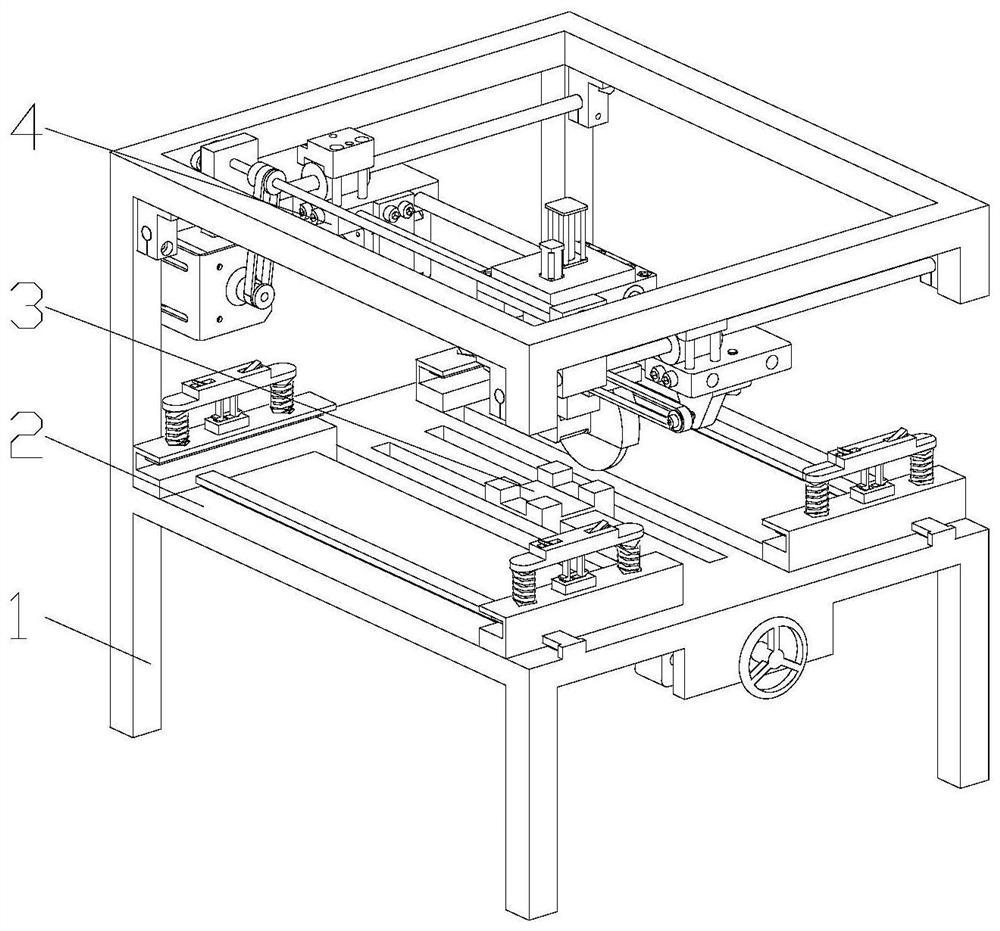

Decorative ceramic tile cutting and positioning device

A positioning device and ceramic tile technology, which is applied in the direction of stone processing tools, work accessories, springs/shock absorbers, etc., can solve the problems of increasing the work intensity of the staff and low work efficiency, so as to reduce labor intensity, increase cutting speed, and ensure The effect of cut quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0050] The difference from Embodiment 1 is that a guide rail 5 and a positioning mechanism 6 matched with the guide rail 5 are also installed on the placement frame 2. The positioning mechanism 6 is installed in the chute 9 and symmetrically installed at the bottom of the placement frame 2. There is a mounting plate 8, and the positioning mechanism 6 includes a positioning clamp 605, a connecting plate 604, a second threaded rod 603, a handle 602 and a slide bar 601, and the guide rail 5 is provided with two, and the two guide rails 5 are symmetrically installed on the placement frame 2, the positioning clips 605 are in one-to-one correspondence with the guide rails 5, and there is a guide groove 606 at the bottom of the positioning clip 605, the guide grooves 606 match the guide rails 5, and the connecting plate 604 is located at the bottom of the placement frame 2 , and the two ends of the connecting plate 604 pass through the chute 9 to connect with the positioning clip 605,...

Embodiment 3

[0054] The difference from Embodiment 1 and Embodiment 2 is that a fixing mechanism 7 is installed on the positioning clip 605, and the fixing mechanism 7 includes a fixing seat 701, a support plate 702, a fixing column 704, a first spring 703, a second spring 705. The connecting rod 706 has an installation hole in the middle of the support plate 702. The inside of the installation hole is provided with a connecting rod 706 and a second spring 705. The connecting rod 706 includes an inclined part and a vertical part, and the connecting rod 706 The connection between the inclined part and the vertical part of the second spring 705 is installed on the support plate 702 through the rotation of the rotating shaft. One end of the second spring 705 is installed on the support plate 702, and the other end is installed on the bottom of the inclined part of the connecting rod 706. When the connecting rod 706 is vertical The bottom of the part is equipped with a limit block 707, the fixe...

Embodiment 4

[0057] The difference from Embodiment 1, Embodiment 2, and Embodiment 3 is that the fixing mechanism 7 also includes a third spring 709 and a clamping plate 708, one end of the third spring 709 is installed on the fixing column 704, and the other One end is installed on the clamping plate 708, and the clamping plate 708 is arranged in the positioning clamp 605, and the third spring 709 acts as a buffer, and can also provide pre-tightening force for the clamping plate 708, and continuously clamp the tiles. The setting of the clamping plate 708 is convenient to spread the pressure on the fixing column 704 to apply on the ceramic tiles, so as to prevent damage to the ceramic tiles caused by excessive force at a single point.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com