Electric connector

An electrical connector and an integrated technology, which is applied in the direction of connection, parts of the connection device, circuits, etc., can solve the problems of high production cost of the circumferential anti-rotation structure, improve production efficiency, reduce production difficulty, and be easy to bend and form Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

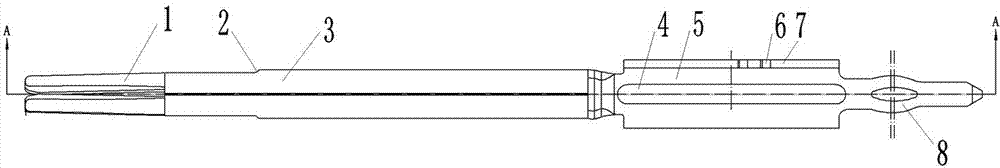

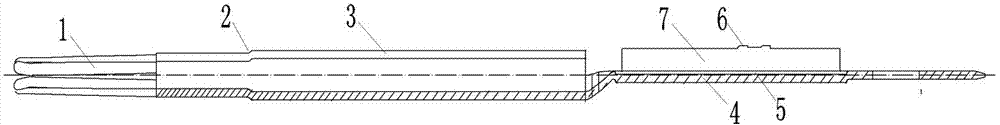

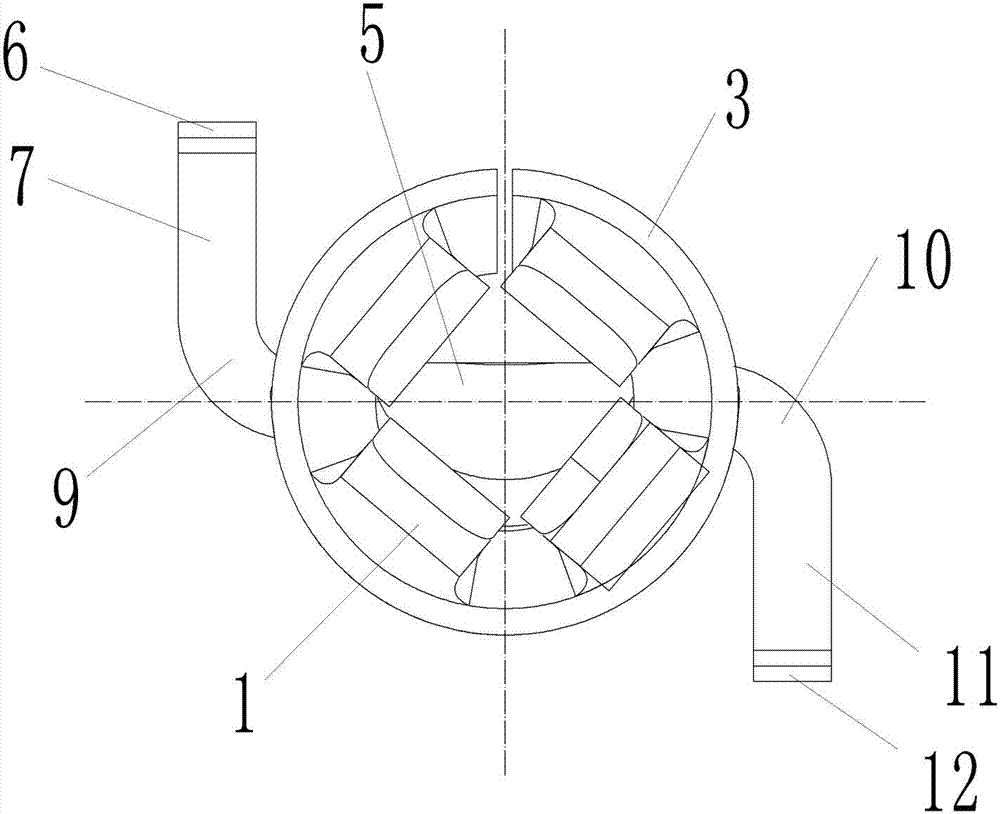

[0022] Examples of electrical connectors are Figure 1~6 As shown: it includes a contact piece and an insulator 13 provided with a contact piece installation hole. The contact piece installation hole includes a circular hole section 15 and a square hole section 14 arranged front and back. The axis of the circular hole section extends along the front and back direction, and the circular hole section The segment and the square hole segment are connected by a limiting step facing backward in the limiting direction. The contact piece includes a contact piece body whose front end is a plug-in end. The contact piece body is provided with a circumferential anti-rotation structure for inserting into a square hole section. The left end of the shaped body 5 is integrally bent upwards with an upper anti-rotation plate. The upper anti-rotation plate includes a vertical plate section 7 of the upper anti-rotation plate whose thickness extends along the left and right directions and a vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com