Patents

Literature

131results about How to "Reduced Risk of Fragmentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

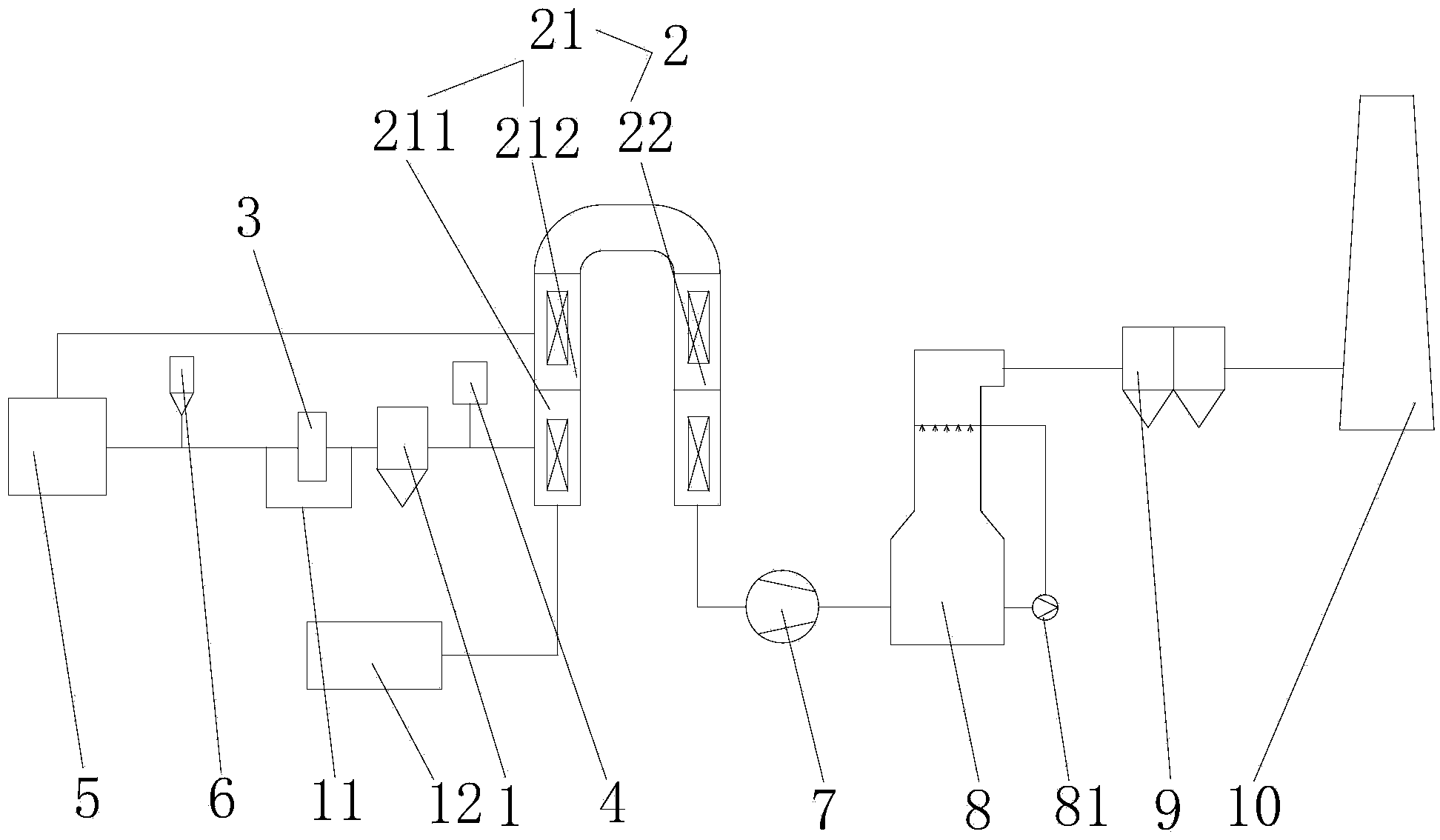

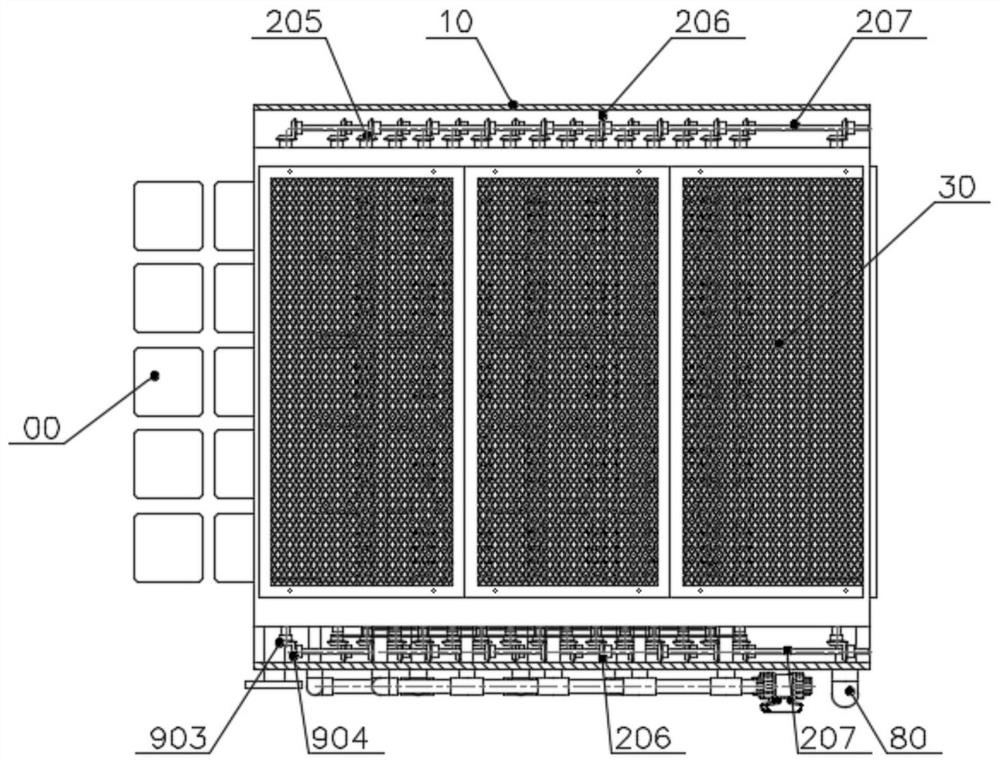

Method and device for removing high-concentration dust in flue gas of glass kiln

ActiveCN104289086AEfficient removalHigh porosityCombination devicesDispersed particle filtrationHigh concentrationFlue gas

Owner:HAIYUAN ENVIRONMENTAL SCI & TECH

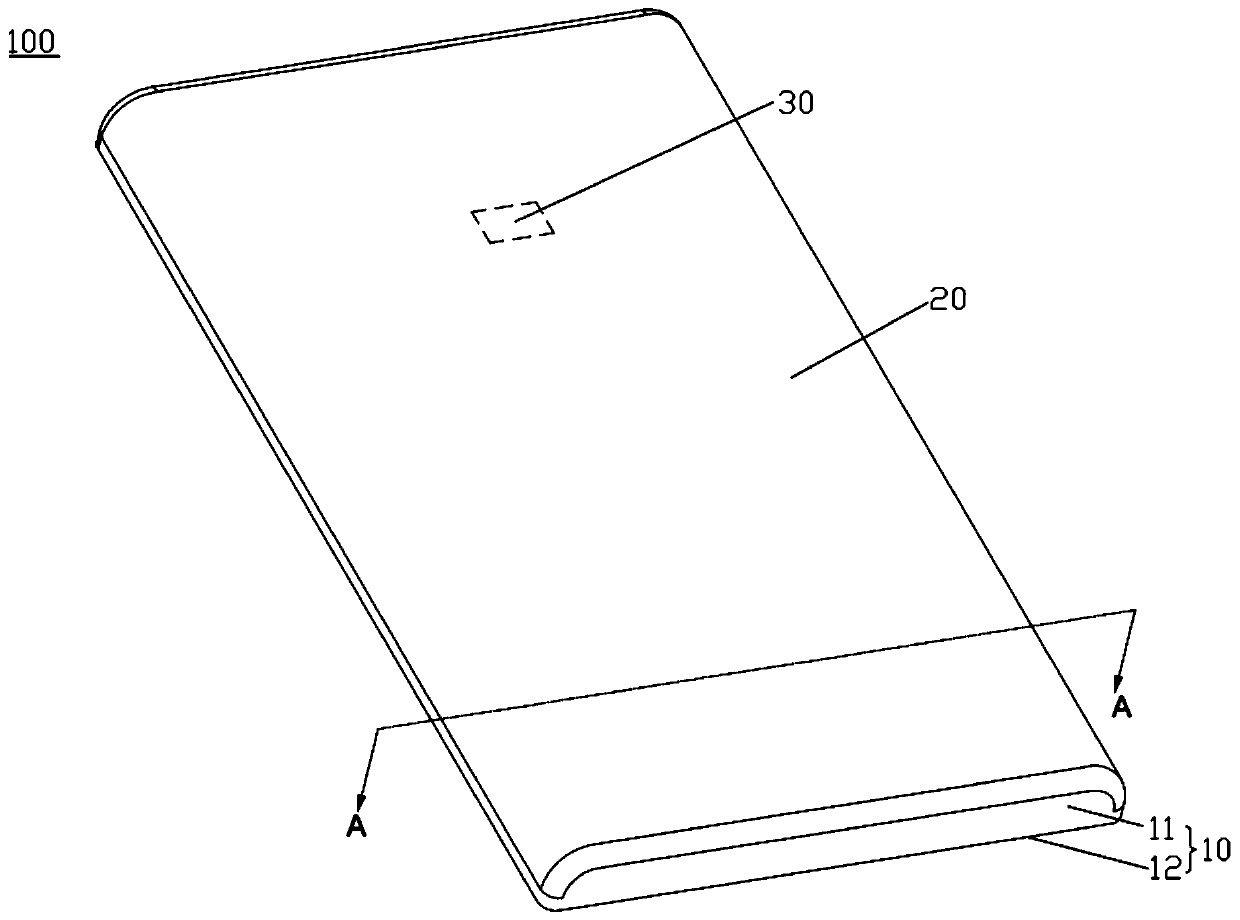

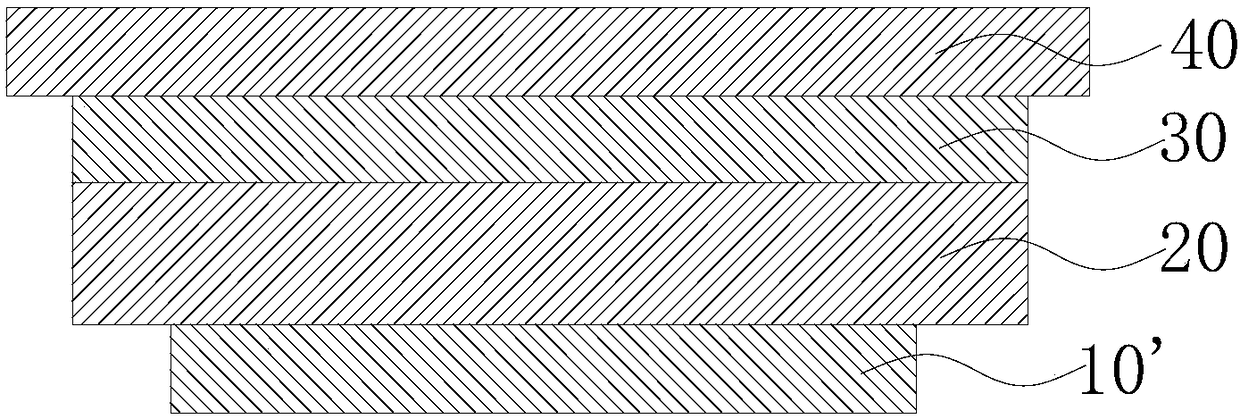

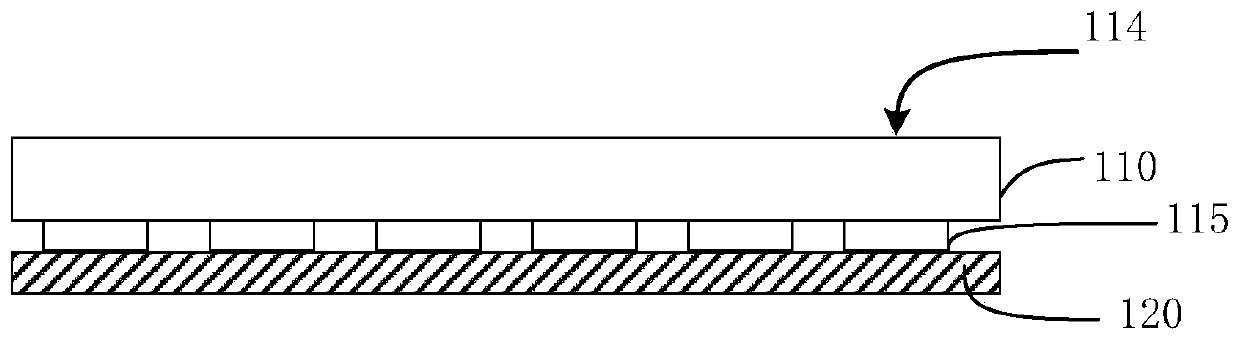

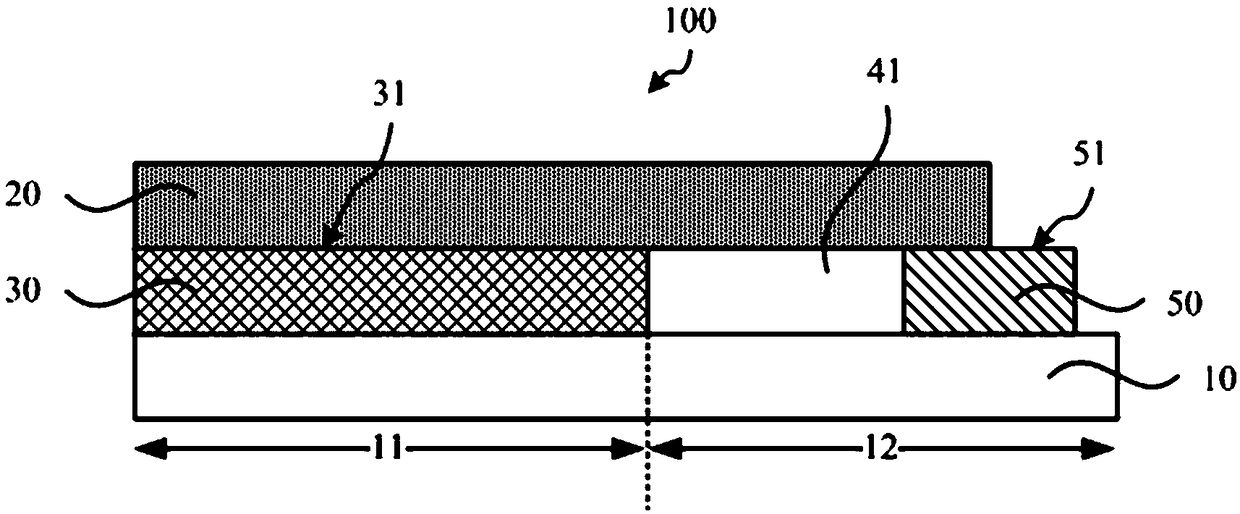

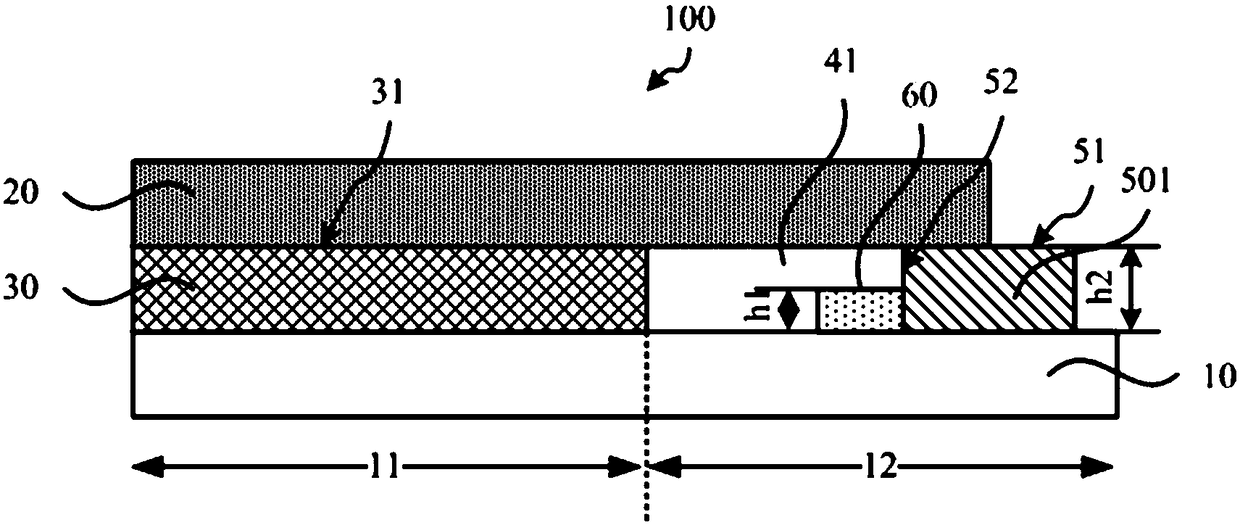

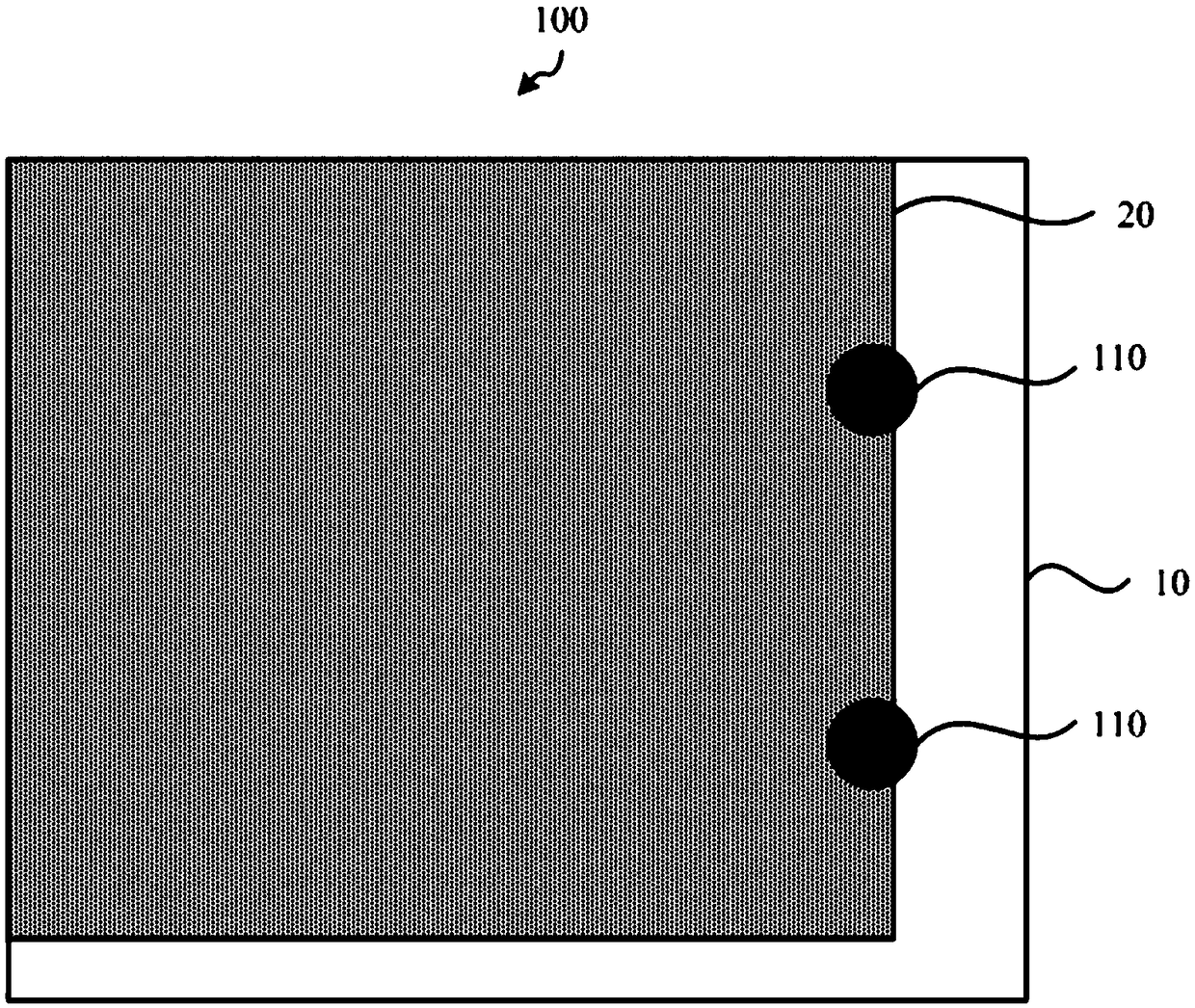

Display screen assembly and mobile terminal

ActiveCN110853496AGood light transmissionDoes not affect the display effectTelephone set constructionsIdentification meansEngineeringComposite plate

The invention provides a display screen assembly. The display screen assembly comprises a display screen, an adhesive layer and a screen cover plate, wherein the adhesive layer is adhered between thedisplay screen and the screen cover plate; the screen cover plate comprises at least two composite board layers, and the materials of the composite board layers comprise at least two amorphous crystalline polymers, so that the strength and the hardness of the screen cover plate are improved, the screen cover plate can effectively protect the display screen, and the risk that the screen cover plateis broken due to falling or collision is reduced. The invention further provides a mobile terminal comprising the display screen assembly.

Owner:HUAWEI TECH CO LTD

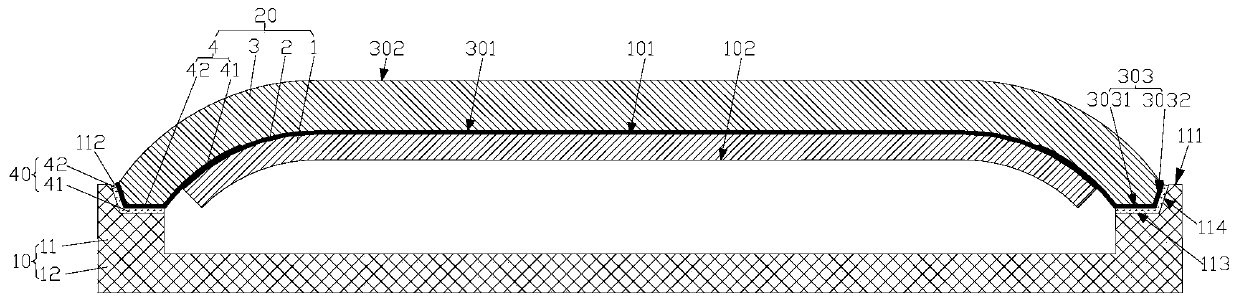

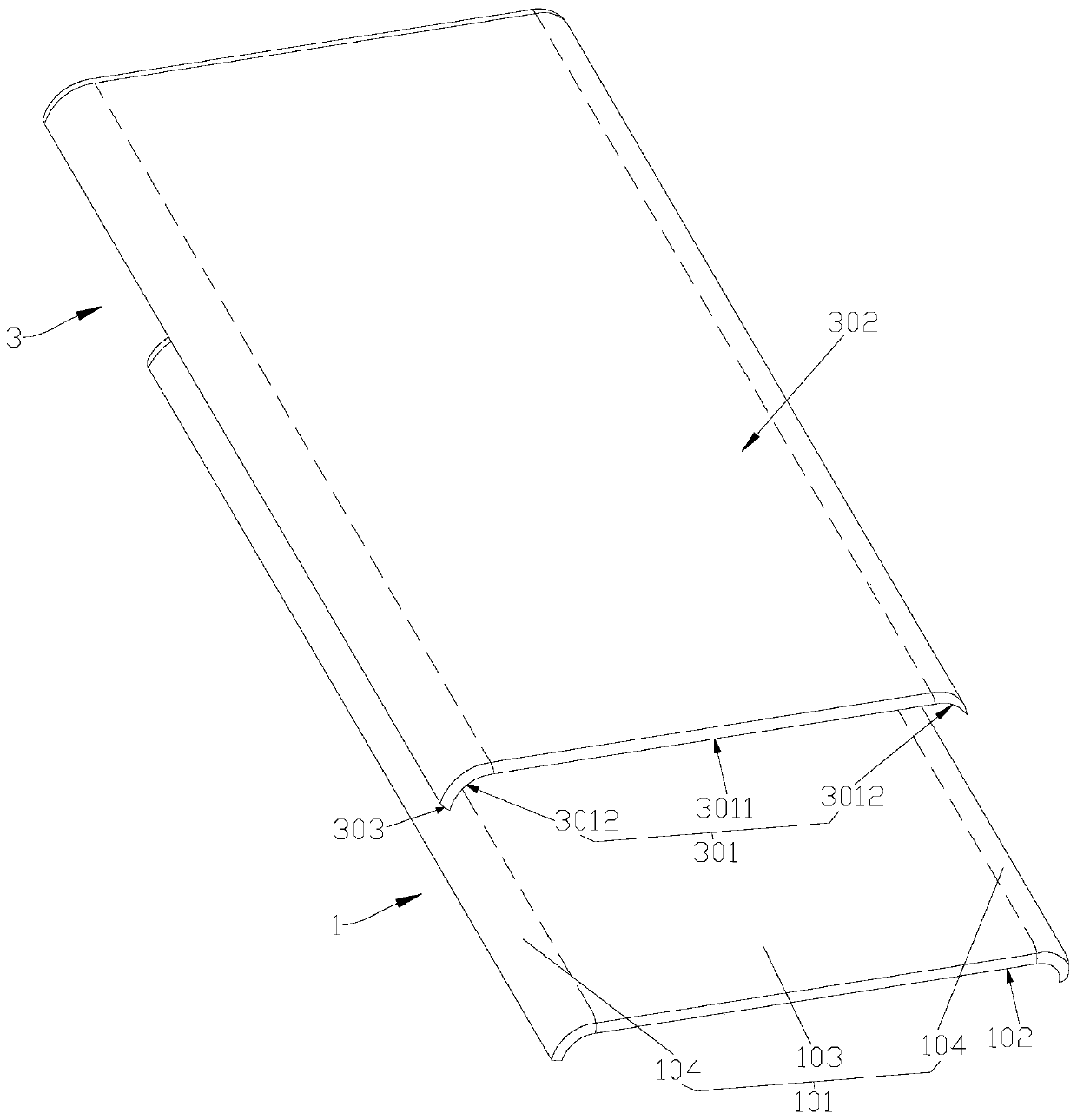

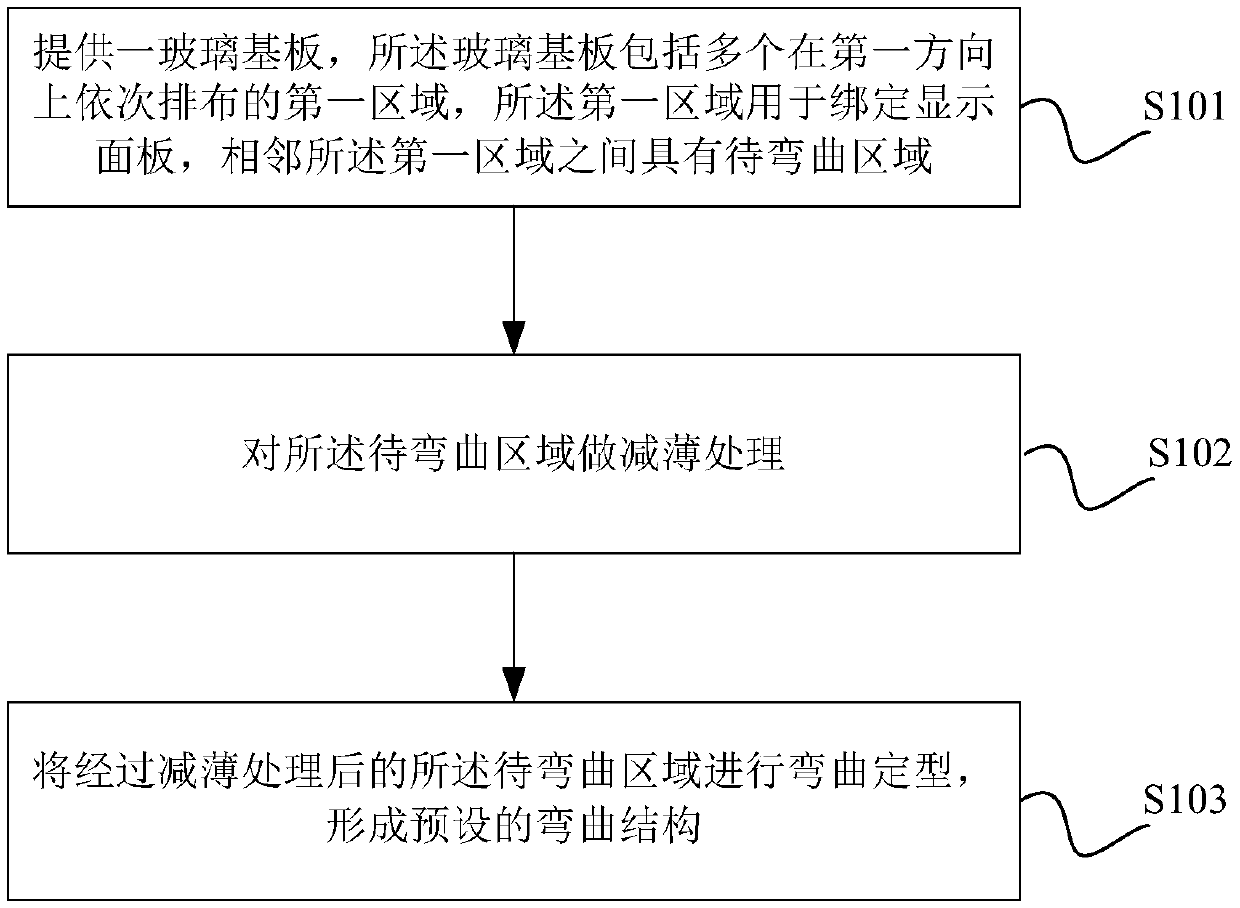

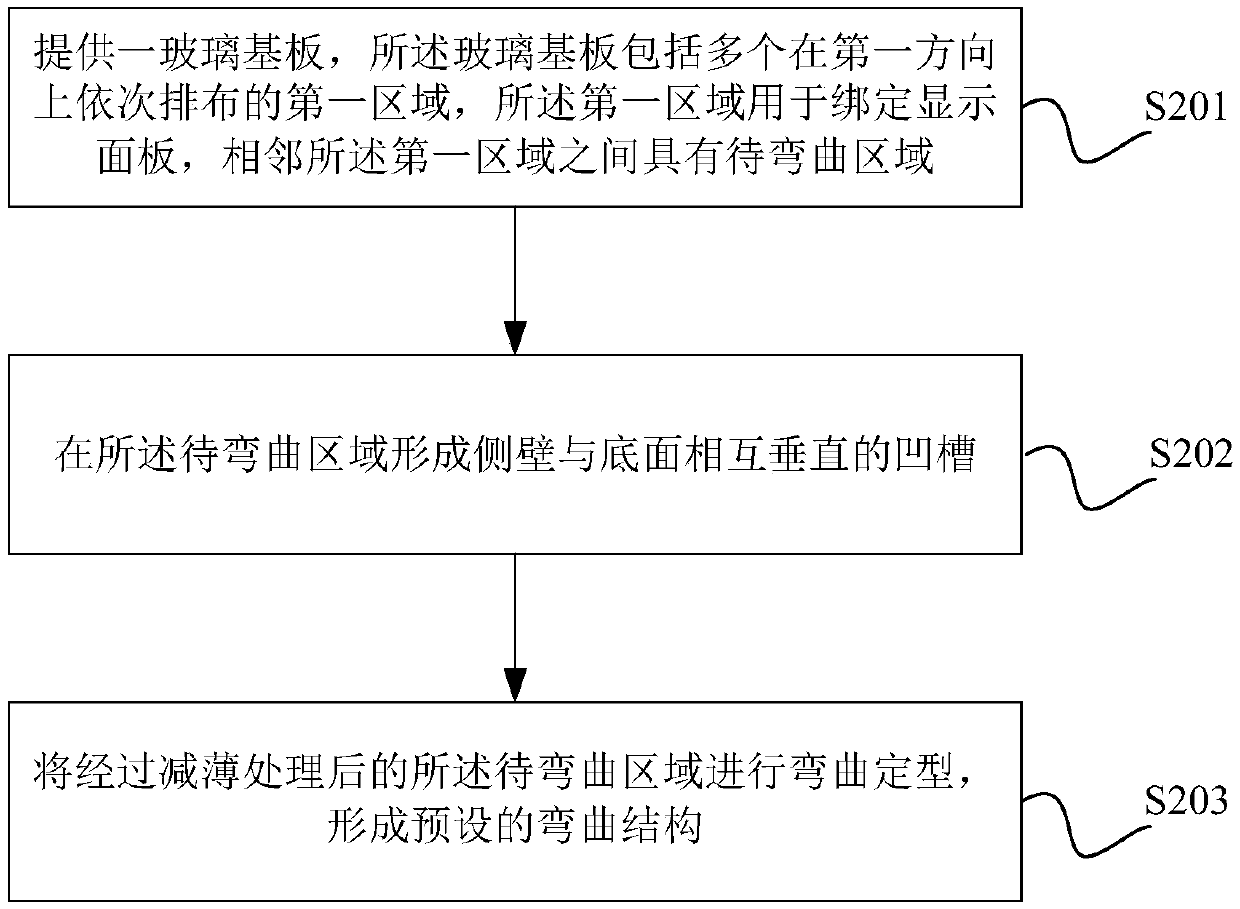

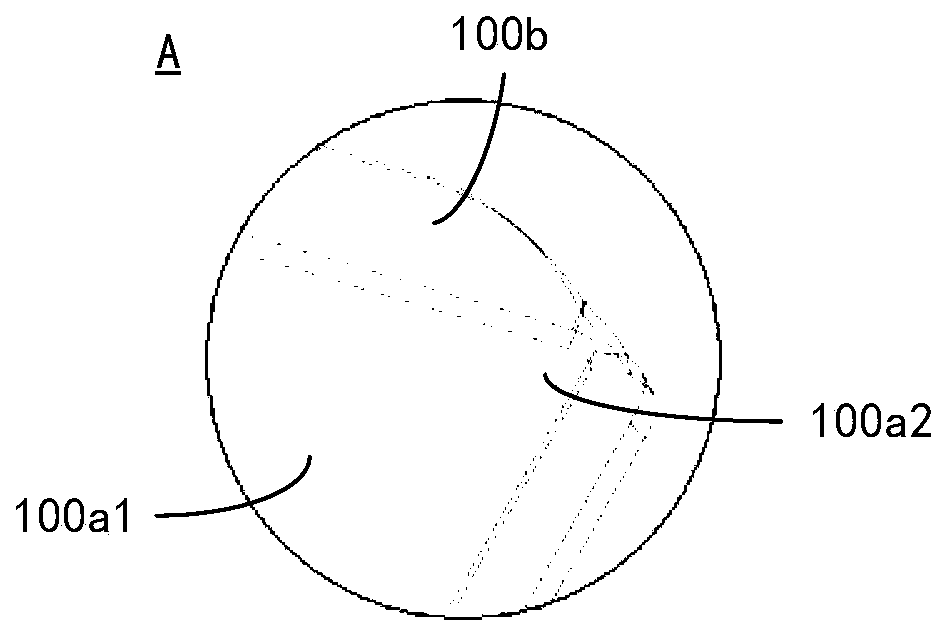

Bending glass cover plate and manufacture method thereof

ActiveCN109081561ASave energyReduced Risk of FragmentationGlass reforming apparatusGlass tempering apparatusGlass coverEngineering

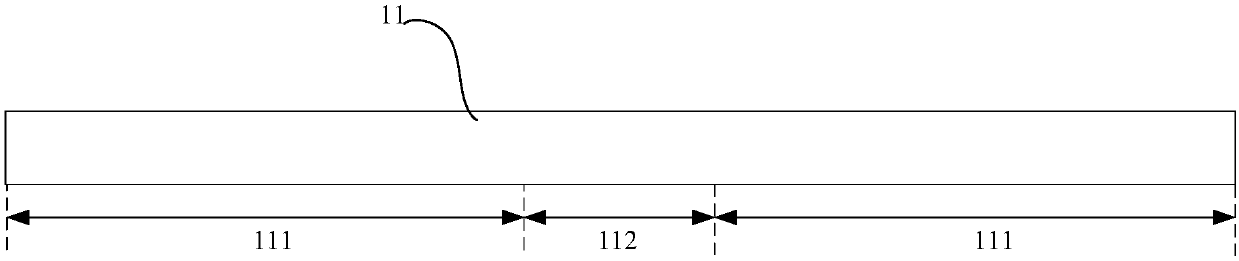

The invention discloses a manufacture method of a bending glass cover plate. The method includes the steps: providing a glass substrate comprising a plurality of first areas; thinning an area to be bent; bending the thinned area to be bent to form a preset bending structure. The first areas are sequentially distributed in the first direction and used for binding display panels, and an area to be bent is arranged between two adjacent first areas. According to the method, a portion to be bent of the area to be bent is thinned, hot bending energy consumption of glass is reduced, so that glass ismore uniformly heated in the hot bending of the glass, cracking risks of the glass caused by heated uniformity are reduced in the heating process, yield is increased, and requirements for device accuracy are reduced, so that device cost is reduced. The invention further provides a bending glass cover plate with the advantages.

Owner:TRULY OPTO ELECTRONICS

Method for bonding preparation of Ge-on-insulator (GOI) through Ge film

ActiveCN104867814ASolve the problem of surface micro voidsReduced fragilitySemiconductor/solid-state device manufacturingSurface energyEngineering

The invention discloses a method for bonding preparation of Ge-on-insulator (GOI) through a Ge film, and relates to GOI. The method comprises the following steps: performing ion implantation on a Ge sheet to form a defect plane; binding PDMS with the processed Ge sheet by use of light cured glue; applying a cutting force parallel to a peeling plane on a processed flexible support substrate, and tearing a surface Ge film from a body Ge substrate along the defect plane to obtain a flexible Ge film; then obtaining the Ge film through polishing, then cleaning the Ge film and an SiO2 / Si wafer, performing bumping with the surface of the wafer by use of plasma, and at the same time, performing activation processing on the surface; attaching the processed Ge film to the SiO2 / Si wafer; fully discharging air of an interface by use of a rolling method; and performing pre-bonding on a sample after processing, afterwards, peeling the flexible susbtrate from a GOI structure, and performing annealing so as to enhance bonding surface energy and improve the bonding intensity.

Owner:XIAMEN UNIV

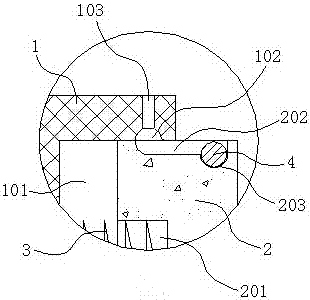

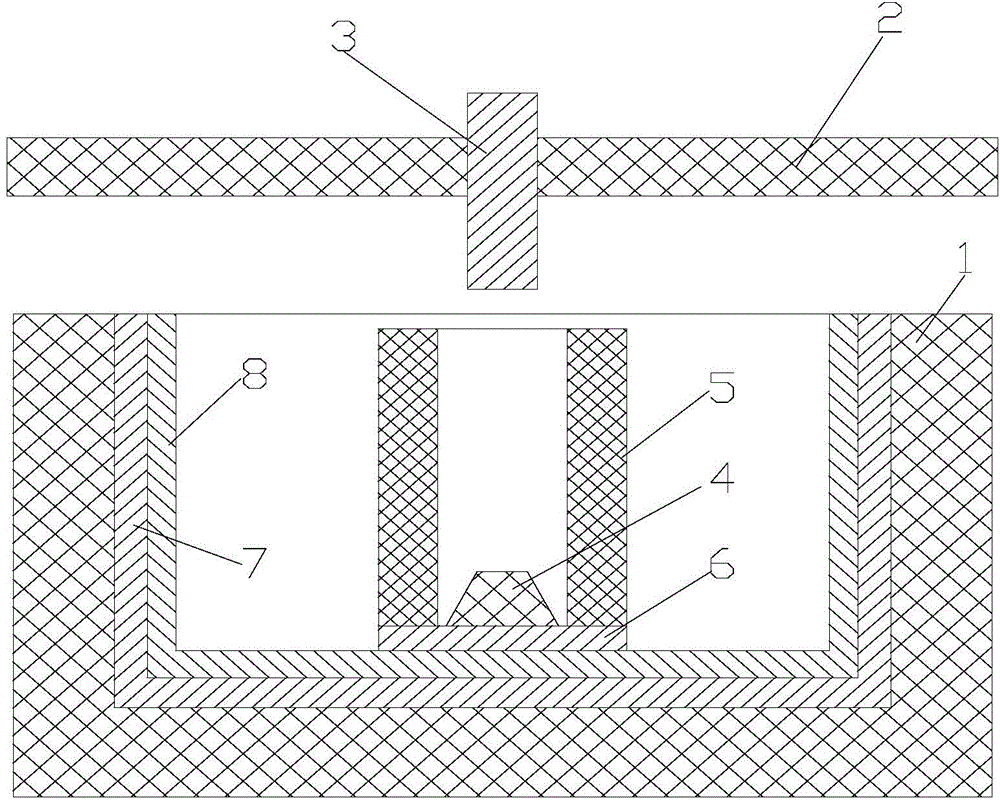

Image pickup module

PendingCN109151261ABig spaceAvoid collisionTelevision system detailsColor television detailsCamera lensOptoelectronics

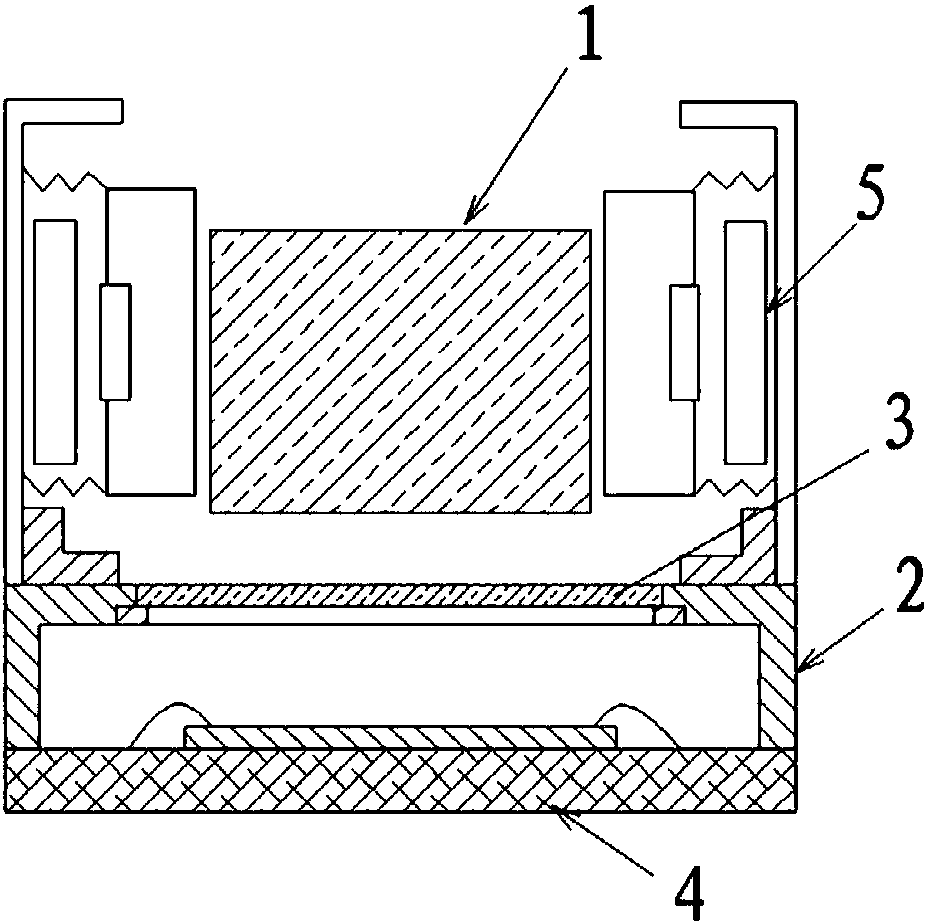

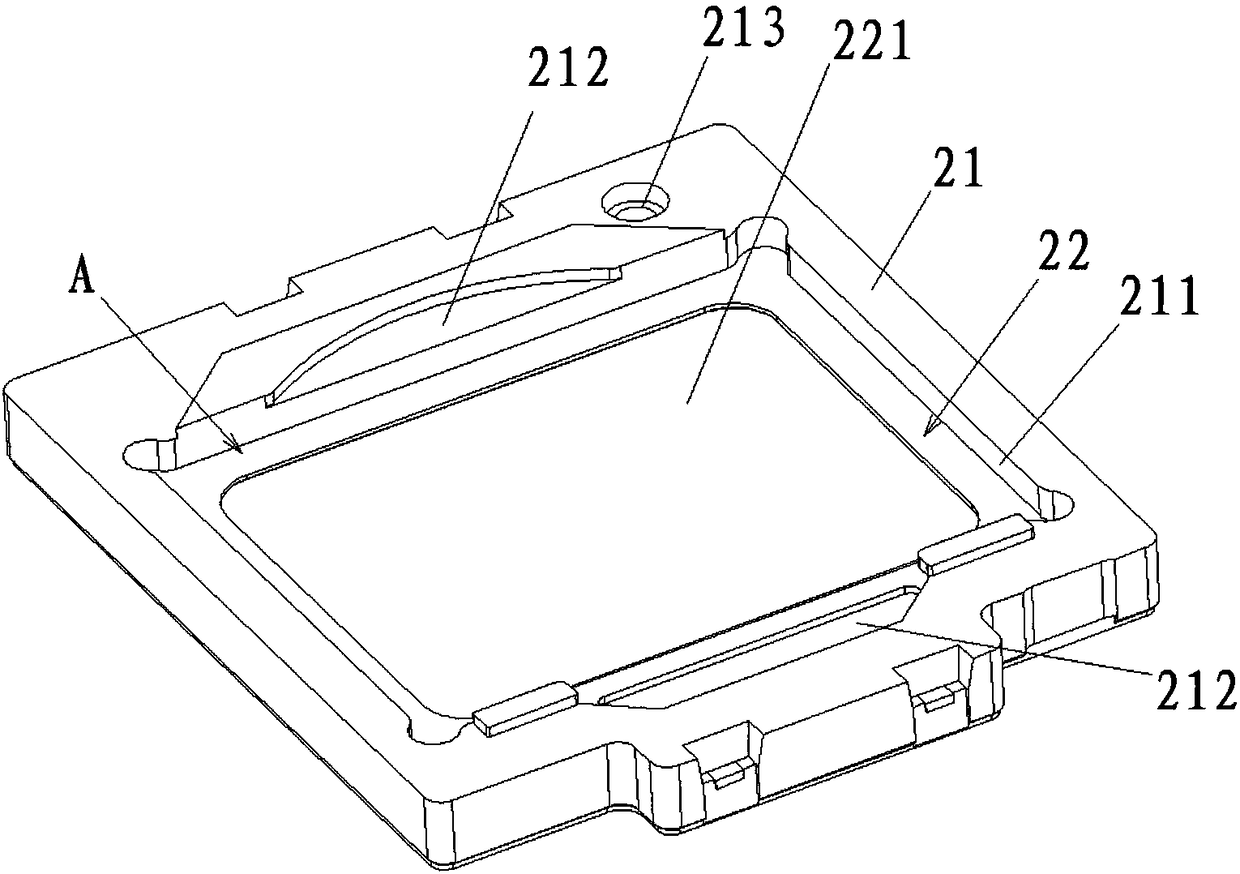

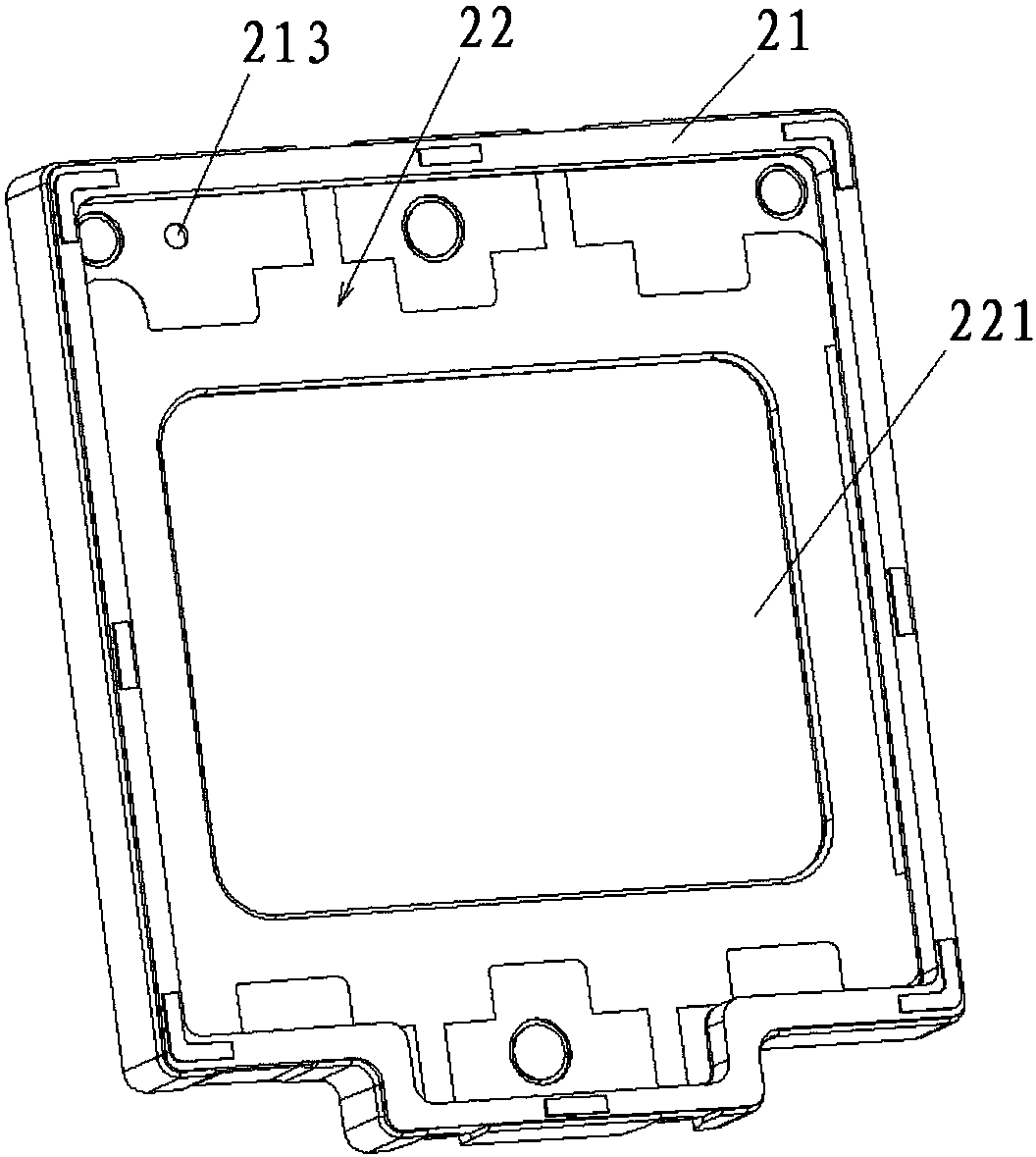

The invention relates to an image pickup module. The image pickup module comprises a lens, a lens holder, a light filter, an imaging assembly and a driving device; the lens holder is located under thelens; the light filter is supported on the lens holder and located under the lens; the imaging assembly is located below the light filter and is fixedly connected with the lens holder; the driving device is used for driving the lens to perform focusing; the lens holder includes a connecting portion and a supporting portion for supporting the light filter; a through hole is formed in the supporting portion; and the thickness of the supporting portion ranges from 0.09 to 0.14 mm. Since the thickness of the supporting portion is set to range from 0.09 to 0.14 mm, the total thickness of the supporting portion and the light filter is decreased. The overall strength of the supporting portion is effectively ensured, so that the deformation of the supporting portion can be prevented. The supporting portion can sufficiently maintain a stable supporting effect for the light filter.

Owner:NINGBO SUNNY OPOTECH CO LTD

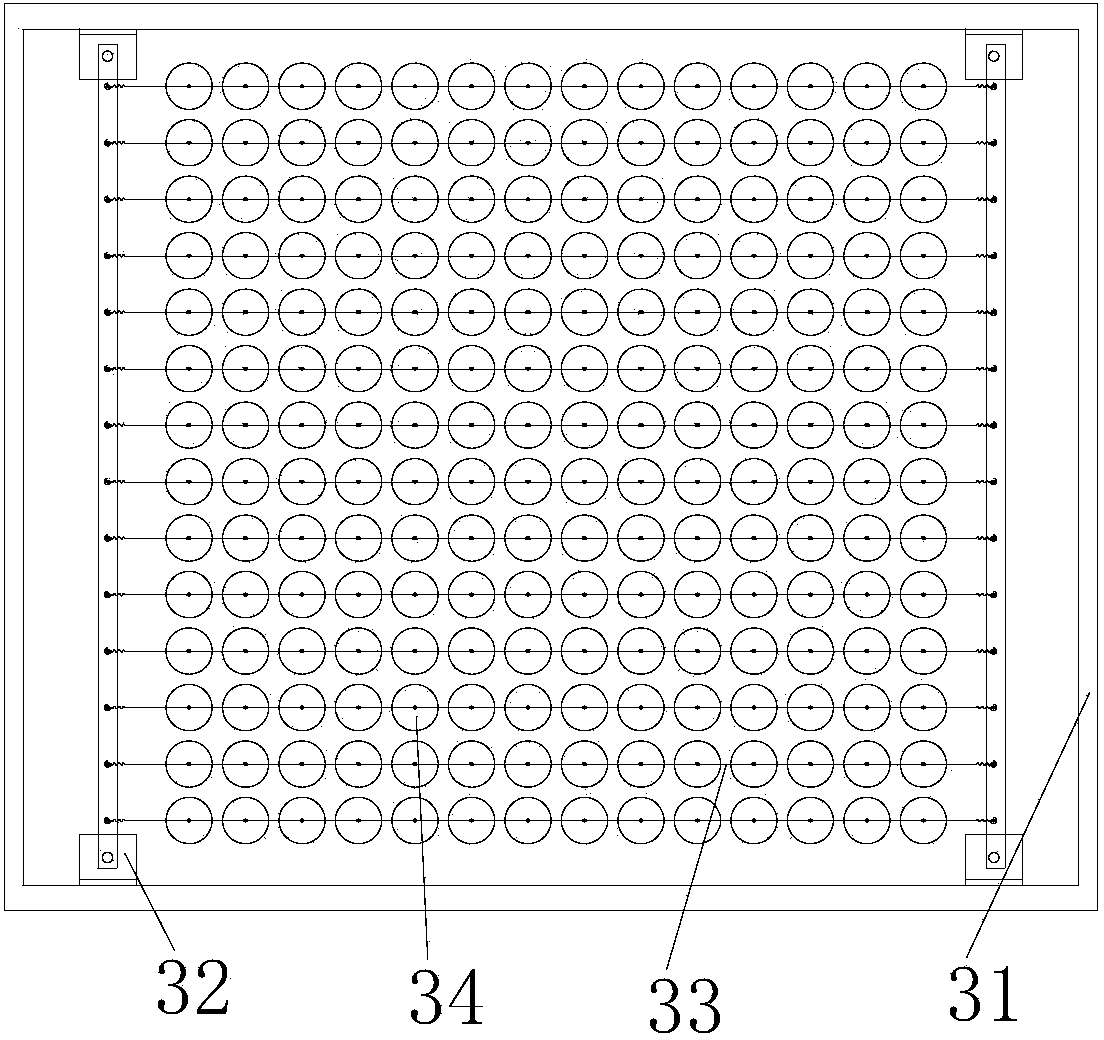

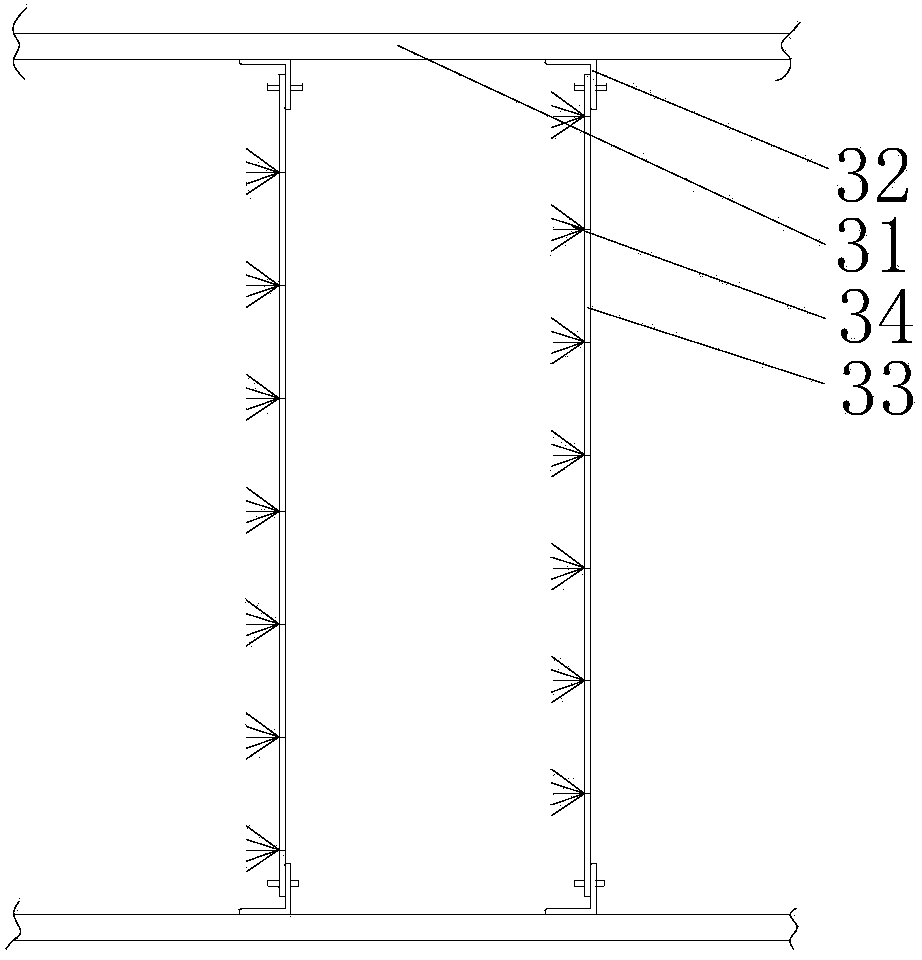

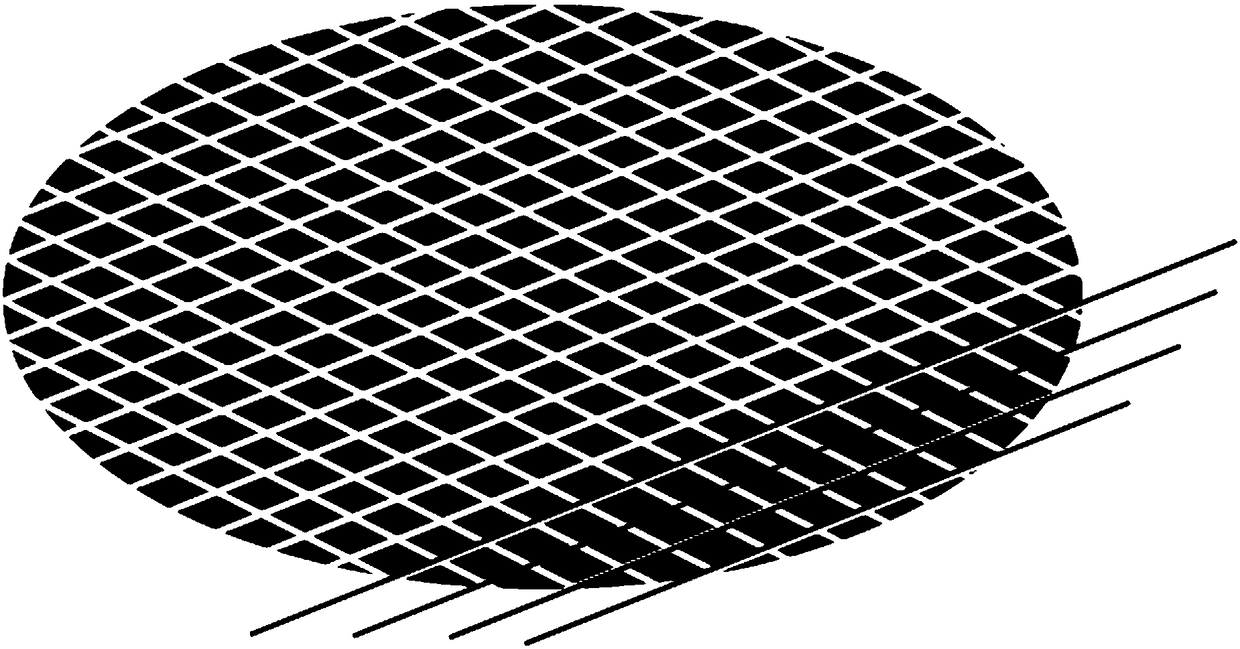

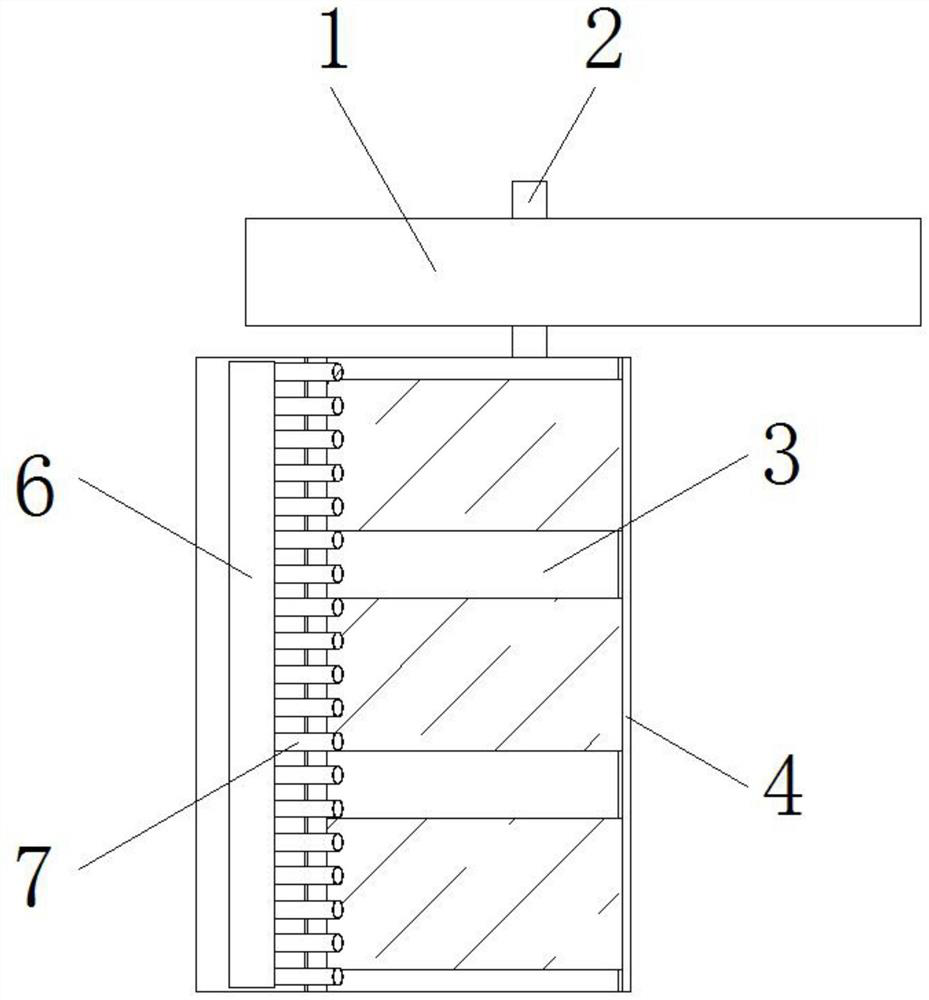

Evaporating plating device and OLED panel evaporating plating method

PendingCN109536886AReduce slipMinimize Wrinkle of Metal MaskVacuum evaporation coatingSputtering coatingOrganic filmCrucible

The invention relates to the technical field of evaporating plating, and provides an evaporating plating device and an OLED panel evaporating plating method. The evaporating plating device comprises aheating crucible which is used for heating evaporating plating materials to enable the evaporating plating materials to be evaporated; and further comprises a magnetic plate which is positioned abovethe heating crucible, provided with magnetism and used for fixing a target substrate which is going to receive the evaporating plating. More than two magnetic objects are arranged in the magnetic plate, wherein the magnetism of the magnetic plate is gradually decreased from the middle to the edge. According to the technical scheme, the magnetism of the magnetic plate in the evaporating plating device is gradually decreased from the middle to the edge, so that the attraction force on the middle part of the target substrate is larger than the attraction force on the edge, the slippage of the target substrate and wrinkles on a metal mask are reduced, and the bonding degree of the metal mask and the substrate can be improved; and the phenomenon that an evaporating plating organic film patternis abnormal can be avoided, the debris risk of the target substrate can be reduced and the service life of the metal mask can be prolonged, so that the production efficiency is effectively improved,and the quality and the production progress of products are ensured.

Owner:FUJIAN HUAJIACAI CO LTD

Elastic buffering decorating plate

Owner:ZHEJIANG CHANGXING BOTA BUILDING MATERIALS CO LTD

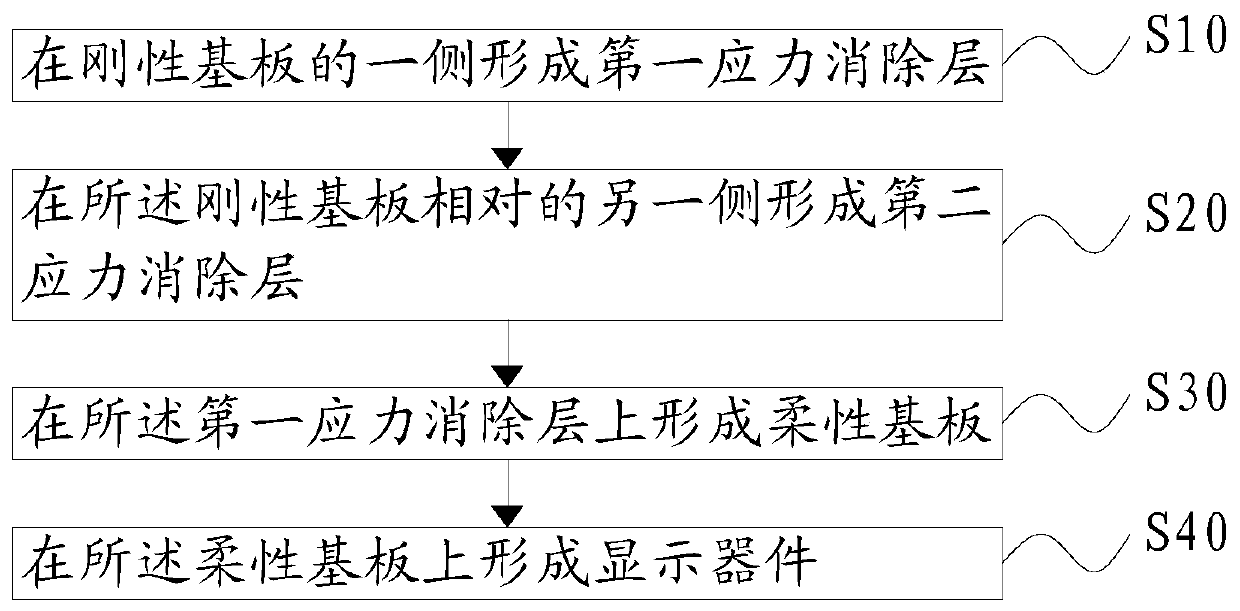

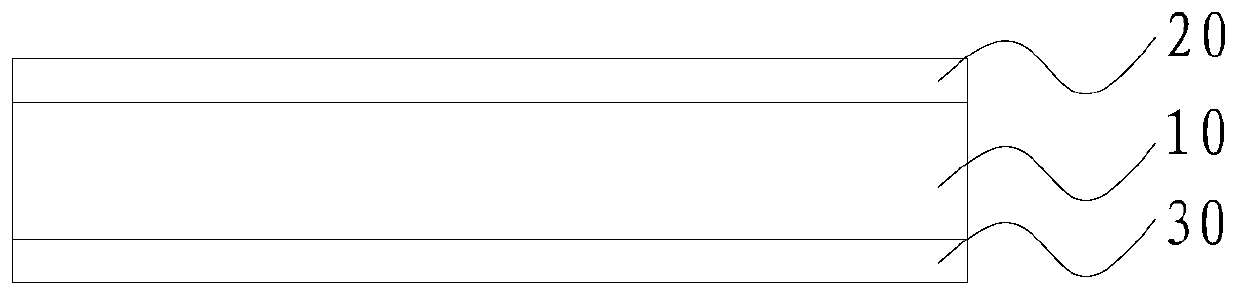

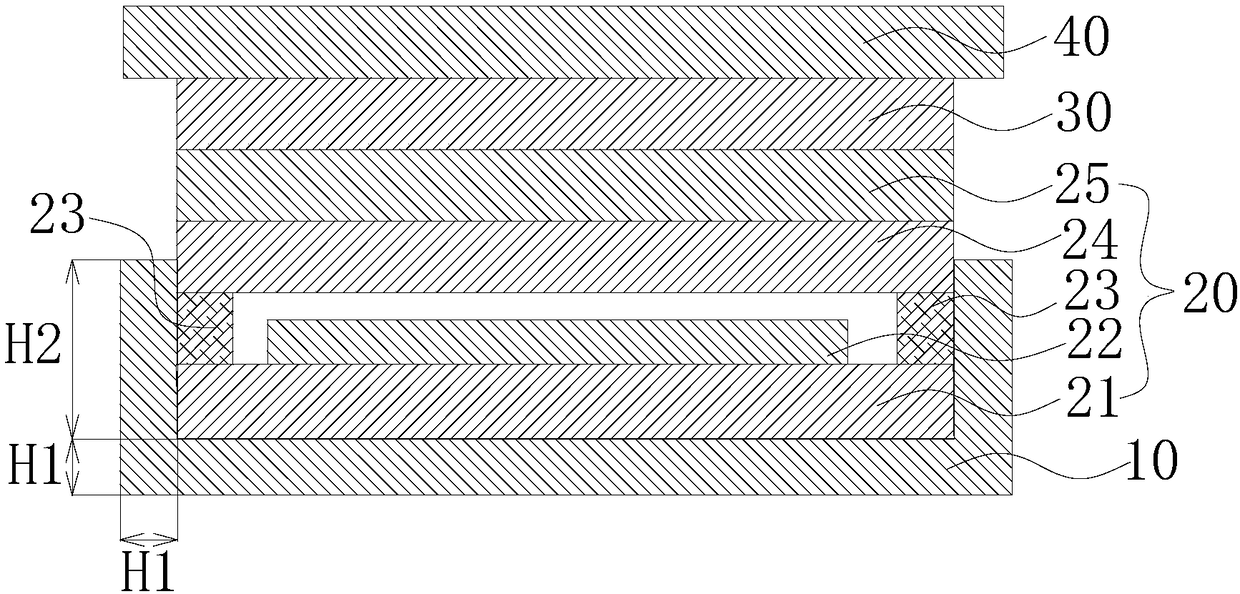

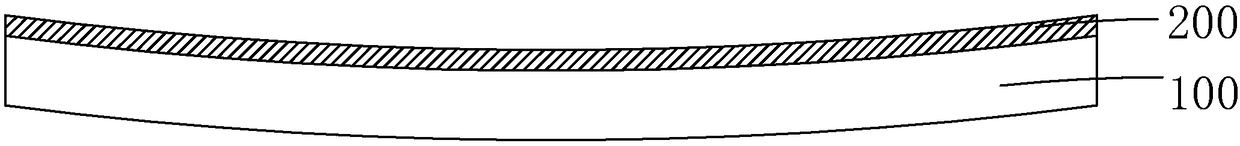

Flexible display panel and preparation method thereof

The invention discloses a preparation method of a flexible display panel. The preparation method comprises the following steps: forming a first stress relief layer on one side of a rigid substrate; forming a second stress relief layer on the other opposite side of the rigid substrate; forming a flexible substrate on the first stress relief layer; and forming a display device on the flexible substrate. The stress relieving layers are prepared on the two opposite sides of the rigid substrate respectively, acting force on the rigid substrate is counteracted by means of the fact that materials onthe two sides are the same in deformation quantity and opposite in deformation direction, stress borne by the rigid substrate is reduced, and therefore the warping problem of the rigid substrate is solved. Besides, when the stress relief layer is made of organic materials, the problems of warping of the rigid substrate and difficult tape-out of a machine in the manufacturing process can be solved,meanwhile, the organic layer can protect the rigid substrate, and the risk of tape-out breakage is reduced.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

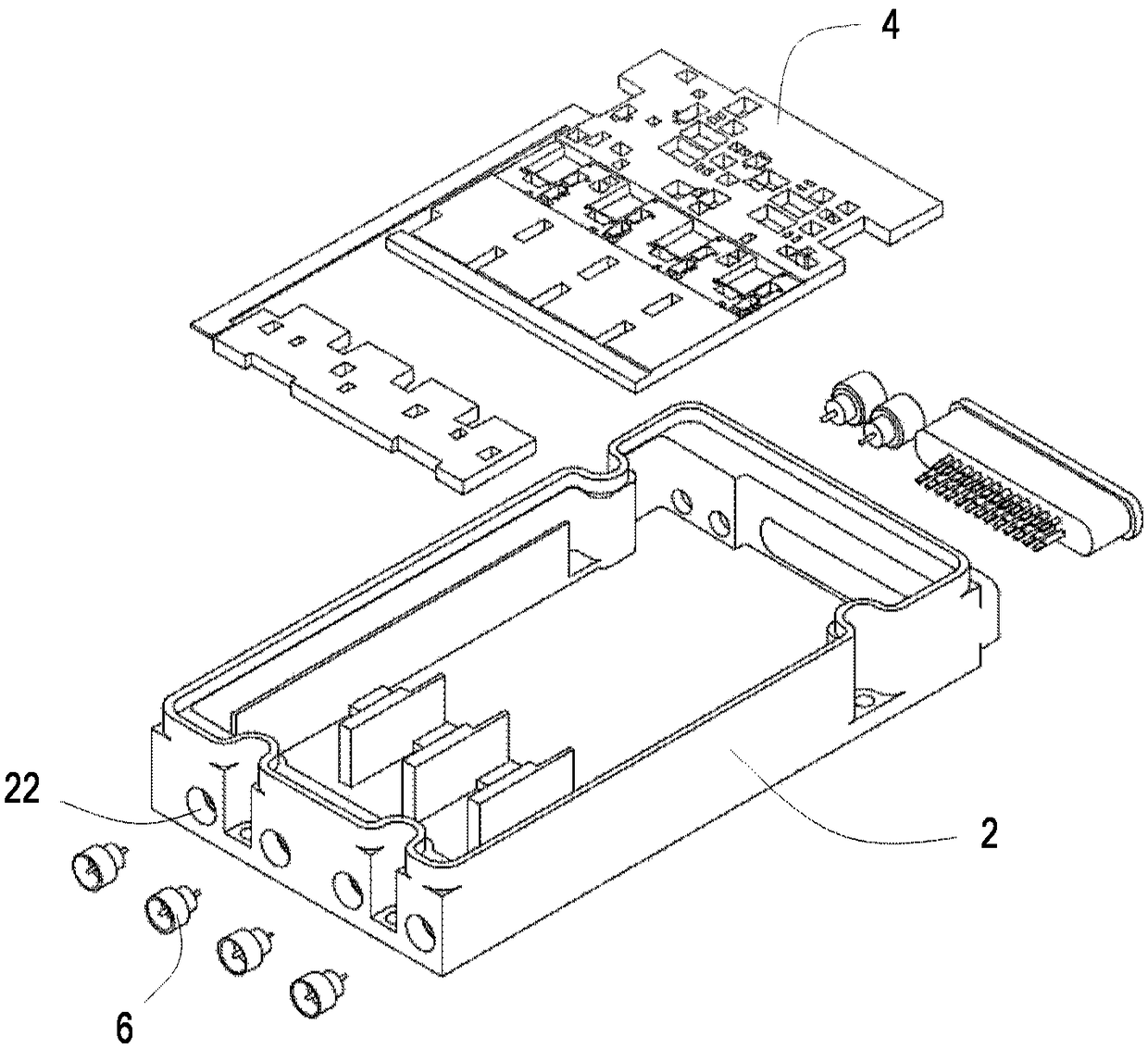

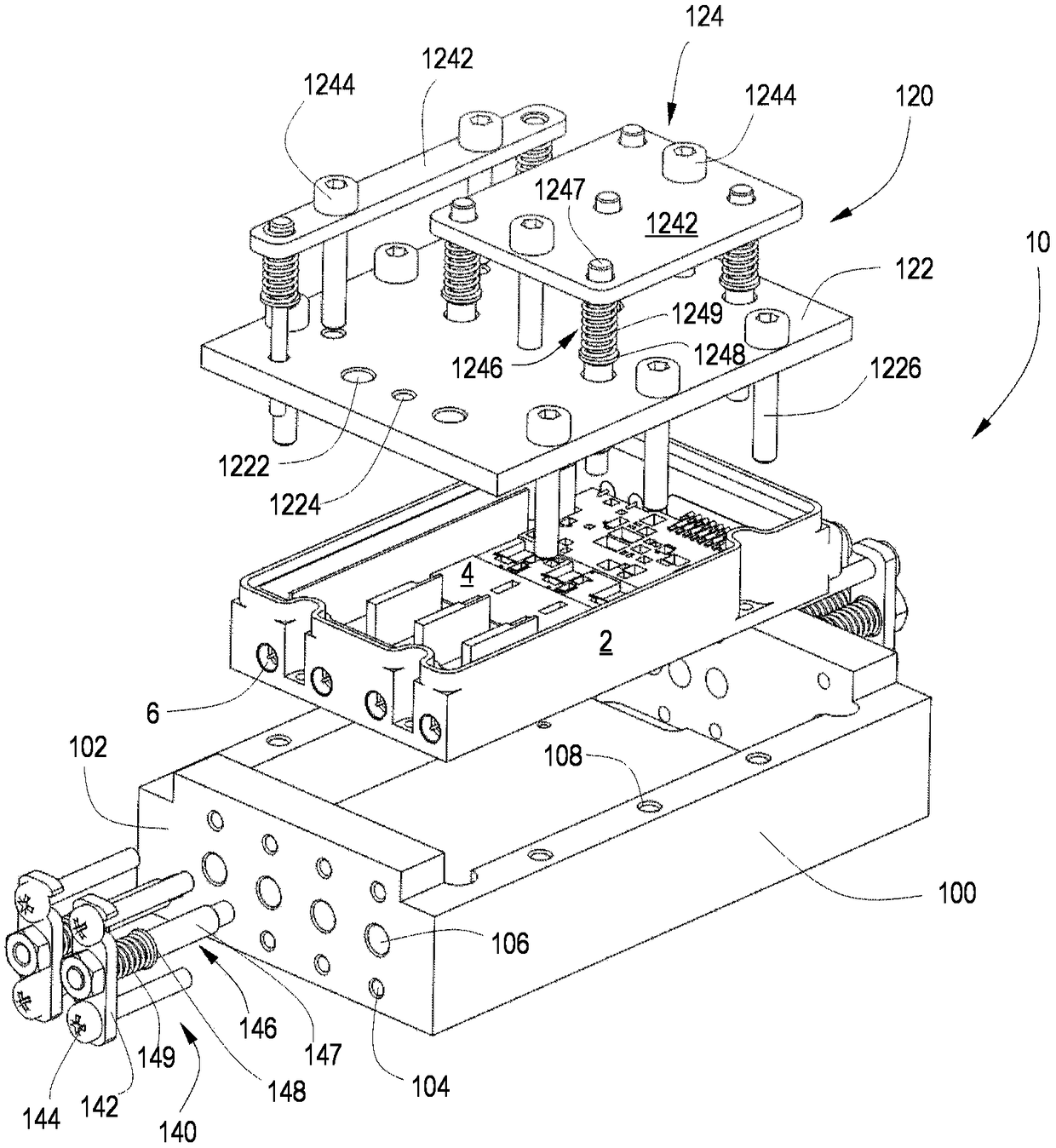

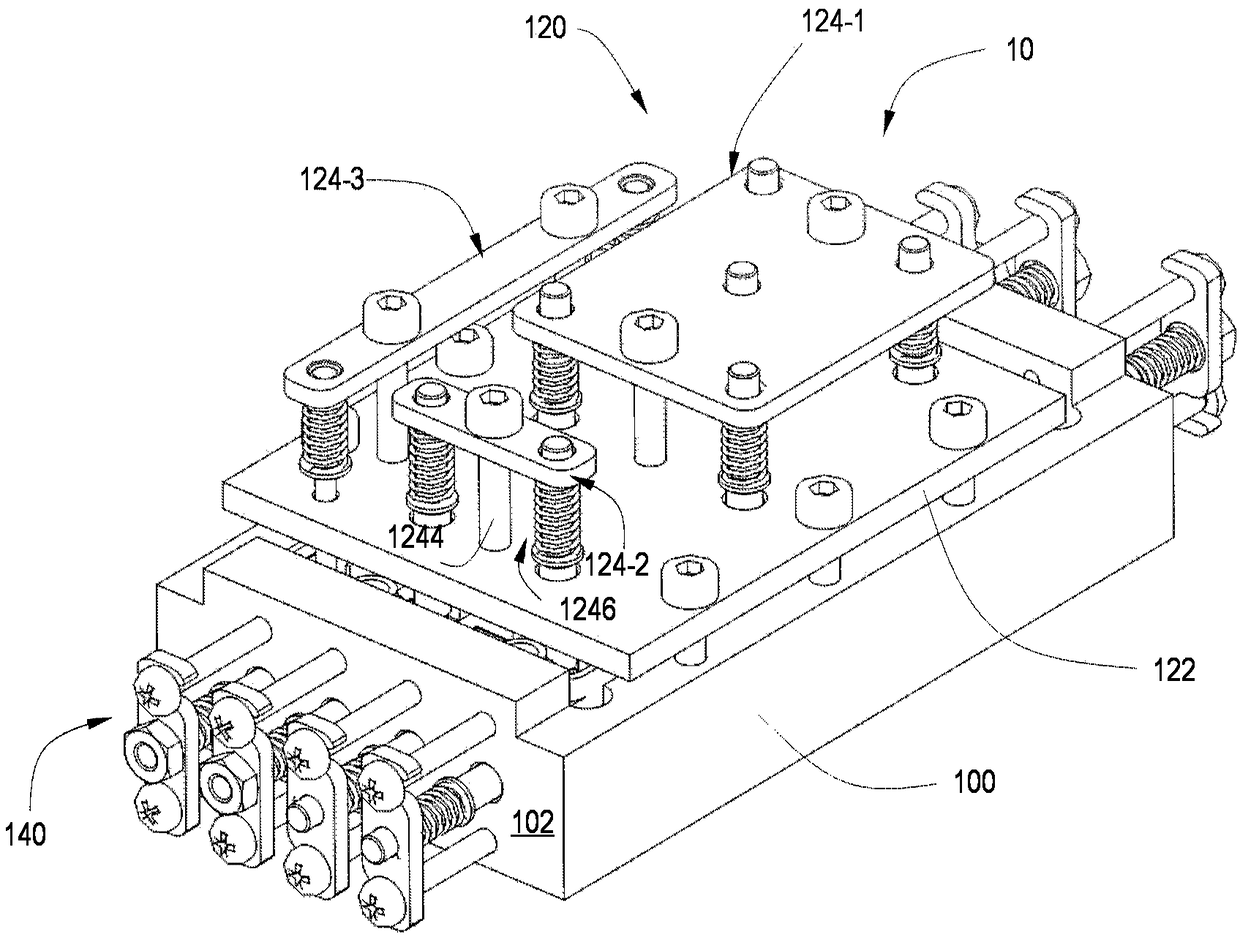

Tool clamp for welding transceiver assembly

InactiveCN108655650AImproving the impact of welding qualityAvoid damageWelding/cutting auxillary devicesAuxillary welding devicesTransceiverThermal deformation

The invention provides a tool clamp for welding a transceiver assembly. The tool clamp comprises a shell for placing the to-be-welded transceiver assembly, a base plate compressing assembly and a connector compressing assembly, wherein the base plate compressing assembly is used for relatively stably supporting the base plate of the transceiver assembly in the housing of the transceiver assembly;and the connector compressing assembly is used for relatively stably supporting the connector of the transceiver assembly in the end wall of the housing. Through compressing the connector and the baseplate, the influence of thermal deformation of the base plate to the welding quality during the welding process can be improved, and the problems about welding cavity, warping, non-tightness and non-firmness during the welding process can be effectively avoided.

Owner:INST OF ELECTRONICS CHINESE ACAD OF SCI

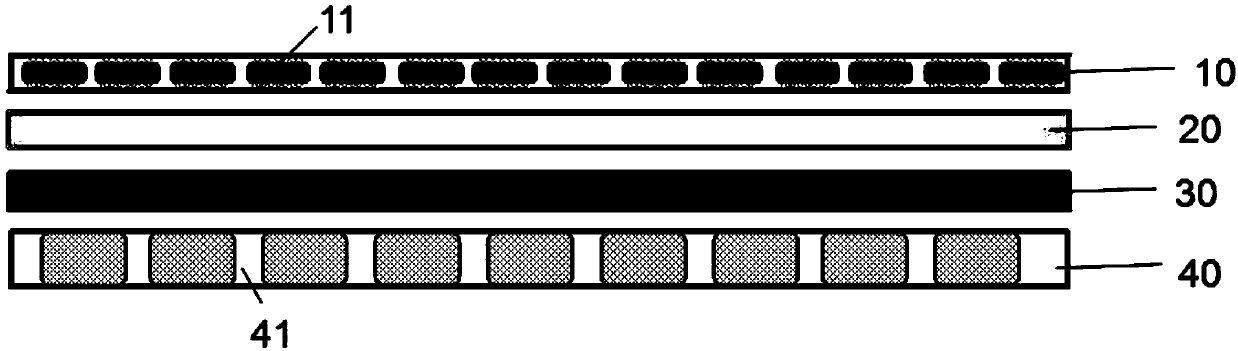

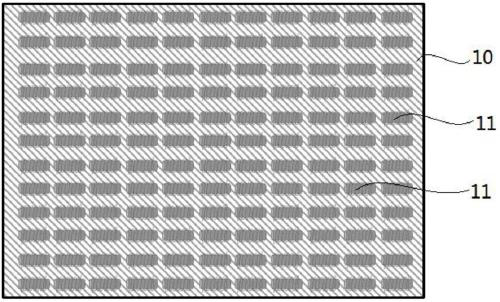

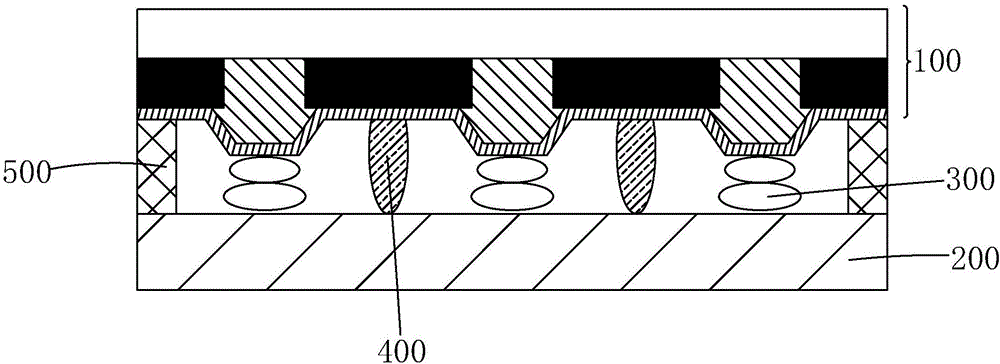

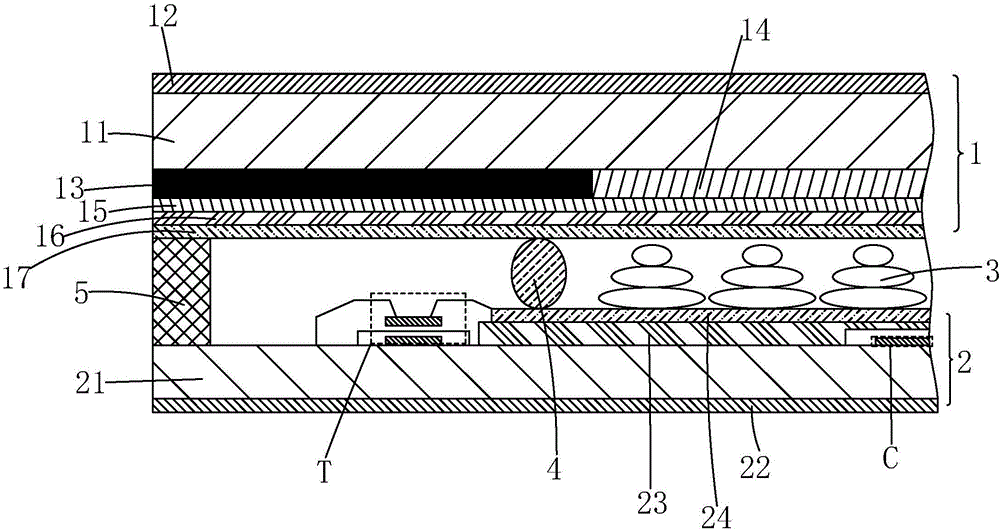

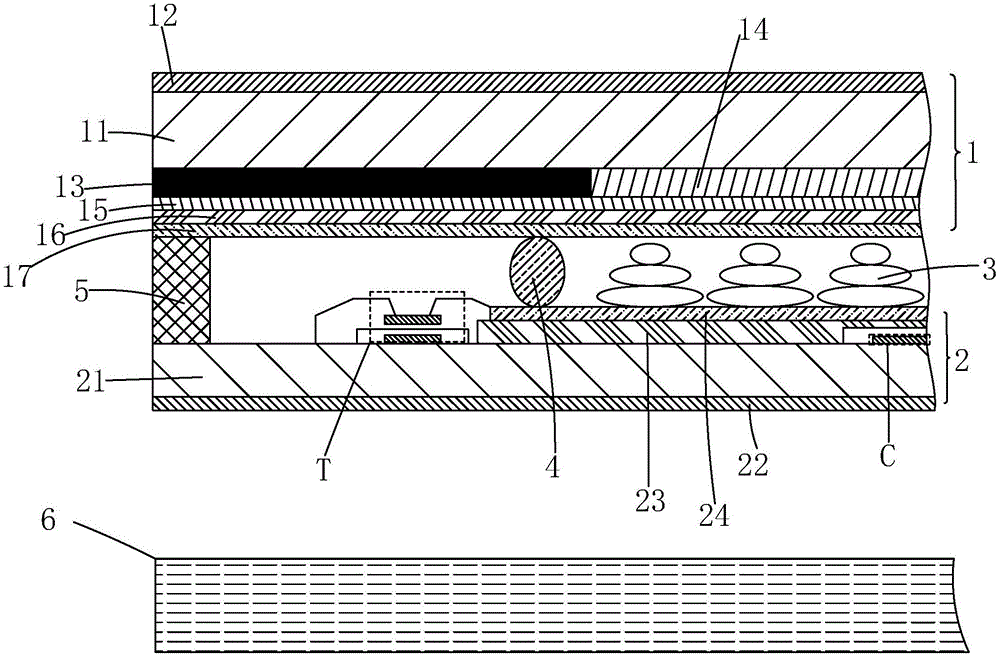

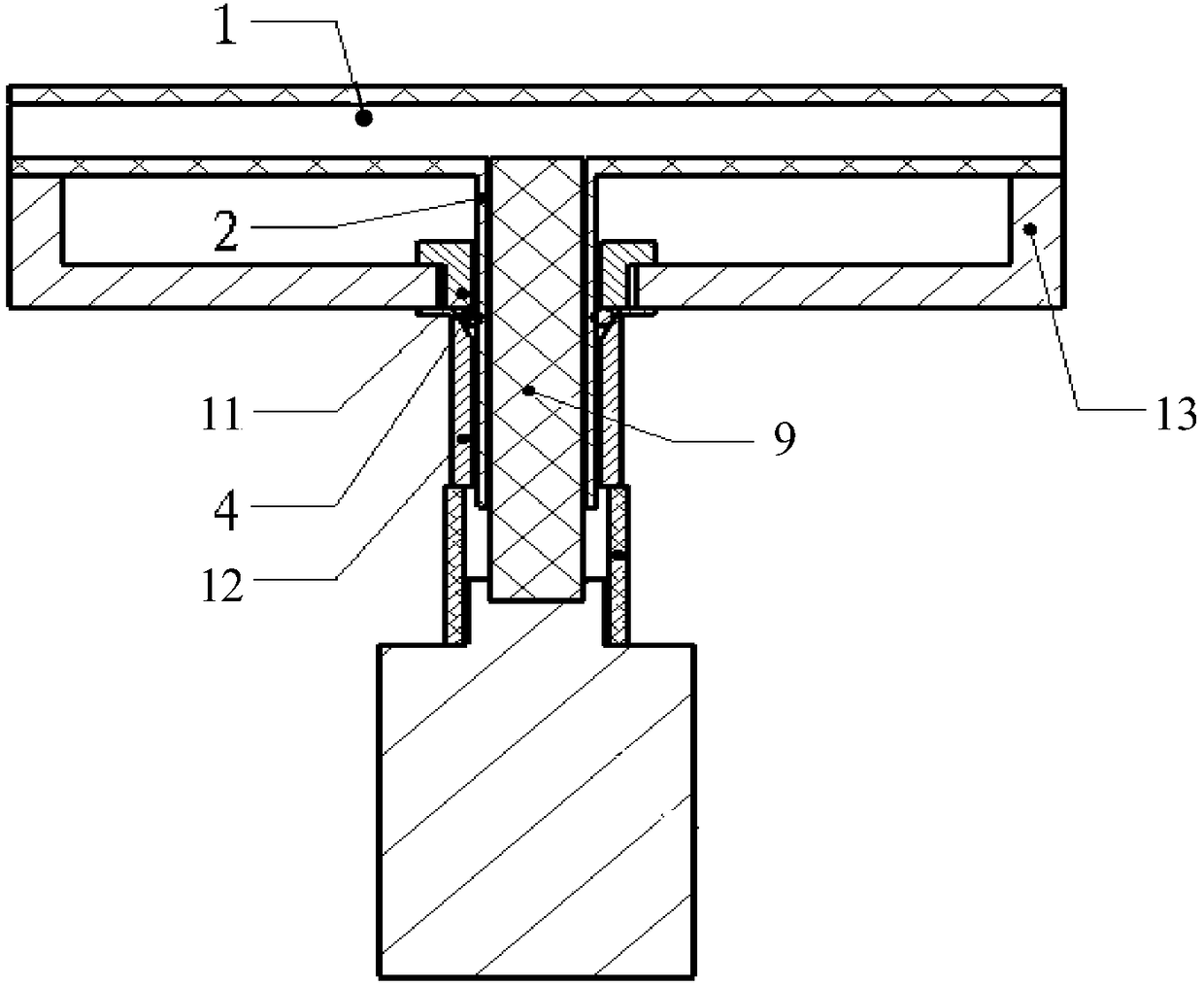

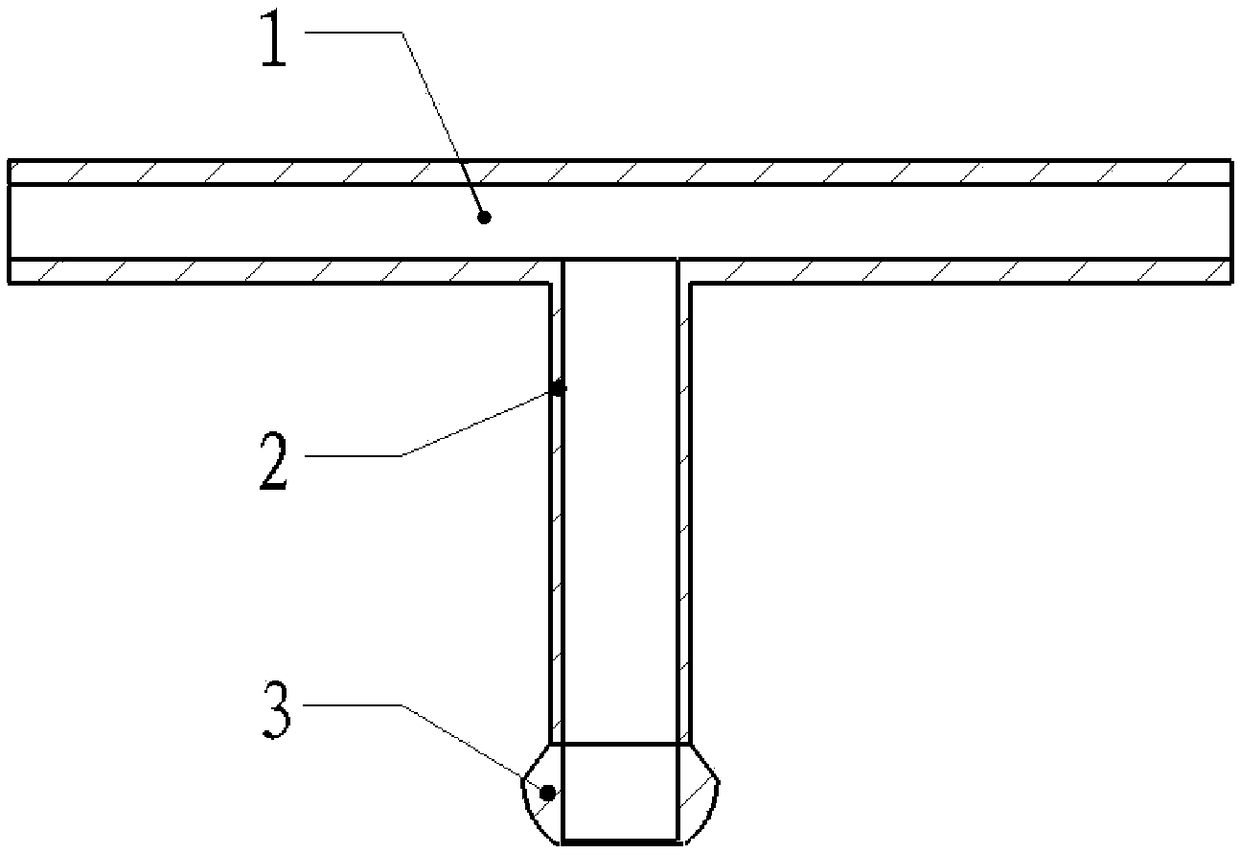

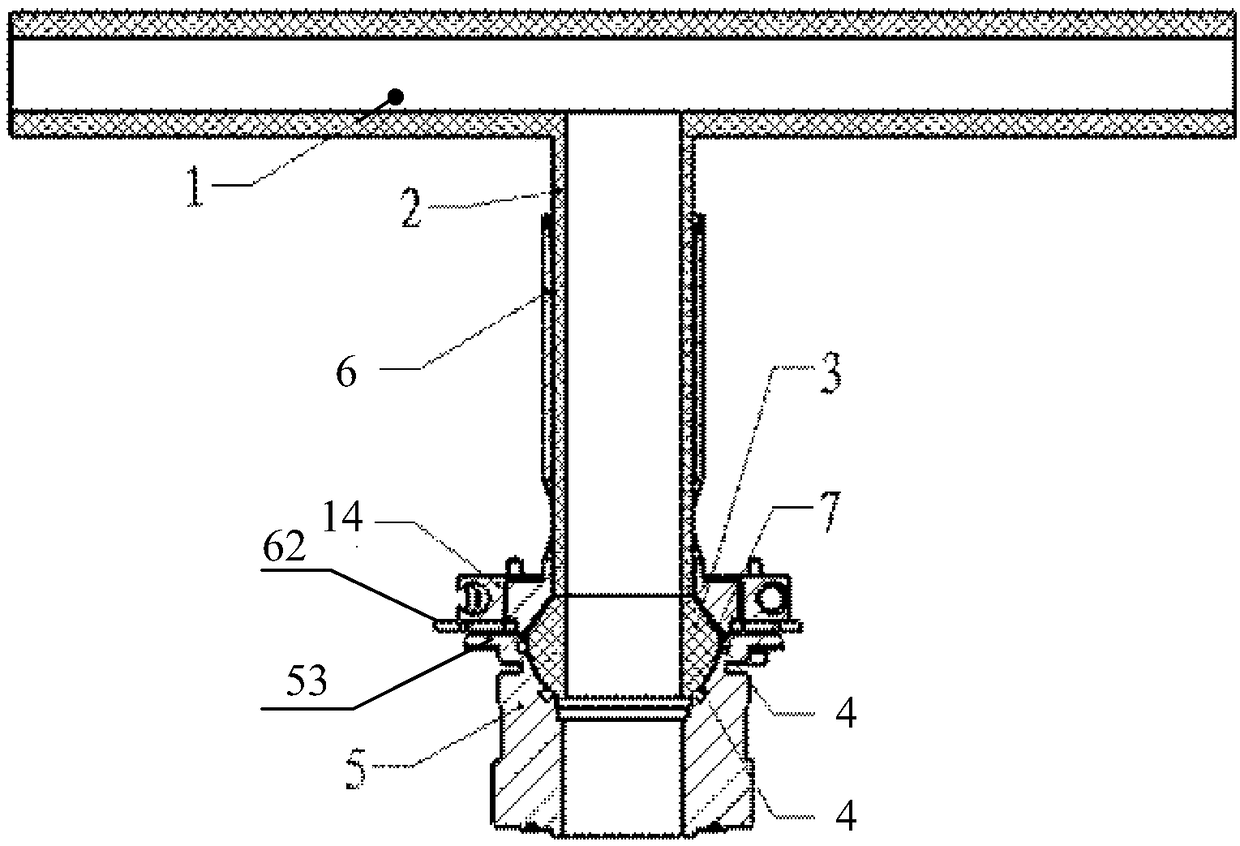

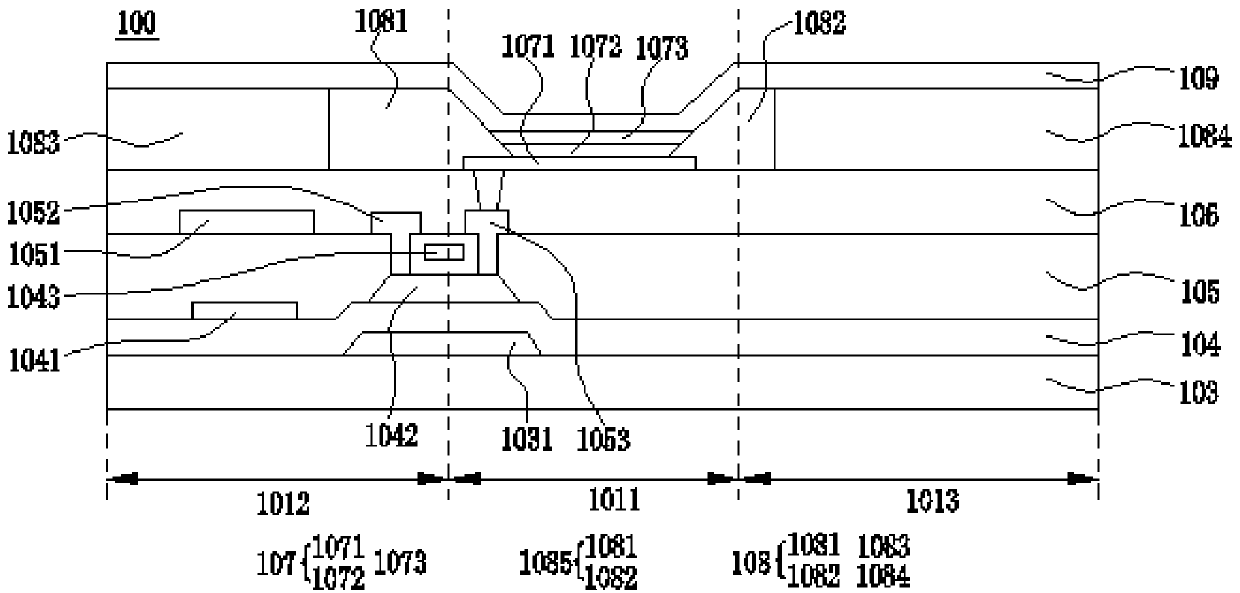

Liquid crystal display panel and liquid crystal display device

InactiveCN106773357AControl deformationUniform thicknessNon-linear opticsLiquid-crystal displayEngineering

The invention provides a liquid crystal display panel and a liquid crystal display device. The liquid crystal display panel includes a color filter (1), a thin film transistor array substrate (2) facing the color filter (1), a liquid crystal arranged between the color filter (1) and the thin film transistor array substrate (2), and a plurality of light resistance spacing columns (4) which are supported between the color filter (1) and the thin film transistor array substrate (2) in a zone between the color filter (1) and the thin film transistor array substrate (2); and the light resistance spacing columns (4) are made of a glue material, one ends of the light resistance spacing columns (4) are fixedly attached on the color filter (1), and the other ends of the light resistance spacing columns (4) are fixedly attached on the thin film transistor array substrate (2). The liquid crystal display panel has high mechanical strength, can lower fracture risk, can allow even thickness of the liquid crystal, and can improve the product yield.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

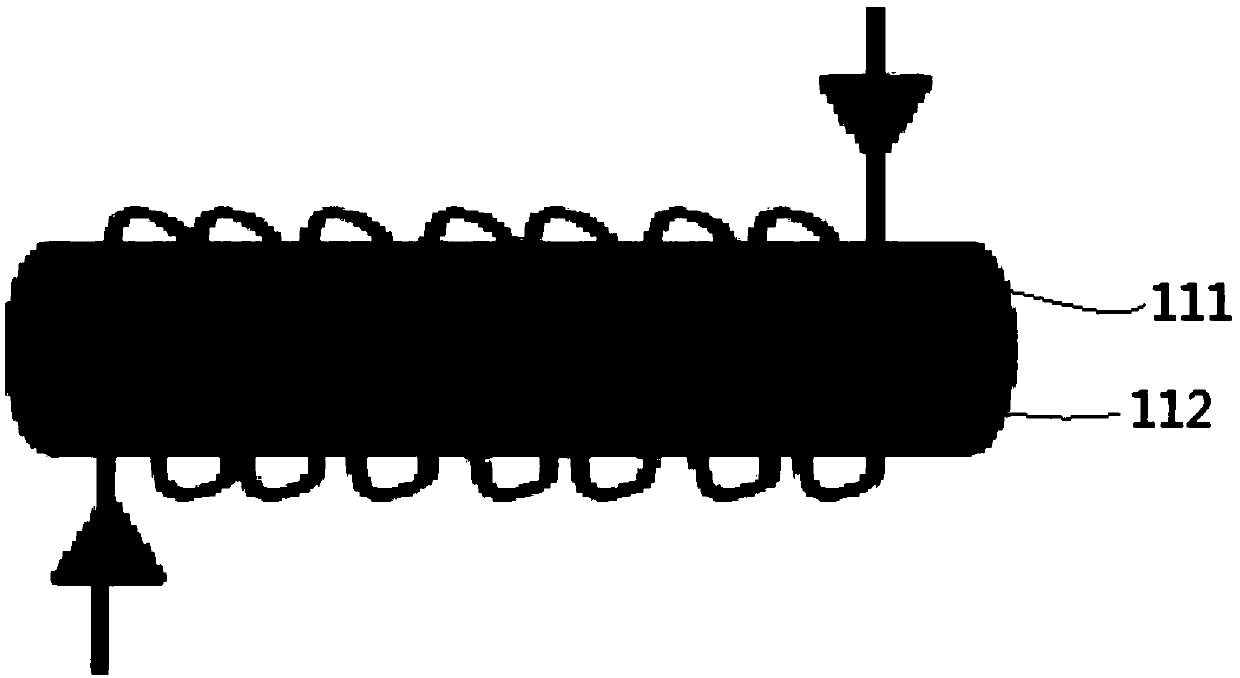

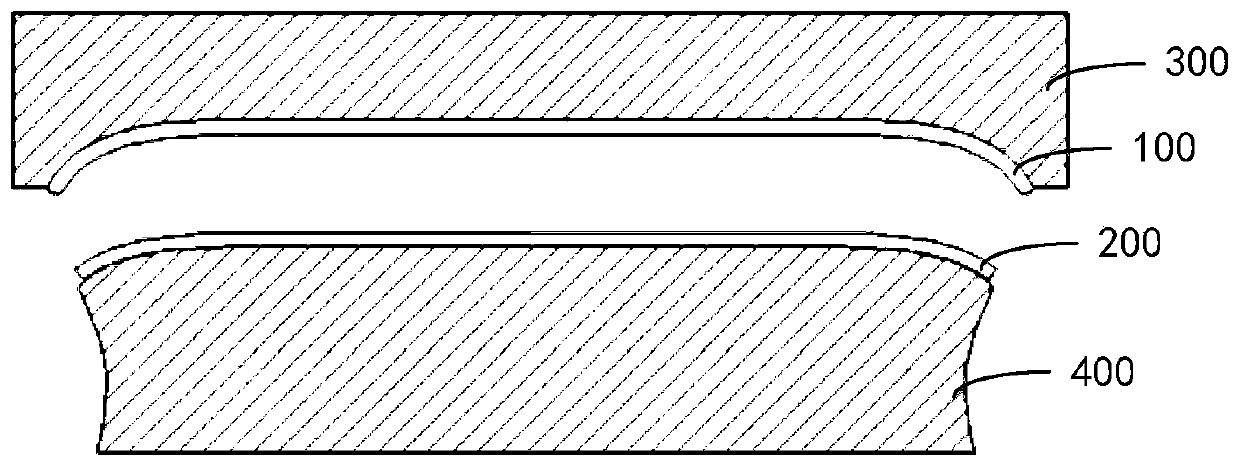

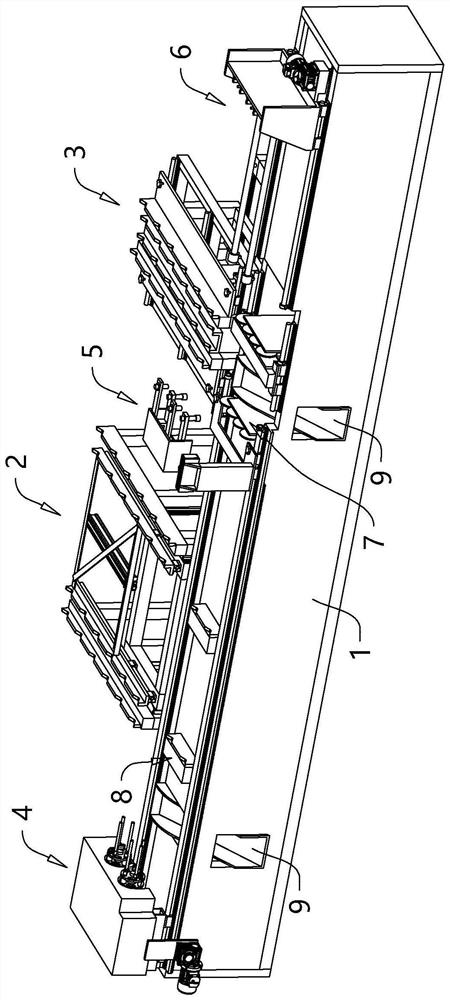

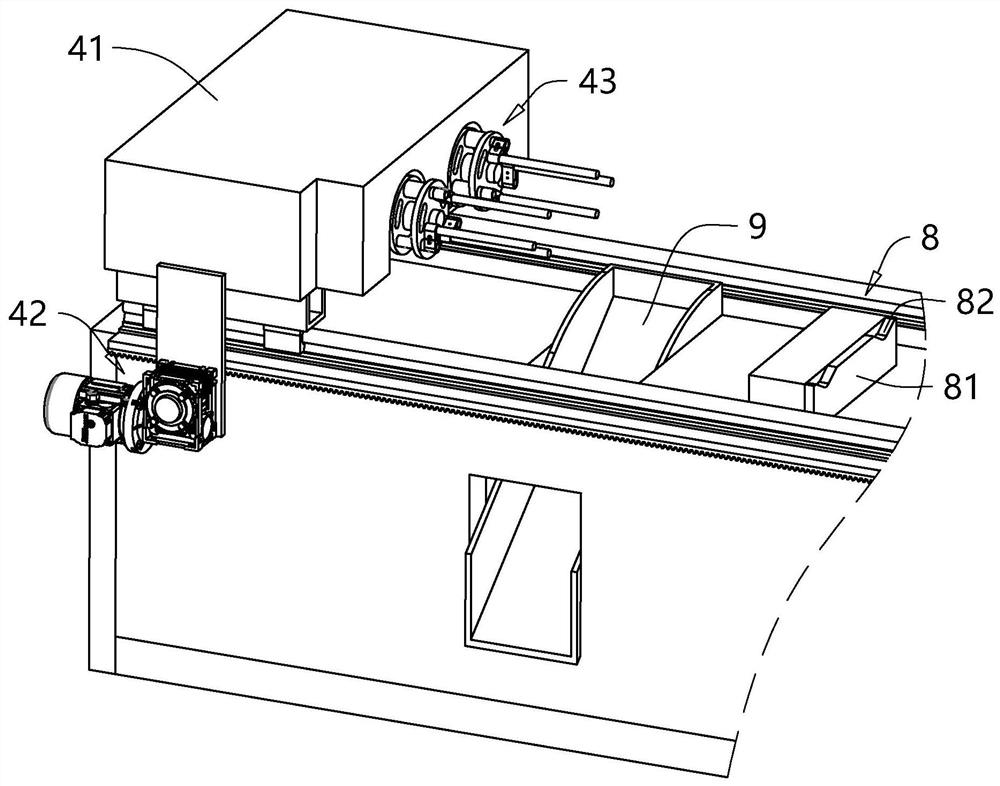

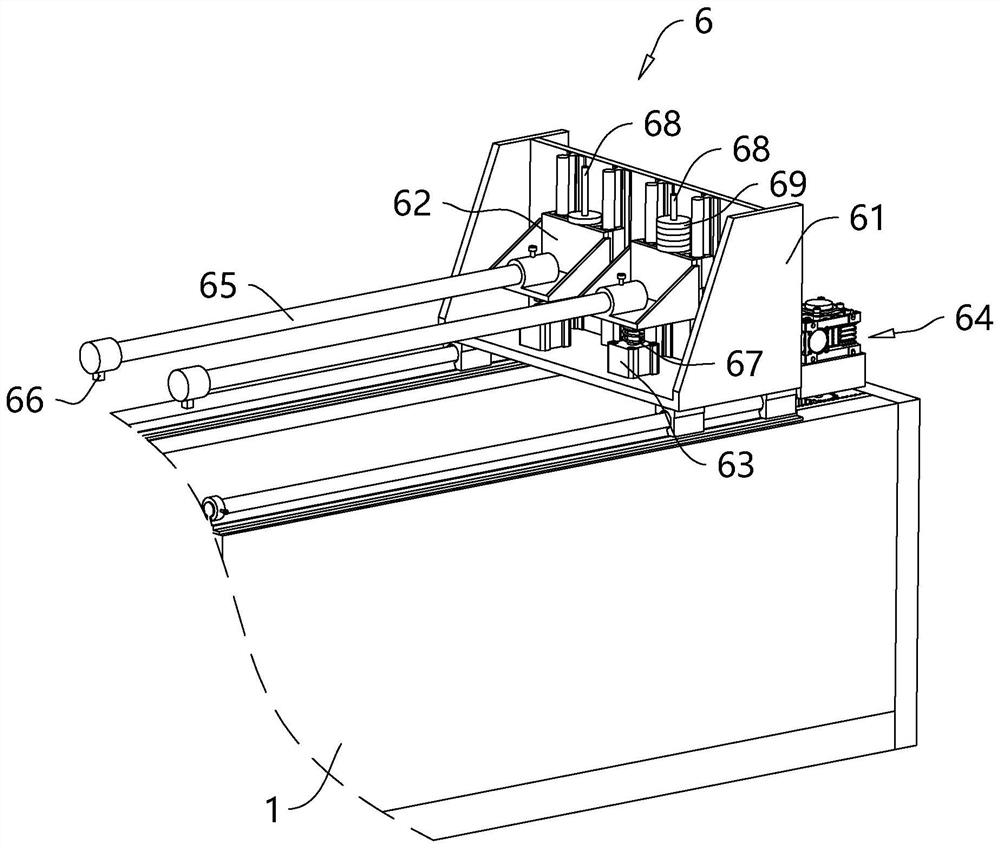

Fitting roller, fitting jig and fitting method of flexible screen and curved cover plate

The embodiment of the invention provides a fitting roller, a fitting jig and a fitting method of a flexible screen and a curved cover plate. The fitting roller comprises a roller cylinder and a fitting part. The fitting part is made of an elastic material and provided with a first bottom surface, a second bottom surface and a peripheral surface. The second bottom surface is attached to the surfaceof the roller cylinder. The first bottom surface comprises a main fitting surface and an end fitting surface. The main fitting surface is parallel to the second bottom surface and is used for being matched with a bottom surface main body of the curved cover plate. The end fitting surface is used for being matched with the bottom surface end angle of the curved cover plate and protrudes out of themain fitting surface. The peripheral surface is connected with the first bottom surface and the second bottom surface and is used for being matched with the curved surface of the curved cover plate.By means of the embodiment of the fitting roller, the fitting jig and the fitting method, roller press fit is adopted, the local fitting sequence of the flexible screen is optimized, and the stress condition of the flexible screen is improved, so that the sufficient fit of the flexible screen and the curved cover plate can be achieved.

Owner:BOE TECH GRP CO LTD +1

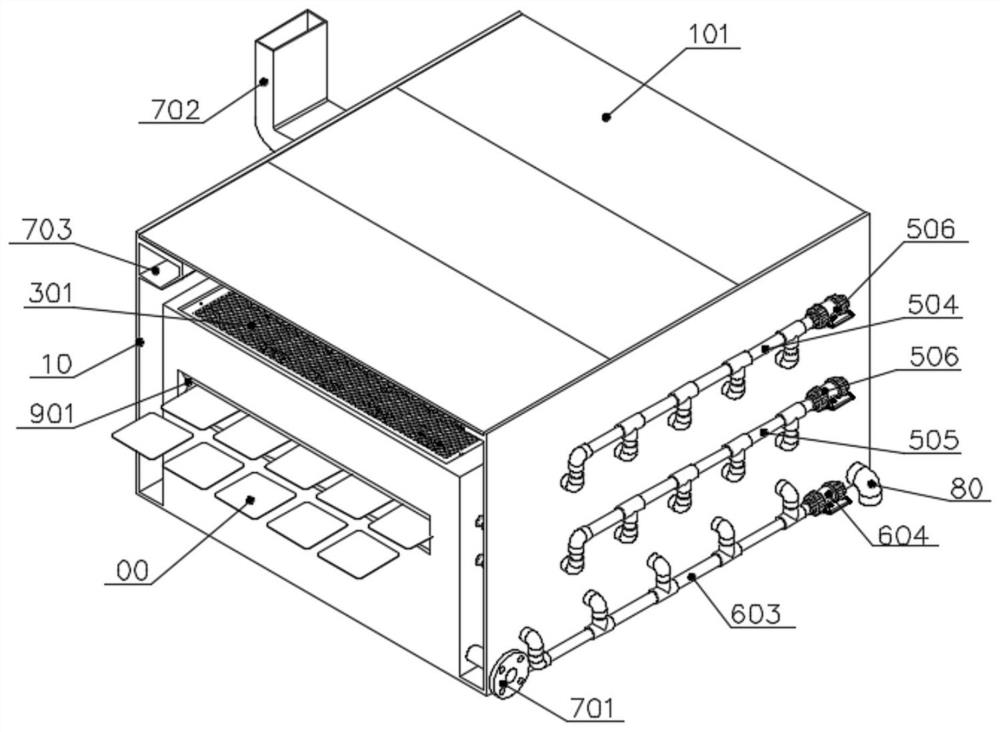

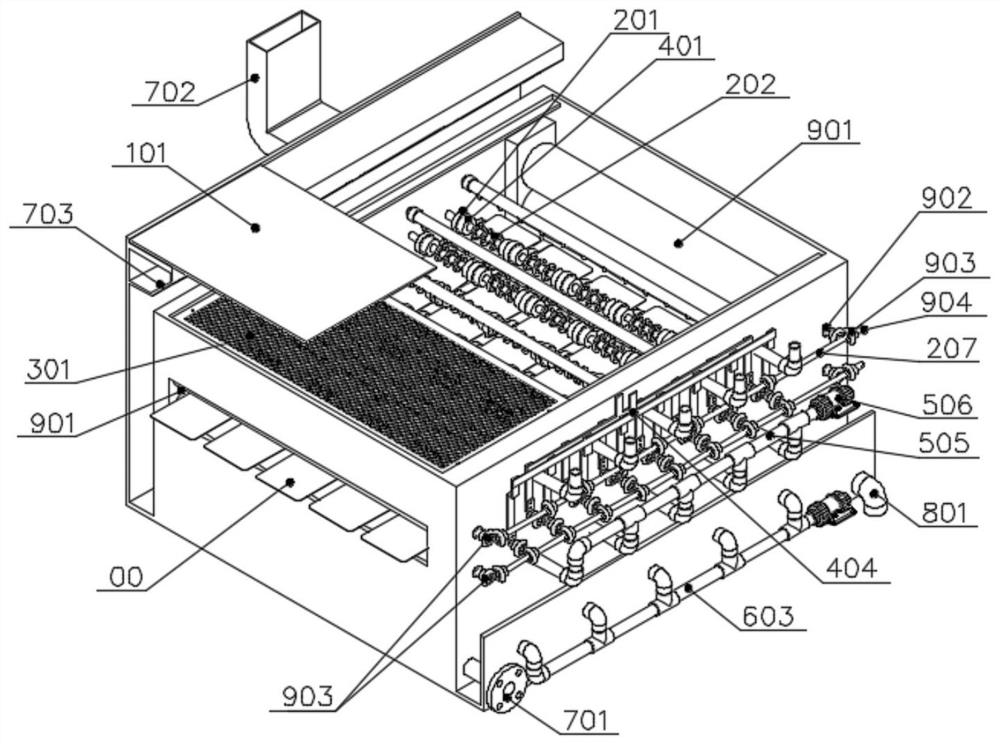

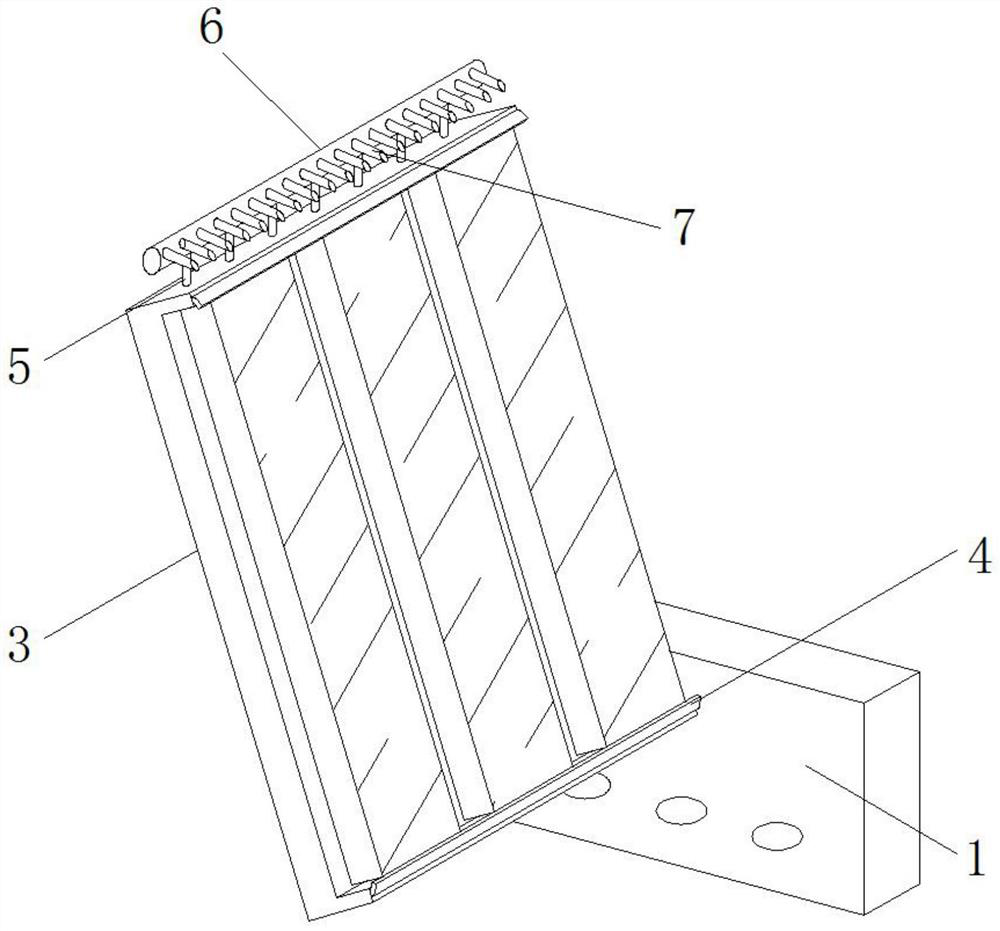

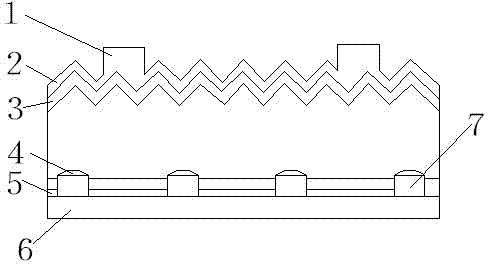

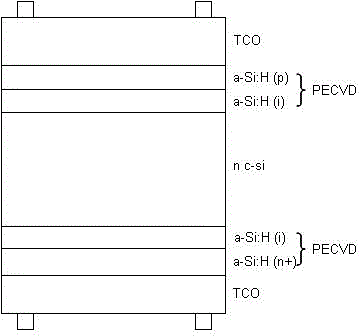

Horizontal coating device for preparing HIT crystalline silicon solar cell

PendingCN114318471AImprove performancePass smoothlyElectrolysis componentsFinal product manufactureElectrical batteryCirculator pump

The invention discloses a horizontal coating device for preparing an HIT crystalline silicon solar cell, which comprises a cell, a tank body, a transmission mechanism, an anode mechanism, a cathode mechanism, a spraying mechanism, an inflating mechanism, a waste discharging mechanism, a circulating filtering mechanism and a liquid blocking mechanism, the anode mechanism and the cathode mechanism are arranged in the tank body and are connected with the rectifier to generate an electric field, the spraying mechanism, the inflating mechanism and the circulating filtering mechanism uniformly deposit copper ions in the tank to grid line electrodes of a plurality of columns of battery pieces, and the circulating filtering mechanism is connected into the spraying mechanism after being circularly filtered by the circulating pump and the filter through the overflow gathering port. And the inlet section and the outlet section of the tank body are respectively provided with a liquid blocking mechanism. By adopting the horizontal coating, the conversion process of battery pieces at the feeding and discharging ends of electroplating equipment between the horizontal direction and the vertical direction is omitted, a hanging tool is not used, the piece breaking rate is reduced, the electroplating quality is improved, the production yield is increased, and the labor cost and the production cost are reduced.

Owner:GS SOLAR FU JIAN COMPANY

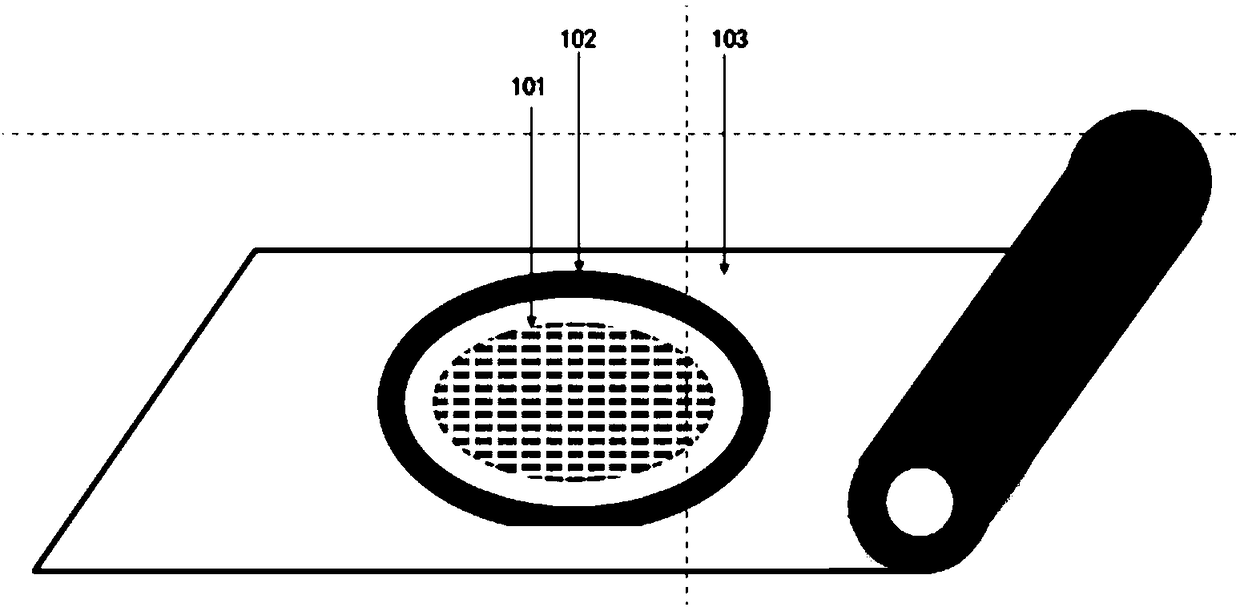

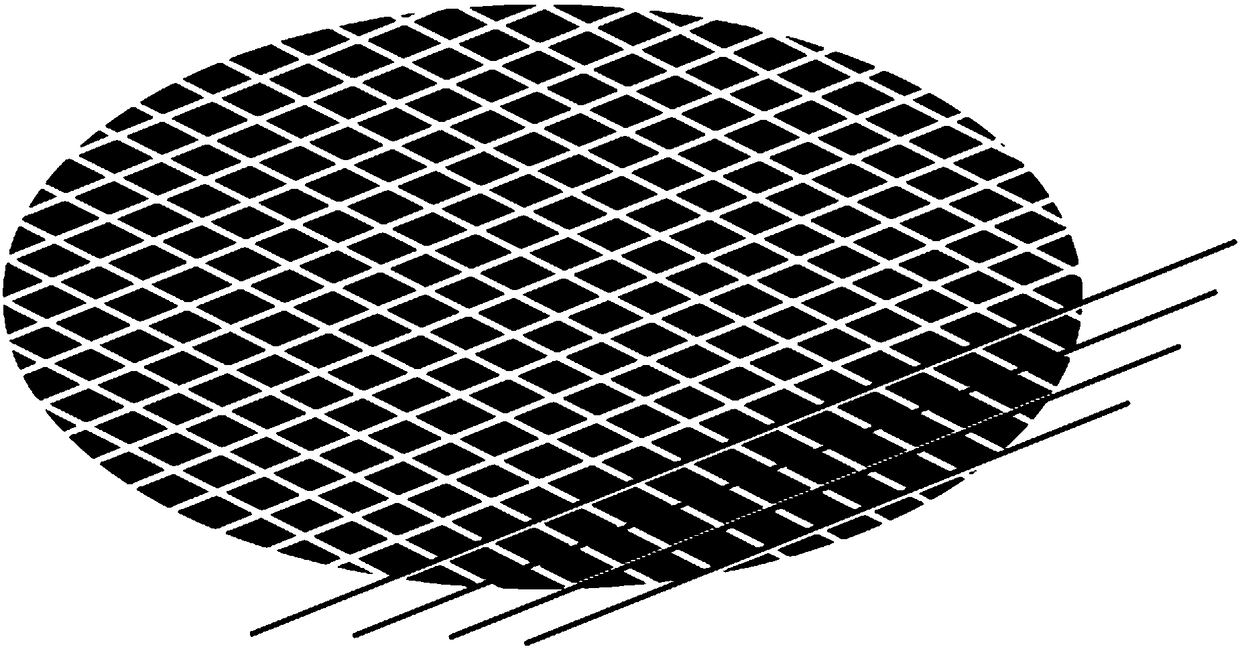

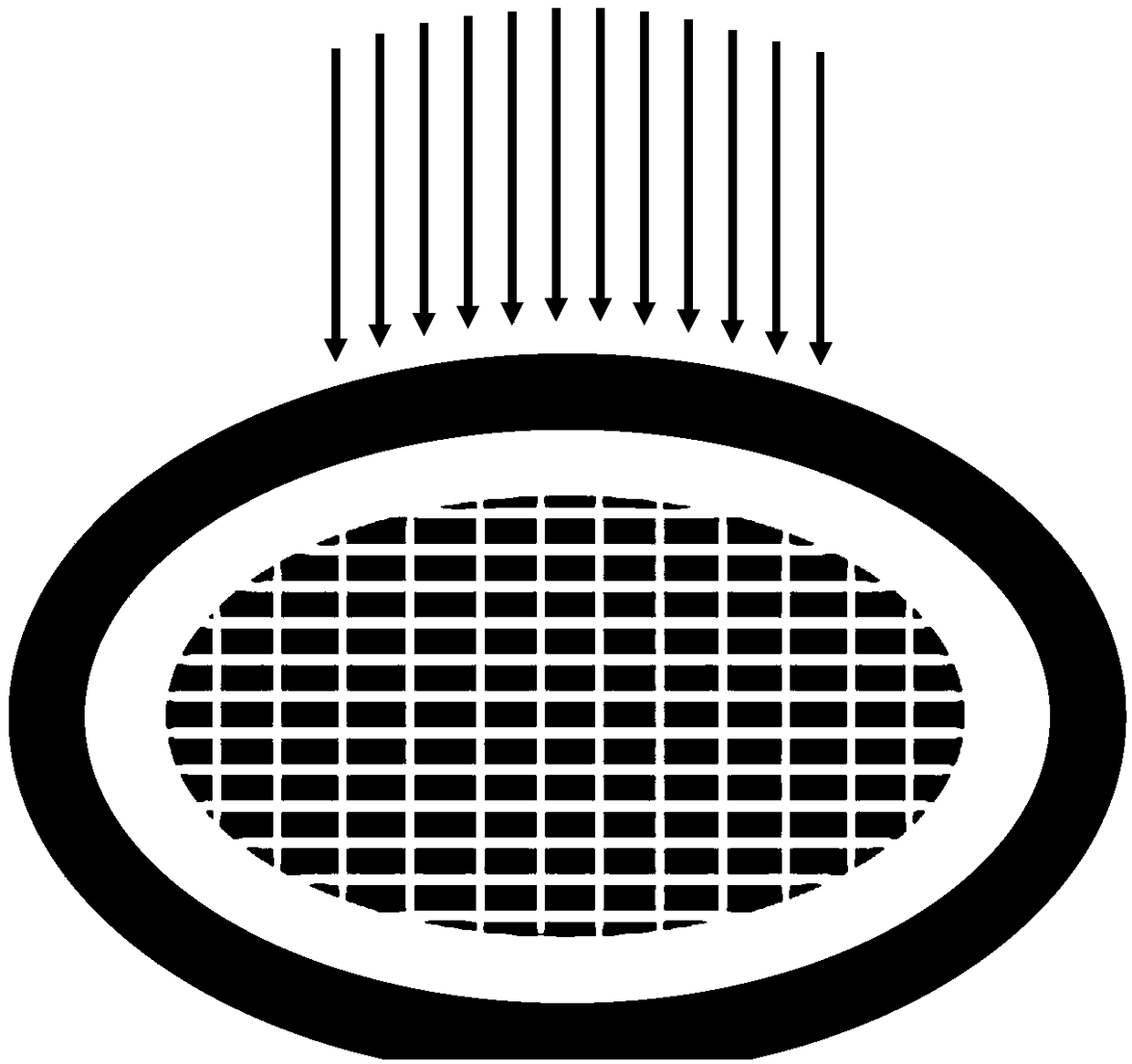

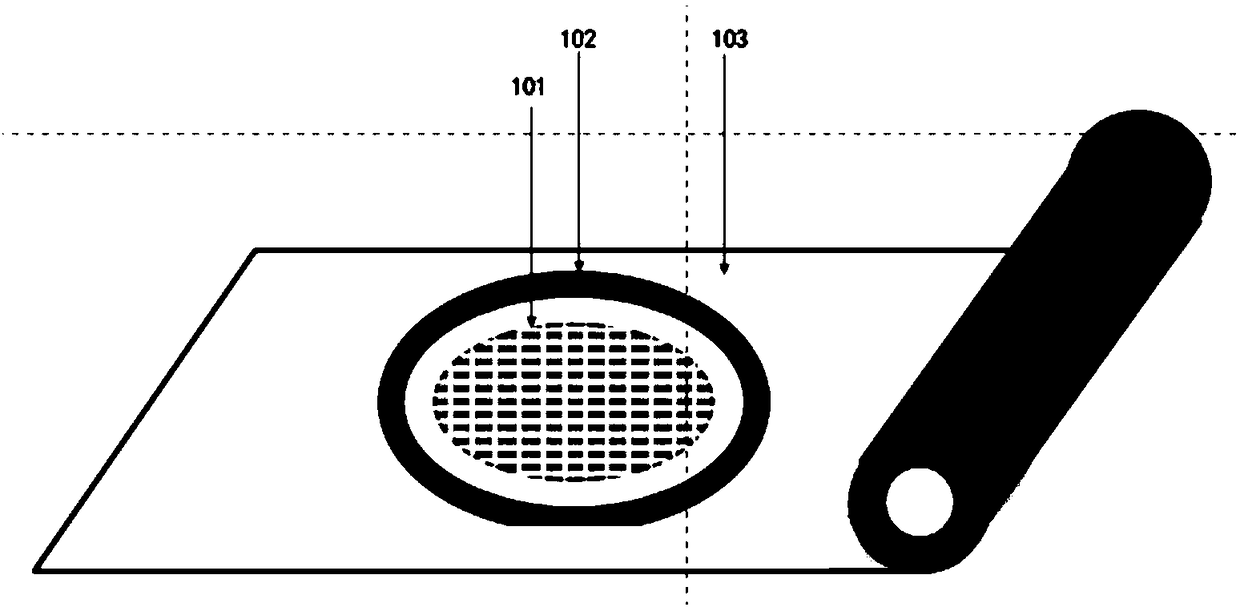

Beam splitting laser cutting method for silicon carbide based wafers

ActiveCN109352185AReduced Risk of FragmentationReduce heat damageLaser beam welding apparatusBeam patternAfter treatment

The invention discloses a beam splitting laser cutting method for silicon carbide based wafers, and the method is used for cutting silicon carbide based wafers into independent chips. The beam splitting laser cutting method for silicon carbide based wafers is characterized by comprising the following steps: pretreatment step; diffraction light splitting step: using an optical grating device (106)to split single-beam laser (105) into multi-beam laser (108) and forming beam patterns; beam splitting cutting step: using a laser cutter to cut silicon carbide based wafers; and after treatment step.The beam splitting laser cutting method for silicon carbide based wafers achieves the technical effects of improving the cutting rate of wafers and at the same time improving the cutting quality of wafers.

Owner:SHENZHEN STS MICROELECTRONICS

Material for filter chamber and filter chamber

InactiveCN104485496AReduce brittlenessImprove thermal conductivityWaveguide type devicesStress relievingDielectric resonator

The invention discloses a material for a filter chamber. The material for the filter chamber is a compound material formed by adding metal into silicon carbide; through the adding amount of the metal, the thermal conductivity of the compound material is higher than 170 W / m.K, and the thermal expansion coefficient is 6.5-11 ppm / DEG C. The compound material disclosed by the invention not only is suitable for manufacturing the chamber in aspect of performance, but also has the thermal expansion coefficient same as or similar to a dielectric resonator ceramic material; a dielectric resonator and the chamber are not required to adopt an existing integrated molding structure, so that the difficulties of processing and manufacturing are reduced; meanwhile, the material has relatively-higher thermal conductivity and can meet the thermal conduction needs, and the problem of unstable working frequency caused by temperature rise due to filter self loss is solved; the formed chamber has high bending strength and small brittleness, and fragmentation risk during the subsequent processing and the use process are reduced; the material is suitable for complicated chambers of a plurality of resonators, negative effect brought by tress concentration is eliminated, and subsequent assembly and use are ensured.

Owner:YUNNAN YUNTIANHUA

Beam splitting laser cutting method for silicon-based wafer

ActiveCN109352184AReduced Risk of FragmentationReduce heat damageLaser beam welding apparatusGratingBeam splitting

The invention discloses a beam splitting laser cutting method for a silicon-based wafer. The beam splitting laser cutting method for the silicon-based wafer is used for cutting the silicon-based waferinto independent chips, and is characterized by comprising the following steps of a pretreatment step; a diffraction light splitting step, wherein a single beam laser (105) is split into a pluralityof beams of laser (108) through a grating device (106) and a light beam pattern is formed; a beam splitting cutting step, wherein a laser cutter of the style is used for cutting the silicon-based wafer; and a postprocessing step. The beam splitting laser cutting method for the silicon-based wafer achieves the technical effects that the wafer cutting speed is increased, and meanwhile the cutting quality of the wafer is improved.

Owner:SHENZHEN STS MICROELECTRONICS

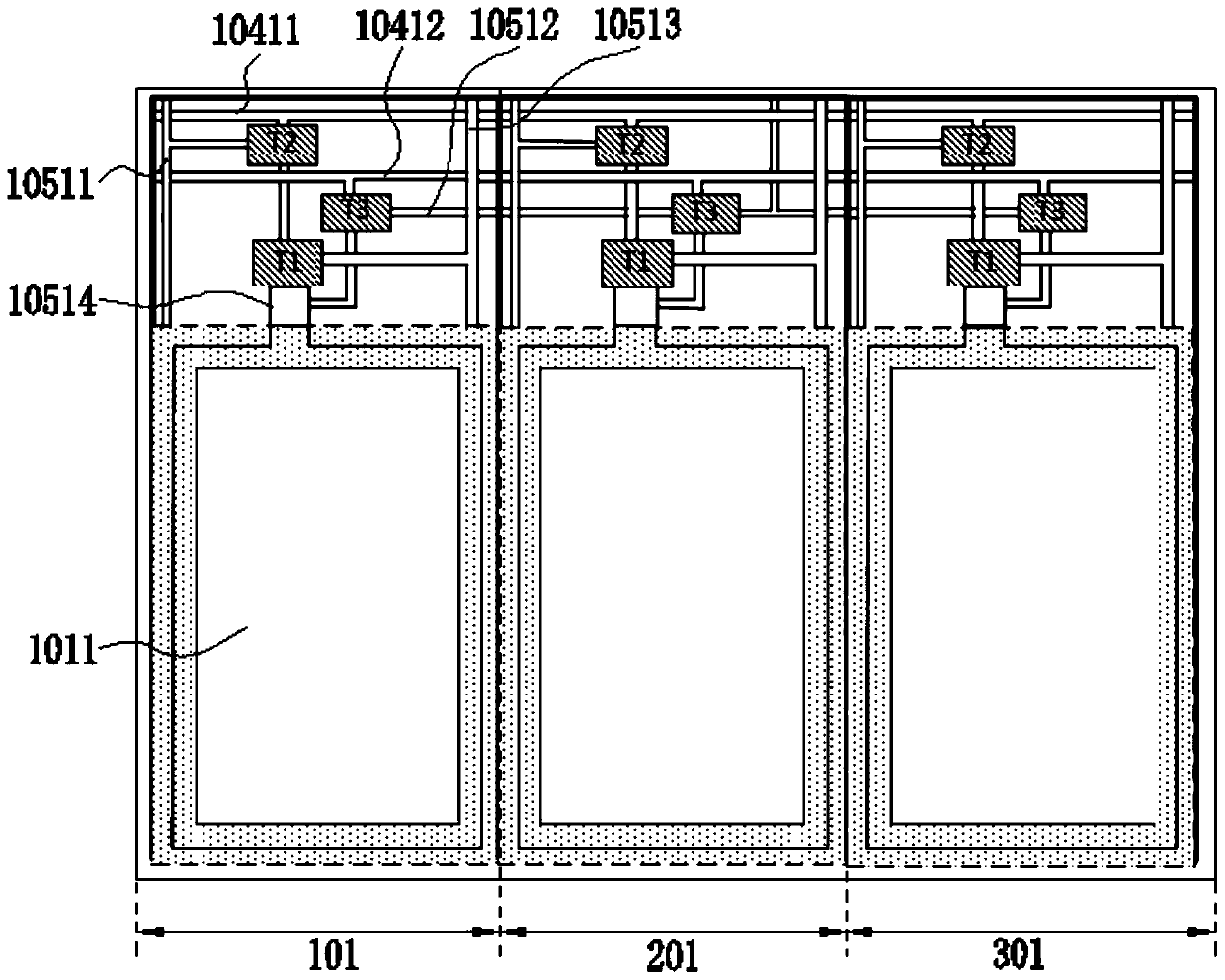

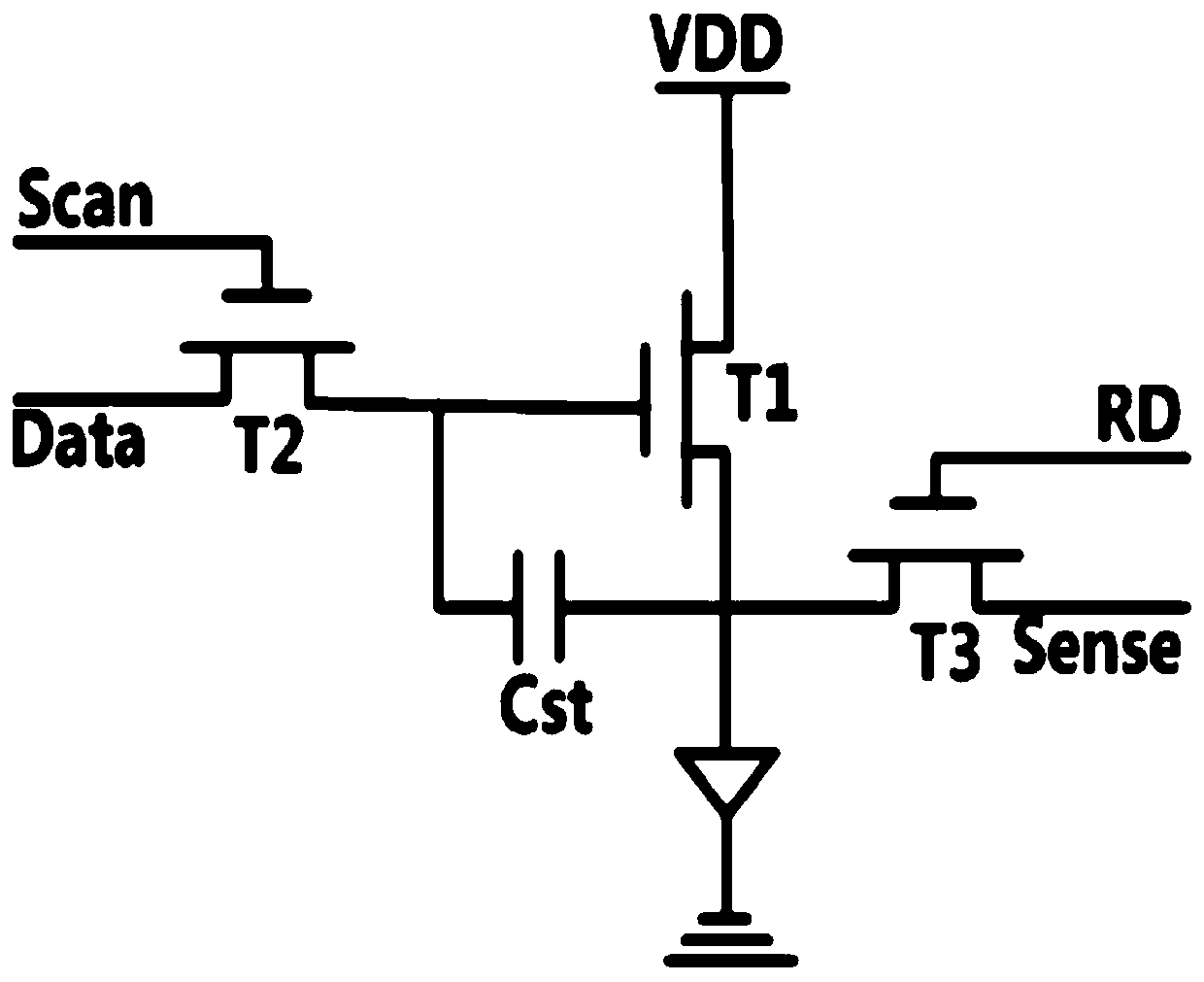

Display panel

InactiveCN109037468AHigh strengthReduce the risk of fragmentationSolid-state devicesSemiconductor/solid-state device manufacturingElectrical and Electronics engineeringTransistor

The invention provides a display panel, comprising a display module, wherein the display module comprises a thin film transistor array substrate; a display unit arranged on the thin film transistor array substrate; a packaging cover plate arranged on the display unit; a packaging material disposed between the thin film transistor array substrate and the packaging cover plate and surrounding the display unit; a protective cover plate arranged on the packaging cover plate of the display module; a bonding layer arranged between the display module and the protective cover plate; and a buffer partdisposed on a side of the thin film transistor array substrate deviating from the display unit and extending along a side surface of the display module toward the packaging material to be at least higher than the packaging material. The attachment method of the buffer part in the display panel not only enhances the packaging effect of the packaging area of the packaging material, but also plays abuffering role on the side surface and the bottom surface of the display panel, the strength of the display panel is effectively improved and the service life of the display panel is prolonged.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

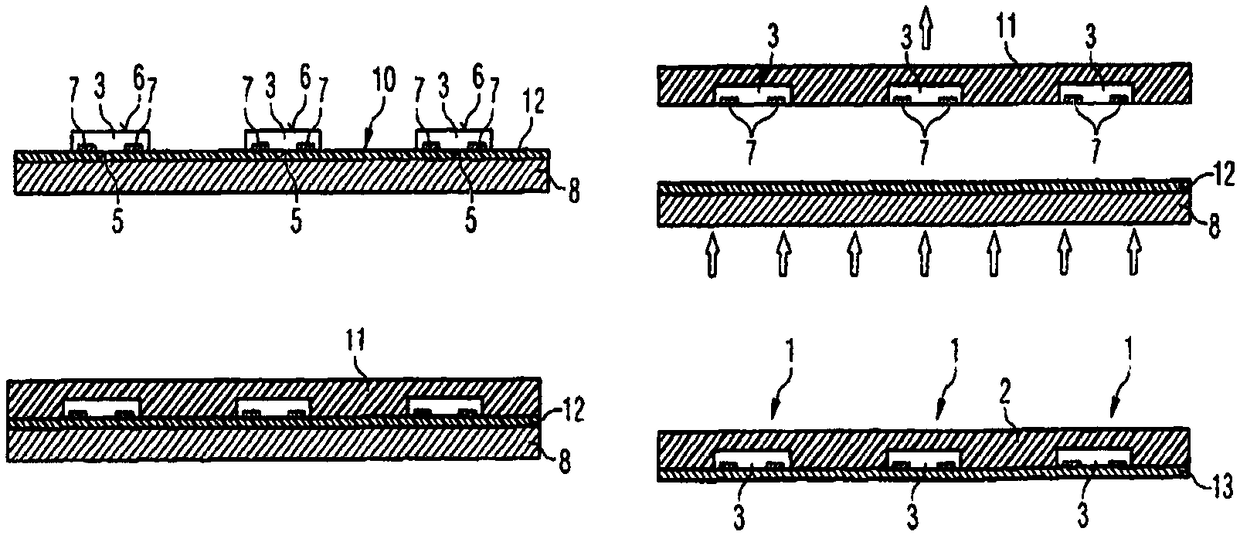

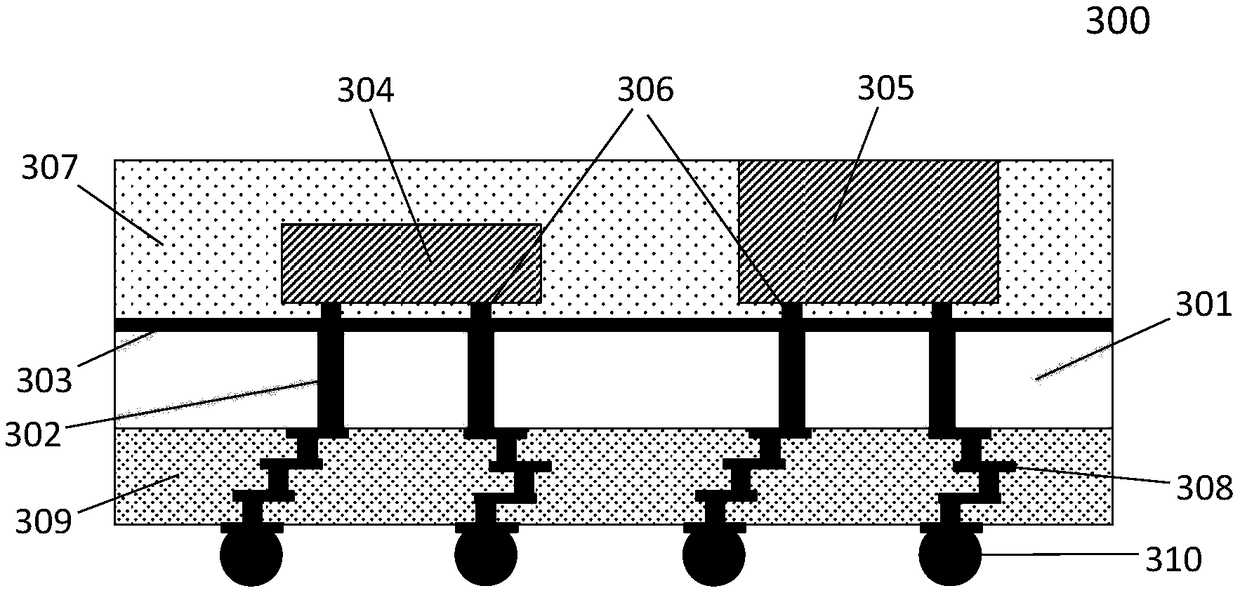

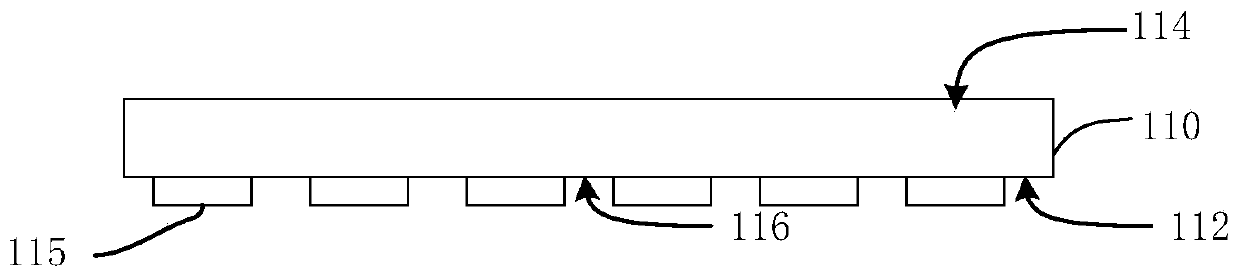

A fan-out type chip packaging structure and a manufacturing method thereof

InactiveCN109216298AFlexible choice of manufacturing processOmit temporary bondingSemiconductor/solid-state device detailsSolid-state devicesSolder ballElectrical and Electronics engineering

The invention discloses a fan-out type chip packaging structure, comprising: a glass substrate; A conductive through hole arranged inside the glass substrate; A chip arranged on the front face of theglass substrate, the chip is electrically connected to the conductive via hole; A plastic encapsulation layer positioned on the front surface of the glass substrate and covering the chip; A first relayout wiring layer disposed on a back surface of the glass substrate, the first relayout wiring layer being electrically connected to the conductive via; And an external solder ball arranged on the back surface of the glass substrate.

Owner:NAT CENT FOR ADVANCED PACKAGING

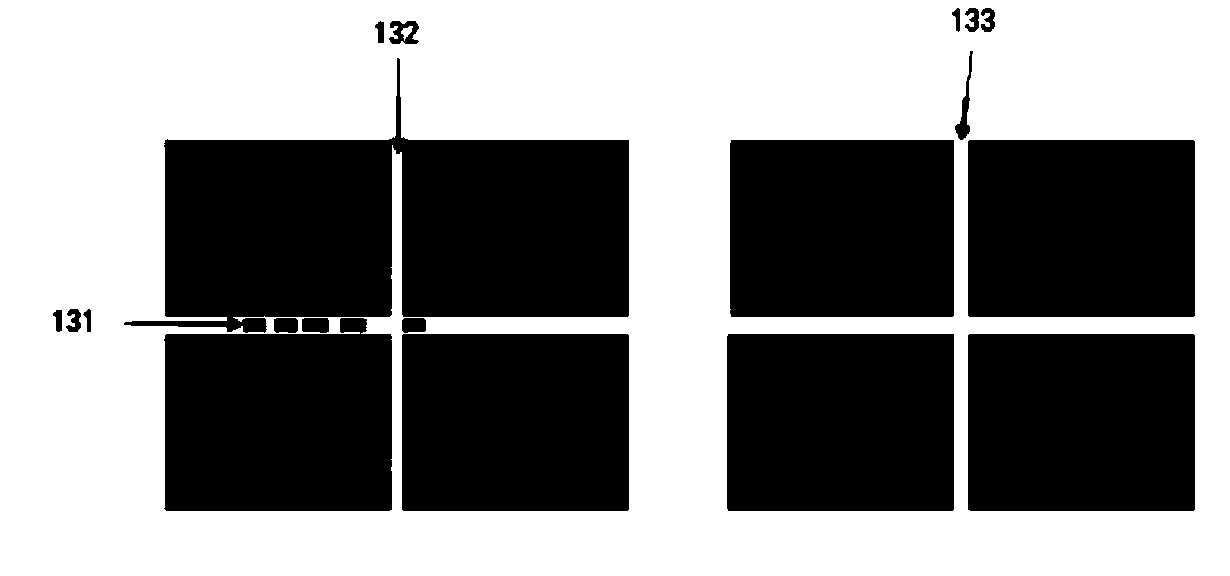

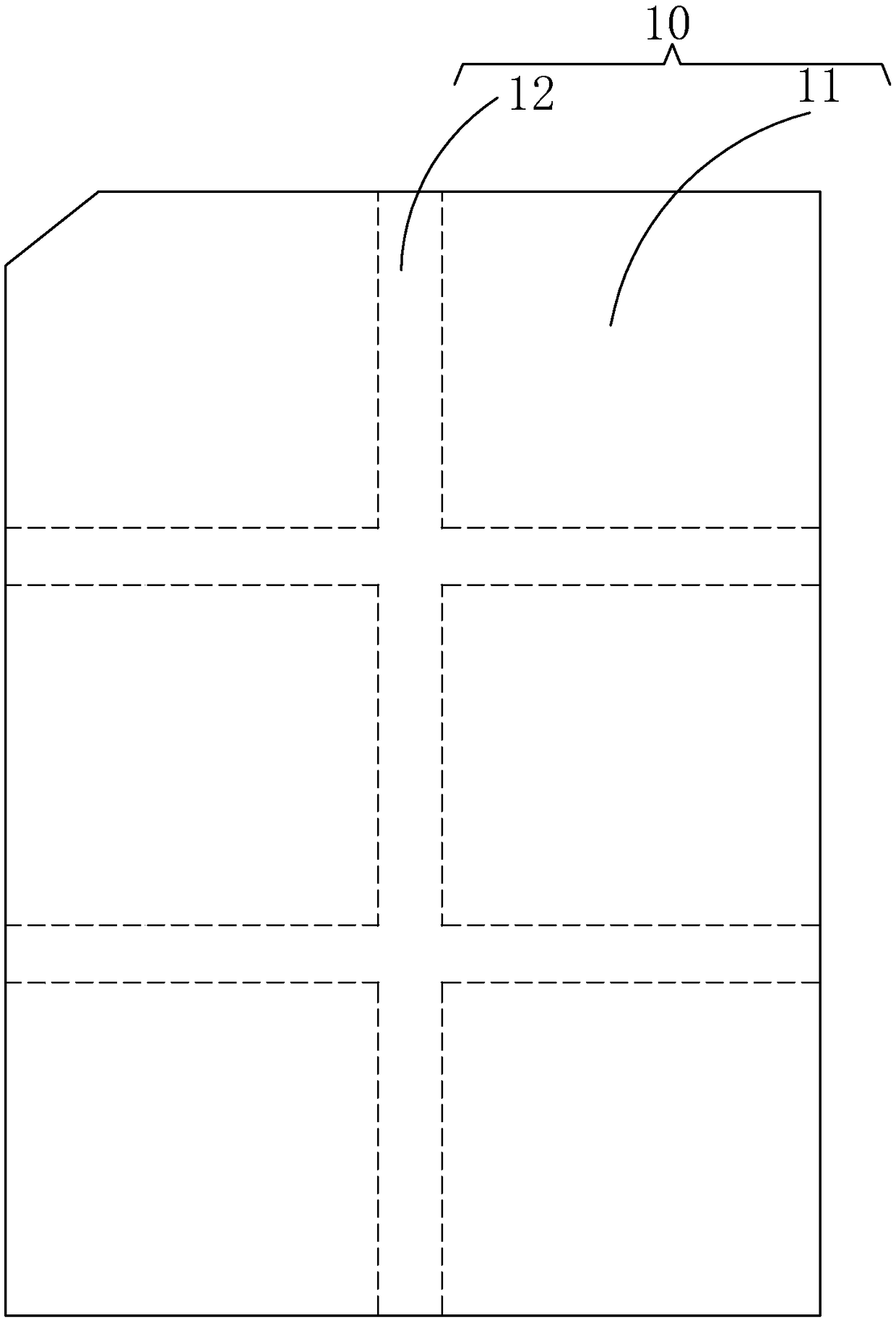

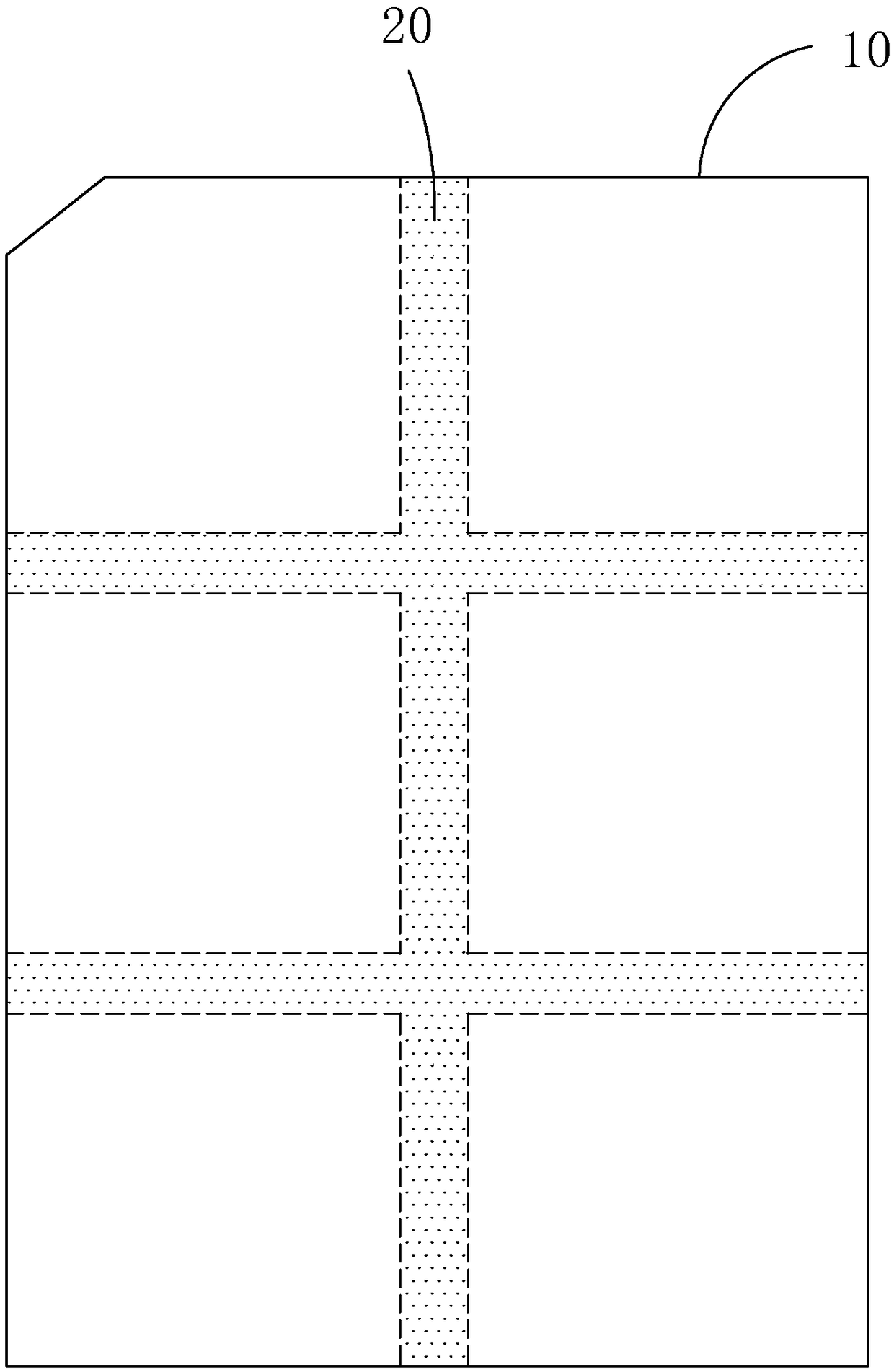

Film forming method for reducing warpage of mother board

ActiveCN108828844AReduce warpageReduced Risk of FragmentationNon-linear opticsEngineeringForming processes

The invention provides a film forming method for reducing warpage of a mother board. The film forming method for reducing the warpage of the mother board comprises the following steps that the motherboard is provided, wherein the mother board comprises a plurality of panel regions arranged in an array and spacer regions located among the adjacent panel regions; partition baffle walls are formed in the spacer regions; metal thin film deposits on the mother board and is naturally broken at the partition baffle walls during deposition, so that the metal thin film comprises a plurality of independent metal blocks corresponding to the panel regions respectively. The partition baffle walls are formed in the spacer regions at first before film forming, so that the metal thin film is partitionedinto the independent blocks by the partition baffle walls in the film forming process, thus, the stress of the metal thin film is released, the warpage of the mother board is reduced, and the fragmentation risk of the mother board in the displacement process is reduced.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

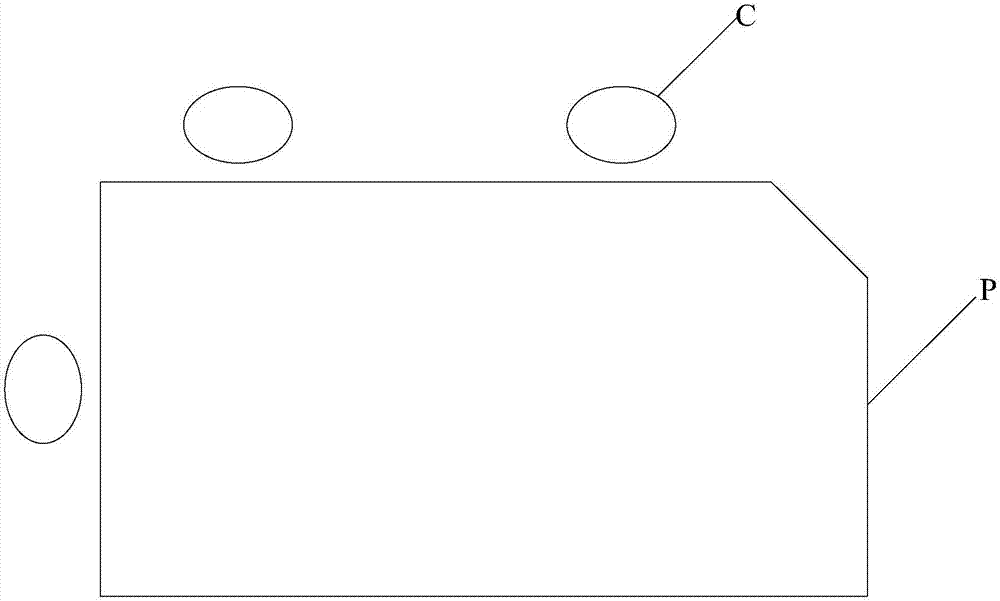

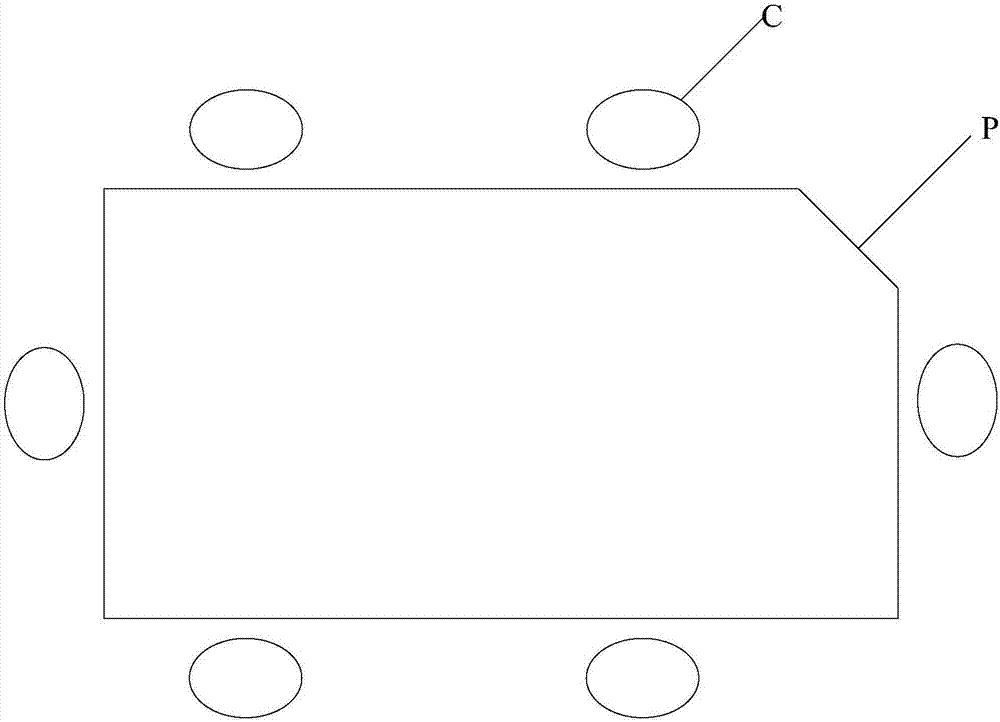

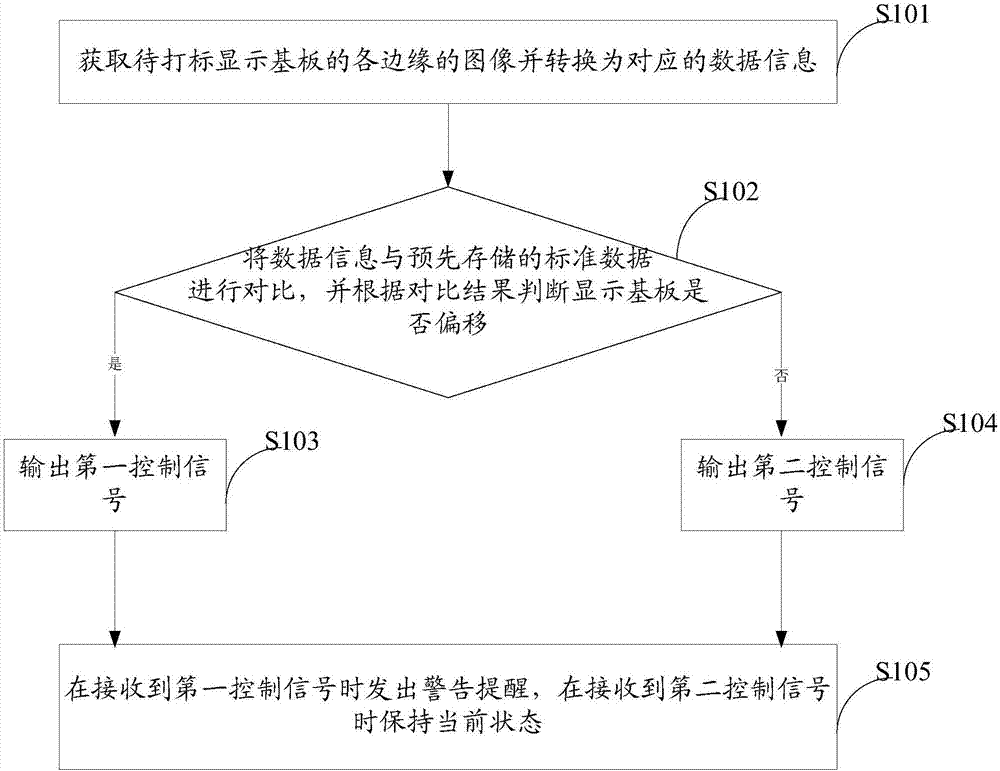

Marking machine and aligning method thereof

InactiveCN106945409AReduced Risk of FragmentationReduce the risk of fragmentation and help control cost lossTypewritersOther printing apparatusComputer moduleBiological activation

The invention discloses a marking machine and an aligning method thereof. The marking machine comprises a carrying table, a plurality of image collectors, a judging module and an alarming module, wherein the periphery of a display substrate located on the carrying table correspond to the multiple image collectors used for collecting images; the numbers of the image collectors corresponding to the two opposite sides of the display substrate are equal, the image collectors corresponding to the two opposite sides of the display substrate correspond in a one-to-one mode, and thus a double-sided alignment system can be formed; image data collected by the image collectors on the two sides are measured together, the alignment values of the two sides are obtained correspondingly, and then whether alignment is abnormal or not is judged according to the fed back comparison of the double-sided alignment values and standard data. Compared with single-sided alignment judgment in the prior art, alignment abnormality can be judged more accurately through the double-sided alignment judgment, so that alignment alarms are controlled more effectively, and the equipment activation is improved; and the frequency of false alignment alarms caused by factors such as poor processes and deviated lenses of the image collectors can be greatly lowered, and the equipment activation is improved effectively.

Owner:BOE TECH GRP CO LTD +1

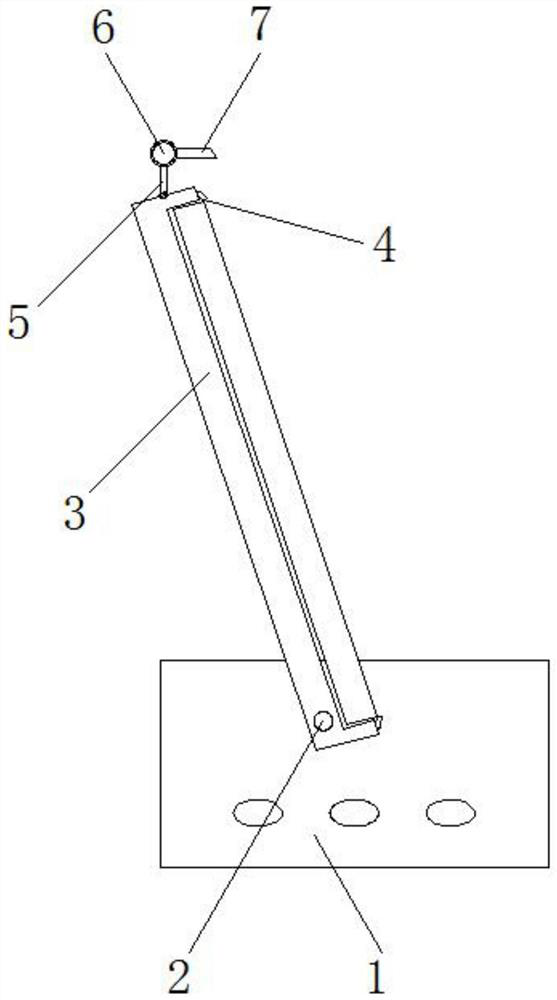

Waterfall flow type special jig for chemical etching and preparation method of ultrathin glass

The invention discloses a waterfall flow type special jig for chemical etching and a preparation method of ultrathin glass. The waterfall flow type special jig comprises a mounting base, a rotating shaft is rotatably connected into the mounting base, a supporting frame is fixedly connected to the front end of the rotating shaft, PVC cover plates are connected to the right ends of the upper side and the lower side of the supporting frame in a clamped mode, supporting rods distributed at equal intervals are fixedly connected to the upper end of the supporting frame, and spraying pipes are mounted at the upper ends of the supporting rods; nozzles distributed at equal intervals are fixedly connected to the right end of the spraying pipe. According to the waterfall flow type special jig for chemical etching and the preparation method of the ultrathin glass, a waterfall flow type chemical etching method is adopted, no pressure is needed on the glass, the glass cannot be broken due to stress, the recovery ratio is high, waste liquid is minimum, the utilization rate of acid liquid is high, a large amount of cost is saved, a conveying belt is used for conveying in the whole process, the apparent effect is good, and rework is not needed; the yield is very high, turnover operation is not needed, the fragment risk is reduced, the etching capacity is improved, and the sealing performance of the upper end and the lower end of the glass is ensured.

Owner:赣州帝晶光电科技有限公司

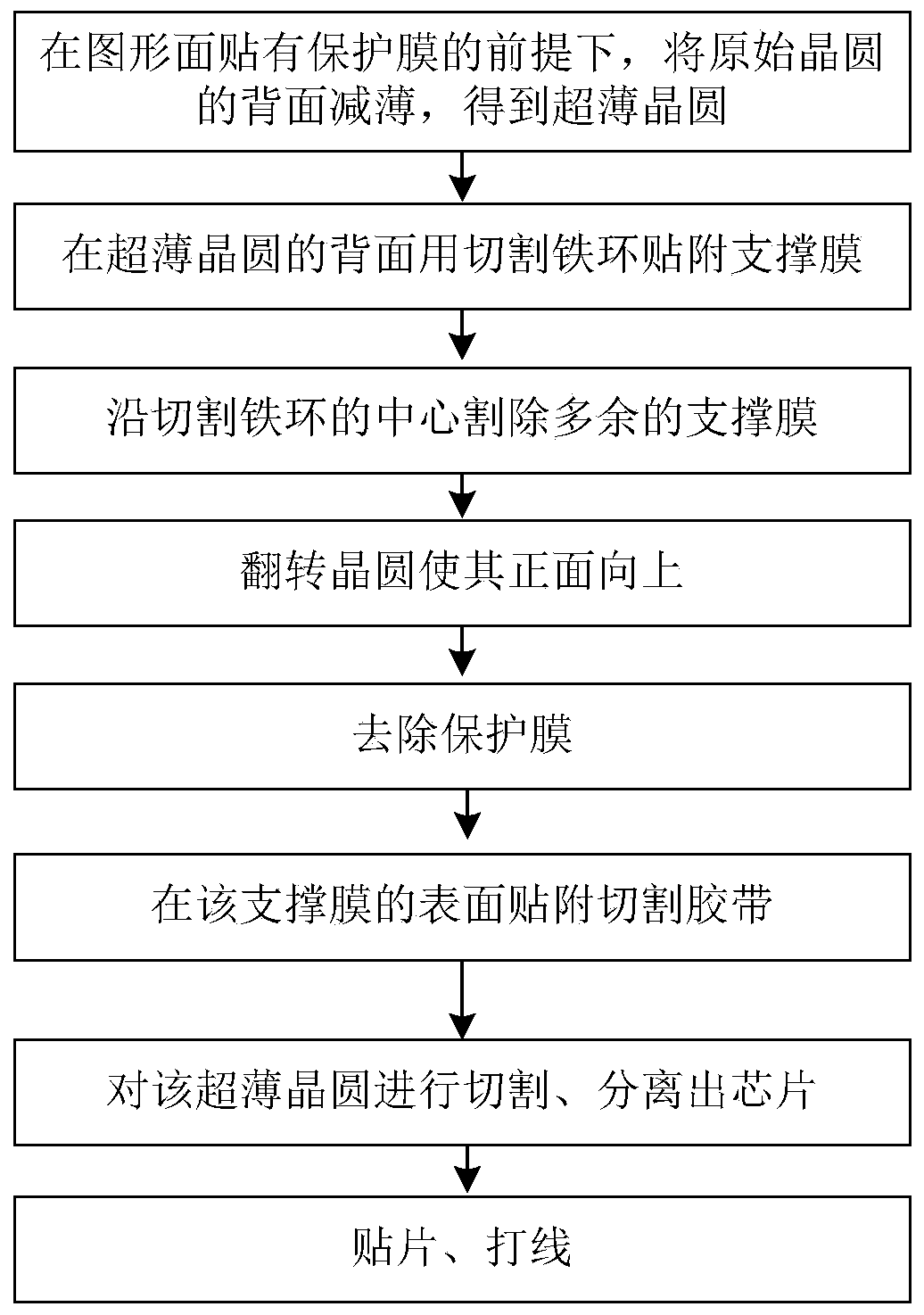

Wafer processing method

ActiveCN110265346AImprove stress distributionImprove the fragmentation problemFinal product manufactureSolid-state devicesEngineeringInternal stress

The invention provides a novel wafer processing method. A supporting film is attached to the back surface of an ultra-thin wafer after thinning, so that the supporting film and the ultra-thin wafer are fused into a whole, the internal stress of the ultra-thin wafer is redistributed, and the chip breaking risk is reduced. After the wafer is cut into a chip, the supporting film is still integrated with the chip, so that the chip breaking problem of the chip in the subsequent packaging processes of chip mounting, wire bonding and the like is improved.

Owner:浙江荷清柔性电子技术有限公司

Glass tube fixed-length cutting equipment

ActiveCN113666623AHigh degree of automationImprove cutting efficiencyGlass severing apparatusGlass productionCutting glassEngineering

The invention relates to glass tube fixed-length cutting equipment, which comprises a cutting table, a driving clamping mechanism and a cutter mechanism, wherein the driving clamping mechanism and the cutter mechanism are slidably connected to the cutting table, the driving clamping mechanism is used for clamping a glass tube and driving the glass tube to rotate, a feeding station and a cutting station are arranged on the cutting table, the driving clamping mechanism and the cutter mechanism are arranged at the two ends of the cutting station correspondingly, the cutter mechanism comprises a cutter moving device and a cutter tube, the cutter tube is provided with a cutter used for abutting against the inner wall of the glass tube, the cutting table is provided with a rotary supporting mechanism located at the cutting station and a fire spraying mechanism, the rotary supporting mechanism can longitudinally slide relative to the cutting table so as to support the part, making contact with the cutter, of the glass tube, and after the cutter is separated from the glass tube, the fire spraying mechanism carries out instant high-temperature heating on the glass tube from the outer side, so that the glass tube is broken and cut. According to the invention, the glass tube is cut in a high-automation-degree mode, a notch of the cut glass tube is smooth, and the rejection rate is low.

Owner:NINGBO BEILUN HANXIN NEW ENERGY TECH

Back contact forming method of passivated emitter and rear contact solar cell

InactiveCN103579418AReduce compound rateImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationContact formationFragmentation rate

The invention discloses a back contact forming method of a passivated emitter and rear contact solar cell. The back contact forming method of the passivated emitter and rear contact solar cell comprises the following steps that (1) a light trapping mechanism is formed on the obverse side of a cell substrate of a first conduction type; (2) doping of a second conduction type is carried out on the obverse side of the cell substrate; (3) an antireflection layer is formed on the obverse side of the cell substrate in a deposition mode; (4) a mask plate is arranged on the top of the back side of the cell substrate; (5) a back passivating dielectric layer is formed on the back side of the cell substrate, and an exposed area, without the passivating dielectric layer, of the back side is formed at the same time; (6) electrode patterns are formed on the back side and the obverse side of the cell substrate respectively, and ohmic contact between electrode metal and silicon is formed in a high-temperature sintering mode. According to the back contact forming method of the passivated emitter and rear contact solar cell, damage caused by laser windowing in the preparation process of the passivated emitter and rear contact solar cell can be eliminated, conversion efficiency of the passivated emitter and rear contact solar cell is improved, the preparation cost of the passivated emitter and rear contact solar cell is reduced, and the risk of the fragmentation rate of module preparation is reduced.

Owner:中电电气(扬州)光伏有限公司

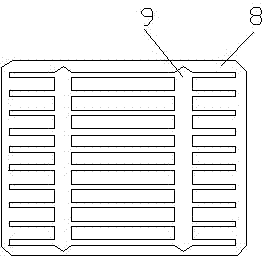

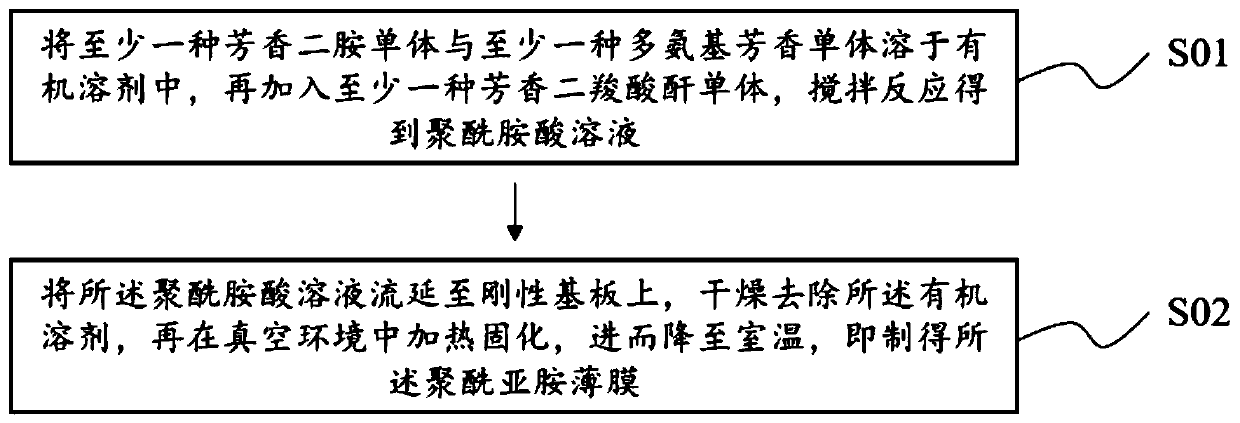

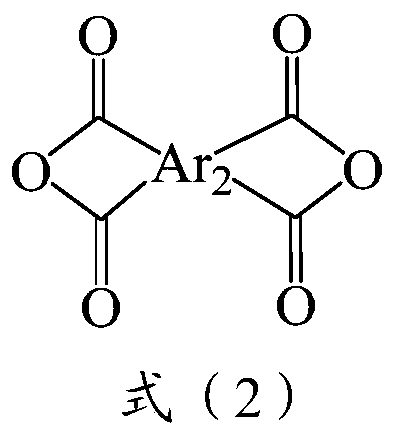

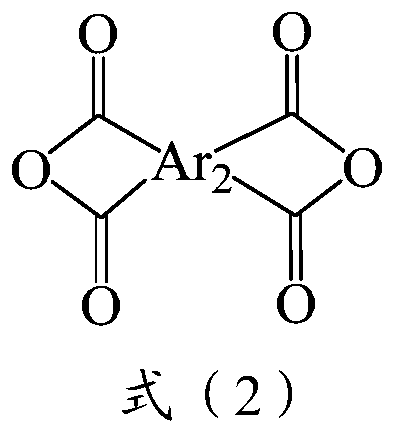

Polyimide, preparation method of polyimide film and flexible display panel

PendingCN111393644AImprove mechanical propertiesReduced Risk of FragmentationSolid-state devicesSemiconductor/solid-state device manufacturingImidePolymer science

The invention discloses polyimide, a preparation method of a polyimide film and a flexible display panel, the polyimide is formed by copolymerization of an aromatic diamine monomer, a polyamino aromatic monomer and an aromatic dicarboxylic anhydride monomer, and the polyamino aromatic monomer comprises at least three amino groups. A small amount of polyamino aromatic monomer is added; in the polyimide forming process, two amino groups in the polyamino aromatic monomer are formed in a main chain of polyimide, and the remaining amino groups are used as side chain groups and can be in dehydrationcondensation bond connection with unreacted carboxyl groups, so that polyimide forms a cross-linked structure, and the mechanical property of polyimide is improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Connecting device and semiconductor machining equipment

ActiveCN108728819AReduced Risk of FragmentationReduce processing stepsSemiconductor/solid-state device manufacturingFrom chemically reactive gasesEngineeringQuartz

The invention discloses a connecting device and semiconductor machining equipment. An upper connecting element is arranged on the outer circumferential wall of a quartz tube by the connecting device in asleeving mode, and therefore a supporting element is fixedly connected with the bottom of the quartz tube and is arranged in a lower connecting element to support the upper connecting element, andthe lower connecting element fixedly connected with the upper connecting element is fixedly connected with a rotating lifting mechanism, so that the quartz tube is fixedly connected with the rotatinglifting mechanism. In this way, a cavity outer cover does not need to be additionally arranged, high accuracy requirements of mounting the quartz tube, a quartz shaft sleeve and the cavity outer coverare achieved, machining and mounting difficulty of parts is reduced; and the quartz tube is not subjected to radial-direction stress when used, and therefore the risk of quartz tube cracking is lowered.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

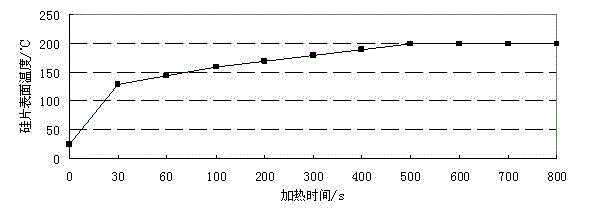

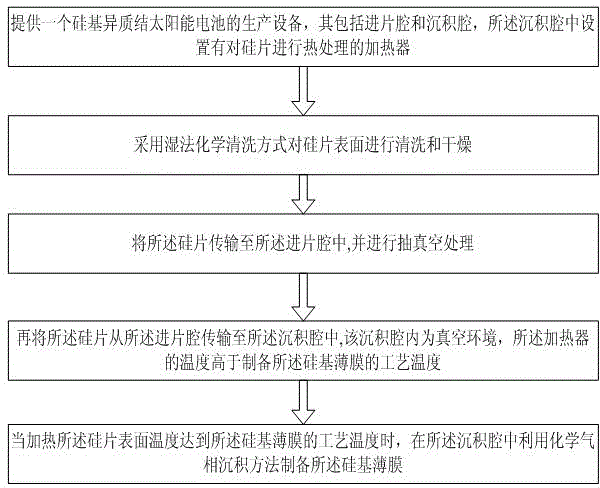

Technology for increasing capacity of silicon-based heterojunction solar cells

ActiveCN104157592AReduce processing timeQuality improvementSemiconductor/solid-state device manufacturingPhotovoltaic energy generationHeterojunctionEngineering

The invention relates to a technology for increasing the capacity of silicon-based heterojunction solar cells. The technology comprises the steps that a production device, which comprises a wafer inlet chamber and a deposition chamber, of the silicon-based heterojunction solar cells is provided, and the deposition chamber is internally provided with a heater which implements heat treatment on silicon wafers; the surfaces of the silicon wafers are cleaned and dried in a wet chemical cleaning method; the silicon wafers are transmitted to the wafer inlet chamber, and vacuumizing is carried out; the silicon wafers are transmitted from the wafer inlet chamber to the deposition chamber, the internal of the deposition chamber includes a vacuum environment, and the preset temperature of the heater is greater than the technical temperature for preparing silicon-based films; and when the surface temperature of the silicon wafers is increased to the technical temperature of the silicon-based films due to heating, the silicon-based films are prepared in a chemical vapor deposition method in the deposition chamber. The technology can improve the equipment capacity and reduce the production cost while ensuring the quality of films.

Owner:IDEAL ENERGY (SHANGHAI) SUNFLOWER THIN FILM EQUIPMENT LTD

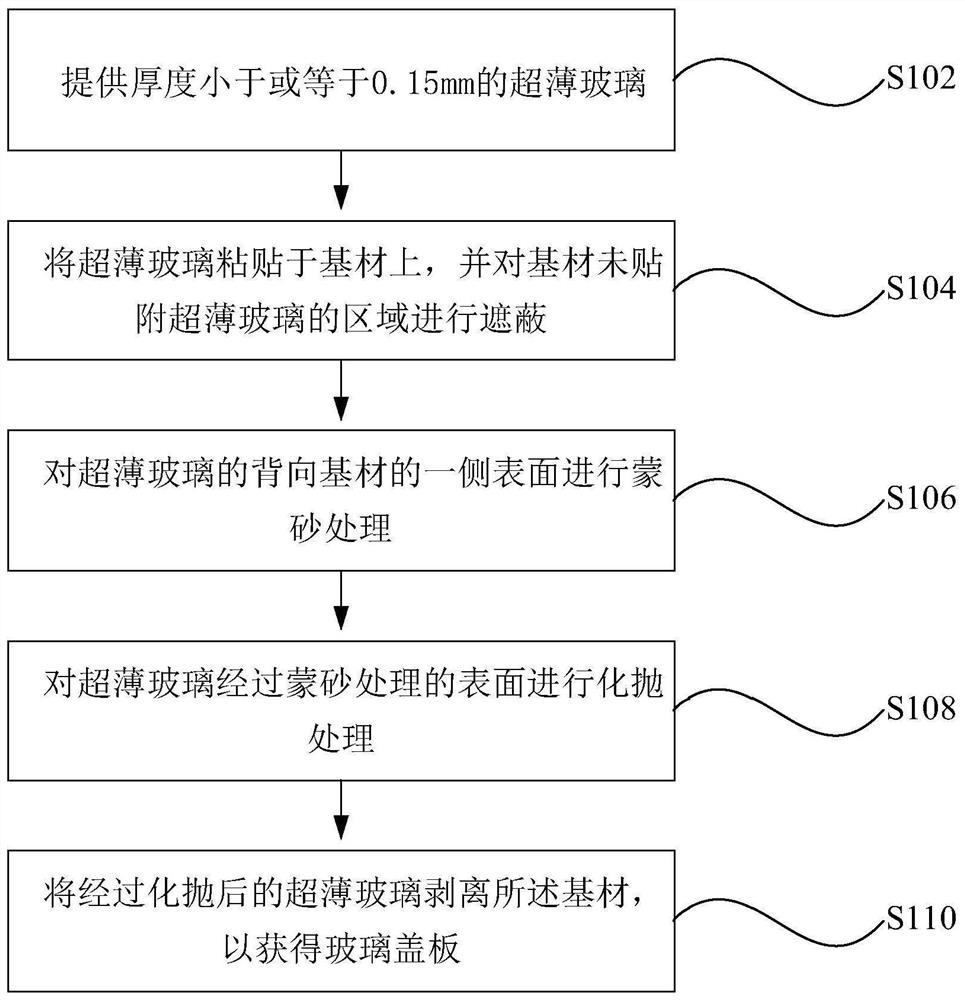

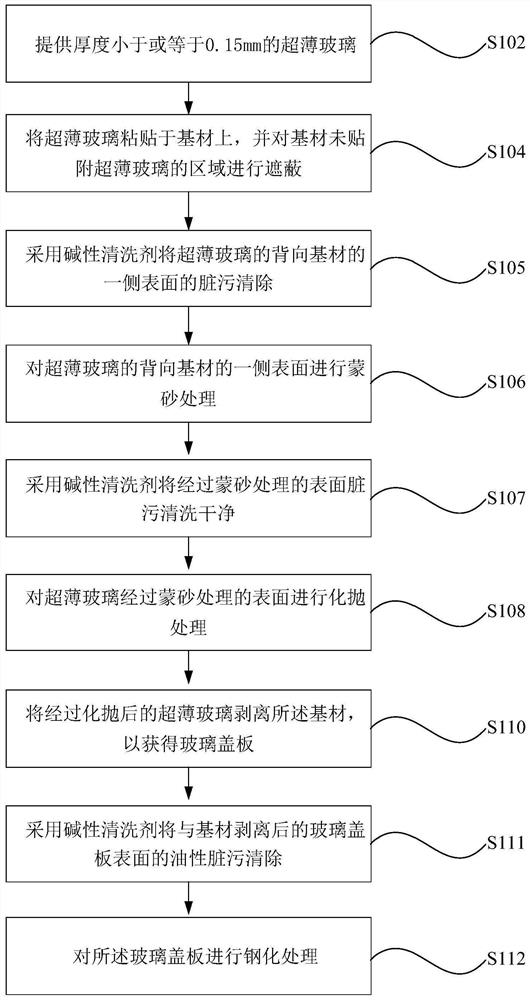

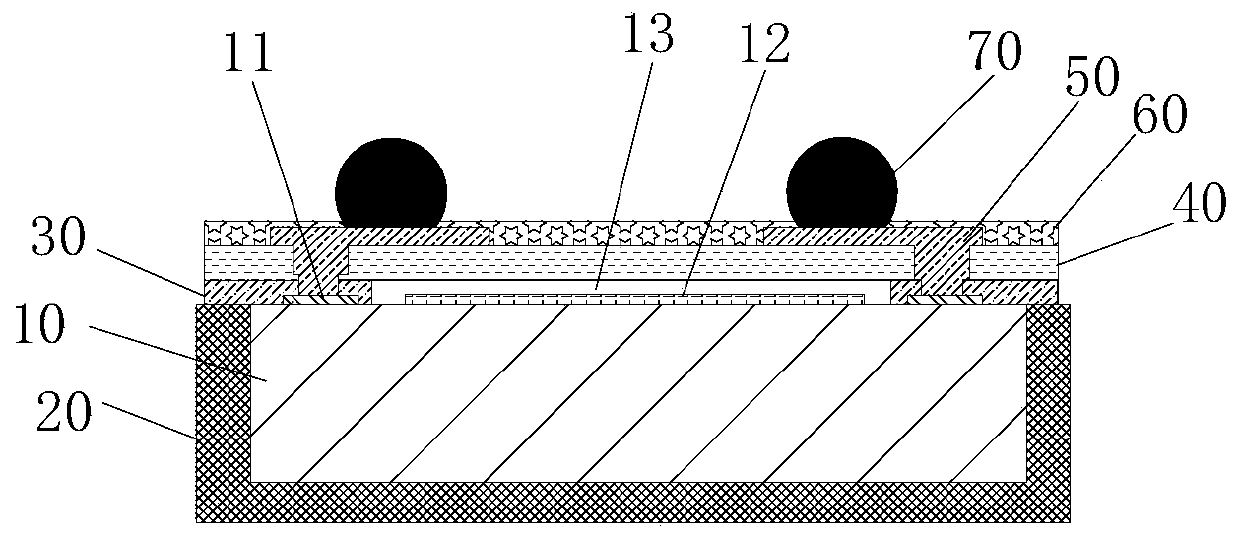

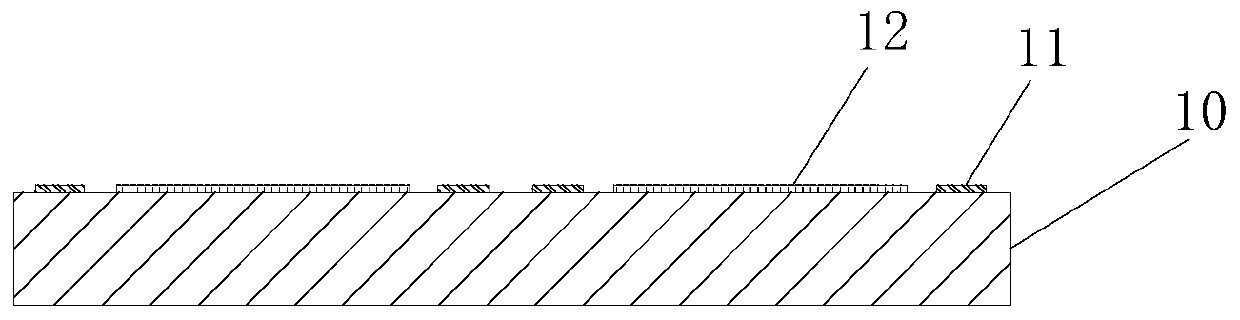

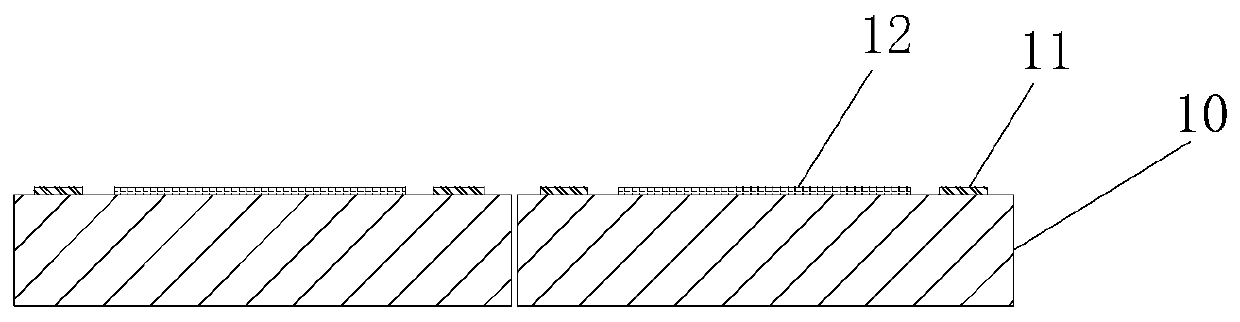

Mobile terminal, flexible display screen, glass cover plate and processing method thereof

PendingCN113121121AGood bending propertiesGood displayTelephone set constructionsIdentification meansEngineeringFlexible display

The invention relates to a mobile terminal, a flexible display screen, a glass cover plate and a processing method thereof. The processing method of the glass cover plate comprises the following steps: providing ultra-thin glass; pasting the ultra-thin glass on the base material, and shielding the area, where the ultra-thin glass is not attached, of the base material; frosting the surface of one side, back to the base material, of the ultra-thin glass; carrying out polishing treatment on the frosted surface of the ultra-thin glass; and stripping the polished ultrathin glass from the base material to obtain the glass cover plate. According to the mobile terminal, the flexible display screen, the glass cover plate and the processing method thereof, the glass cover plate prepared by utilizing the processing method of the glass cover plate not only has good bending performance, but also has a relatively good anti-dazzle effect, so that the folding performance and the display effect can be effectively ensured when the glass cover plate is applied to the flexible display screen and the mobile terminal.

Owner:WGTECH JIANGXI

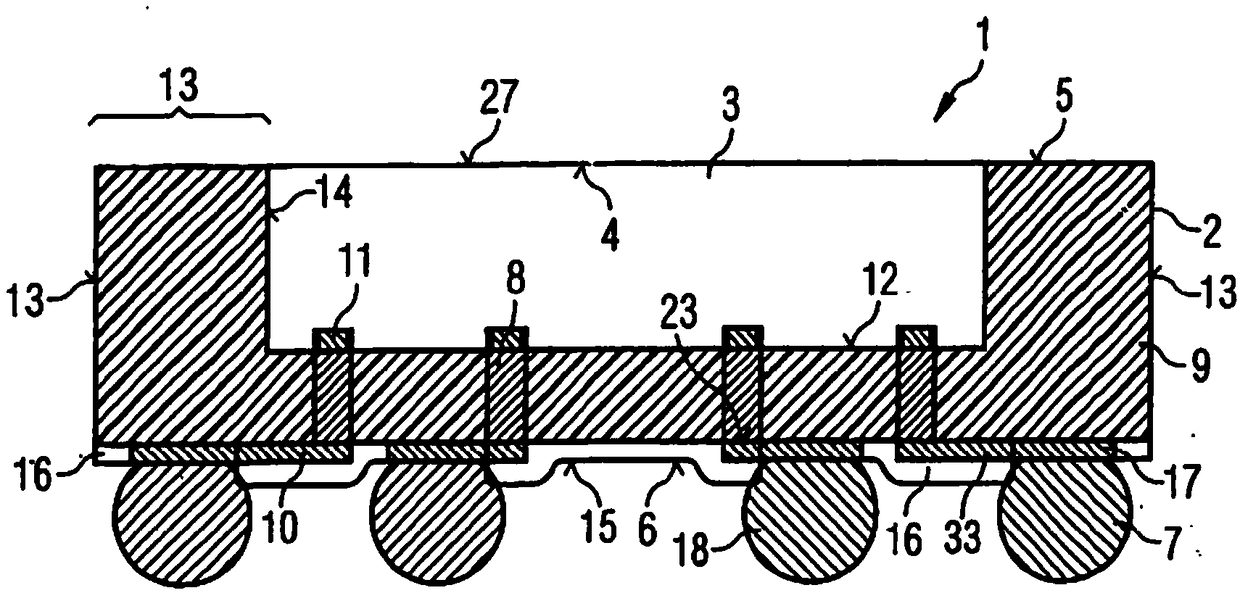

Three-dimensional packaging structure and method for bonding wall fan-out device

PendingCN110729255AHigh structural reliabilityReduce riskTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesEngineeringStructural engineering

The invention discloses a three-dimensional packaging structure and method for a bonding wall fan-out device. The first surface of the device is provided with a functional area and a plurality of bonding pads. The three-dimensional packaging structure is characterized in that all surfaces of the device, except the first surface, are provided with an encapsulating material; a wall structure is prepared on the first surface of the device and extends to the first surface of the encapsulating material; the wall structure partially covers at least one bonding pad, and first openings are formed at the bonding pads respectively; a cover plate is arranged to be bonded to the wall structure, so that a cavity structure is formed in the functional area of the device; and at least one second opening communicated with the first openings is formed in the cover plate; and the surface of the cover plate is provided with metal interconnection structures which are electrically connected with the bondingpads through the first openings and the second openings. With the three-dimensional packaging structure and method for the bonding wall fan-out device of the invention adopted, overall structure reliability can be improved, risks are reduced, and cost is reduced.

Owner:XIAMEN SKY SEMICON TECH CO LTD

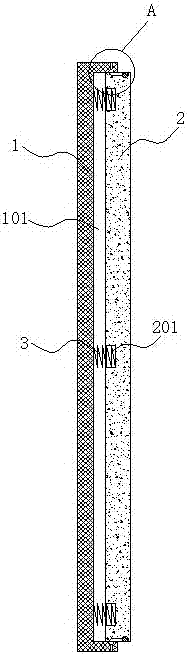

Display device

The embodiment of the invention provides a display device, wherein a spacer structure is arranged in a first gap between a first substrate and a second substrate, and the surface of the spacer structure towards the second substrate is flush with the surface of a color film substrate towards the second substrate, so that the spacer structure in the first gap between the first substrate and the second substrate has the same supporting force as the color film substrate, the shape variable of the substrate in the display device is reduced when the press test is carried out and the complete machineis assembled so as to reduce the risk of fragmentation and further improve the yield of the display device.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

OLED display panel

ActiveCN110867474AReduced Risk of FragmentationReduce the difficulty of repairSolid-state devicesSemiconductor devicesHemt circuitsEngineering

The invention provides an OLED display panel. The pixel definition layer in the OLED display panel is provided with an opening area and a non-opening area; the opening area and the pixel unit are oppositely arranged, and the non-opening area is provided with a lightproof layer surrounding the pixel unit. The non-opening area is provided with a transparent layer corresponding to a circuit layer, thereby ensuring that the light-emitting surface of the OLED display panel can directly see the repairing effect of the metal wiring in the circuit layer without turning over, reducing the repairing difficulty and reducing the fragment risk caused by turning over the OLED display panel.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com