Patents

Literature

59results about How to "Easy to bend and shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

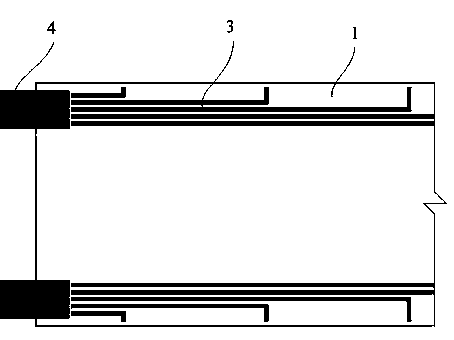

Bending glass cover plate and manufacture method thereof

ActiveCN109081561ASave energyReduced Risk of FragmentationGlass reforming apparatusGlass tempering apparatusGlass coverEngineering

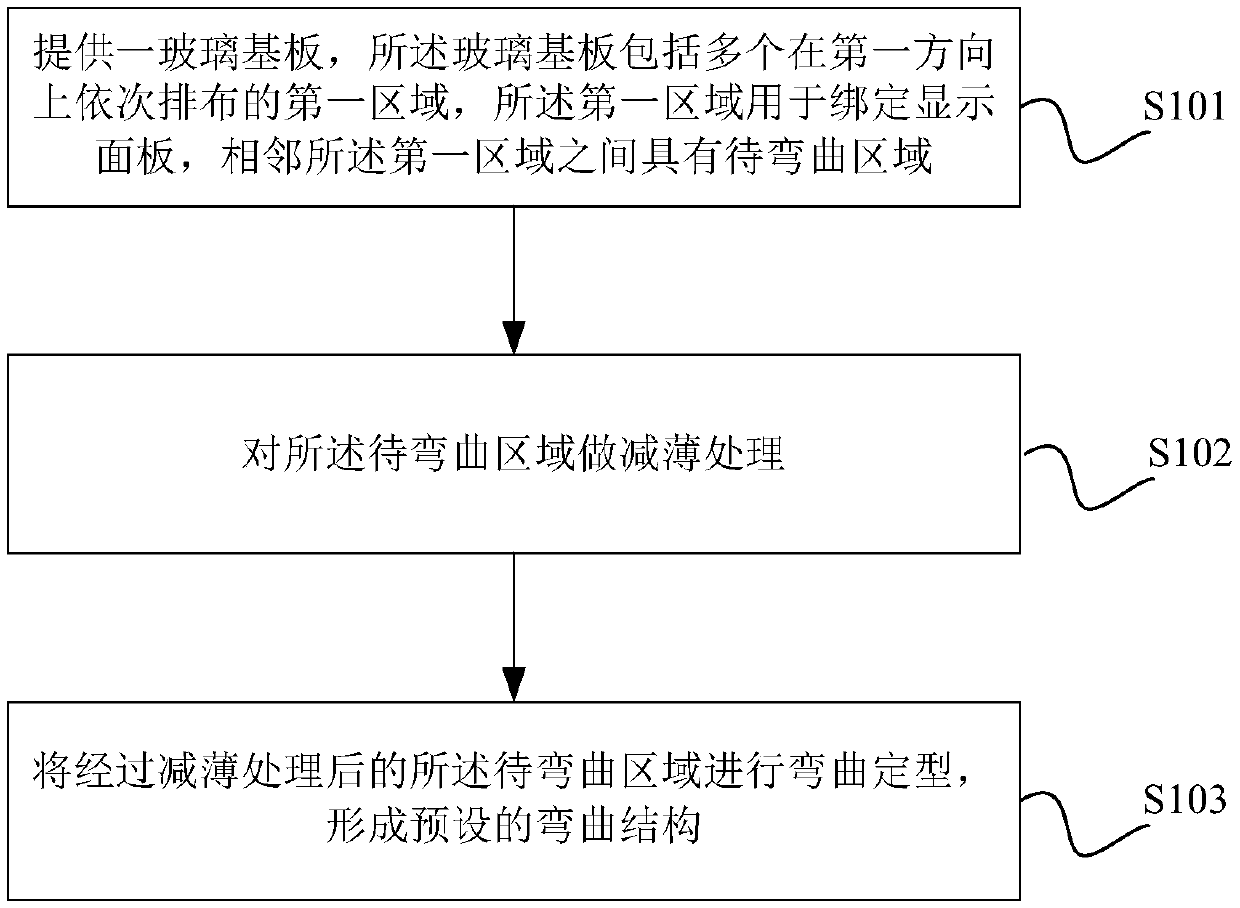

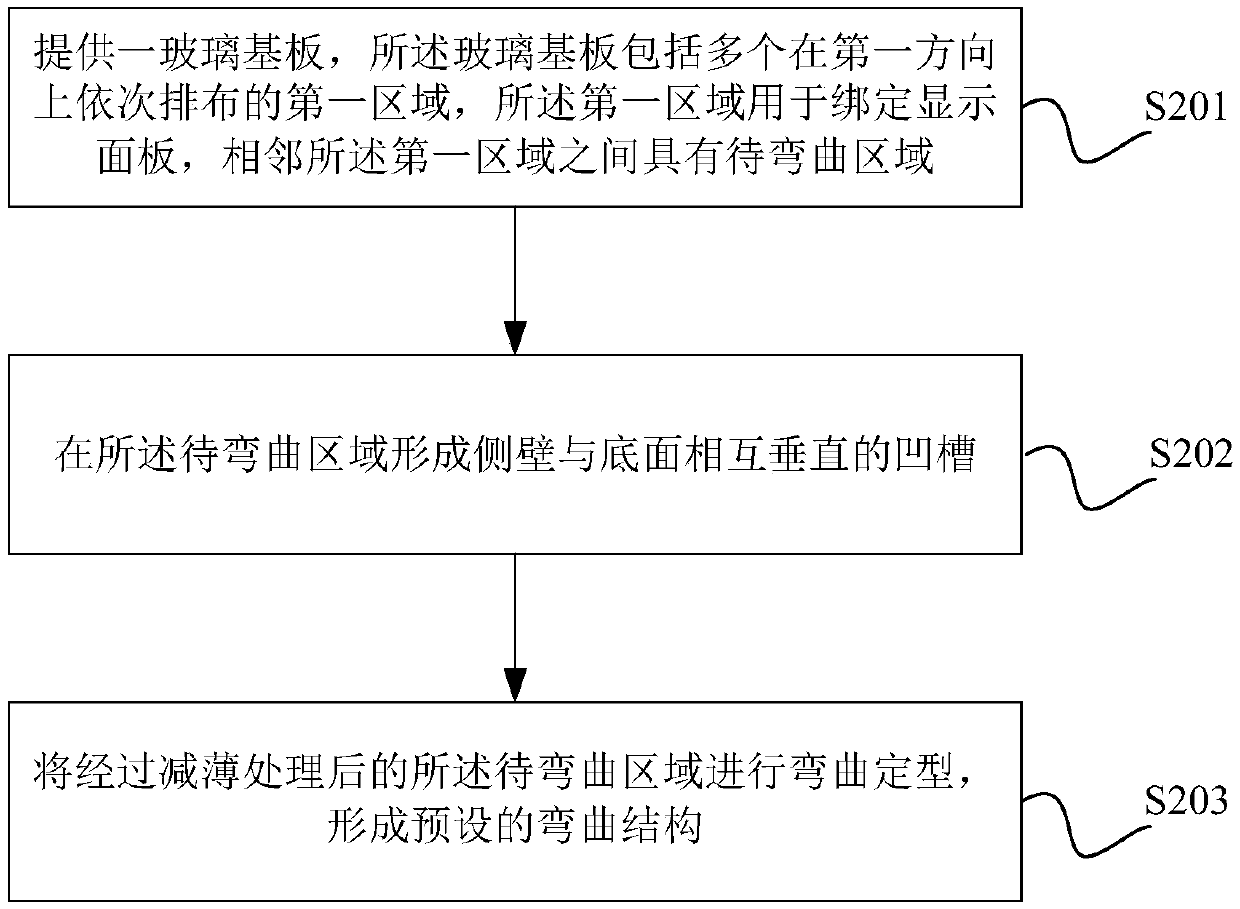

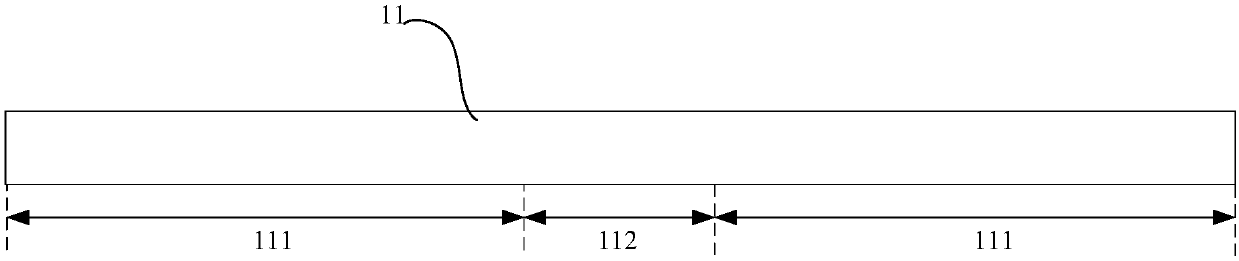

The invention discloses a manufacture method of a bending glass cover plate. The method includes the steps: providing a glass substrate comprising a plurality of first areas; thinning an area to be bent; bending the thinned area to be bent to form a preset bending structure. The first areas are sequentially distributed in the first direction and used for binding display panels, and an area to be bent is arranged between two adjacent first areas. According to the method, a portion to be bent of the area to be bent is thinned, hot bending energy consumption of glass is reduced, so that glass ismore uniformly heated in the hot bending of the glass, cracking risks of the glass caused by heated uniformity are reduced in the heating process, yield is increased, and requirements for device accuracy are reduced, so that device cost is reduced. The invention further provides a bending glass cover plate with the advantages.

Owner:TRULY OPTO ELECTRONICS

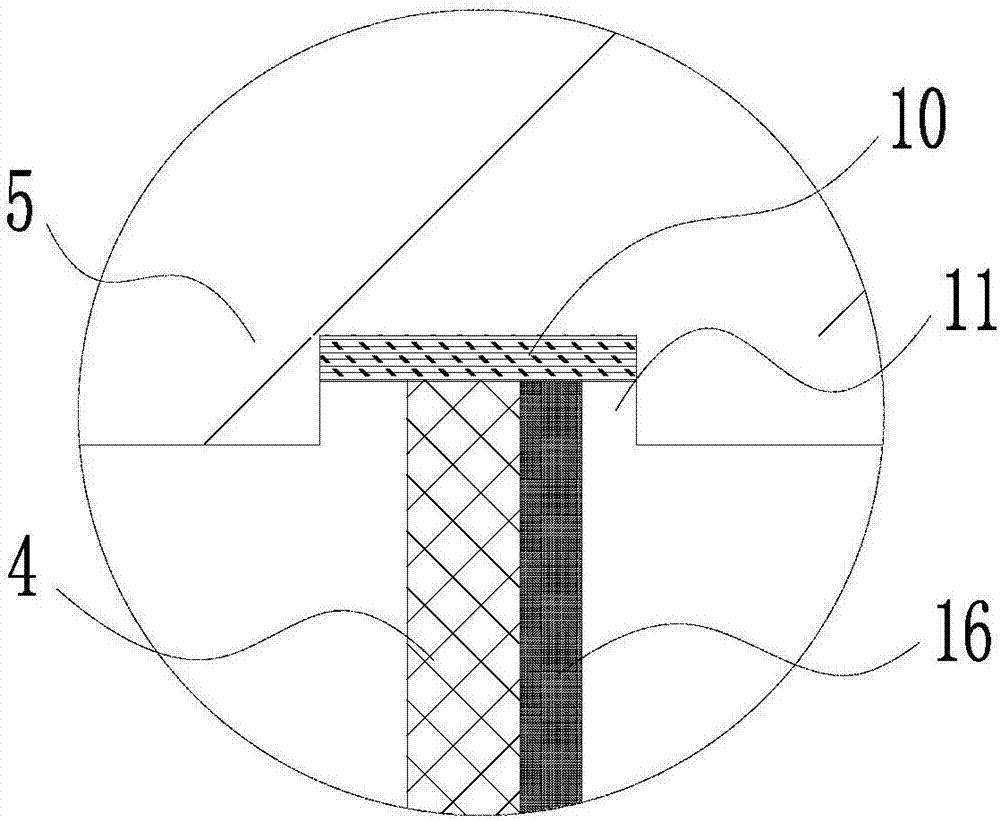

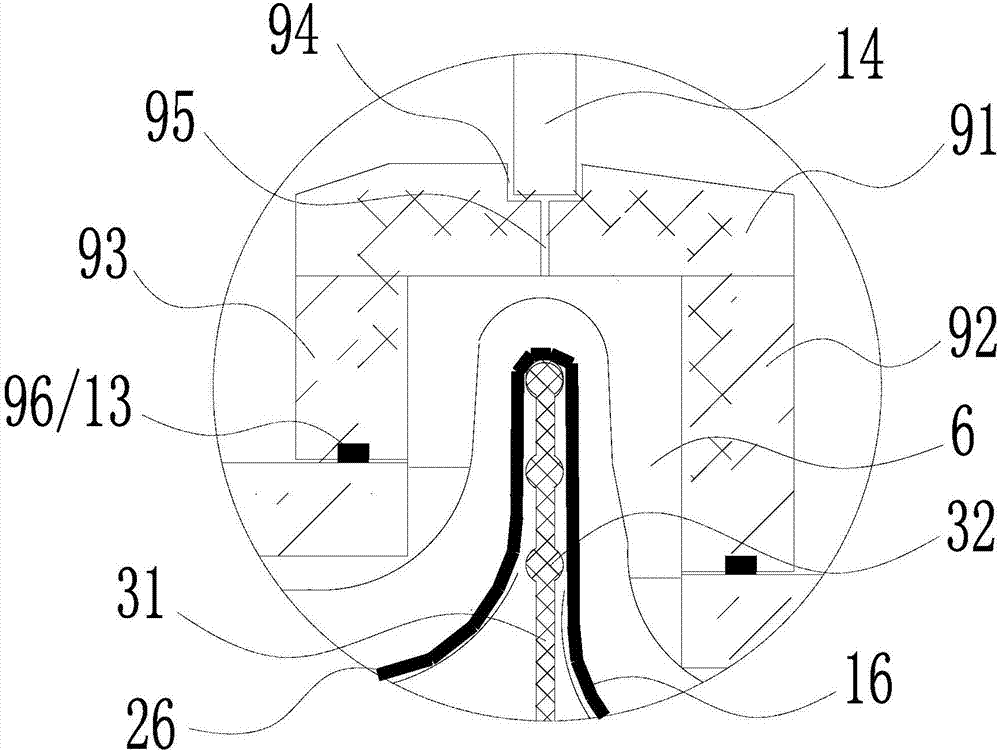

Bathroom waterproof system and construction method

ActiveCN106978856AEasy to pour constructionEasy to fixSills/thresholdBuilding insulationsEngineeringCement mortar

The invention relates to the field of building decoration and provides a bathroom waterproof system which is simple in structure can convenient to construct and can effectively prevent water molecules in a bathroom from leaking outward and a construction method. The technical problems that in the prior art, the leakage proof effect of the bathroom is poor, the situation that a floor, a door sleeve and the like in a dry area mould and decay is quite prone to occurring, and the attractive degree of overall decoration is reduced are solved. The bathroom waterproof system comprises a bathroom floor base layer and a dry area floor base layer connected with the bathroom floor base layer. Ground decoration paving layers are laid on the surfaces of the bathroom floor base layer and the dry area floor base layer correspondingly. An elastic water retaining plate and the lower end of an elastic water retaining strip are arranged between the bathroom floor base layer and the corresponding ground decoration paving layer in a clamped mode, wherein the upper end of the elastic water retaining plate extends upward to the exterior of the ground decoration paving layer and connected on the bottom face of a doorsill plate in a closed mode, and the upper end of the elastic water retaining plate extends upward to the exterior of the ground decoration paving layer and connected with a cement mortar retaining strip in an airtight mode. The cement mortar retaining strip divides the corresponding floor decoration paving layer into a bathing area and a rest area.

Owner:GREENTOWN DECORATION ENG GRP CO LTD

Process for rolling production of decorative drawing aluminum strip by double rollers

The invention discloses a process for rolling production of a decorative drawing aluminum strip by double rollers, belongs to the field of metal surface processing, and comprises the steps of: rolling and drawing: carving a decorative pattern on the surface of the roller by a cutter automatically controlled by a program, and rolling by placing the aluminum strip between the rollers; degreasing: performing chemical clean for the surface of the rolled and drawn aluminum strip to remove greasy dirt and pollutants on the surface; anodizing: through electrolytic oxidation, converting the surface of the aluminum strip into an oxide film; and hole sealing: sealing the hole by deionized water or distilled water. The invention has the beneficial effects that various types of decorative aluminum products on the drawing surface can be produced according to demand, the decorative pattern on the surface of the drawing aluminum plate is better in uniformity, the roller decorative pattern rolled is three-dimensional and layered so that the roller decorative pattern is stronger in metallic texture, the greasy dirt and pollutants on the surface in the degreasing step are removed, so that the surface of the aluminum strip is fully contacted with the treatment solution, so as to obtain uniform treatment effect, and the hole sealing process is performed to stabilize the anodized film.

Owner:江苏鑫皇铝业发展有限公司

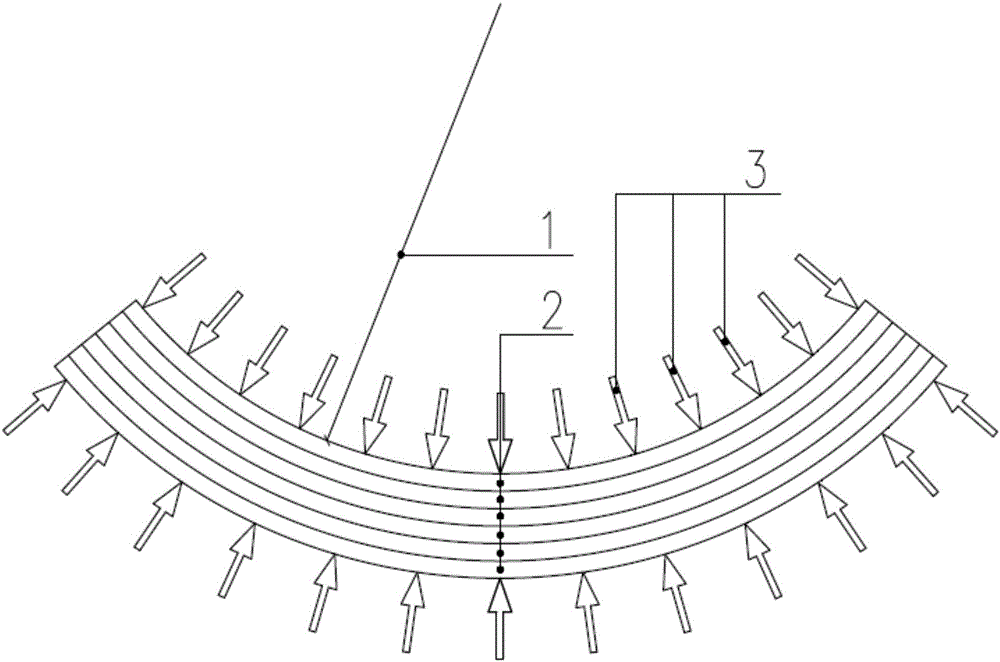

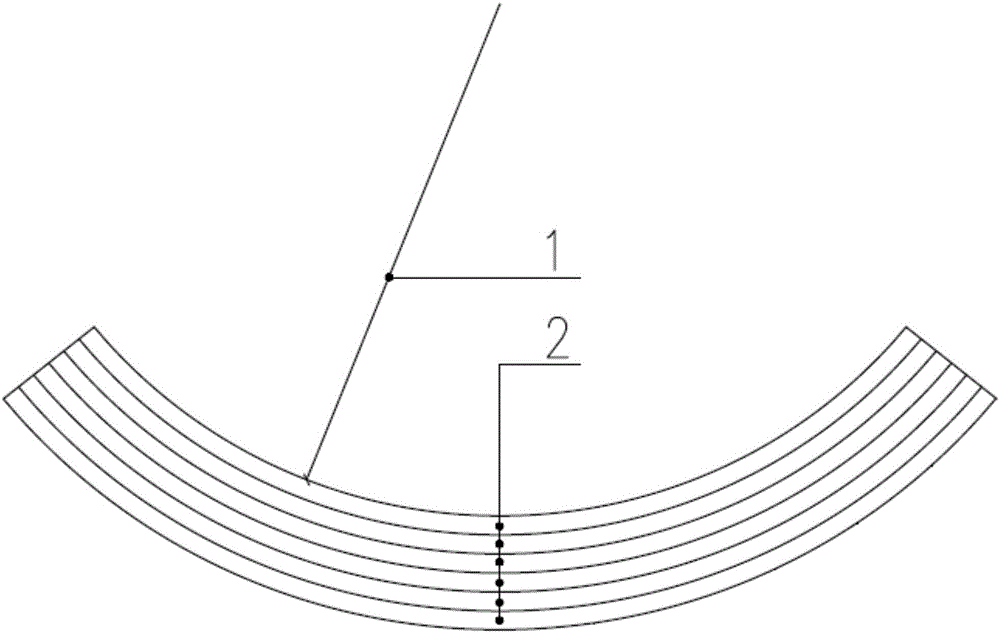

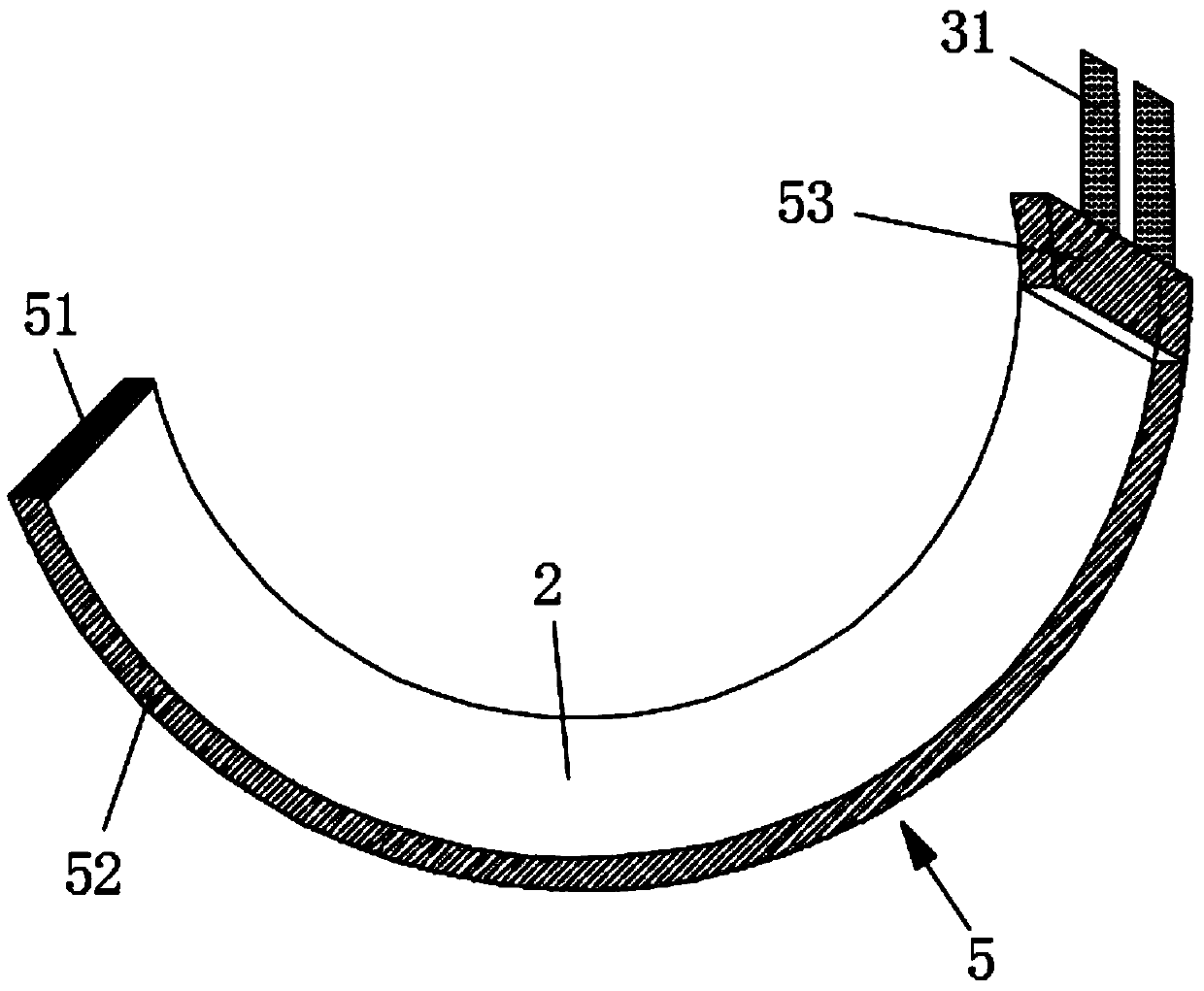

Arc laminated wood component forming method based on wood plasticity

ActiveCN106378849AReliable shapeAccurate shapeOther plywood/veneer working apparatusLaminationMaterials scienceCoating

The invention discloses an arc laminated wood component forming method based on wood plasticity, and belongs to the field of laminated wood preparing. The method comprises the five working procedures including wood water containing rate adjustment, wood lamination coating, profile modeling, pressurizing and pressure unloading curing. Through adjustment of the water containing rate of wood and the component machining environment condition, a wood laminated board is machined according to the design curvature radius of an arc laminated wood component, and it is ensured the prepared component has the precise design shape; through the adjustment of the water containing rate of wood and the component machining environment condition, the design curvature radius of the arc laminated wood component is directly adopted for coating and pressurizing, the precision of the quality and the shape of the arc laminated wood component can be effectively ensured, and the problems that machining of a traditional arc laminated wood component relies on experiences for adjusting the curvature radius, due to the defects of knots and the like or the reasons of the lamination thickness and the like, the wood lamination board is broken, and after the preparing of the arc laminated wood component, due to shape springback, the shape is inconsistent with the design shape are solved.

Owner:NANJING UNIV OF TECH

Arc-shaped flexible package lithium battery and manufacturing method thereof

PendingCN109585905AGood flexibilityReduce the difficulty of arc forming processFinal product manufactureElectrode carriers/collectorsPlastic filmEnergy density

The invention discloses an arc-shaped flexible package lithium battery and a manufacturing method thereof. The arc-shaped flexible package lithium battery comprises an arc-shaped roll core, an electrode, and a diaphragm bag; the arc-shaped roll core covers an arc-shaped aluminum plastic film on the outer surface of the arc-shaped roll core; the electrode is led out from one end of the roll core; the arc-shaped roll core comprises an electrode piece; the diaphragm bag covers the outer side of the electrode piece; the electrode is led out from the horizontal direction of the electrode piece; andthe electrode piece is wound in the direction parallel to the electrode piece. The structural cell has the characteristic of high flexibility in the length direction, thereby facilitating arc shaping, 0-180 DEG arc shape bending of the battery can be realized; and the volume energy density of the battery is improved through the manufacturing method.

Owner:GUANG DONG VDL NEW ENERGY CO LTD

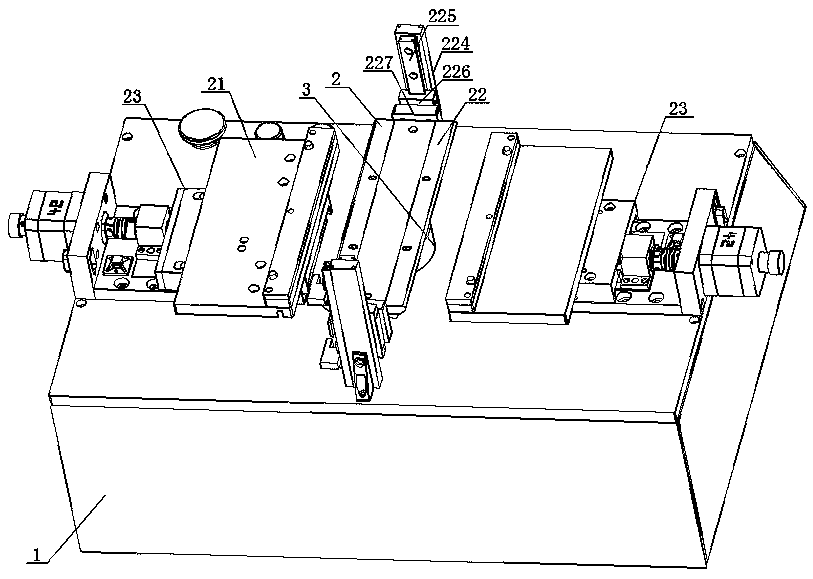

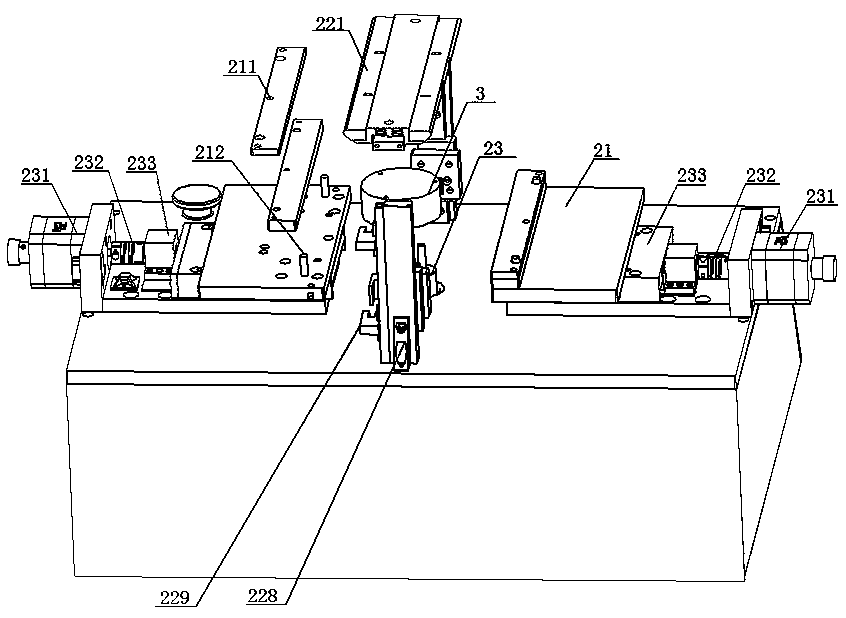

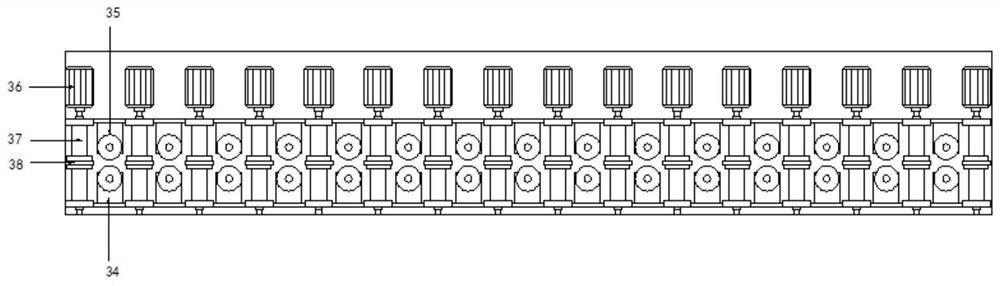

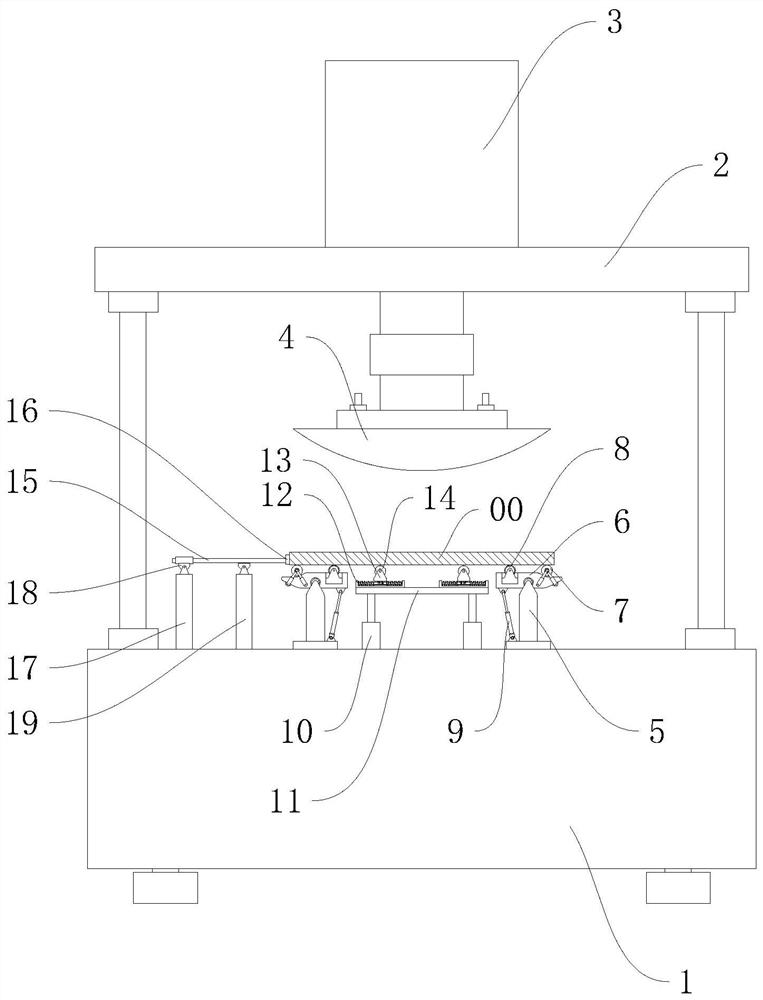

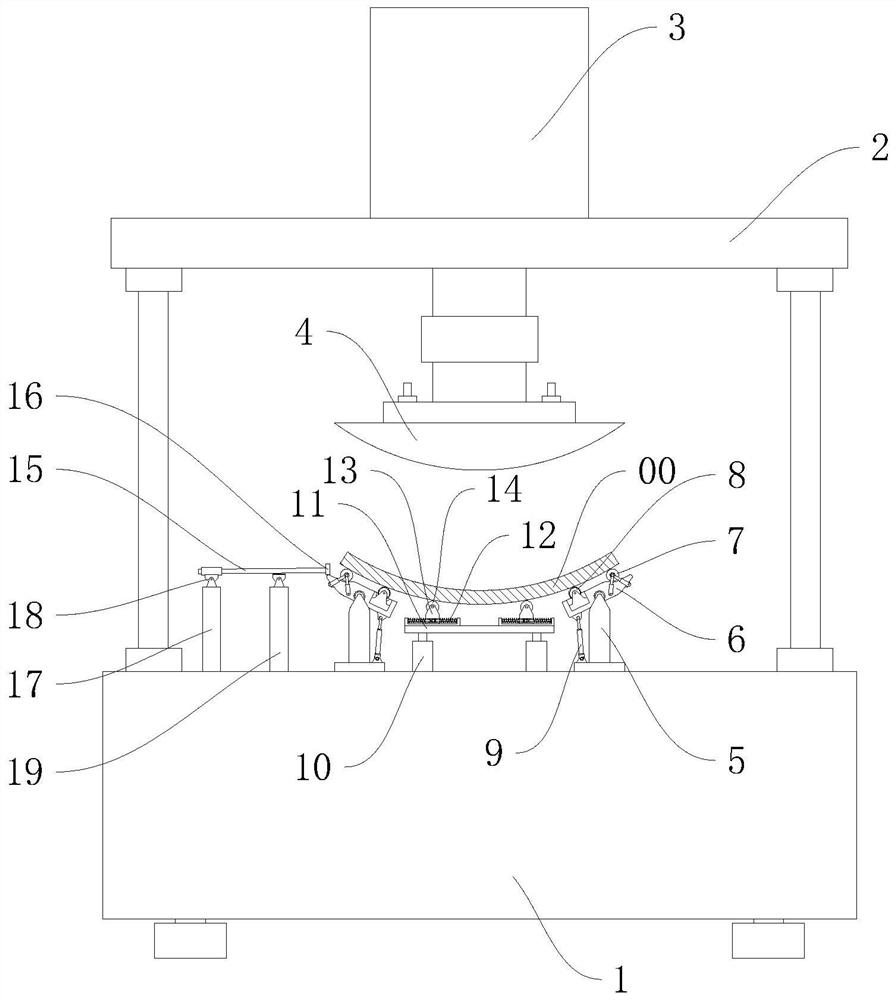

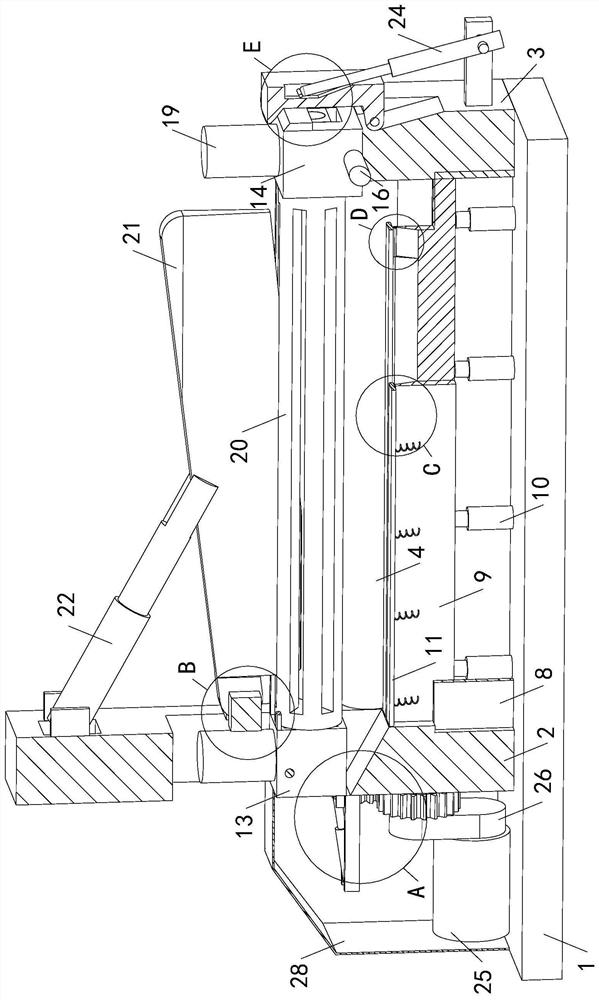

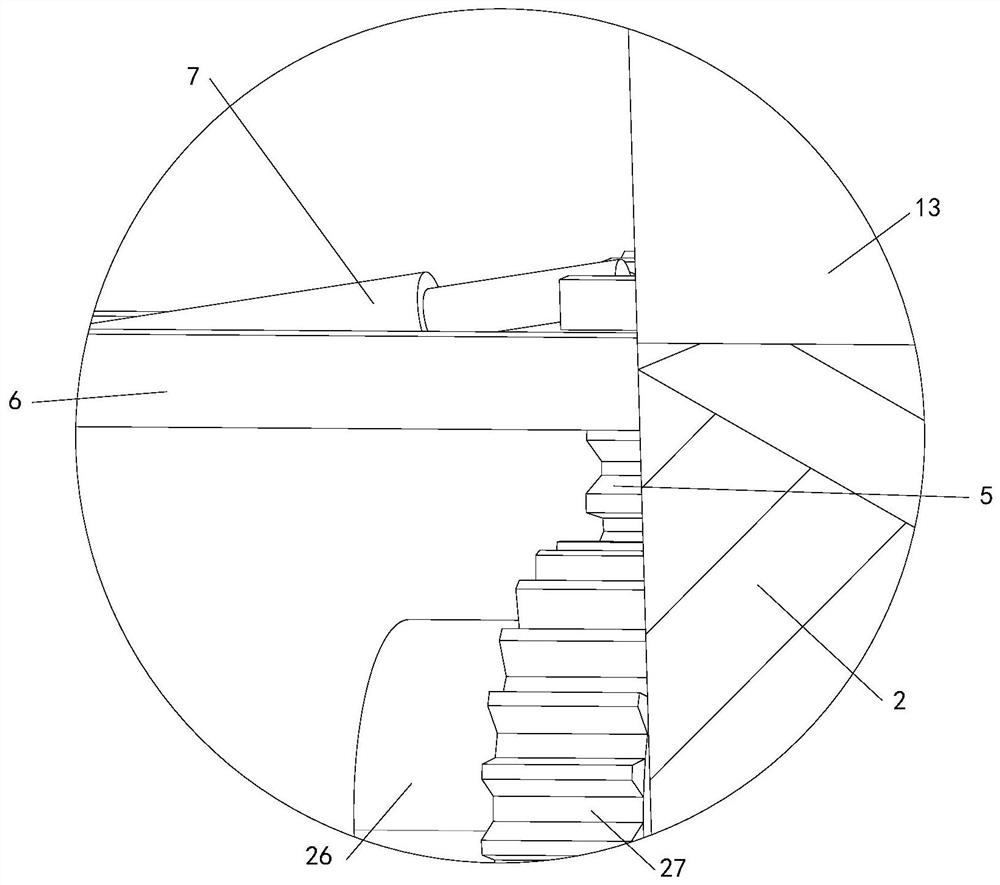

Bending machine for OLED screen test

PendingCN111089789AStrong dimension spanLarge size spanMaterial strength using steady bending forcesMaterial strength using repeated/pulsating forcesMechanical engineeringStress sensors

The present invention provides a bending machine for an OLED screen test. The bending machine comprises a cabinet body, a bending mechanism and a pressure sensor; the cabinet body is provided with thebending mechanism and the pressure sensor; the bending mechanism comprises ballast tables, a placement table and a moving device; the ballast tables are arranged on both sides of the placement table;the moving device comprises a plurality of moving components, which are lateral moving components and vertical moving components respectively; the ballast tables are connected with the lateral movingcomponents to achieve left and right movement of the ballast tables; the placement table is connected with the vertical moving components to achieve up and down movement of the placement table; and the pressure sensor is arranged below the placement table and is configured to test the pressure when an OLED screen is bent. According to the bending machine for the OLED screen test provided by the present invention, the versatility is strong, bending on both sides can be realized, the bending experiment efficiency is higher, the experimental result is more stable and objective, the bending machine is compatible with the OLED screen, and a large size span is achieved.

Owner:四川湛海科技有限公司

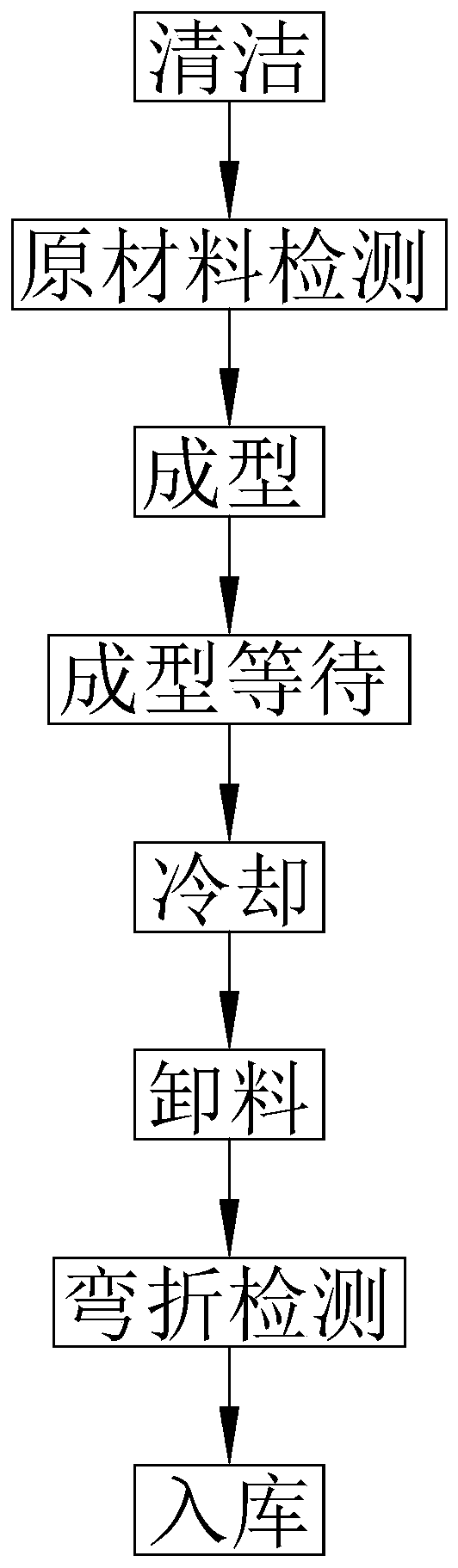

Civil defense door board bending process and device thereof

InactiveCN109702058AAvoid wasting resourcesAvoid processingShaping toolsMetal-working feeding devicesSteel platesEngineering

The invention discloses a civil defense door board bending process, and relates to the field of civil defense doors. The process comprises the following steps: cleaning: dust and other particles attached on the surfaces of steel plates are removed; raw material detection: the structural strength and the flatness of the steel plates are detected to eliminate unqualified steel plates; molding: partsto be bent of the steel plates are heated; and then, the steel plates are bent by adopting a pressing plate, or in the state of bending the steel plates by the pressing plate, the bent parts of the steel plates are heated; molding waiting time: the state of bending the steel plates by the pressing plate is lasted by 3-5 minutes; cooling: the pressing plate is cooled by adopting cooling liquid; and unloading: the bent steel plates are taken down. Aiming at the problem of instable bend molding in the prior art, the process adopts the heating mode to conveniently reach stable bending angle afterbending of the steel plates; and in addition, the cooling liquid is used for quickly reducing the stability of the bent parts of the steel plates and improving the passivity of materials of the bentparts, so that the molded steel plates are difficultly deformed.

Owner:上海海钊民防设备有限公司

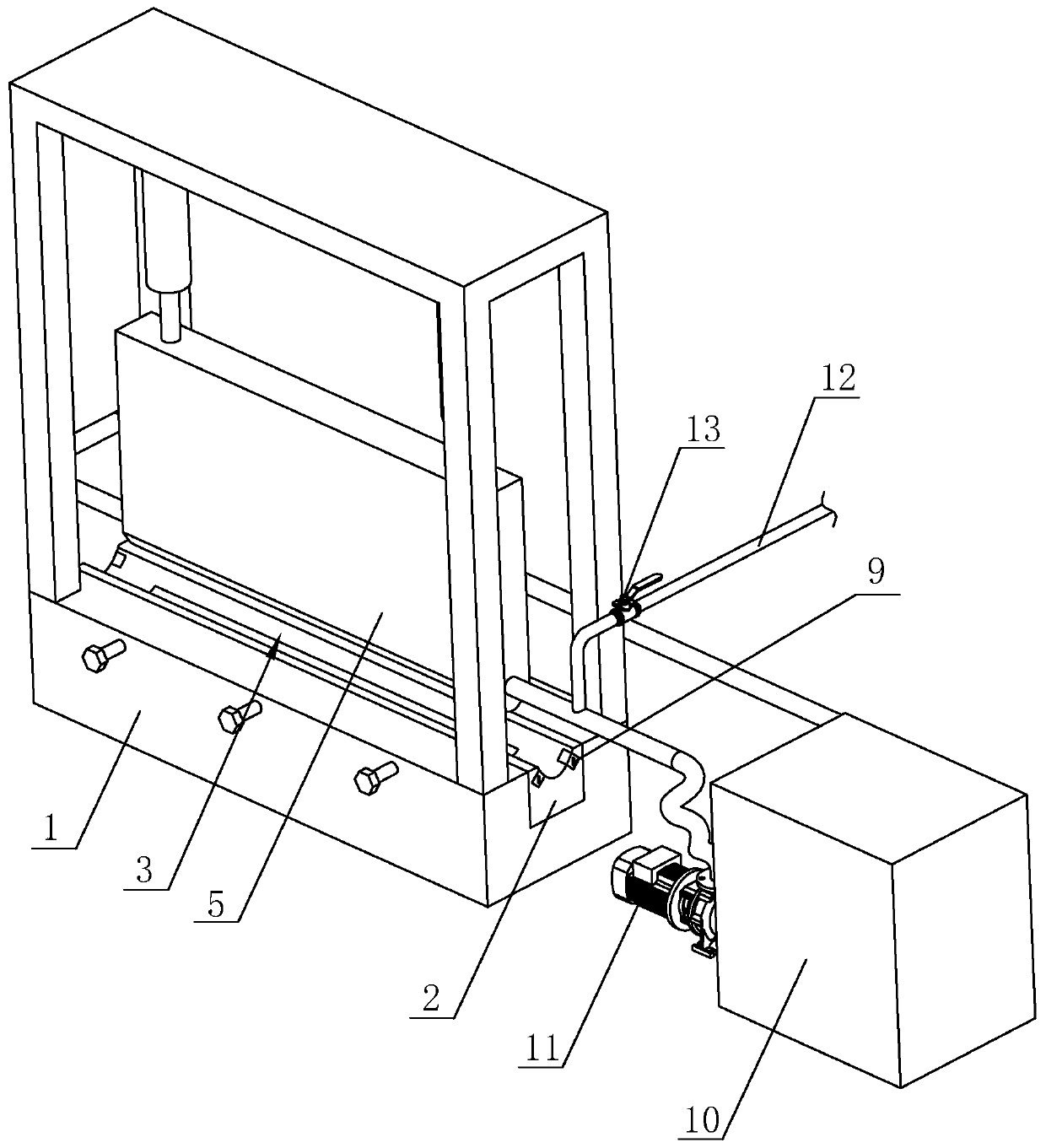

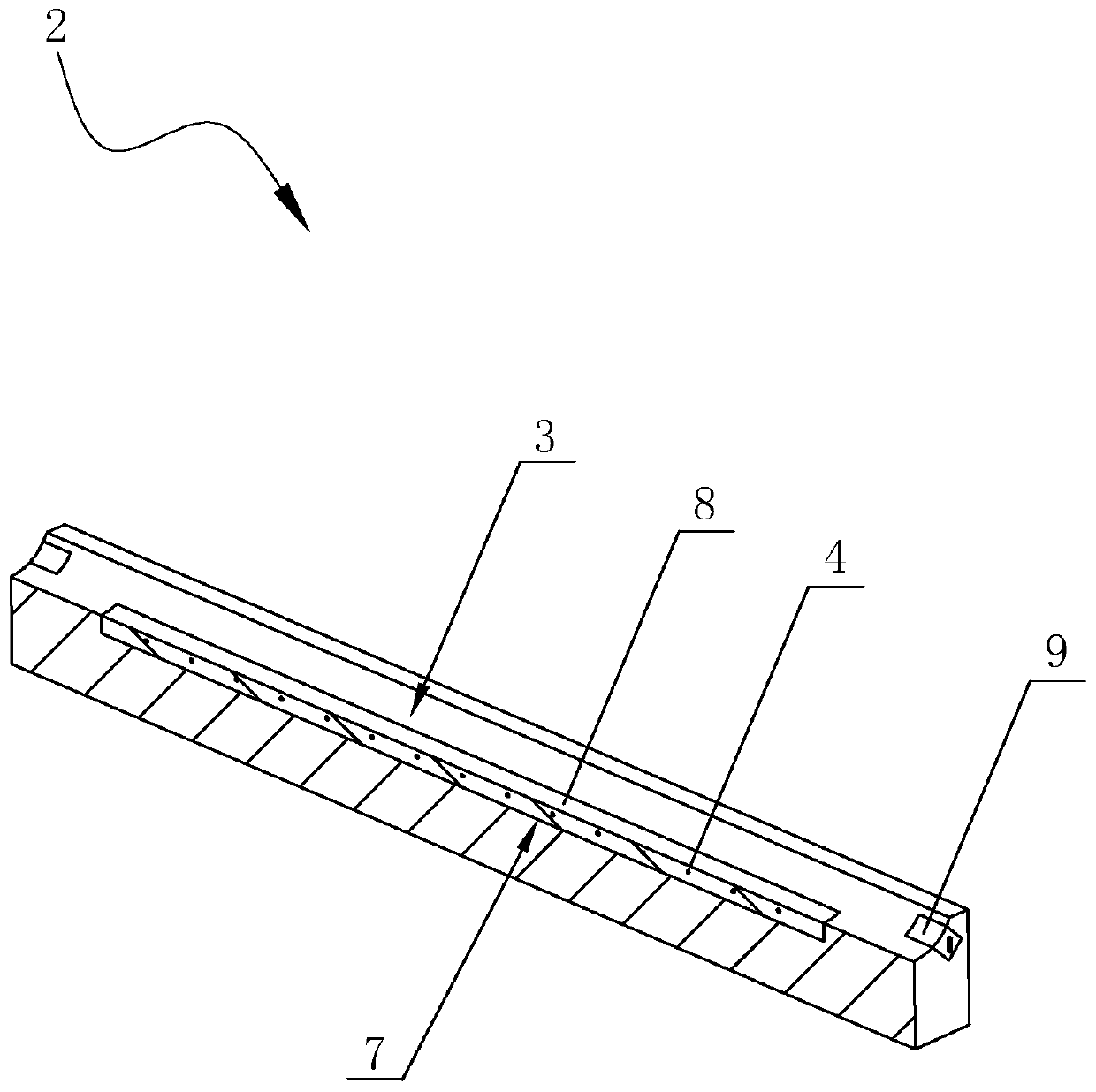

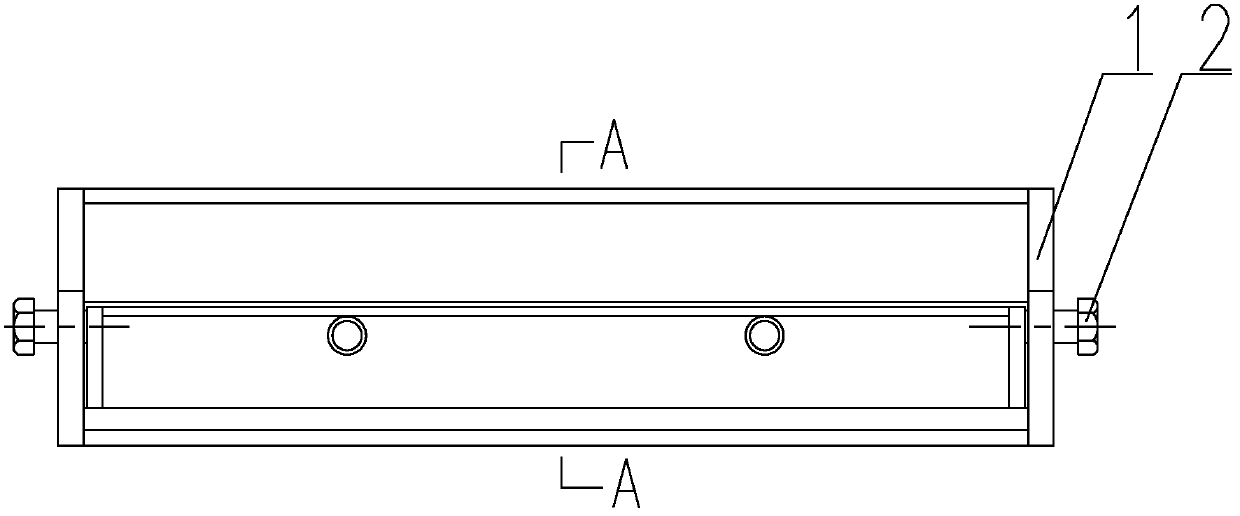

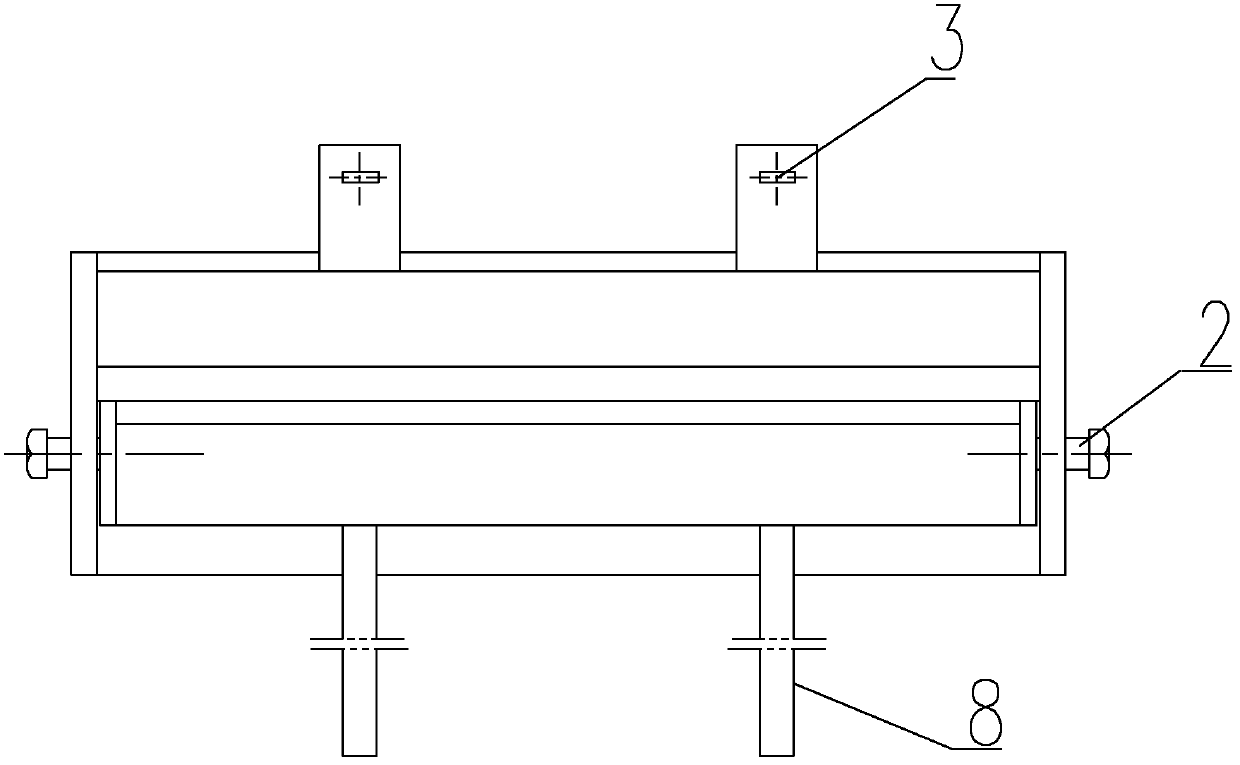

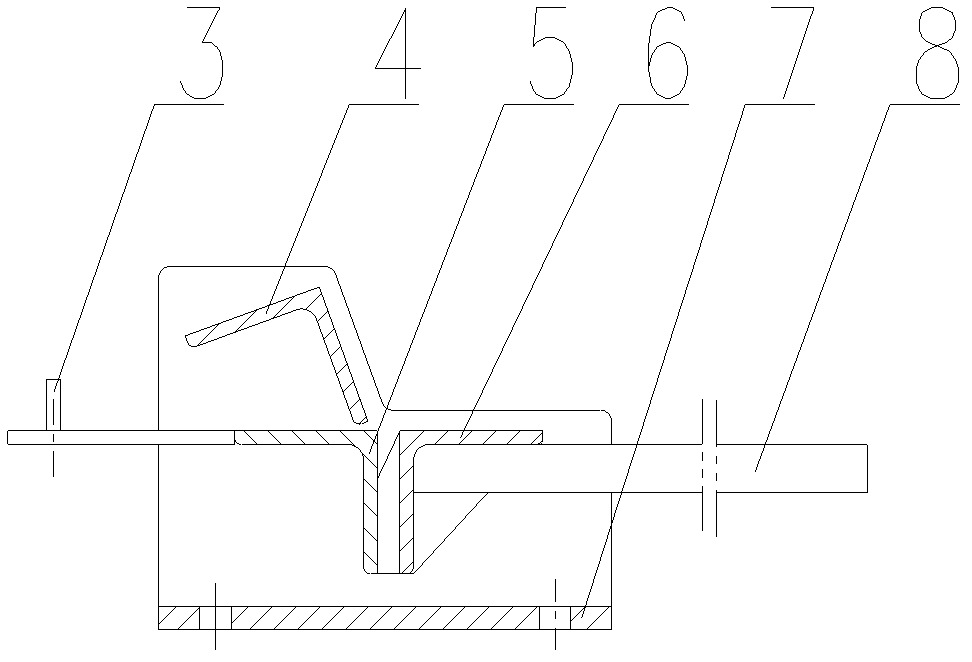

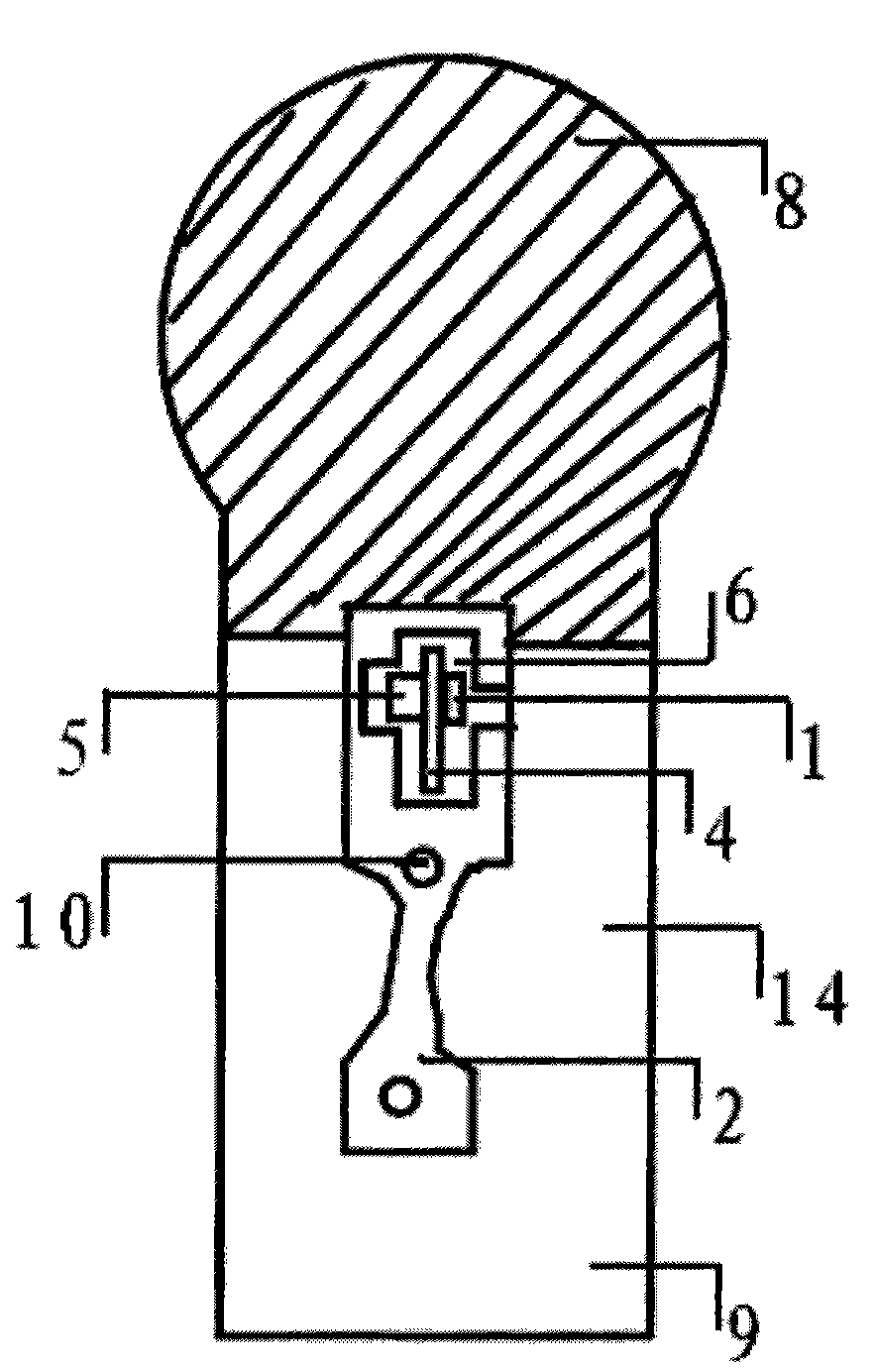

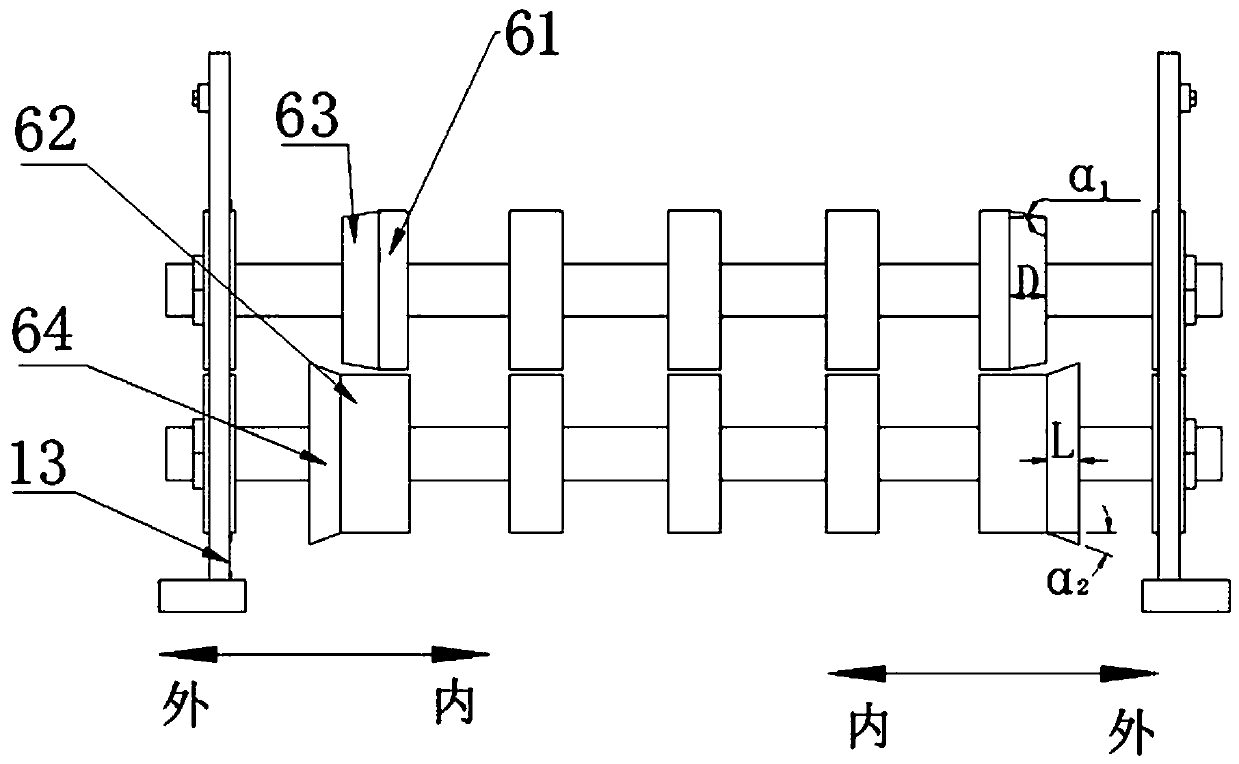

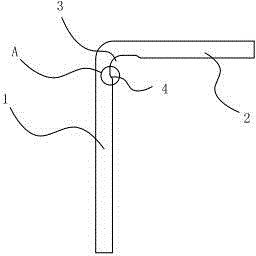

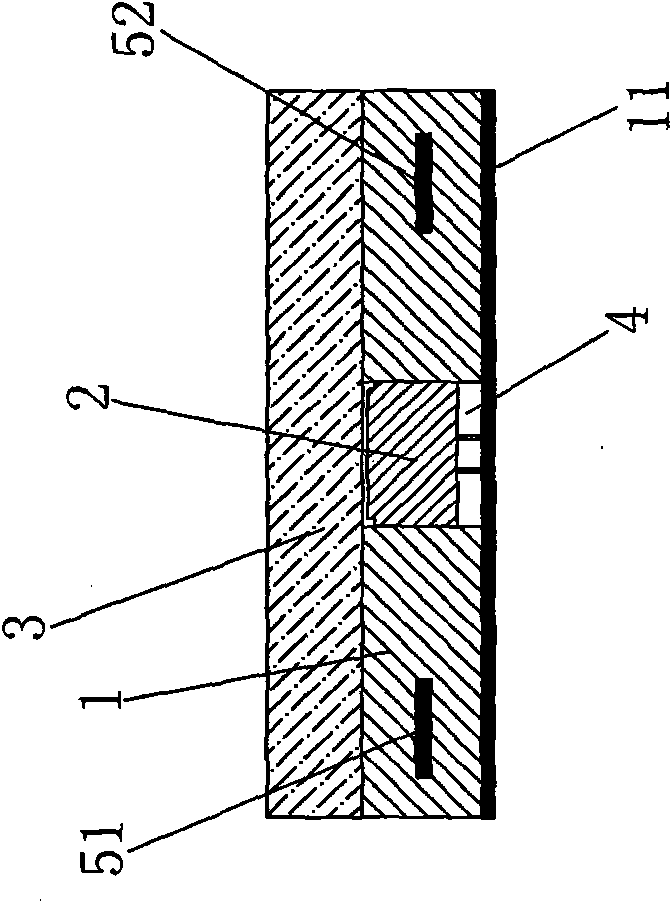

Device for bending edges of paperboard manually

InactiveCN102436922AEasy to bend and shapeSimple structureMechanical working/deformationInductances/transformers/magnets manufactureTransformerPaperboard

The invention discloses a device for bending edges of a paperboard manually, which is mainly used for bending and forming an insulating paperboard used in a transformer and belongs to the technical field of transformer manufacturing. The device comprises a base (7), wherein the left side and the right side of the base (7) are provided with brackets (1); a limiting beam (4) and a fixing beam (5) are arranged between two brackets (1); the limiting beam (4) and the fixing beam (5) are arranged opposite to each other vertically and are fixedly connected with the brackets (1) on the two sides of the base; a space through which the paperboard can pass is reserved between the limiting beam (4) and the fixing beam (5); a rotatable turning beam (6) of which two ends are connected with the brackets (1) on the two sides of the base is arranged in front of the fixing beam (5); the turning beam (6) is provided with handles (8); and the rear part of the fixing beam (5) is provided with a positioning mechanism. The device for bending the edges of the paperboard manually has a simple structure, can bend and form paperboards conveniently, is convenient to operate, has high processing efficiency, high bending quality and low bending rebound, and does not damage or contaminate the insulation of the paperboards.

Owner:SHANDONG POWER EQUIP

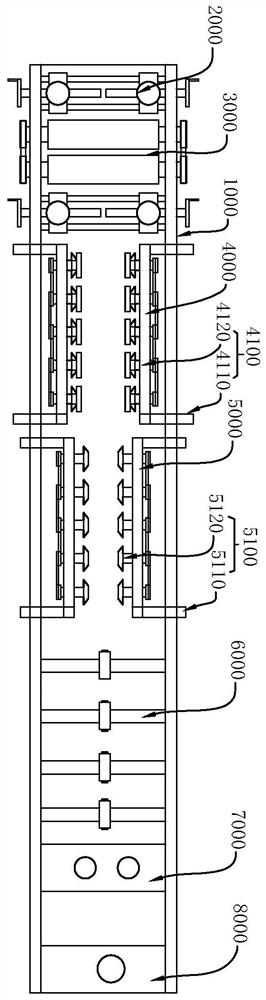

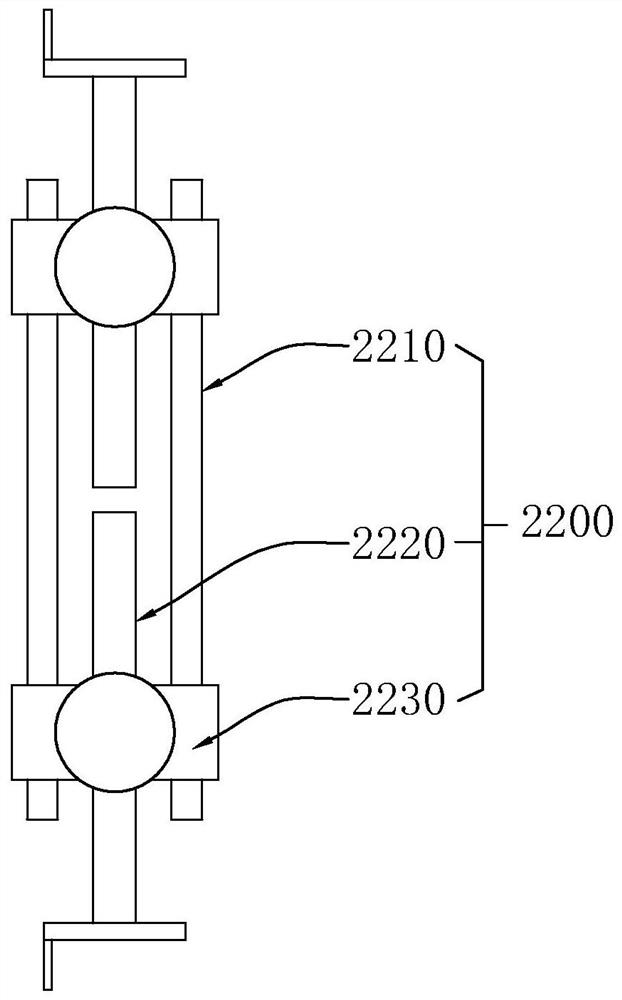

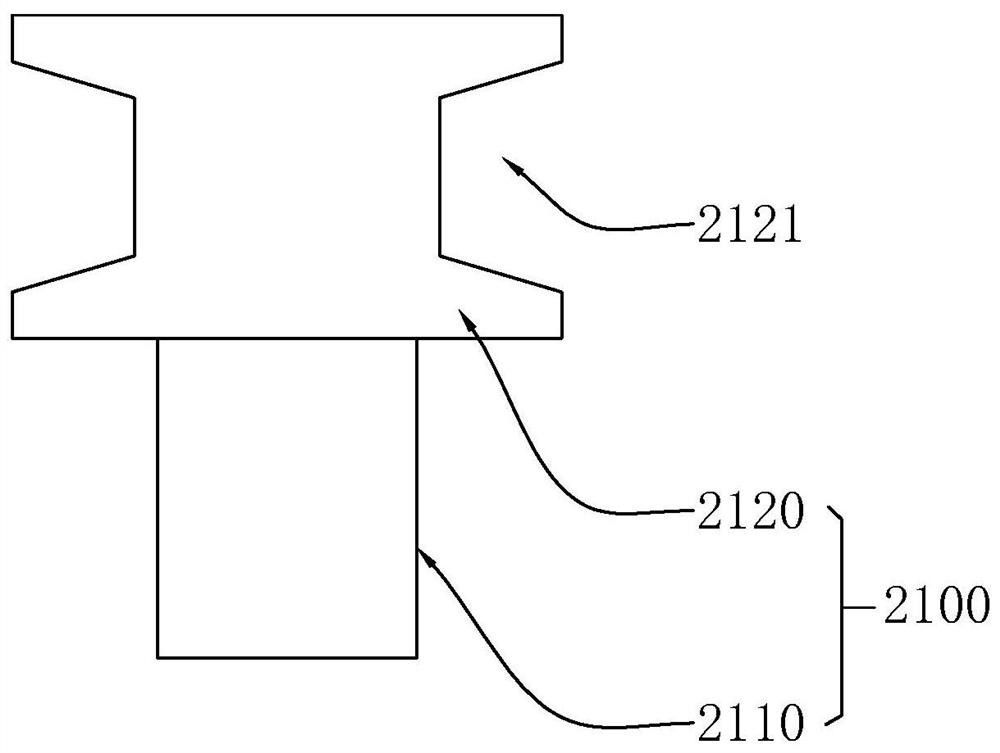

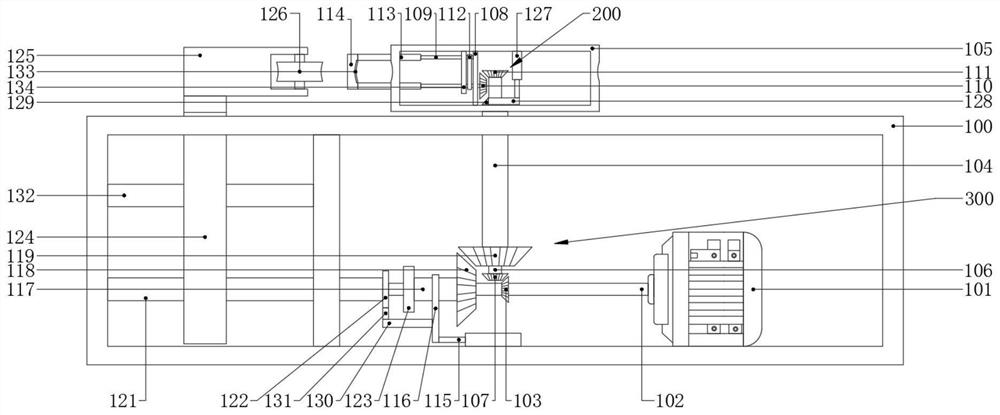

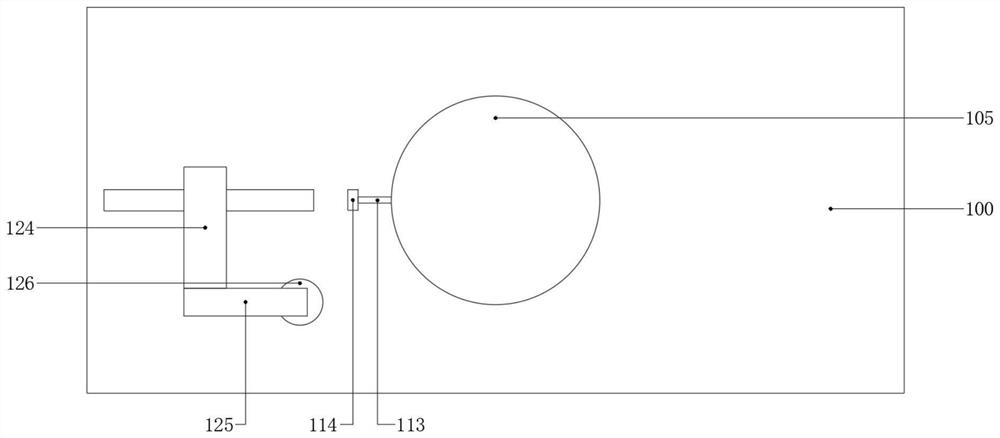

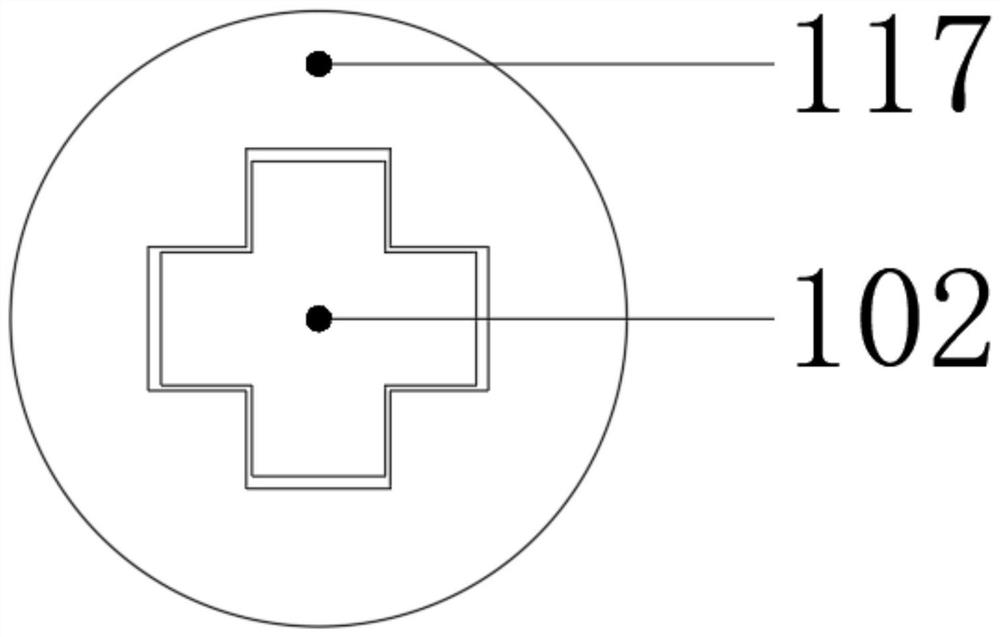

C-shaped steel forming machine

InactiveCN112008419AAvoid displacementAvoid deformationOther manufacturing equipments/toolsPunchingMolding machine

The invention relates to a C-shaped steel forming machine. The C-shaped steel forming machine comprises a rack, and a guiding and positioning assembly, a flattening assembly, a side bending assembly,a middle bending assembly, a ribbing assembly, a punching assembly and a shearing assembly which are arranged on the rack in sequence, the C-shaped steel forming machine has the beneficial effects that the guiding and positioning assembly is used for guiding and positioning a steel plate to enter the flattening assembly, displacement and deformation of the steel plate are prevented, the feeding stability of the steel plate is improved, and the production efficiency is improved. The flattening assembly is mainly used for flattening the steel plate, subsequent bending forming is facilitated, andthe product quality of the C-shaped steel is improved. The C-shaped steel is firstly fixed and then punched through the pre-fixing punching mechanism, the punching precision is improved, then the C-shaped steel is positioned and sheared through the positioning and shearing mechanism, the shearing precision is improved, and the production quality of the C-shaped steel is improved in the whole production process.

Owner:济南市鼎冉金属制品有限公司

Automatic production line for outer frame forming

PendingCN113500636AImprove product qualityImprove pass rateFramesMetal working apparatusManufacturing engineeringAutonomation

The invention discloses an automatic production line for outer frame forming. The automatic production line comprises a production line body, the production line body is composed of a feeding mechanism, a cutting system, a conveying system and a forming system, an operation table is arranged on the side face of the feeding mechanism, and the cutting system, the conveying system and the forming system are all installed on the surface of the operation table. The cutting system, the conveying system and the forming system are all installed on the surface of the operation table, the cutting system comprises a feeding table, a bracket is arranged on the upper portion of the feeding table, a clamping groove matched with a plate is formed in the bracket, and the stability of raw material conveying is guaranteed; and a mounting frame is arranged at the upper part of the feeding table, and a hydraulic cylinder is arranged on the top of the mounting frame; and a movable block is arranged at the power output end of the hydraulic cylinder, a cutter is arranged at the bottom of the movable block, and the cutter can cut the edge of the entering plate.

Owner:安徽森源环境技术有限公司

Manufacturing method for forming three-dimensional grating image-text on concave part of printing product and product made by method

The invention provides a manufacturing method for forming three-dimensional grating image-texts in a specific region at the surface of a printing product according to design requirements, and the three-dimensional grating image-text region is lower than other regions of the surface of the printing product. The method comprises the following steps of: firstly printing three-dimensional image-texts on different regions of the surface of paper by three-dimensional printing; then performing impressing on the three-dimensional image-text regions on the paper by a concave-convex marking press to form a concave cavity; filling polyester resin in the concave cavity; coating or printing a transparent resin layer which is easy to deform under heat and pressing on the surface of the polyester resin layer; and finally impressing the surface of the transparent resin layer by a cylinder grating board, so that the surface of the polyester resin is provided with a semi-cylindrical curved surface which is symmetrical with the cylinder grating board structure. The manufacturing method has the characteristics of being mature in process, easy to operate and control and exact in printing; and the printing product with the three-dimensional grating image-texts at the concave part manufactured by the method is easy to bend and shape, and is especially suitable for being used as package material of high-grade products such as cigarettes, wines or cosmetics.

Owner:YANBIAN CHANGBAISHAN PRINTING

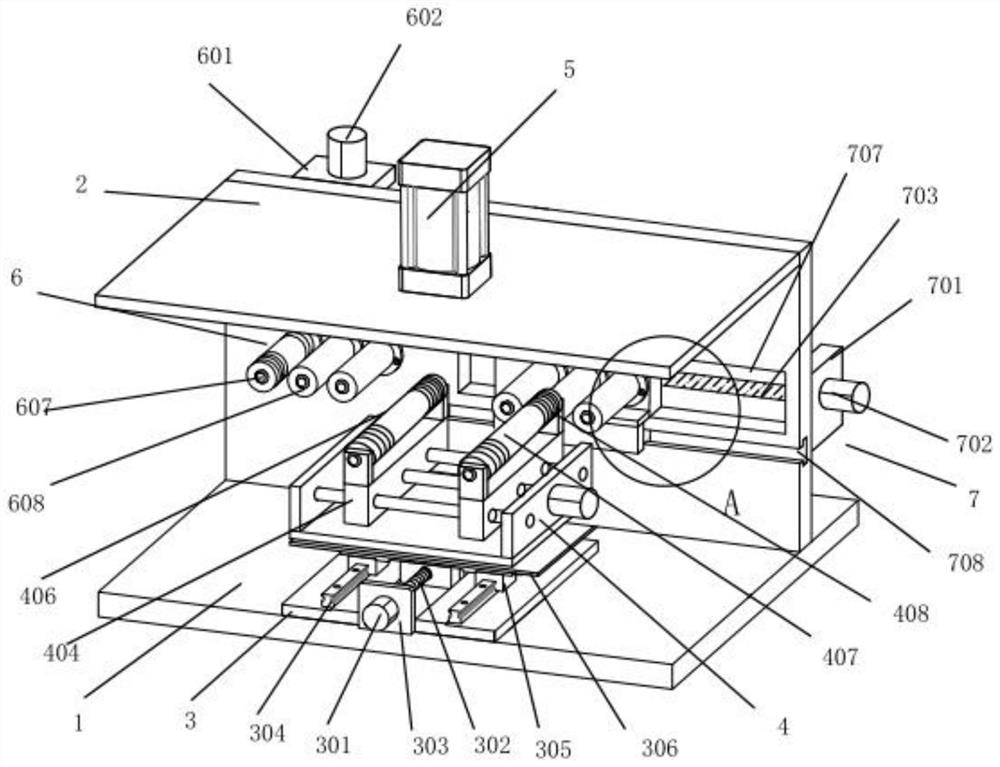

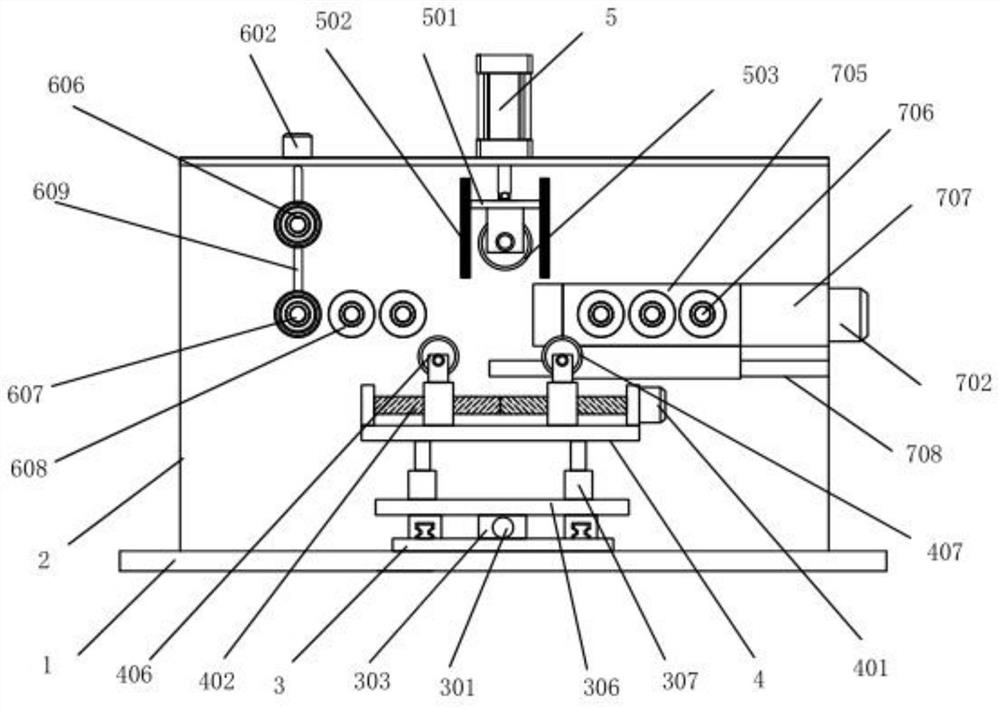

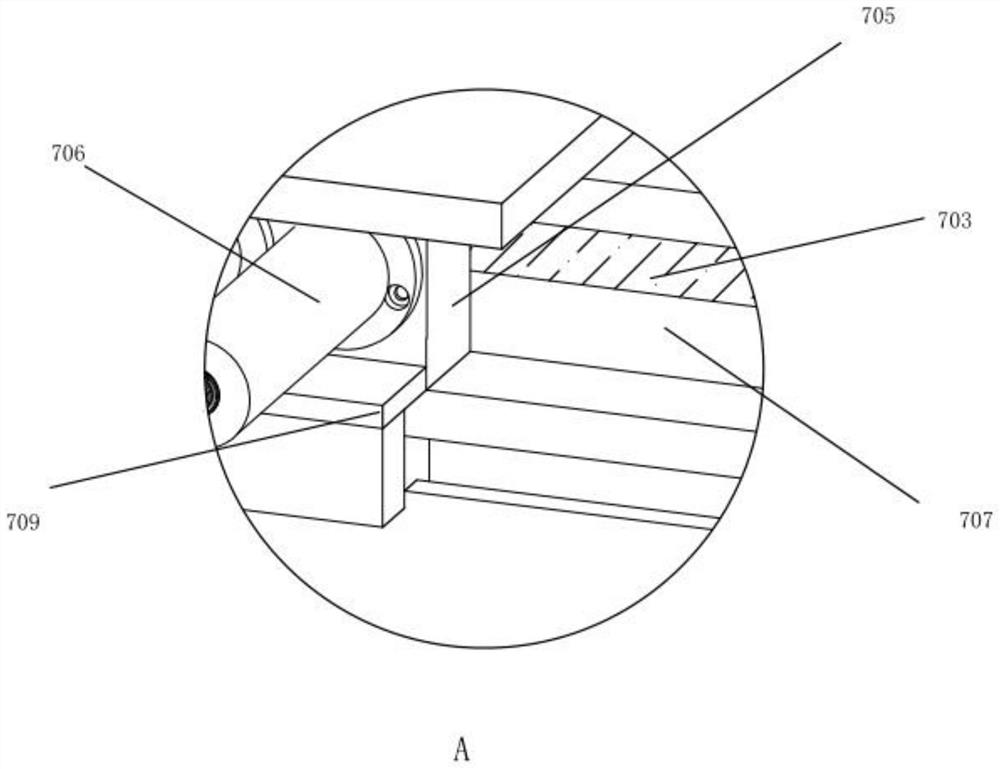

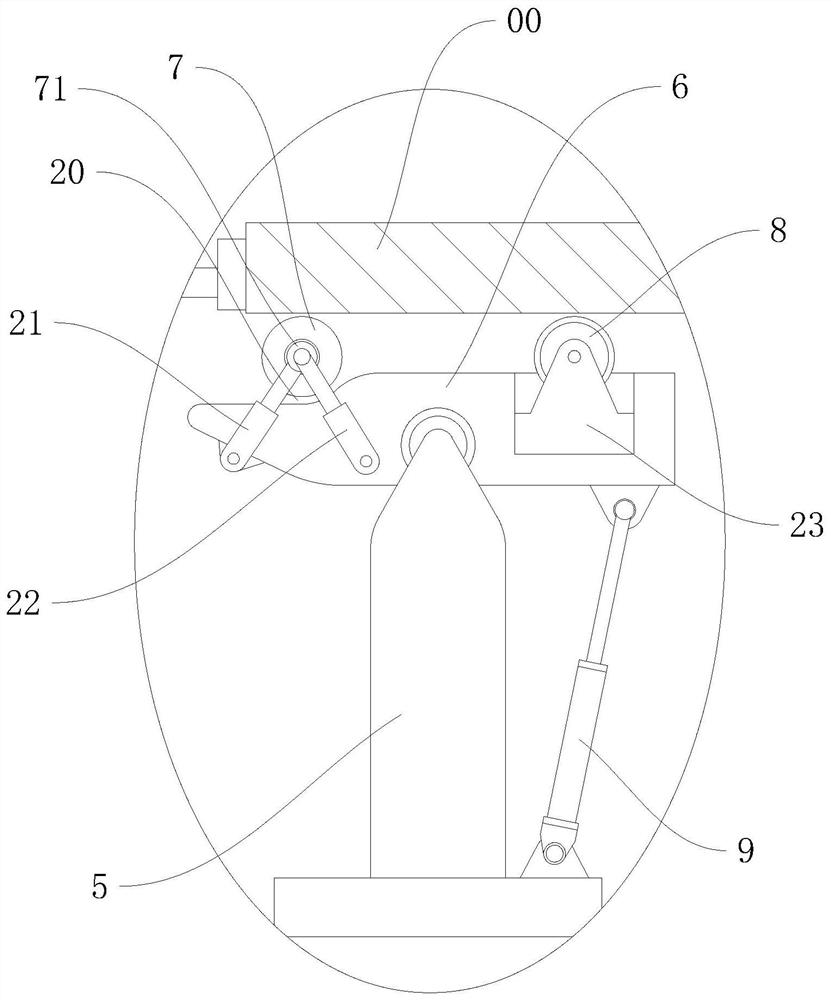

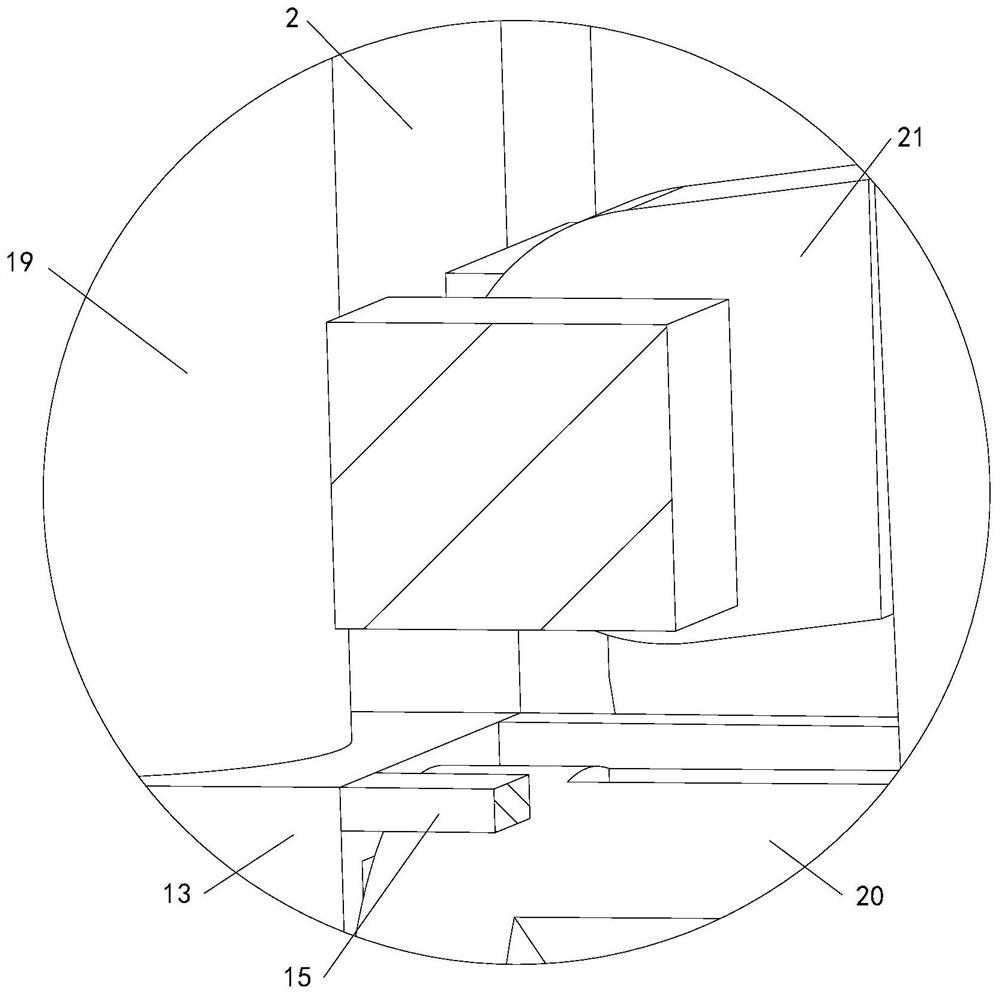

Multi-deflection bending and shaping device for furniture wood processing and working method

InactiveCN111761672APracticalEasy to bend and shapeWood stock bendingWood machiningStructural engineering

The invention discloses a multi-deflection bending and shaping device for furniture wood processing and a working method. The multi-deflection bending and shaping device comprises a base, an L-shapedplate frame is fixedly arranged on the base, a first supporting plate is fixedly arranged on the plate surface of the base, a second supporting plate is arranged over the first supporting plate, a U-shaped auxiliary frame is arranged over the second supporting plate, a first auxiliary hot roller and a second auxiliary hot roller are fixedly arranged on the U-shaped auxiliary frame, an air cylinderis fixedly arranged in the middle of the top surface of a horizontal plate of the L-shaped plate frame, a piston rod of the air cylinder penetrates through the horizontal plate of the L-shaped plateframe to be fixedly connected with a pressing plate, a main hot roller is fixedly arranged on the pressing plate, and a main conveying frame and an auxiliary driven frame are arranged on vertical plates, located on the two sides of the main hot roller, of the L-shaped plate frame correspondingly. The multi-deflection bending and shaping device can be used for conveying, bending and shaping plateswith different thicknesses, and is high in practicability and wide in application range.

Owner:安徽纬奥特工艺品有限公司

Connecting method for solar cell array front and back face circuits

InactiveCN103928554ADoes not affect collapsed volumeConnection thickness is smallPhotovoltaic energy generationSemiconductor devicesMetal sheetEngineering

The invention discloses a connecting method for solar cell array front and back face circuits. The method comprises the steps of (1), laying a sheet-shaped solar cell welding disc on the front face of a substrate, and laying a sheet-shaped cable on the back face of the substrate; (2) welding the two ends of a metal sheet to the solar cell welding disc on the front face of the substrate and the cable on the back face of the substrate respectively. Due to the facts that the solar cell welding disc is in a sheet shape, the cable is in a sheet shape, and the metal sheet is adopted to be connected with the cable and the solar cell welding disc, the connecting thickness is small due to the connecting mode, and the drawing size of a solar cell array is not affected.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Aluminum rod piece forming machining device

ActiveCN113560386AConforms to bending arcEasy to bend and shapeMetal-working feeding devicesPositioning devicesEngineeringMachine

The invention discloses an aluminum rod piece forming machining device, relates to the technical field of bending presses, and aims at solving the problem of poor bending and shaping effect of aluminum rod pieces. The aluminum rod piece forming machining device is characterized by comprising a lower machine rack and an upper machine rack, wherein a bending die is installed on the upper machine rack through a hydraulic rod; two main supporting assemblies are arranged at two sides, corresponding to the lower side of the bending die, of the lower machine rack; each main supporting assembly comprises a supporting base used for supporting two ends of an aluminum rod; a supporting frame is hinged to each supporting base; and the supporting frames can reversely swing towards the two sides of the bending die. An outer shaping roller and an inner shaping roller are arranged in positions, corresponding to two sides of a hinging shaft, of the upper part of each supporting frame and are used for abutting against the lower side surface of the supporting aluminum rod. An elastic supporting piece is also comprised, and is used for elastically maintaining the supporting frame. The bending forming effect on an aluminum pipe is good, so that the curve formed by bending the aluminum pipe into an arc is smoother.

Owner:嘉兴赛德家具股份有限公司

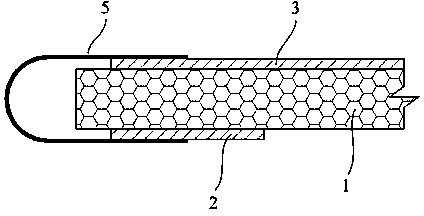

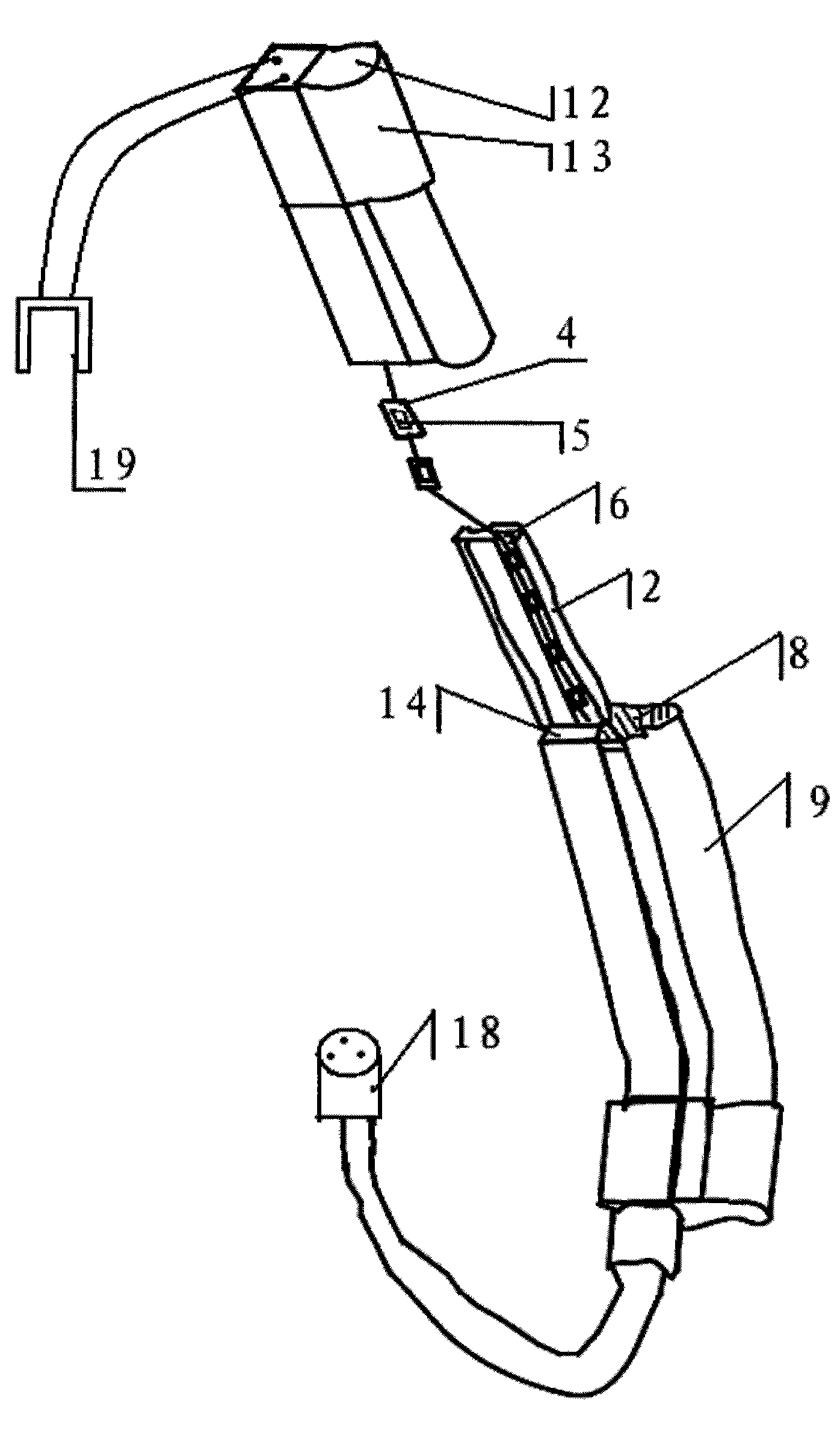

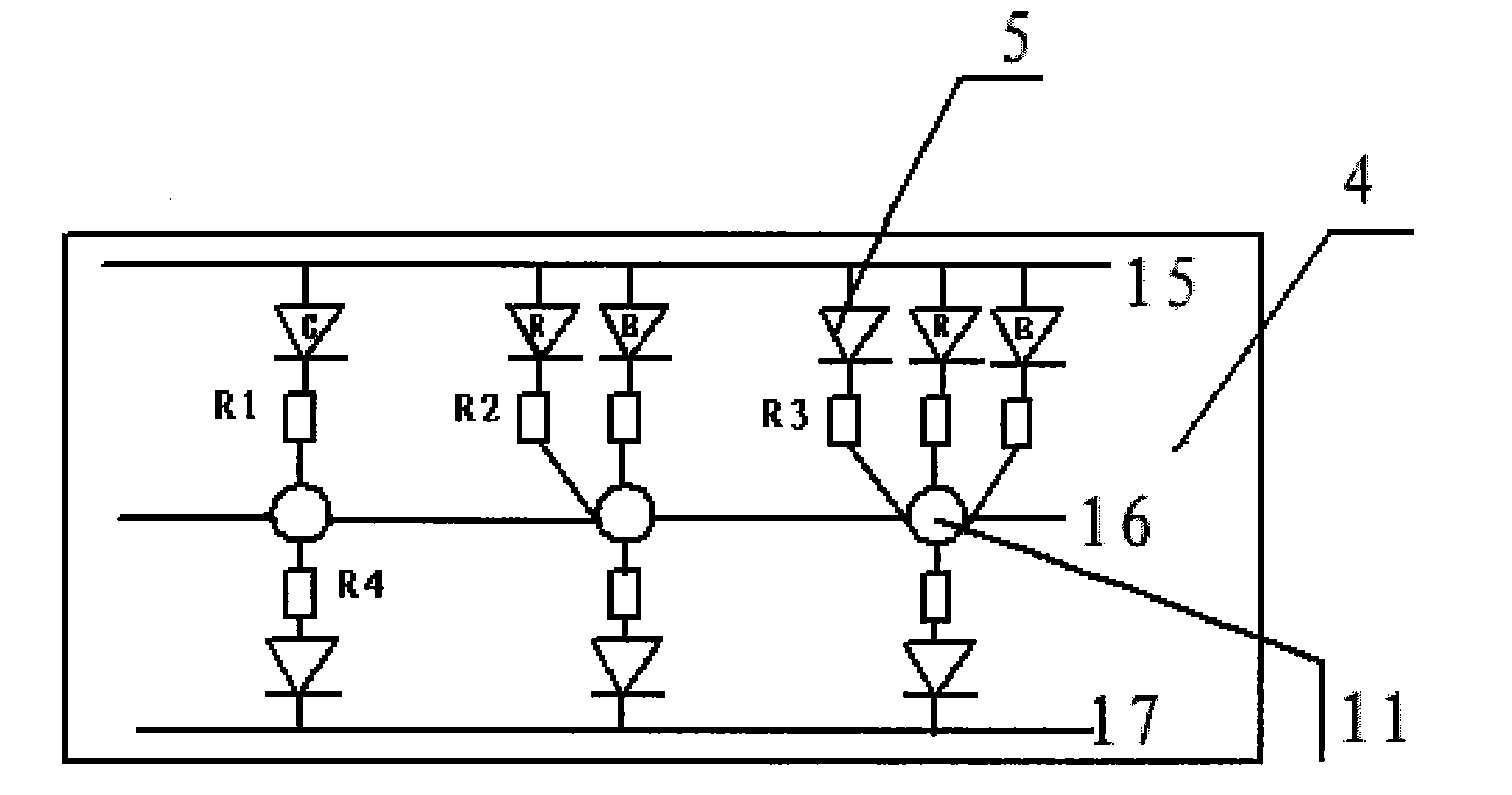

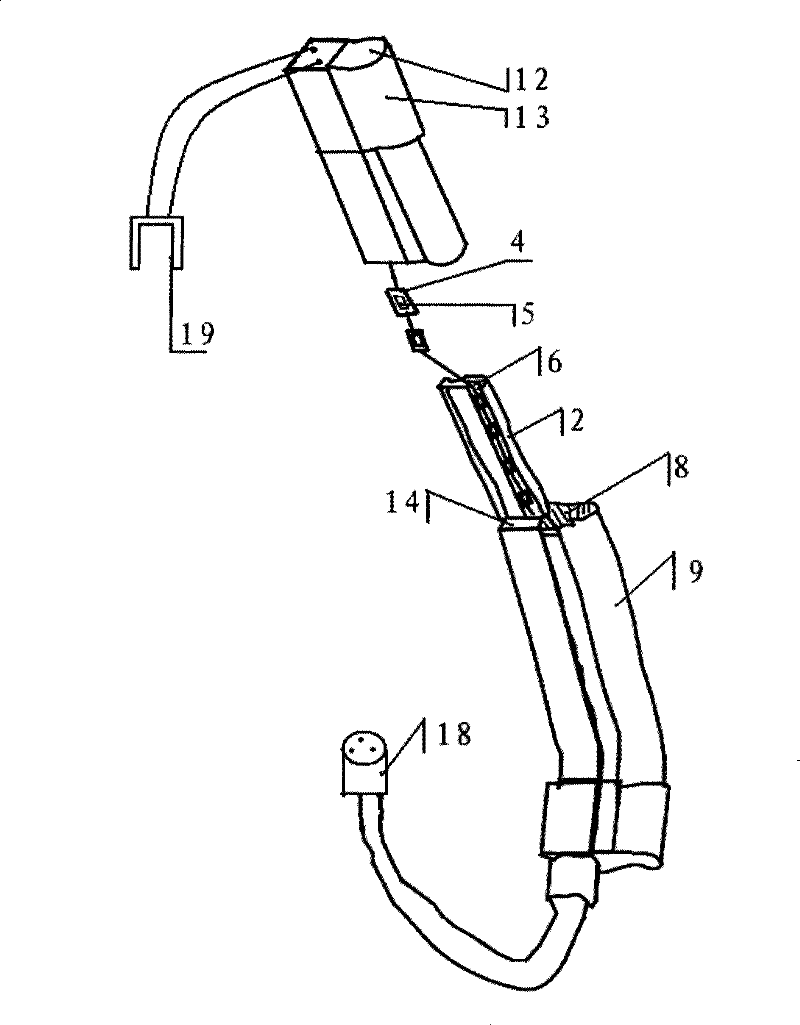

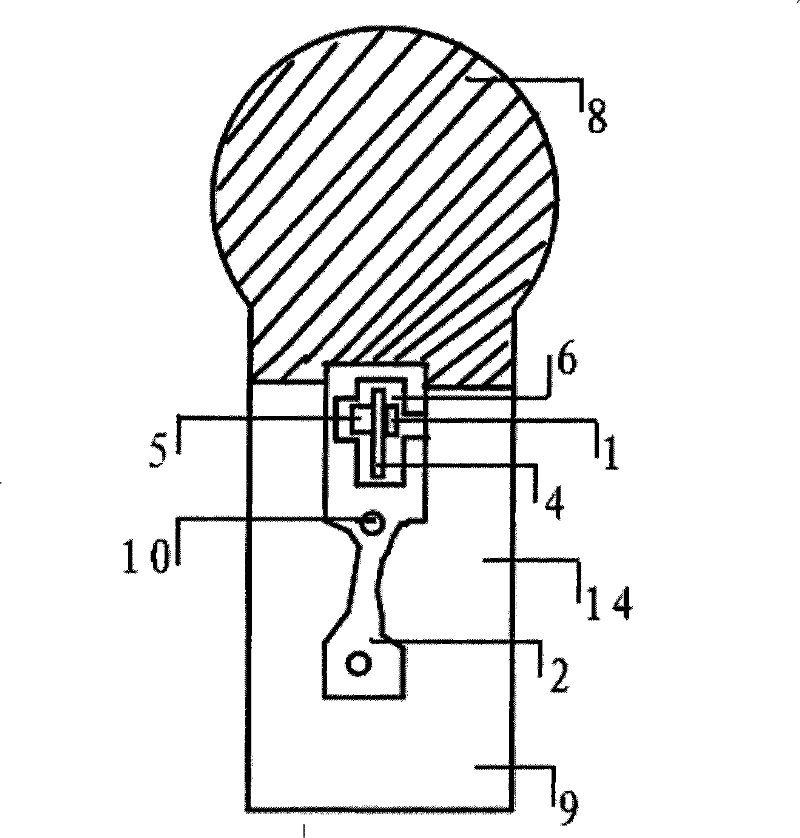

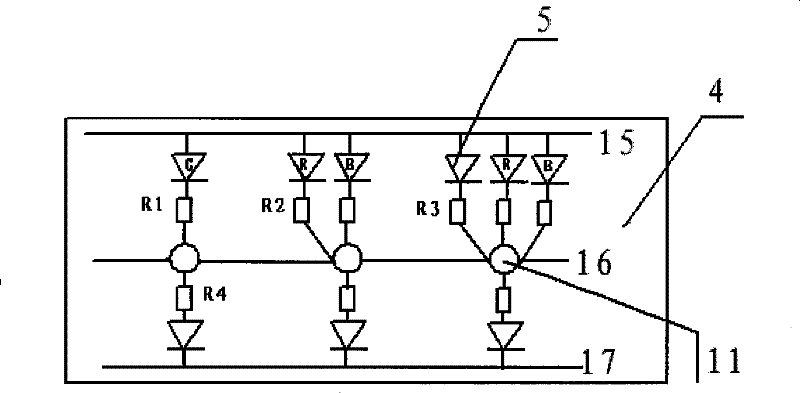

Ultrathin flexible neon lamp integrated with single-wire transmission control chip

InactiveCN101634410AReduce in quantityImprove reliabilityLight source combinationsPoint-like light sourceInput controlEngineering

The invention discloses an ultrathin flexible neon lamp integrated with a single-wire transmission control chip, which comprises a flexible non-light tight core wire, an LED lamp string arranged in the core wire, a flexible non-light tight coating layer coated outside the core wire, a flexible non-light tight light diffuser arranged above the core wire and having equal length with the core wire, and a flexible light shielding layer positioned on two sides of the core wire on the lower part of the coating layer, wherein the LED lamp string consists of a plurality of display units which are connected with one another through power supply positive and negative electrode circuits and a signal control circuit; and a lighting transmission drive control chip is a single-wire transmission drive control chip which inputs control signals through the signal control circuit and directly drives and controls the LED of the display units to emit light. The lamp body of the ultrathin flexible neon lamp is thin, has better flexibility and is easier for bending modeling.

Owner:BEIJING ZHONGQING MICRO ELECTRIC TECH

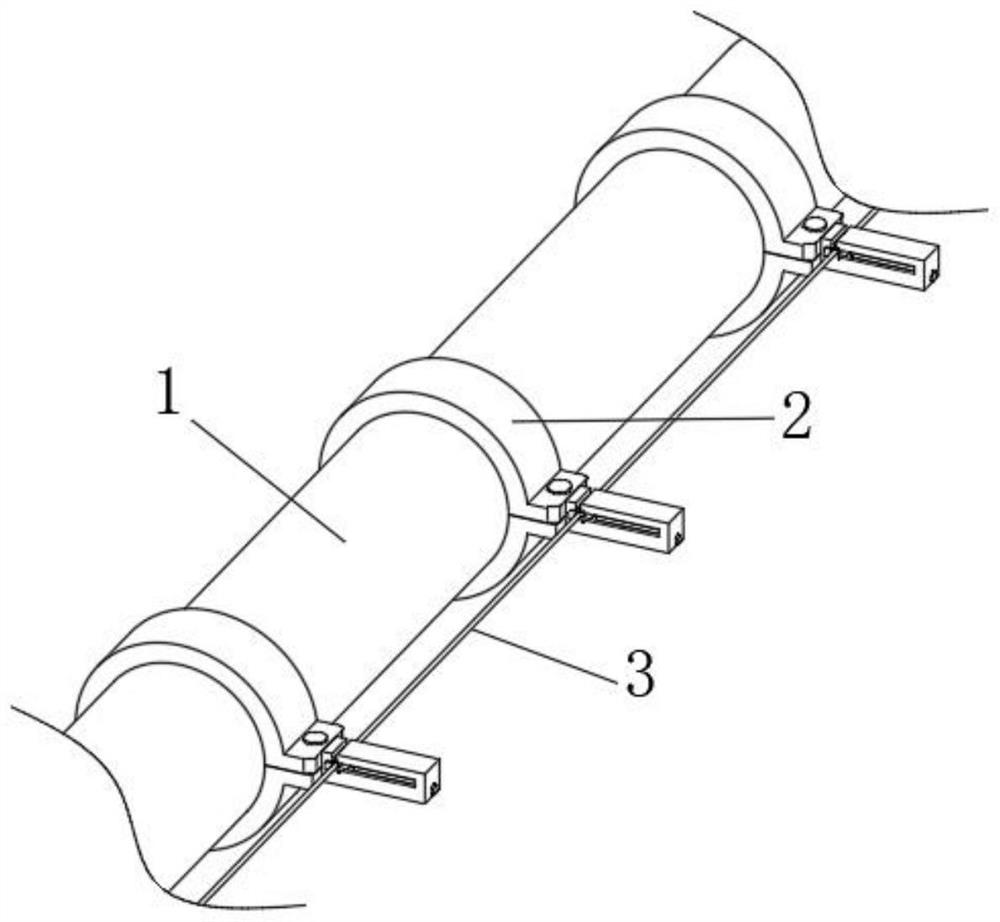

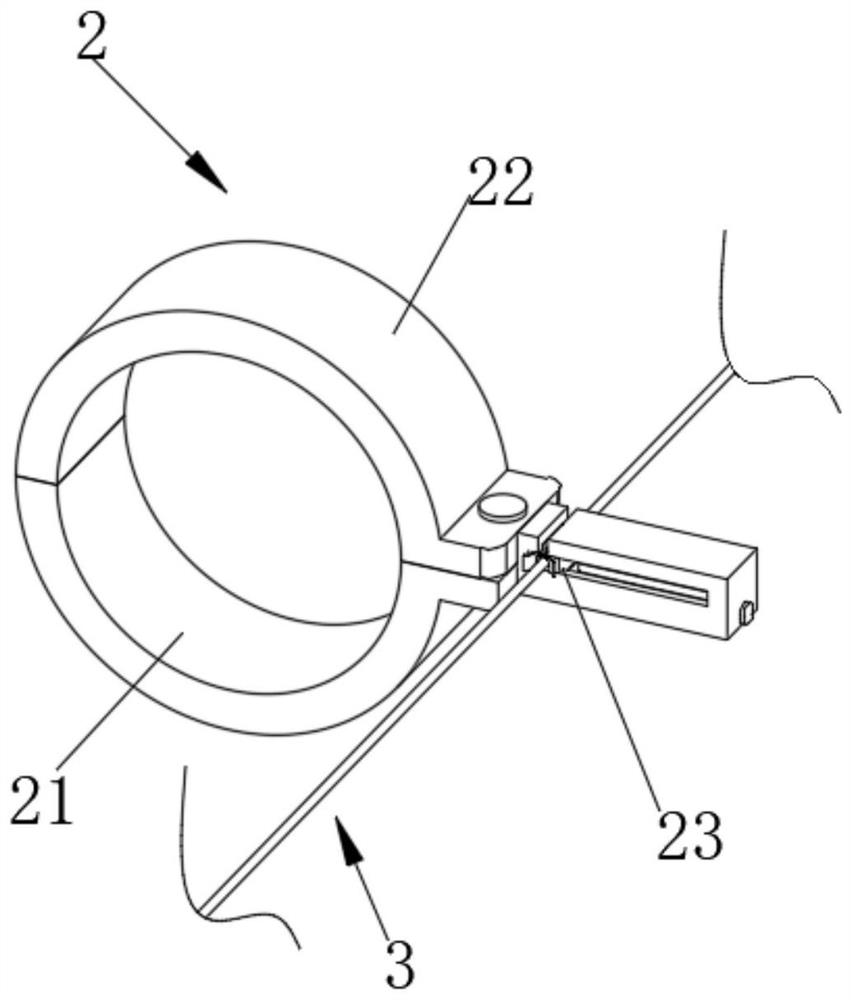

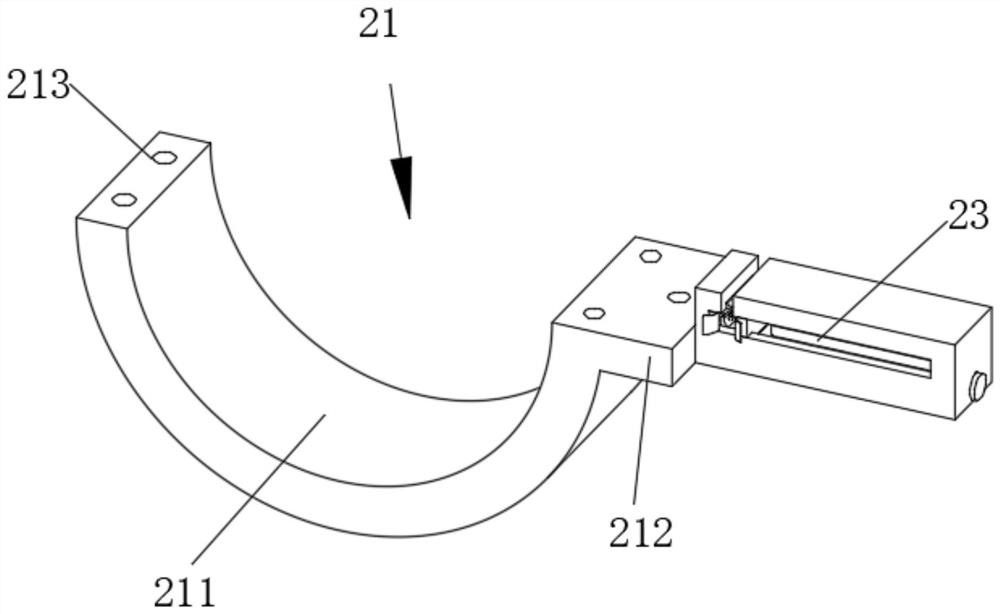

Pipe fitting structure bending machining device for mechanical equipment production and assembly

PendingCN112958662AGood for bending and formingAvoid damage to pipe fittingsDomestic articlesPhysicsElectric machinery

Owner:安徽恒瑞电子电器设备有限公司

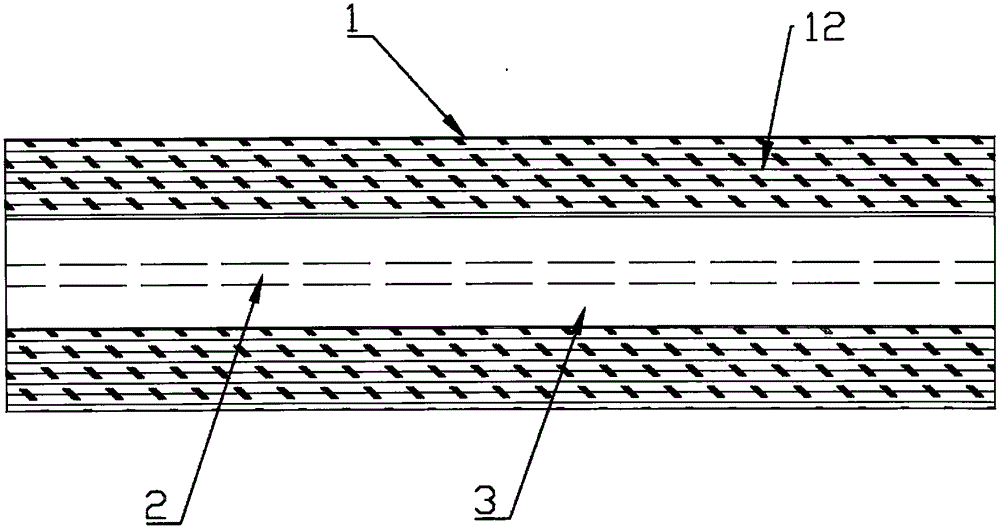

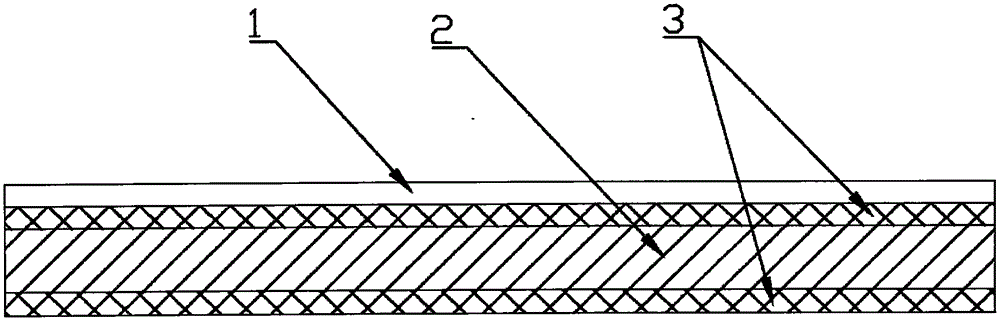

Shaping packaging tape

InactiveCN103879662AEasy to bend and shapeEasy to useFlexible elementsEngineeringElectrical and Electronics engineering

The invention discloses shaping packaging tape. The shaping packaging tape comprises a rectangular packaging tape body. A plurality of groove patterns evenly arranged are arranged on the upper surface and the lower surface of the packaging tape body. The packaging tape body is internally provided with two sets of metal wires evenly arranged, the metal wires are arranged between gaps of the groove patterns and are cylinders, the length of the metal wires is equal to the length of the packaging tape, and the diameter of the metal wires is 1 mm. According to the shaping packaging tape, the packaging tape body is internally provided with the metal wires, the packaging tape can be bent and shaped conveniently, meanwhile, the metal wires are arranged between the gaps of the groove patterns of the packaging tape body, the packaging tape with the needed width can be torn according to the demand and can be used conveniently, cost is saved, and meanwhile the working efficiency is improved.

Owner:苏州市依星橡塑有限公司

Warning tape

InactiveCN105280089APlay a positioningEasy to bend and shapeStampsIdentification meansAdhesiveMetallurgy

The invention discloses a warning tape with a metal wire. The warning tape comprises a thin film base layer. Warning marks are printed on the upper surface of the thin film base layer, and a layer of adhesive is coated on the lower surface of the thin film base layer; the metal wire is adhered on the lower surface of the thin film base layer and is arranged along the length direction of the thin film base layer. The warning tape has the advantages that positioning and folding shaping facilitating effects can be realized by the metal wire in the warning tape, accordingly, the warning tape can be arranged along required trend without being affected by soil, and excellent warning effects can be realized.

Owner:ZHEJIANG WEIYE PLASTIC CO LTD

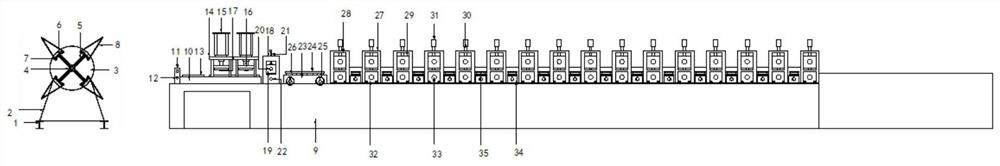

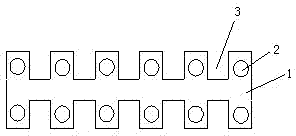

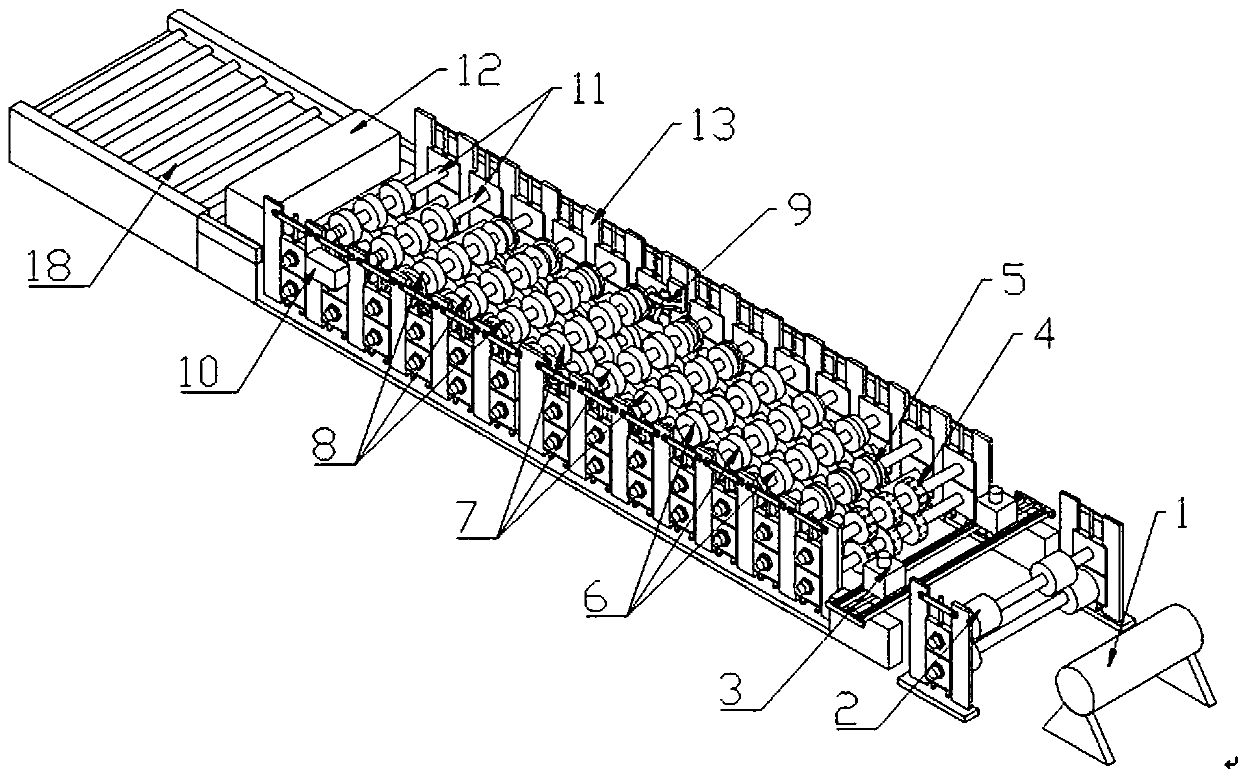

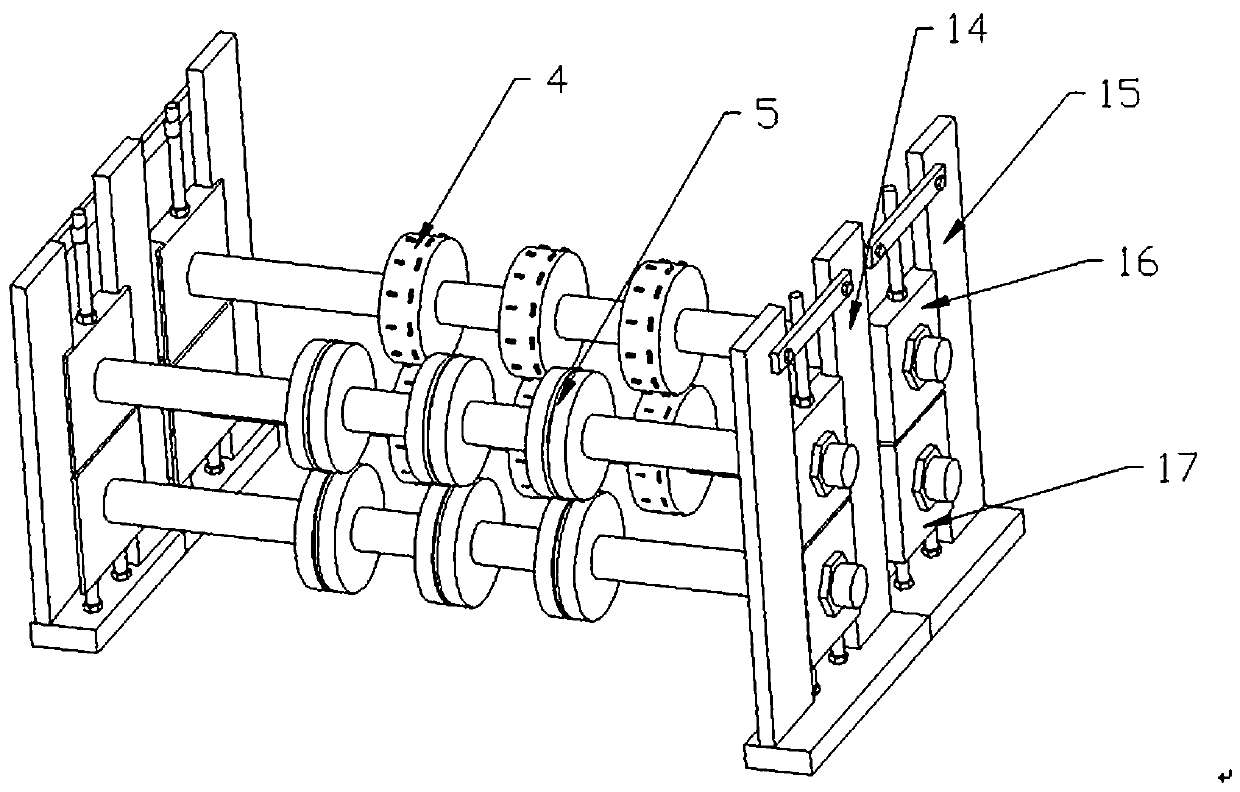

Building climbing frame walk plate machining device

PendingCN107716585AImprove transmission efficiencyImprove processing efficiencyMetal working apparatusProcessing plantsEngineering

The invention discloses a building climbing frame walk plate machining device. The building climbing frame walk plate machining device comprises a feeding device, a punching device and a cut-off device. The lower portions of the punching device and the cut-off device are provided with tracks used for enabling the punching device and the cut-off device to move. A bending device is arranged betweenthe punching device and the cut-off device and comprises a bent-pressing wheel group, a bent-folding wheel group, an edge-folding wheel group and a bending device fixing plate. Conical discs are arranged in bent-folding wheel group. The middle of each set of bent-pressing wheel group is provided with conveying wheels, and the two ends of each set of bent-pressing wheel group are provided with a pair of upper bent-pressing wheel and lower bent-pressing wheel which relatively rotate. The middle of each set of bent-folding wheel group is provided with conveying wheels, and the two ends of each set of bent-folding wheel group are provided with a pair of upper bent-folding wheel and a lower bent-folding wheel which relatively rotate. The middle of each set of edge-folding wheel group is provided with conveying wheels, and the two ends of each set of edge-folding wheel group are provided with a pair of upper edge-folding wheel and lower edge-folding wheel which rotate relatively. The building climbing frame walk plate machining device is high in machining efficiency, high in degree of automation, suitable for machining sheet materials of high width or strength and suitable for a machining plant, and used for building climbing frame walk plate machining.

Owner:四川驰腾建筑劳务有限公司

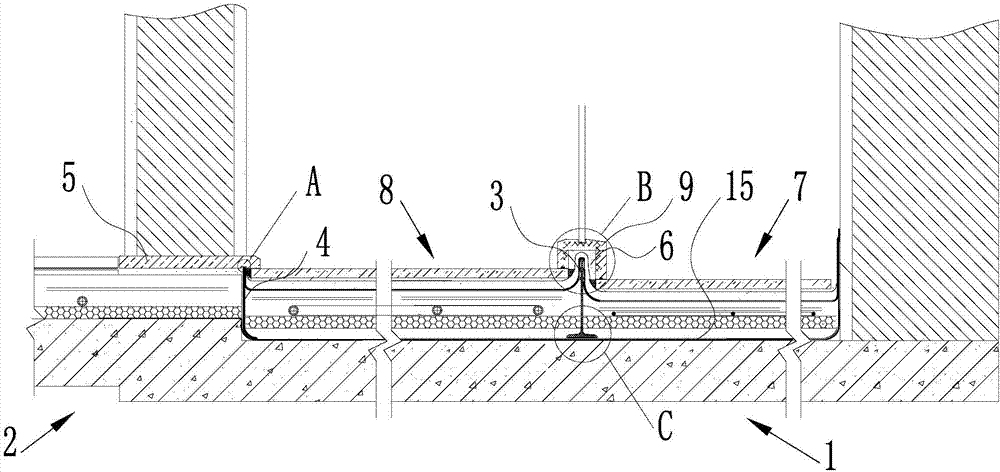

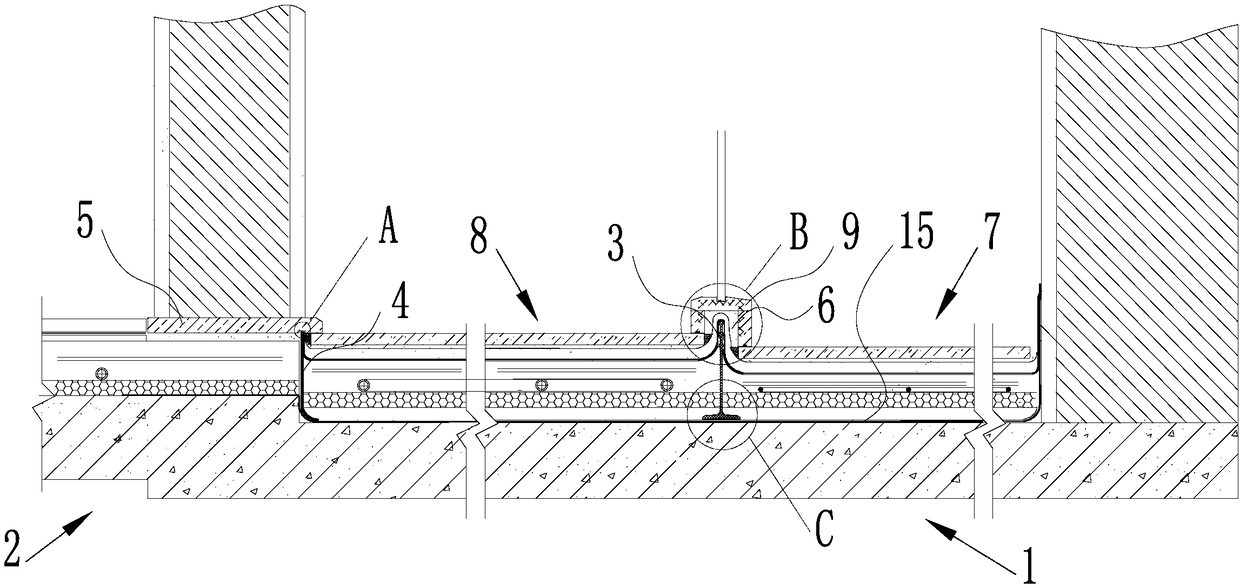

Waterproof system and construction method for toilet

ActiveCN106978856BEasy to fixPrevent leakageSills/thresholdBuilding insulationsFloor slabEngineering

The invention relates to the field of building decoration and provides a bathroom waterproof system which is simple in structure can convenient to construct and can effectively prevent water molecules in a bathroom from leaking outward and a construction method. The technical problems that in the prior art, the leakage proof effect of the bathroom is poor, the situation that a floor, a door sleeve and the like in a dry area mould and decay is quite prone to occurring, and the attractive degree of overall decoration is reduced are solved. The bathroom waterproof system comprises a bathroom floor base layer and a dry area floor base layer connected with the bathroom floor base layer. Ground decoration paving layers are laid on the surfaces of the bathroom floor base layer and the dry area floor base layer correspondingly. An elastic water retaining plate and the lower end of an elastic water retaining strip are arranged between the bathroom floor base layer and the corresponding ground decoration paving layer in a clamped mode, wherein the upper end of the elastic water retaining plate extends upward to the exterior of the ground decoration paving layer and connected on the bottom face of a doorsill plate in a closed mode, and the upper end of the elastic water retaining plate extends upward to the exterior of the ground decoration paving layer and connected with a cement mortar retaining strip in an airtight mode. The cement mortar retaining strip divides the corresponding floor decoration paving layer into a bathing area and a rest area.

Owner:GREENTOWN DECORATION ENG GRP CO LTD

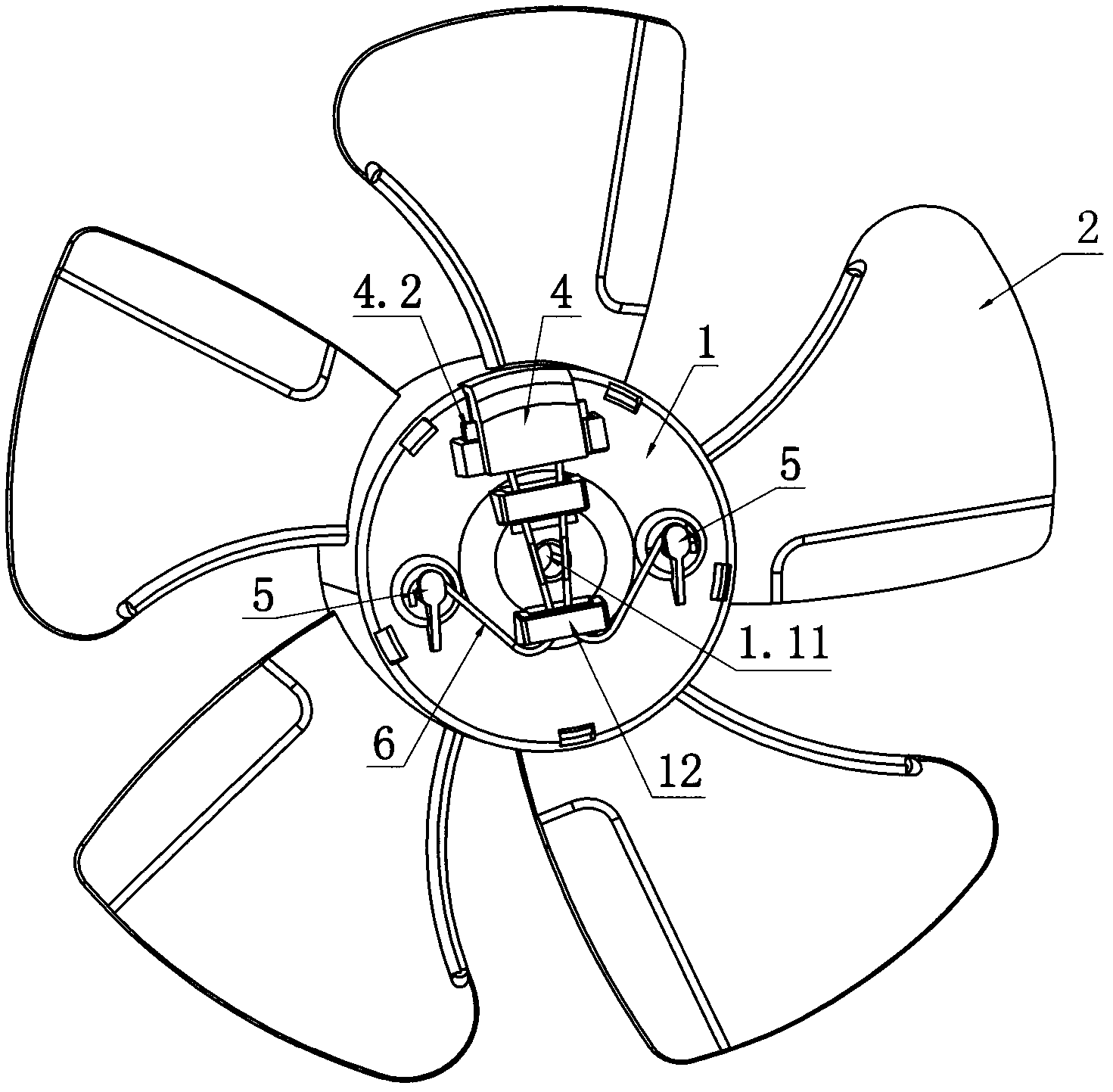

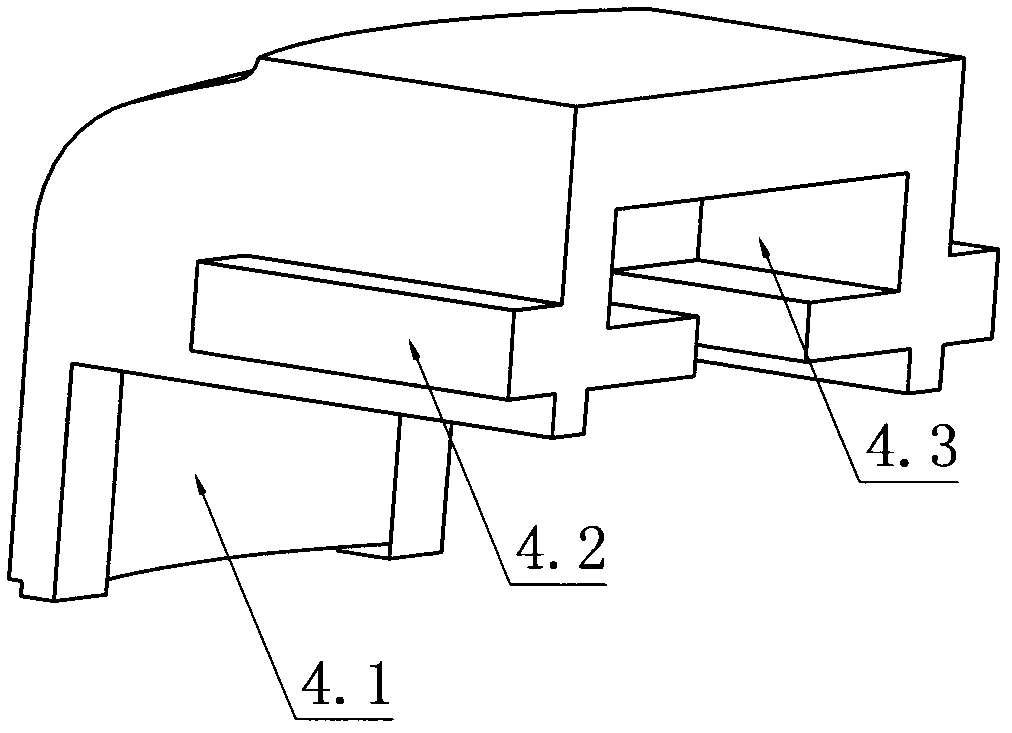

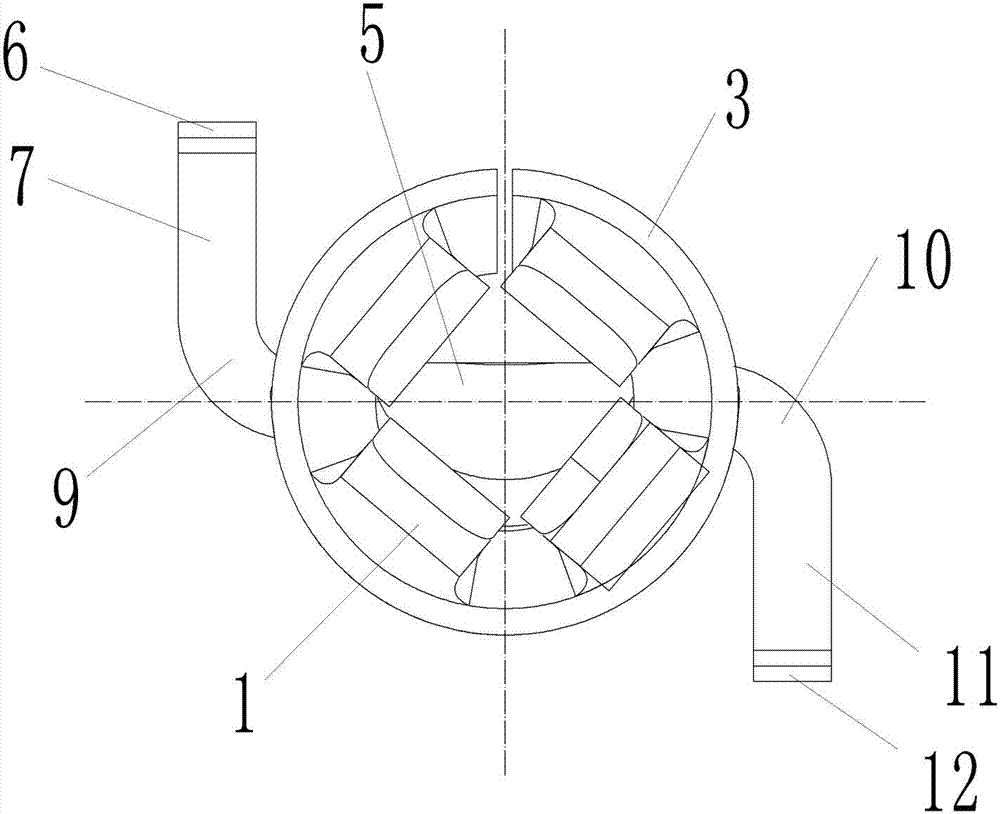

Fan blade

The invention discloses a fan blade comprising a fan blade seat (1). The fan blade (1) is internally provided with a seat core (1.1), and an axial through hole (1.11) for the insertion of an output shaft of a motor is arranged on the seat core (1.1). The fan blade further comprises a fixing device capable of fixing blades on the output shaft of the motor, and the fixing device is arranged on the fan blade seat (1). The invention has the advantages that the fan blade is conveniently fixed on the output shaft of the motor, is conveniently detached and has high safety.

Owner:NINGBO APG APPLIANCE & TECH CO LTD

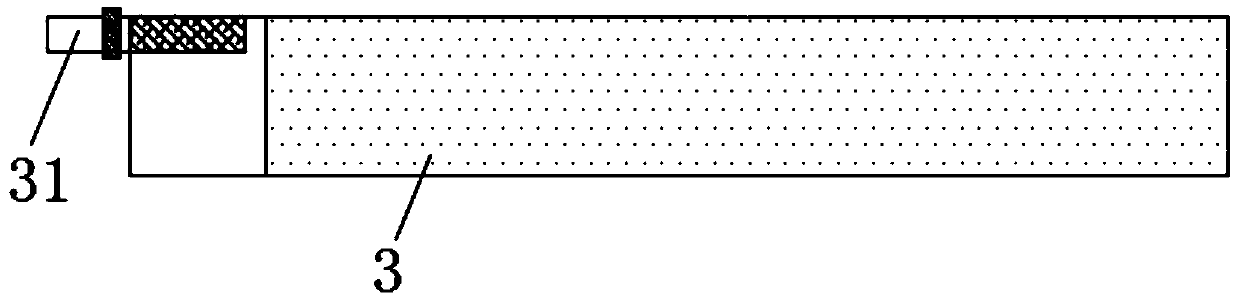

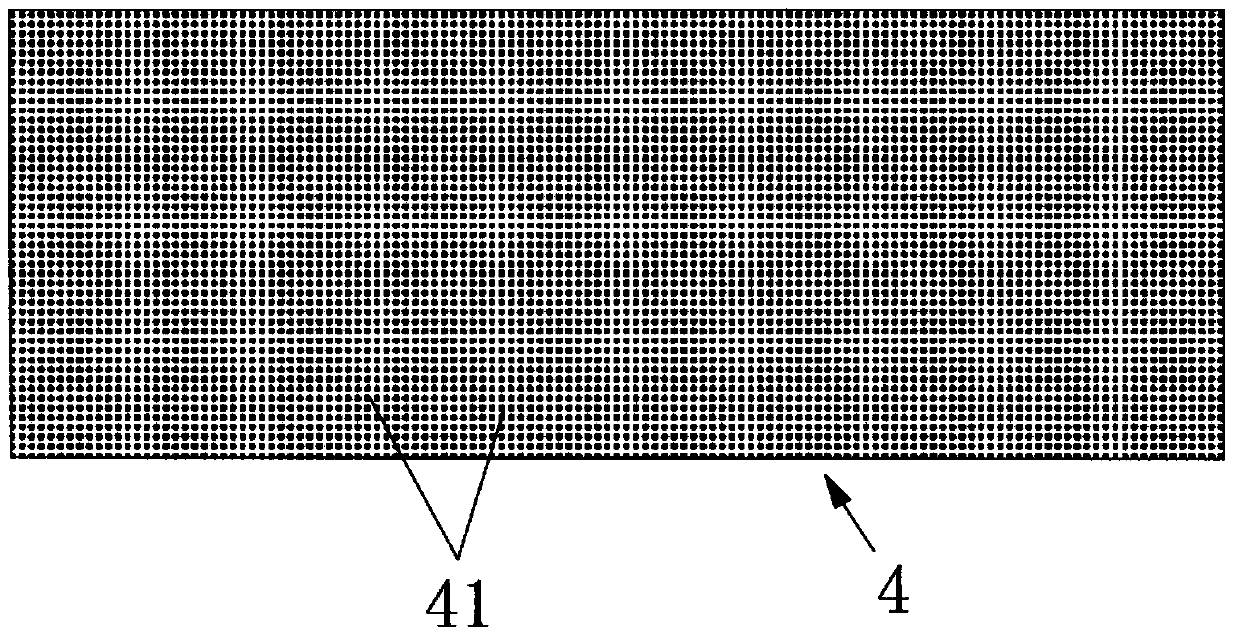

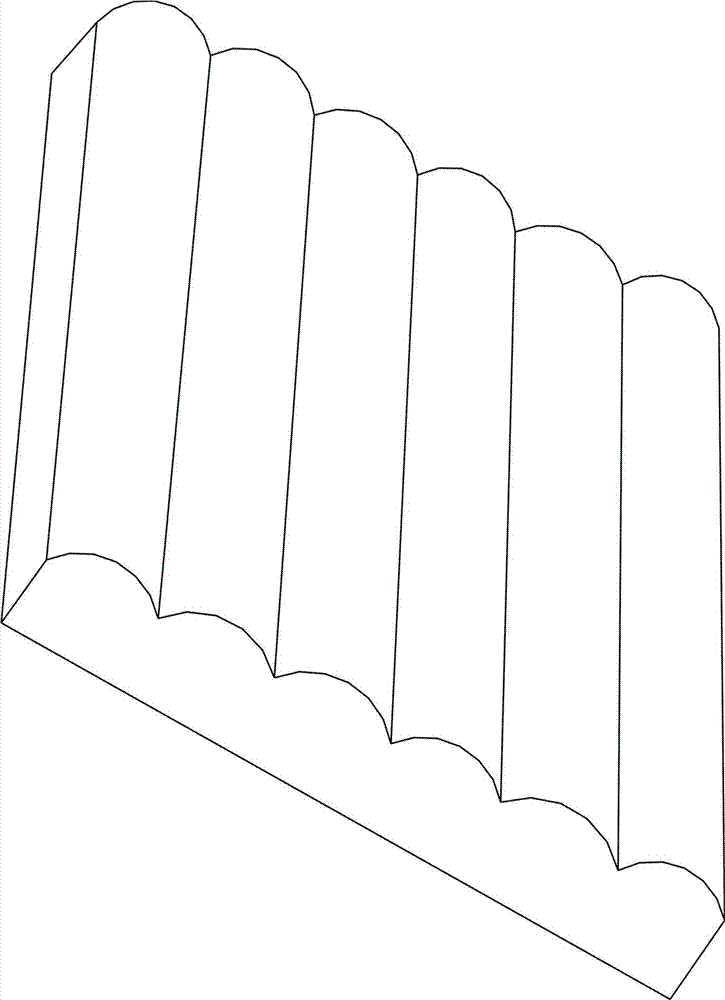

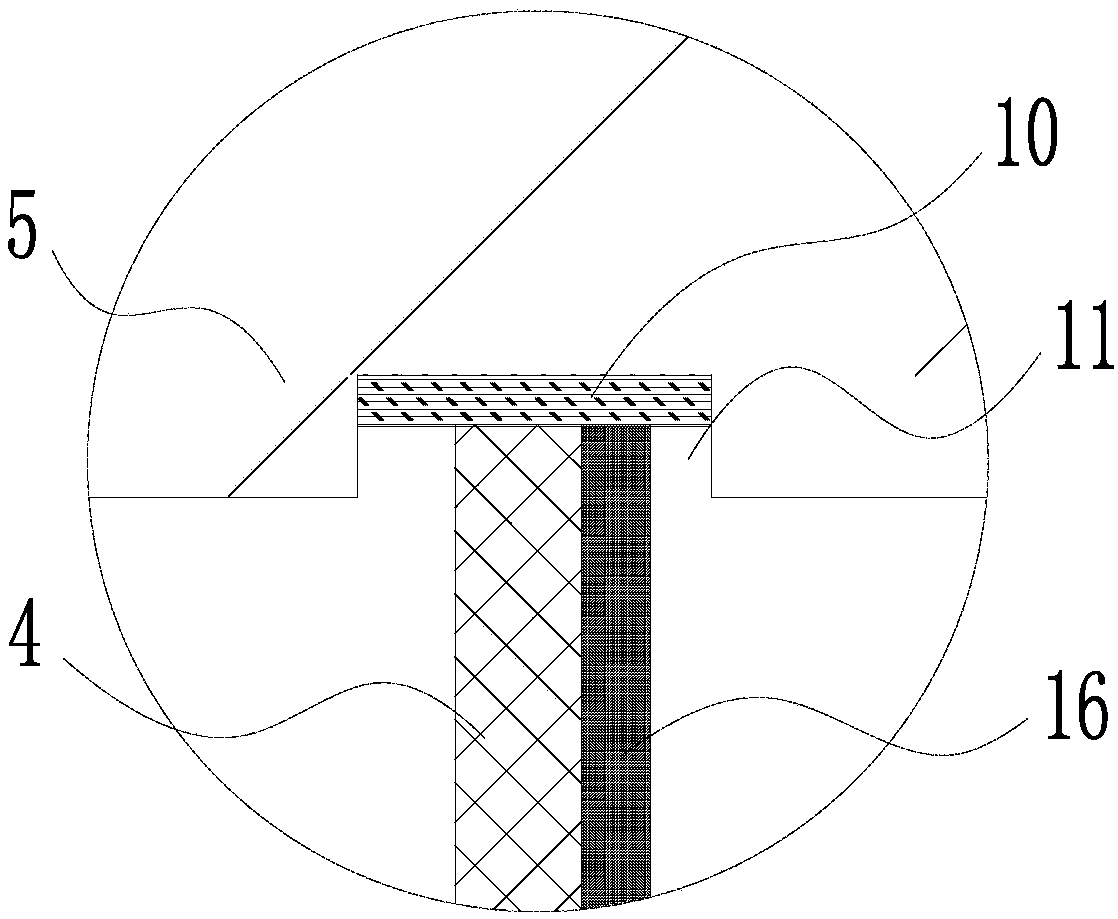

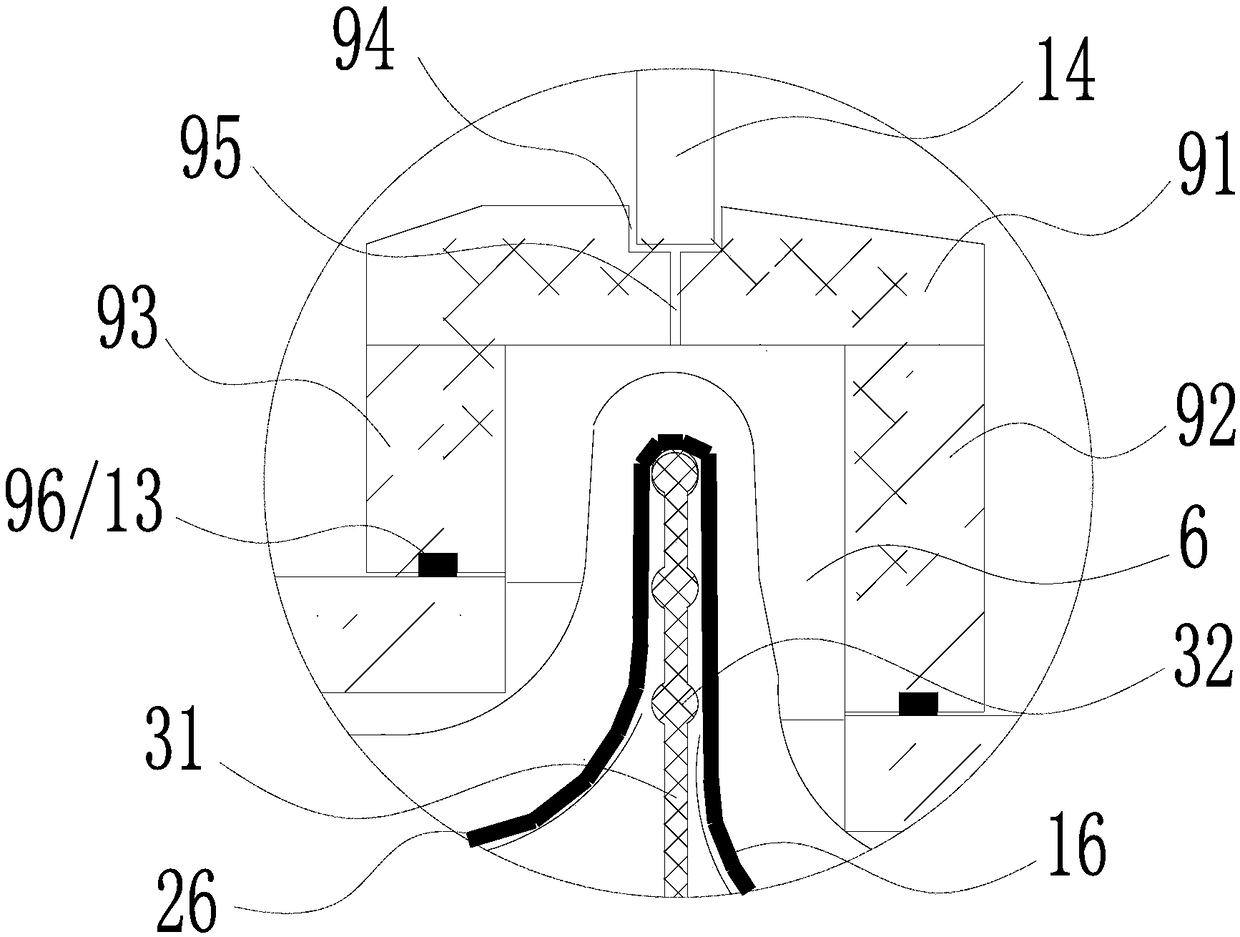

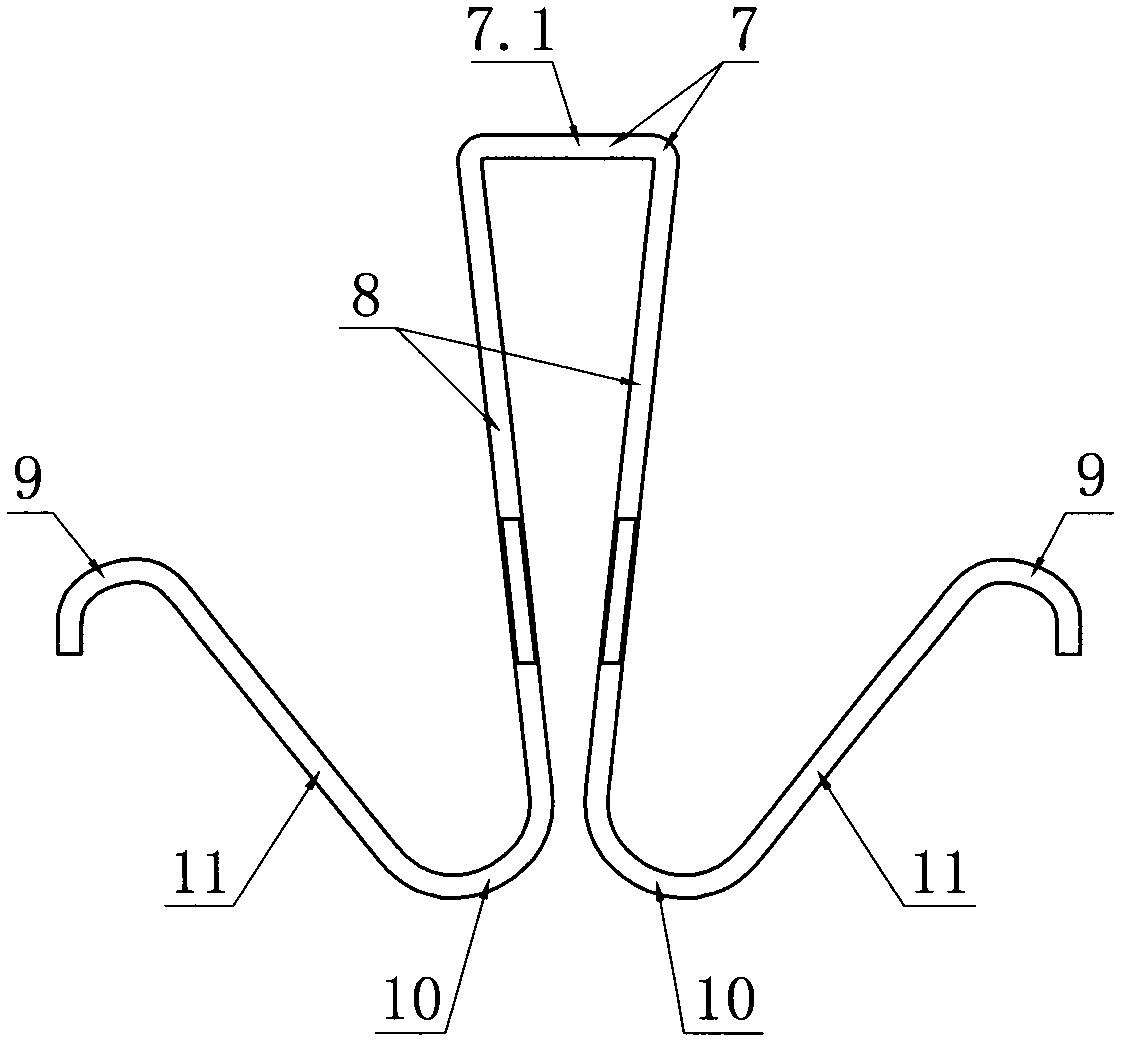

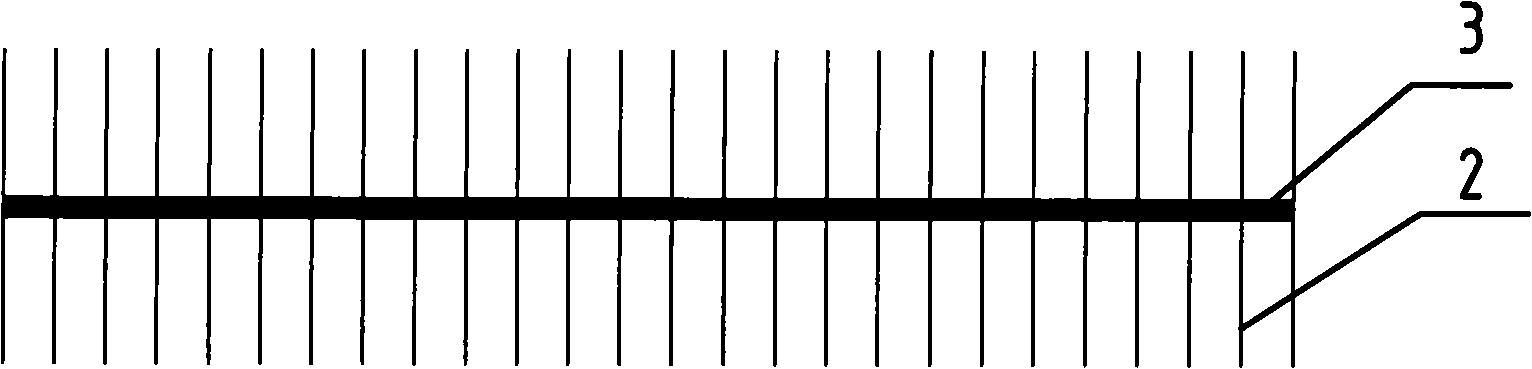

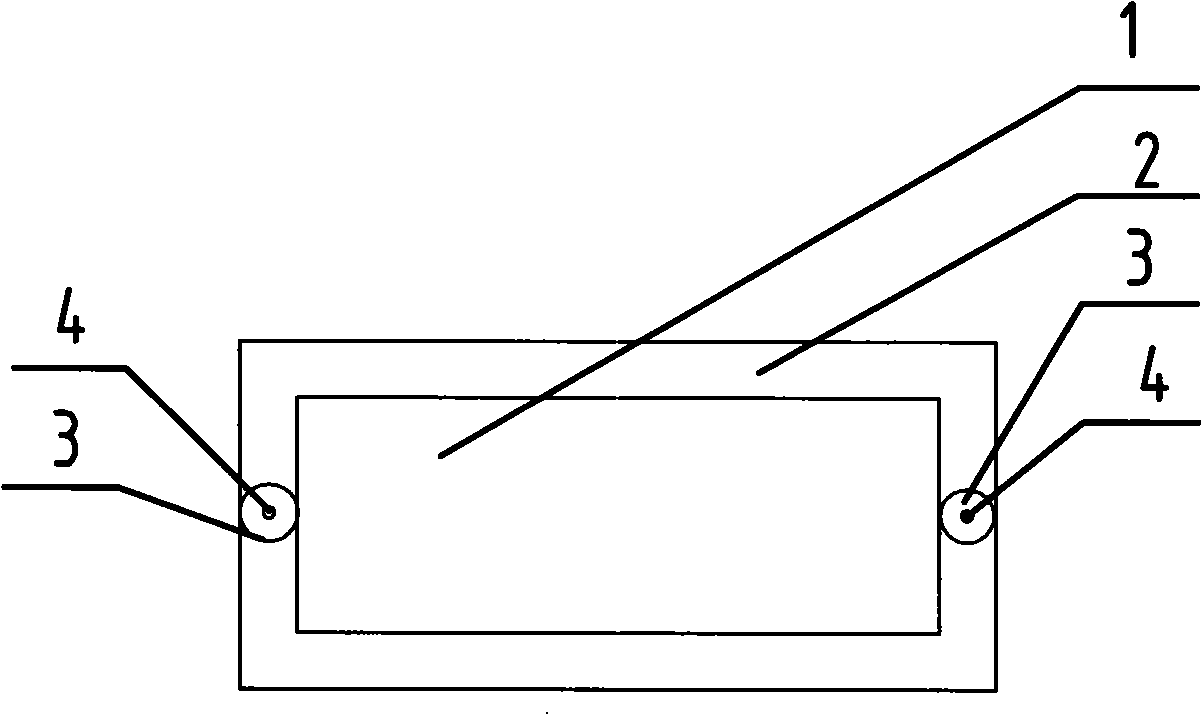

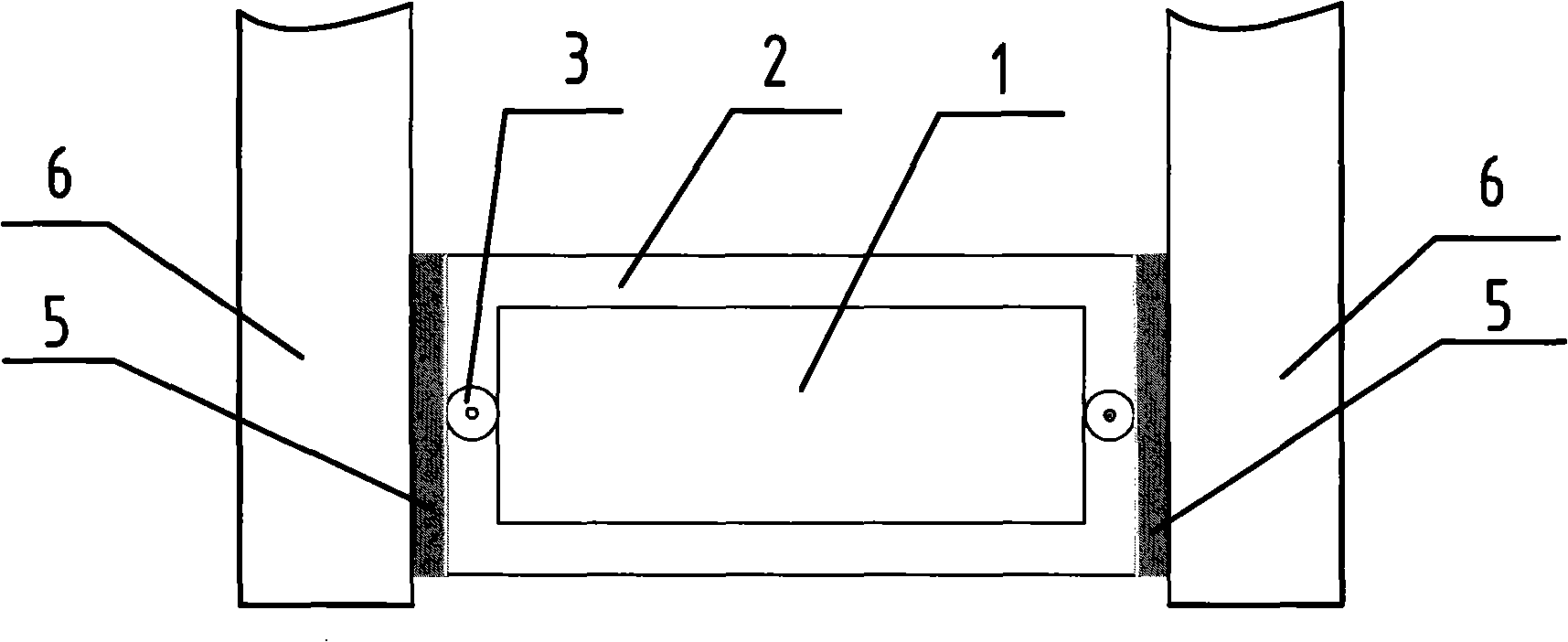

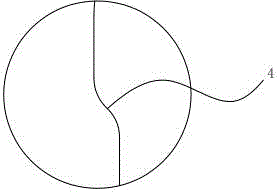

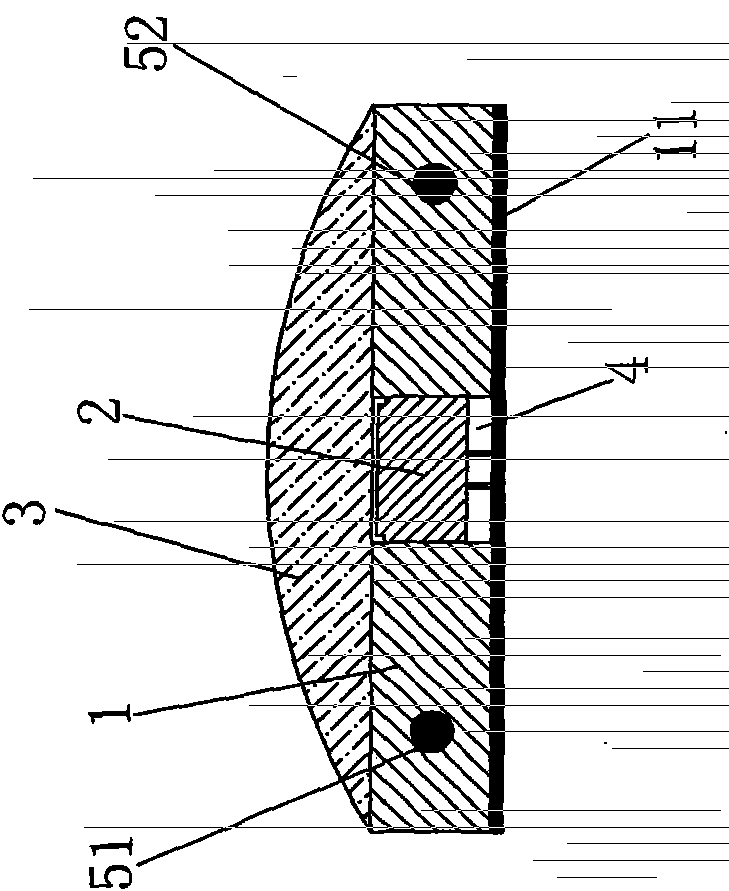

Hollow glass spacing section bar

InactiveCN101285365AGood heat and sound insulationEasy to bend and shapeWing framesUnits with parallel planesEngineeringMetal

The invention provides a hollow glass spacing profile, relating to a hollow glass spacing-closing material, in particular to a hollow glass spacing profile with cold-bent shaped integral bulkhead. The hollow glass spacing profile comprises a corrugated hollow pipe (2) which is processed and molded with thermoplastic macromoleclar polymer as raw material and has a cross section basically as a rectangular frame, as well as two thermoplastic macromoleclar polymer reinforcing ribs (3) with built-in rigid metal wires (4). The reinforcing ribs (3) are perpendicular to ripples and are arranged along the center lines of two glass support sides of the corrugated hollow pipe (2). The invention provides the hollow glass spacing profile which is good in heat-sound insulation effect, easy to bend and shape, simple in manufacture process, low in cost, capable of being coiled, convenient for storing, transporting and processing operation, and suitable for the application in a plurality of aspects, such as the manufacture of hollow glass doors and windows for houses, vehicles, ships and aircrafts.

Owner:SHANDONG NATERGY ENERGY TECH CO LTD

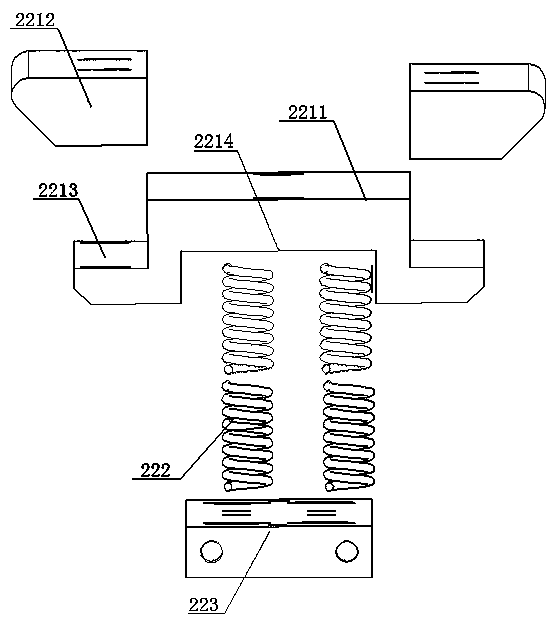

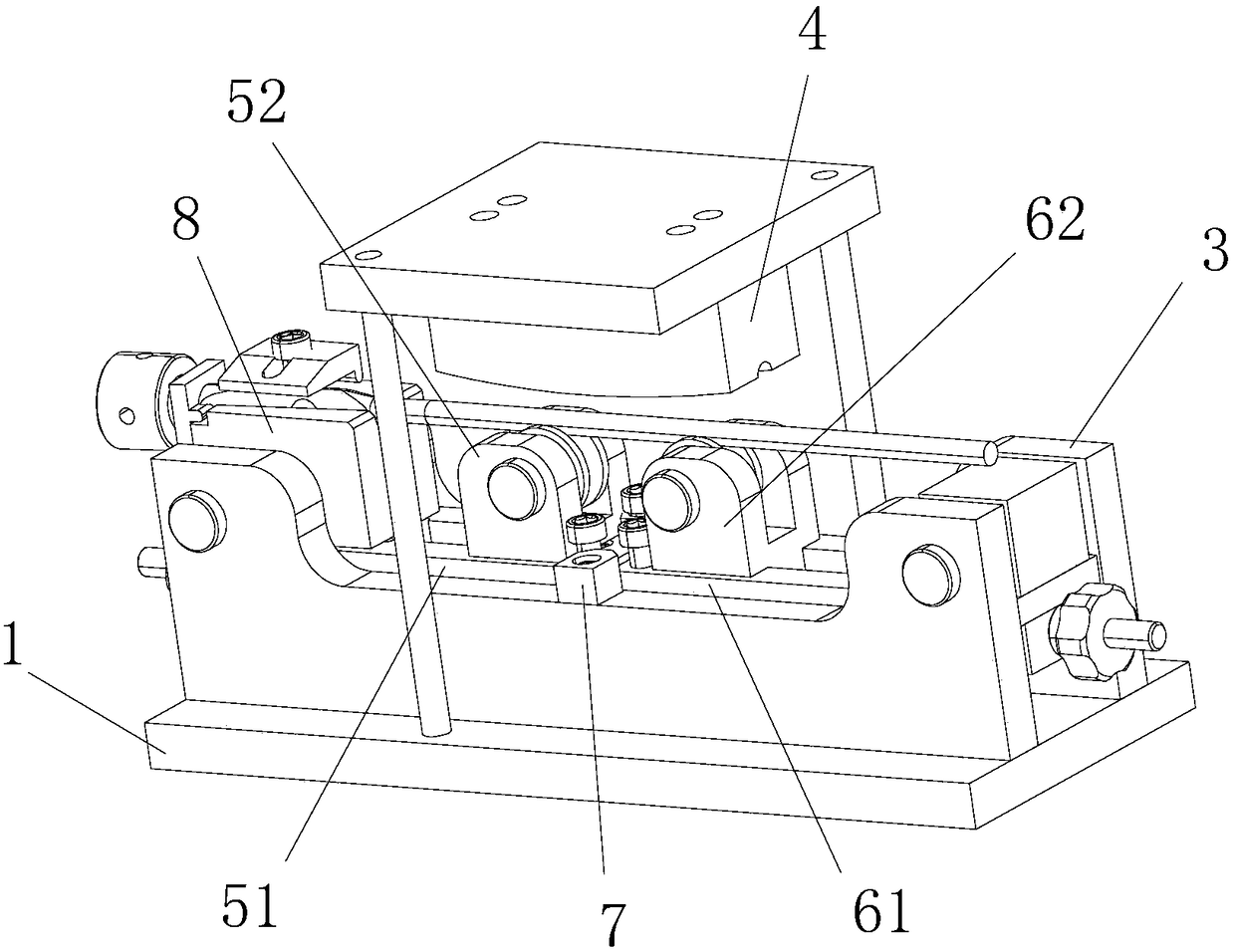

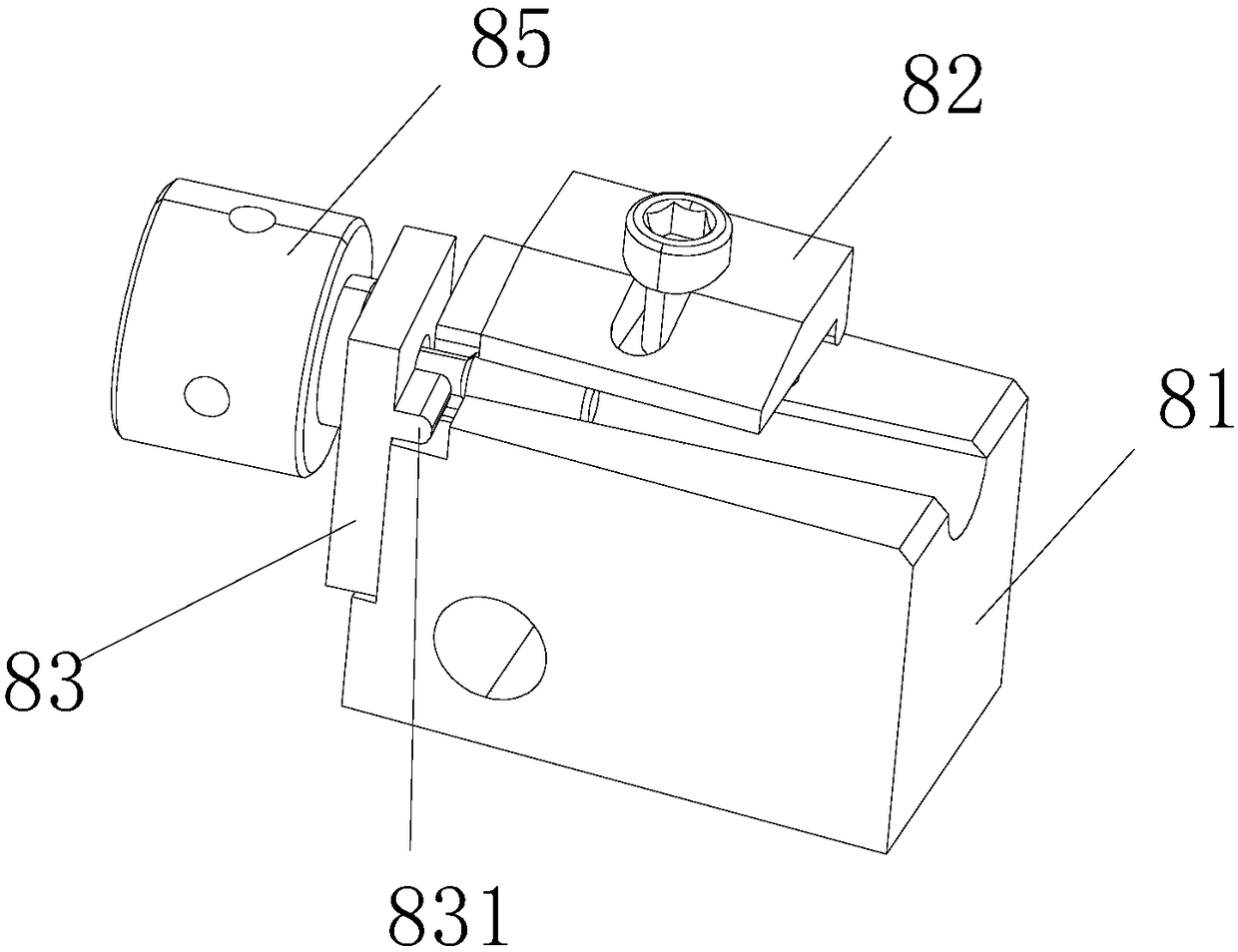

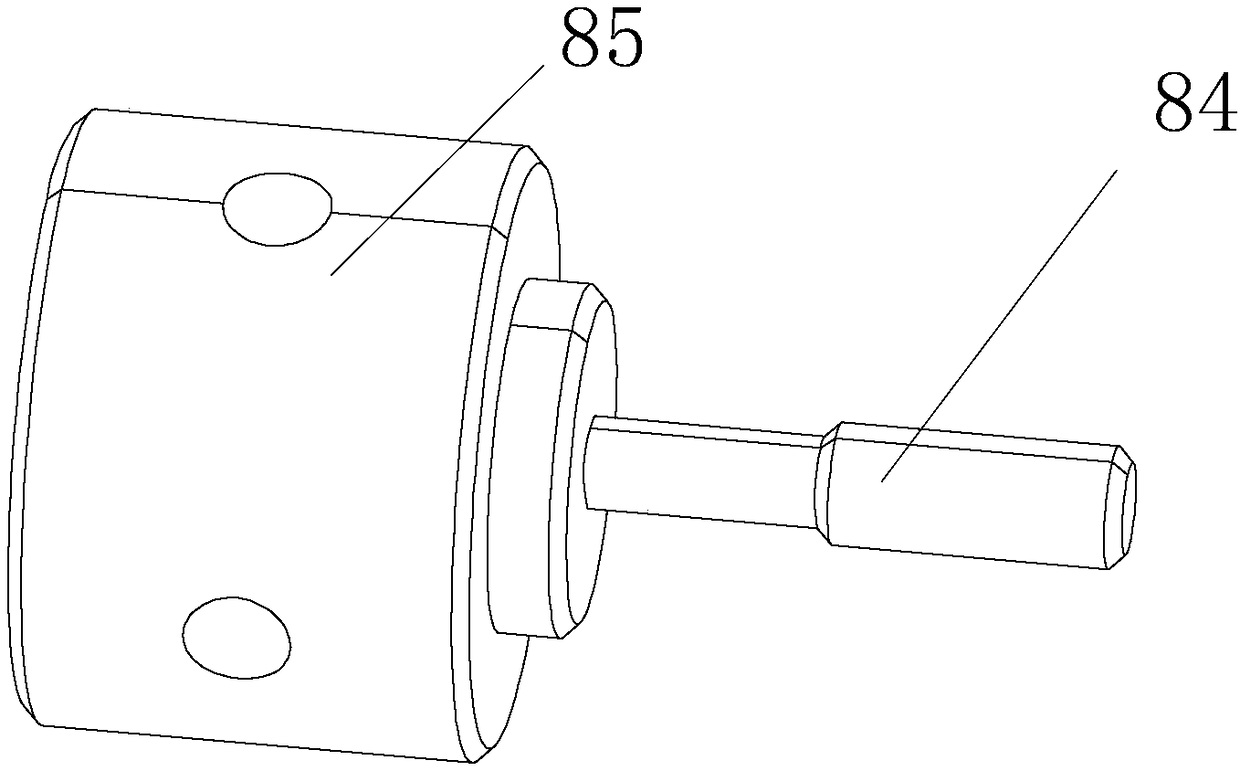

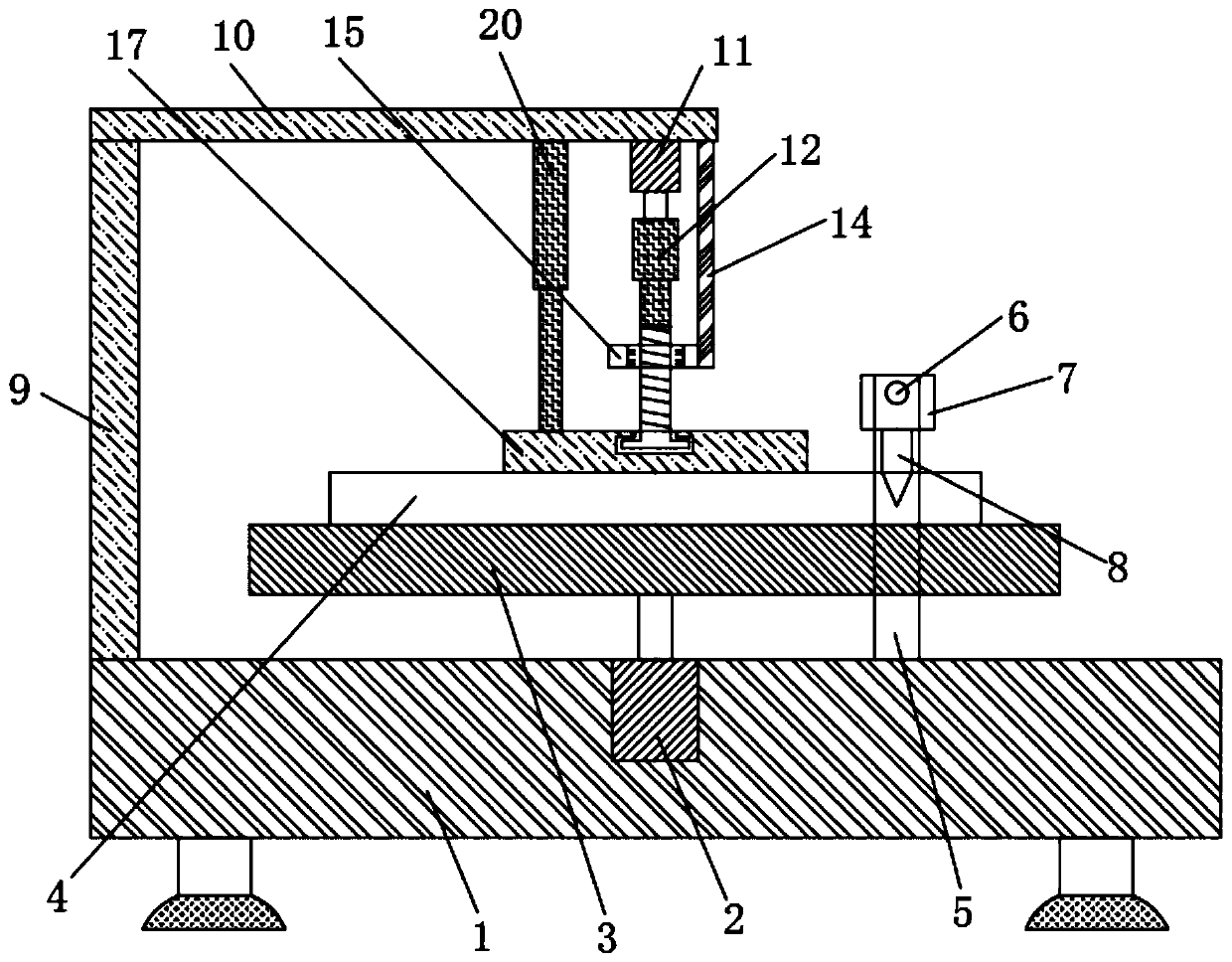

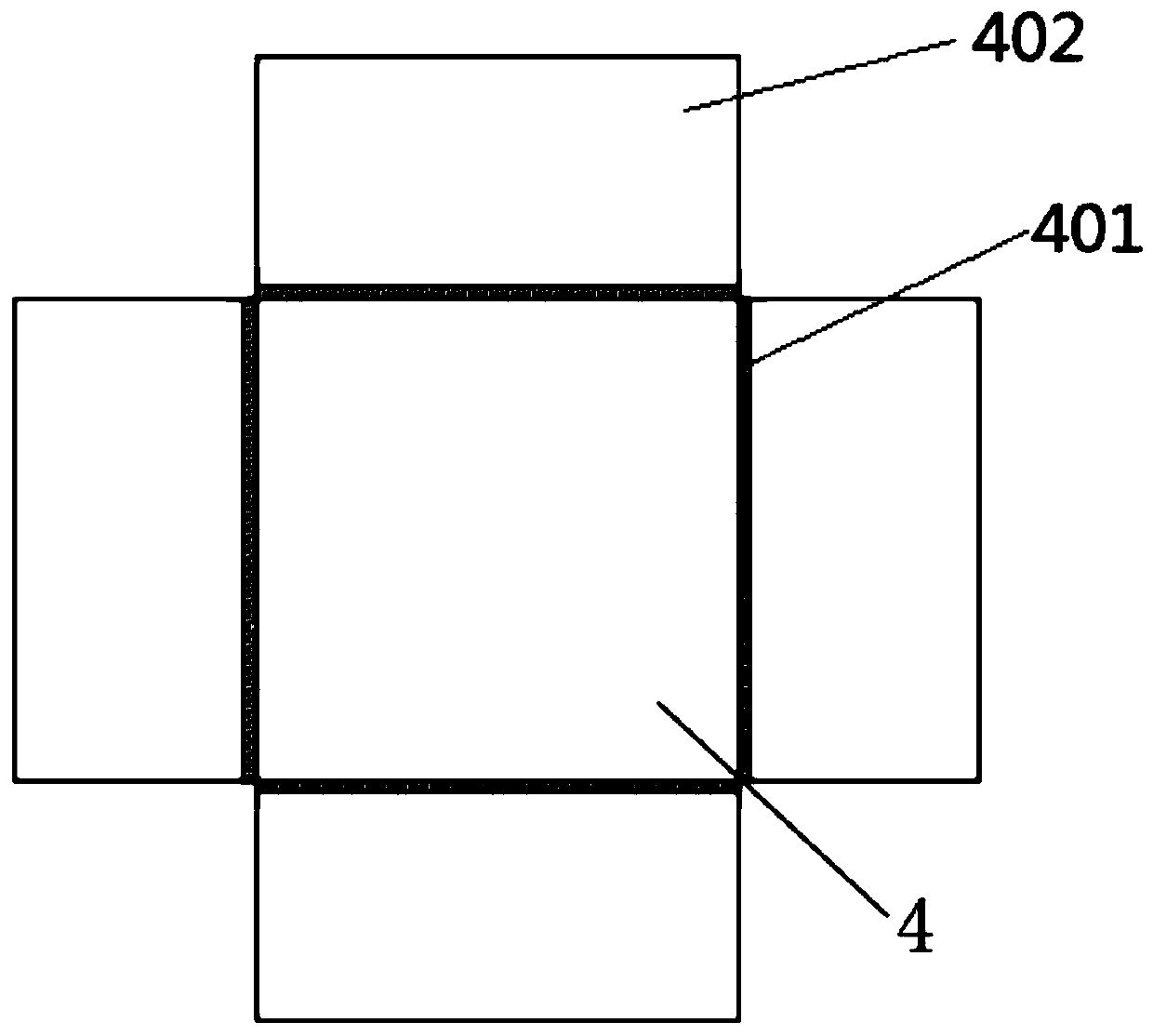

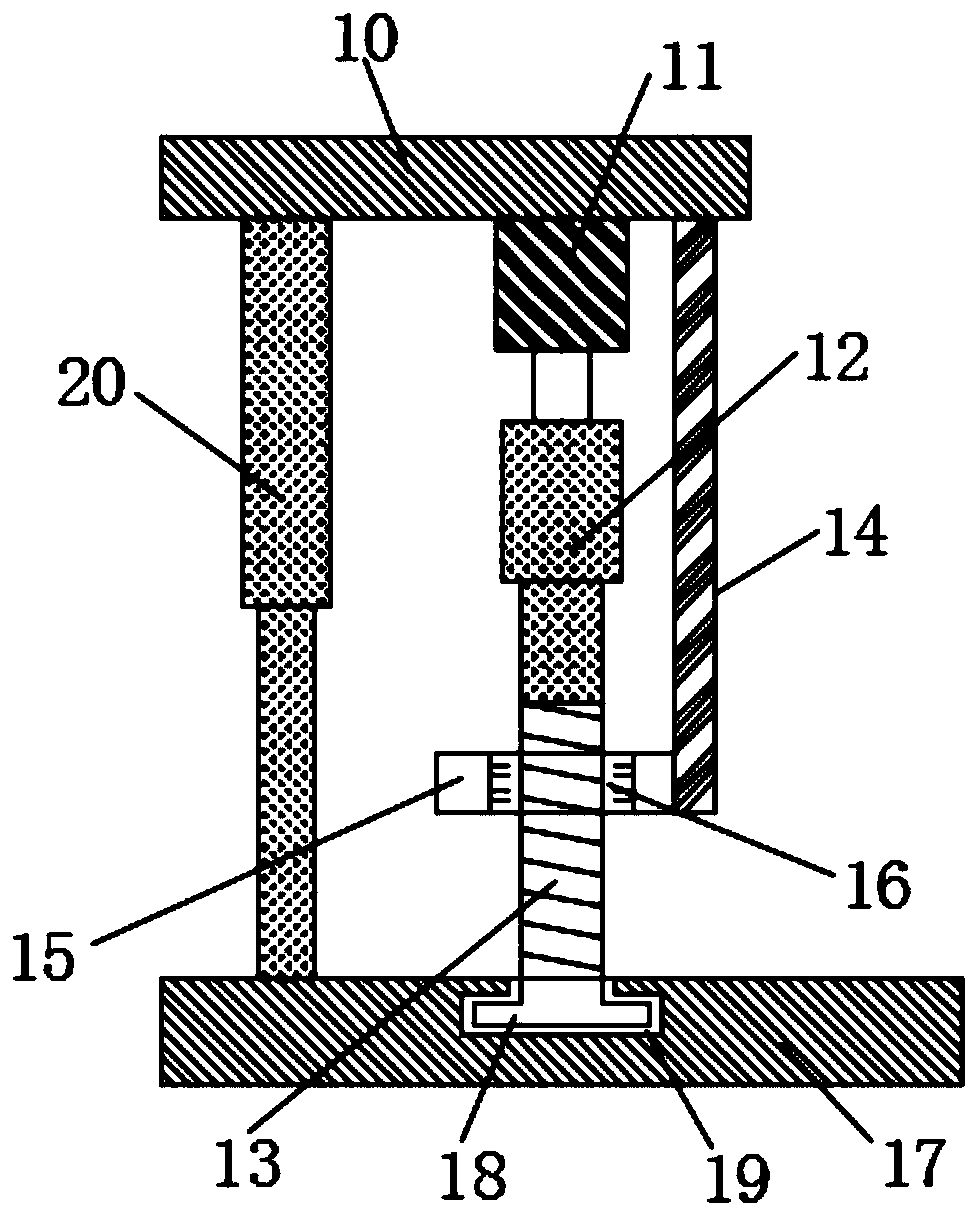

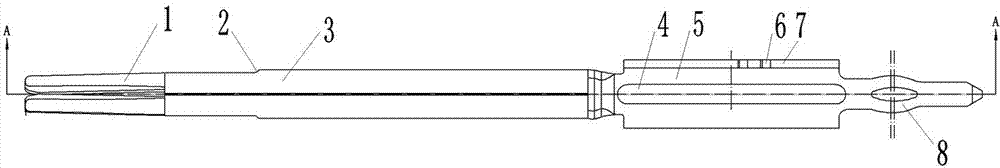

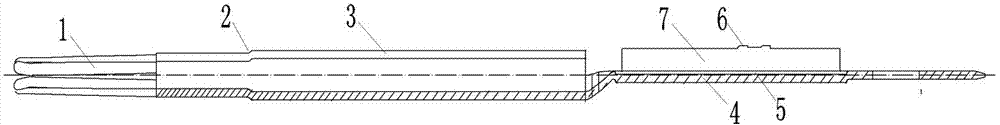

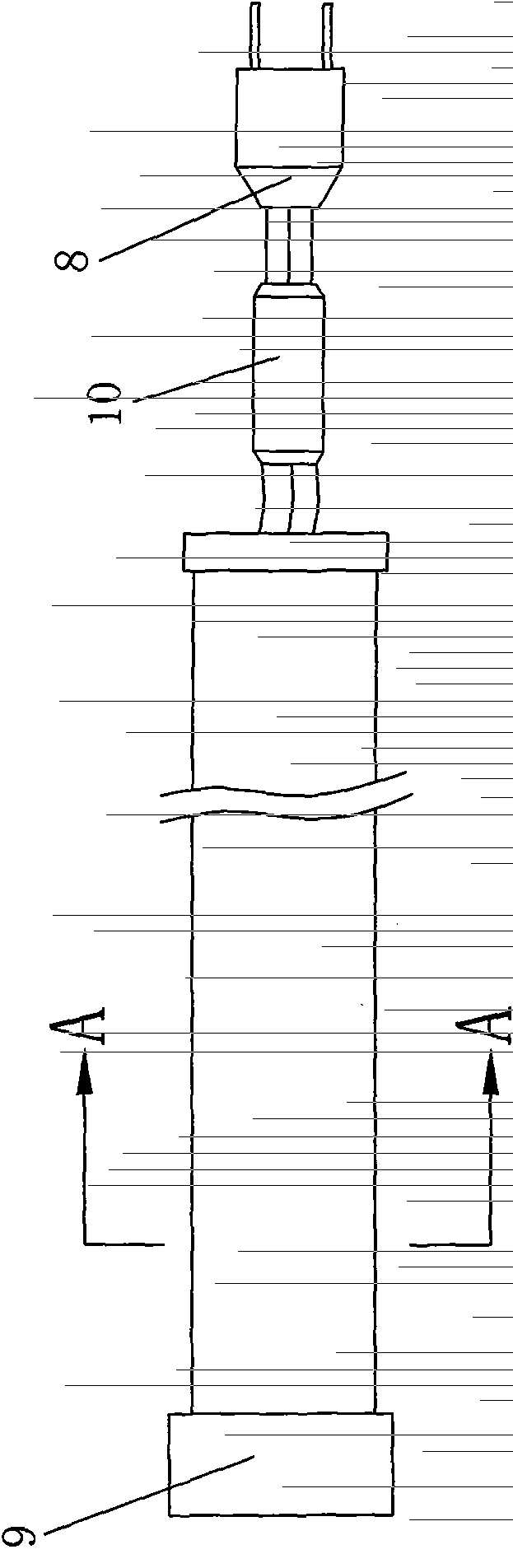

Elastic bending tool for femoral intramedullary nails

PendingCN108478269AFacilitates a smooth transitionBending stabilityInternal osteosythesisEngineeringBone marrow

The invention relates to an elastic bending tool for femoral intramedullary nails, comprising a base; a presser block is arranged above a bending station; a forming surface is provided with a pressergroove; left and right support plates that are rotatable are arranged between two mounting side plates; the left end of the left support plate is rotationally connected with the two mounting side plates through pins; a left spring is arranged blow the right end of the left support plate; the right end of the right support plate is rotationally connected with the mounting side plates via pins; a right spring is arranged below the left end of the right support plate; a retaining plate is arranged in the middle of each mounting side plate; the left support plate is provided with a left support wheel; a right support wheel is arranged on the right support plate; the left of the left support plate is provided with a clamping device to clamp the proximal end of an intramedullary nail; during operation, an intramedullary nail to be bent is placed on the clamping device, the left support wheel and the right support wheel; the two support plates may form obtuse structure when the intramedullarynail is under pressure; the two support wheels can be rotated and spread such that smooth transitional forming is achieved for the intramedullary nail.

Owner:江苏艾为康医疗器械科技有限公司

Plate rolling machine for repairing plate blank line

The invention relates to the technical field of plate bending machines, in particular to a plate rolling machine for repairing plate blank line. The plate rolling machine for repairing the plate blank line comprises a base and further comprises a mounting frame and a supporting frame; the mounting frame and the supporting frame are both connected with the base; two lower round rollers are connected between the mounting frame and the supporting frame; the two lower round rollers are both connected with driven gears; a lifting lower mold mechanism is connected between the mounting frame and the supporting frame; an upper roller mechanism and an upper mold mechanism are mounted on the mounting frame; the mounting frame is connected with an electric telescopic push rod through a fixing frame; the electric telescopic push rod is connected with the upper roller mechanism; a locking and unlocking mechanism is mounted on the supporting frame; a driving mechanism is mounted on the base; the top end and the bottom end of an electric telescopic rod are connected with a V-shaped mounting strip block and the base respectively; the V-shaped mounting strip block is connected with two steering strip plates; and the multiple tension springs are connected between the two steering strip plates and the V-shaped mounting strip block. Cylinder molding and bending are facilitated, the use limitation is lower, the plates obtained after molding are completed are taken down in a labor-saving mode, the molding quality is better, and the production efficiency is higher.

Owner:唐山曹妃甸工业区长白机电设备检修有限公司

Ultrathin flexible neon lamp integrated with single-wire transmission control chip

InactiveCN101634410BReduce in quantityImprove reliabilityLight source combinationsPoint-like light sourceInput controlEngineering

The invention discloses an ultrathin flexible neon lamp integrated with a single-wire transmission control chip, which comprises a flexible non-light tight core wire, an LED lamp string arranged in the core wire, a flexible non-light tight coating layer coated outside the core wire, a flexible non-light tight light diffuser arranged above the core wire and having equal length with the core wire, and a flexible light shielding layer positioned on two sides of the core wire on the lower part of the coating layer, wherein the LED lamp string consists of a plurality of display units which are connected with one another through power supply positive and negative electrode circuits and a signal control circuit; and a lighting transmission drive control chip is a single-wire transmission drive control chip which inputs control signals through the signal control circuit and directly drives and controls the LED of the display units to emit light. The lamp body of the ultrathin flexible neon lamp is thin, has better flexibility and is easier for bending modeling.

Owner:BEIJING ZHONGQING MICRO ELECTRIC TECH

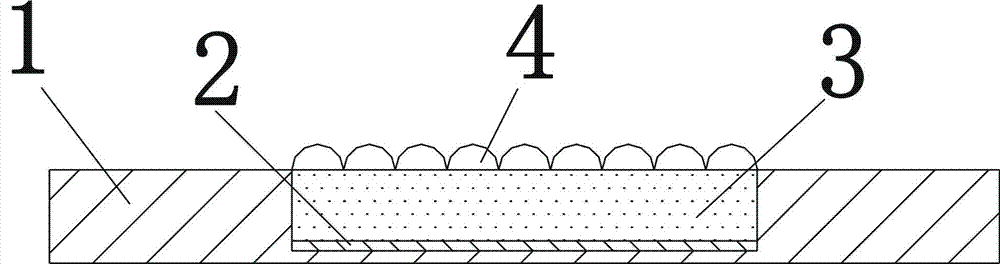

Pulp molding and three-dimensional bending process

ActiveCN111074694AEasy to bend and shapeDegradable without changeTextiles and paperMolded pulpPolymer science

The invention relates to the technical field of pulp molding, and discloses a pulp molding and three-dimensional bending method. A box body with a draft angle is obtained through pulp molding, the periphery of the box body is provided with a plane, a product with a vertical angle is obtained through bending, and the problem that a pulp molding integrally-formed product with the vertical angle cannot be obtained at present is effectively solved.

Owner:WING FAT (HENAN) MOLDED FIBER TECH DEV CO LTD

Method for manufacturing easy-forming angle aluminum

InactiveCN105697996AAvoid cracksQuality improvementElongated constructional elementsAluminum canEngineering

The invention relates to a method for manufacturing an easy-forming angle aluminum. The manufactured angle aluminum by adoption the method has the benefit effects that: a bent position of the angle aluminum is provided with a reduction groove which facilitates bent-forming of the angle aluminum; cracks can be avoided during bent processing; the quality of the angle aluminum can be improved; the service life of the angle aluminum can be prolonged; and a protective effect on a corner of a heat exchanger can be achieved.

Owner:WUXI JIANG YUAN ALUMINUM IND

Electric connector

ActiveCN104505625AReduce manufacturing difficultyEasy to bend and shapeSecuring/insulating coupling contact membersElectricityCurrent electric

The invention relates to an electric connector, which comprises a contact and an isolator, wherein a contact mounting hole is formed in the isolator, the contact comprises a contact body, the front end of contact body is a plug end, the contact body is provided with a circumferential rotation stopping structure, the contact mounting hole comprises a square hole section by which the circumferential rotation stopping structure can be installed, the circumferential rotation stopping structure comprises a plate-shaped body, the left end of the plate-shaped body is integrally bent up to form an upper rotation stopping plate, the upper rotation stopping plate is provided with a left side plane which is used for sticking to the hole wall of the left side of the square hole section; the right side of the plate-shaped body is integrally bent down to form a lower rotation stopping plate, the lower rotation stopping plate is provided with a right side plane which is used for sticking to the hole wall of the right side of the square hole section, the extension directions of the left side plane and the right side plane are perpendicular to the left-right direction. By adopting the electronic connector, the problem that the circumferential rotation stopping structure of a contact in the current electric connector needs to be manufactured by machining, and cause high manufacturing cost of the circumferential rotation stopping structure can be solved.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

Power line capable of realizing shaping wiring effect based on multi-section loop structure

PendingCN114520446AEasy to routeEasy to bend and shapeCoupling parts mountingStructural engineeringPower cord

The invention relates to the technical field of power line shaping and wiring, in particular to a power line capable of achieving the shaping and wiring effect based on a multi-section loop structure. The shaping device comprises an electric wire and a plurality of shaping devices arranged on the electric wire, and the plurality of shaping devices are provided with drawing cords used for connecting the plurality of shaping devices together; the shaping device comprises a pull rope frame and a cover frame arranged on the upper side of the pull rope frame, one side of the pull rope frame is provided with an occlusion adjusting device used for adjusting the position of the wire drawing fiber rope, and the occlusion adjusting device comprises a driving frame and a wire clamping device arranged in the driving frame and used for clamping the wire drawing fiber rope. According to the invention, the position of the wire drawing fiber rope is clamped and positioned through the occlusion adjusting device, so that the wire drawing fiber rope pulls the electric wire, the electric wire is pulled and bent, the positioning of the electric wire by using a lantern ring is avoided, the electric wire can be bent and positioned at some positions which cannot be positioned, the shaping effect of the electric wire is completed, and the wiring of the electric wire is facilitated.

Owner:天长市富达电子科技股份有限公司

Ultrathin flexible lamp band

ActiveCN101858527BGood flexibilityNot easy to break and damageElectric circuit arrangementsElectric lightingElectricityCurrent limiting

Owner:GUANGDONG TONGFANG ILLUMINATIONS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com