Device for bending edges of paperboard manually

An edge folding device and cardboard technology, applied in the field of transformer manufacturing, can solve the problems of inability to meet large-scale production, large rebound of insulating cardboard, easy damage to insulation, etc., and achieve the effects of simple structure, small bending rebound and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing and non-limiting embodiment:

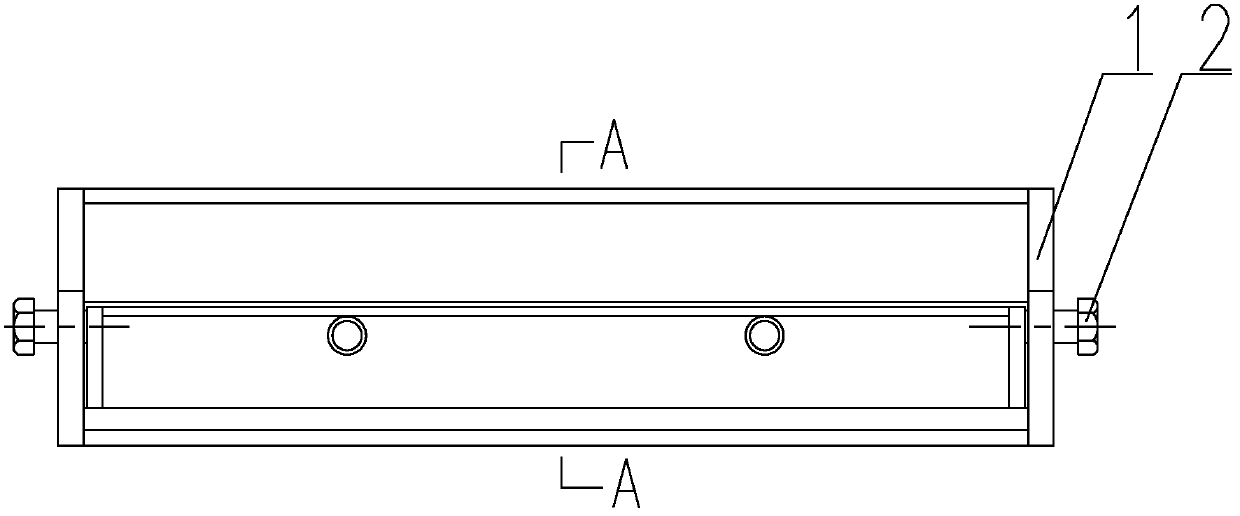

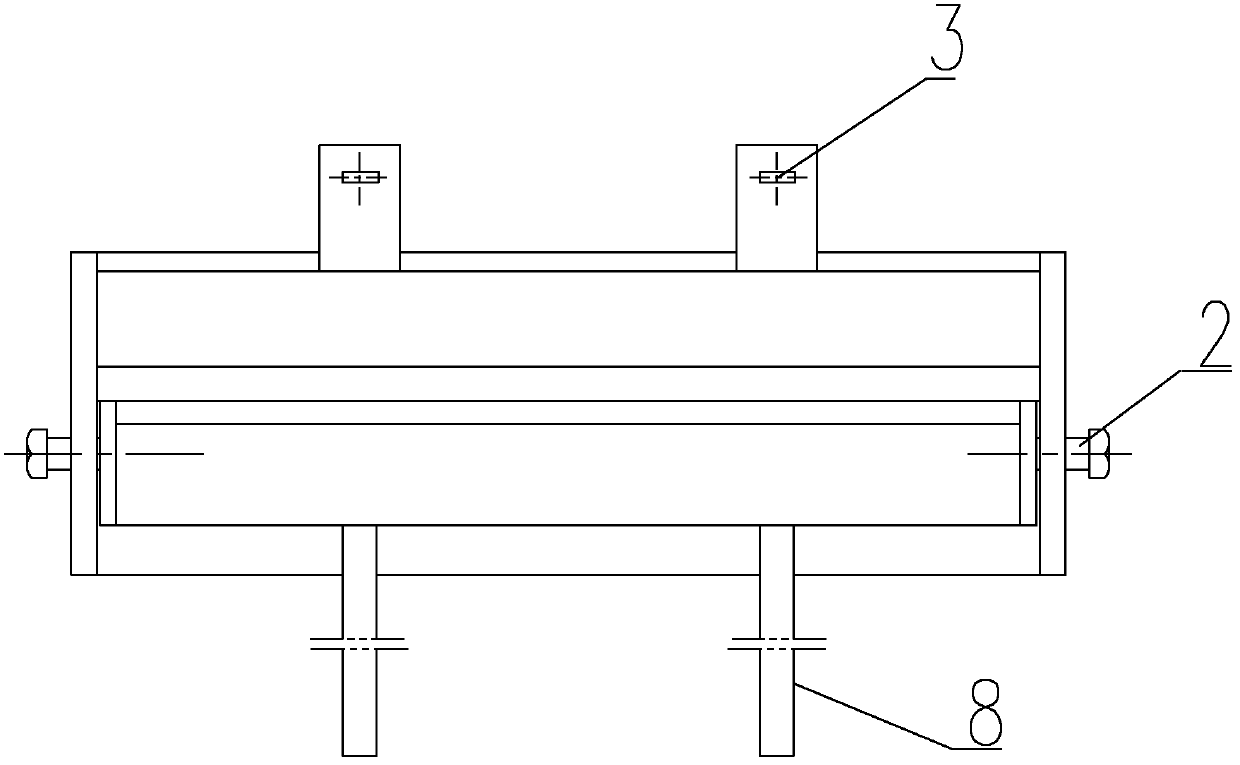

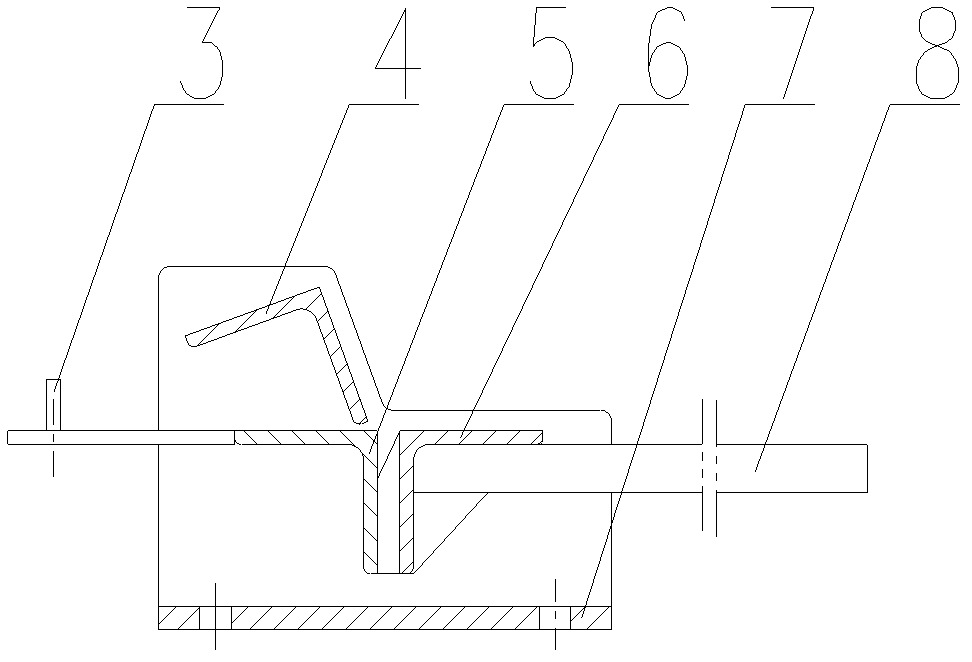

[0016] as attached Figure 1-3 Shown is a cardboard manual hemming device, which includes a base 7 , a limit beam 4 , a fixed beam 5 , and an overturning beam 6 . The left and right sides of the base 7 are respectively provided with brackets 1 . The limiting beam 4 and the fixed beam 5 are arranged between the two brackets 1 , and the limiting beam 4 and the fixed beam 5 are arranged correspondingly up and down and are respectively fixedly connected with the brackets 1 on both sides. There is a gap between the limit beam 4 and the fixed beam 5 to allow the cardboard to pass through. An overturning beam 6 is arranged in front of the fixed beam 5 , and the two ends of the overturning beam 6 are respectively connected with the brackets 1 on both sides of the base 7 through the rotating shaft 2 , and the overturning beam 6 can rotate around the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com