Coil device

A coil device and coil technology, applied in the field of coil devices and ferrite cores, can solve problems such as no mention of resin materials, no public solutions, etc., to achieve the effects of preventing cracks, satisfying miniaturization, and avoiding stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0127] Next, first to fifth aspects of the present invention will be described with reference to the drawings.

[0128] 1st form of this invention

[0129] Next, a first embodiment of the present invention will be described with reference to the drawings. In addition, in the drawings, the same symbols indicate the same or corresponding parts.

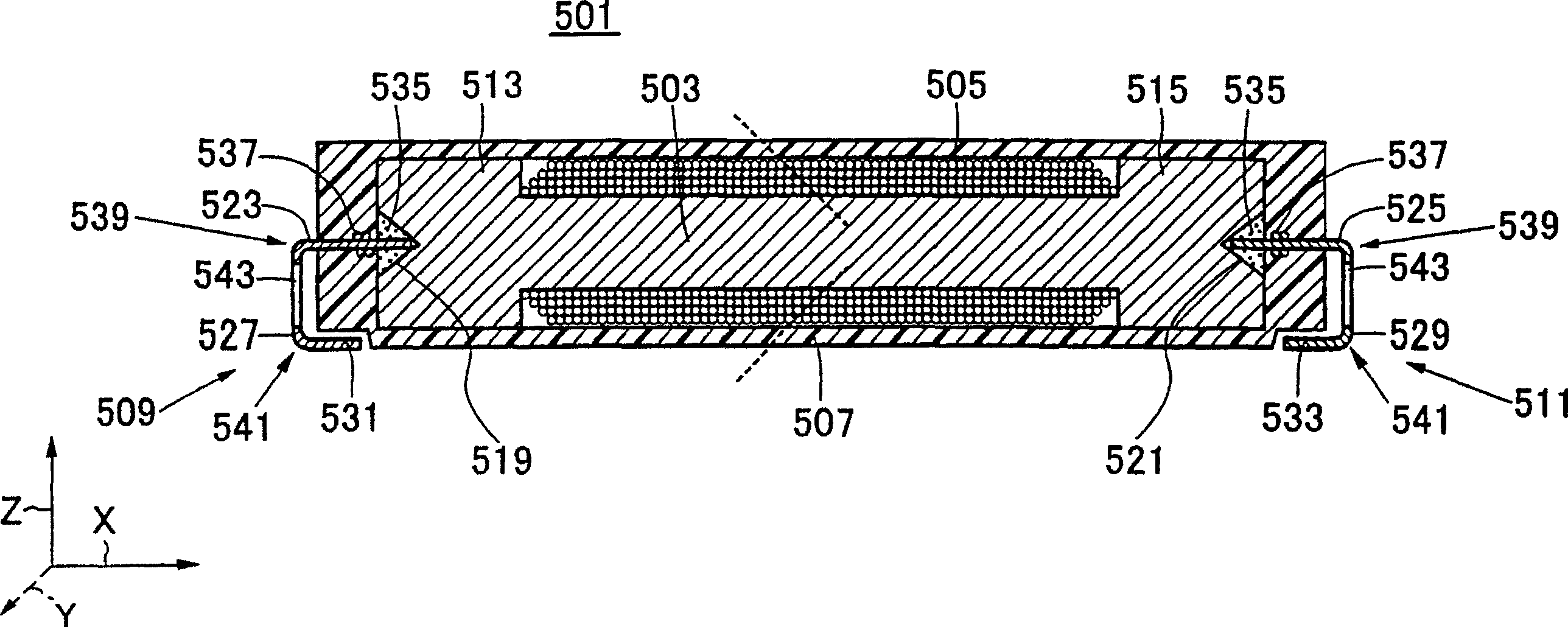

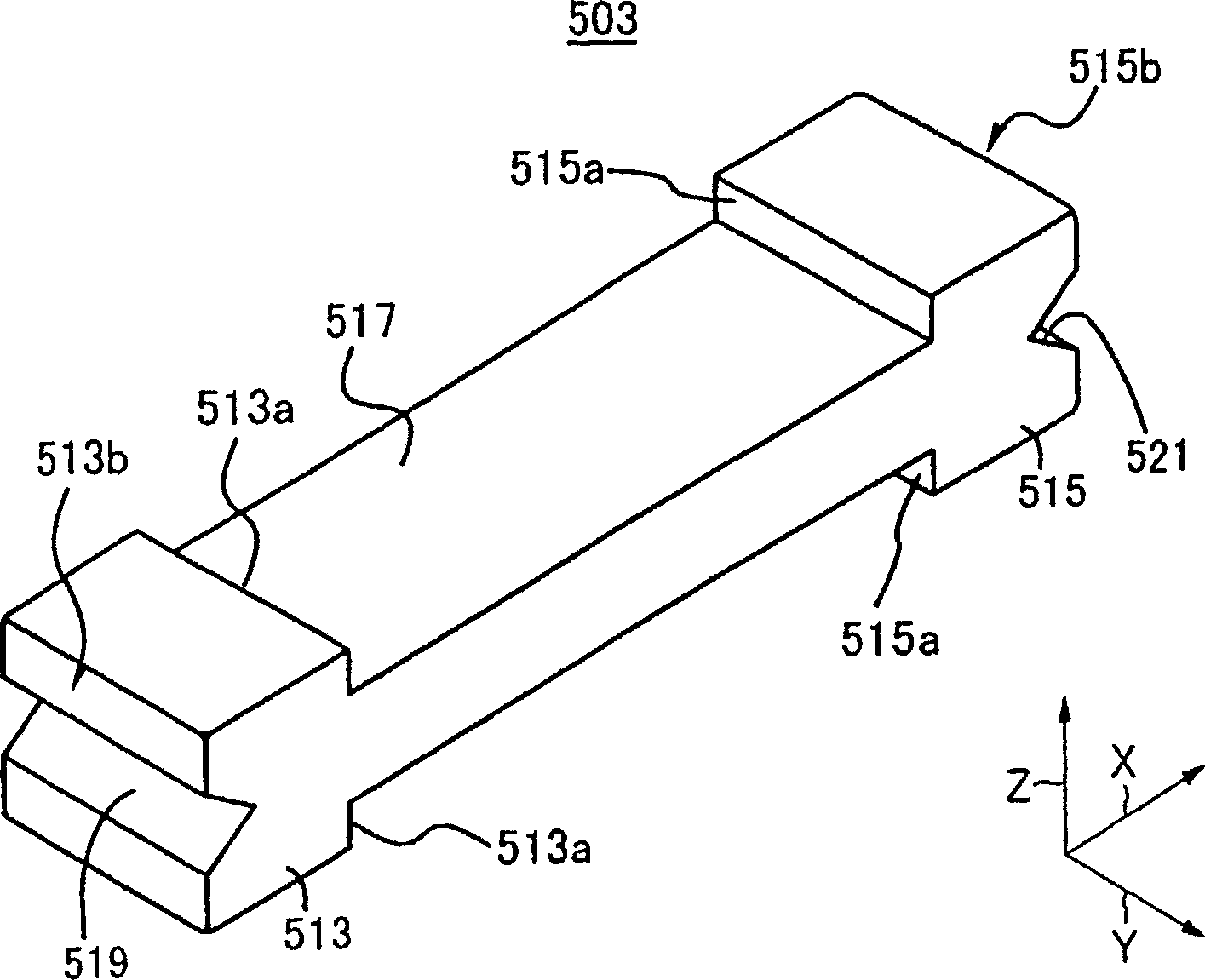

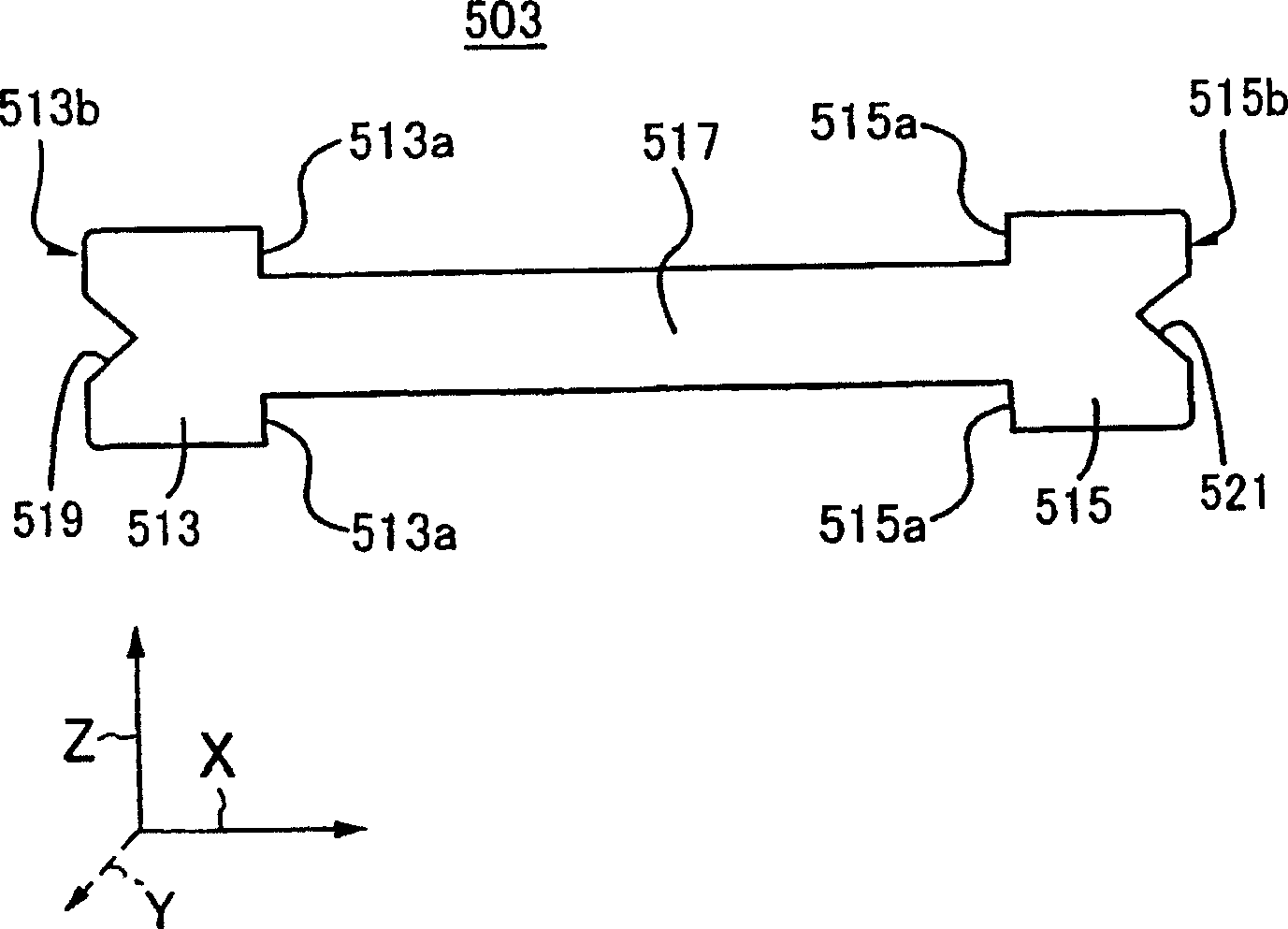

[0130] figure 1 The longitudinal section of the coil device of this embodiment is shown. The coil device 501 mainly includes: a ferrite core 503 , a coil 505 , an insulating outer casing 507 and a pair of terminals 509 and 511 . In addition, the coil device 501 is applicable to, for example, a two-way keyless entry system in an automobile that does not require button operation, an immobilizer, a tire pressure monitoring system, and the like.

[0131] The coil 505 is composed of a wire wound around the ferrite core 503 on the outer peripheral surface of the ferrite core 503 . An insulating outer case 507 is provided to cover the ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com