Bending glass cover plate and manufacture method thereof

A technology for a glass cover plate and a manufacturing method, which is applied to glass manufacturing equipment, glass forming, glass tempering and other directions, can solve the problems of glass materials that are not easy to bend, cannot be greatly bent, and the manufacturing process is difficult, and it is easy to achieve a softening degree. , The effect of reducing the difficulty of the production process and reducing the risk of glass breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

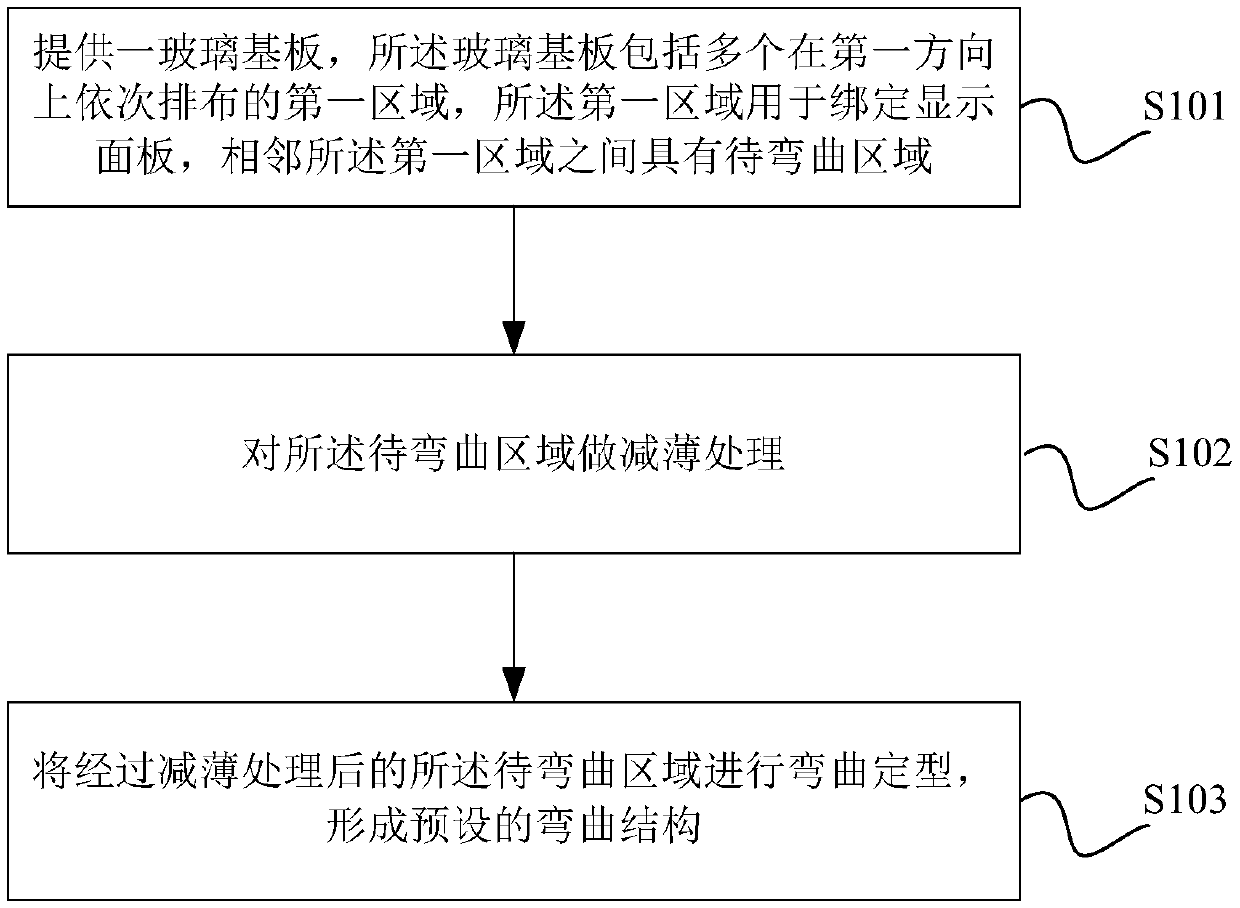

Method used

Image

Examples

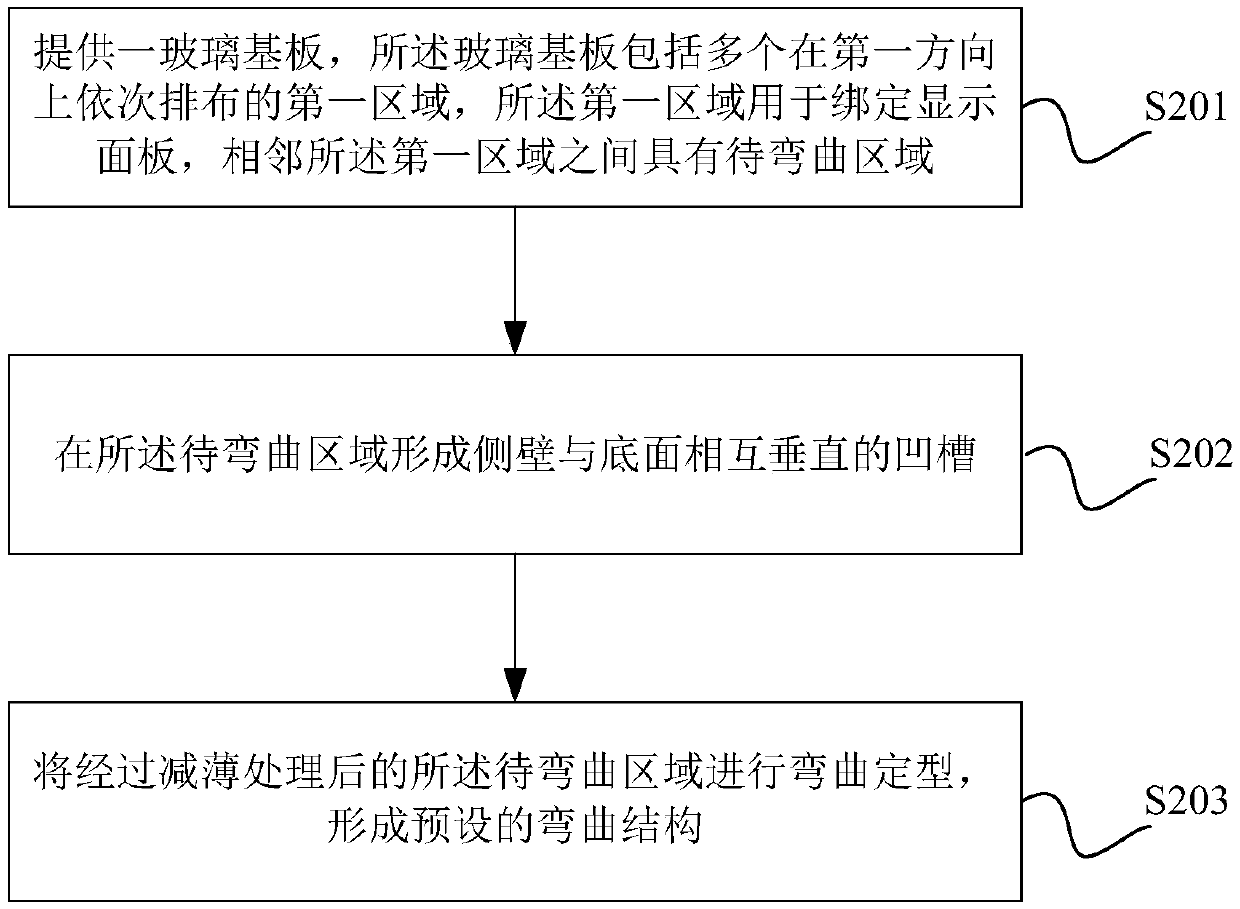

specific Embodiment approach 2

[0058] On the basis of the specific implementation mode 1, a specific method of thinning the area to be bent is proposed, the flow chart of which is as follows figure 2 As shown, it is referred to as the second specific embodiment, including:

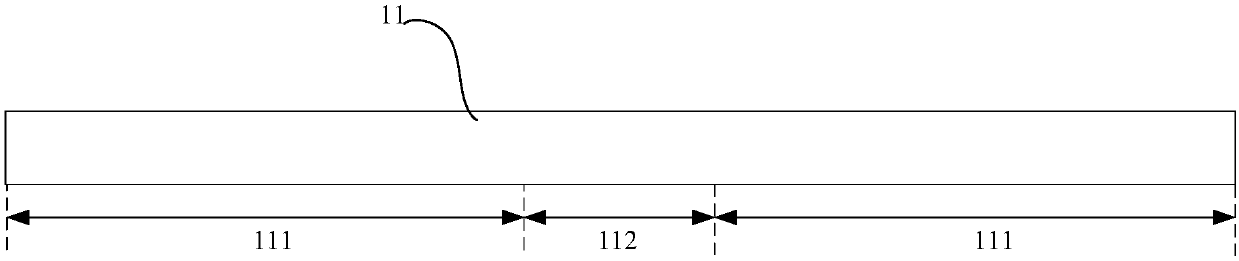

[0059] Step S201: if image 3 As shown, a glass substrate 11 is provided, and the glass substrate 11 includes a plurality of first regions 111 sequentially arranged in a first direction, and the first regions 111 are used for binding display panels, adjacent to the first There is a region 112 to be bent between the regions 111 .

[0060] Step S202: if Figure 4 shown and Figure 5 As shown, a groove 12 is formed in the region to be bent 112 , where the sidewall 121 and the bottom surface 122 are perpendicular to each other. in, Figure 5 for Figure 4 A partial enlarged view corresponding to the position of the groove 12.

[0061] It should be noted, Figure 4 and Figure 5 The groove in the middle is only a schematic diagram ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com