Method for manufacturing easy-forming angle aluminum

A manufacturing method and technology for forming corners, which are applied to slender components, building components, etc., can solve the problems of easy cracks at the bend of corner aluminum, poor protection of heat exchangers, and reduced quality of corner aluminum, so as to avoid The effect of cracks, extended service life, improved quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0015] A kind of manufacturing method of easy formable angle aluminum of the present invention comprises the following steps:

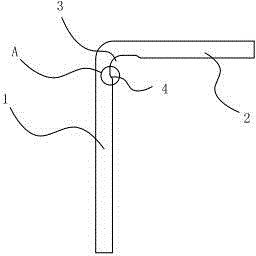

[0016] The first step: processing the blank to obtain the angle aluminum body formed by bending the first panel 1 and the second panel 2;

[0017] Step 2: finely grind the inner side of the bending part of the first panel 1 and the second panel 2 to form a thinning groove 3;

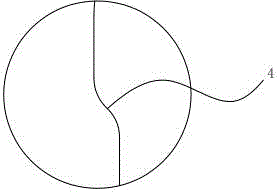

[0018] The third step: the connection between the thinning groove 3 and the first panel 1 and the second panel 2 is finely ground again, and the arc-shaped transition part 4 is processed, and the arc-shaped transition part 4 is located at both ends of the thinning groove 3, The arc-shaped transition part 4 avoids the stress concentration at the edge of the thinning groove 3 and improves the quality of the angle aluminum.

[0019] The above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com