Novel chilling block for casting

A cold iron, a new type of technology, applied in the field of casting, can solve the problems of casting scrap, increase casting welding repair rate, looseness, etc., to achieve the effect of improving heat conduction, improving chilling effect, and increasing heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

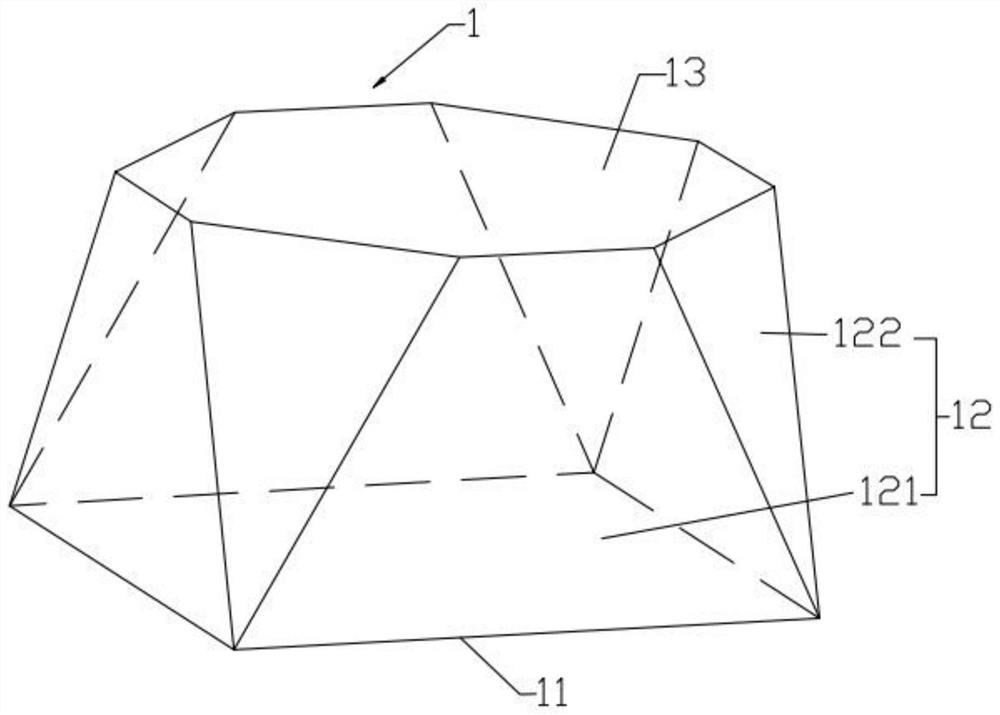

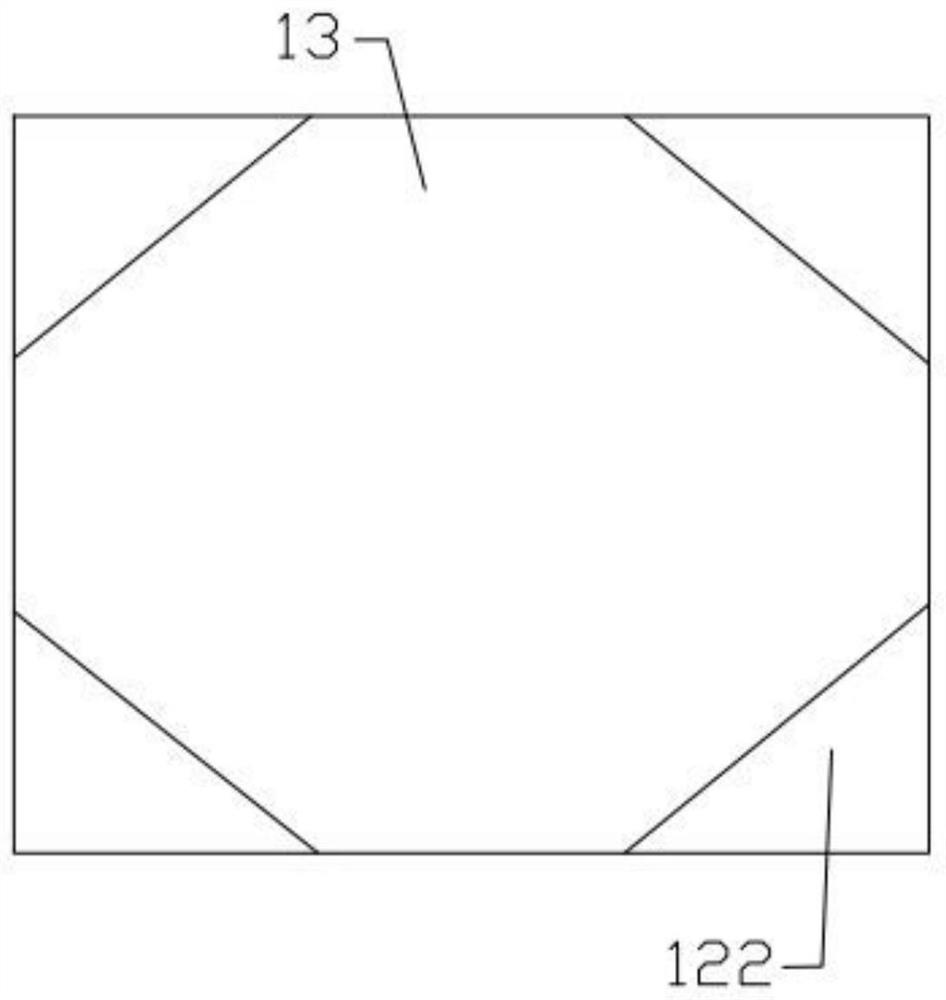

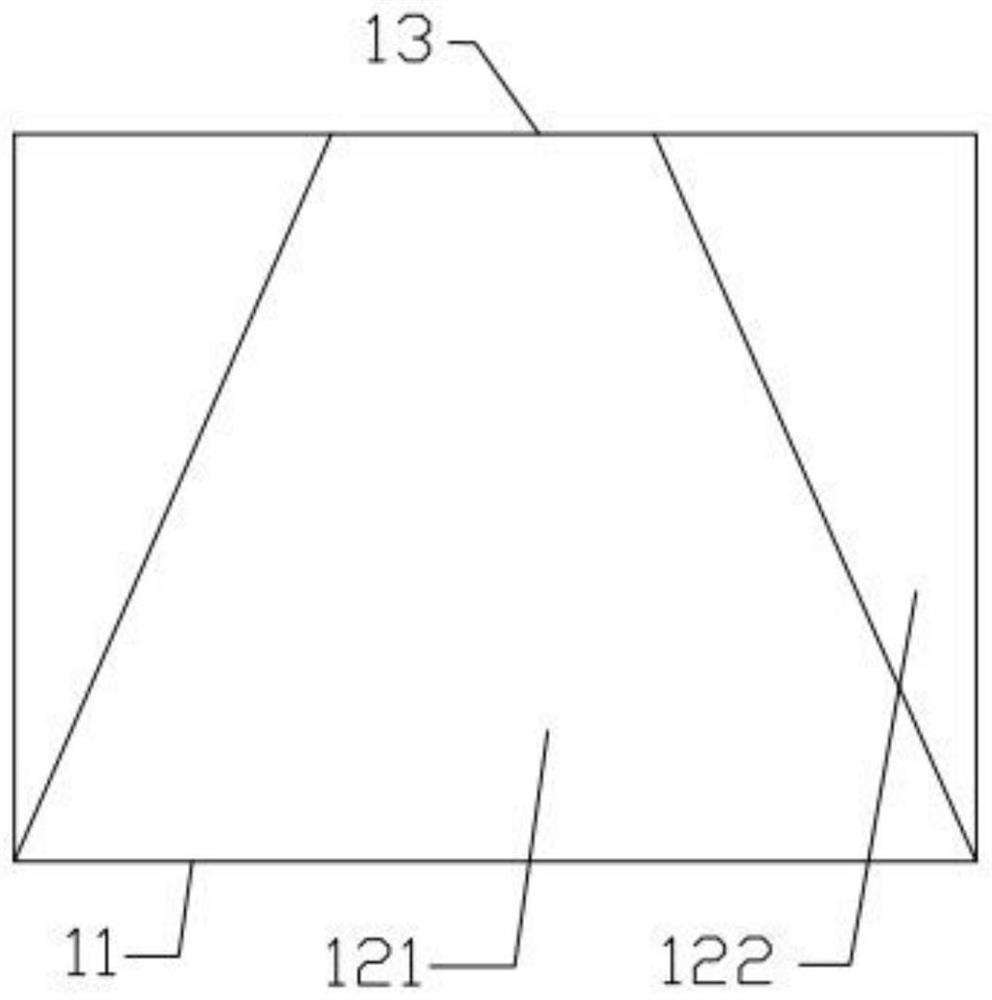

[0028] A new type of cold iron for casting, see Figure 1 to Figure 4 , the cold iron 1 has a bottom surface 11, a top surface 13 and a side surface 12, the bottom surface 11 is used to contact the surface of the casting 2, the bottom surface 11 and the top surface 13 are connected by the side surface 12, and the cross-sectional area of the cold iron 1 is from the bottom surface 11 to the top Face 13 tapers off. The thickness of the cold iron 1 gradually decreases from the center to the edge. The side 12 includes a trapezoidal first side 121 and a triangular second side 122. The first side 121 and the second side 122 are arranged at intervals connected end to end. Adjacent trapezoids and triangles share the same waist. The top edge of each trapezoid and the base of the triangle form the limit of the top surface 13, and the bases of each trapezoid form the limit of the bottom surface 11.

[0029] In this embodiment, the cold iron 1 is remade from a rectangular cold iron. Ba...

Embodiment 2

[0040] refer to Figure 5 , in this embodiment, the bottom surface 11 is triangular, the top surface 13 is hexagonal, other features can be the same or similar to the features in embodiment 1, such as also having the first side 121 and the second side 122, the first side is trapezoidal , the second side is triangular. However, in this embodiment, the number of the first side 121 is three, and the number of the second side is three, which can also achieve the effect of uniform chilling transition.

Embodiment 3

[0042] refer to Figure 6 , in this embodiment, the bottom surface 11 is a pentagon, and the top surface 13 is a decagon. Other features can be the same or similar to those in Embodiment 1, such as also having a first side 121 and a second side 122, the first side Trapezoidal with a triangular second side. However, in this embodiment, the number of the first side 121 is five, and the number of the second side is five, which can also achieve the effect of uniform chilling transition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com