Sucting tube of refrigerator

A suction pipe, refrigerator technology, applied in the direction of fluid circulation arrangement, refrigeration components, refrigerators, etc., can solve the problems of weak shock resistance and vibration resistance, easy cracks in the annular pipe 22, etc., and achieve the effect of preventing cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

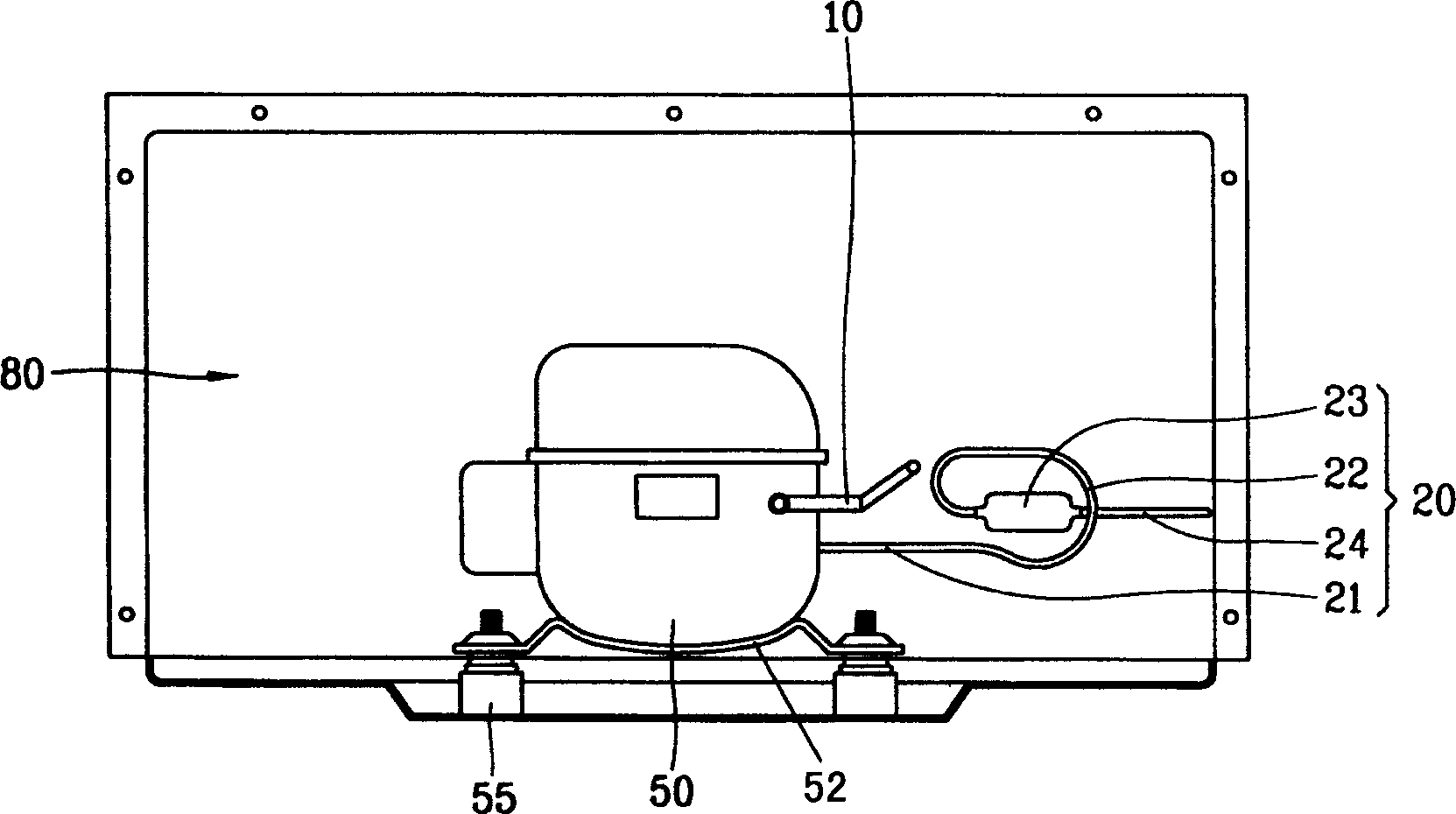

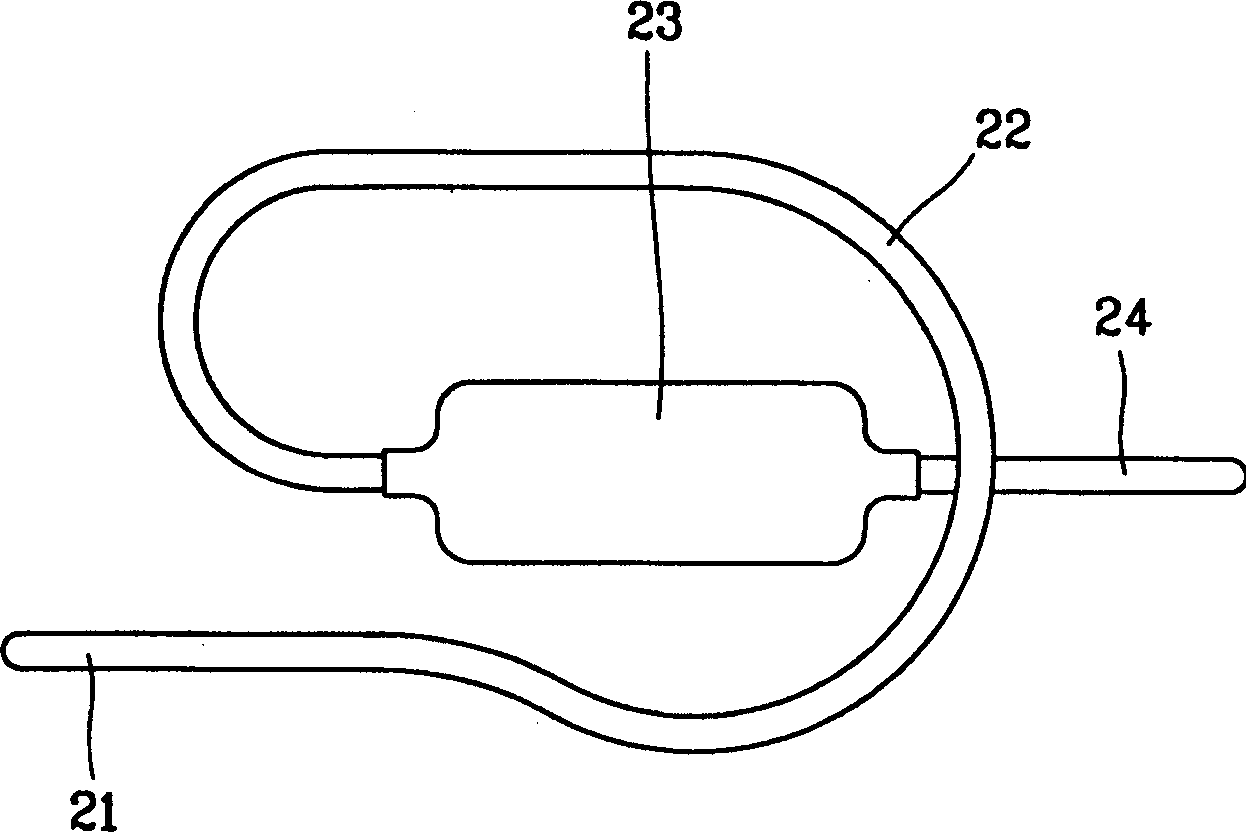

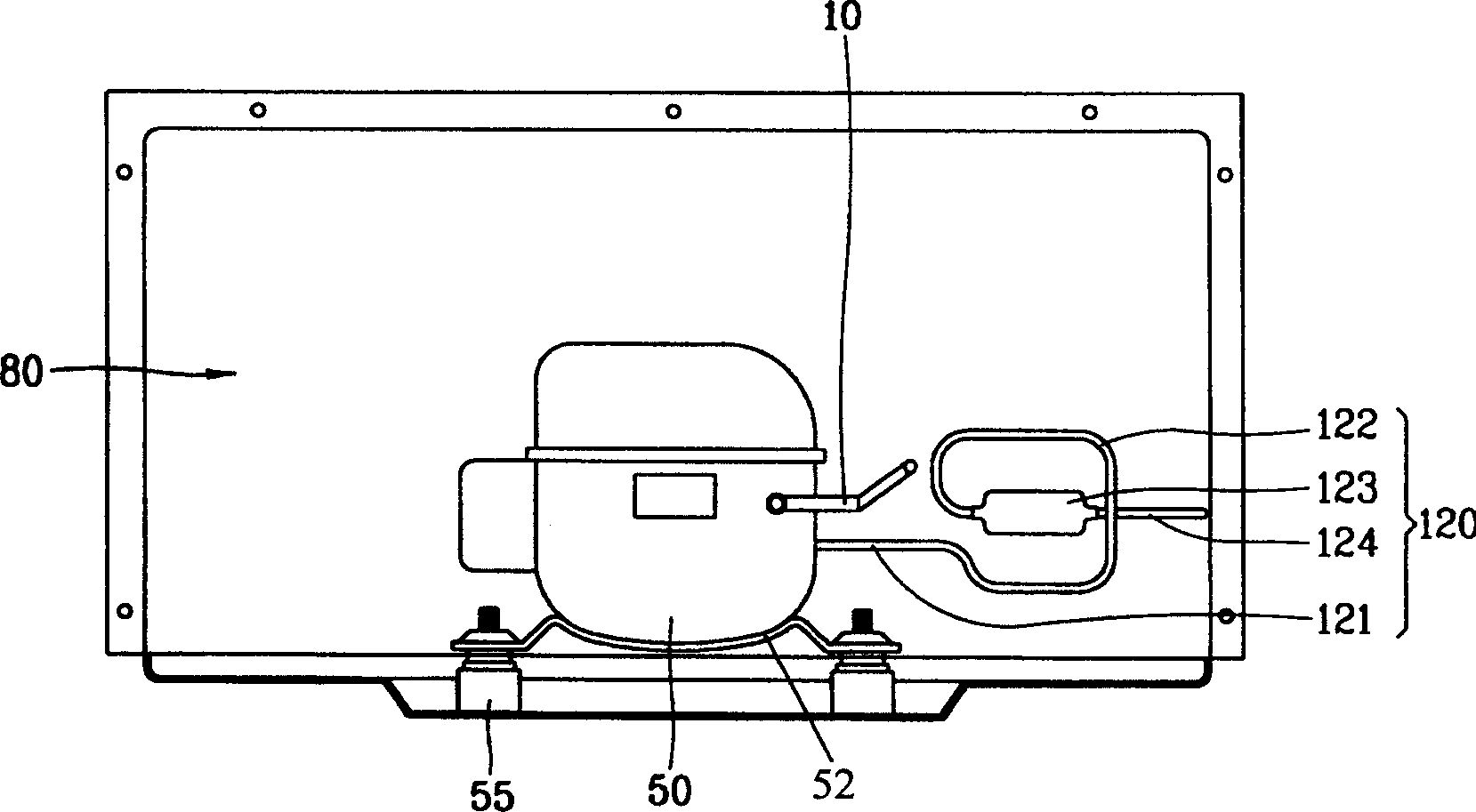

[0012] Such as image 3 As shown, the compressor 50 provided in the present invention provided in the machine room 80 on the lower side of the refrigerator is fixedly combined with the bottom surface of the machine room 80 by means of the fixed base 52 and shock-absorbing rubber 55 on its lower side, and the side surface of the compressor 50 The output pipe 10 and the suction pipe 120 are connected. Such as Figure 4 As shown, the suction pipe 120 includes: a compressor coupling pipe 121 connected to the compressor 50; an annular pipe 122 that can buffer the vibration transmitted by the compressor 50; The muffler 123 on the type pipe 122; One end is connected on the muffler 123, and the other end is then connected to the evaporator connecting pipe 124 on the evaporator not shown in the figure. The annular pipe 122 adopts a polygonal structure, which is composed of a plurality of work-hardened parts 122A formed by bending the suction pipe 120 at each corner of the polygon and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com