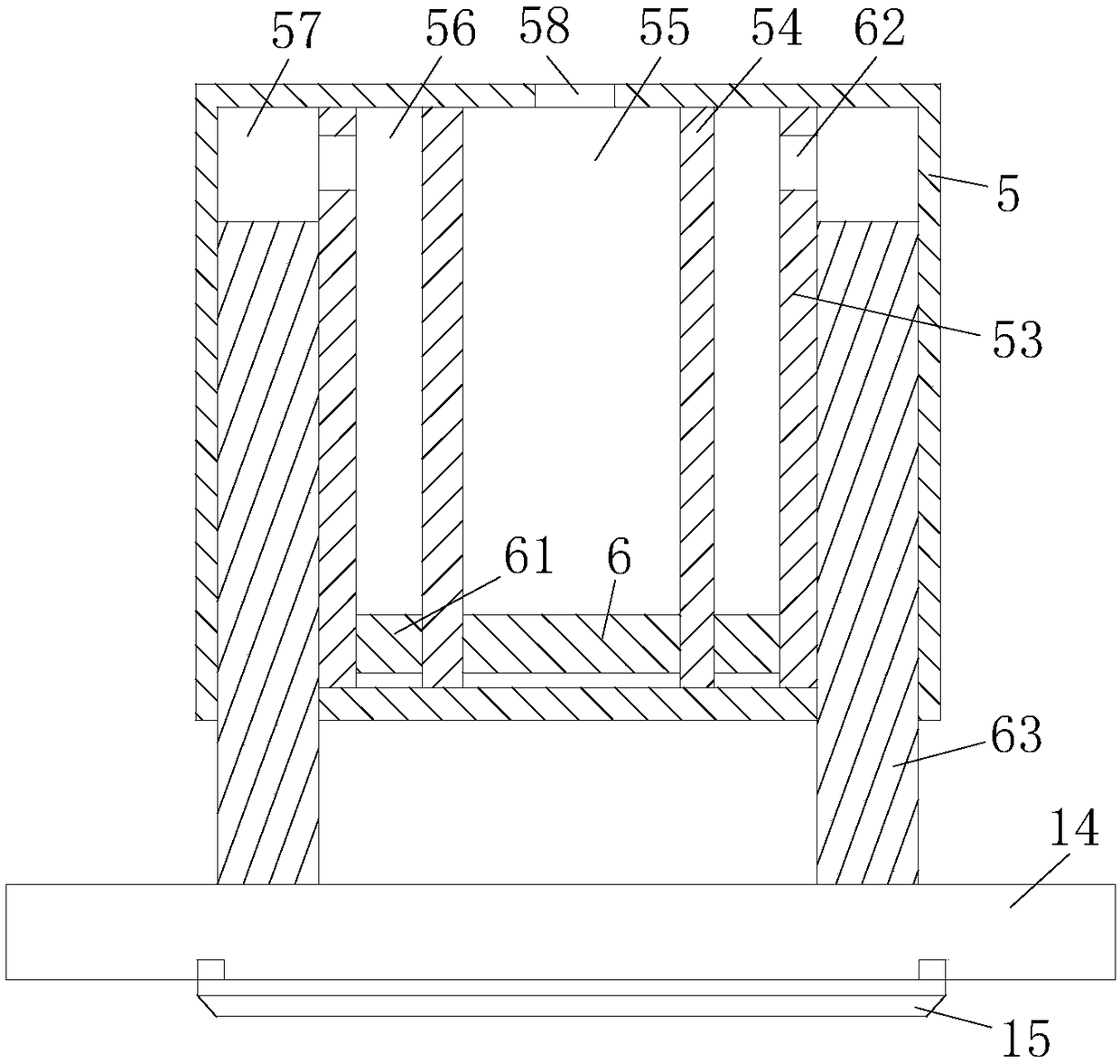

Cutting Segment for Cutting Tool and Cutting Tools

ActiveUS20080202488A1Increase cutting rateExtended useful lifeBonded abrasive wheelsSaw bladesBrickCutting oil

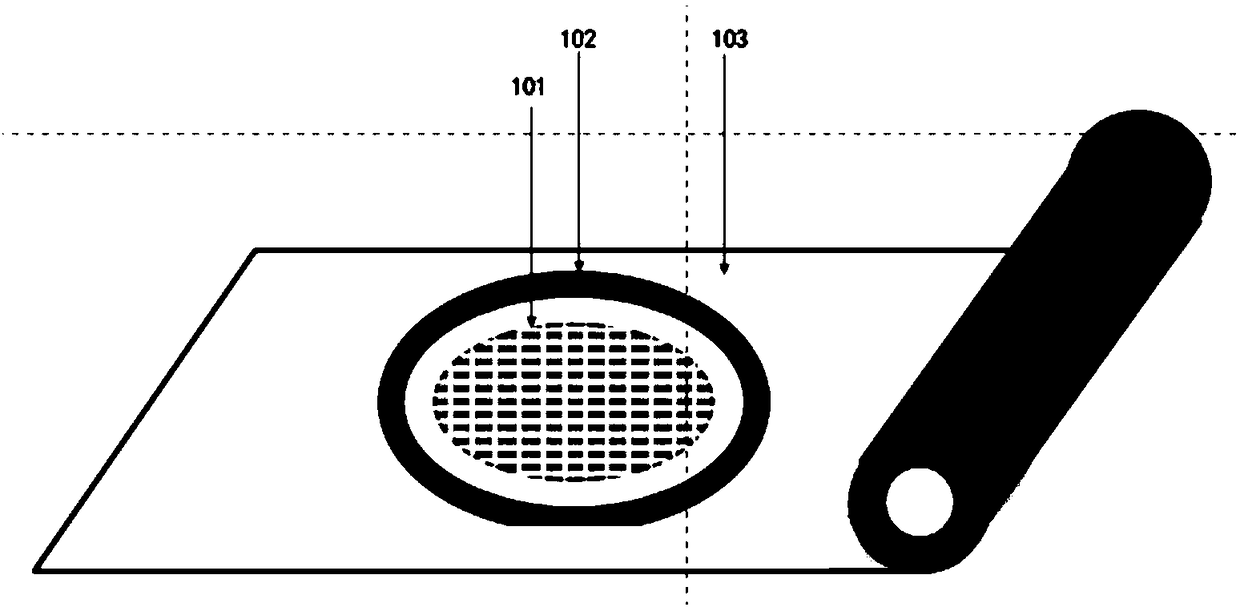

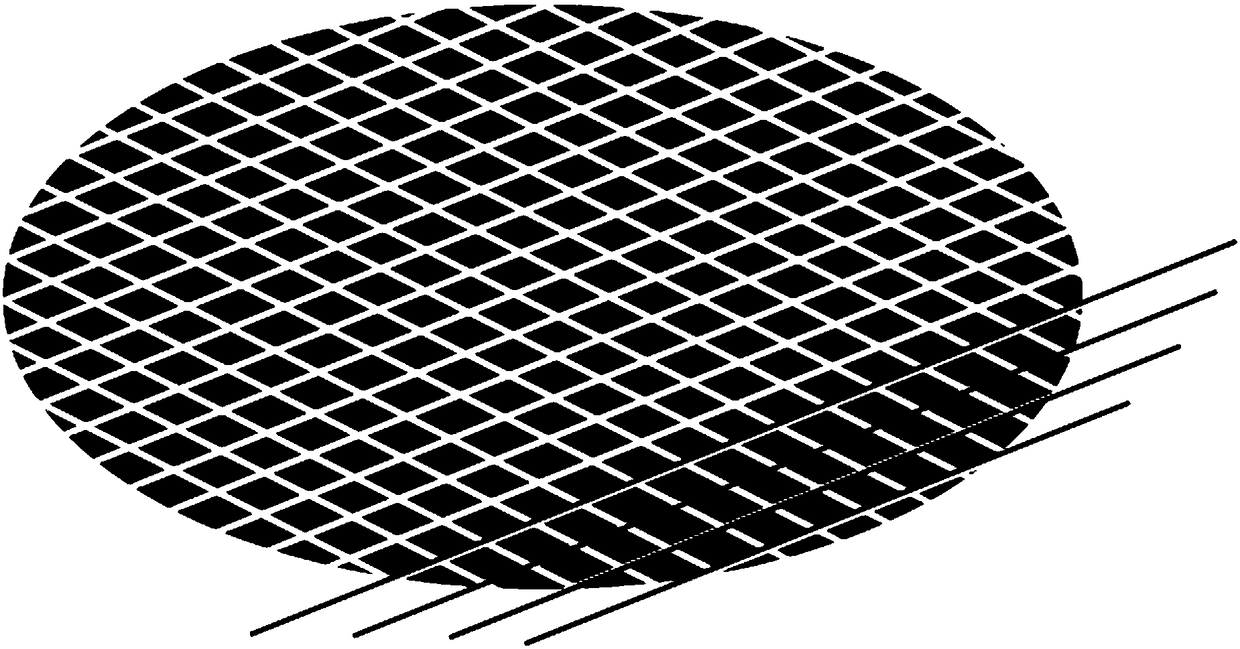

The invention provides a cutting segment for a cutting tool for cutting or drilling a brittle work piece such as stone, bricks, concrete and asphalt, and a cutting tool having the cutting segment. The cutting segment includes a cutting surface for cutting a work piece and a plurality of abrasive particle layers. The abrasive particle layers are disposed perpendicular to a cutting direction. Each of the abrasive layers has a plurality of abrasive particle rows in a width direction of the cutting segment. Each of the abrasive rows has a plurality of abrasive particles arranged in a line. Further, the abrasive layers have a plurality of blank sections therebetween. In the blanks sections, abrasive particles are absent or have a concentration of 70% or less with respect to those in the abrasive rows. In addition, the blank sections include relatively thick blank sections and relatively thin blank sections.

Owner:NIWA DAIYAMONDO INDS +1

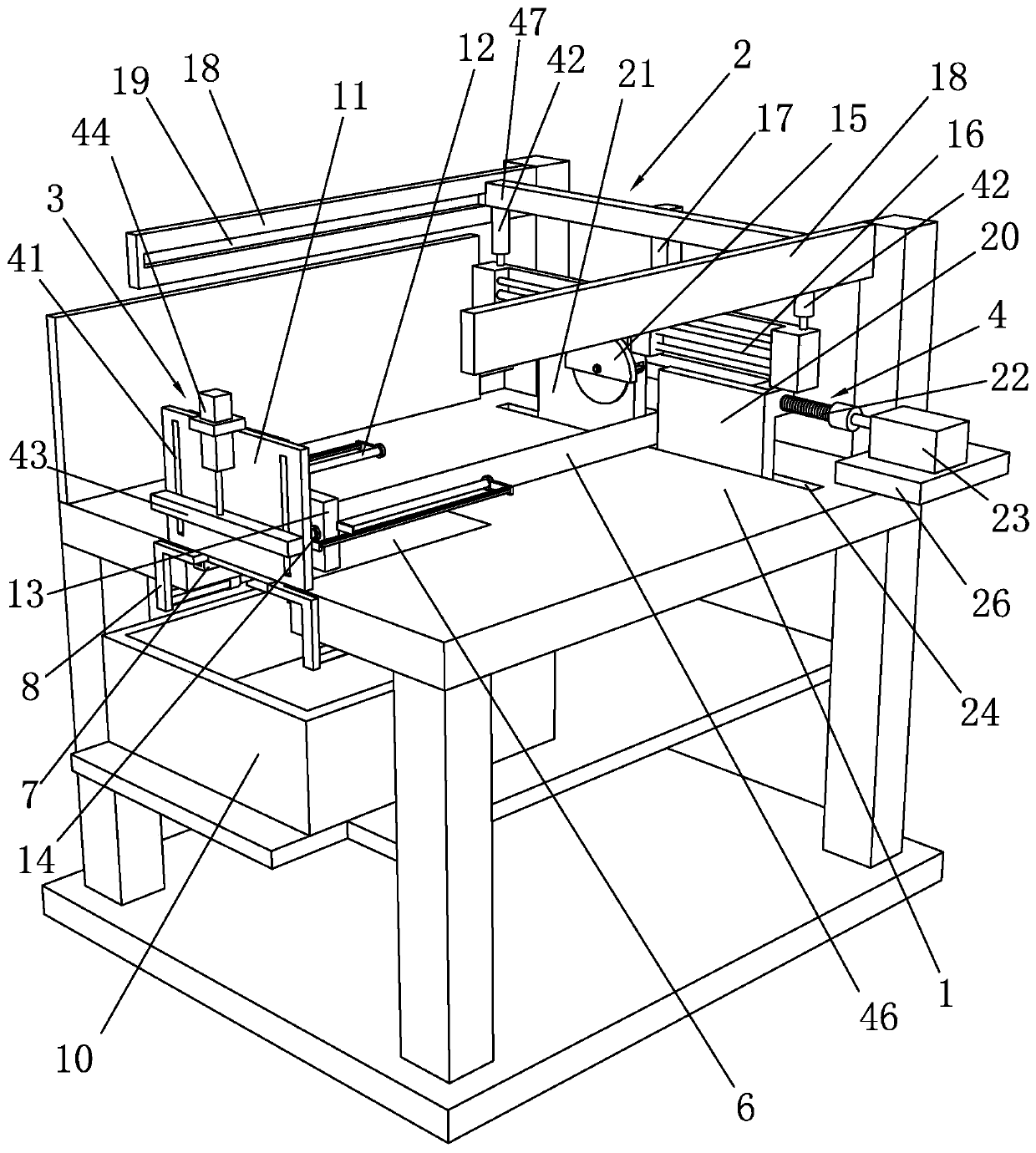

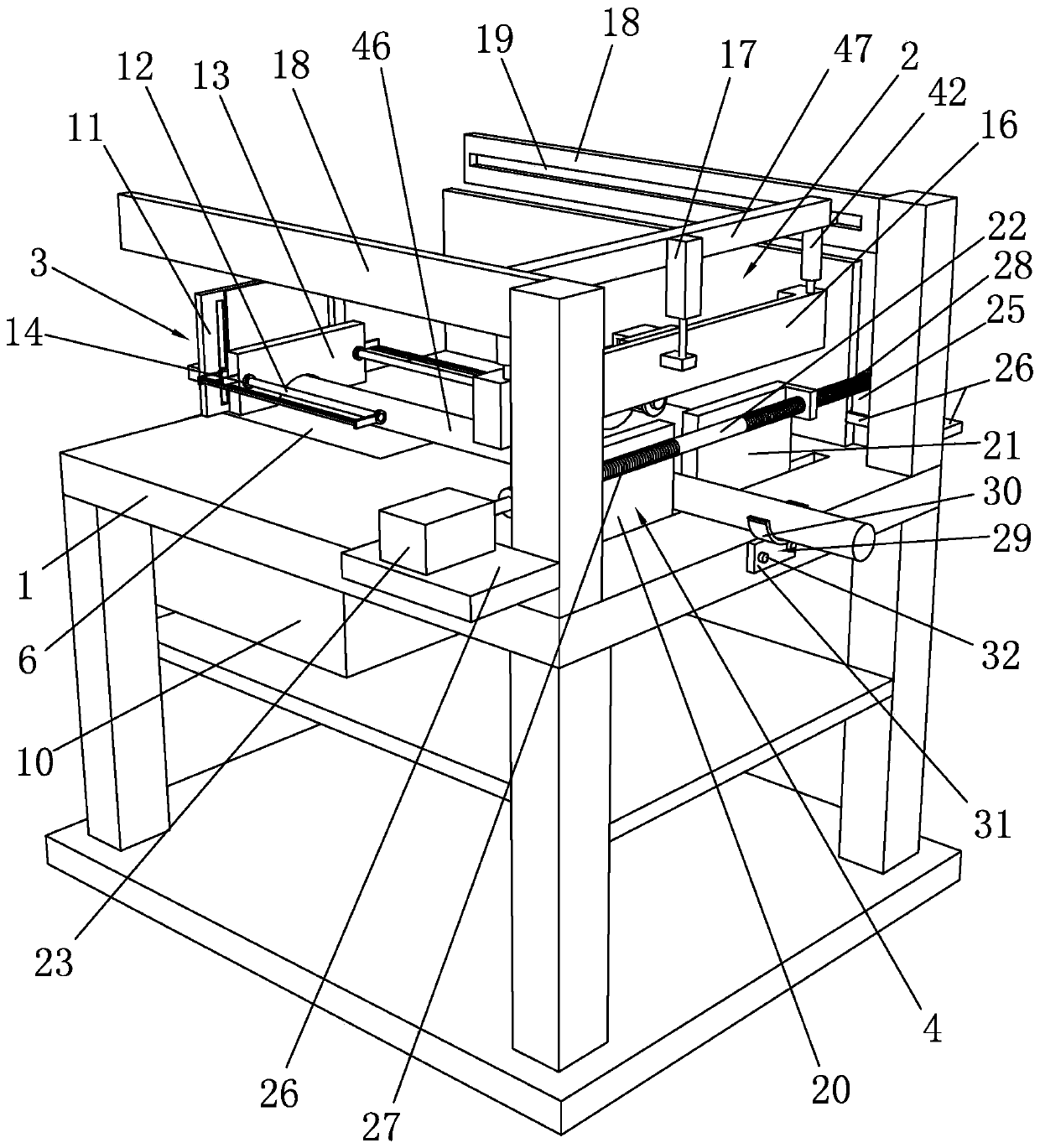

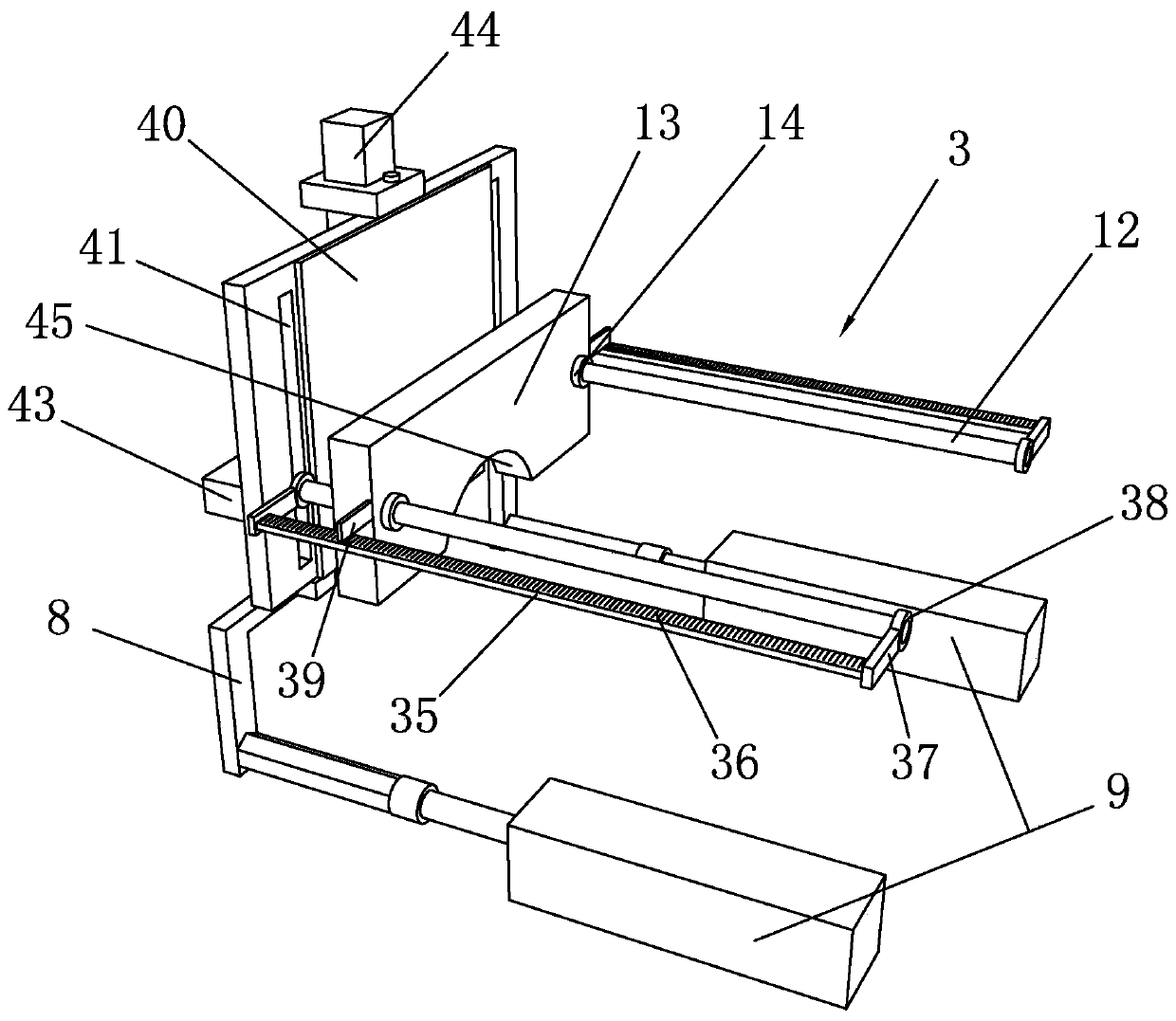

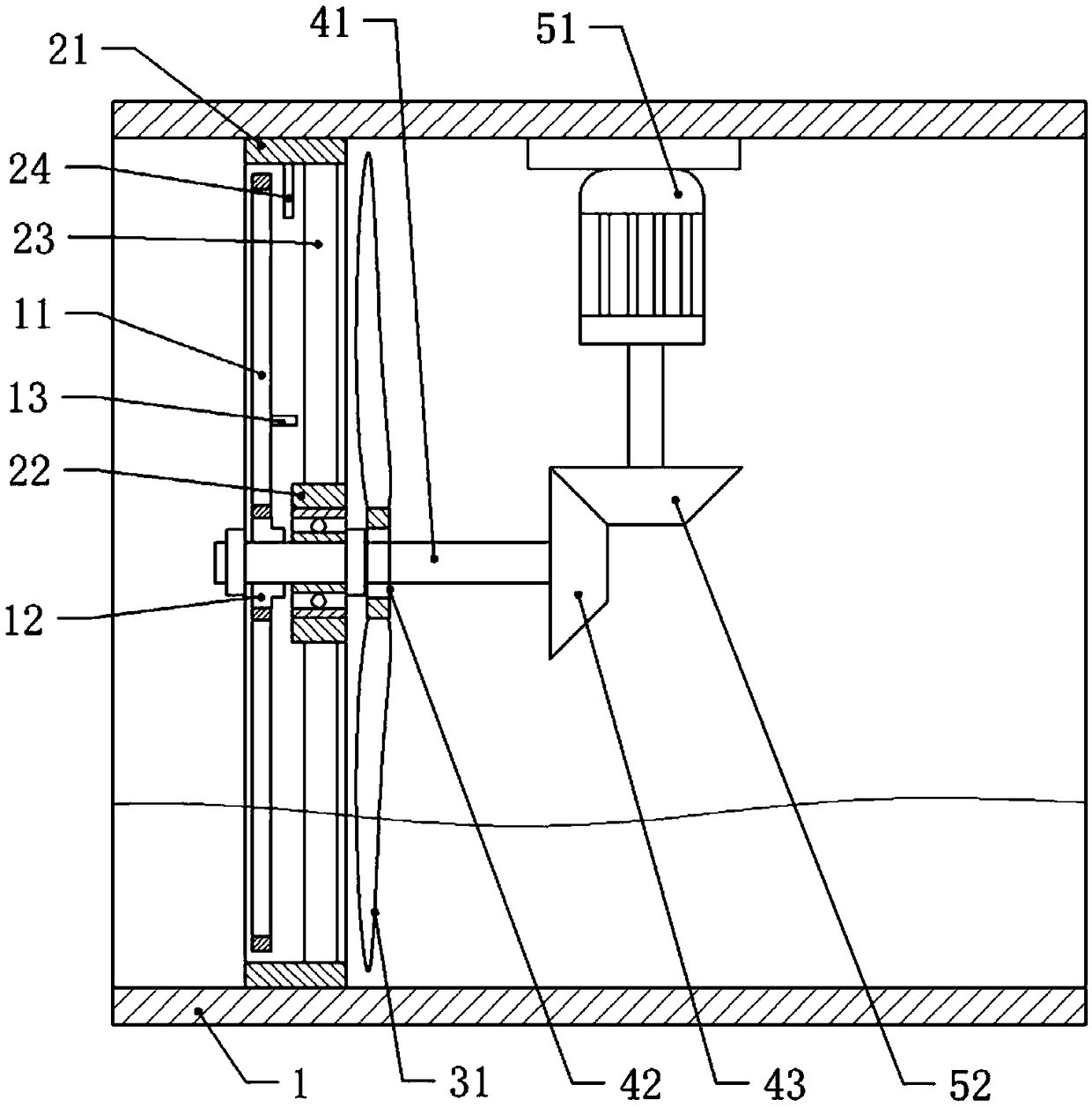

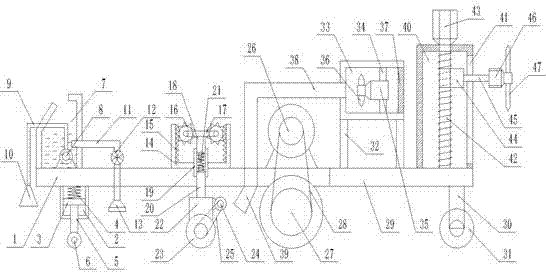

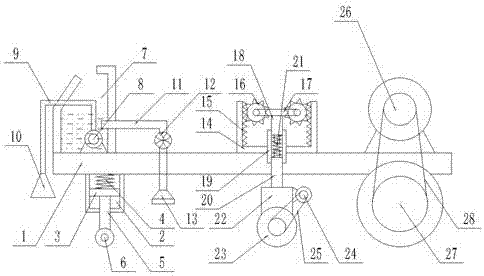

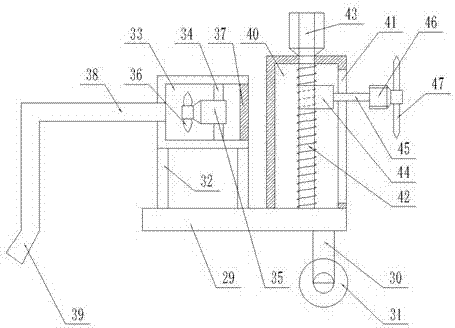

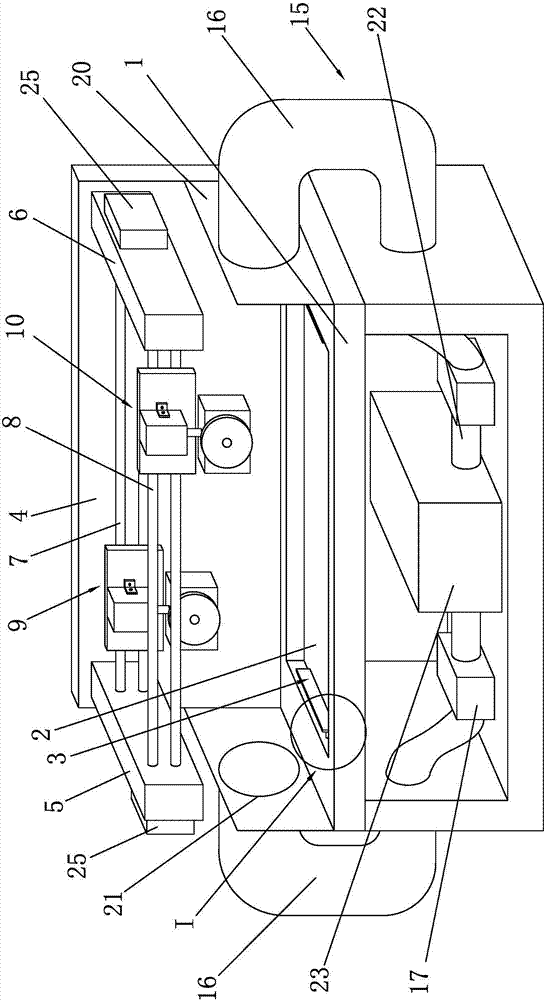

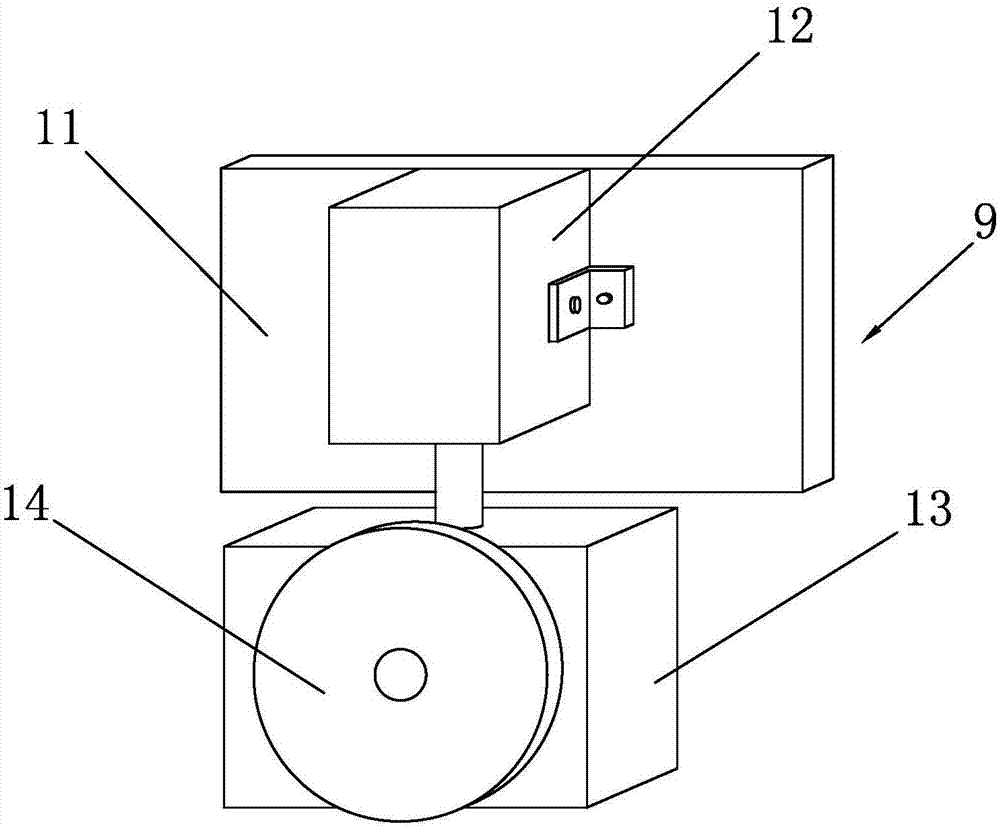

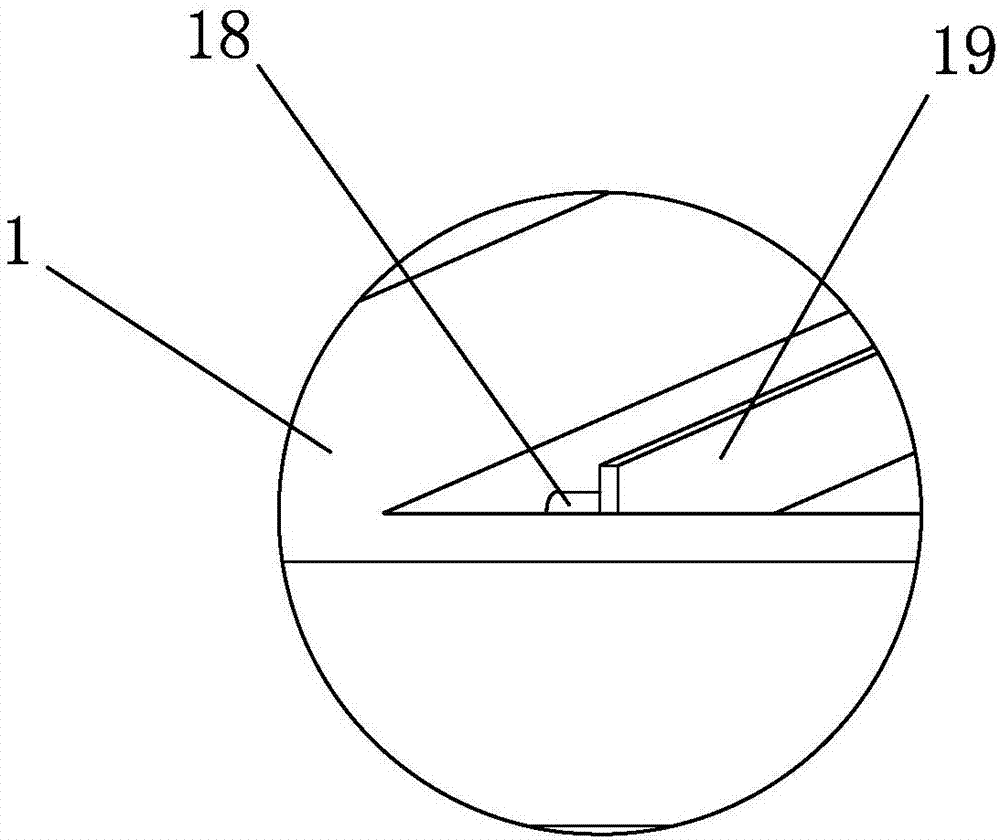

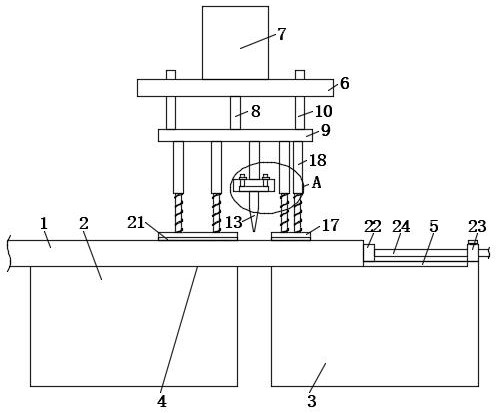

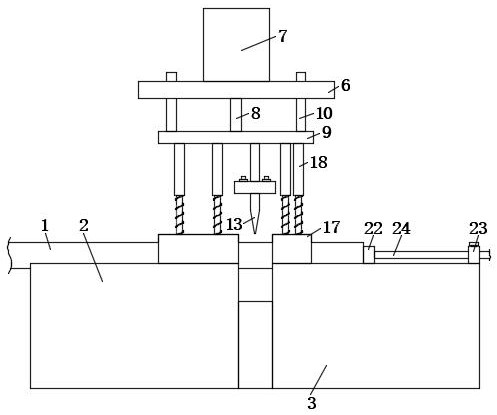

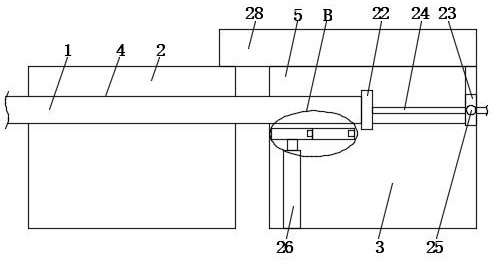

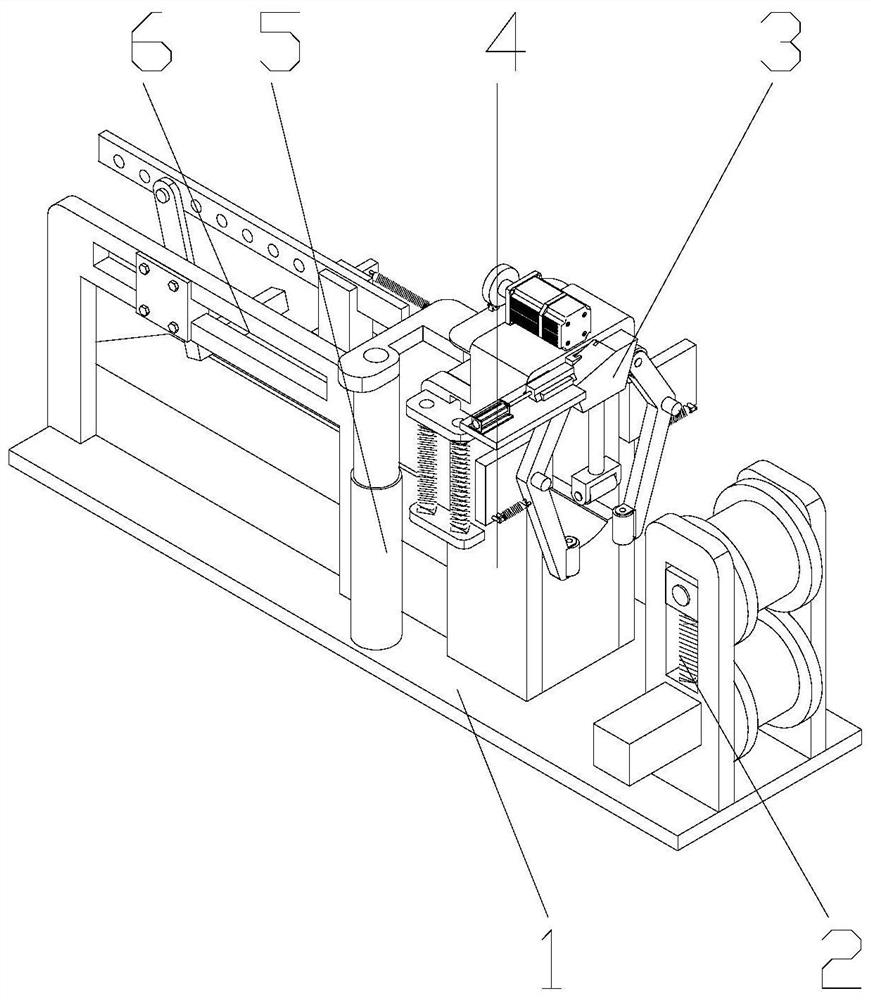

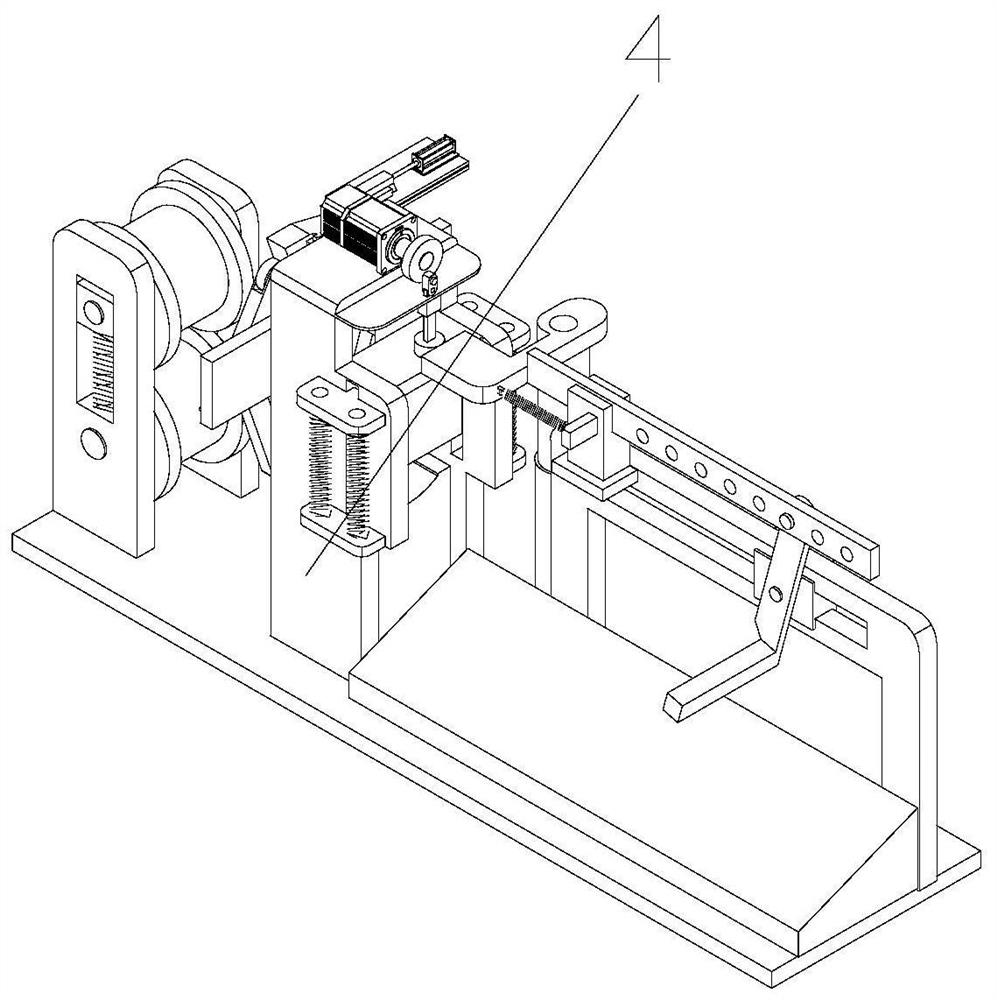

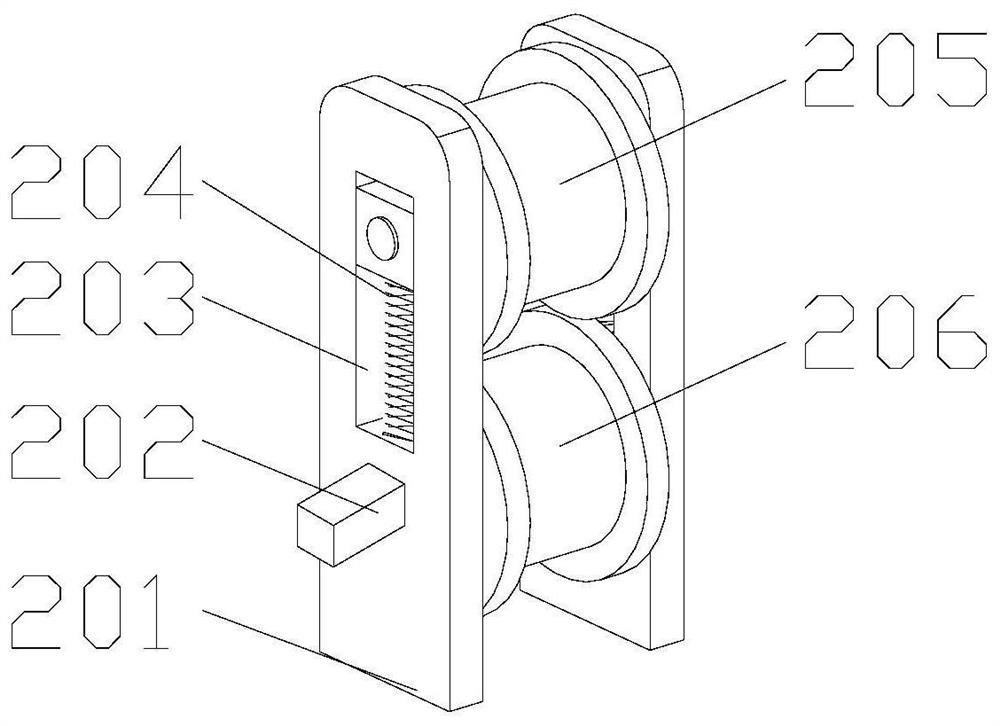

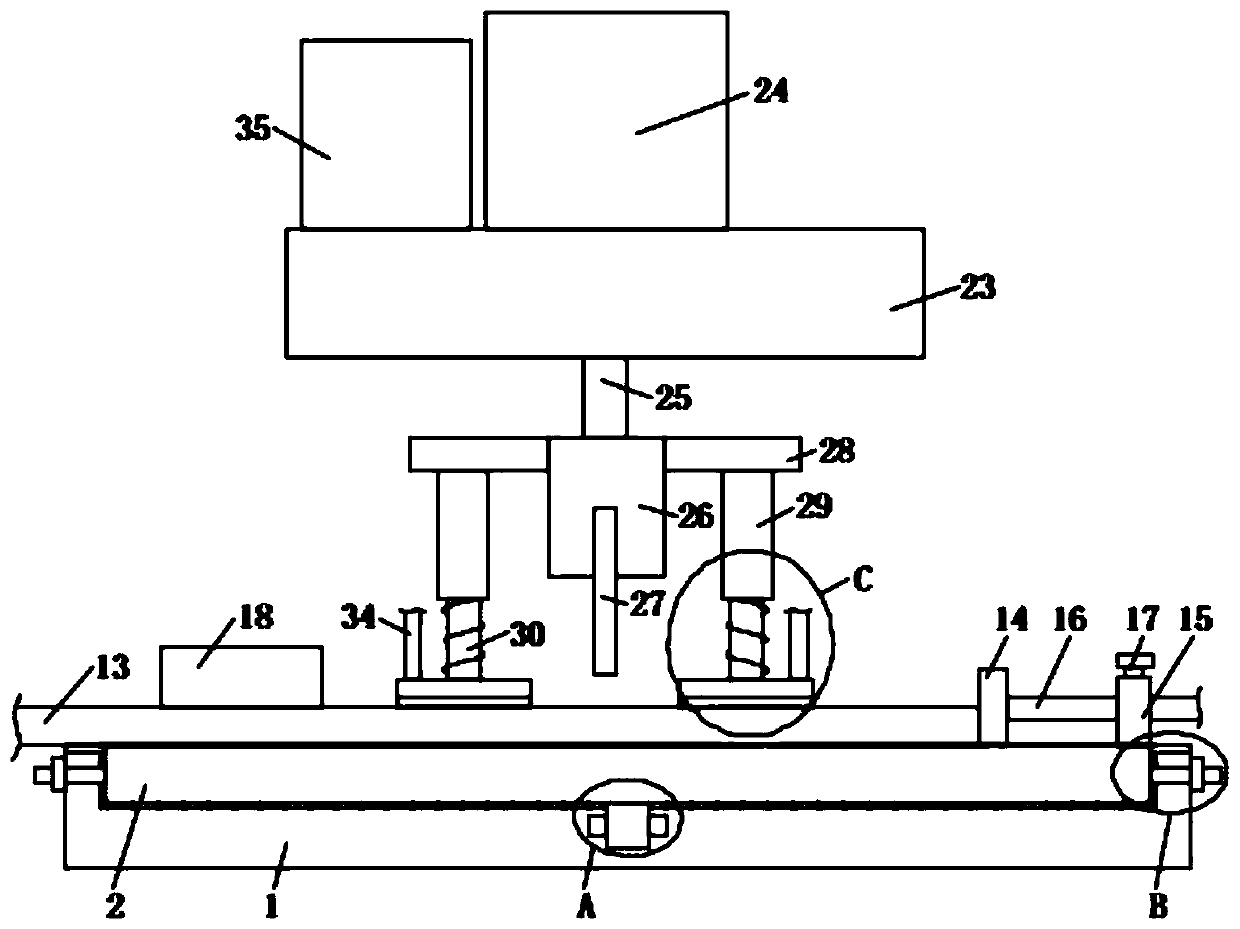

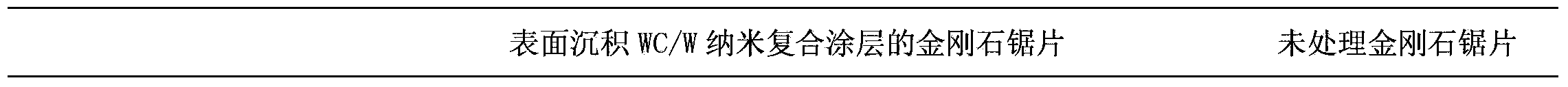

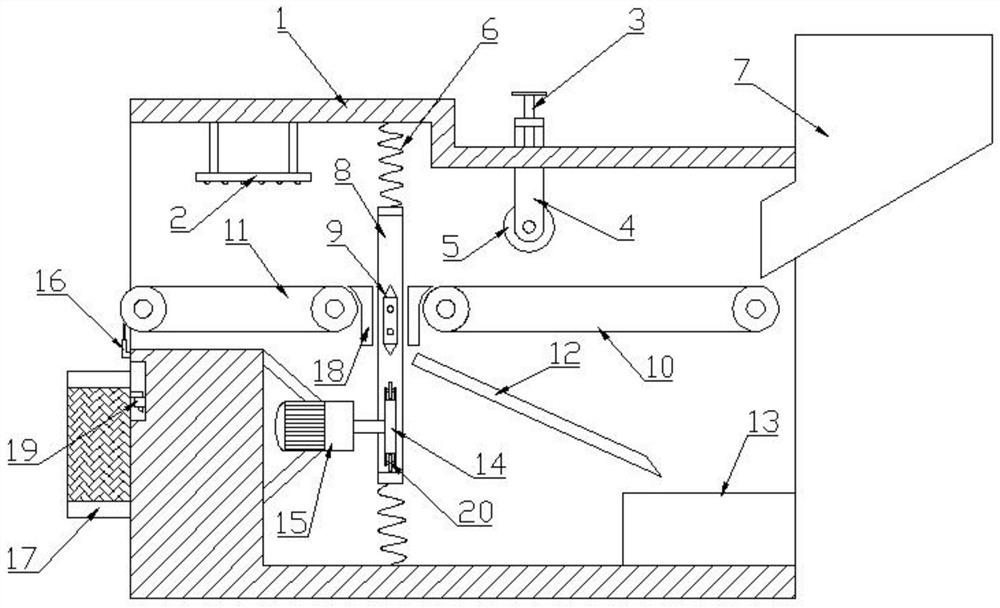

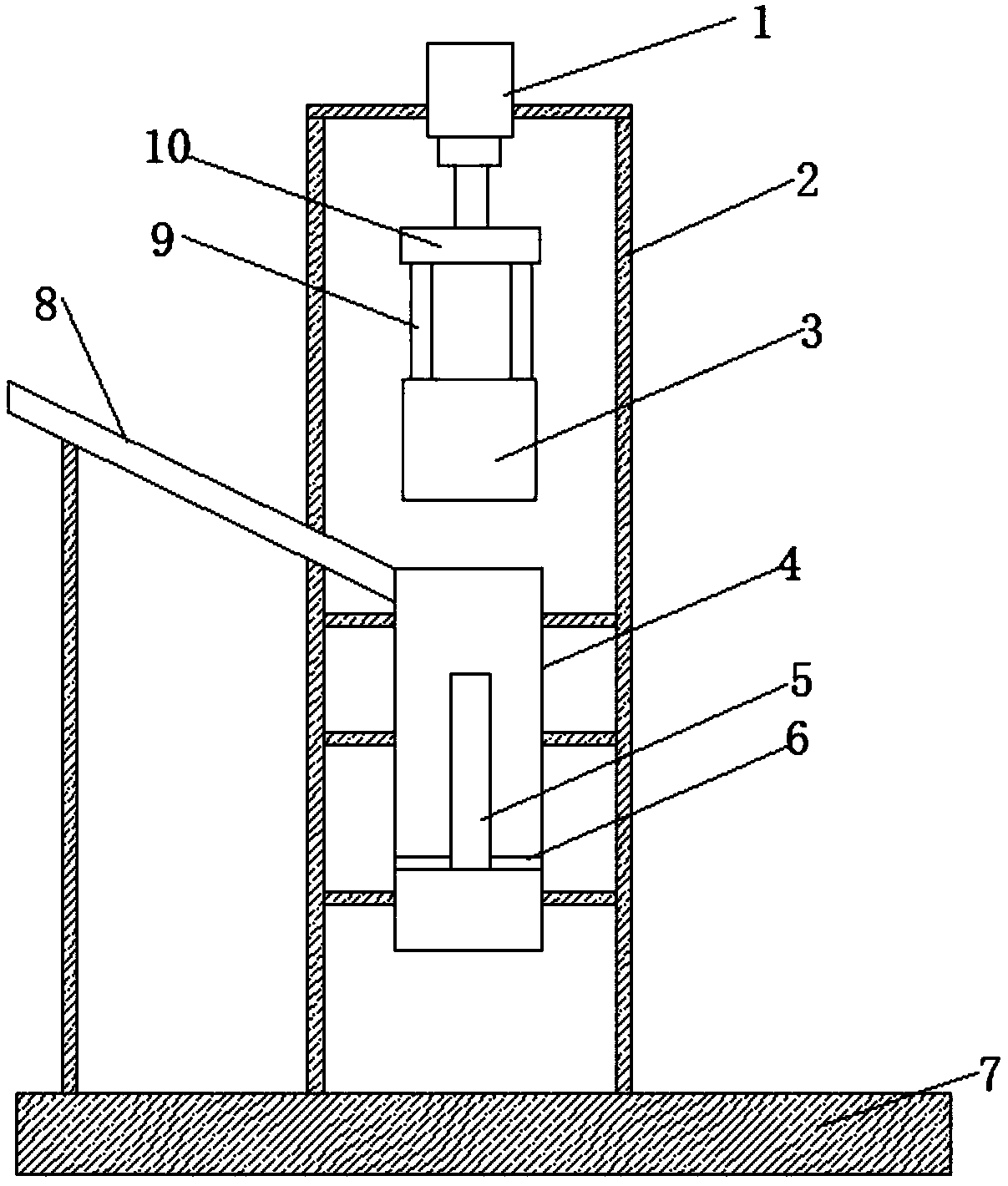

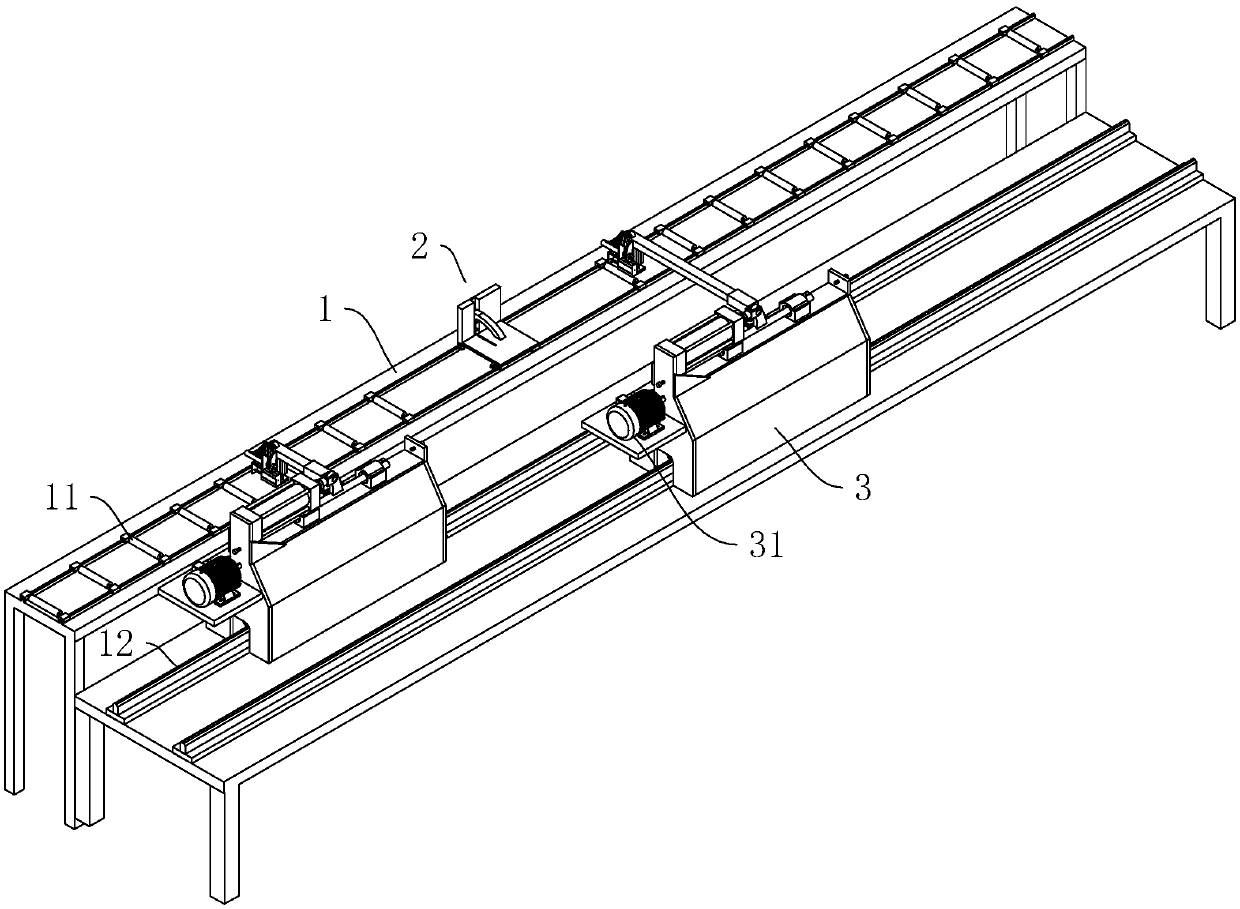

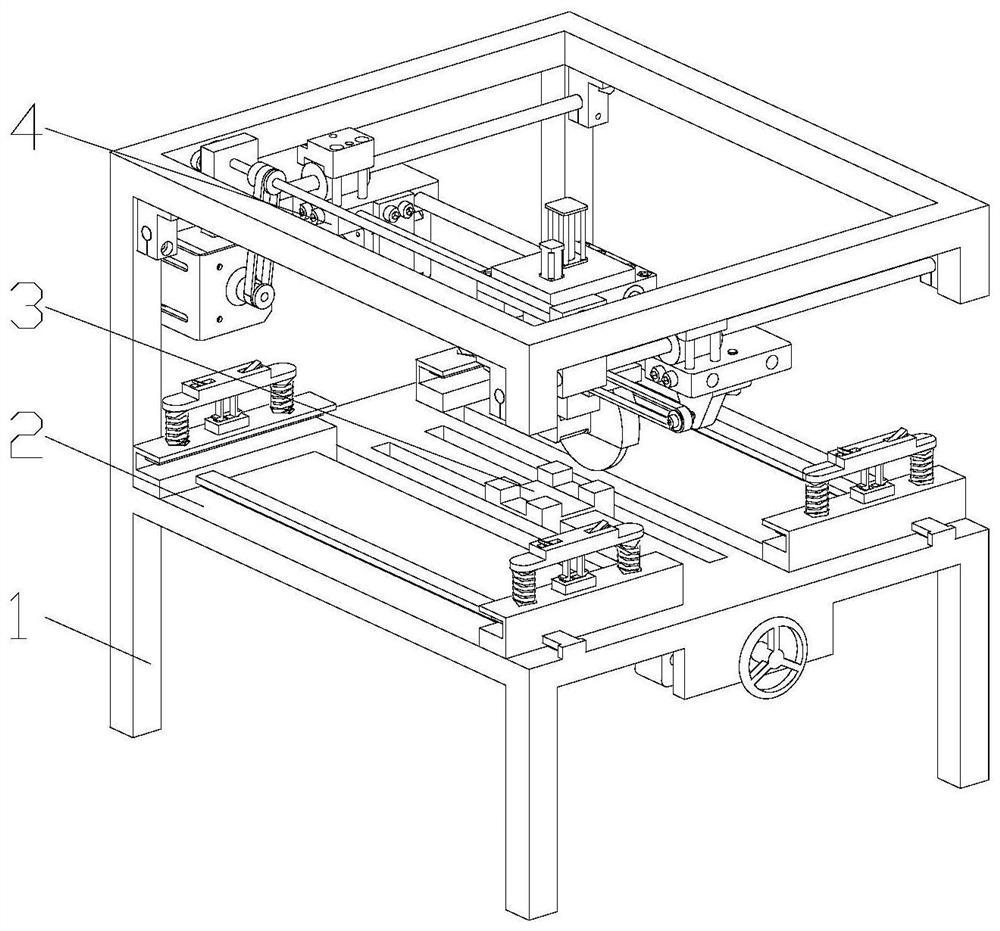

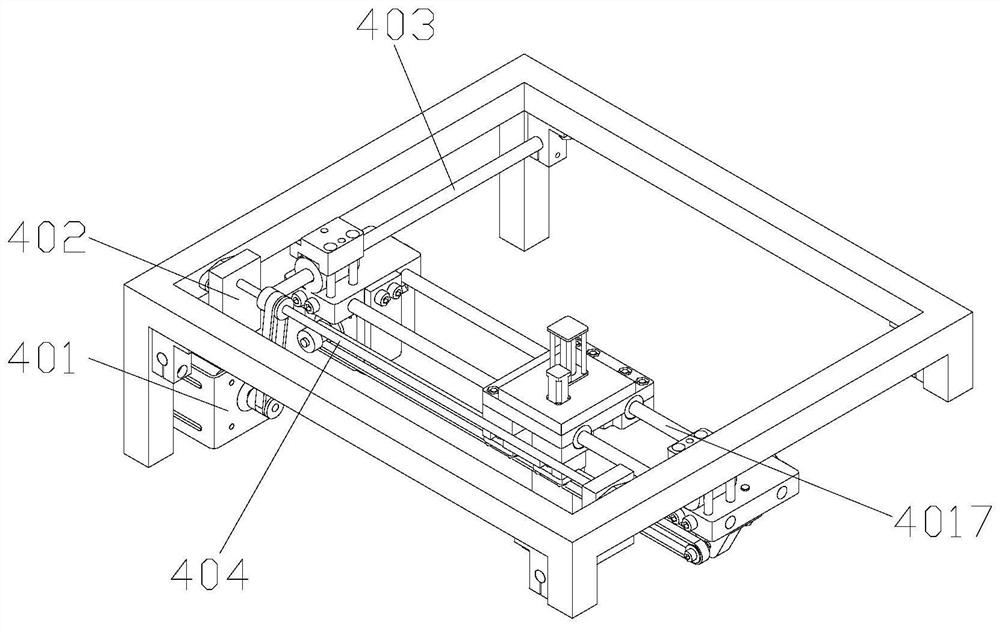

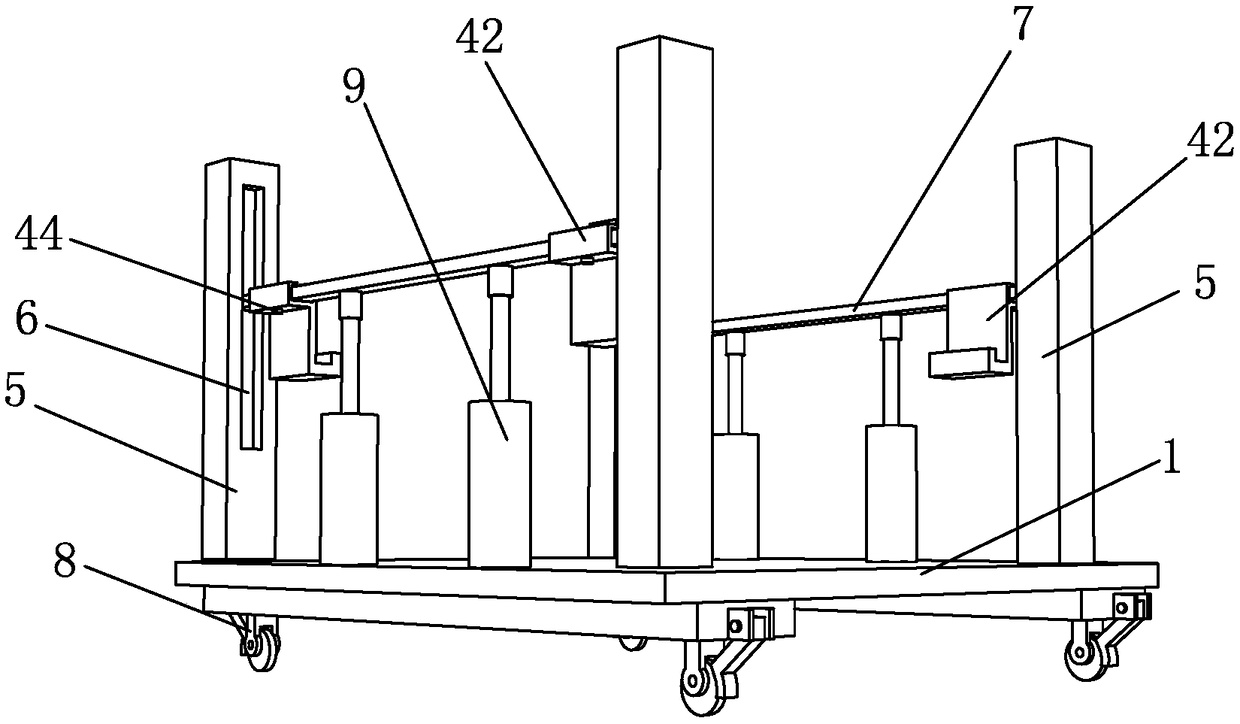

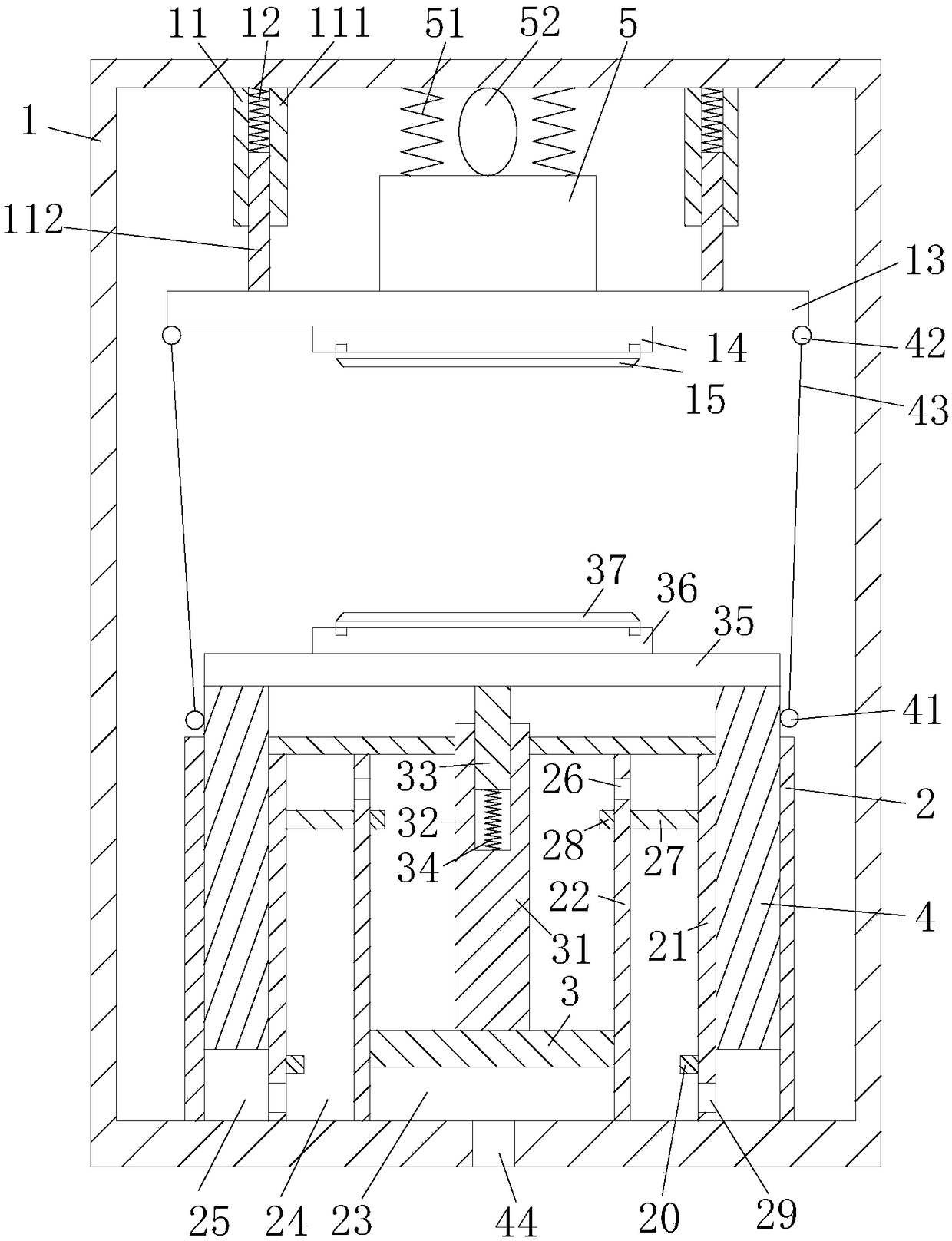

Fixed-length cutting device for stainless steel tube

ActiveCN109719570ACompact and reasonable structure designEasy to useMeasurement/indication equipmentsFeeding apparatusEngineeringLength measurement

The invention discloses a fixed-length cutting device for a stainless steel tube. The fixed-length cutting device for a stainless steel tube comprises a cutting platform and a cutting head group, andfurther comprises a length determining assembly and a clamping assembly; the left side end of the cutting platform is provided with an opening groove, a cutting panel is arranged in the opening groove, and a material collecting box is arranged under the cutting panel; and the length determining assembly comprises a fixed side plate, positioning screws and a positioning pressing plate, the fixed side plate is located over the left end of the opening groove and fixedly connected with the top face of the cutting platform, the positioning screws are symmetrically arranged on the front side and theback side of the fixed side plate, and the two ends of the positioning pressing plates are arranged on the two positioning screws in a sleeving mode separately. According to the fixed-length cuttingdevice for the stainless steel tube, the structure is simple, the practicability is high, operation is easy, use is convenient, not only can the cutting rate and the cutting precision of the stainlesssteel tube be improved, but also the cutting length standard can be guaranteed every time only through one time of cutting length measurement, the manual labor intensity is effectively reduced, the error rate brought by each time of manual measurement is decreased, and resources and the cost are saved.

Owner:ANHUI KINGWE PIPE IND

Highly-effective high accuracy sapphire polishing liquid and preparation method thereof

ActiveCN101230239AEnhanced flattening efficiencyReduce the burden onEdge grinding machinesPolishing compositionsSurface-active agentsSolid content

The invention provides an efficient high-precision sapphire polishing solution and the preparing method, which relates to the polishing technology on sapphire, in particular to the polishing solution technology which can finely polish the surface. Firstly, nano silica sol particles, the particles diameters of which are 15-80 nanometers, are dispersed into water to form suspension; and then complexation agent is added into the suspension; and then surface active agent is added into the suspension; finally, the PH value of the suspension is regulated to 10-11. The invention has simple and rational production process, can be produced simply, contains low solid content, has high polishing efficiency, has strong stability, can hardly deposit on the surface of the polishing machine and the object to be polished, can hardly be air-dried on the surface of the sapphire after polishing due to the unique fluidity, and can lighten the burden of the following cleaning process greatly.

Owner:江苏集萃中以科技产业发展有限公司

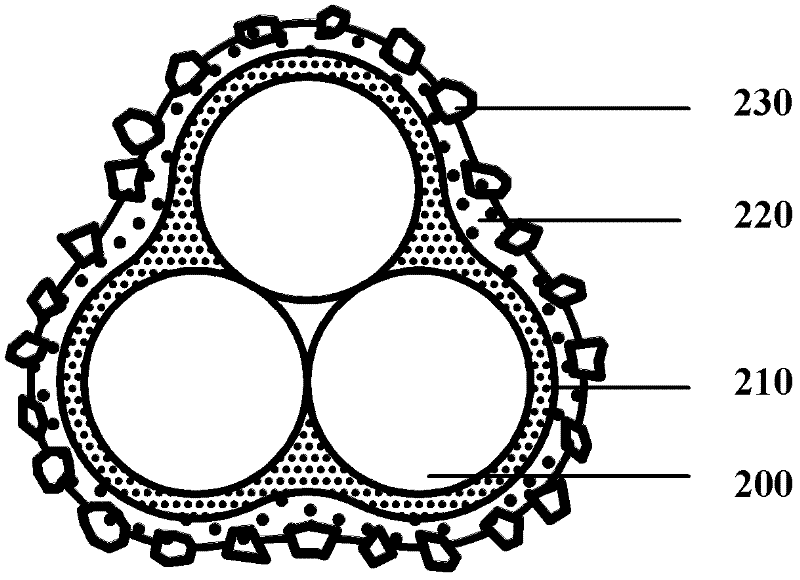

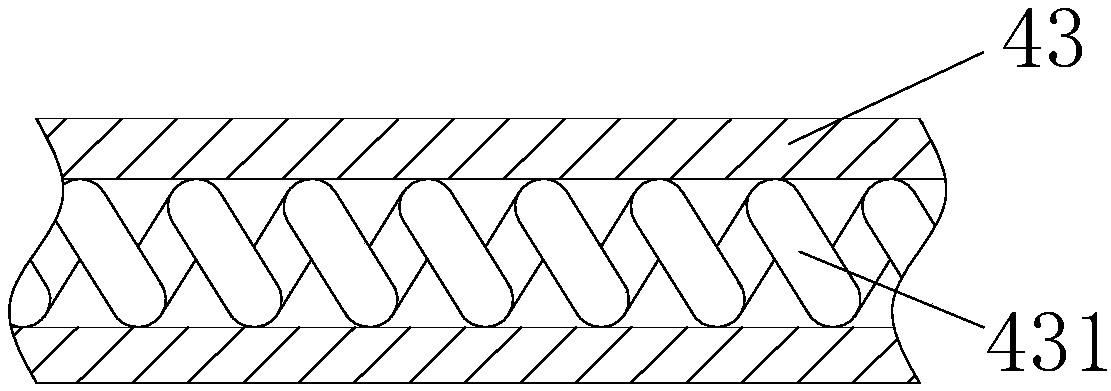

Diamond wire saw with stranded core and manufacturing process thereof

InactiveCN102489781AImprove reliabilityAvoid breakingMetal sawing tool makingMetal sawing toolsDiamond wire sawWire saw

The invention provides a diamond wire saw with a stranded core, which comprises the stranded core, a buffer layer and an abrasive layer, wherein the stranded core is formed of multiple stranded metal wires, and the abrasive layer is provided with diamond abrasive grains. The diamond wire saw with the stranded core has the advantages of high reliability, quick cutting, breakage resistance, long service life, easiness in recovery and the like.

Owner:李园

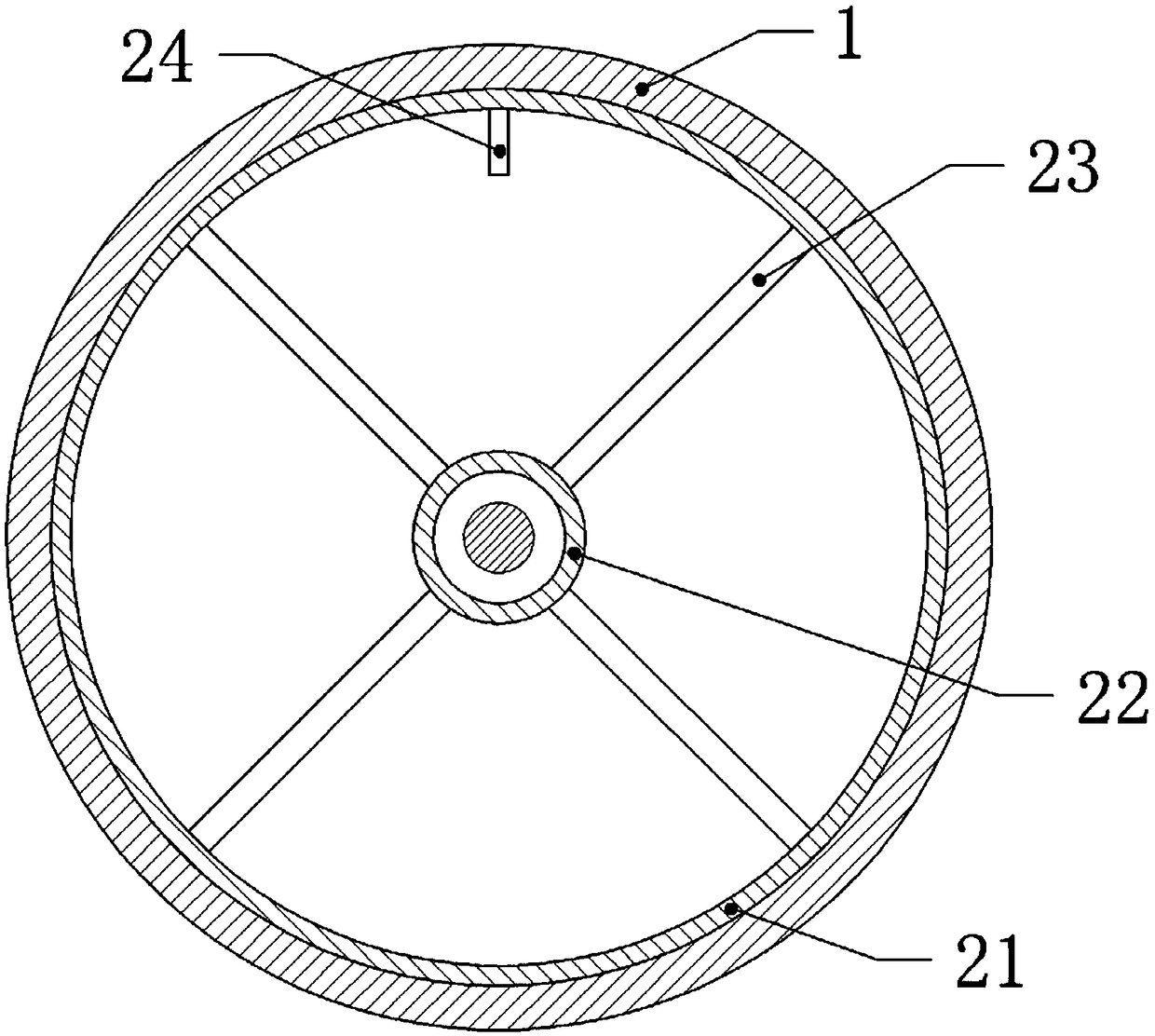

Domestic sewage pipe anti-blocking device

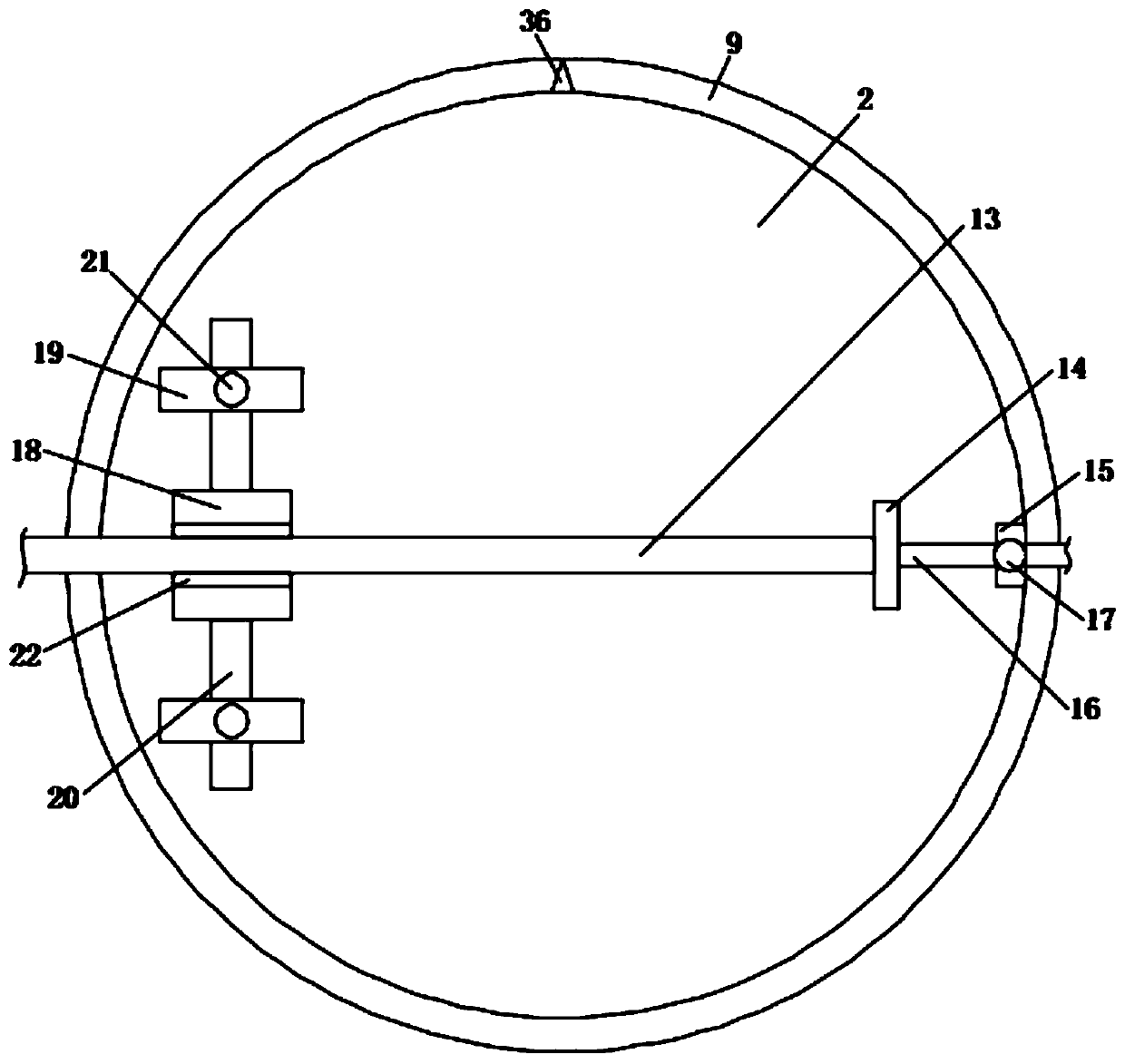

ActiveCN109208736APlay a role in fixing garbageAvoid entanglementSewer cleaningSewer pipelinesImpellerDrive shaft

The invention relates to a piping device, a domestic sewage pipe anti-blocking device include brackets, ring fence, Impeller knives, shafts and motors, a torque limiter is fixedly connected to the center of rotation of the annular fence, a limit bar is arranged on that annular fence, Bracket and fixed connection, shift lever is arranged on that bracket, a tension spring is connected between the bracket and the ring fence. The impeller cutter sleeve is fixedly connected with the transmission shaft, an overrunning clutch is arranged at the end of the transmission shaft along the water flow direction, a driven bevel gear is fixedly connected with the star wheel of the overrunning clutch, a motor is fixedly connected with a pipeline, and a driving bevel gear is fixedly connected with the shaftend of the motor, and the driving bevel gear is meshed with the driven bevel gear. The domestic sewage pipe anti-blocking device with the above structure intercepts the garbage together for centralized treatment, accelerates the flow velocity of the water while cutting the garbage, plays the role of scouring and cleaning the inner wall of the pipe, accelerates the garbage transportation, and prevents the garbage from accumulating again.

Owner:阜阳市世科智能设备有限公司

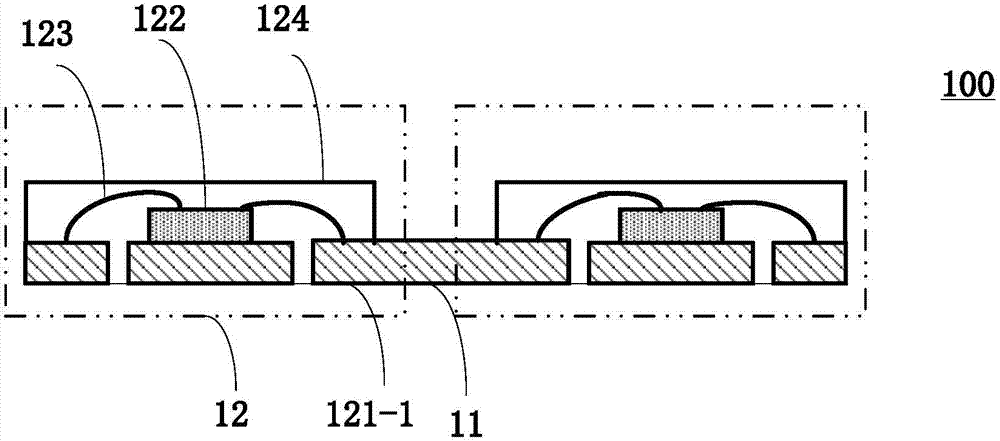

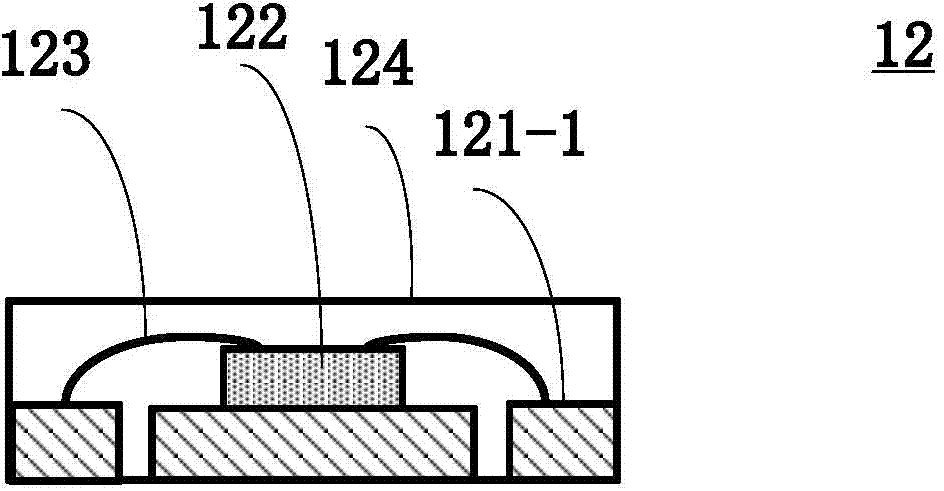

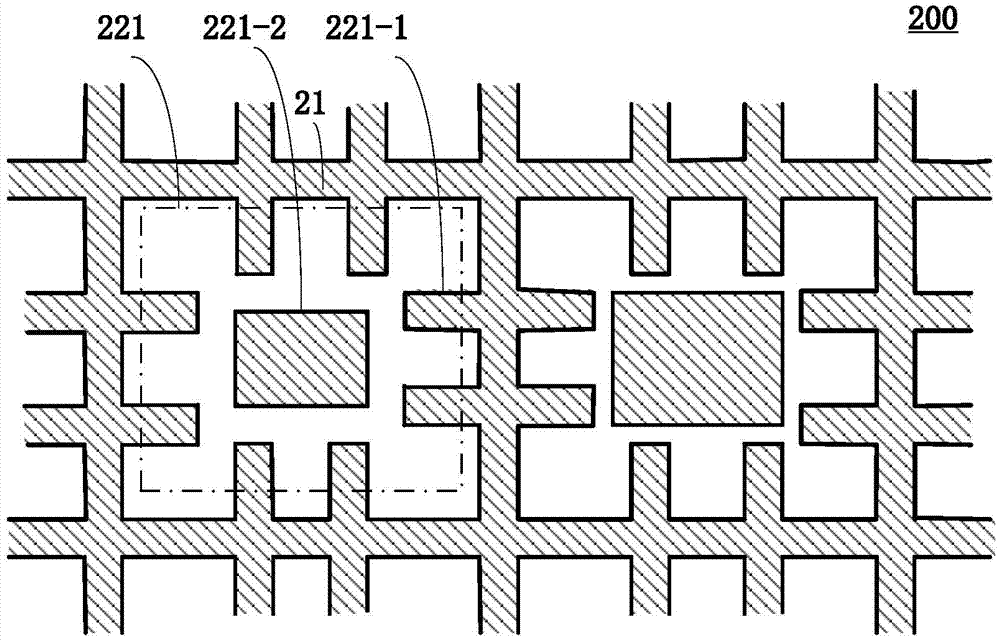

Non-outer-pin packaging structure and manufacturing method and wire frame of non-outer-pin packaging structure

InactiveCN103928353AReduce thicknessReduce frictionSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingMetal

The invention provides a non-outer-pin packaging structure and a manufacturing method and a wire frame of the non-outer-pin packaging structure. The non-outer-pin packaging structure comprises the wire frame, a chip, a plurality of electric connection elements and a plastic packaging body. The wire frame comprises a wire frame unit and a connecting support. The wire frame unit comprises a plurality of pins connected with the connecting support, and the thickness of the ends, away from the wire frame unit, of the pins is smaller than the thickness of the pins. The chip is electrically connected to the pins through the electric connection elements. The plastic packaging body packages the chip and the electric connection elements and encapsulates the pins. The ends, away from the center of the wire frame unit, of the pins can have first parts with the thickness smaller than that of the pins, one side of each first part is a cutting channel, the metal thickness at the cutting positions is reduced, the loss of a cutter can be reduced, the cutting efficiency can be improved, the contact area between the pins and plastic packaging materials is increased, and the packaging reliability of the chip can be improved.

Owner:SILERGY SEMICON TECH (HANGZHOU) CO LTD

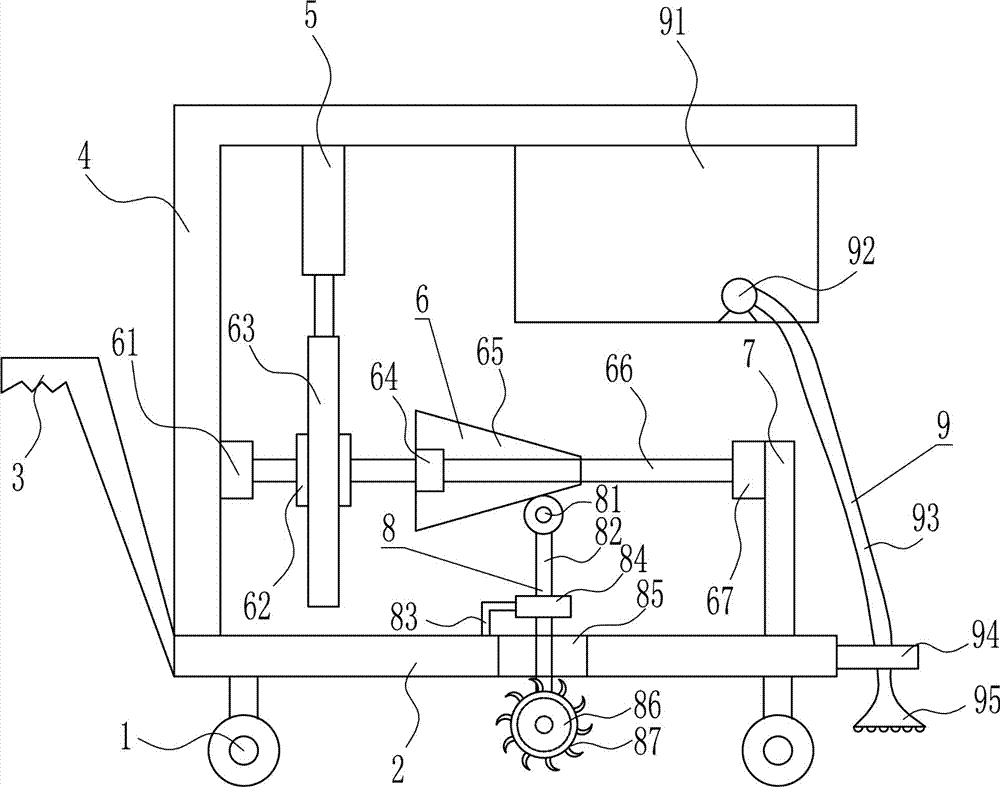

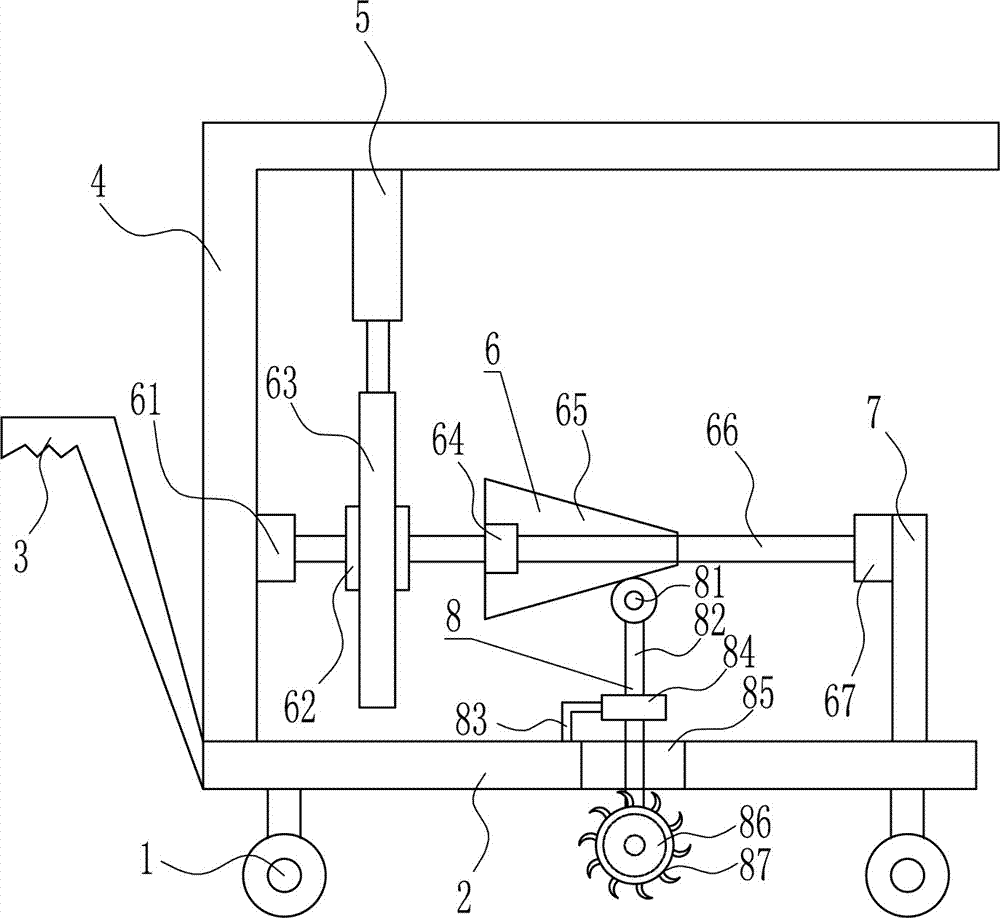

Road cutting device for construction of roads and bridges

The invention discloses a road cutting device for construction of roads and bridges. The road cutting device comprises a first base, a mouth-shaped seat, a sliding block, a spring, a support rod, a guide wheel, a water chamber, a water pump, a water pipe, a spray head, a first air duct, an exhaust fan and the like. The road cutting device disclosed by the invention has the advantages of reasonableand simple structure, low production cost, convenience in mounting, no raising of dust during cutting, high cutting speed, time saving and labor saving; a rotating motor drives a driving wheel to move; the water pump pumps water; dust fall is realized by using the spray head; the exhaust fan extracts dust into the water chamber for adsorbing; a fan motor drives a draft fan; the dust enters from asecond exhaust nozzle and is filtered by a filter screen to remove the dust, so that the dust is effectively controlled and raising of the dust is avoided; a gear adjusts the height of a cutting blade; a connecting spring is arranged so as to improve buffer performance; a driving motor drives the cutting blade to cut; a lifting motor drives a lifting seat to adjust the height; a cutting motor drives a rotary cutting blade to cut; high cutting speed, time saving and labor saving are realized.

Owner:李雨林

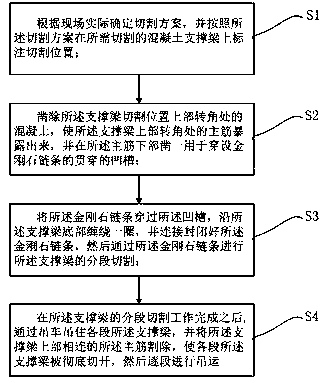

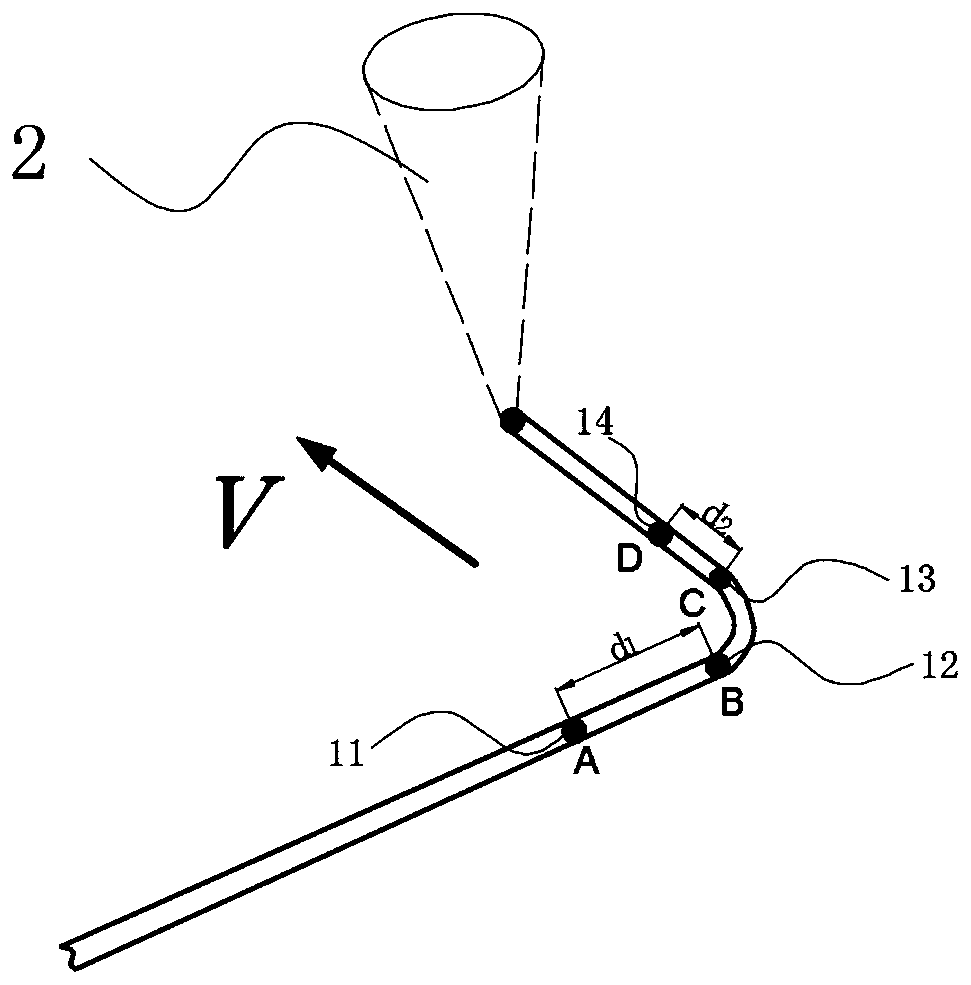

Concrete support beam no-support disassembly method

ActiveCN108612109AReduce construction proceduresReduce construction costsExcavationsStructural engineeringEngineering

The invention provides a concrete support beam no-support disassembly method. The method comprises the following steps: (a) a cutting scheme is actually determined according to the scene; and a cutting position is marked on a concrete support beam needing to be cut according to the cutting scheme; (b) concrete at the upper corner of the cutting position of the support beam is drilled off, so thata main rib at the upper corner of the support beam is exposed; and a through groove for enabling a diamond chain to penetrate through is drilled in the lower part of the main rib; (c) the diamond chain penetrates through the groove to wind the bottom of the support beam by one lap; the closed diamond chain is connected; and then, the segmented cutting is performed on the support beam through the diamond chain; and (d) after the segmented cutting work of the support beam is finished, each section of the support beam is lifted through a crane; and the main rib connected to the upper part of thesupport beam is cut off, so that each section of the support beam is thoroughly cut off, and is lifted for transportation one by one.

Owner:CHINA MCC20 GRP CORP

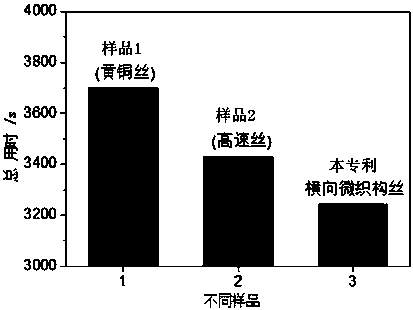

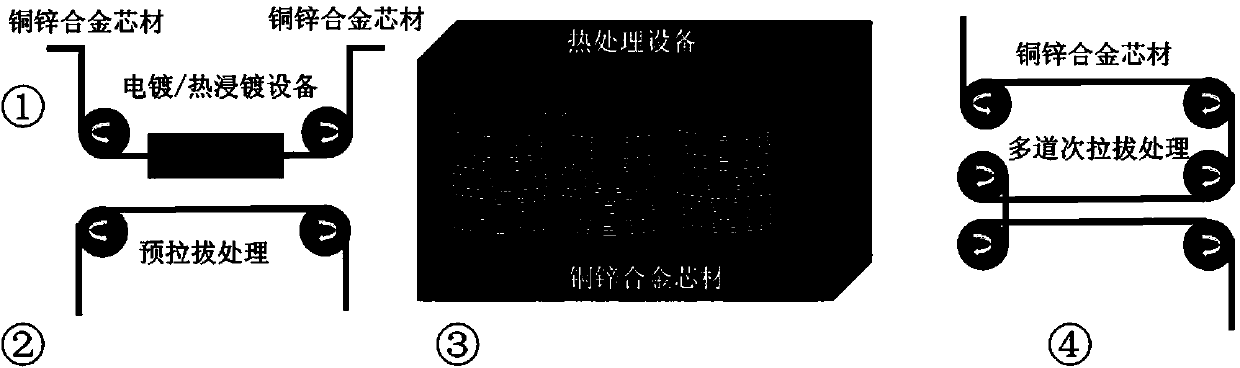

Preparation method of textured plating layer electrode wire

InactiveCN107671379AEasy to useImprove cooling effectHot-dipping/immersion processesElectrical-based machining electrodesZinc alloysStress relief

Owner:NINGBO KANGQIANG MICRO ELECTRONICS TECH CO LTD

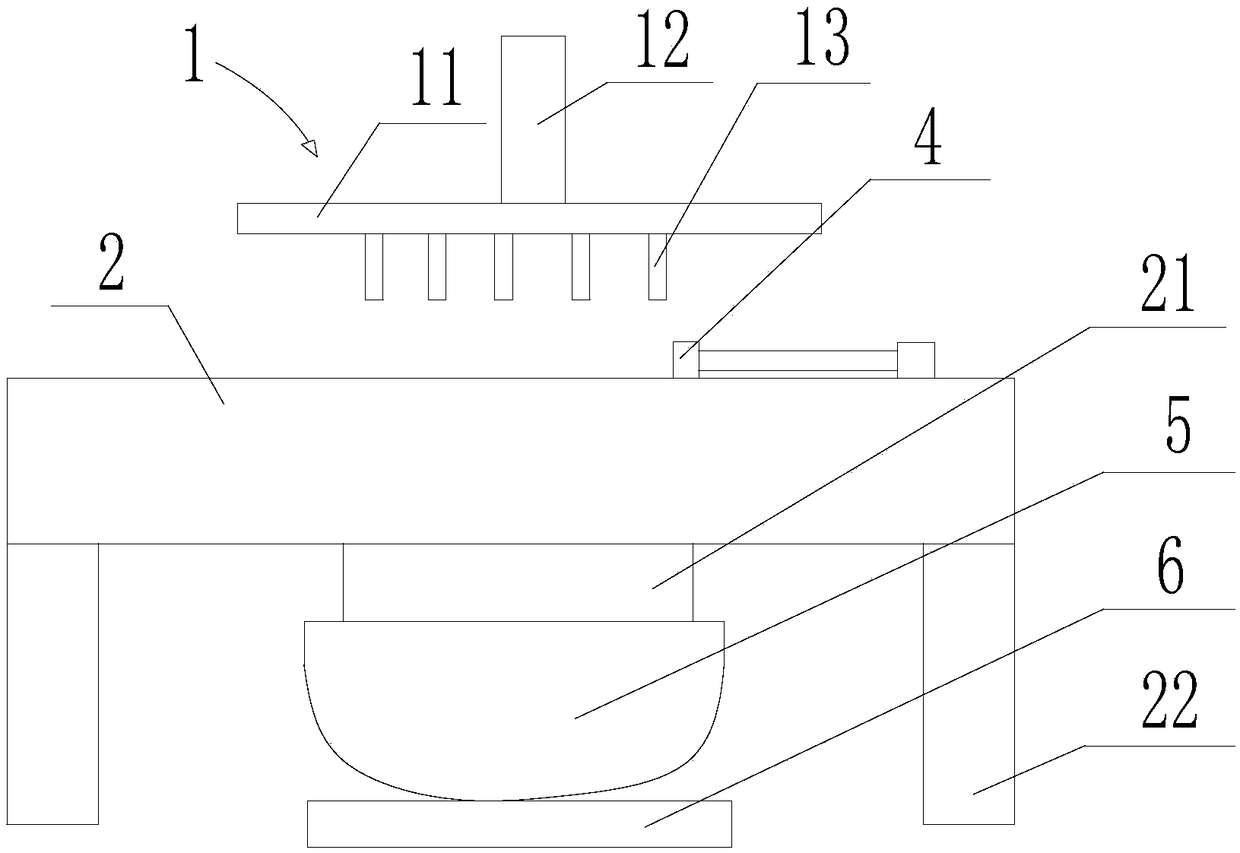

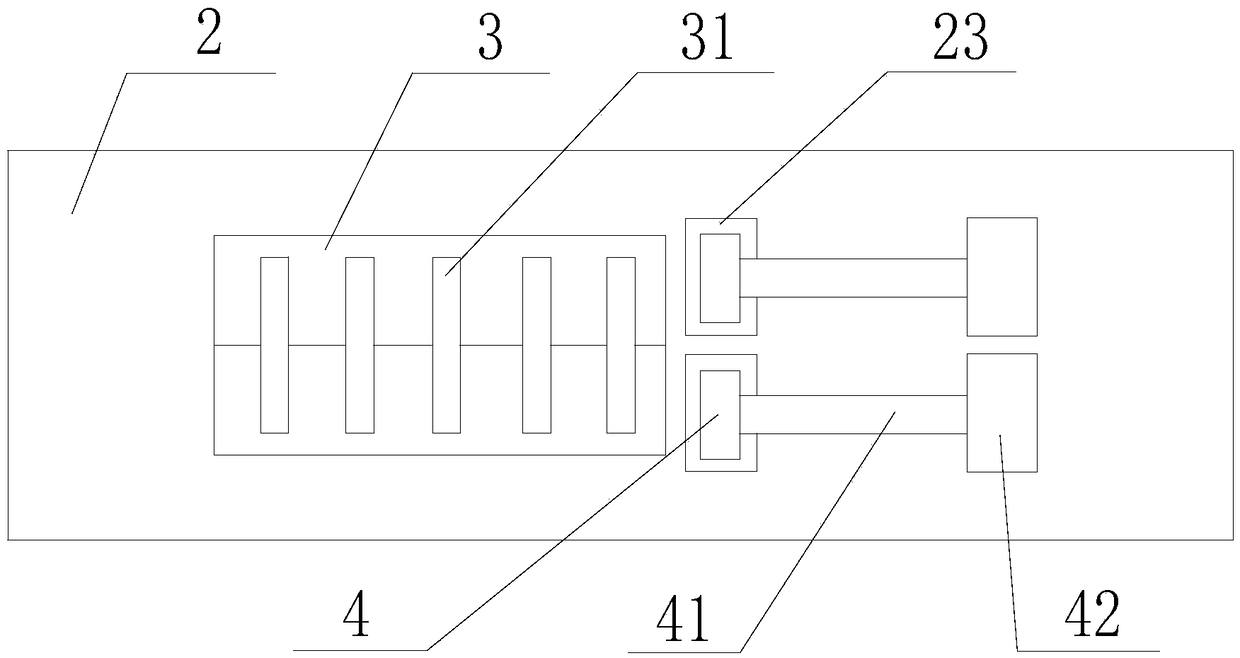

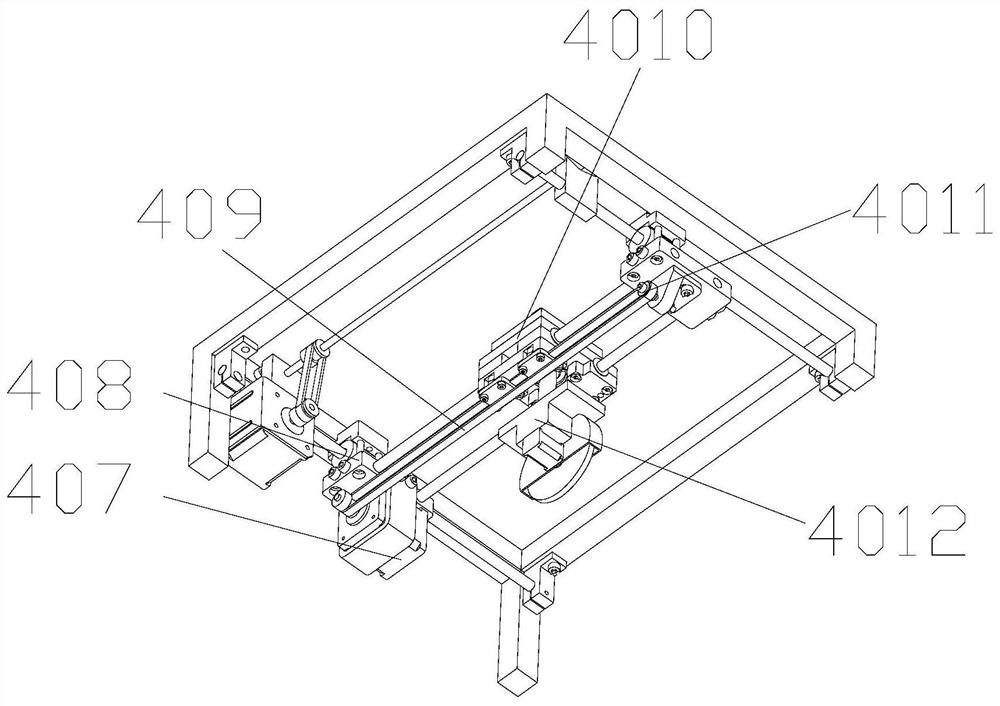

Automatic sheet cutter for producing vacuum laminated glass

InactiveCN106927667AReasonable location designEasy to useGlass severing apparatusEngineeringLaminated glass

The invention discloses an automatic cutting machine for the production of vacuum laminated glass, which comprises a cutting table, a cutting device and a dust collection device. The rear end face of the cutting table is provided with a mounting plate, the left side of the mounting plate is provided with a left positioning plate, the right side of the mounting plate is provided with a right positioning plate, and a first screw rod and a first screw rod are arranged between the left positioning plate and the right positioning plate. The second screw rod, the cutting device includes a first cutting assembly and a second cutting assembly, and the left and right sides of the cutting table are provided with dust suction devices, and the dust suction devices include elastic dust suction pipes and dust suction pumps. The invention is simple in structure, strong in practicability, and automatic in operation. The glass in the placement tank is positioned and clamped by the clamping device, and then the glass is cut simultaneously by the first cutting assembly and the second cutting assembly to increase the cutting rate. , At the same time, the glass shavings generated during cutting are absorbed by the vacuum device, and the overall structure design is more reasonable.

Owner:嵊州市赫利玻璃制品有限公司

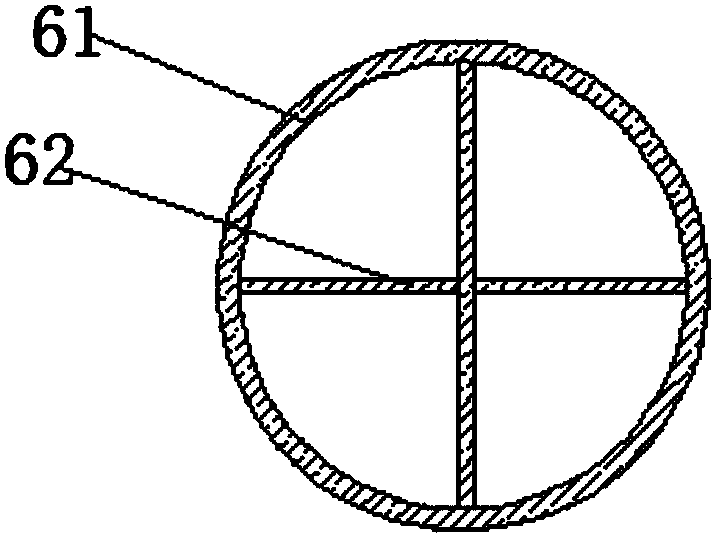

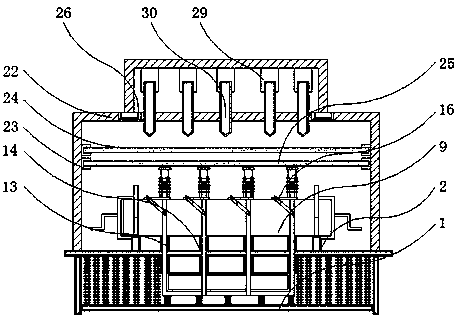

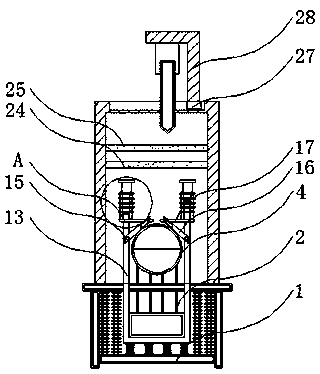

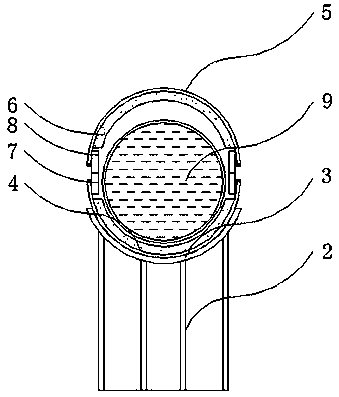

Pipe cutting device for MPP cable protection pipe

InactiveCN112297075AEasy to useImprove practicalityMetal working apparatusEngineeringStructural engineering

The invention discloses a pipe cutting device for an MPP cable protection pipe. The device comprises a protection pipe and a pipe cutting device body matched with the protection pipe, the pipe cuttingdevice body comprises a first machining table and a second machining table which are matched with each other, the protection pipe is placed at the top end of the first machining table and the top endof the second machining table, a positioning groove matched with the protection pipe is formed in the top wall of the first machining table, a containing groove matched with the protection pipe is formed in the top wall of the second machining table, a top plate is jointly and fixedly installed at the top end of the first machining table and the top end of the second machining table, a hydraulicmachine is fixedly installed on the top wall of the top plate, and a piston rod is fixedly installed at the output end of the hydraulic machine. An automatic discharging device is arranged on the second machining table, a telescopic air cylinder drives a push rod to push the cut protection pipe down from the second machining table through the containing groove, cut pipes do not need to be collected manually, the labor intensity of workers is low, and the using effect is good.

Owner:张浩强

Pavement cutting apparatus used for road and bridge construction

The invention relates to a pavement cutting apparatus, and especially relates to a pavement cutting apparatus used for road and bridge construction. A technical problem to be solved in the present invention is to provide the pavement cutting apparatus used for road and bridge construction, having the advantages of no dust flying during cutting, high cutting rate, and time and labor saving. The pavement cutting apparatus used for road and bridge construction comprises universal wheels, a baseboard, a pusher, a left support, a cylinder and a driving device; and the bottom of the baseboard is provided with the universal wheels, the pusher is arranged at the left end of the baseboard, the left support is arranged at the left side of the top of the baseboard, the cylinder is arranged at the left side of the top in the left support, the driving mechanism is arranged at the middle portion of the right side of the left support, a right support is arranged at the right side of the top of the baseboard, and a cutting device is arranged at the middle portion of the baseboard. The pavement cutting apparatus used for road and bridge construction has the advantages of no dust flying during cutting, high cutting rate, and time and labor saving.

Owner:李建云

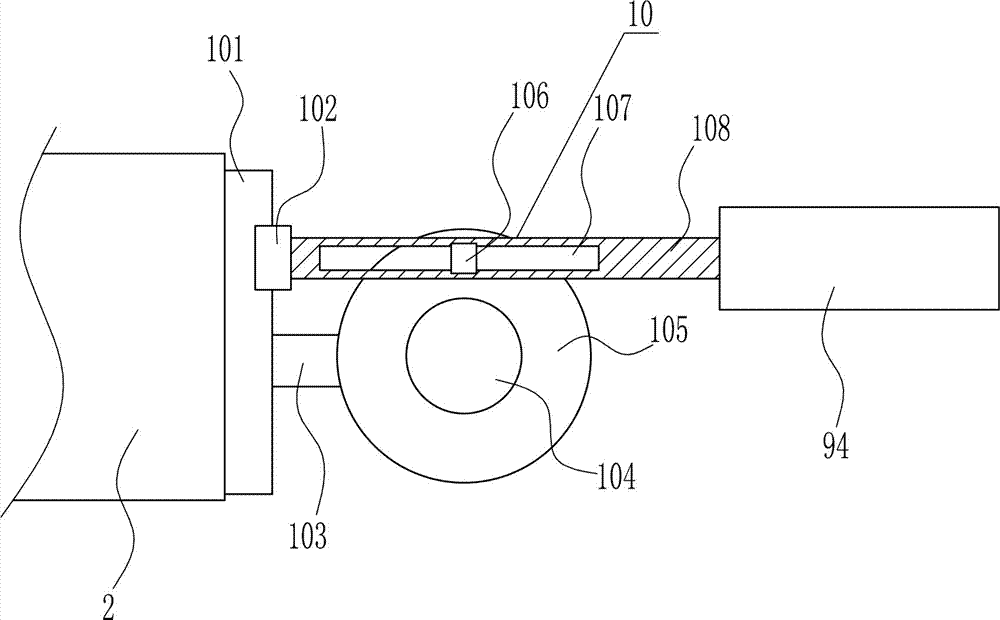

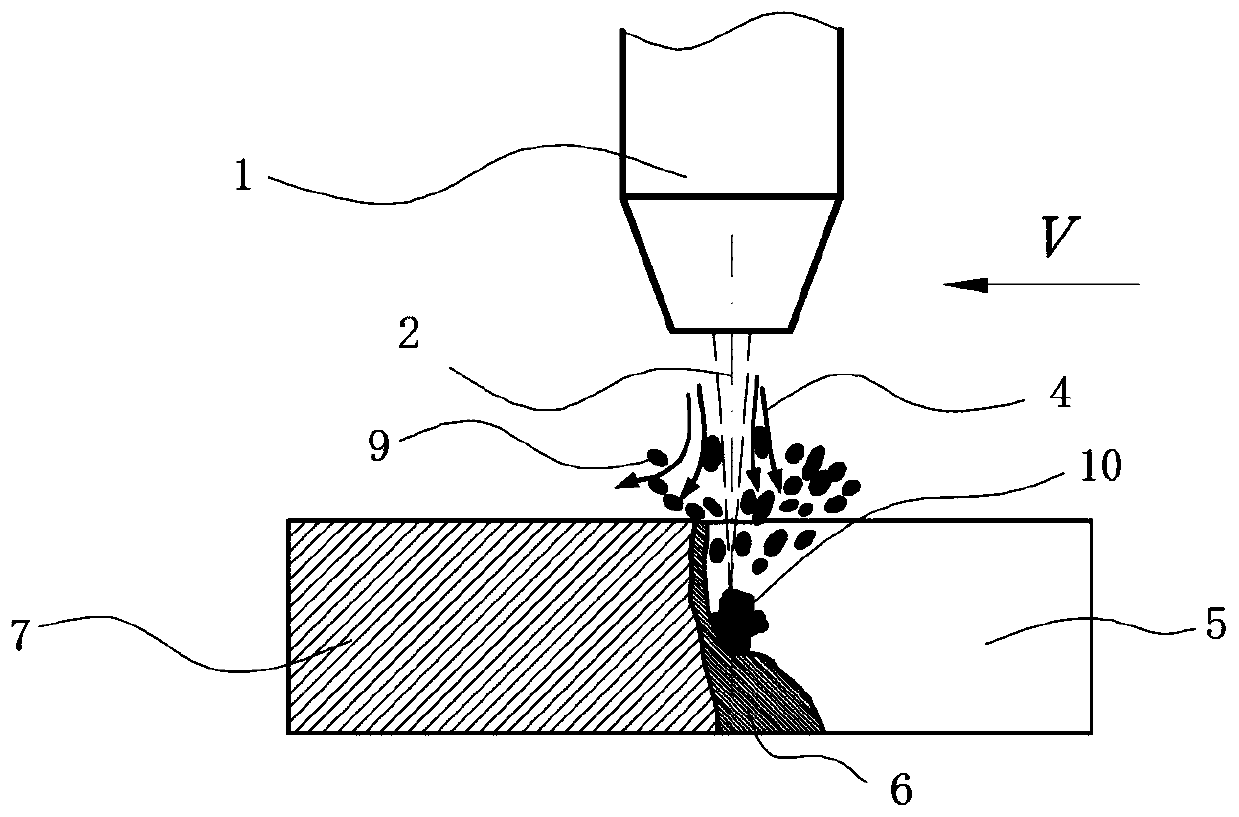

Beam splitting laser cutting method for silicon-based wafer

ActiveCN109352184AReduced Risk of FragmentationReduce heat damageLaser beam welding apparatusGratingBeam splitting

The invention discloses a beam splitting laser cutting method for a silicon-based wafer. The beam splitting laser cutting method for the silicon-based wafer is used for cutting the silicon-based waferinto independent chips, and is characterized by comprising the following steps of a pretreatment step; a diffraction light splitting step, wherein a single beam laser (105) is split into a pluralityof beams of laser (108) through a grating device (106) and a light beam pattern is formed; a beam splitting cutting step, wherein a laser cutter of the style is used for cutting the silicon-based wafer; and a postprocessing step. The beam splitting laser cutting method for the silicon-based wafer achieves the technical effects that the wafer cutting speed is increased, and meanwhile the cutting quality of the wafer is improved.

Owner:SHENZHEN STS MICROELECTRONICS

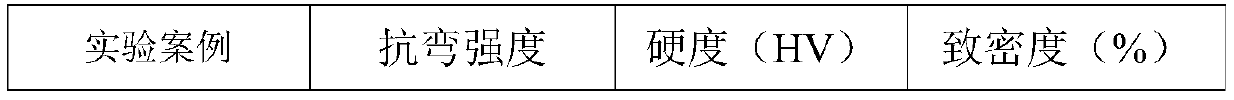

High-performance metal ceramic cutting tool and preparation method thereof

InactiveCN110004345AImprove toughnessHigh hardnessTransportation and packagingMetal-working apparatusAlcoholPolyvinyl alcohol

The invention relates to a high-performance metal ceramic cutting tool and a preparation method thereof. The high-performance metal ceramic cutting tool is prepared from the following components in parts by mass: 55 to 65 percent of TiC0.5N0.5, 5 to 15 percent of WC, 6 to 9 percent of Ni, 5 to 8 percent of Co, 10 to 14 percent of Mo2C, and 3 to 6 percent of NbC, wherein the particle size of the TiC0.5N0.5 is 100 to 150nm, and the C-N ratio is 0.5. The method comprises the following steps of S1, putting the materials in a nylon ball-milling tank, adding ethyl alcohol, and adopting a sintered carbide ball for carrying out planetary ball milling; S2, drying a slurry mixed in the S1 in a drying box, adding a polyvinyl alcohol solution for pelletizing after drying, and then putting in a mold for pressing; and S3, degreasing a material obtained in the S2 in a vacuum furnace, wherein the sintering temperature is 1480 to 1500 DEG C, and the heat preservation time is 1.5 to 3h. The metal ceramic cutting tool provided by the invention has good toughness and hardness, and in the cutting process, the metal ceramic cutting tool not only has high wear resistance but also can bear a larger impactat the same time.

Owner:GUANGDONG UNIV OF TECH

Power tube cutting device for power construction

ActiveCN112476014AGuaranteed smoothQuality assuranceMetal working apparatusPositioning apparatusStructural engineeringMechanical engineering

The invention discloses a power tube cutting device for power construction. The power tube cutting device comprises a bottom plate, wherein a conveying mechanism, a cutting mechanism, a limiting mechanism and an adjusting mechanism are mounted on the bottom plate; the conveying mechanism is mounted at one end of the bottom plate; the cutting mechanism is mounted on the bottom plate and on one sideof the conveying mechanism; a fixing mechanism is mounted on the cutting mechanism; the adjusting mechanism is mounted at the other end of the bottom plate and matched with the limiting mechanism; and the limiting mechanism is mounted on the bottom plate and between the adjusting mechanism and the cutting mechanism and matched with the cutting mechanism. The power tube cutting device can guarantee the flatness of a notch of a power tube and the quality of the power tube, can guarantee the cutting of the power tube with the same length, can adjust the length of the power tube as required, guarantees the cutting quality of the power tube, guarantees the normal use of the power tube, reduces the production cost and improves the working efficiency.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO TAOXIAN POWER SUPPLY CO

Stainless steel tube cutting machine with wide application range

PendingCN111375821AConvenient angleEasy to processTube shearing machinesShearing machine accessoriesMachiningMaterials science

The invention discloses a stainless steel tube cutting machine with a wide application range. The stainless steel tube cutting machine comprises a base, a machining table is rotatably mounted on the top wall of the base, a rotating groove mutually matched with the machining table is formed in the top wall of the base, an annular baffle mutually matched with the rotating groove is fixedly mounted on the outer side wall of the top end of the machining table, the annular baffle is located on the upper side of the rotating groove, the bottom end of the annular baffle is in mutual contact with thetop wall of the base, a connecting device is arranged between the machining table and the base, steel tubes are jointly placed on the top walls of the machining table and the annular baffle, and a positioning plate mutually matched with the steel tubes is movably mounted on the top wall of the machining table. According to the stainless steel tube cutting machine with the wide application range, multi-angle surface cutting and groove machining can be conveniently carried out on the steel tubes, a cutting knife cannot shift relative to the steel tubes during cutting, the phenomenon of internalsinking and folding cannot happen to cutting positions of the steel tubes, the application range is wide, the cutting quality of the steel tube cutting machine is improved, and the practical effect isgood.

Owner:吴磊

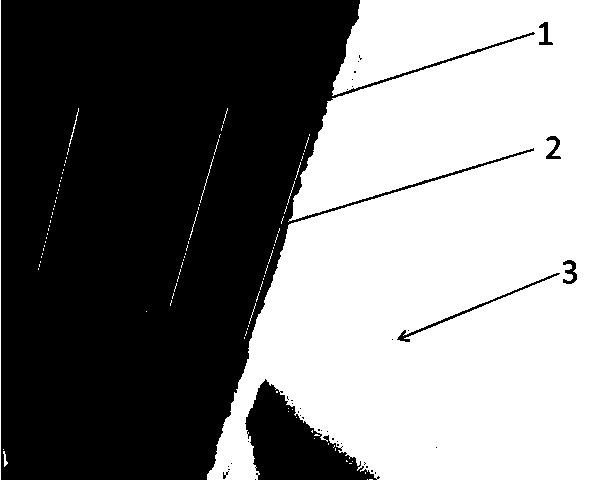

Preparation method for diamond particles deposited with WC/W (wolfram carbide/wolfram) composite coating on surfaces

InactiveCN103352200ASimple manufacturing processImprove mechanical propertiesVacuum evaporation coatingSputtering coatingCemented carbideDeposition process

The invention discloses a preparation method for diamond particles deposited with a WC / W (wolfram carbide / wolfram) composite coating on the surfaces. According to the preparation method, the WC / W nano-composite coating is synthesised on the surfaces of the diamond particles by realizing a primary treatment via a dual-cathode plasma sputtering deposition method, and WC in the coating is formed via an interface in-situ reaction between W and the surfaces of the diamond particles during a dual-cathode plasma sputtering deposition process. According to the preparation method disclosed by the invention, the bonding strength and a holding force between the diamond particles and a metal binder, and the compressive strength of the diamond particles are obviously improved. In addition, the WC / W nano-composite coating deposited on the surfaces of the diamond particles has a protective effect on the diamond particles, thus preventing diamond from being oxidized and graphitized during high-temperature sintering and high-temperature grinding processes. The WC / W nano-composite coating in the preparation method disclosed by the invention is mainly suitable for manufacturing a diamond tool by taking a W-Co hard alloy as a matrix, and the diamond tool obtains a high exposure, thus improving the grinding sharpness and the machining efficiency of a grinding tool, and obviously prolonging the service life of the grinding tool.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +2

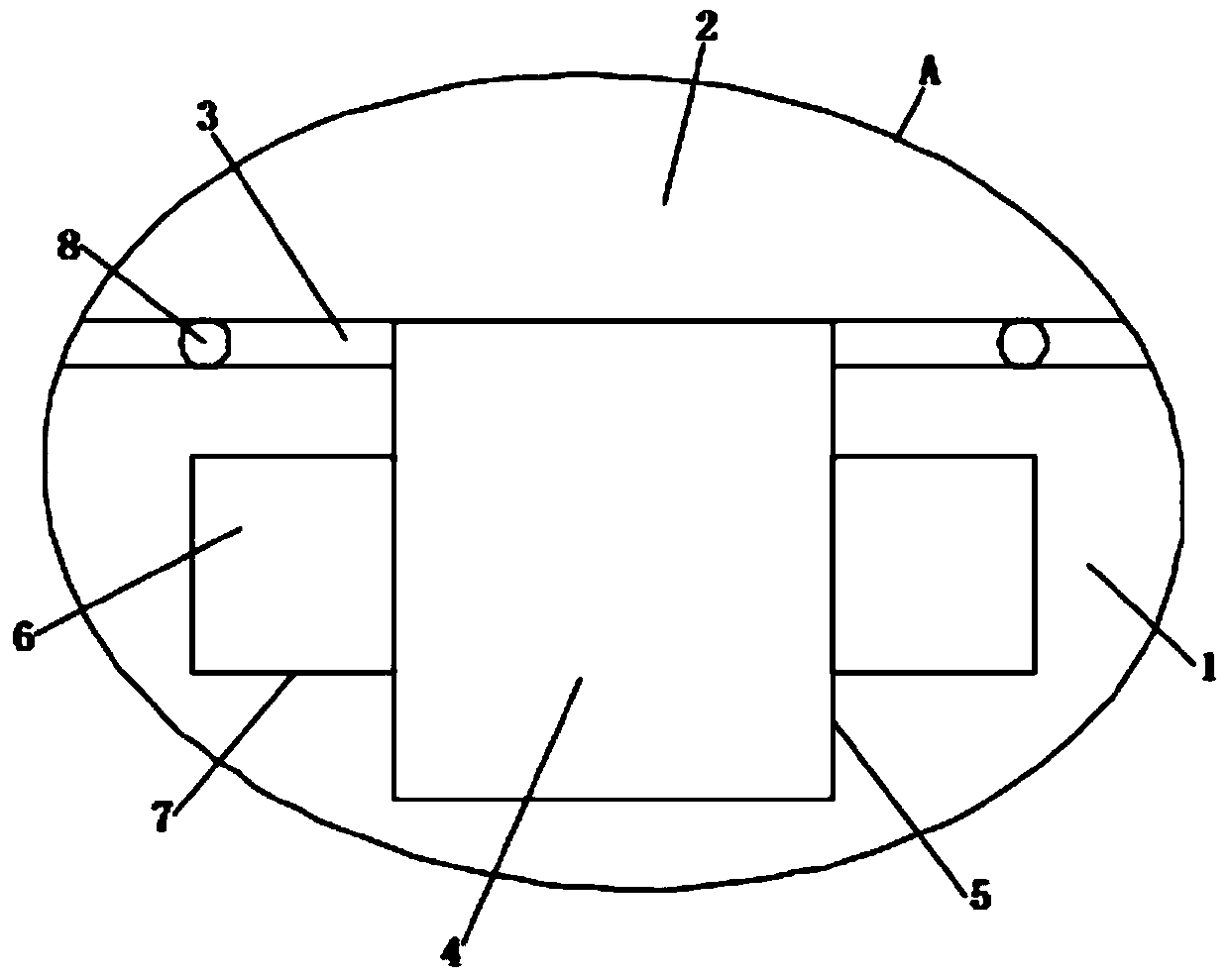

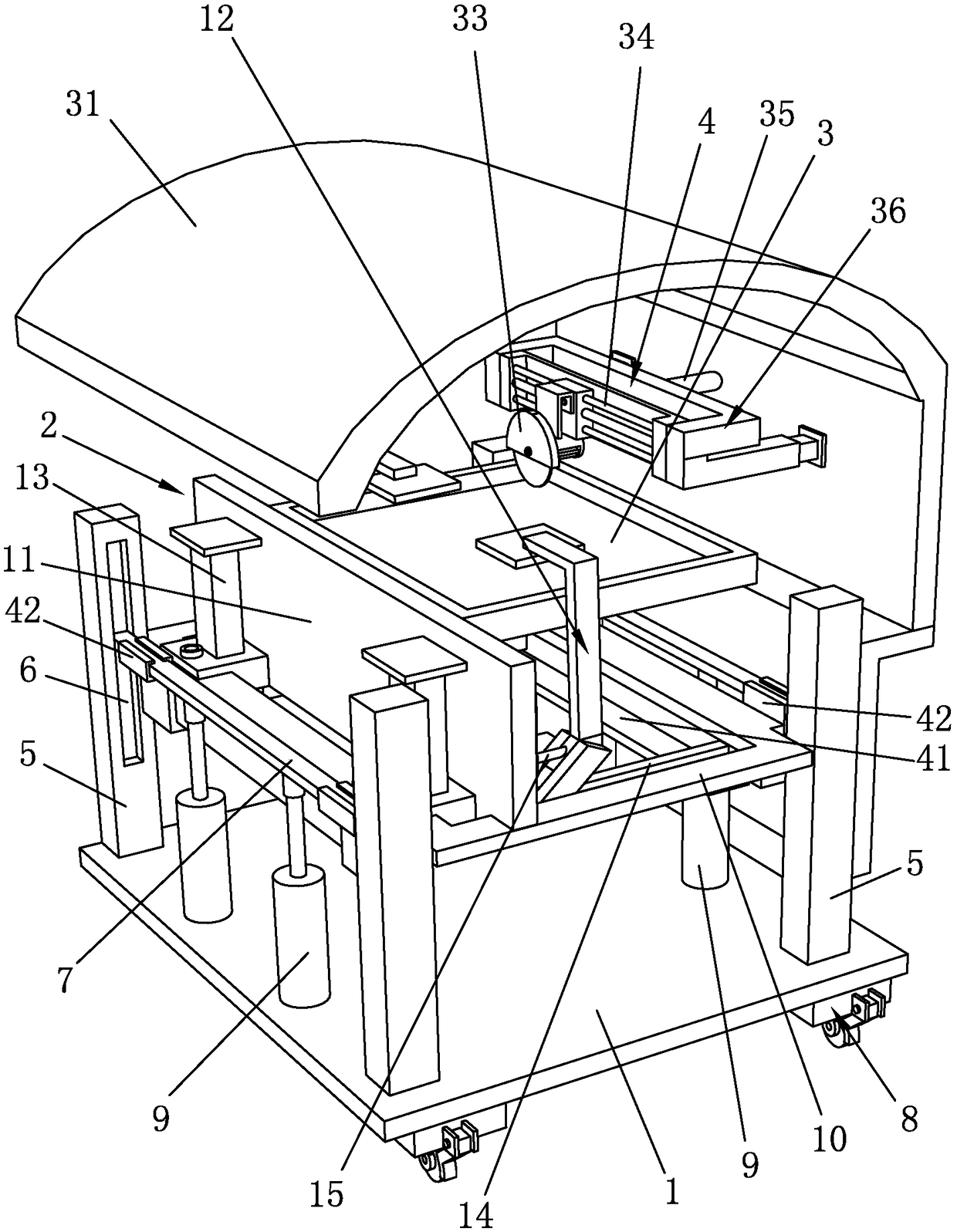

Full-automatic vegetable chopping equipment

InactiveCN111958646ARealize moving up and downSimple structureCleaningMetal working apparatusAgricultural engineeringEngineering

The invention discloses full-automatic vegetable chopping equipment. The full-automatic vegetable chopping equipment comprises a rack. A knife holder capable of moving up and down is arranged inside the rack. A blade is detachably connected with the knife holder. The knife holder is driven by a driving device. A right conveyor belt and a left conveyor belt which are mounted on the rack are arranged on the two sides of the knife holder correspondingly. A vegetable hopper mounted on the rack is mounted above one end of the right conveyor belt. A detachable vegetable basket is arranged below theend, far away from the knife holder, of the left conveyor belt. A sterilization component is arranged above the left conveyor belt. The full-automatic vegetable chopping equipment is simple in structure. Vegetables are fed onto the right conveyor belt from the vegetable hopper and move along with the right conveyor belt. A driving motor drives an elliptical wheel to rotate. The knife holder and the blade can move up and down through the elliptical wheel under the action of springs. The full-automatic vegetable chopping equipment implements cutting through a double-faced knife edge and doublesthe cutting rate. The cut vegetables move along with the left conveyor belt and fall into the vegetable basket to complete the process of feeding, cutting and collecting the vegetables in sequence. The full-automatic vegetable chopping equipment achieves the automatic cutting effect and greatly improves the cooking efficiency.

Owner:合肥人和节能环保设备制造有限公司

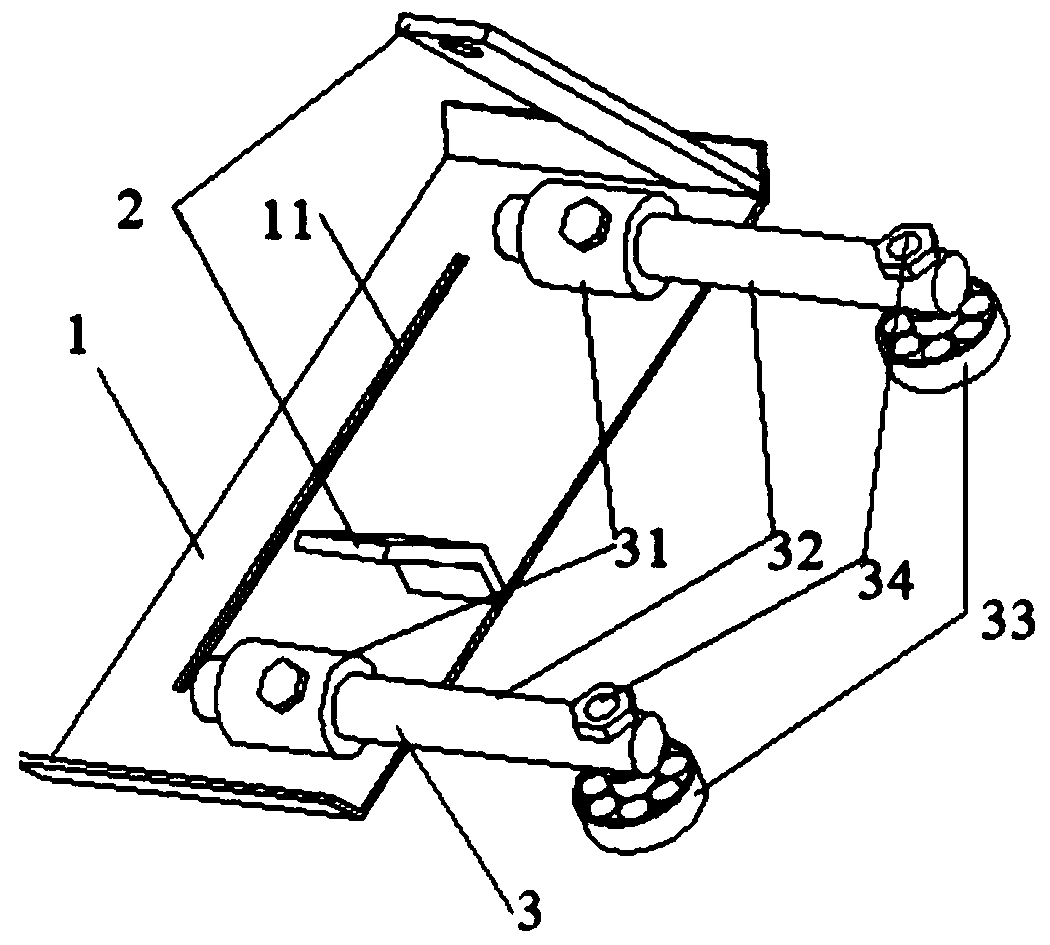

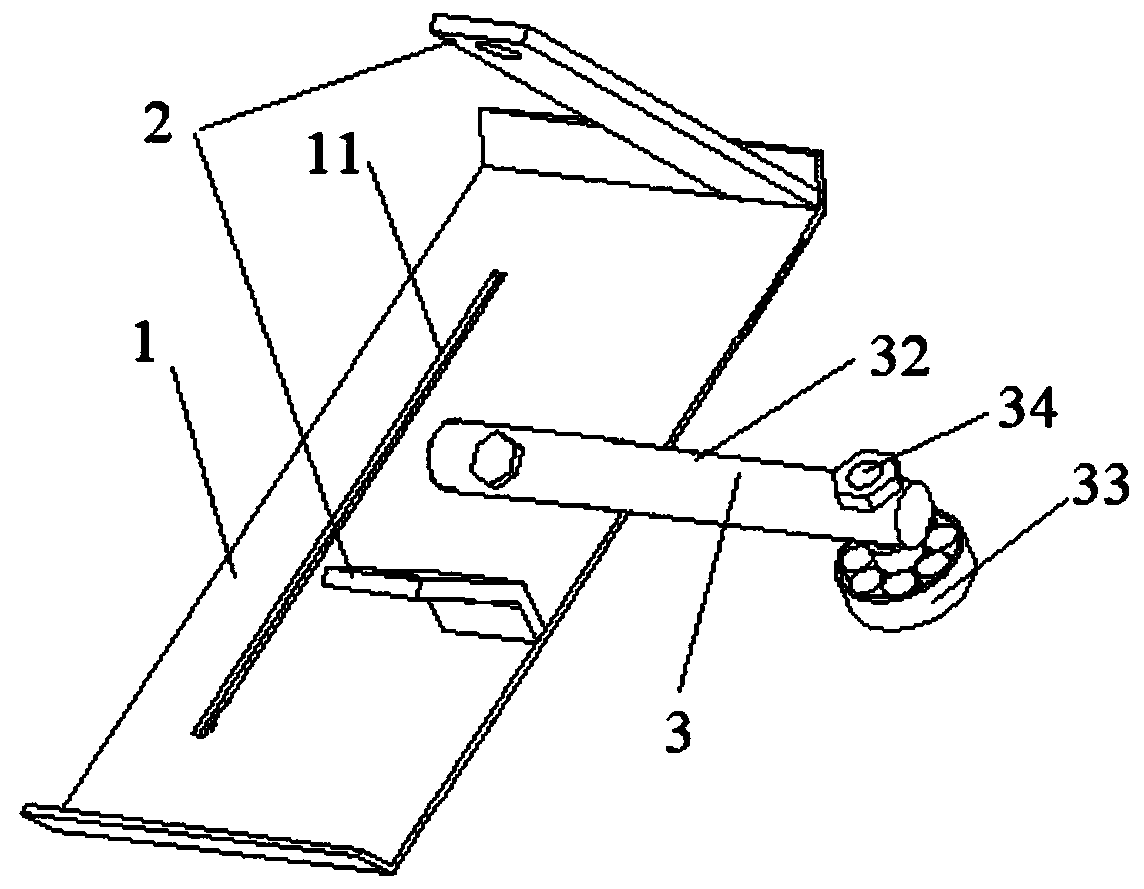

Angle grinder positioning tool

ActiveCN110394721AReduce intensitySolve the problem of overworkPortable grinding machinesGrinding/polishing safety devicesAngle grinderEngineering

The invention provides an angle grinder positioning tool. The tool comprises a guide plate, mounting supports fixedly connected with the guide plate, and positioning devices fixed to the guide plate.The positioning devices comprise positioning rods connected with the guide plate and positioning rollers connected with the positioning rods. During use, an angle grinder is fixed to the positioning tool, the guide plate of the positioning tool makes contact with the product surface, the positioning rollers are attached to the outer edge of the product, and through adjusting the connecting position of the positioning rods and the guide plate or the connecting position of the positioning rods and the positioning rollers, the cutting size is adjusted. Through the angle grinder positioning tool,labor intensity of a worker is reduced, cutting efficiency is improved, and the product cutting quality is ensured.

Owner:双一科技盐城有限公司

Medicinal material slicing machine based on improving slicing efficiency

InactiveCN108858312AIncrease cutting rateImprove cutting efficiencyMetal working apparatusEngineeringMechanical engineering

The invention discloses a medicinal material slicing machine based on improving the slicing efficiency, which comprises a cutting mechanism and a cutting table, wherein supporting legs are arranged atthe bottom of the cutting table; a first through groove is arranged on the cutting table; two support plates are rotatably arranged at the bottom of the first through groove; the support plates are controlled by a stepping motor for rotation of 90 degrees to achieve horizontal or vertical placement, the two support plates just enclose the first through groove, a plurality of notches are arrangedon the support plates, and when the two support plates are horizontally placed, the notches arranged on the two support plates are communicated with each other, at least one clamping element matched with the support plates is arranged on the cutting table, the cutting mechanism is arranged above the support plates; the cutting mechanism comprises a telescopic rod; the lower end of the telescopic rod is provided with a horizontal plate; a plurality of cutting sheets are arranged at the lower end of the horizontal plate; the cutting sheets can pass through the notches; a material guide cylinderis arranged below the first through groove on the cutting table, and a storage bag is connected with the material guide cylinder. According to the invention, the problem of low efficiency caused by prior single sheet cutting and manual packaging is solved.

Owner:绵阳晶凯圣生物科技有限公司

Cutting device for fruit processing

InactiveCN108145765AIncrease cutting rateSimple structureFruit stoningMetal working apparatusEngineeringFlange

The invention discloses a cutting device for fruit processing. The cutting device comprises a supporting base, wherein a steel pipe, a driving device and a fruit conveying slide are fixed on the upperpart of the supporting base through a support; an output shaft of the driving device is connected to a fixing plate through a flange plate, connecting rods are welded to the side, away from the output shaft of the driving device, of the fixing plate, the ends, away from the fixing plate, of the connecting rods are weld to the side wall of one end of a pressing column, and the pressing column is located right above the steel pipe; an inner cavity of the steel pipe is fixedly provided with a core removing pipe through a fruit cutting device body, and the edge of a feeding end of the steel pipeis welded to a discharging end of the fruit conveying slide; and the fruit cutting device body comprises blades and a fixing ring, and two ends of the blades are welded to the side wall of the inner side of the fixing ring. According to the cutting device for fruit processing, the cutting speed is high, core removal and dicing are integrated, and fruits can be rapidly and massively cut; and the cutting device has the advantages of being simple in structure, low in manufacturing cost and easy to popularize widely.

Owner:佛山杰致信息科技有限公司

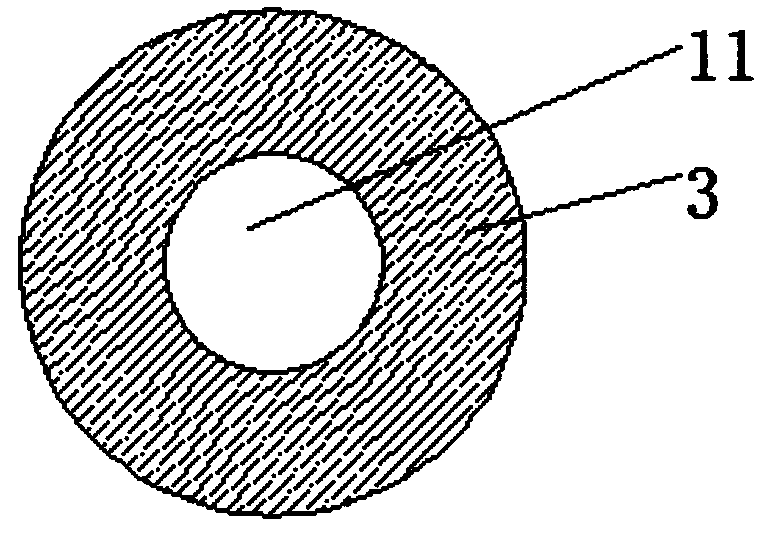

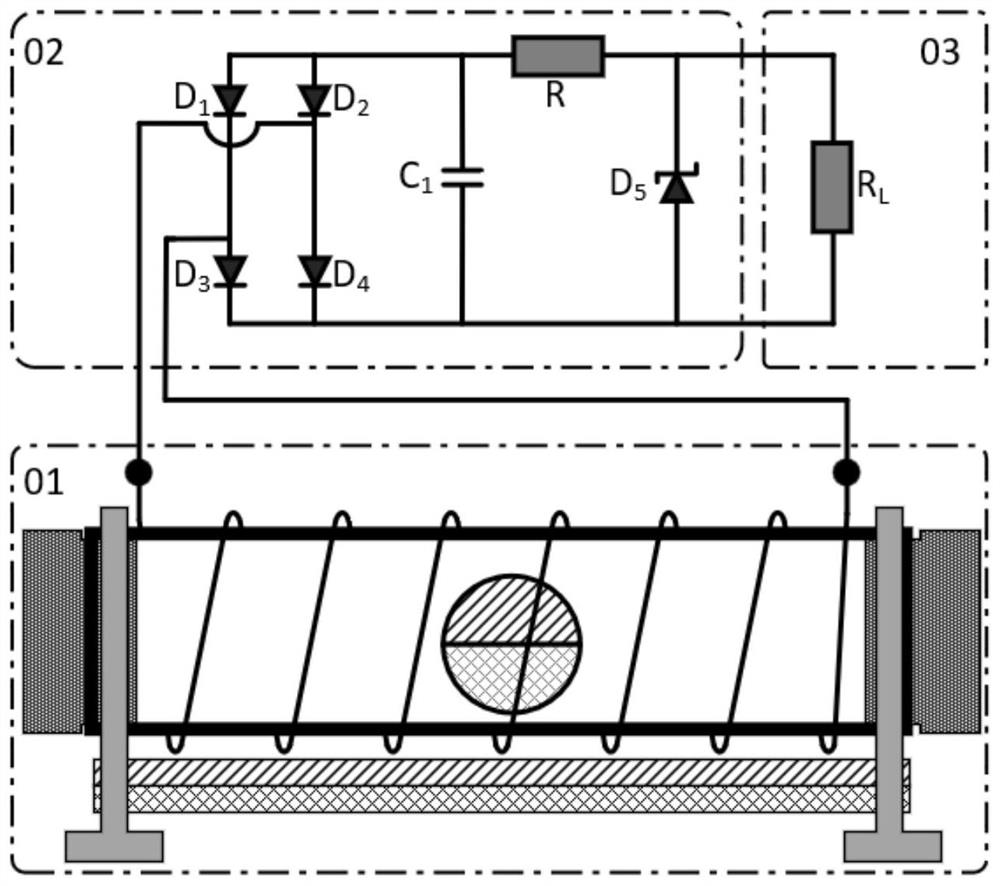

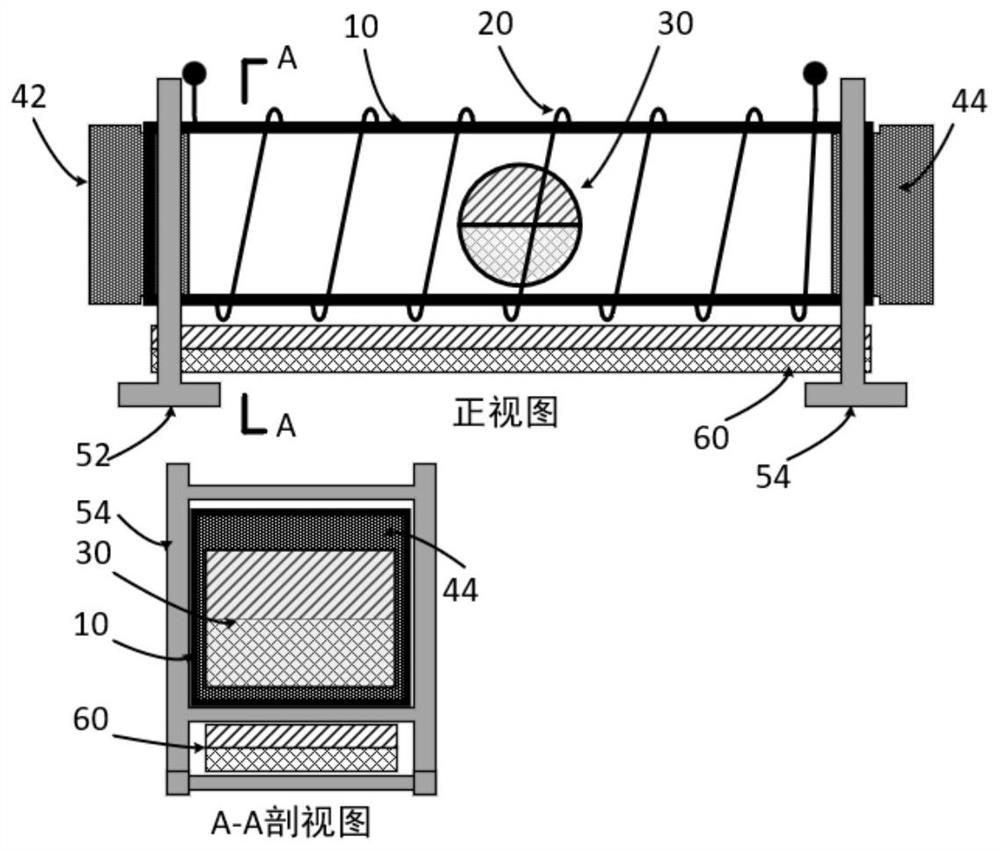

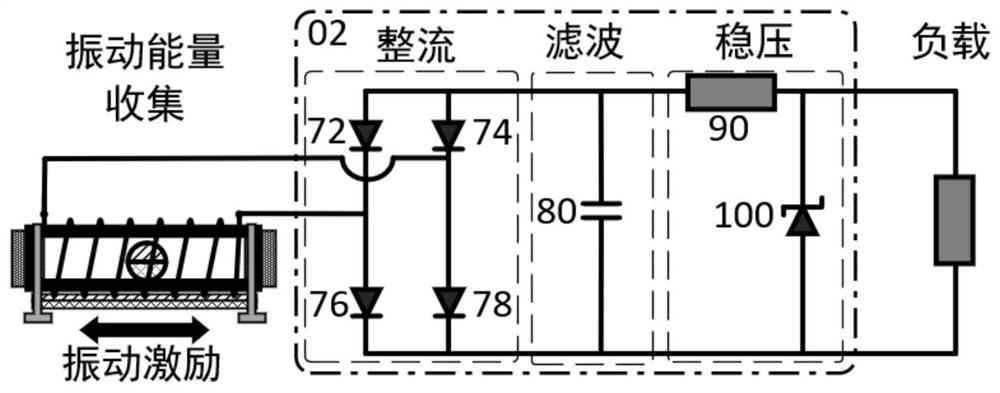

Weak multistable vibration power generation device based on rolling magnet

InactiveCN112737264ASimple structureHigh flux cutting rateAc-dc conversion without reversalAssociation for rectificationSingle phaseCapacitance

The invention discloses a weak multistable vibration power generation device based on a rolling magnet. The weak multistable vibration power generation device comprises a vibration power generation device body, a rectifying, filtering and voltage stabilizing circuit and a load module which are sequentially connected through wires. The vibration power generation device comprises a rectangular section pipe, a long coil and a radial magnetization cylindrical magnet. The interior of the rectangular section pipe is of a tubular structure with a rectangular section hole cavity, and a radial magnetization cylindrical magnet capable of freely rolling in the axial direction of the rectangular section pipe is contained in the rectangular section pipe. The long coil is continuously wound on the outer wall of the rectangular section pipe along the same direction; a left end cover and a right end cover respectively cover the two ends of the rectangular section pipe, and the two ends of the rectangular section pipe are respectively fixed on the left connecting clamp and the right connecting clamp; the left and right ends of the magnet at the lower end of the rectangular-section pipe are respectively fixed at the lower parts of the left connecting clamp and the right connecting clamp; the rectifying, filtering and voltage stabilizing circuit comprises a single-phase bridge type rectifying circuit, a capacitor filtering circuit and a parallel voltage stabilizing circuit which are electrically connected in sequence; and the load module comprises a load.

Owner:SOUTHWEST JIAOTONG UNIV

Convenient-to-maintain laser manufacturing device capable of reducing pollution

InactiveCN109570772AReduce pollutionPromote repairLaser beam welding apparatusTubular articlesManufacturing technologyEngineering

The invention discloses a convenient-to-maintain laser manufacturing device capable of reducing pollution and relates to the technical field of round pipe manufacturing. The convenient-to-maintain laser manufacturing device capable of reducing the pollution specifically comprises to a workbench and connecting rods, a first placing strip is fixedly welded to the upper end of the workbench, guide plates are arranged on the outer walls of the tops of vertical rods, the connecting rods are fixedly welded to the two sides of the upper end of the workbench, mounting blocks are fixedly welded to theinner walls of the connecting rods, reflection plates and focusing plates are arranged on the inner walls of the mounting blocks, the focusing plates are arranged below the reflection plates, slidingchutes are formed in the edges of the tops of the connecting rods, sliding blocks are arranged inside the sliding chutes, and a movable frame is fixedly welded to the tops of the sliding blocks. According to the convenient-to-maintain laser manufacturing device capable of reducing the pollution, a curved surface of a covering ring and a curved surface of a mounting ring are arranged in a matched mode, the fixing effects are achieved on the head end and the tail end of a to-be-cut round pipe, and the arrangement that the curved surfaces are attached to each other can be used to rotate the to-be-cut round pipe in the process of cutting the round pipe.

Owner:深圳利都科技有限公司

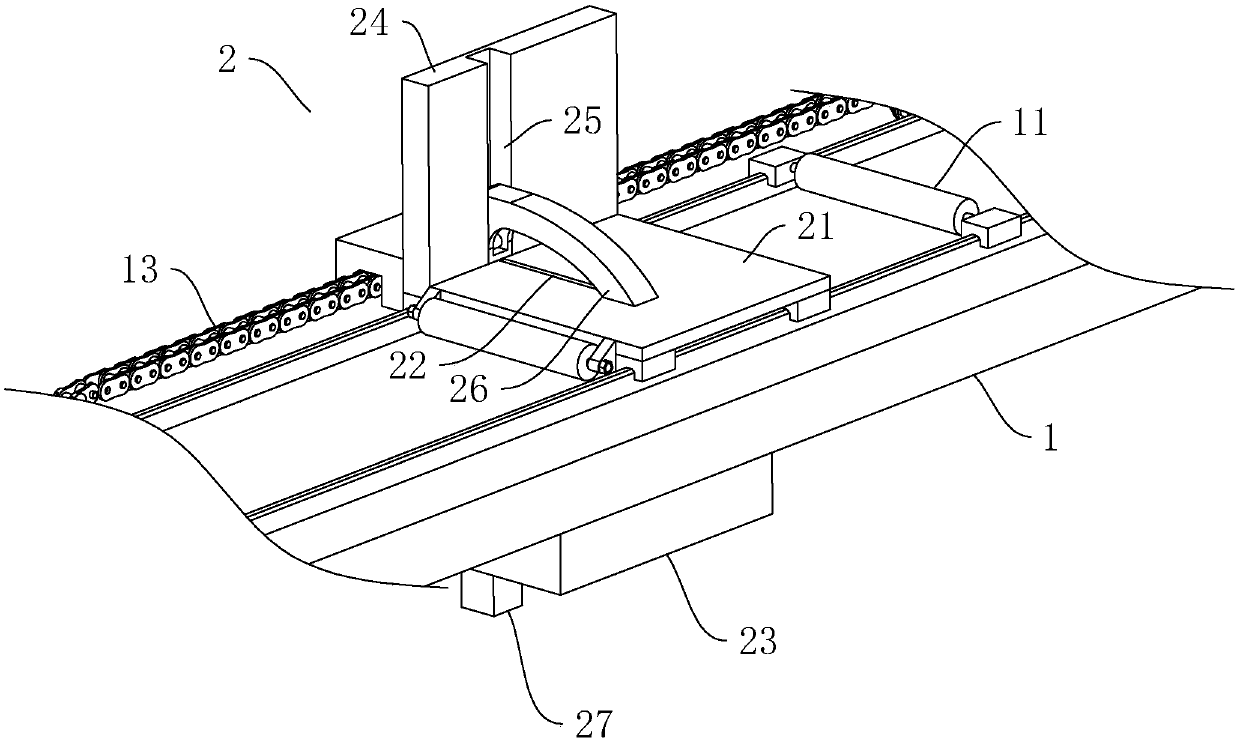

Cutting device for aluminum bar

ActiveCN109604702ARealize non-stop cuttingImprove cutting efficiencyShearing machinesMetal working apparatusContinuous/uninterruptedEngineering

The invention discloses a cutting device for an aluminum bar, and relates to the technical field of machining of aluminum materials. The device comprises a conveying frame, a cutting mechanism is arranged in the middle of the conveying frame, a pair of sliding rails is arranged on one side of the conveying frame side by side, supporting frames are connected to the sliding rails in a sliding mode,walking motors are arranged on the side walls of the supporting frames, sliding rods are connected to the upper end faces of the supporting frames in a sliding mode, first air cylinders drive the sliding rods to slide, racks are arranged on the side walls of the sliding rods, rotating shafts are rotationally connected to the supporting frames, gears meshed with the racks are arranged on the outerwalls of the rotating shafts, cantilevers are horizontally arranged on the rotating shafts, clamping mechanisms used for clamping the aluminum bar are arranged on the cantilevers, and the lower end surface of the cantilever located on the outer side is higher than the upper end surface of the other cantilever. The cutting device for the aluminum bar has the advantages and effects that the aluminumbar can be conveyed through the supporting frames which are arranged in a staggered mode, so that it is guaranteed that the aluminum bar is always in a conveyed state, continuous and uninterrupted cutting work of the aluminum bar can be achieved, the cutting speed of the aluminum bar is increased, and the effect of high working efficiency is achieved.

Owner:台州市金美铝业股份有限公司

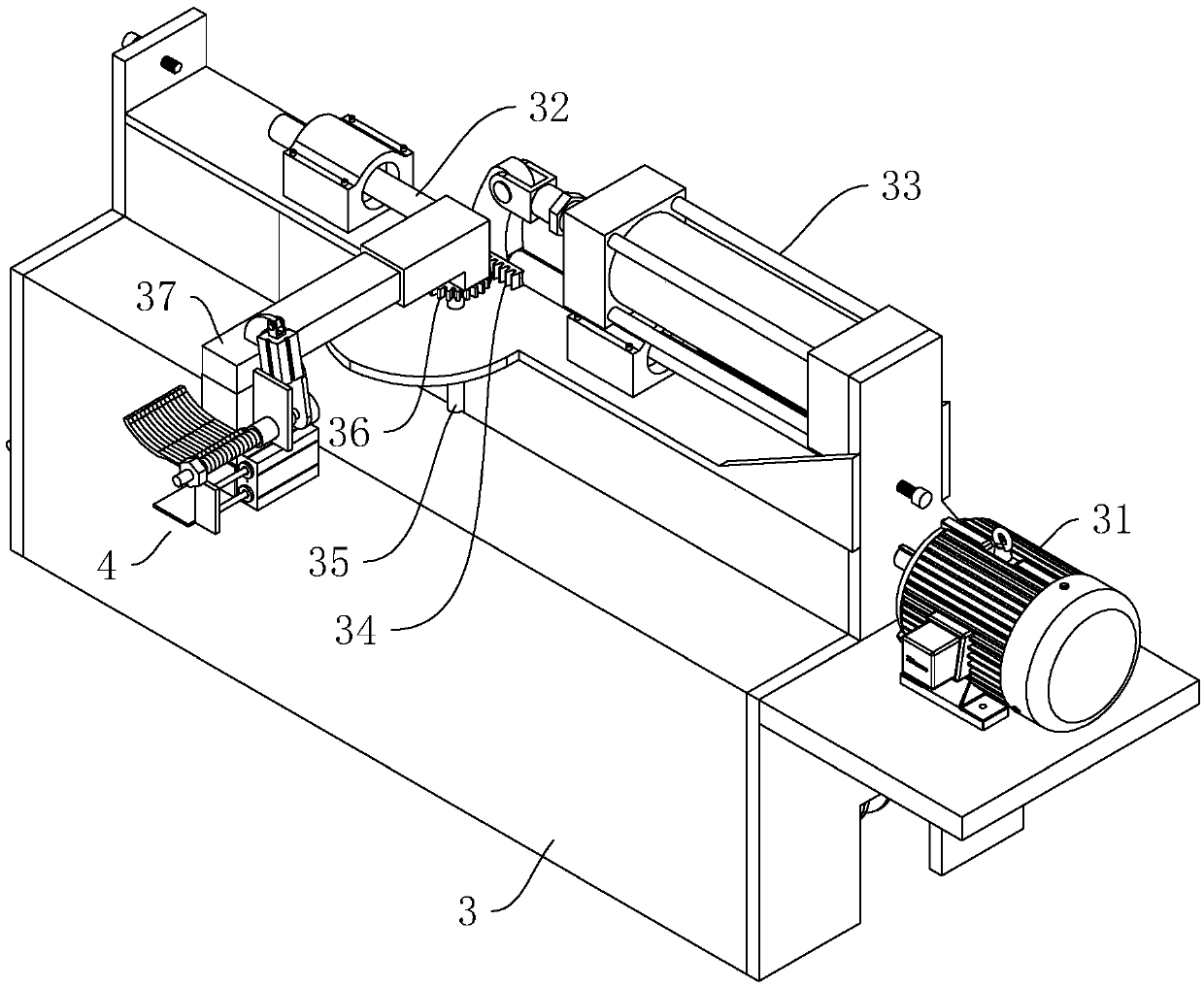

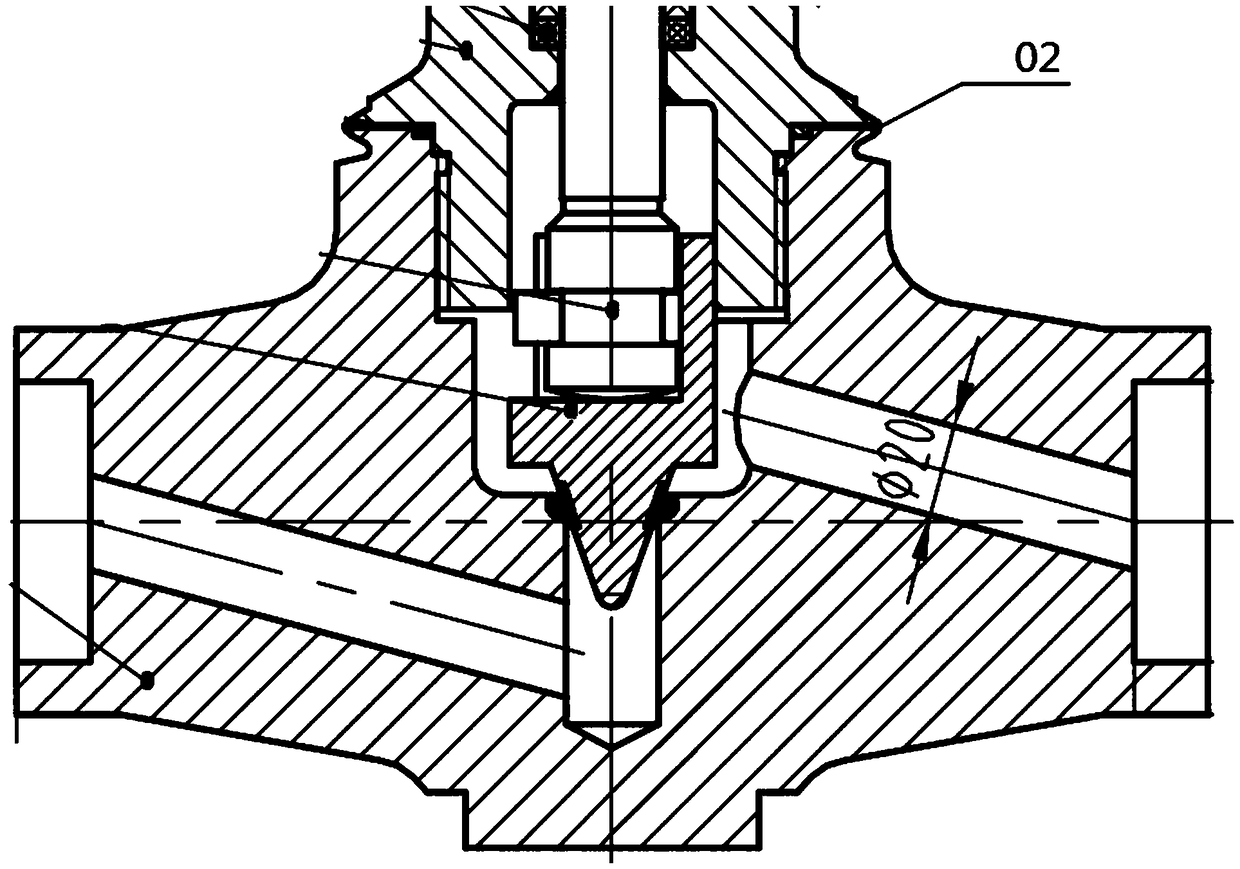

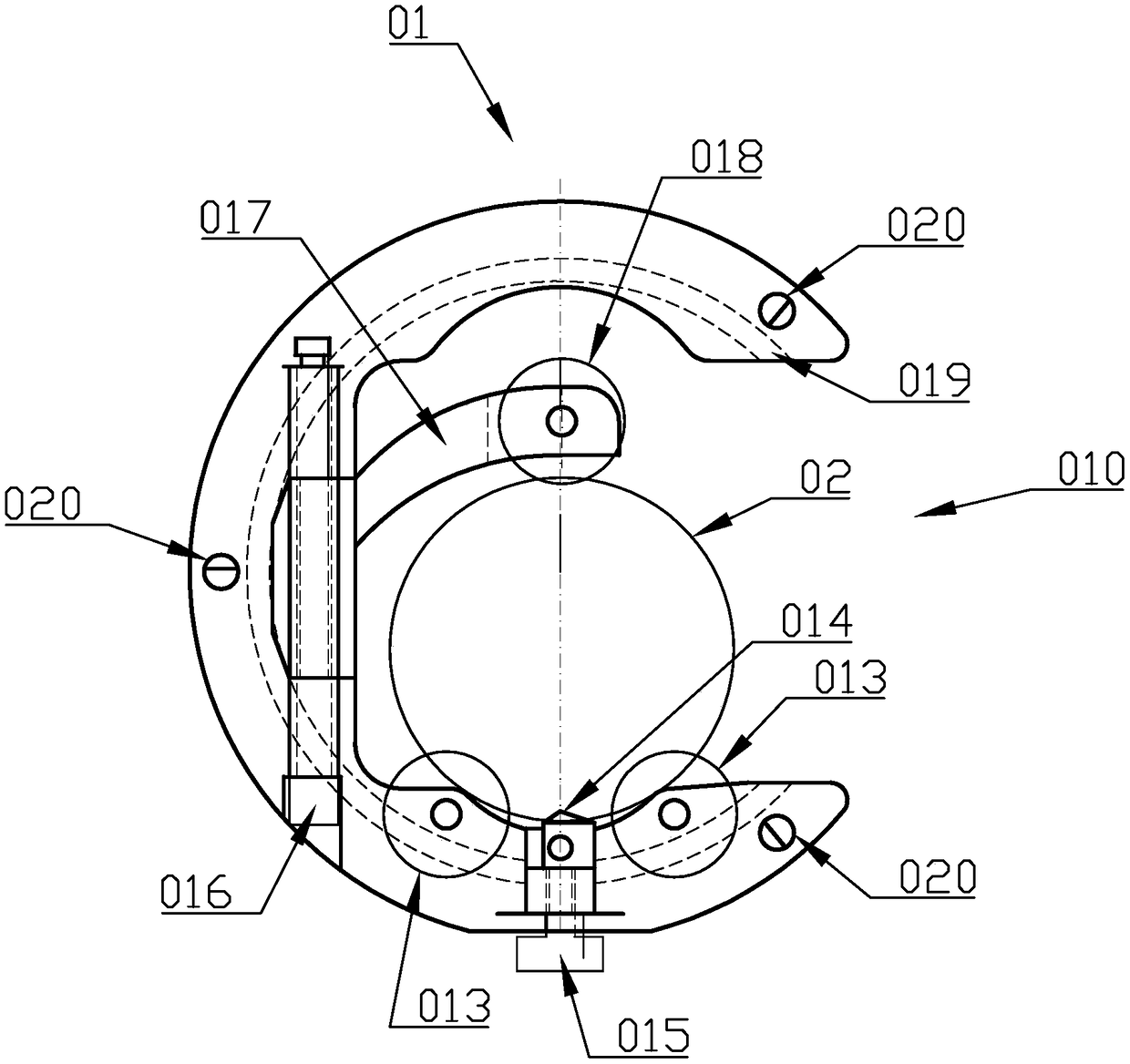

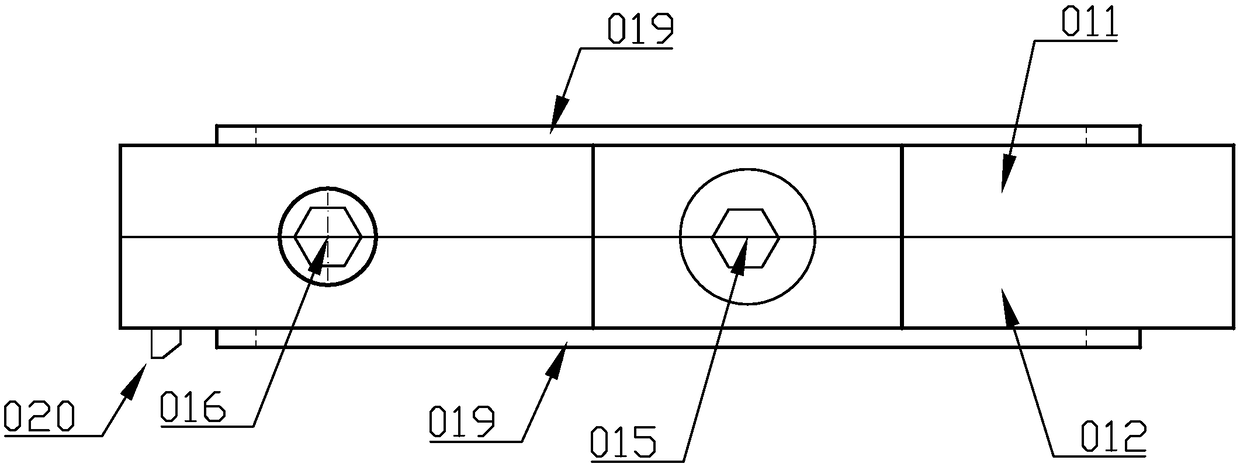

Ratchet type sealing welding ring cutter

The invention discloses a ratchet type sealing welding ring cutter. According to the ratchet type sealing welding ring cutter, the welding line cutting precision is high, the time is saved, and equipment body is not easily damaged. The ratchet type sealing welding ring cutter comprises an inner ring used for cutting a sealing welding ring; a first opening used for allowing the sealing welding ringto extend thereinto is formed in the inner ring; the inner ring comprises an upper inner ring and a lower inner ring connected to the upper inner ring, and two first rolling wheel are clamped betweenthe upper inner ring and the lower inner ring; a cutter head used for cutting the sealing welding ring is arranged between the two first rolling wheel, a screw rod is arranged on one sides of the first rolling wheel, and a screw rod nut is arranged on the screw rod; and the screw rod nut is connected to a positioning rod, a second rolling wheel is arranged at the end part of the positioning rod,and the connecting lines among the two first rolling wheels and the second rolling wheel define a triangle for clamping the sealing welding ring.

Owner:海盐沃企机电设备有限公司

Decorative ceramic tile cutting and positioning device

ActiveCN113547650AReduce labor intensityIncrease cutting rateWorking accessoriesVibration suppression adjustmentsCeramic tilesEngineering

Owner:阿郎装饰股份有限公司

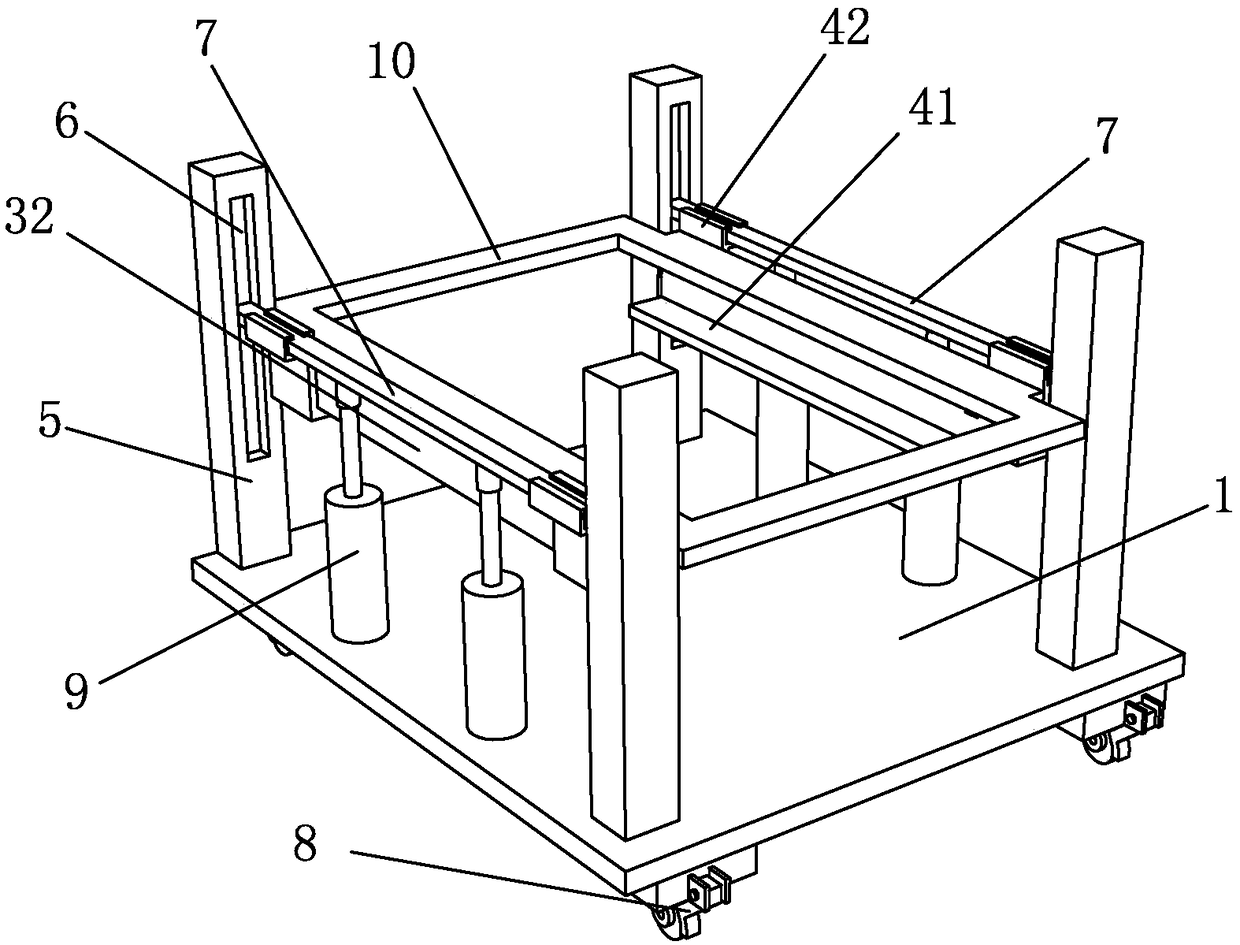

Cutting device for production of hardware accessories

ActiveCN108971649AGuaranteed connection strengthEnsure the firmness and stability of the installationOperations securityAutomation

The invention discloses a cutting device for production of hardware accessories. The cutting device comprises a supporting base, a clamp component, a cutting platform and a cutting component. Supporting stand columns are arranged on the four corners of the top surface of the supporting base, and mobile sliding grooves are formed in the supporting stand columns. A supporting cross rod is arranged between every two left-right adjacent supporting stand columns, the two ends of the supporting cross rod are both clamped in the mobile sliding grooves, and a lifting column is arranged on the bottom surface of the supporting cross rod. A fixed clamping frame is arranged between the two supporting cross rods, and the clamp component is connected with the fixed clamping frame and comprises a mounting plate and clamp bodies. The cutting device has the advantages of clever and reasonable integral structure design and operation automation, reduces labor intensity, improves an operating safety performance, reduces potential safety hazards, and improves cutting speed and cutting precision. Moreover, the clamp bodies can be replaced according to the shapes of different hardware accessories. Meanwhile, the whole clamp component is more conveniently disassembled, assembled and replaced, so that the whole device is conveniently disassembled and transported, and follow-up repair and maintenance are also convenient.

Owner:佛山市顺德区运恒金属制品有限公司

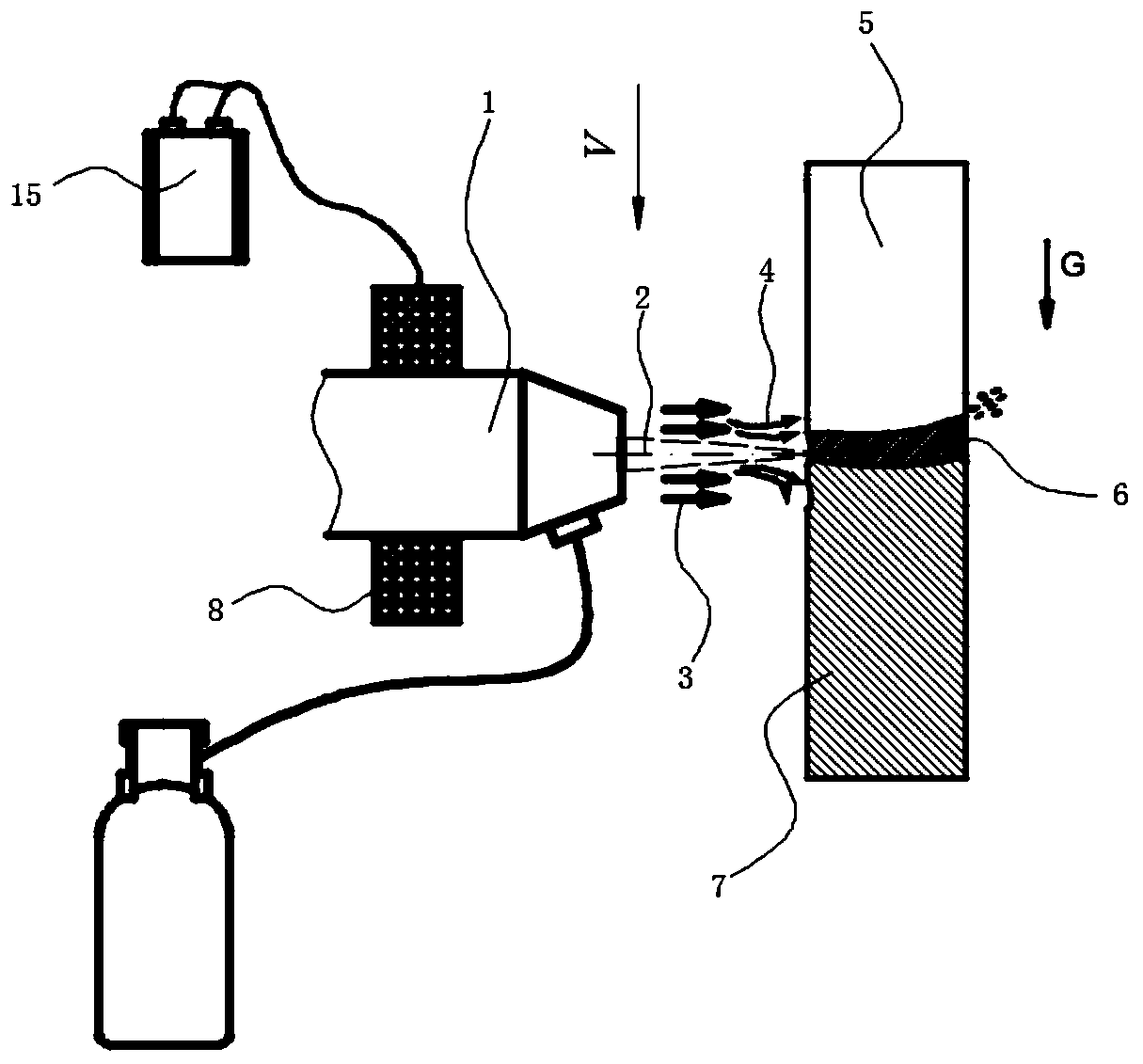

Thick plate laser cutting method

ActiveCN110293325AAvoid "reverse spray" phenomenonImprove cutting effectLaser beam welding apparatusThick plateEngineering

The invention relates to a thick plate laser cutting method. The thick plate laser cutting method is characterized by comprising the following steps of 1, fixing an electromagnetic coil onto a laser cutting head, wherein the electromagnetic coil can move along with the laser cutting head; 2, vertically placing and fixing a workpiece to be cut; 3, defining a corner cutting leading-in section and aleading-out section in a laser cutting track; 4, activating a laser cutting system, cutting auxiliary gas and an electromagnetic field power source, perpendicularly irradiating the surface of the workpiece to be cut by laser beams to realize laser cutting of a thick plate; 5, adjusting the electromagnetic field power source when the laser beams move to a starting point of the corner cutting leading-in section to start corner region cutting; 6, adjusting the electromagnetic field power source when the laser beams move to an end point of the corner cutting leading-out section to finish corner region cutting; and 7, turning off a laser generator, the electromagnetic field power source and the cutting auxiliary gas to complete the cutting process when a cutting tail end point is reached. Compared with the prior art, the thick plate laser cutting method is good in cutting effect.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Building board cutting machine

ActiveCN109366757AAvoid shakingPlay a limiting roleWorking accessoriesStone-like material working toolsArchitectural engineeringEnergy consumption

The invention belongs to the technical field of building board processing equipment, and particularly relates to a building board cutting machine which comprises a frame body. A first sealed barrel isdivided into a first cavity, a second cavity and a third cavity through a first separation plate and a second separation plate; a drive rod is fixedly connected to the upper surface of a first slideblock; a groove is formed in the upper surface of the drive rod; a slide rod is arranged at the upper end of the drive rod; the lower end of the slide rod penetrates through the groove; a second spring is fixedly connected between the slide rod and the bottom part of the groove; a first limiting block is fixedly connected to the inner wall of the second separation plate; a second limiting block isfixedly connected to the inner wall of the first separation plate; the second spring can play a role in buffering, so that a second cutter is effectively prevented from moving instantly, a device anda building board are prevented from shaking, and the cutting accuracy is improved; and the first limiting block and the second limiting block can achieve limiting effects. According to the building board cutting machine provided by the invention, a first cutter and the second cutter are driven by gas so as to cut the building board, and the building board cutting machine has the characteristics of stable structure, high cutting accuracy and low energy consumption.

Owner:阜阳市鑫源建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com